Cylinder diameter-adjustable lifting device

A technology of lifting device and cylinder diameter, which is applied in the field of selective laser melting equipment, can solve the problems of waste of development time, waste of materials, and low utilization rate of equipment, and achieve the effects of improving printing efficiency, improving the accuracy of powder feeding, and reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

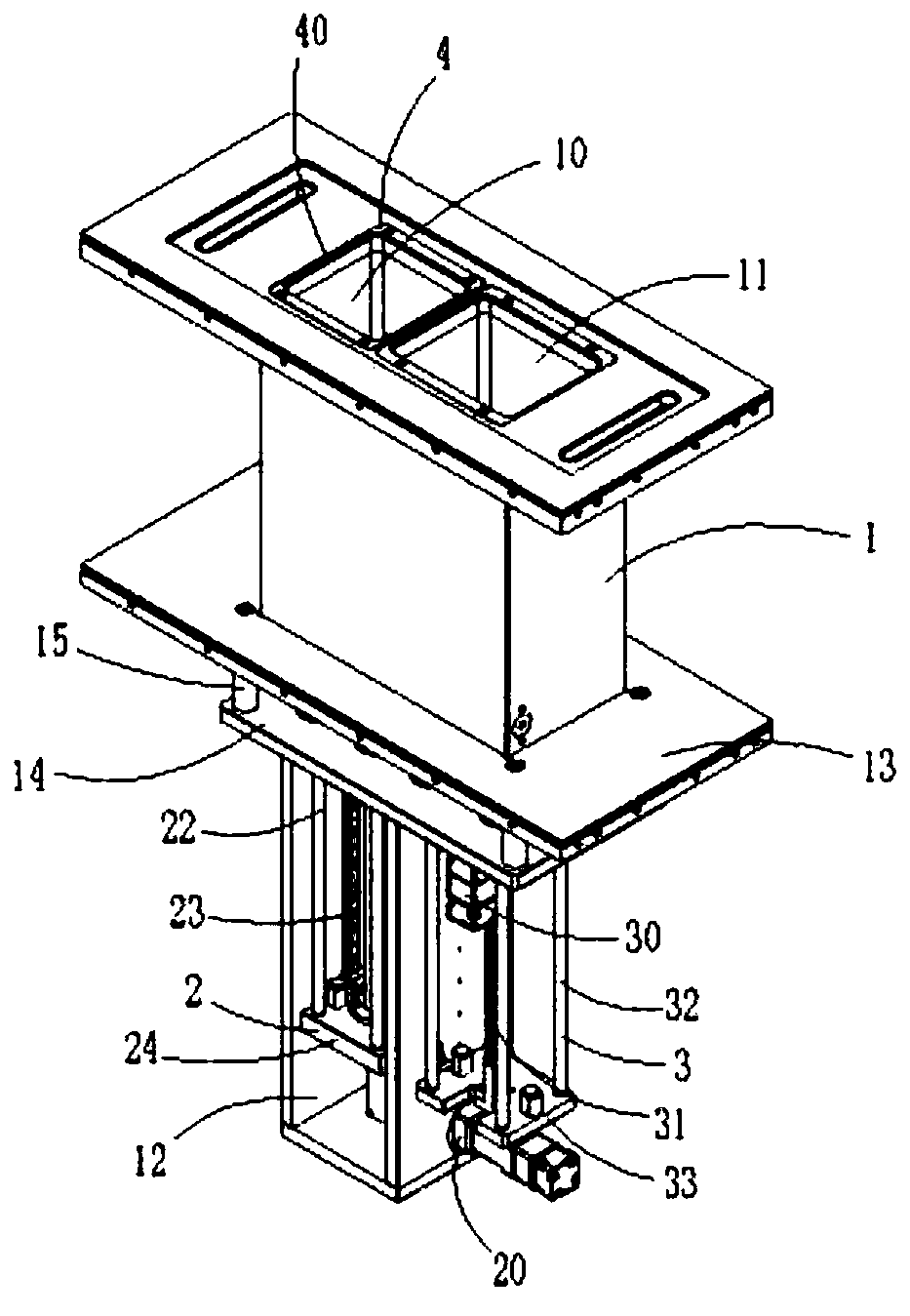

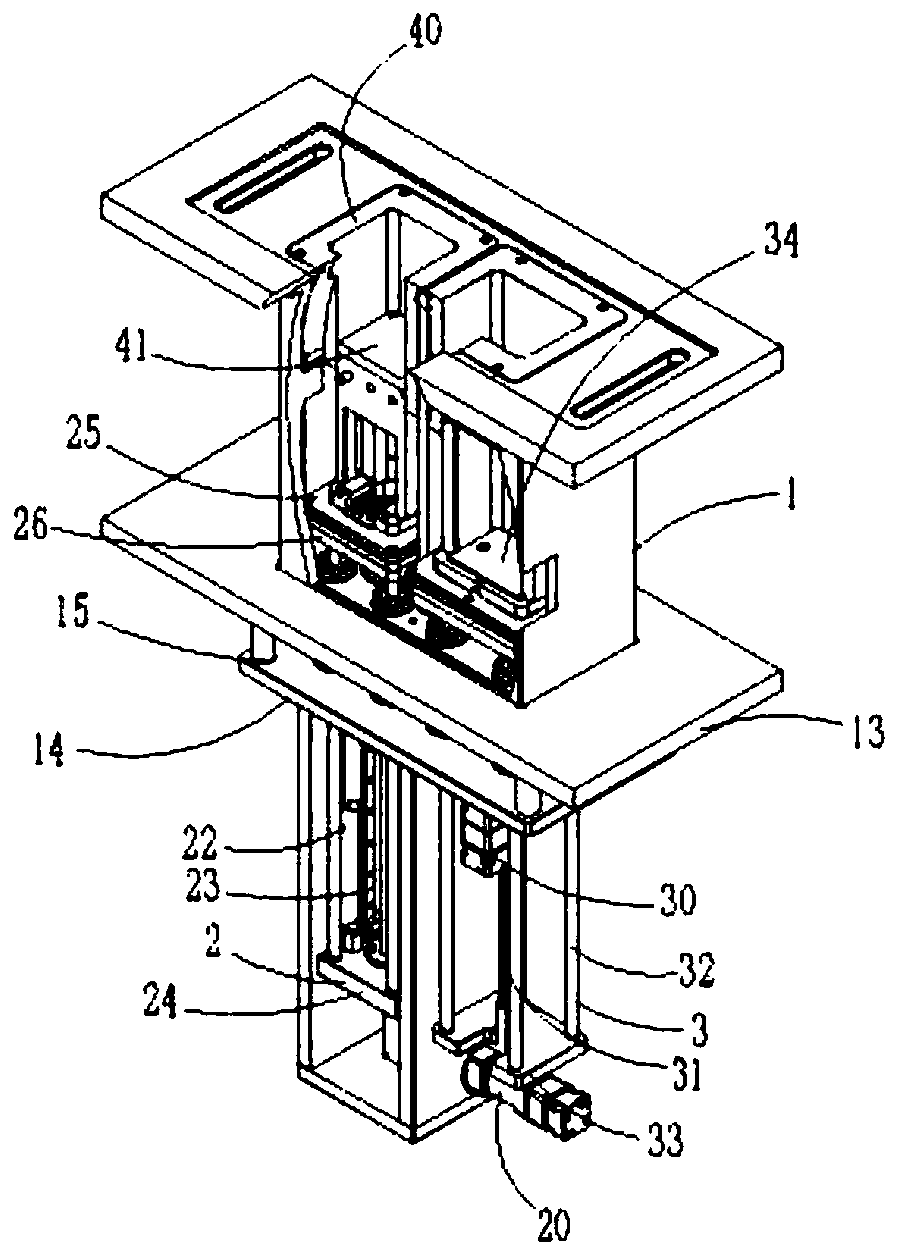

