Punctate pattern ink-jet printing system and method

A technology of inkjet printing and printing nozzles, which is applied in the inkjet printing system of dot graphics and the field of inkjet printing, can solve the problems of high difficulty in implementation, high research cost, weakening the advantages of inkjet printing methods, etc., and achieve high feasibility , simple design, universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

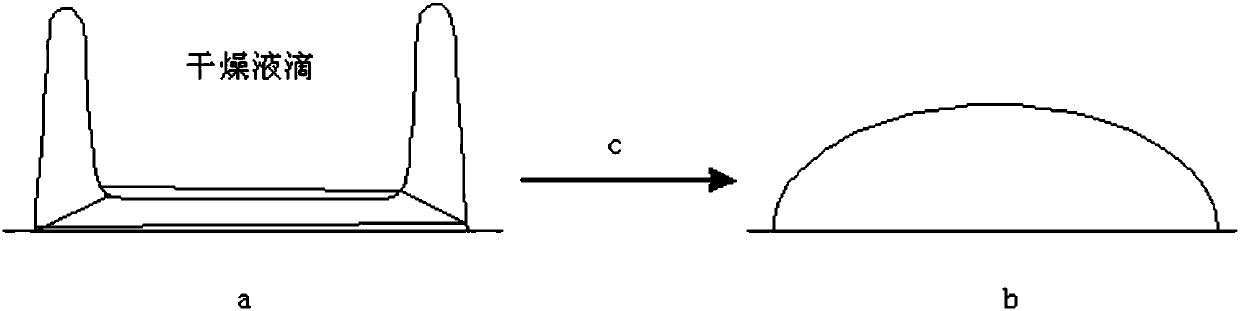

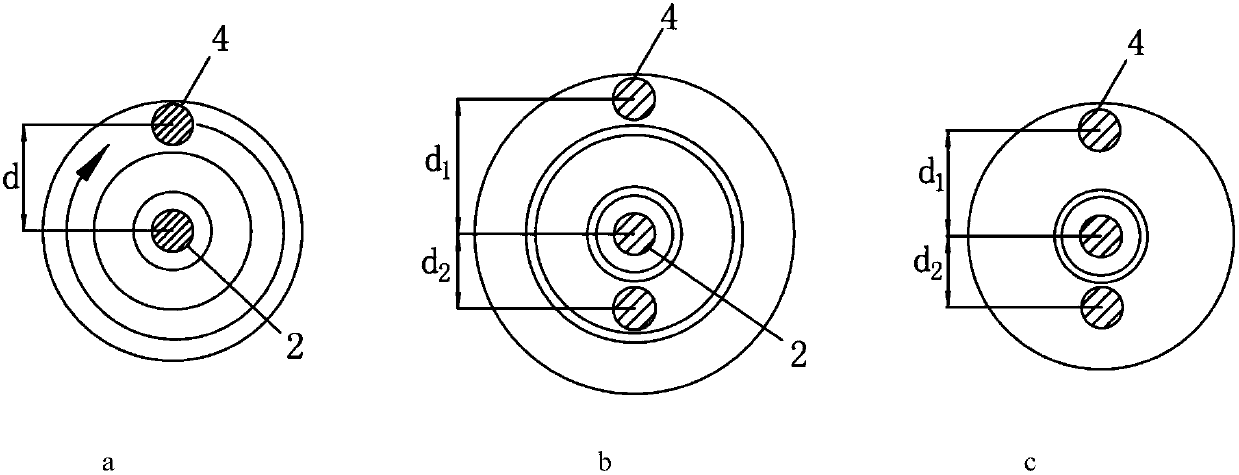

[0035] 1. Inhibition of the "coffee ring" effect of a single droplet, which can be tuned by ink, substrate, and device (Figure 1). The method of the present invention to realize dot printing without "coffee ring" is to print multiple printing rings (take two rings as an example) on the outside of the printing point at the same time, and the shape of the printing point after drying is printed by the outer ink solvent. The distance from it and the line width of each ring are determined, so the design requirements for the nozzle system are put forward:

