Patents

Literature

130results about How to "Reduce combustion noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

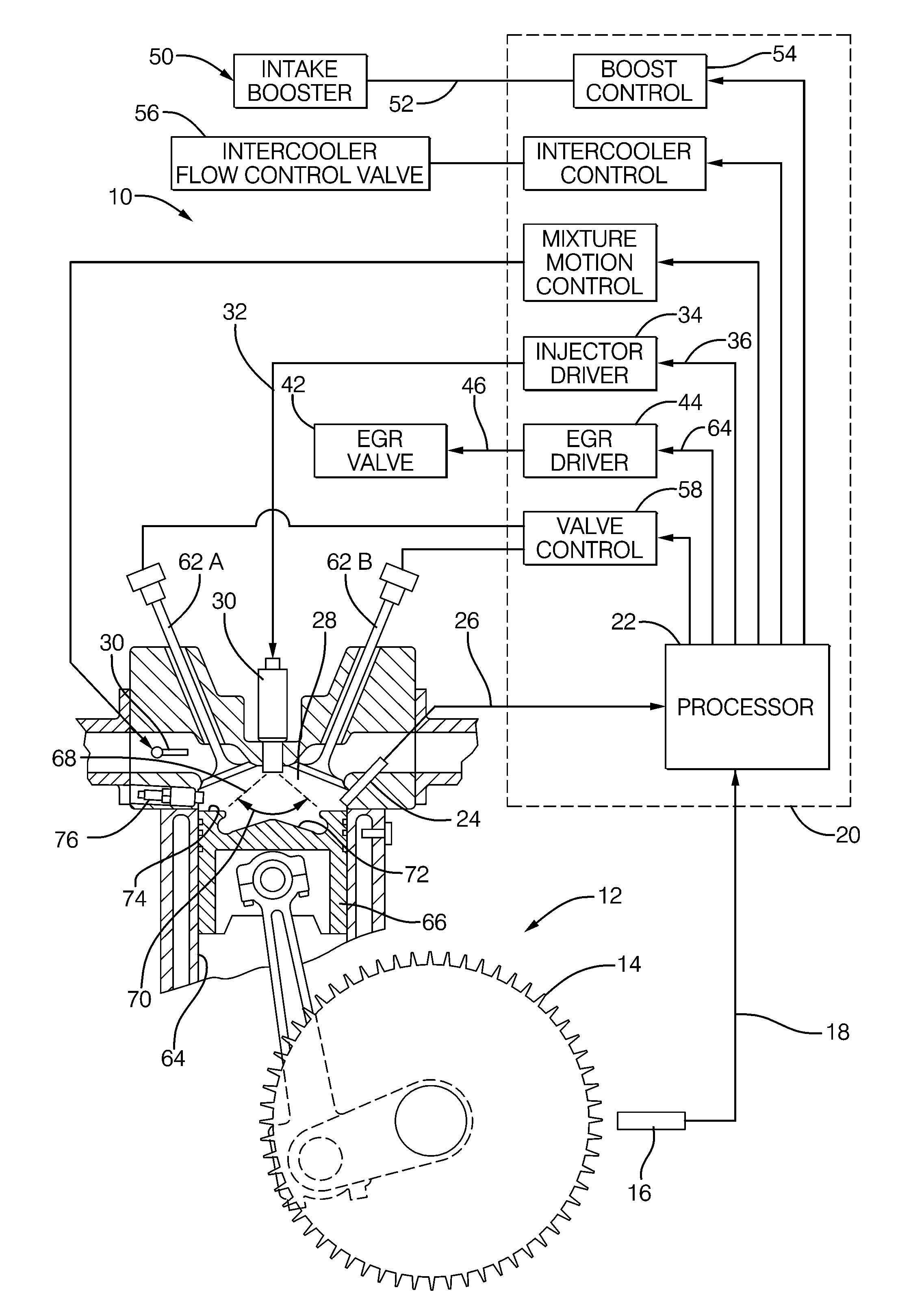

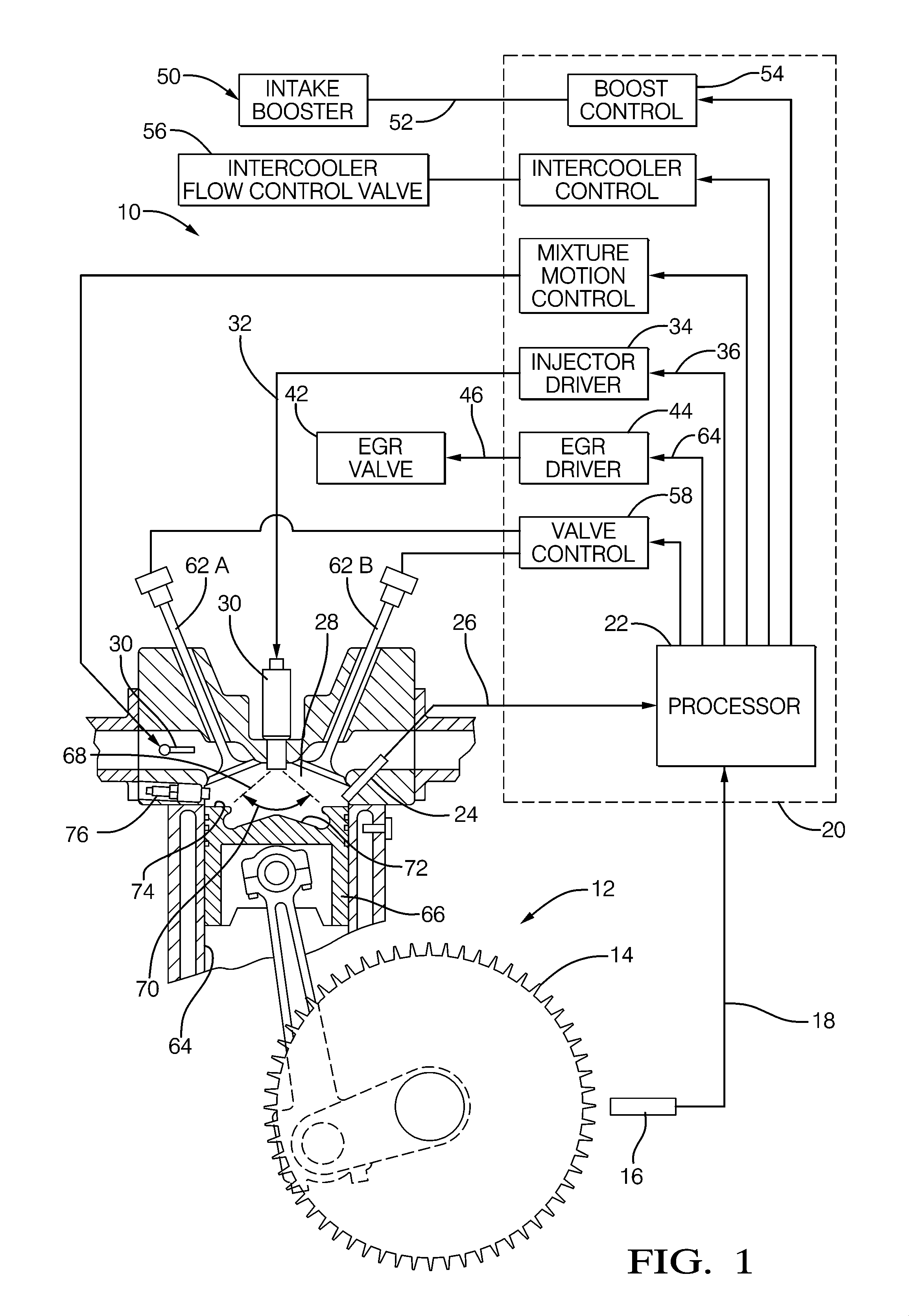

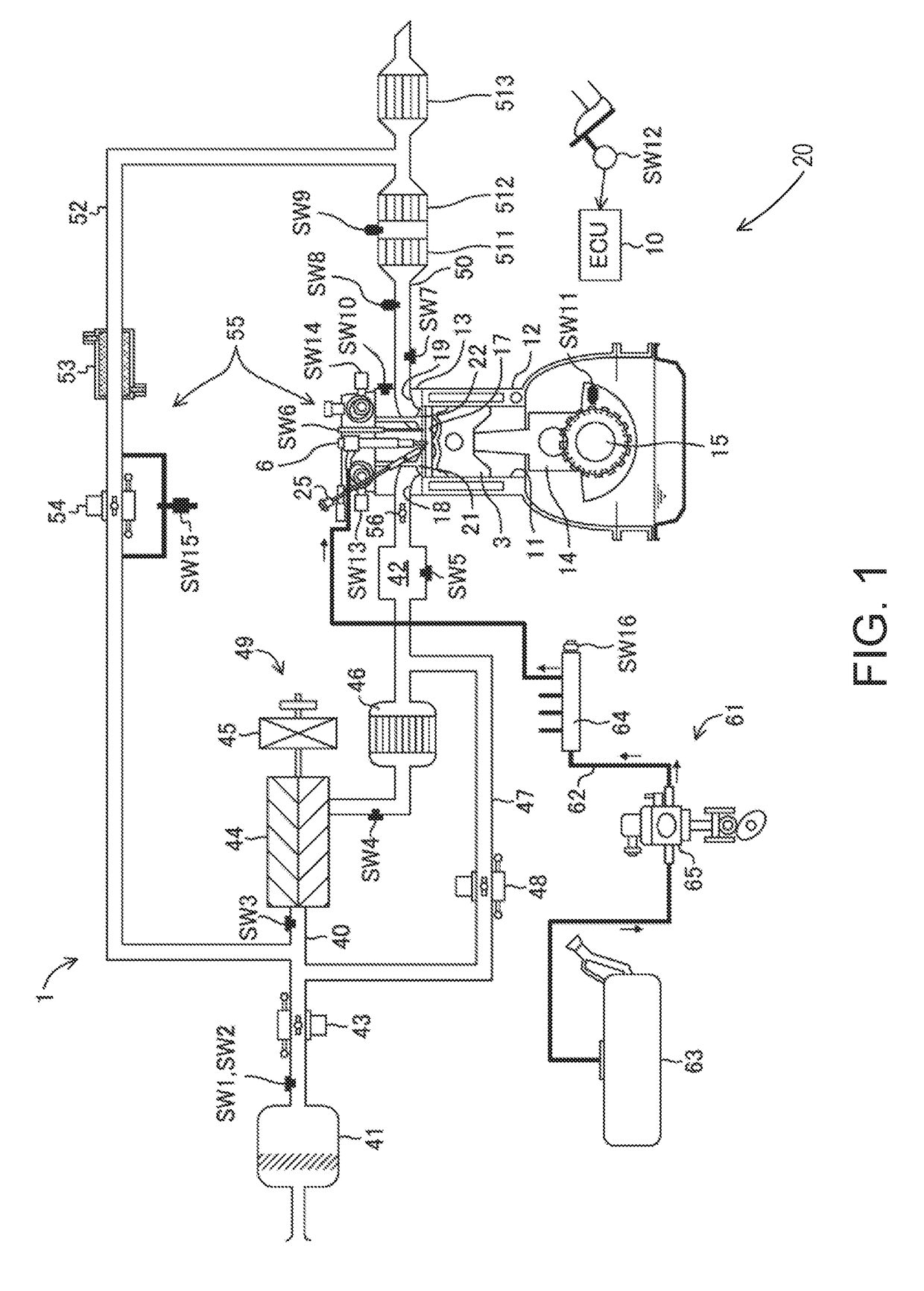

High-Efficiency Internal Combustion Engine and Method for Operating Employing Full-Time Low-Temperature Partially-Premixed Compression Ignition with Low Emissions

InactiveUS20130213349A1Improve efficiencyIncrease relative volatilityElectrical controlInternal combustion piston enginesLow noiseGasoline