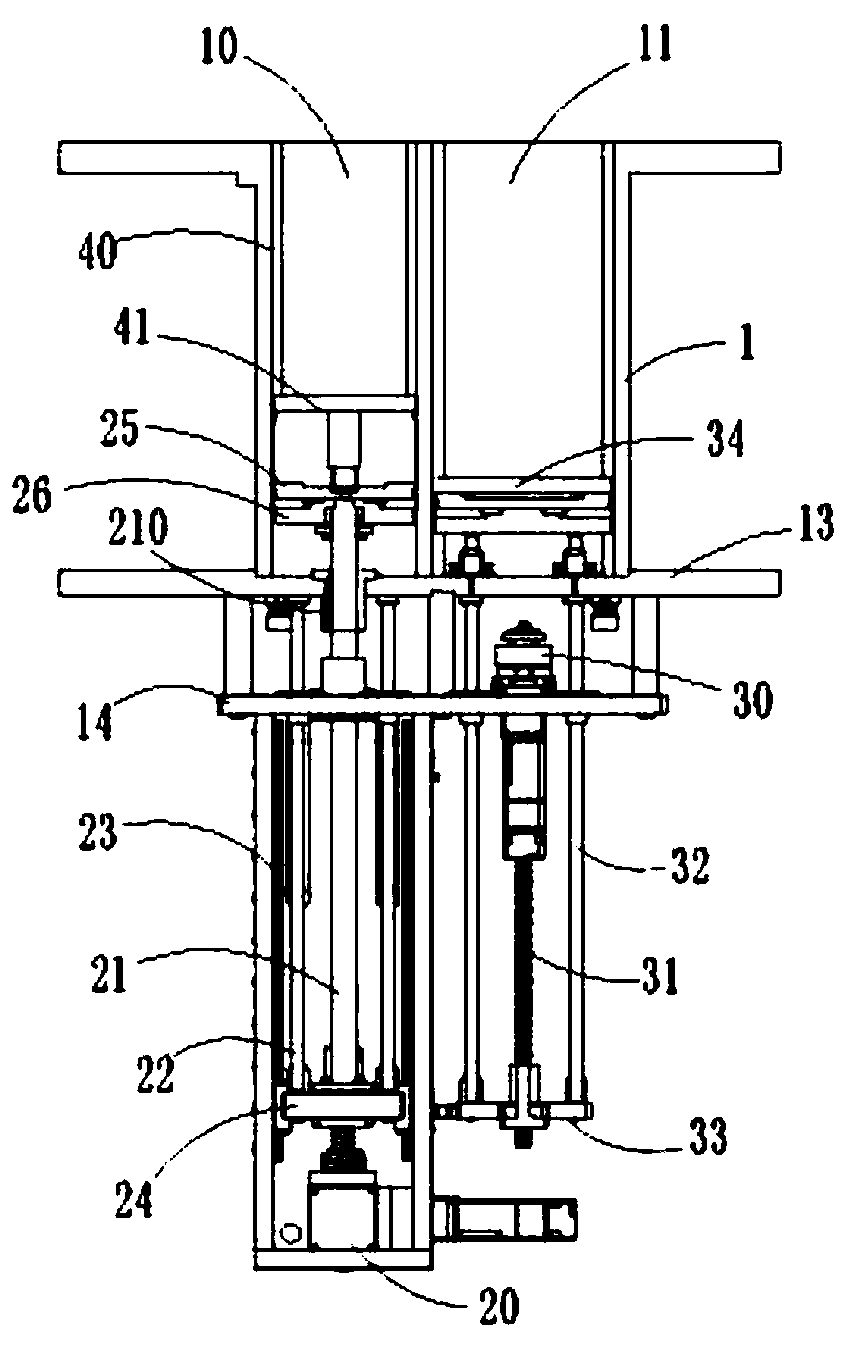

[0019] Example: such as figure 1 , 2 A lifting device with a variable cylinder diameter that can select different printing formats as shown in . The body 1 includes a molding chamber 10, a powder feeding chamber 11 and a transmission chamber 12. The molding chamber 10 and the powder feeding chamber 11 are arranged side by side at the upper end inside the outer cylinder body 1 of the lift chamber, and the transmission chamber 12 is arranged at the lower end inside the outer cylinder body 1 of the elevator chamber. And the transmission chamber 12 corresponds to the upper and lower positions of the molding chamber 10, the lower end of the molding chamber 10 and the powder feeding chamber 11 is provided with a partition 13, and the upper end of the transmission chamber 12 is provided with a partition 2 14, between the partition 13 and the partition 2 14 Fixedly connected by connecting column 15;

[0020] Such as figure 2 , 3As shown, the forming chamber lifting mechanism 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com