Line printing method and device for three-dimensional line printing machine

A technology of three-dimensional printing and printing machine, applied in the direction of additive processing, etc., can solve the problems of not considering the demand for strength, easy to be broken, insufficient strength, etc., to meet printing needs, enhance strength, and improve printing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

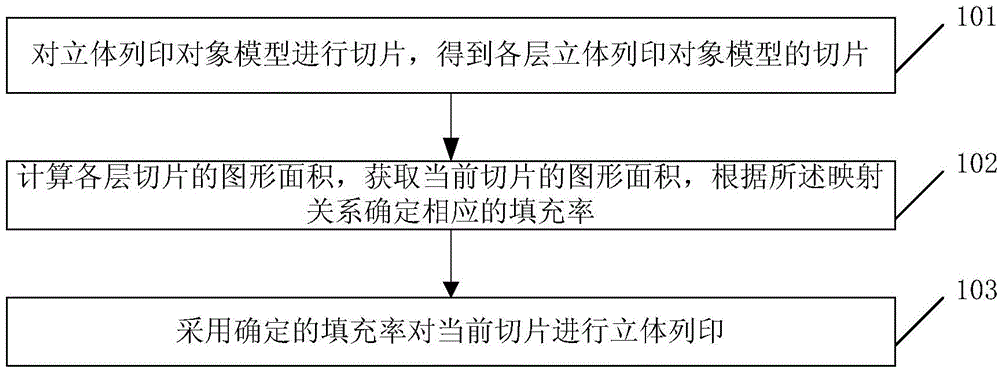

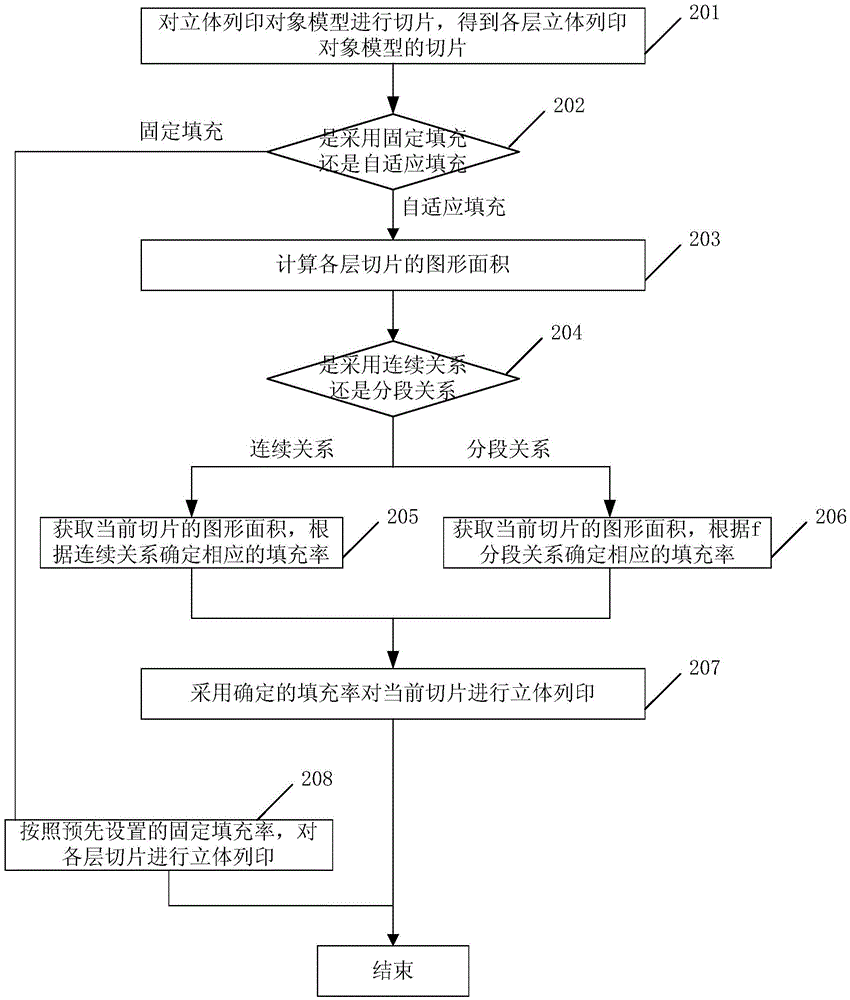

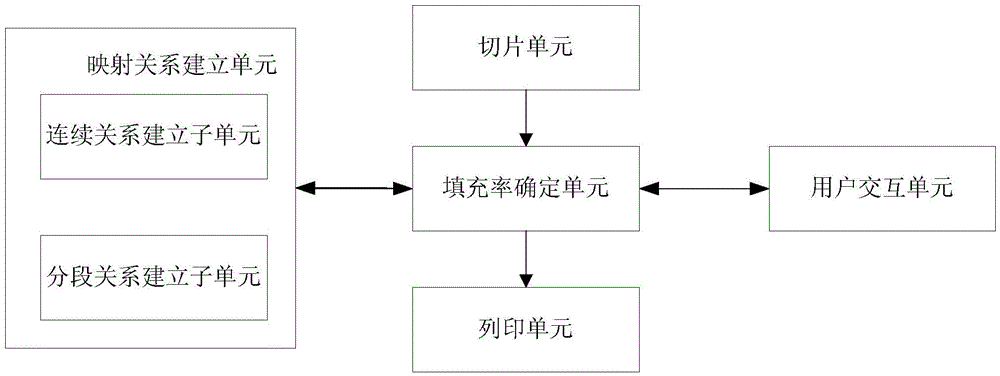

[0022] The existing 3D printing technology adopts a fixed filling method, which is relatively mechanical; this causes some parts of the 3D printing object model to be easily broken during or after printing due to their insufficient strength. After further analysis, the inventors found that the most easily broken parts appear in the smaller parts of the 3D printing object model. In order to solve this technical problem, the present invention establishes the mapping relationship between the slice graphic area and the filling rate, and performs graphic filling based on the mapping relationship. Therefore, the strength of the smaller parts in the three-dimensional printing object model is enhanced, and the printing quality is improved.

[0023] see f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com