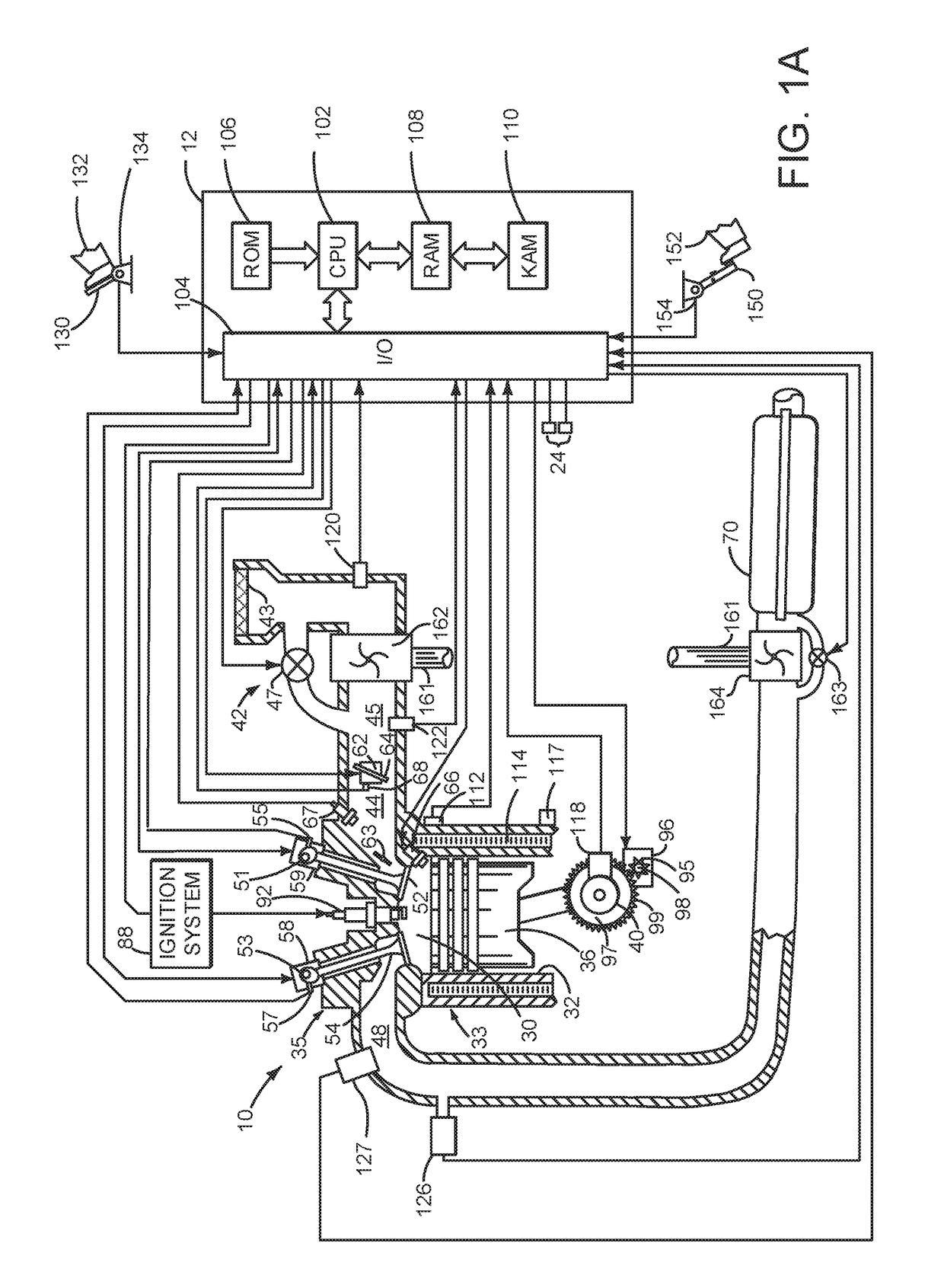

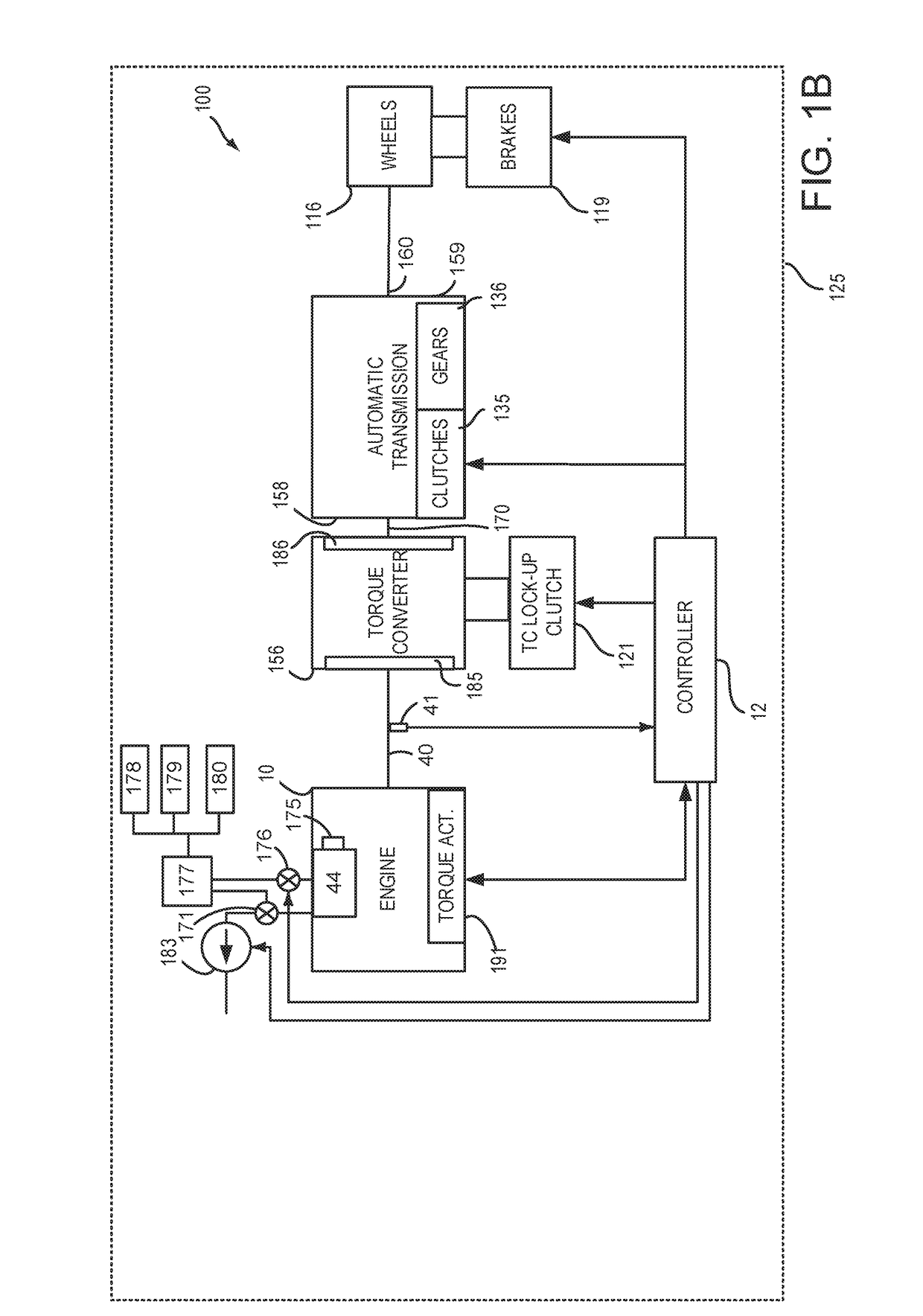

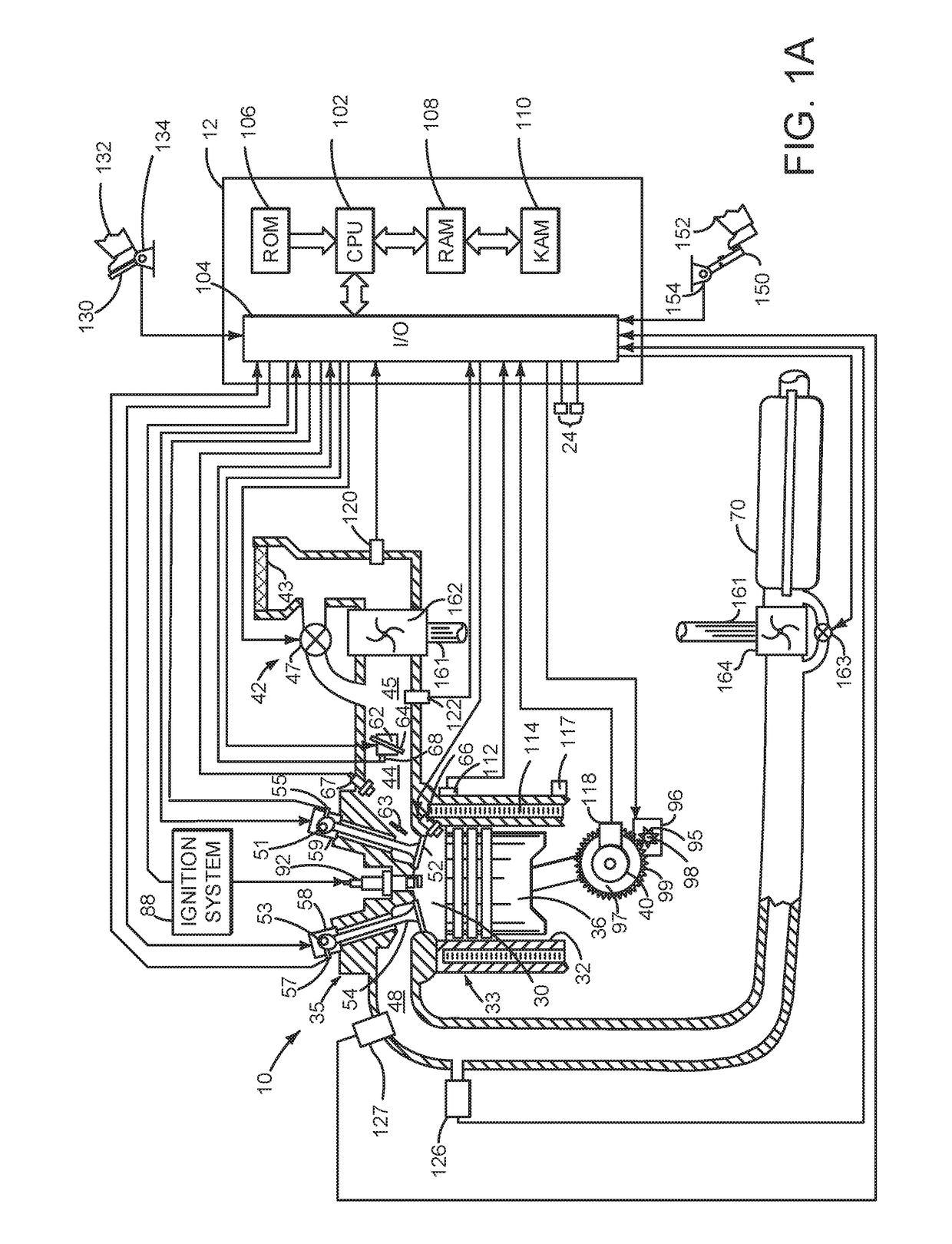

An engine system and a method of controlling a combustion process in an internal combustion engine are disclosed. The combustion process is based on compression ignition of a stratified air-fuel mixture using a high octane fuel such as gasoline. Multiple fuel injections may be used in a given combustion cycle. Fuel injection timing, EGR, exhaust rebreathing, late intake valve closing, and intake boost are controlled to enable autoignition over essentially the entire speed and load operating range of the engine, while providing reduced emissions, low noise, and low fuel consumption.

Owner:DELPHI TECH IP LTD

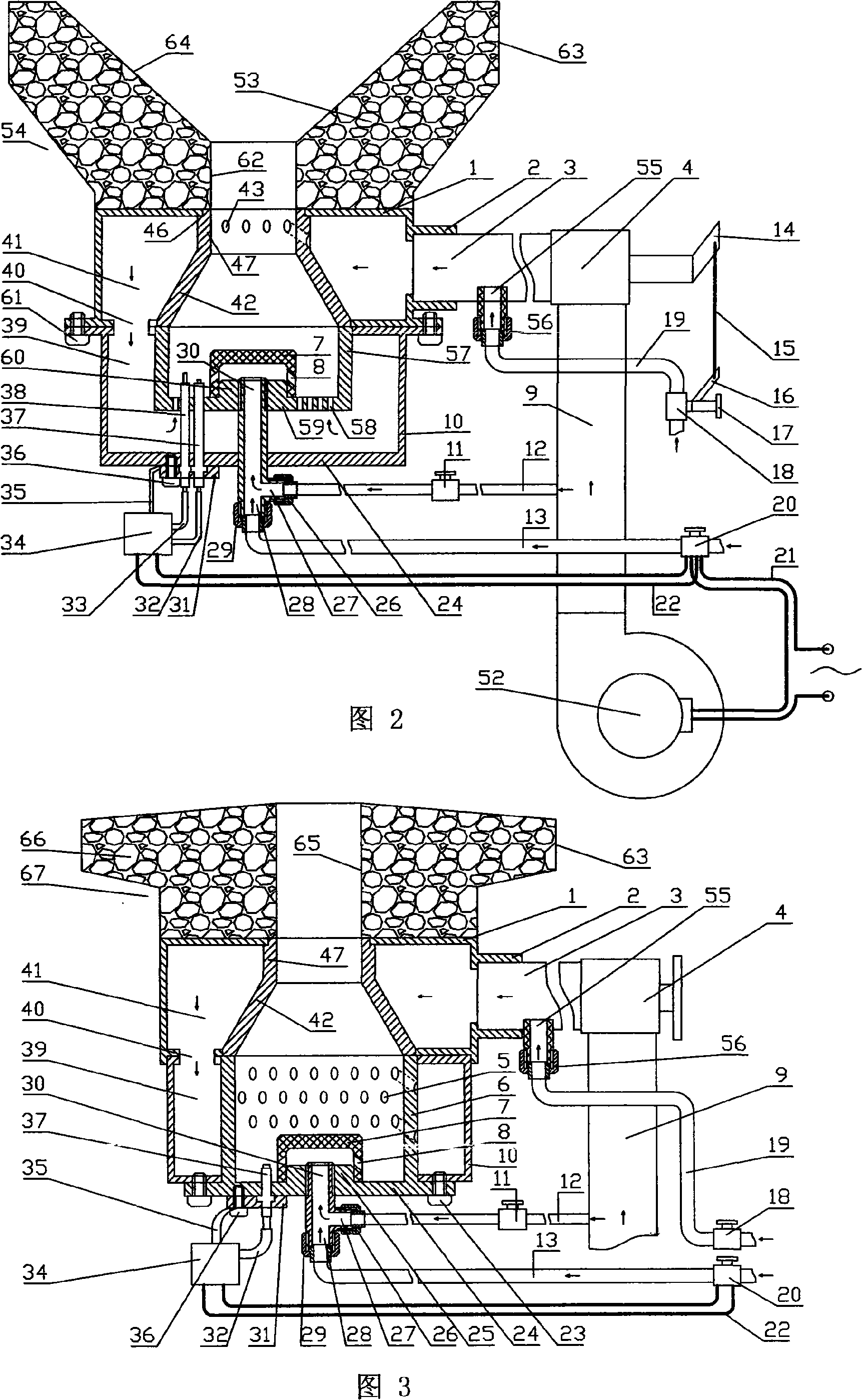

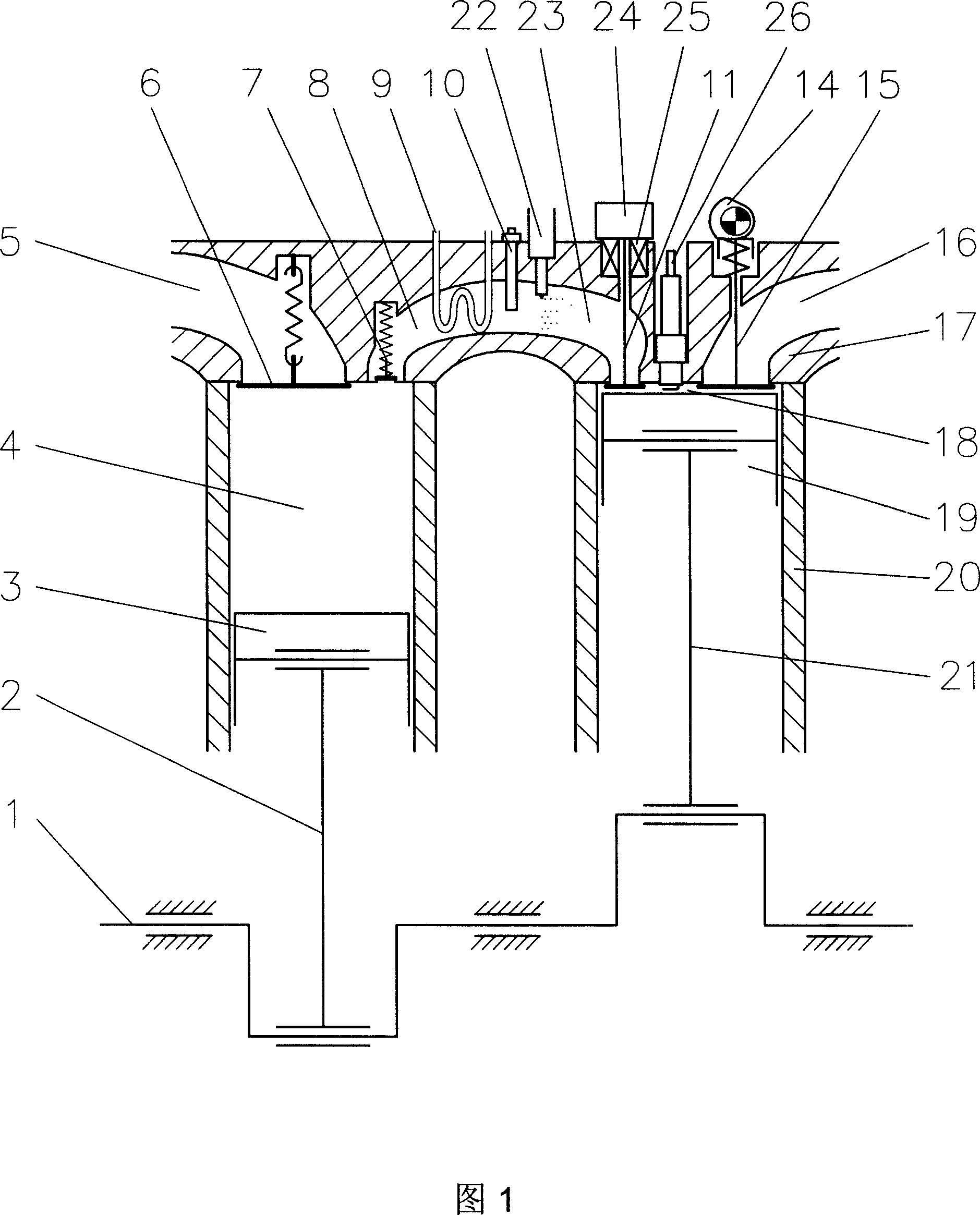

High-efficiency energy-saving high speed combustor of gas range

The invention is a high-efficiency, energy-saving and high-speed burner for a gas cooker used in catering industry and includes a burner, a pre-heater, a pre-mixing small fire burner, a fireproof fire ring, an electronic ignition system and a regulating device. After being necked down, the burning flame is ejected with high speed rotation to form the rotary rapid ejection burning flame, thereby realizing sufficient burning, facilitating boiler heating, and increasing the heating speed with low burning noise and high heat efficiency. The high-efficiency, energy-saving and high-speed burner for the gas cooker has the advantages of simple manufacture, easy maintenance, sufficient burning, high flame temperature, convenient boiler heating, improved heating speed, low power of the equipped blower fan, low burning noise, high thermal efficiency, convenient regulation, full-automatic ignition, concentrative firepower, intensive fire, energy conservation, strong adaptability, capability of meeting different requirements, wide application, easy processing, low manufacture cost and suitability for mass production.

