High power gas catalytic burner

A gas catalysis and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of complex structure of high-power catalytic burners, difficulty in uniform preheating of catalyst carriers, and failure of catalytic burners to work normally. , to achieve the effect of compact structure, volume reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

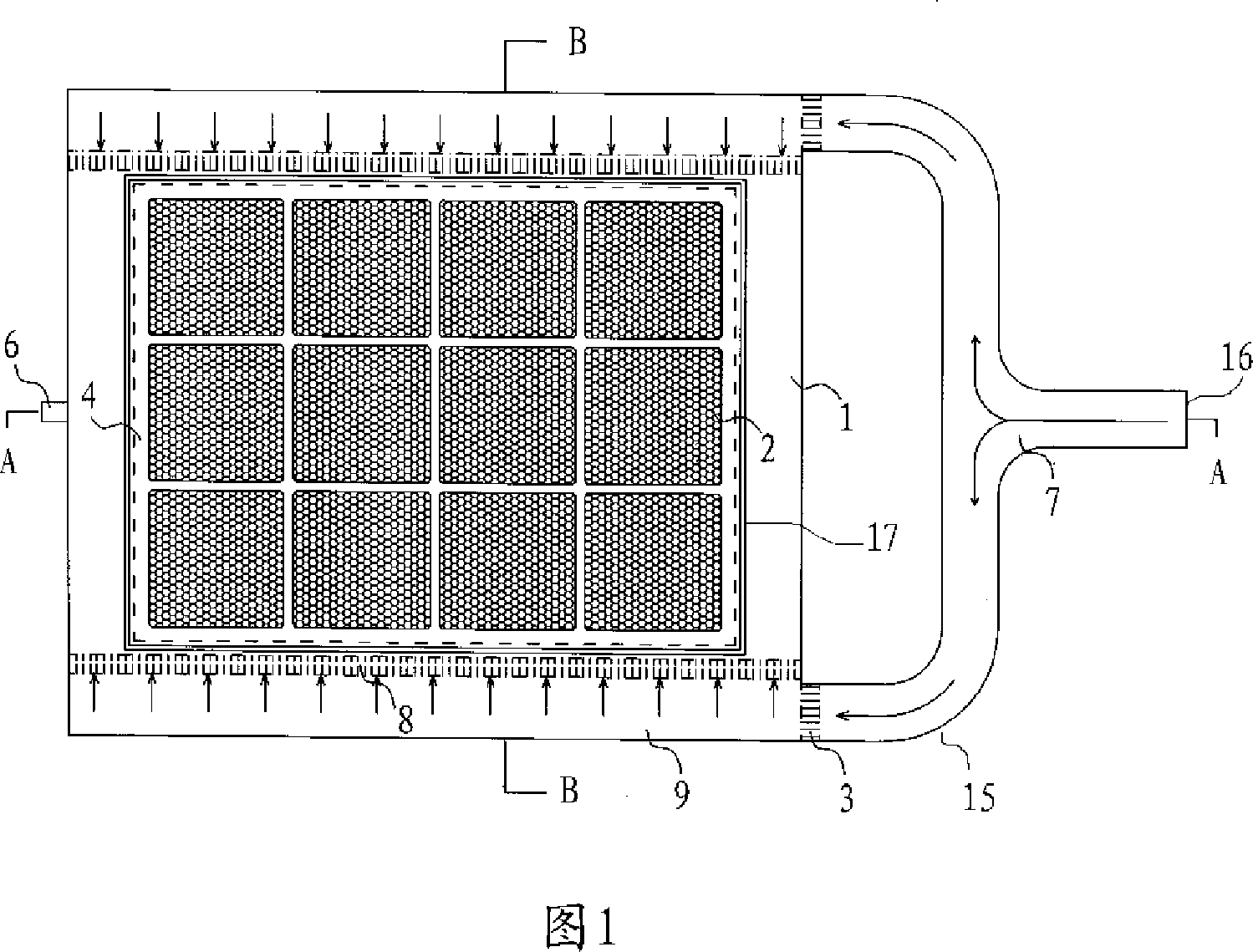

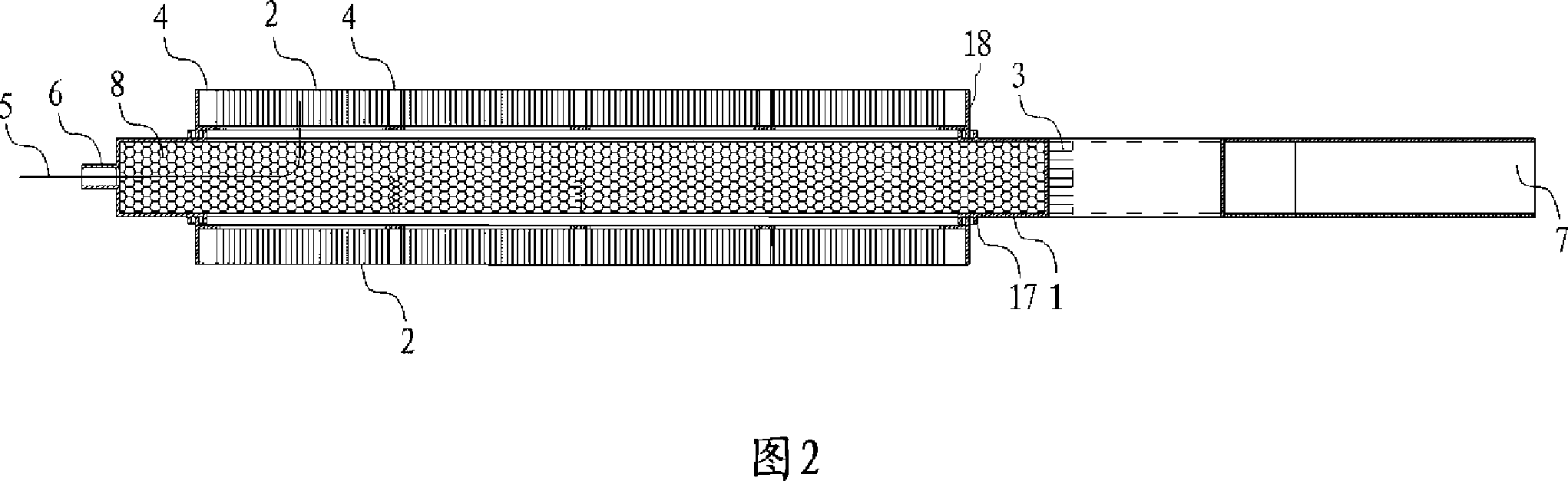

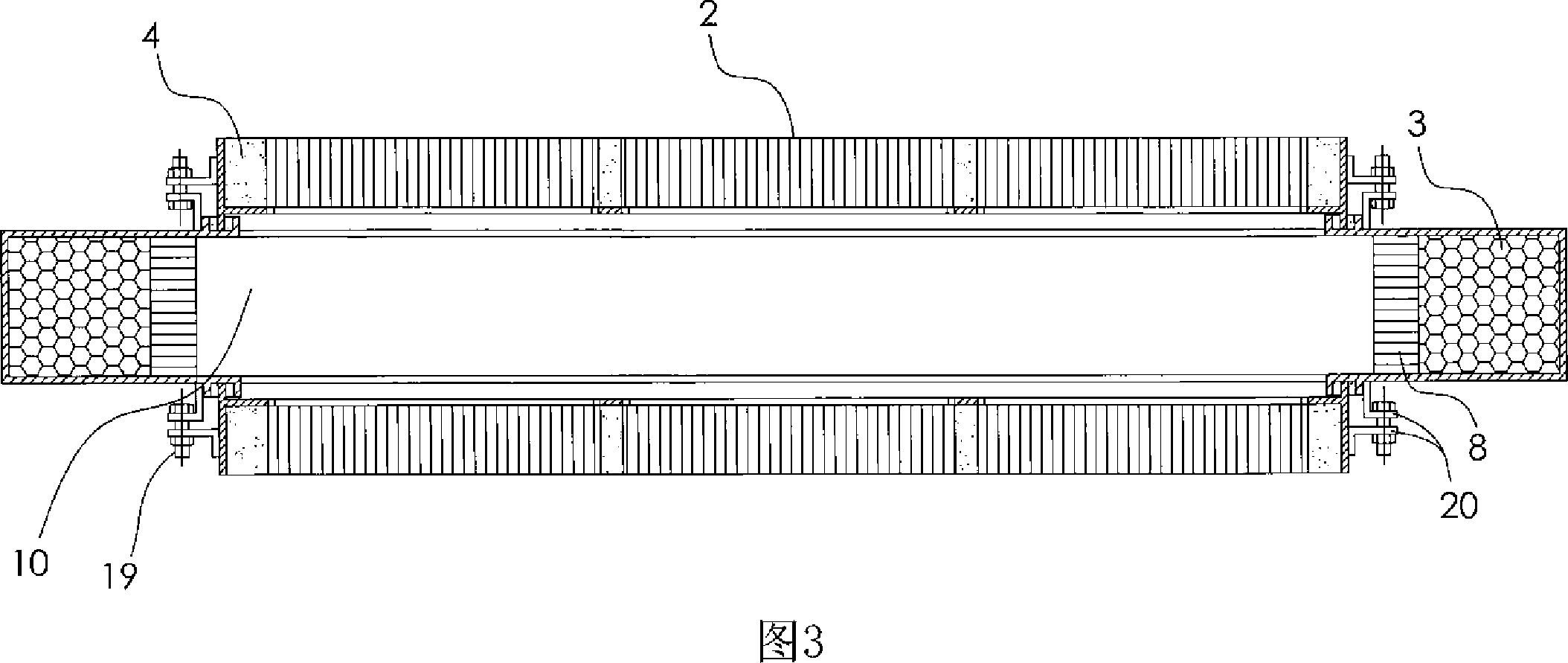

[0034]The structure of the high-power gas catalytic burner in Embodiment 1 is shown in Figures 1 to 3: for this high-power gas catalytic burner, the inlet end 16 of the gas pipeline is connected to one end of the pipeline tee 7, and the pipeline three The other two ends of the channel 7 are respectively