Ultraviolet-cured rotary silk-screen printing ink with LED as light source

A rotary screen and ultraviolet technology, which is applied in ink, household utensils, applications, etc., can solve the problems of endangering the health of operators, operator injury, environmental pollution, etc., and achieves simple and easy setup, reduced emissions, and fastness of combination high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

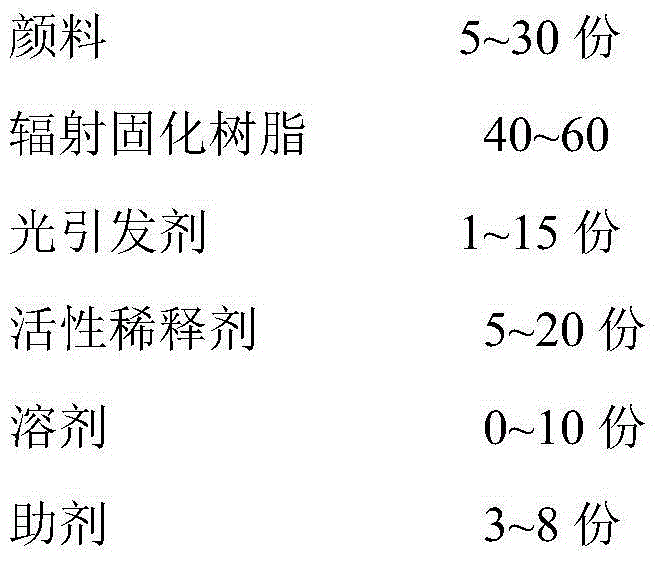

[0037] The formula is shown in the table below, and the amounts of the components are parts by weight.

[0038]

[0039]

[0040] The photoinitiator is 2,2-dimethoxy-1,2-diphenylethanone, benzophenone, α-hydroxy ketone, 1-hydroxyl-cyclohexyl ketone, α-amino ketone, acyl One or more of phosphine or benzoylformate;

[0041] Trimethylolpropane Triacrylate (TMPTA)

[0042] The mercapto-modified polyester acrylate is LED01.

[0043] Urethane acrylate is EB8415.

[0044] The polyester acrylate is GENOMER3485.

[0045] The polyether acrylate is PO94F.

[0046] Trimethylolpropane triacrylate is TMPTA.

[0047] Alpha-aminoketone Irgacure 369.

[0048] The monoacylphosphine is Darocur TPO-L.

[0049] The solvent is propylene glycol methyl ether

[0050] The defoamer is HX-2086.

[0051] The dispersant is Solspers 24000.

[0052] The leveling agent is HX-3390.

[0053] Preparation method: (a) first add the dispersant to part of the solvent, then disperse the pigment in the...

Embodiment 2

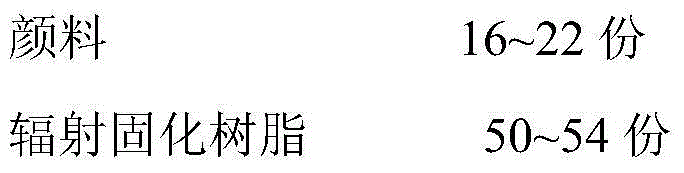

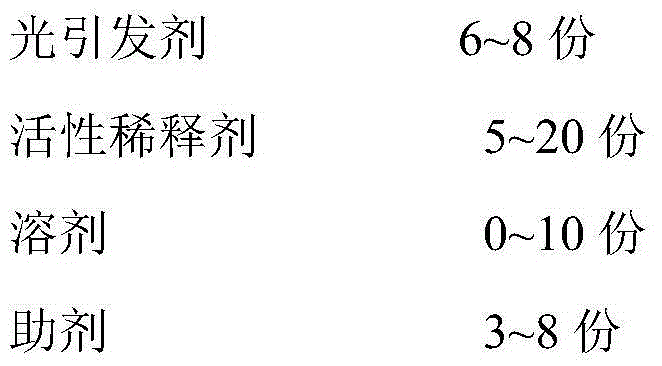

[0057] The formula is shown in the table below, and the amounts of the components are parts by weight.

[0058]

[0059] The mercapto-modified polyester acrylate is LED01.

[0060] Polyurethane acrylate is Photomer6008.

[0061] Epoxy acrylate is EB3708.

[0062] The polyether acrylate is GENOMER3414.

[0063] Acrylate modified glycerin is OTA480.

[0064] Alpha-Hydroxyketone Irgacure 127.

[0065] Phenyl bisphosphine oxide is Omnirad808.

[0066] The defoamer is HX-2056.

[0067] The dispersant is DISPERBYK168.

[0068] The leveling agent is Tego450.

[0069] Preparation method: (a) first add the dispersant to part of the reactive diluent, and then disperse the pigment in the reactive diluent containing the dispersant to form component 1; (b) add the remaining reactive diluent to the radiation-curable resin to form component 1 Divide into 2; (c) Mix component 1 and component 2, leveling agent and defoaming agent evenly, add photoinitiator before printing, stir and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com