Owner:尹华金

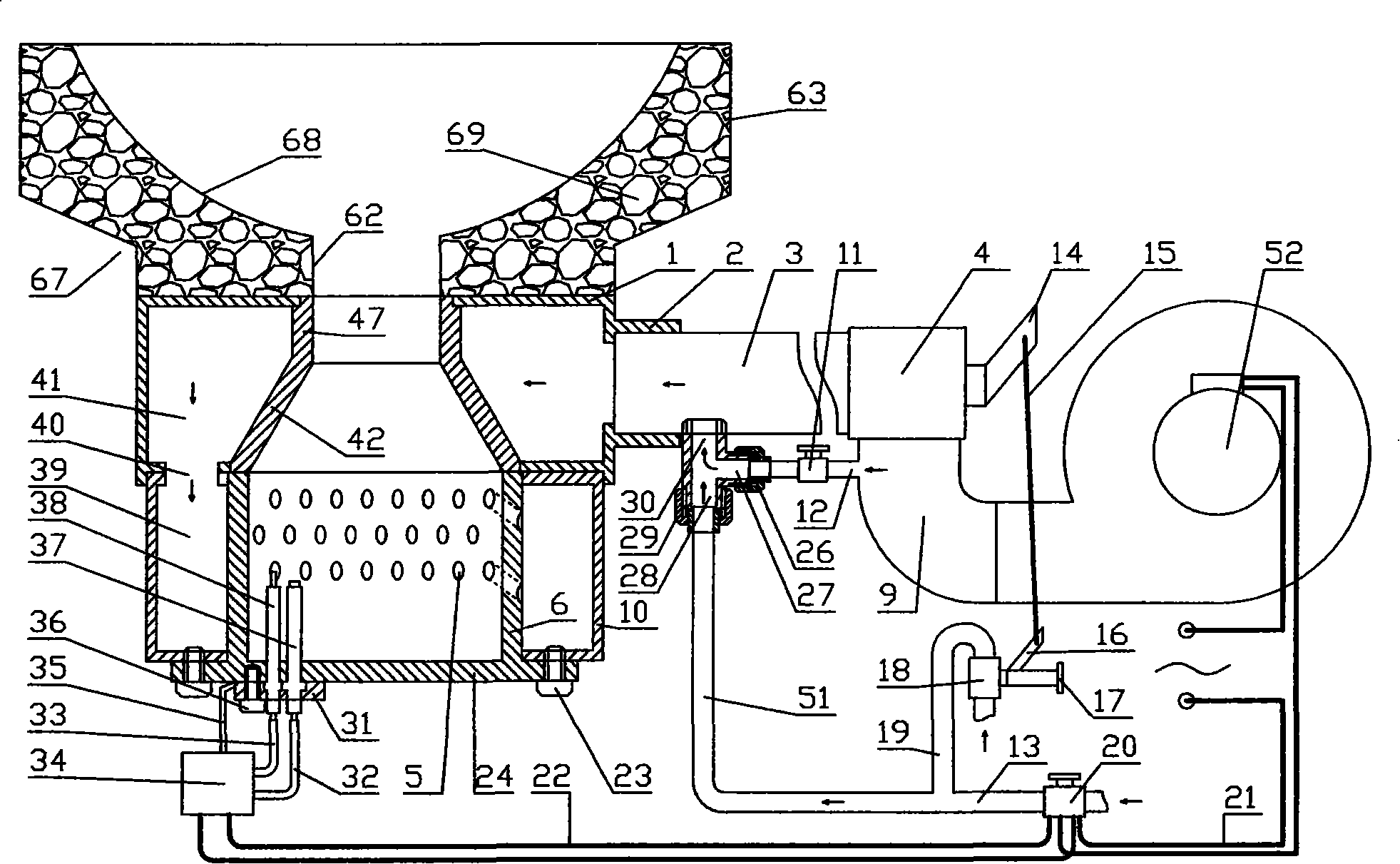

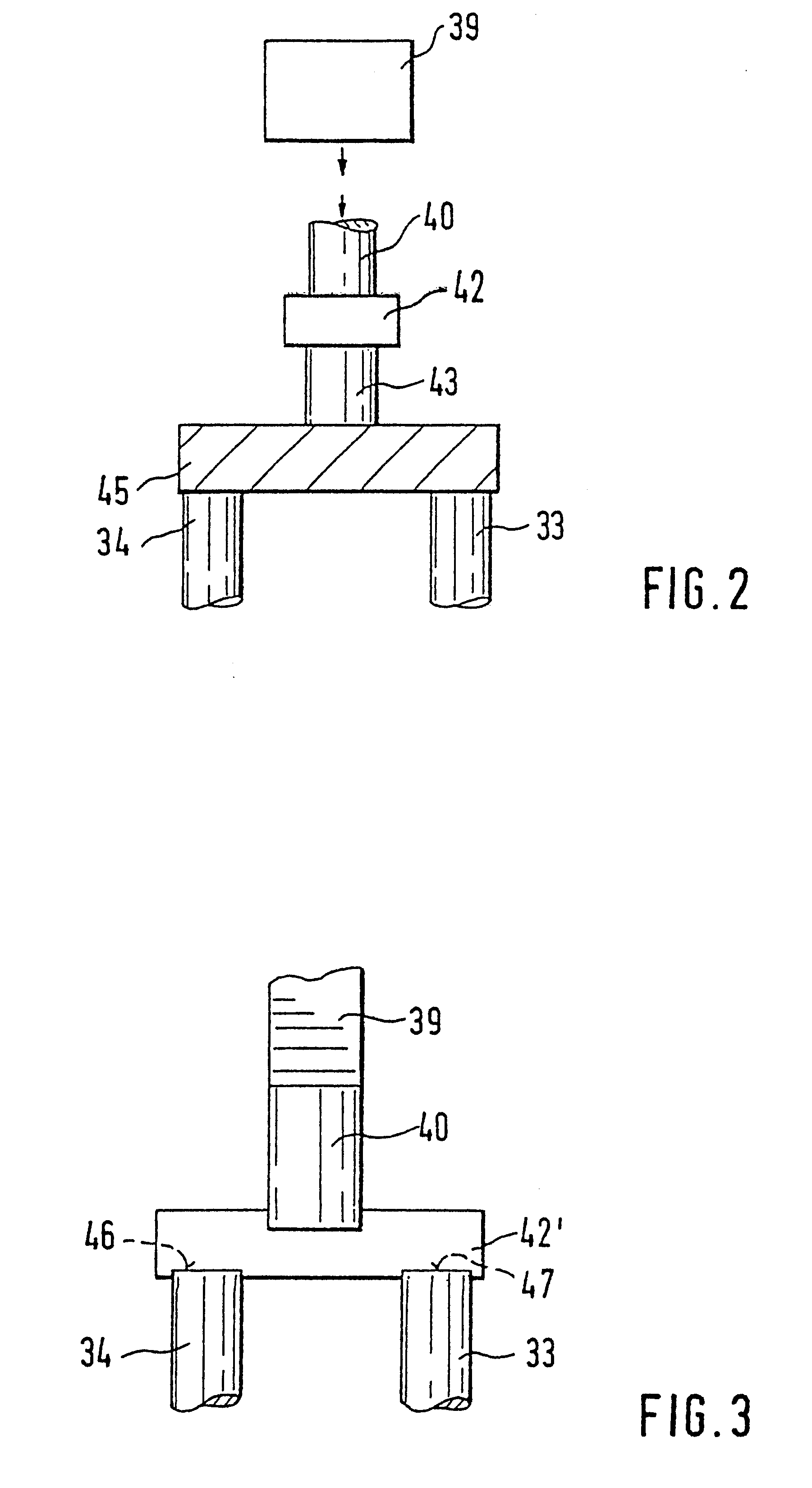

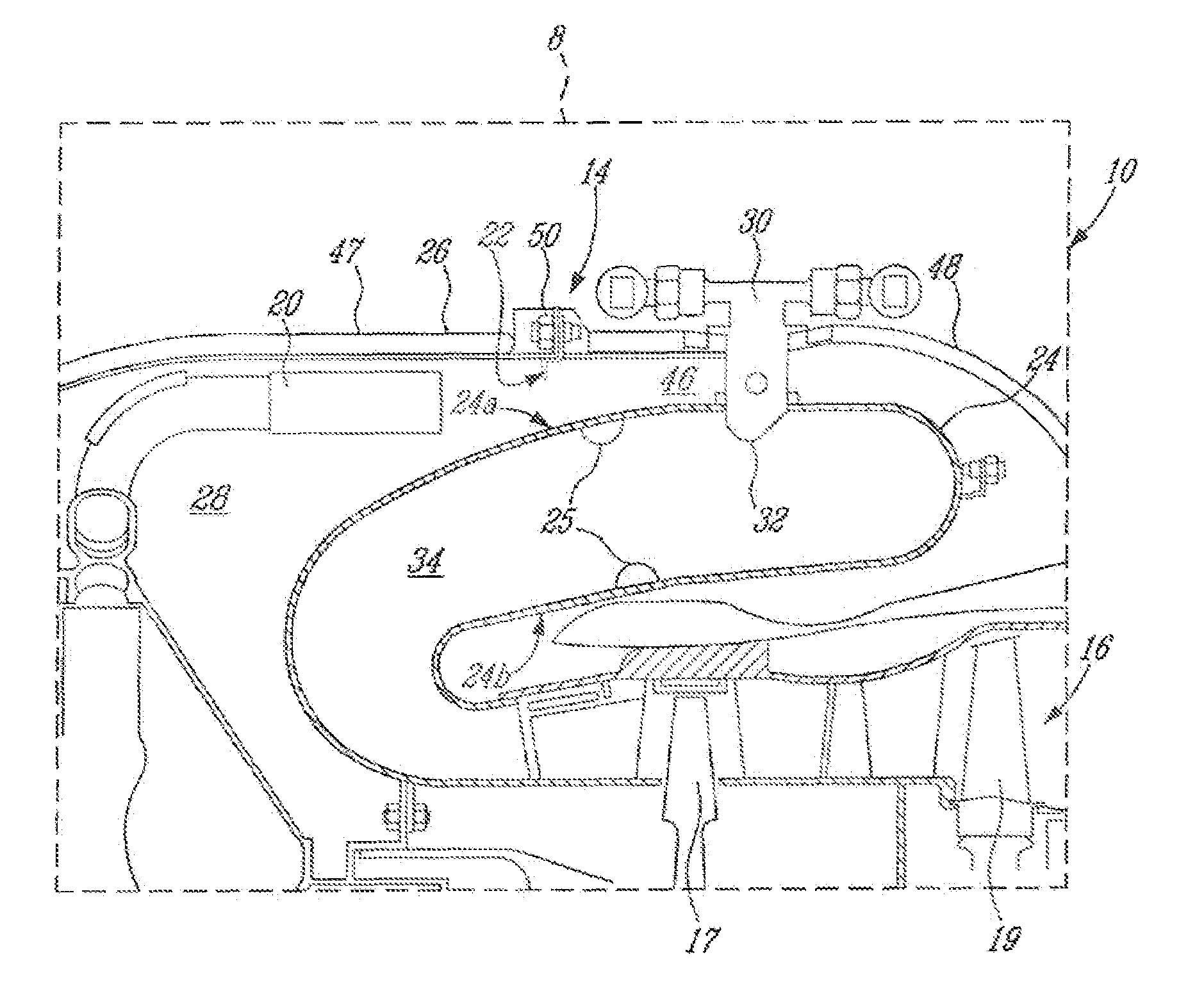

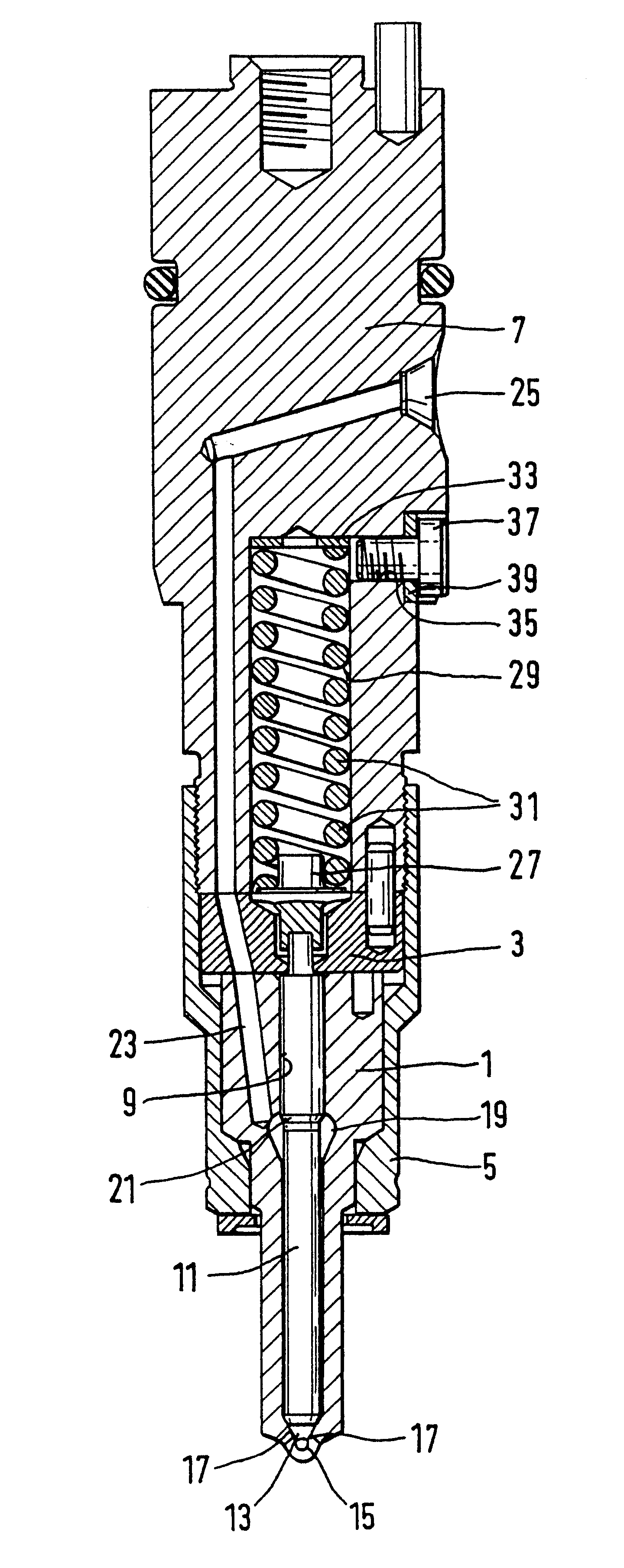

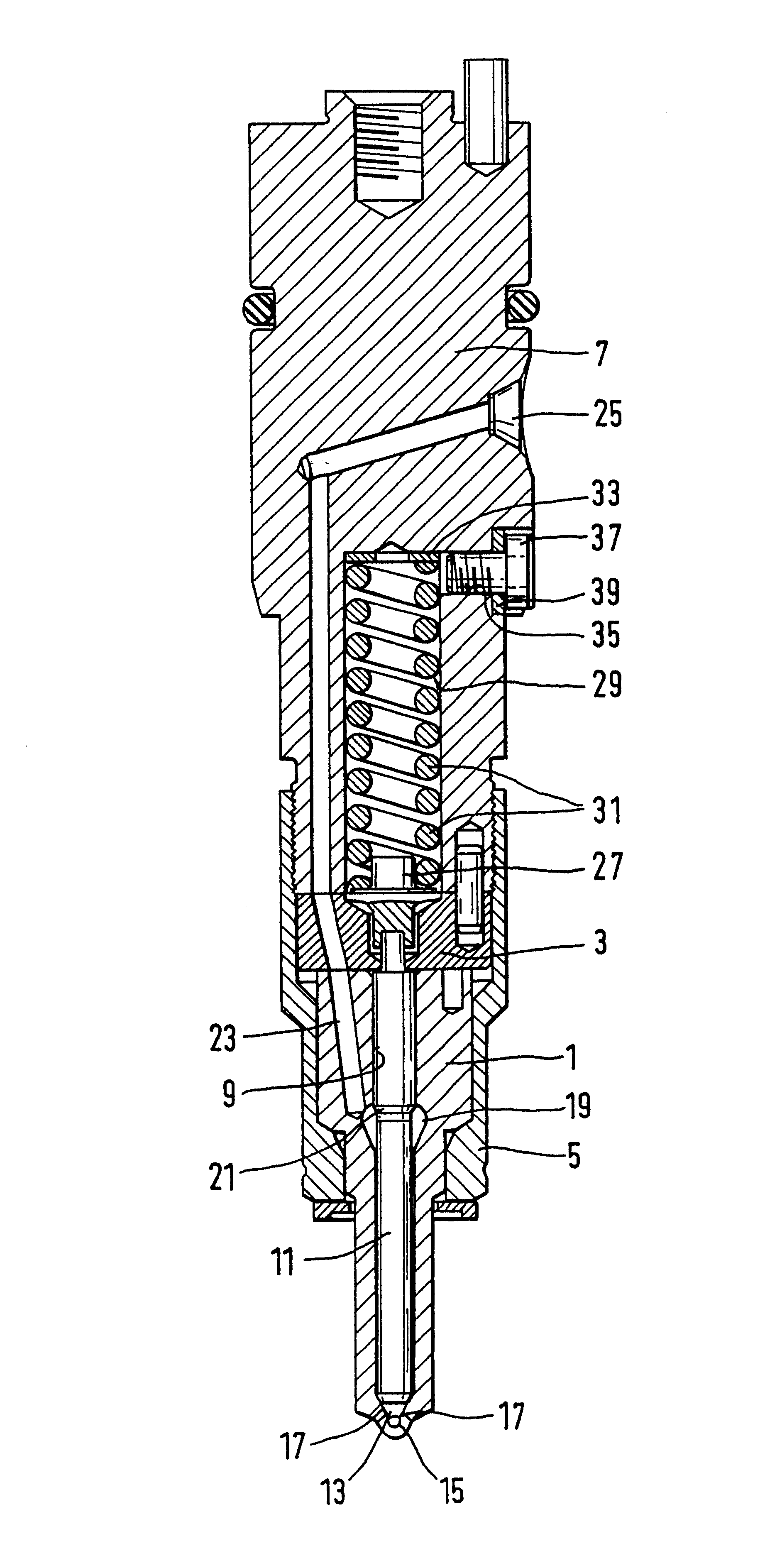

Fuel injection valve

InactiveUS6328017B1Limited durationLow structural costEngine controllersMachines/enginesCombustionEngineering

A fuel injection valve for an internal combustion engines is proposed, in which the control of the fuel injection valve member is controlled through the control of the pressure of a control chamber (25). This chamber is either relieved by means of a control valve (31) or is subjected to a high pressure, which brings the fuel injection valve member into the closed position. At the same time as the relief of the control chamber, a valve member (33) of a safety valve (32) that controls the fuel supply to the fuel injection valve is opened so that upon opening of the fuel injection valve, high-pressure fuel simultaneously also can travel by way of a pressure line (12) from a high-pressure fuel reservoir (14) to the injection openings (8) of the fuel injection valve (1). After the end of the injection, the valve member (33) is closed again, together with the closing of the fuel injection valve member (5). Consequently, in the event of a malfunction, unwanted fuel is prevented from reaching injection for a long period of time and consequently possibly destroying the associated engine due to overdosing.

Owner:ROBERT BOSCH GMBH

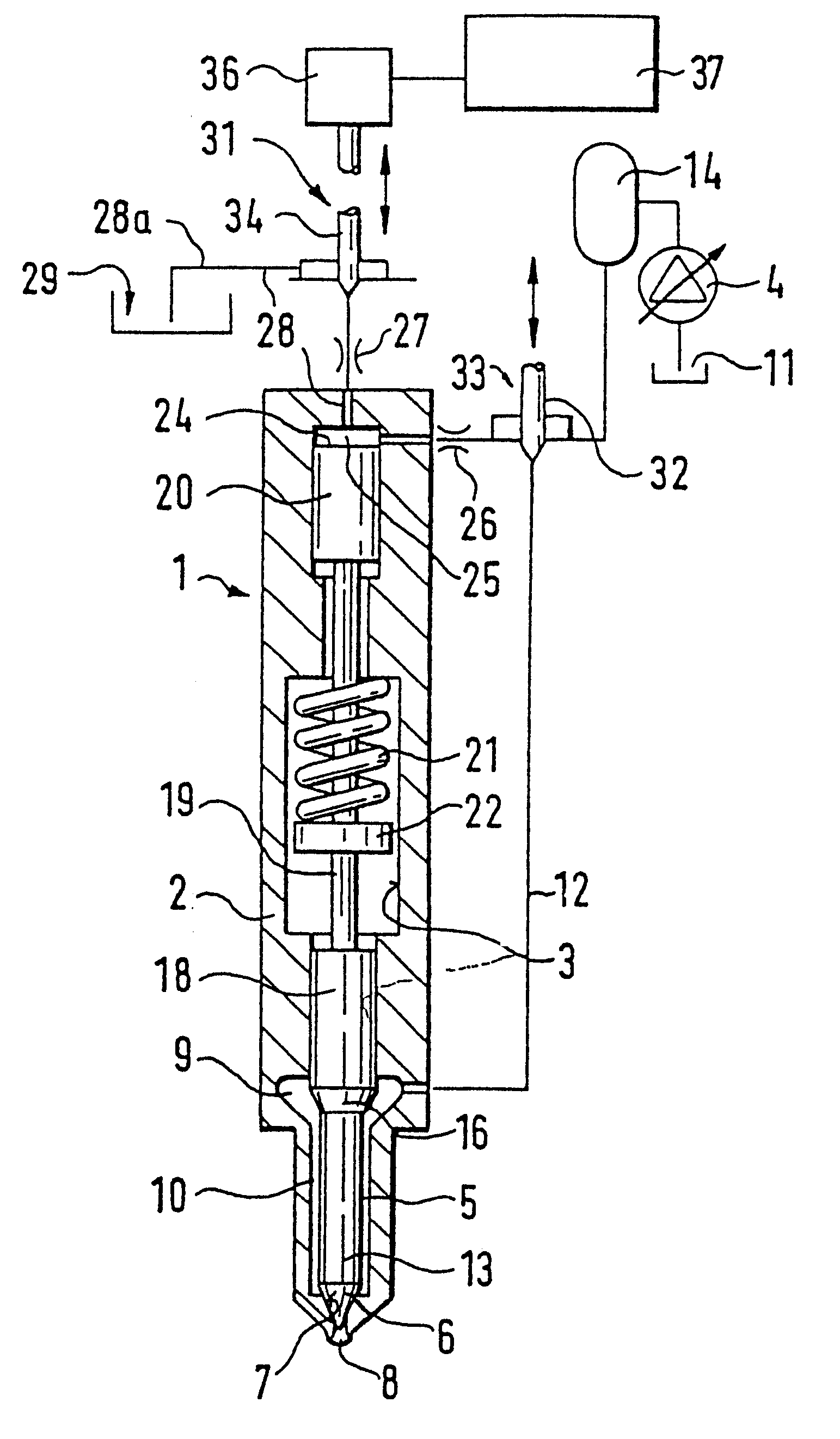

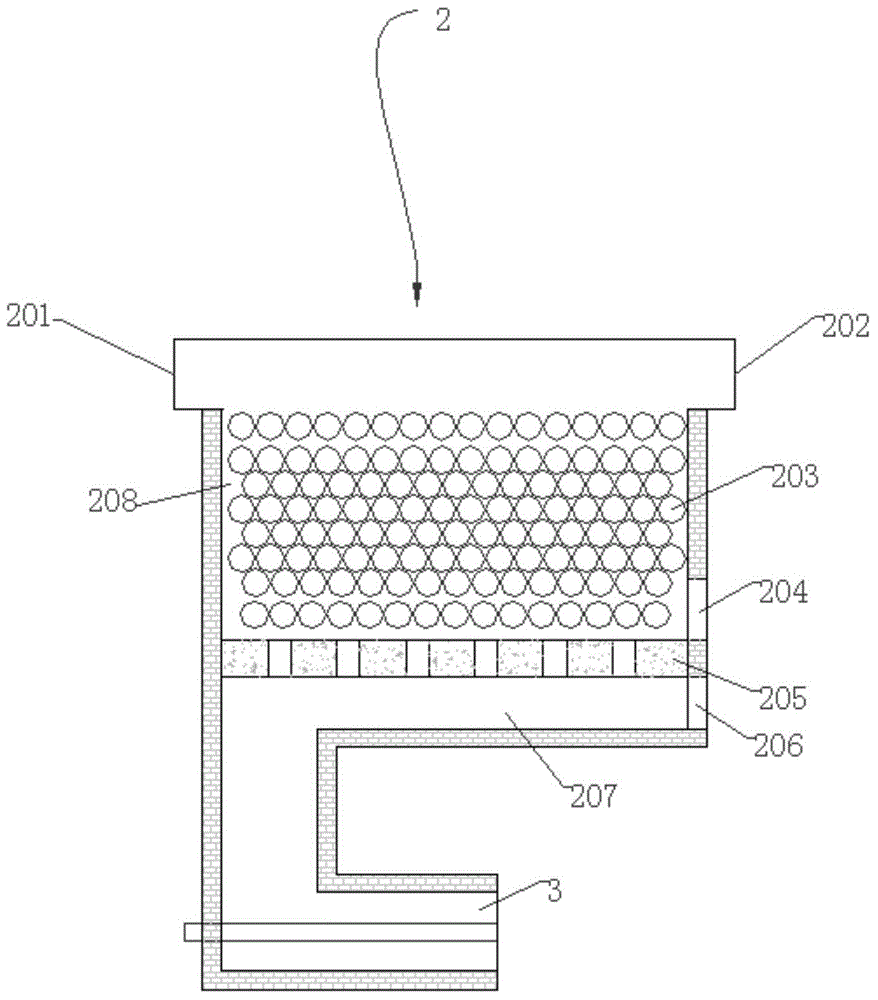

Low-exhaustion high-efficiency energy-saving combustor

InactiveCN101504140AReduced Power RequirementsWell mixedDomestic stoves or rangesElectrical heating fuelCombustorEngineering

The invention relates to a low-emission energy-efficient burner, which comprises a sleeve shaped furnace end cover. The lower side of the furnace end cover is connected with a circular fuel gas distributing box, a cylindrical air dispersing and fuel gas mixing device used for mixing air and the fuel gas is arranged between the furnace end cover and the fuel gas distributing box, and the fuel gas distributing box is provided with an independent central pipe for inputting the air and an independent fuel gas inlet hole for inputting the fuel gas; and the cylindrical surface of the air dispersing and fuel gas mixing device is provided with a plurality of mutually interval grooves inclined upwards, and the surfaces of the grooves are provided with air dispersing holes for discharging the air. The structure buffers and depressurizes the entering pressure fuel gas and the air, better mixes the both, reduces the fan power demand and greatly reduces the burning noise. The dispersed air and fuel gas are fully mixed in the grooves inclined upwards, then circumgyrate upwards, and reach a turbination platform shaped flame hole after convoluting and secondary mixing. The full mixing makes the burning flame stable, full and not easy to be extinguished. Additionally, the burner simplifies the structure of flame ionization detection and reduces the cost.