in the shape of 90-degree elbows 15, and are connected to the mixed gas channel 9 surrounding the peritoneal cavity of the catalytic burner. Fluid rectifiers are respectively arranged at the inlet and outlet of the mixed gas channel 9. The first fluid rectifier 3 is located at the junction of the pipeline tee 7 and the mixed gas channel 9, and the second fluid rectifier 8 is located at the junction of the mixed gas channel 9 and the abdominal cavity 10 of the burner. A group of catalyst carrier modules 2 placed in the frame 18 are respectively connected to both sides of the burner abdominal cavity 10, and the gaps around each catalyst carrier module are filled with high-temperat...

Embodiment 2

[0047] Fig. 4 is the structural schematic diagram of the non-parallel combination application embodiment of two groups of catalytic burners of the present invention, this is to use two groups of high-power gas catalytic burners and three groups of finned heat exchangers 11 to carry out heat exchange, in order to prevent heat exchanger Condensed water droplets on the catalytic carrier module 2 lead to the actual effect of the catalyst. The catalytic burner adopts a vertical combustion form. Two sets of gas catalytic burners and three sets of heat exchangers are arranged one-to-one. The heating surface of the device is parallel, and the parallel distance is 4cm, which is beneficial to the radiation heat exchange between the catalytic combustion and the heat exchanger. The heat exchangers are connected in series by connecting pipes 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com