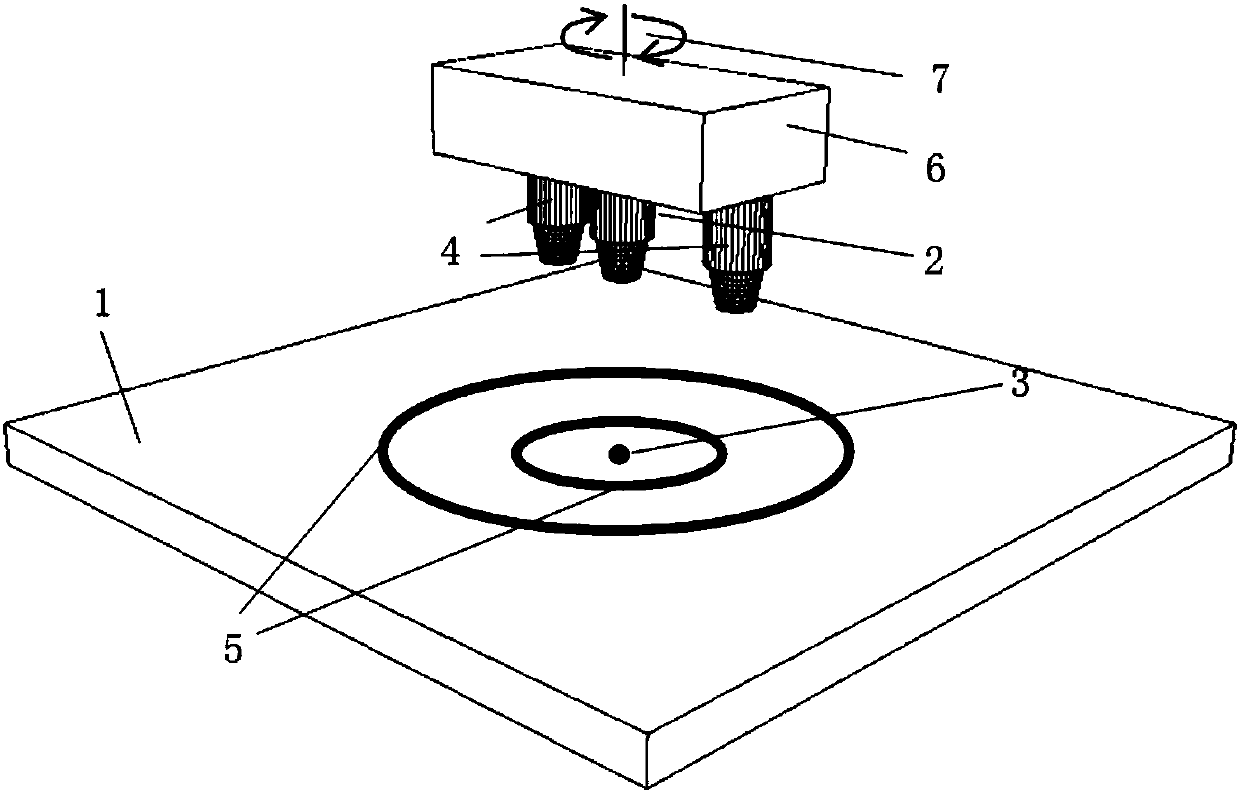

[0036] Such as figure 2 As shown, the inkjet printing system in the present invention includes a printing substrate 1 and a nozzle device, the nozzle device is arranged above the printing substrate 1, and the nozzle device includes an ink printing nozzle 2, a solvent printing nozzle 4 and a printing nozzle The moving assembly 6; the ink printing nozzle 2 and the solvent printing nozzle 4 are loaded on the printing nozzle moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com