Owner:林光涌

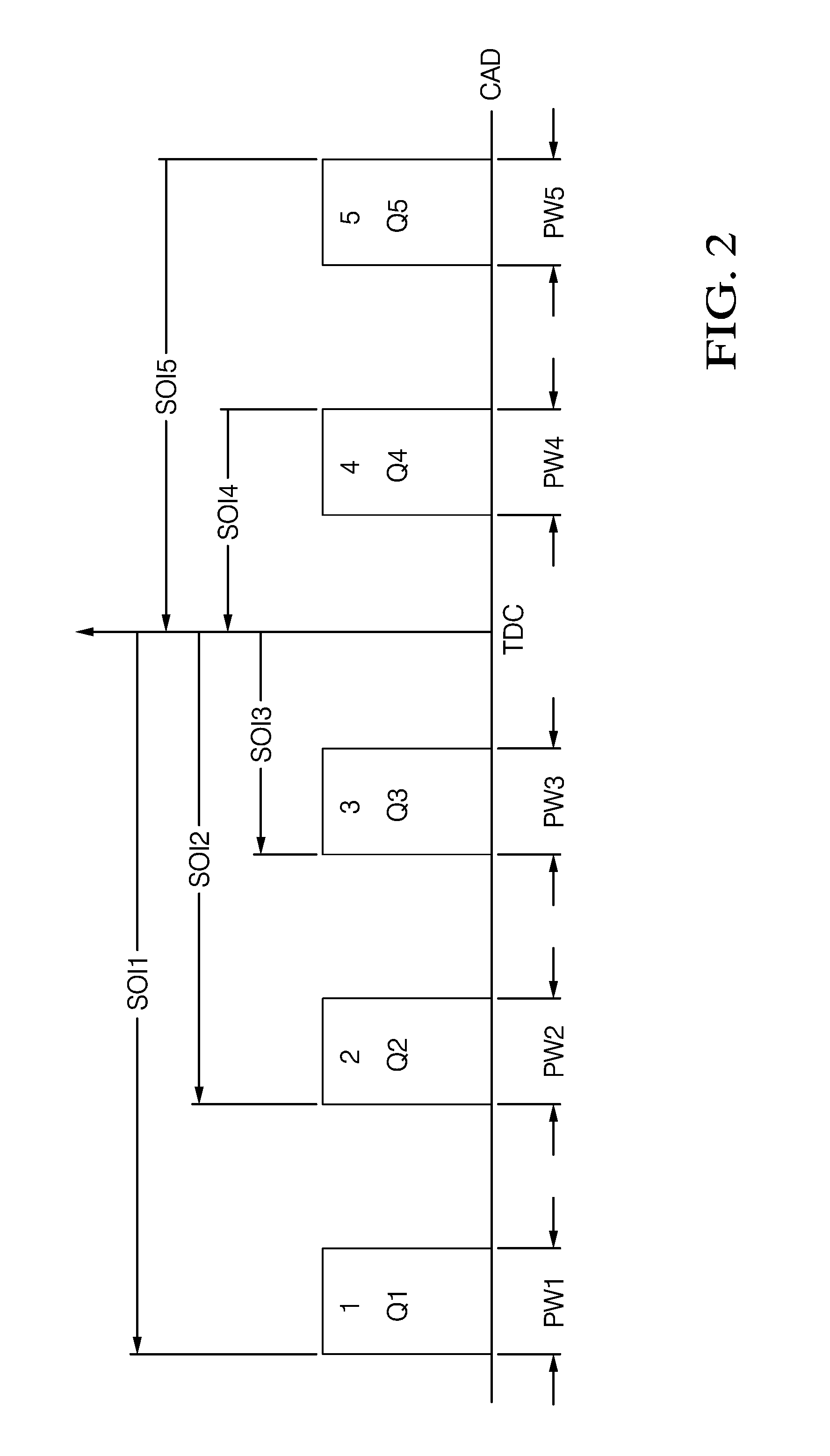

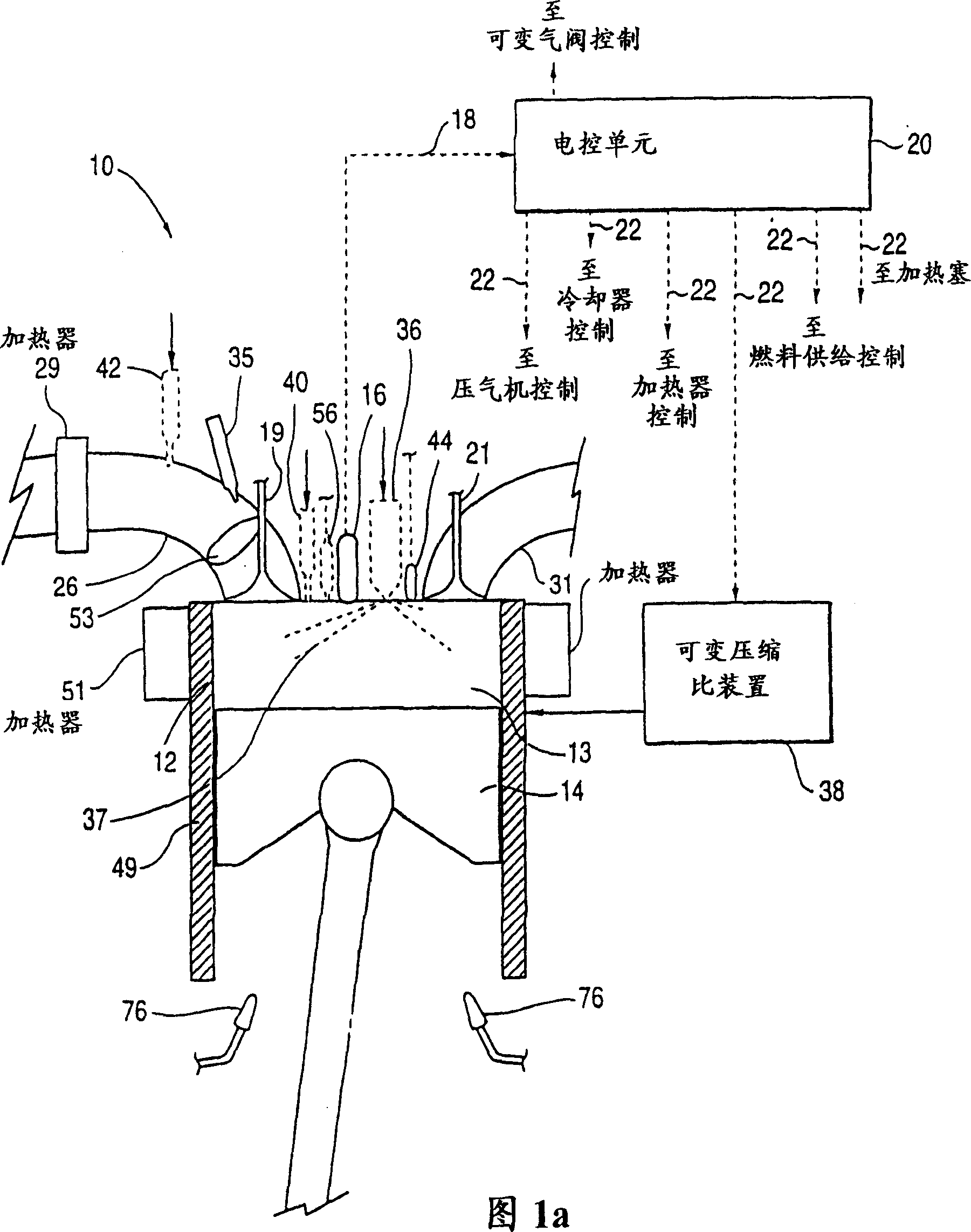

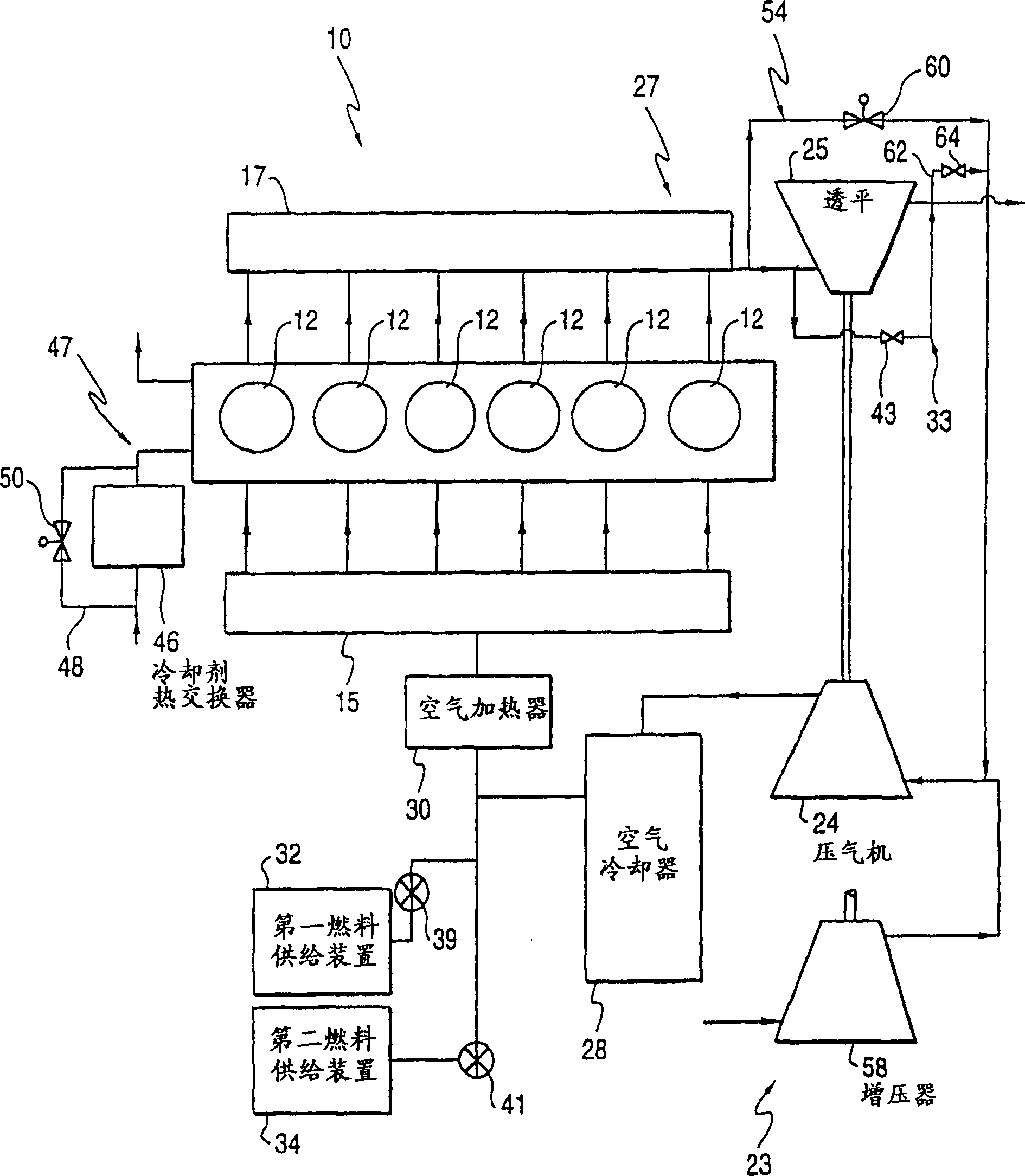

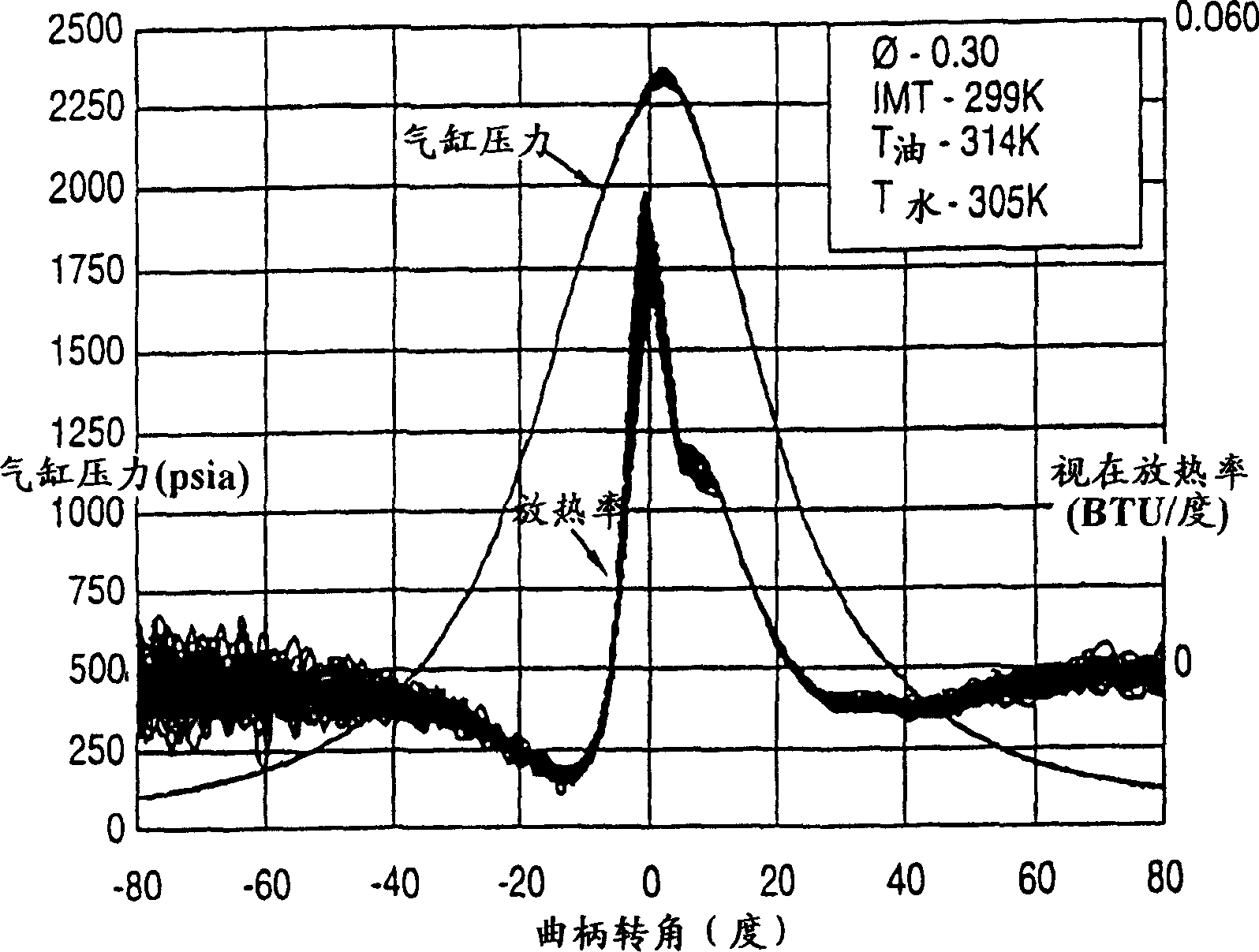

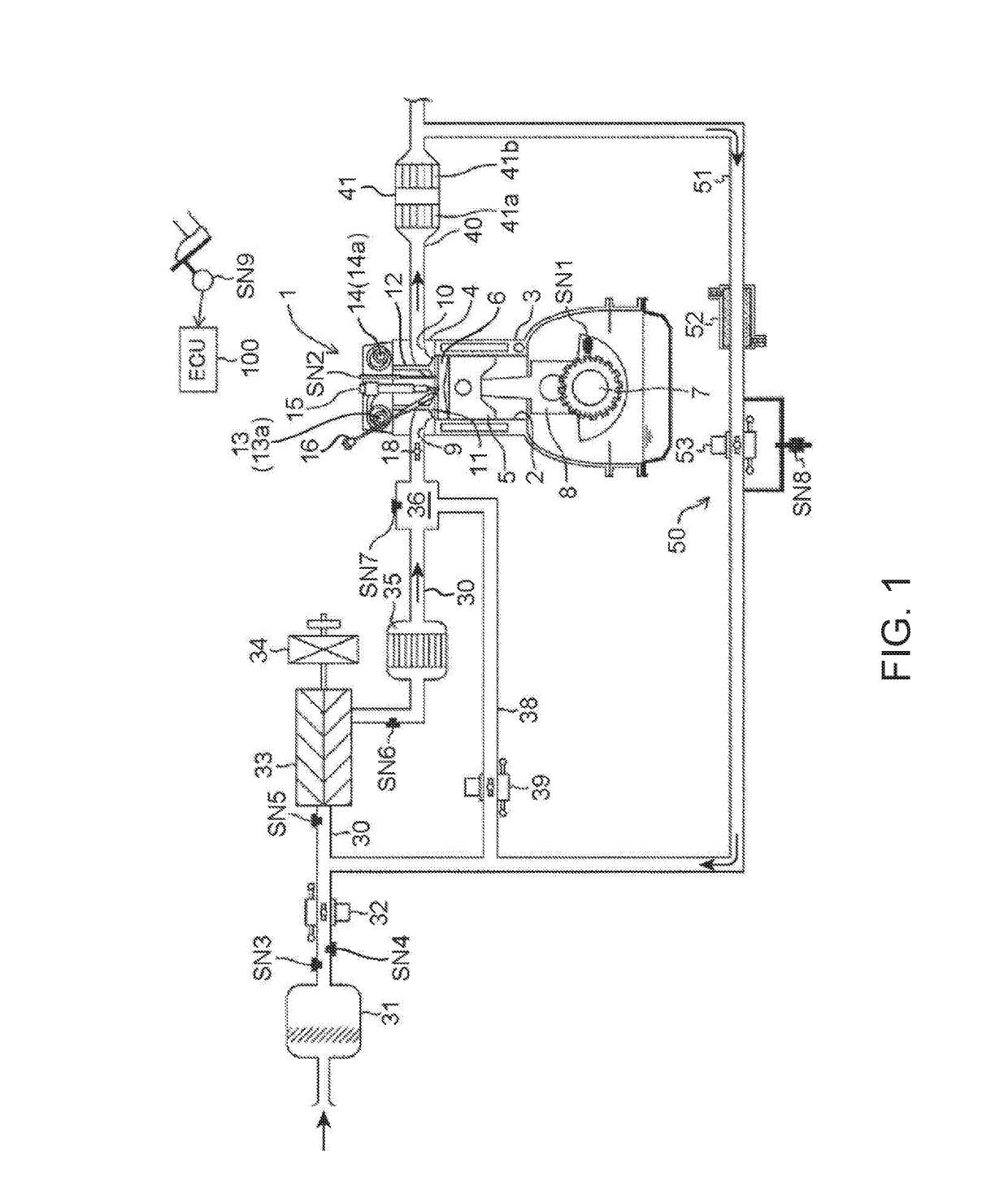

Premixed charge compression ignition engine with optimal combustion control

InactiveCN1624305AControl control systemEffective controlElectrical controlInternal combustion piston enginesTemperature controlActive feedback

The present invention provides a premixed charge compression ignition engine and control system (10), which can effectively trigger combustion and maintain stable combustion by means of compression ignition, while achieving extremely low nitrogen oxide emissions, good overall efficiency and Acceptable combustion noise and cylinder pressure. The engine and control system (10) of the present invention can effectively control the combustion process by controlling certain control variables of temperature control, pressure control, mixture self-ignitability control and equivalence ratio control, that is, the time of combustion initiation, the combustion rate , duration of combustion and / or completeness of combustion. The combustion control system (10) provides active feedback control of combustion and includes a sensor for detecting engine operating conditions representative of a combustion process, such as ignition of combustion, and generating a corresponding engine operating condition signal (18) , such as the pressure sensor (16).

