Coating newsprint and making method thereof

A manufacturing method and technology of newsprint, applied in the direction of papermaking, paper machine, pigmented coating, etc., can solve the problems of large consumption of fiber raw materials, high whiteness requirements of pulp, blurred printed characters, etc., to save ink consumption, ink High saturation, clear screen printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

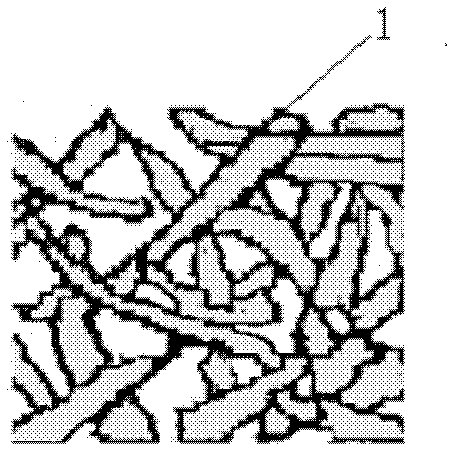

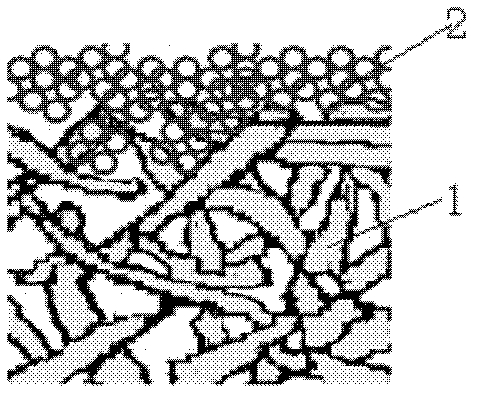

[0034] Surface coated newsprint preparation

[0035] Add 0.35kg / t of polyacrylamide (PAM) retention aid to 48.5% whiteness deinking pulp, 40g / t of dye basic magenta, 9kg / t of quaternary ammonium cationic starch, and distribute the pulp through the headbox , wire forming, four-roller three-nip compound pressing, pre-drying, surface coating and finishing, post-drying, coiling, and rewinding outside the machine. Obtained 380 tons of coated newsprint with specifications of 781mm and 1562mm required by customers. The online pulp concentration is 0.95wt%, pH7.6, the headbox freeness is 70CSF, the underwire white water pulp concentration is 0.42wt%, and the headbox PCD is 260uq / l. Coating weight 8g / m 2 . Surface coating material formula: a mixture of 100 parts of inorganic mineral pigment coating grade calcium carbonate, 10 parts of coating adhesive starch and 1 part of synthetic latex (carboxylated styrene-butadiene latex); the coating material has a solid content of 52.3wt% and ...

Embodiment 2

[0037] Surface coated newsprint preparation

[0038]Add 47.2% whiteness deinking pulp to polyacrylamide retention aid 0.42kg / t paper, dye basic purple 48g / t paper, quaternary ammonium cationic starch 8kg / t paper, and distribute pulp through headbox, wire part Forming, four-roller three-nip composite pressing, pre-drying, surface coating and finishing, post-drying, winding by winder, and rewinding outside the machine. Obtain 320 tons of coated newsprint with specifications of 781mm and 1562mm required by customers. The online pulp concentration is 0.83wt%, pH7.8, the headbox freeness is 95CSF, the underwire white water pulp concentration is 0.43wt%, and the headbox PCD is 270uq / l. Coating weight 7.8g / m 2 . Surface coating material formula: the mixing of 100 parts of inorganic mineral pigments, 11 parts of coating adhesive starch and 1.5 parts of synthetic latex (carboxylated styrene-butadiene latex). The coating material has a solid content of 52.7wt%, a viscosity of 320mpa...

Embodiment 3

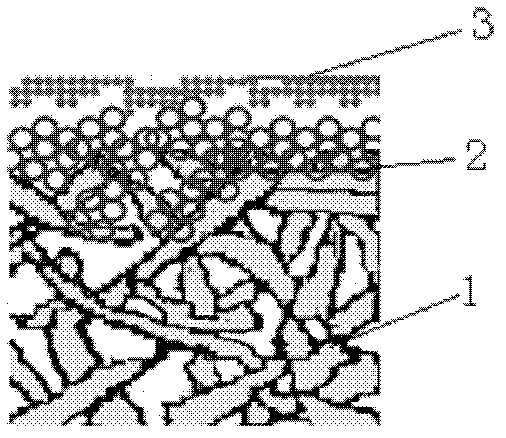

[0040] Surface coated newsprint preparation

[0041] Add 0.32kg / t of polyacrylamide retention aid to 49.8% whiteness deinking pulp, 36g / t of dye (basic purple) paper, 9.5kg / t of quaternary ammonium cationic starch, and distribute the pulp through the headbox , wire forming, four-roller three-nip compound pressing, pre-drying, surface coating and finishing, post-drying, coiling, and rewinding outside the machine. Obtain 650 tons of coated newsprint with specifications of 781mm and 1562mm required by customers. The online pulp concentration is 0.9wt%, pH7.5, the headbox freeness is 80CSF, the underwire white water pulp concentration is 0.38wt%, and the headbox PCD is 220uq / l. Coating amount 9g / m 2 , Surface coating material formulation: 100 parts of inorganic mineral pigments, 12 parts of coating adhesive starch and 2 parts of synthetic latex (carboxylated styrene-butadiene latex). The coating material has a solid content of 54.2wt%, a viscosity of 450mpa.s, and a pH of 8.6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com