Vibrating piezoelectric spray head system

A technology of vibration pressure and vibrating plate, applied in the field of 3D printing, can solve the problems of scrapping, high fluid viscosity, easy plugging, etc., and achieve the effect of simple replacement, easy control of flow rate and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

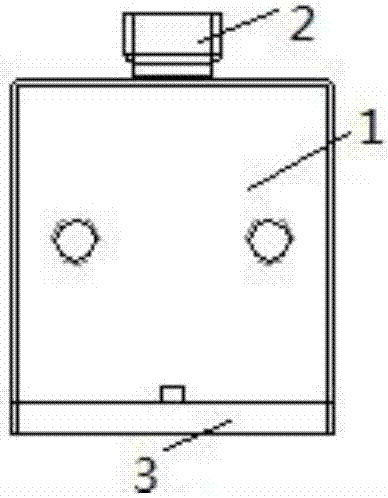

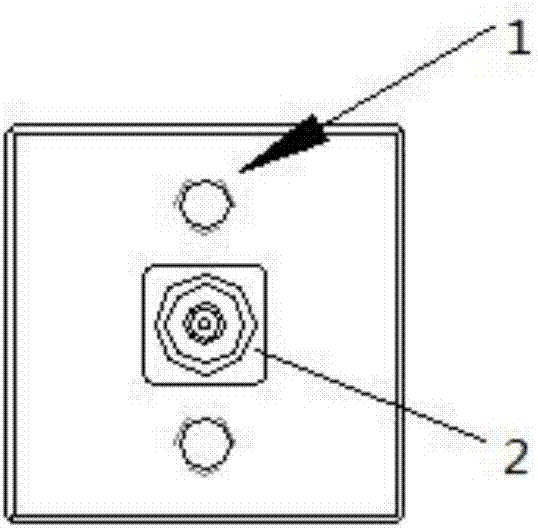

[0024] refer to Figure 1 to Figure 7 , a vibrating piezoelectric nozzle system of the present invention, comprising a liquid storage chamber 1, a liquid supply joint 2 and a liquid outlet, the liquid supply joint 2 is arranged above the liquid storage chamber 1, and the liquid outlet is arranged on the liquid storage chamber 1 At the bottom, a groove for installing a piezoelectric ceramic vibration mechanism 4 is provided at the bottom of the liquid storage chamber 1, and a piezoelectric ceramic vibration mechanism 4 for vibrating to eject fluid is installed in the groove.

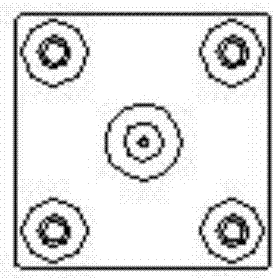

[0025] The piezoelectric ceramic vibrating mechanism 4 comprises a ring-shaped piezoelectric ceramic vibrating piece 42 and a metal piece 41 bonded together, and the ring-shaped piezoelectric ceramic vibrating piece 42 and the metal piece 41 are provided with a protrusion communicating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com