Owner:CUMMINS INC

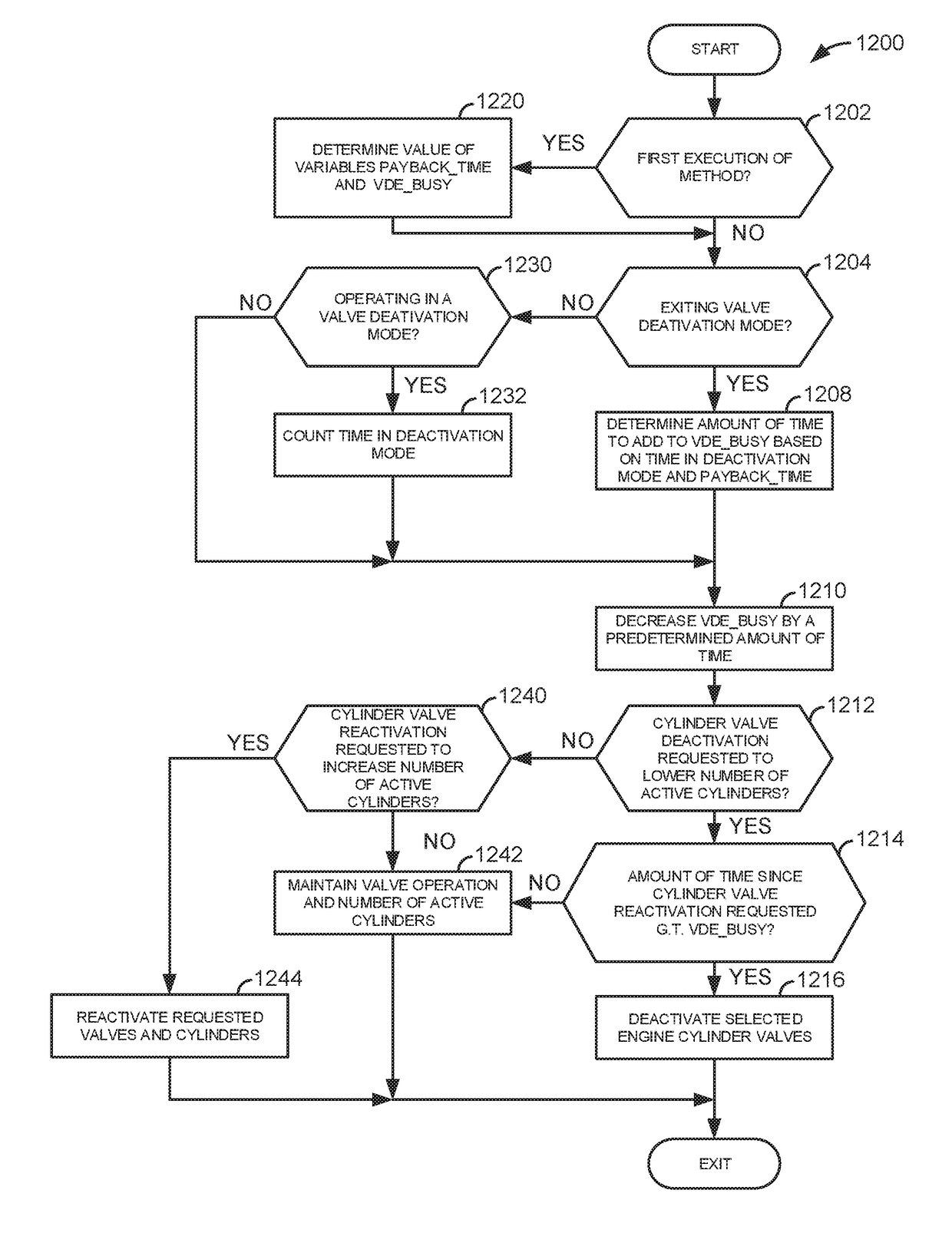

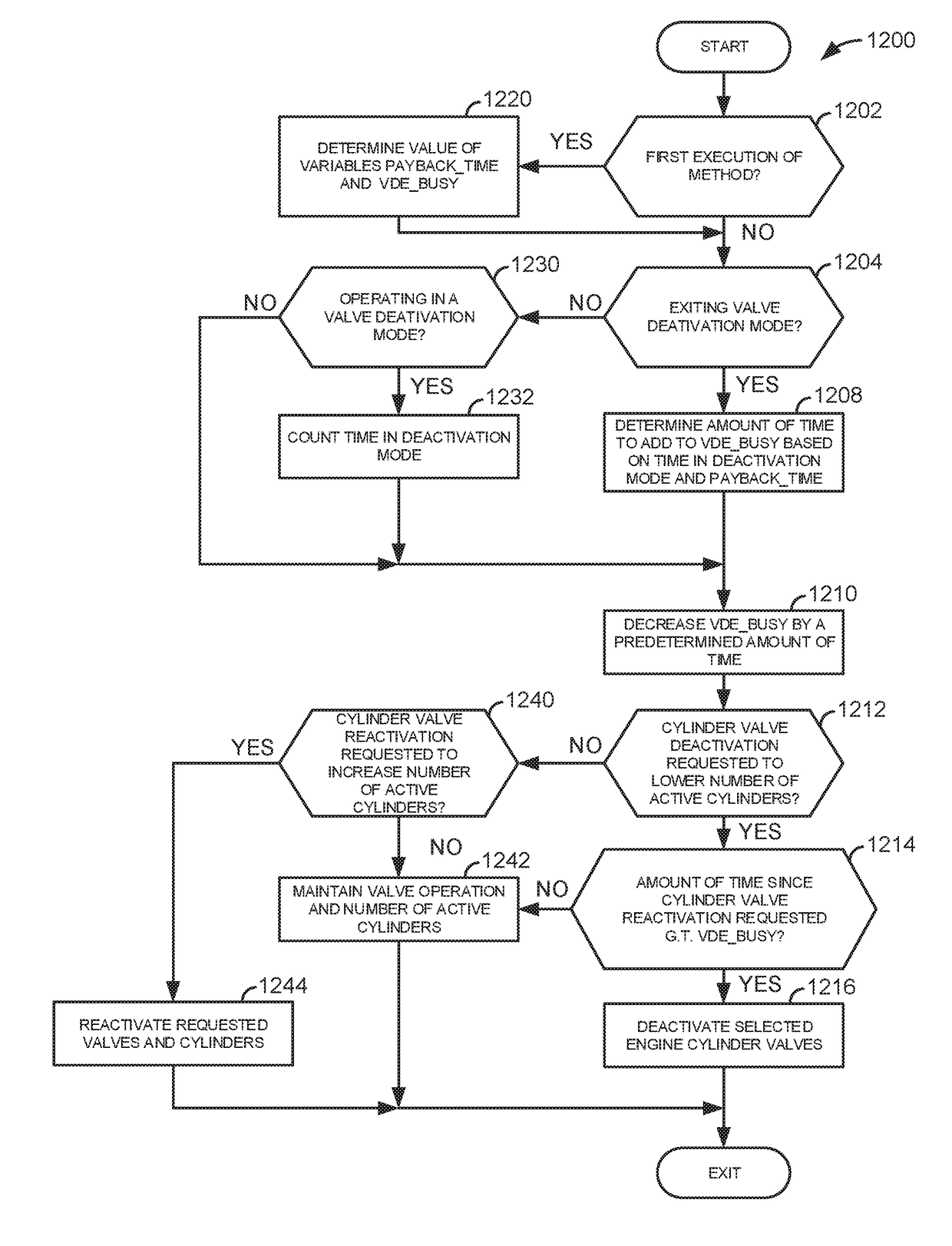

System for method for controlling engine knock of a variable displacement engine

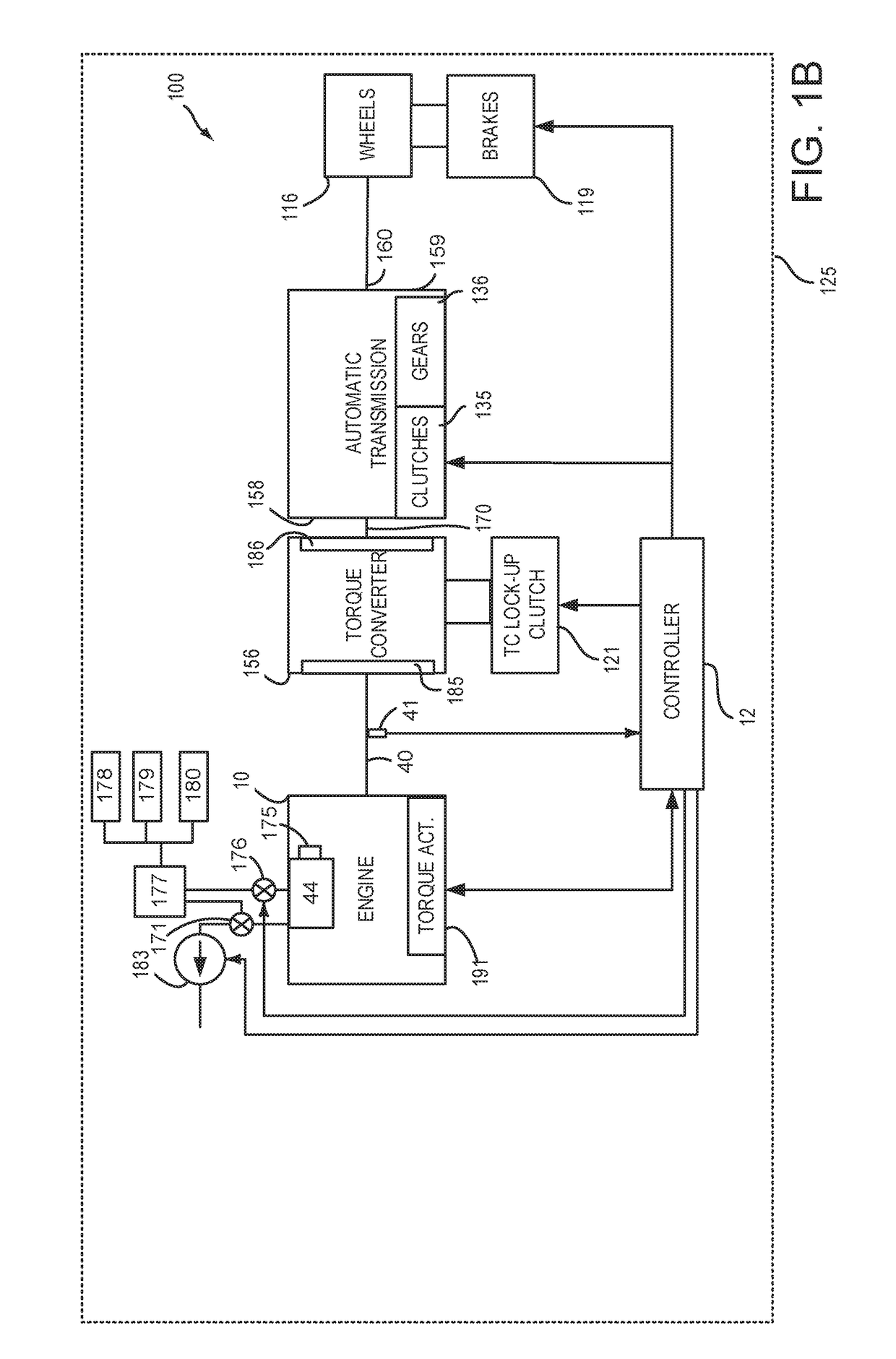

ActiveUS20170356367A1Improve and degrade capacityImprove signal-to-noise ratioElectrical controlInternal combustion piston enginesVariable displacementAutomotive engineering

Owner:FORD GLOBAL TECH LLC

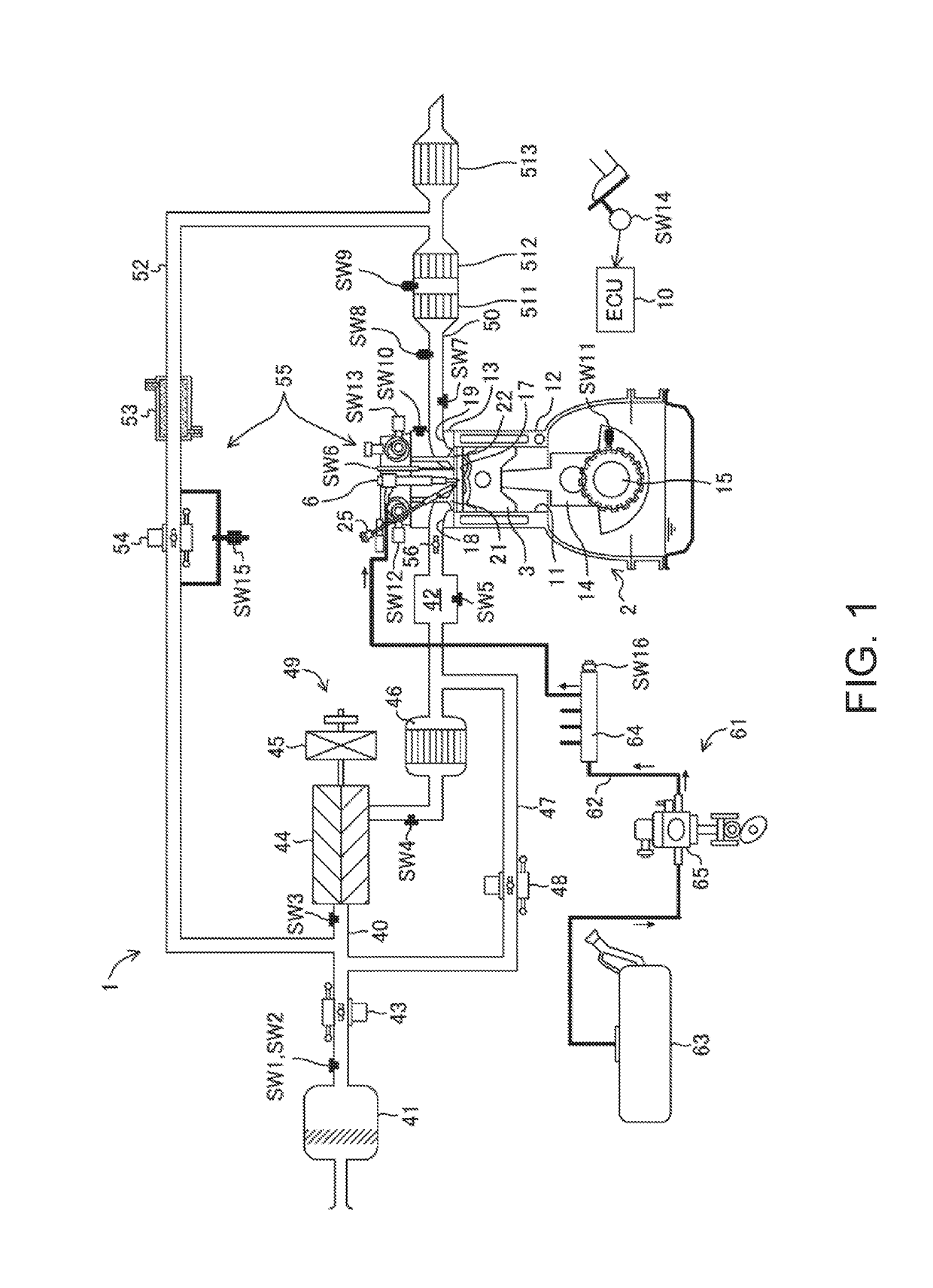

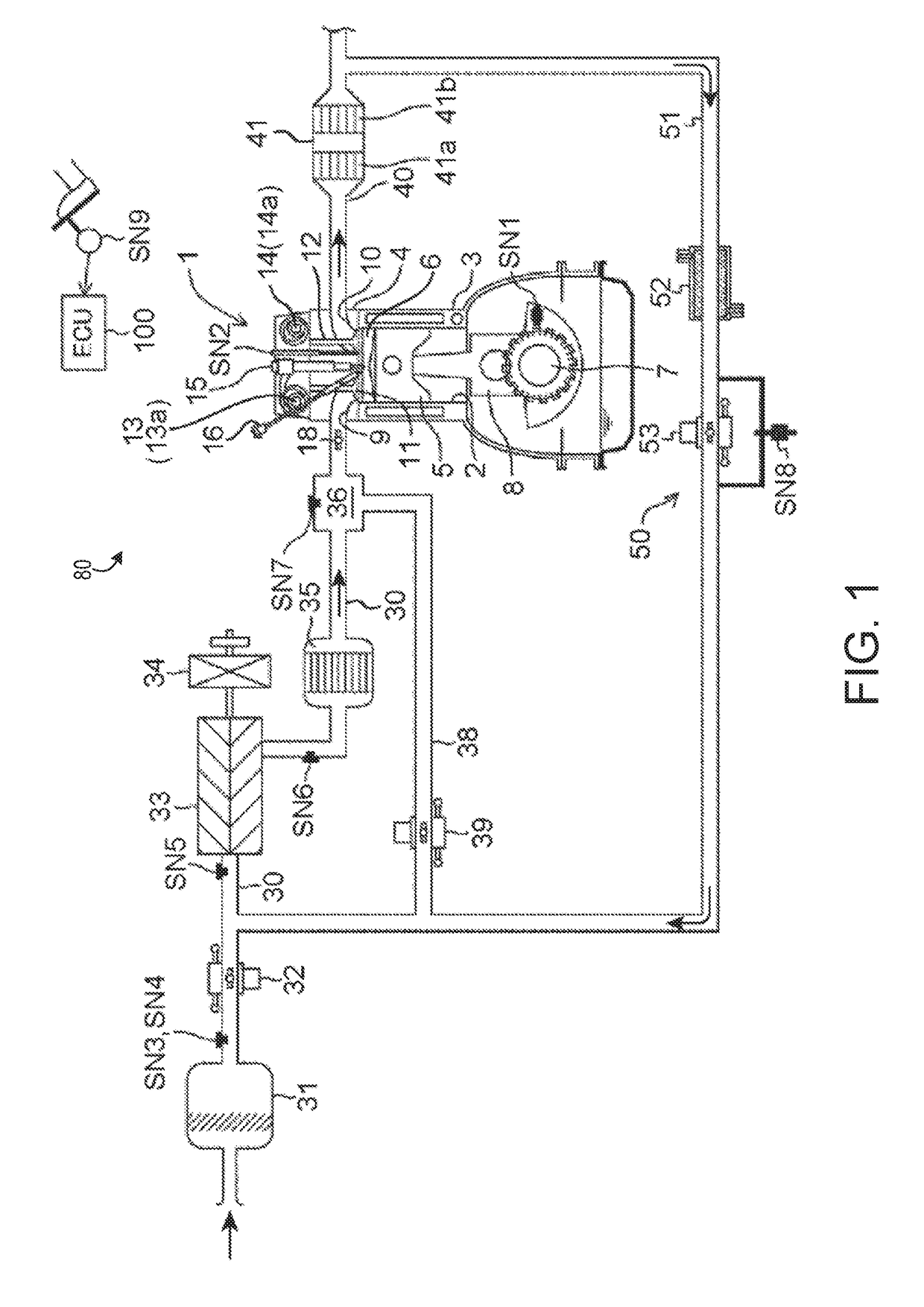

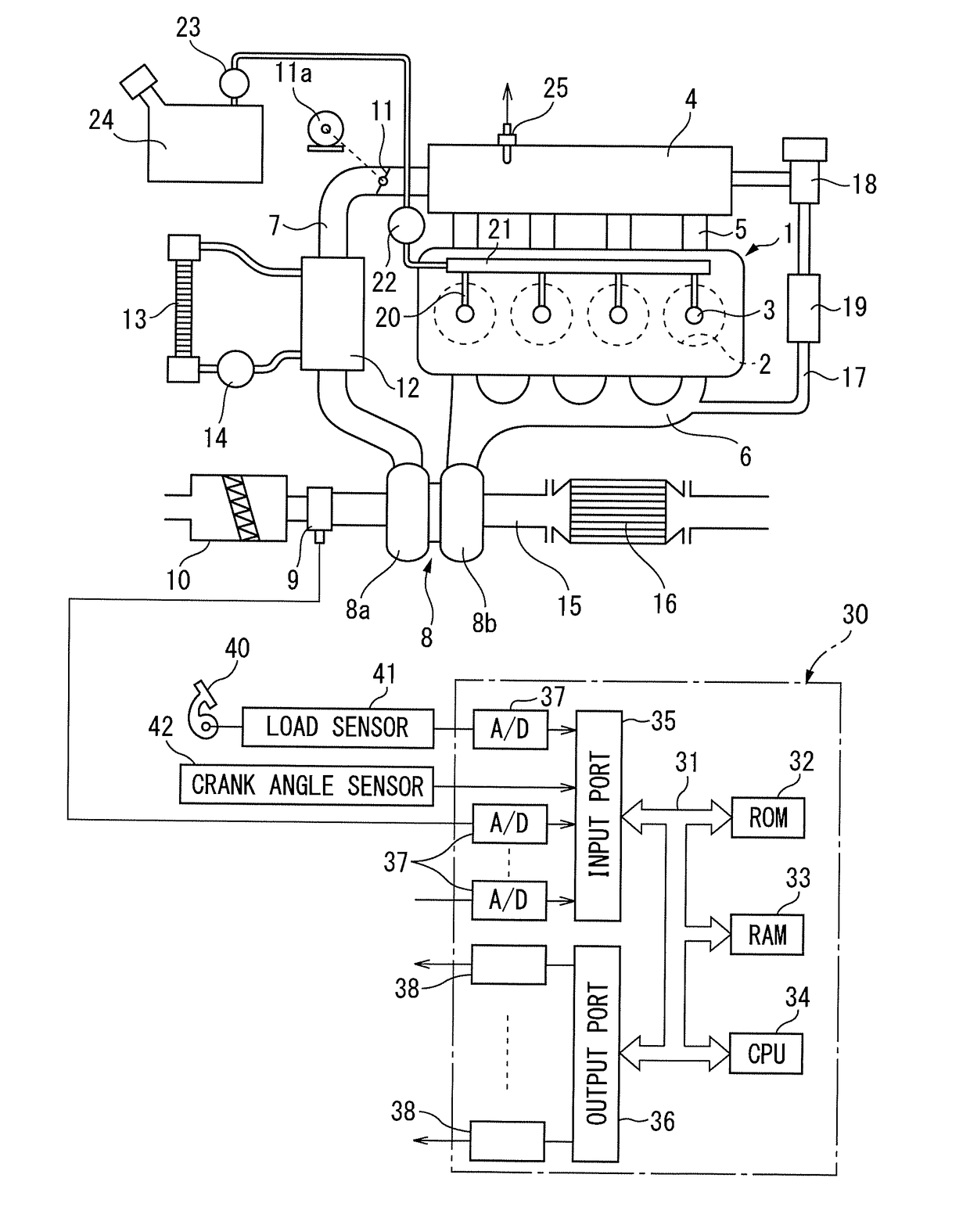

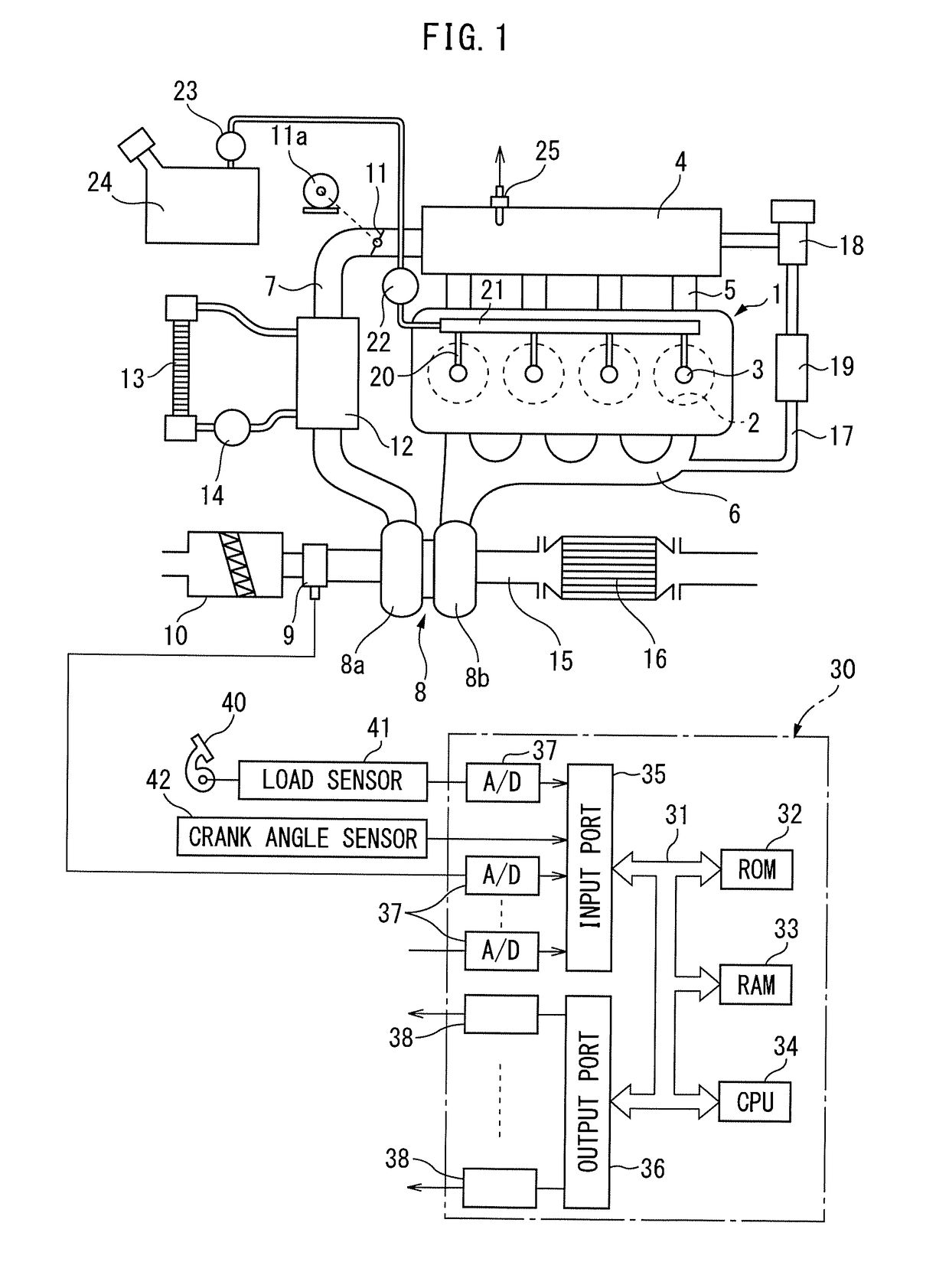

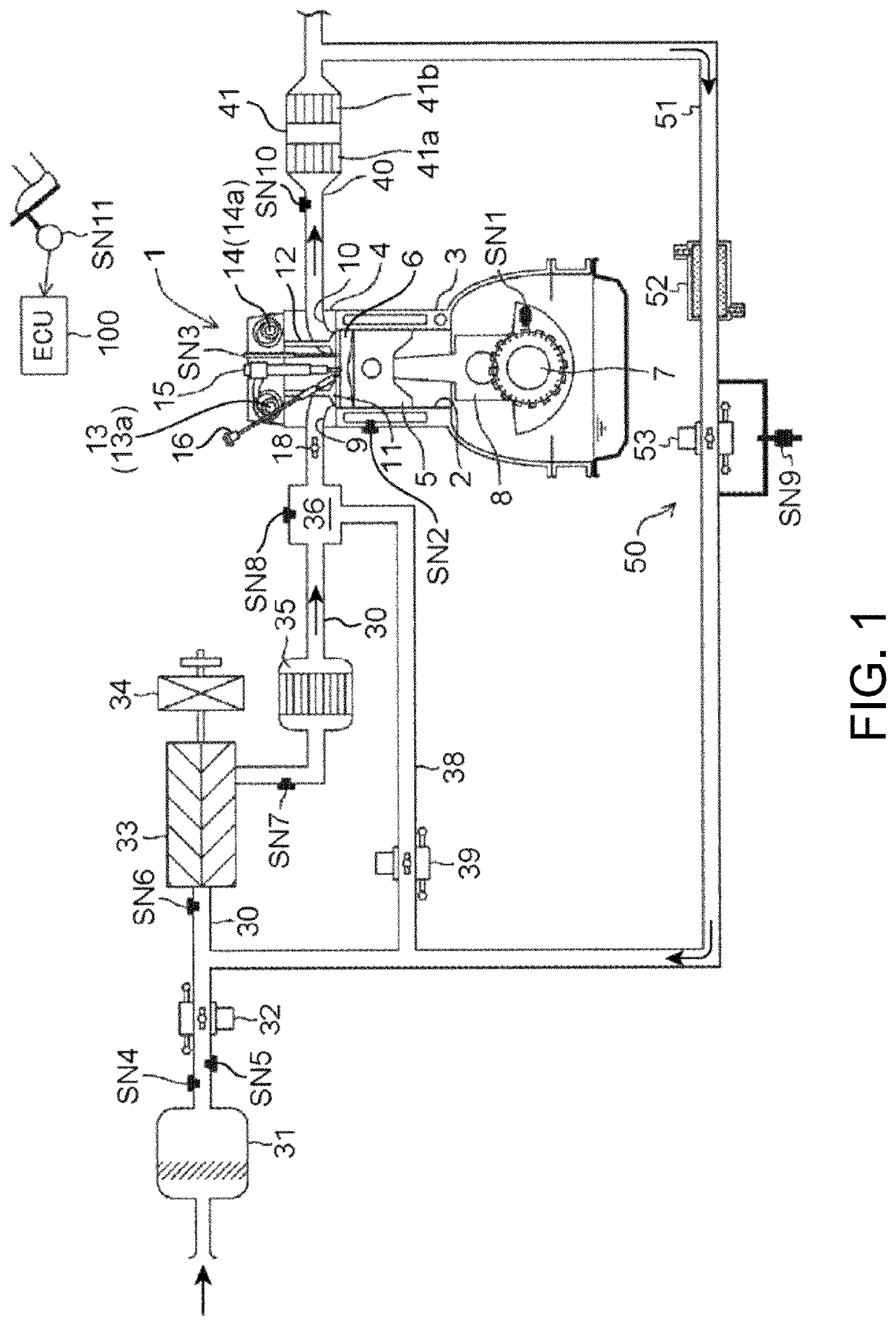

Control system of compression-ignition engine

ActiveUS20180334989A1Improve liquidityImprove performanceElectrical controlInternal combustion piston enginesCombustion chamberControl system

A control system of a compression-ignition engine is provided, which includes an engine configured to cause combustion of a mixture gas inside the combustion chamber, an injector attached to the engine and configured to inject fuel into the combustion chamber, a spark plug disposed to be oriented into the combustion chamber and configured to ignite the mixture gas inside the combustion chamber, and a controller connected to the injector and the spark plug and configured to operate the engine by outputting a control signal to the injector and the spark plug, respectively. After the spark plug ignites the mixture gas to start combustion, unburned mixture gas combusts by self-ignition. The controller outputs the control signal to the injector so that a fuel injection timing is advanced when the engine operates at a high speed than at a low speed.

Owner:MAZDA MOTOR CORP

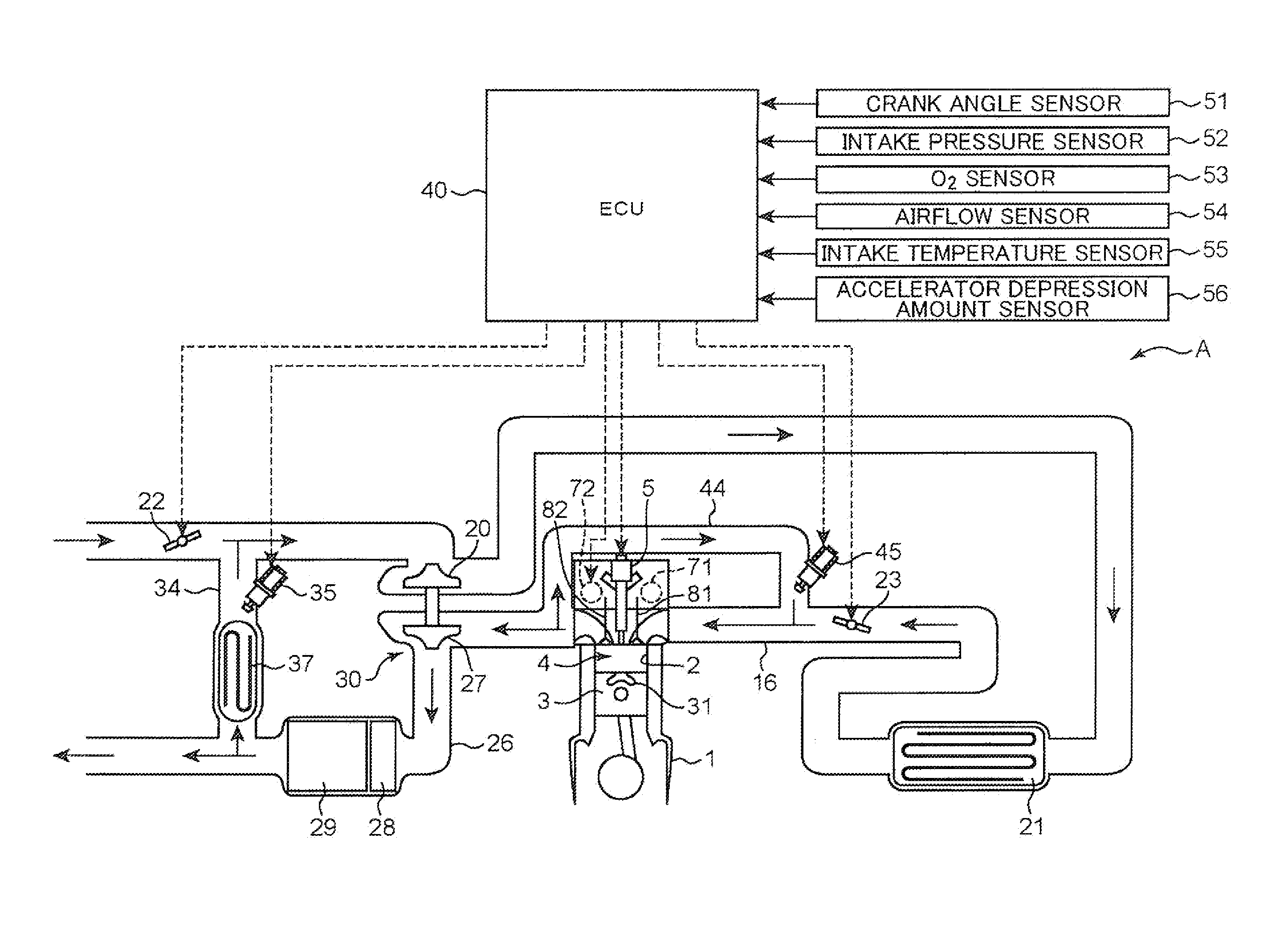

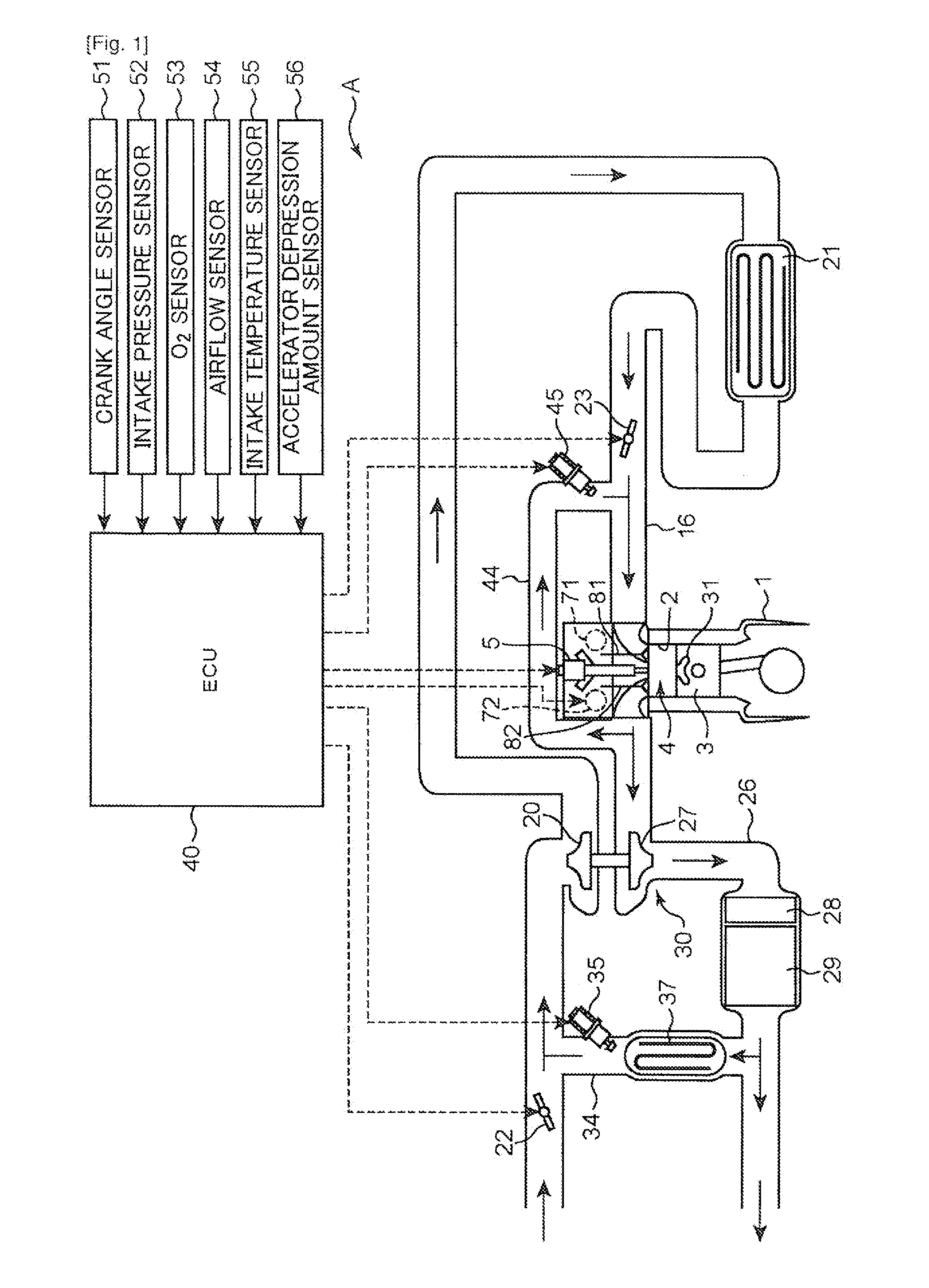

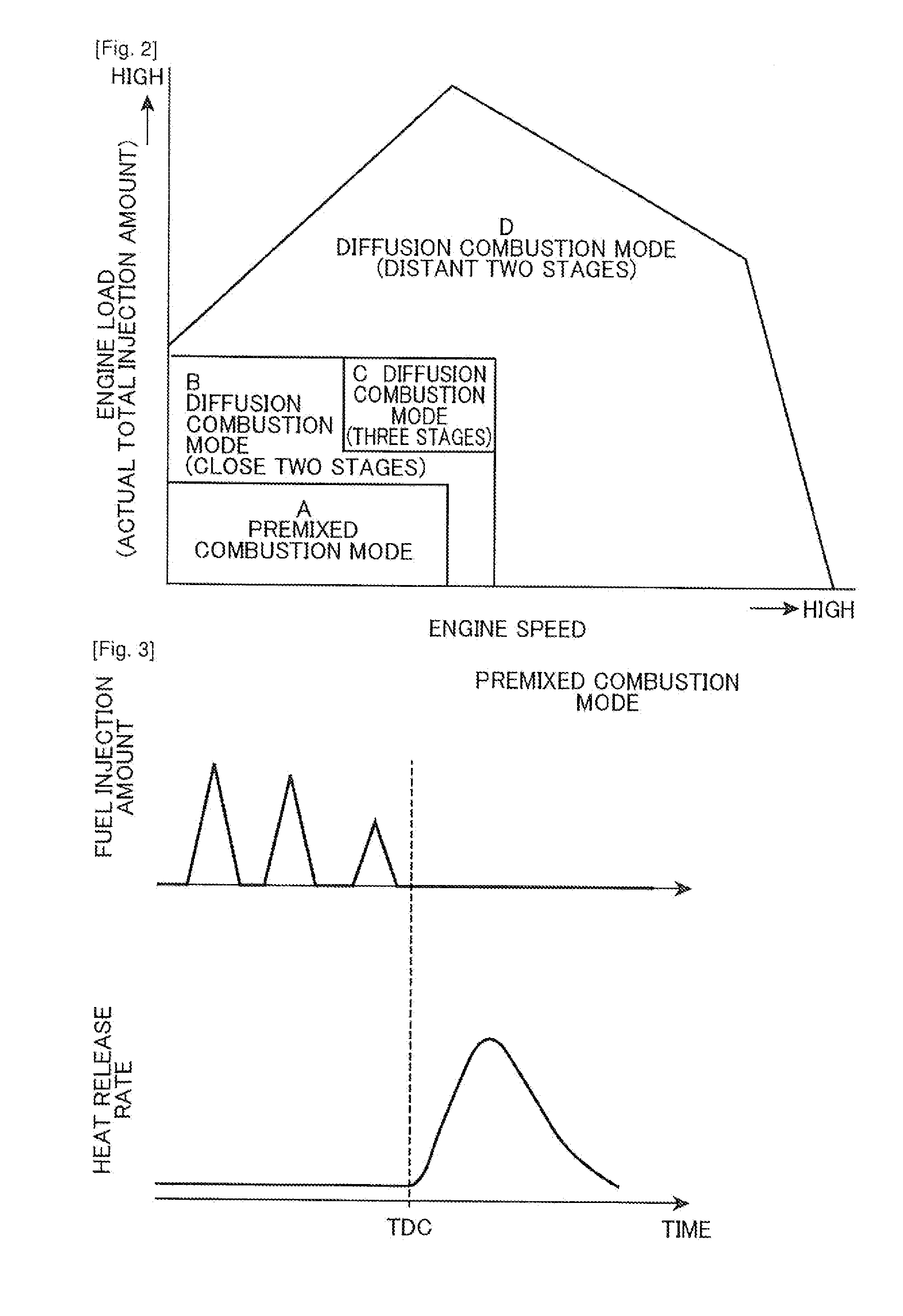

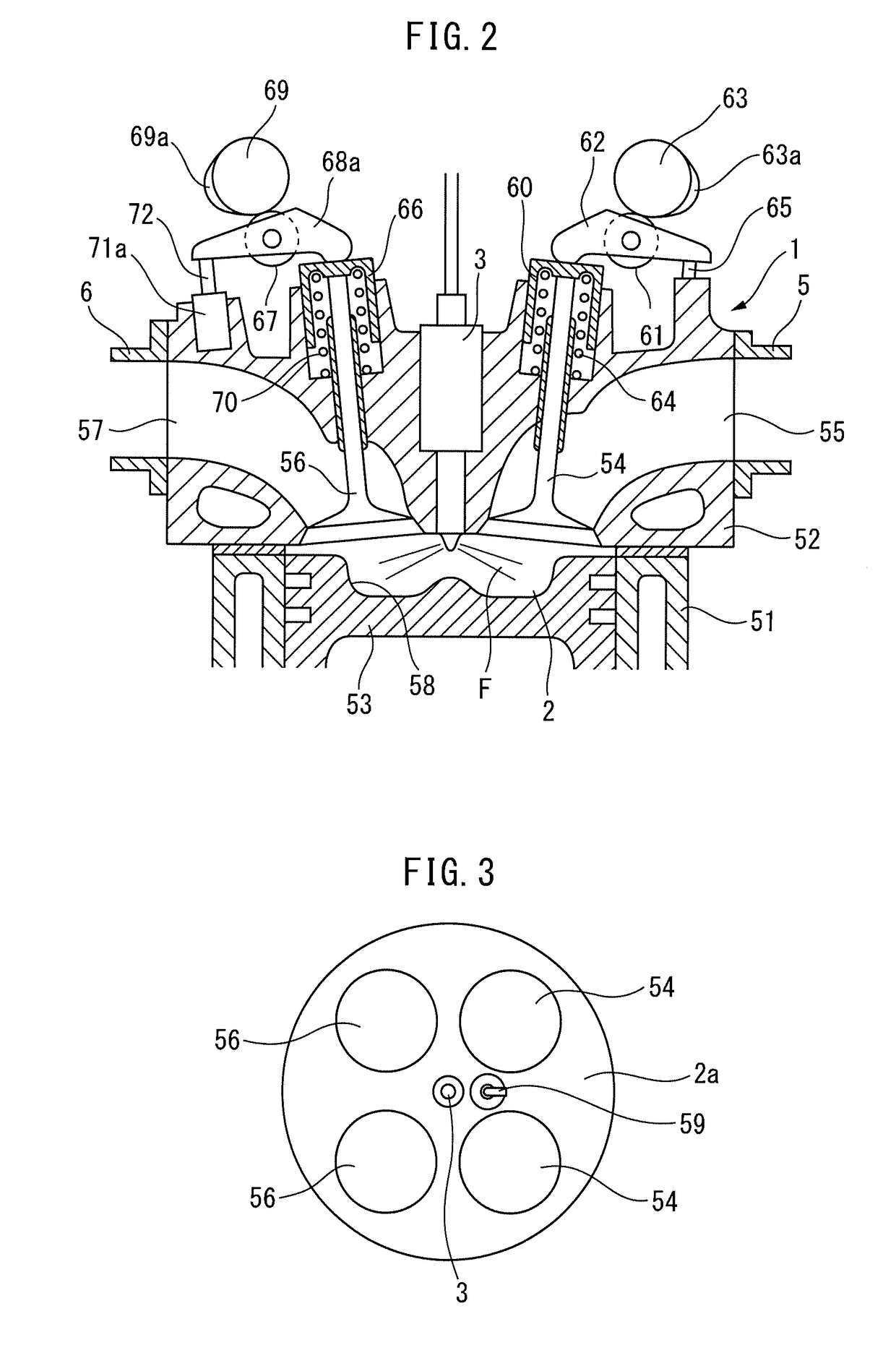

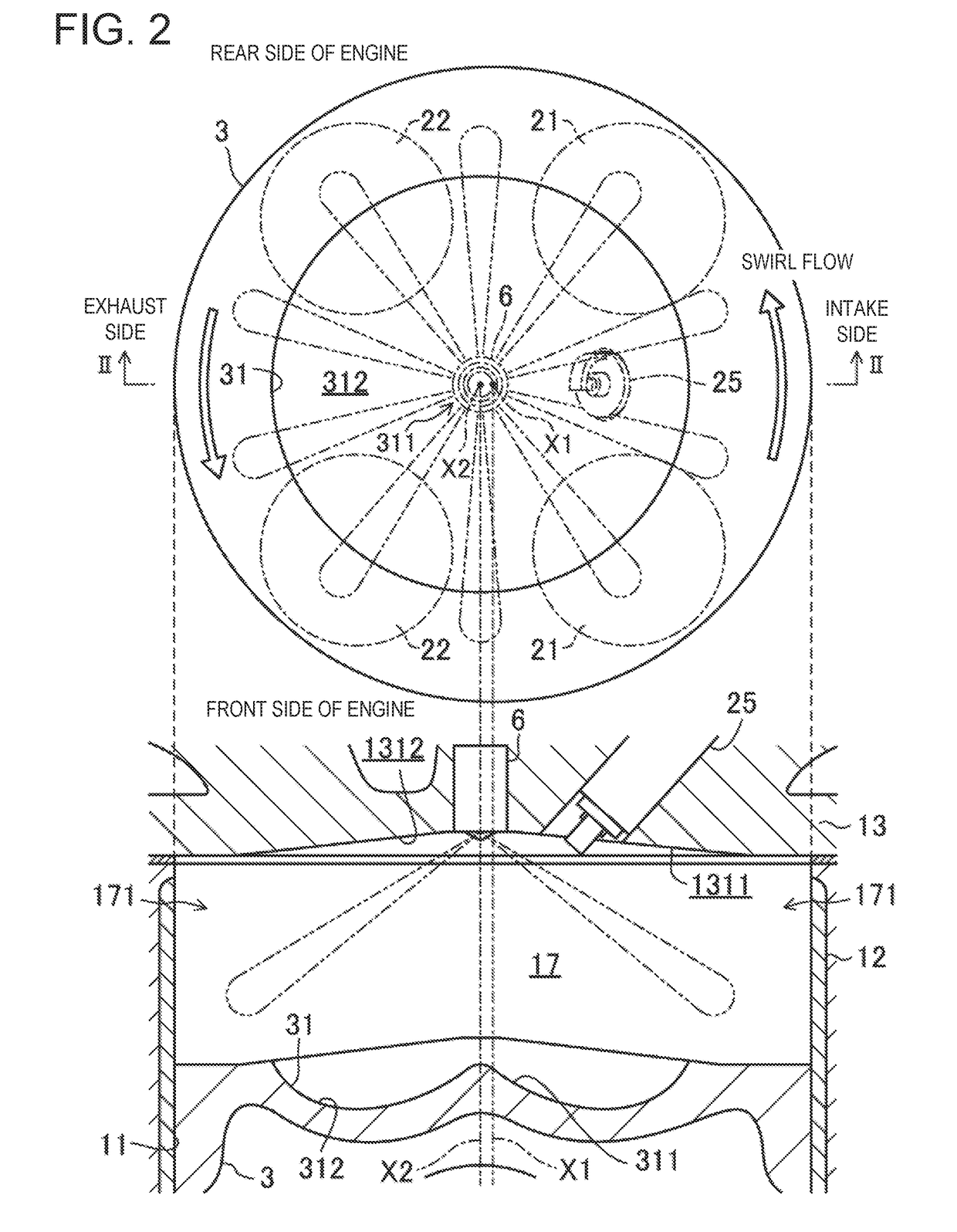

Diesel engine for automobile, control device and control method

ActiveUS20130073186A1Shorten ignition delaySlow down main combustionElectrical controlInternal combustion piston enginesLow speedTop dead center

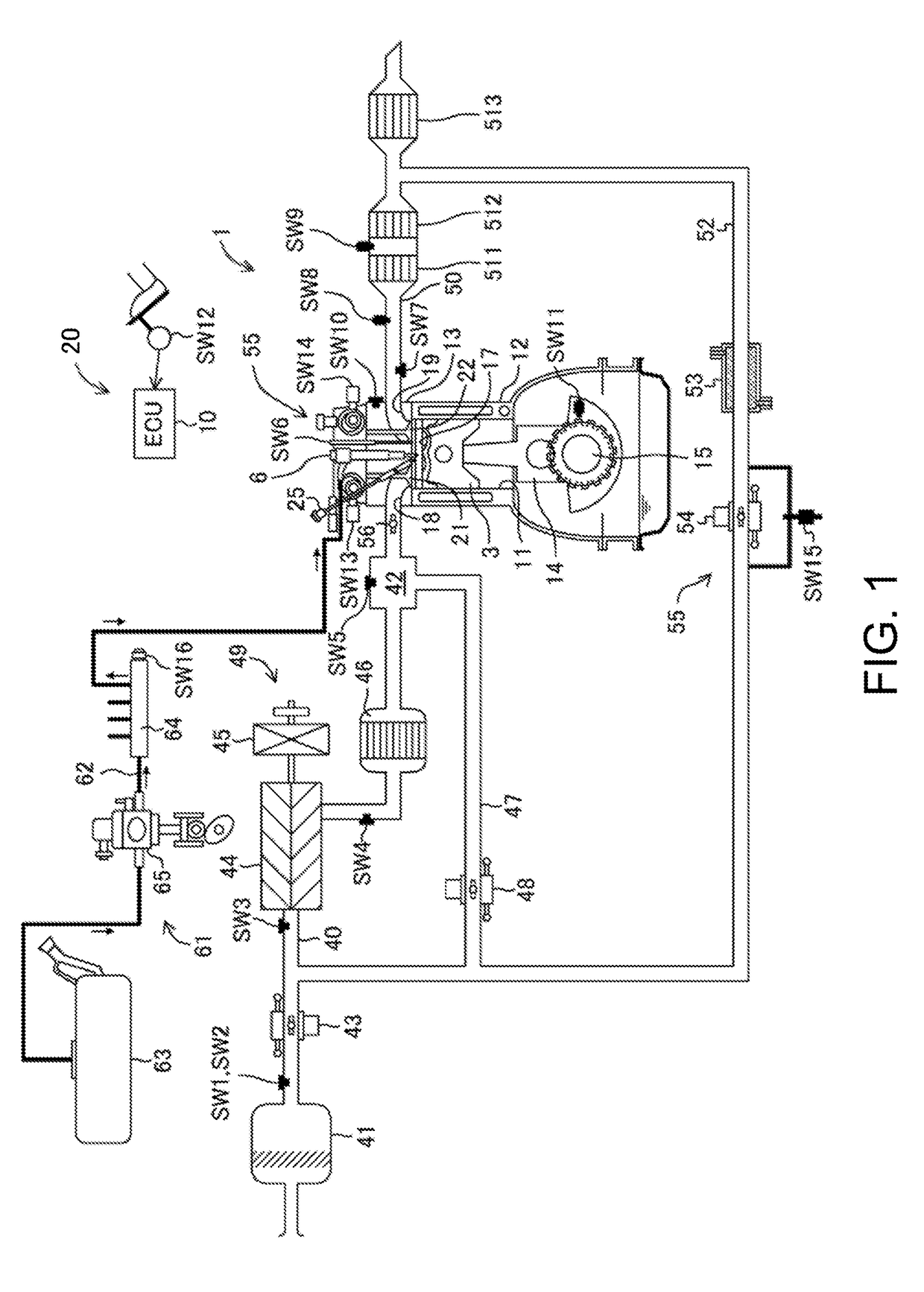

A geometric compression ratio in an engine main body 1 is set to 15 or less. Injection control means (ECU 40) performs a main injection of injecting fuel near a compression top dead center, and a preceding injection prior to the main injection at a specific region of predetermined load within an operating region on a relatively low-speed side. The injection control means performs, as the preceding injection, a pilot injection of performing injection at a timing such that at least part of a fuel spray reaches outside a cavity 31 on a top face of a piston, and a pre-injection of injecting fuel at a predetermined timing after the pilot injection, to suppress thereby ignition of the fuel injected by the pilot injection and shorten an ignition delay of the fuel injected by the main injection.

Owner:MAZDA MOTOR CORP

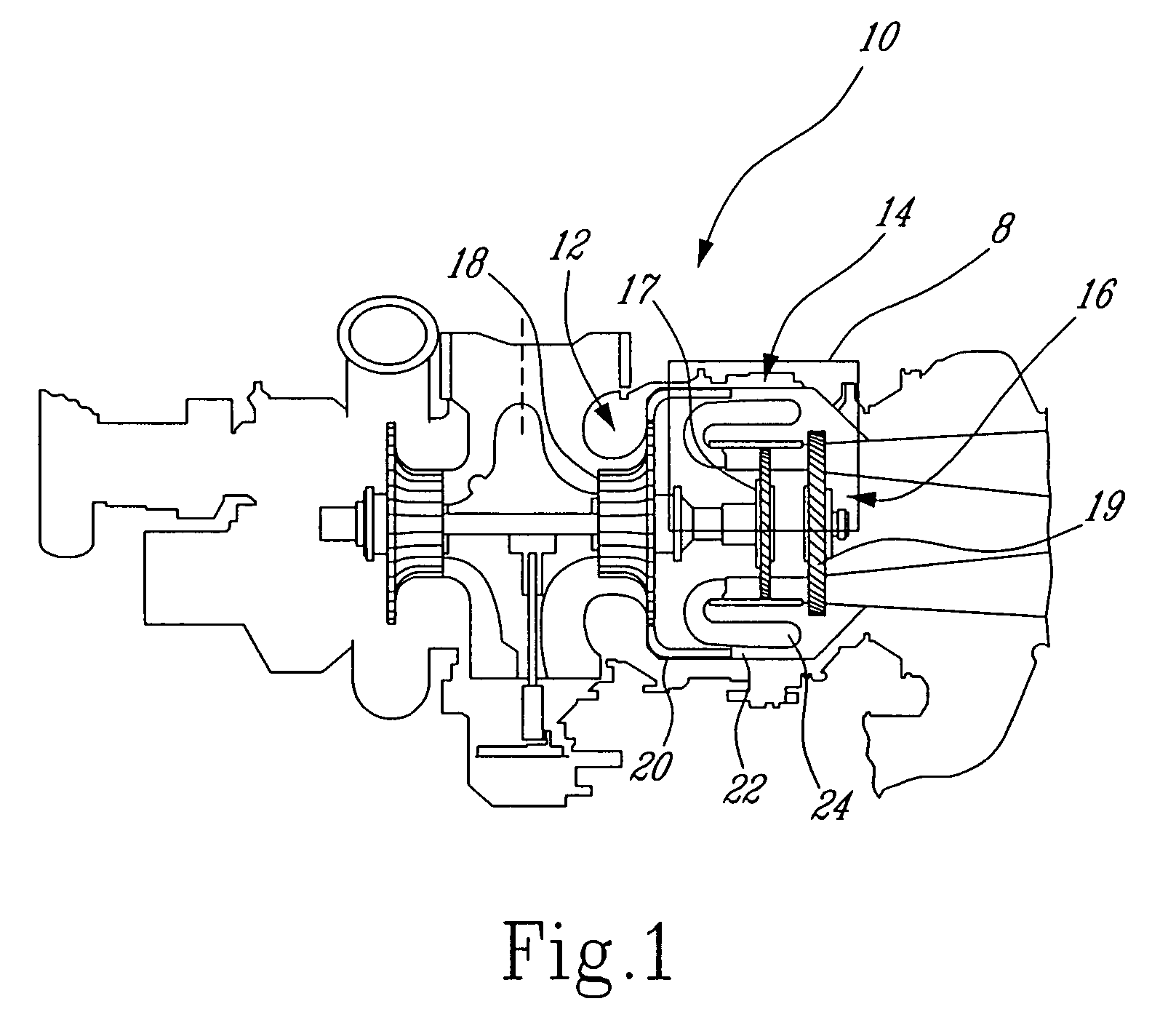

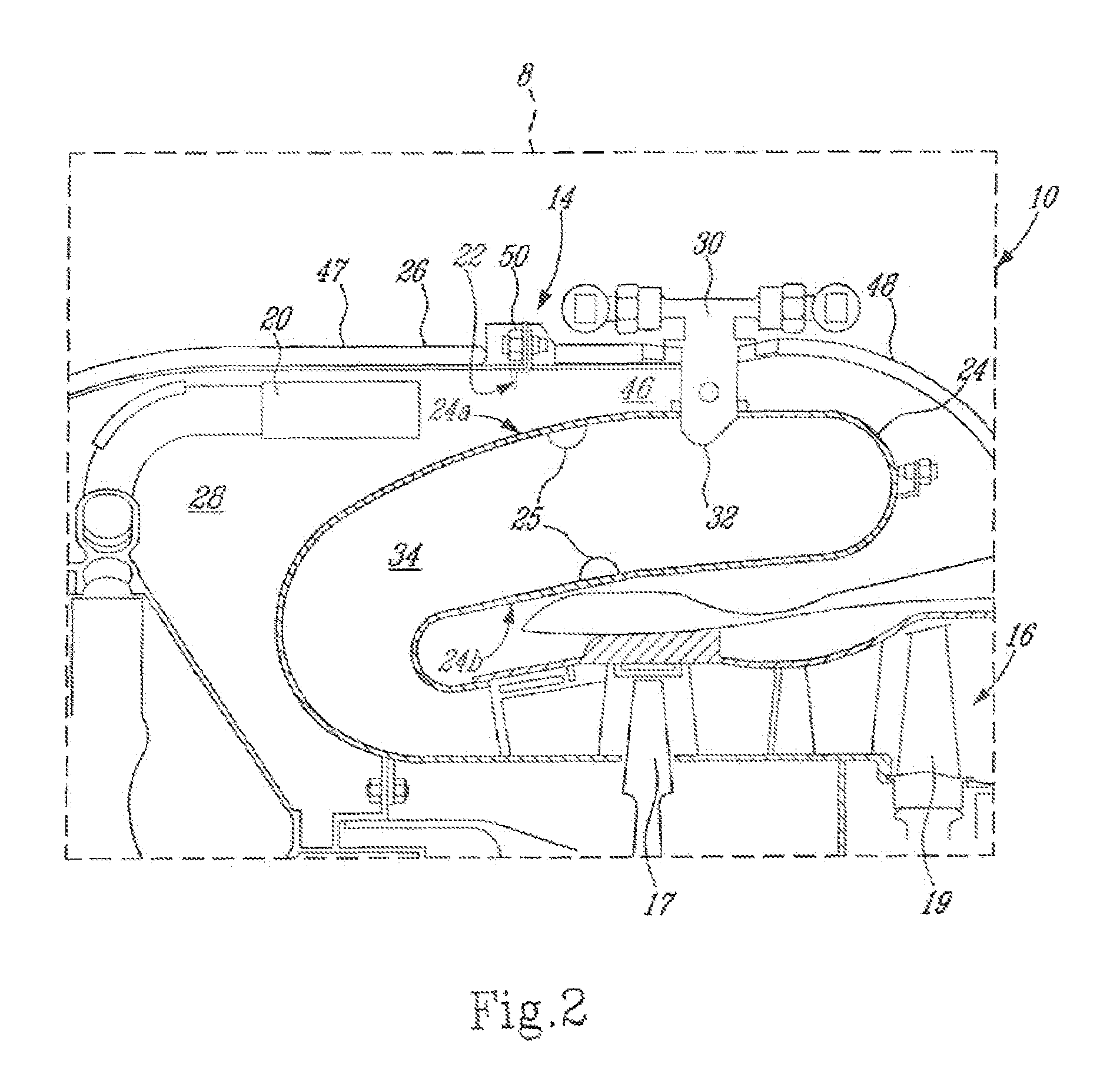

Boosted engine

ActiveUS20190093575A1Reduce componentsReduce smoke and dust generationElectrical controlInternal combustion piston enginesFlame propagationCombustion chamber

A boosted engine is provided, which includes an engine body formed with a combustion chamber, a spark plug, a fuel injection valve, a booster, a boost controller, and a control unit including an operating range determining module and a compression end temperature estimating module. In a high load range, the fuel injection valve and the spark plug are controlled so that a mixture gas inside the combustion chamber starts combustion through flame propagation by ignition of the spark plug, and unburned mixture gas then combusts by compression ignition, and the boost controller is controlled to bring the booster into a boosting state. When a gas temperature inside the combustion chamber exceeds a given temperature at CTDC, the fuel injection valve is controlled so that a fuel injection end timing occurs on a compression stroke, and the spark plug is controlled so that the mixture gas is ignited after CTDC.

Owner:MAZDA MOTOR CORP

System for method for controlling engine knock of a variable displacement engine

ActiveUS20170356366A1Improve and degrade capacityImprove signal-to-noise ratioElectrical controlInternal combustion piston enginesEngineeringVariable displacement

Owner:FORD GLOBAL TECH LLC

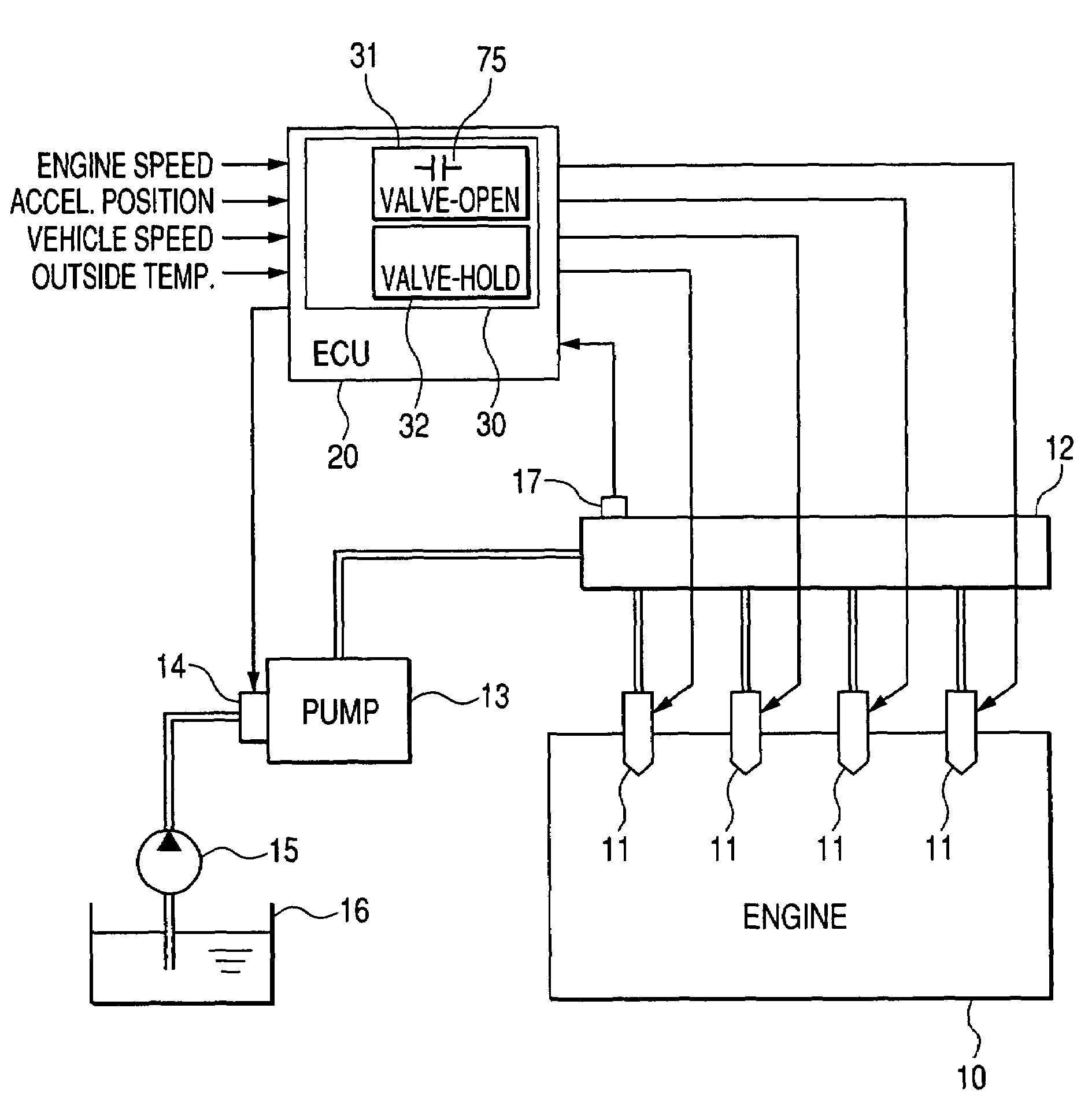

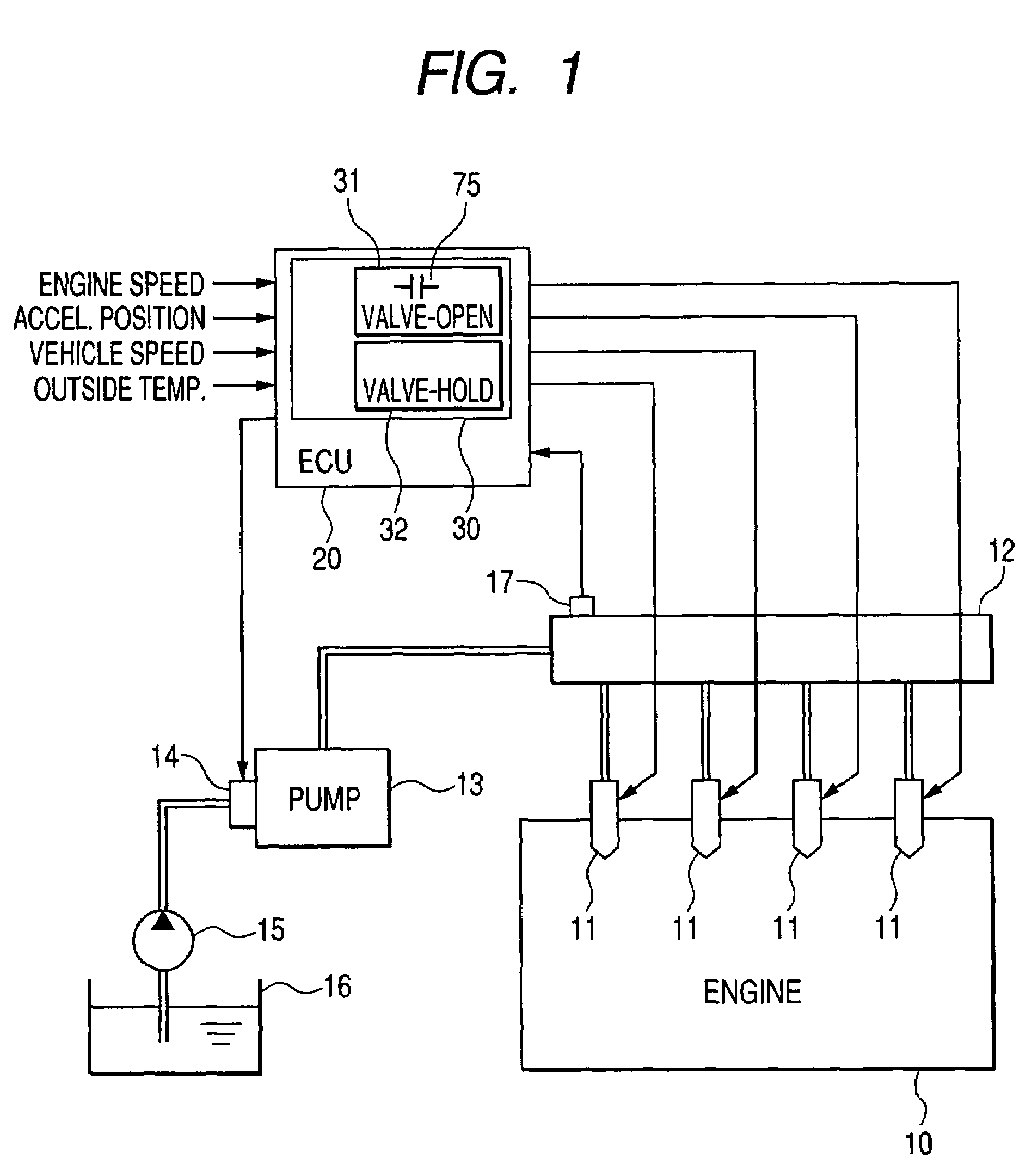

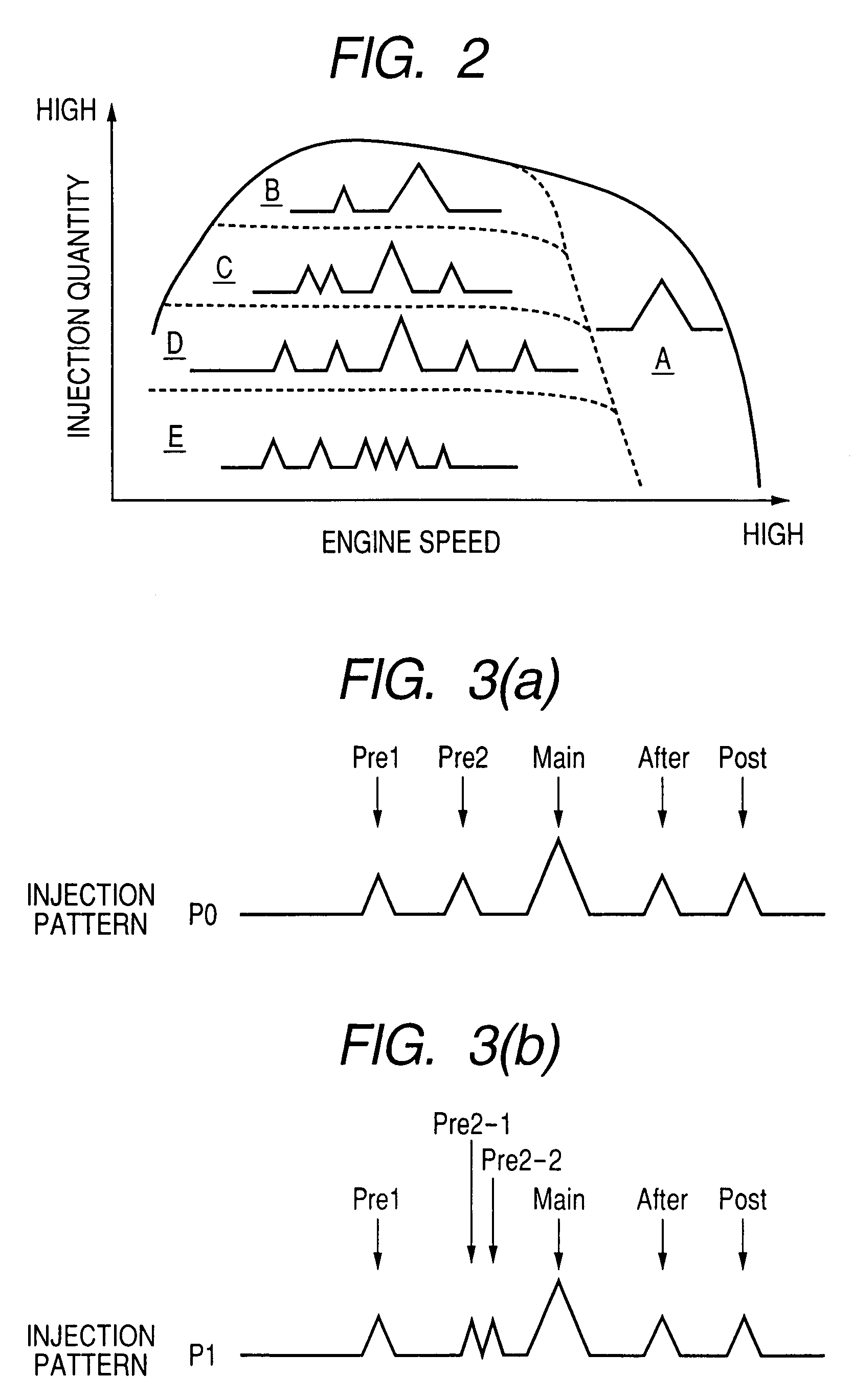

Fuel injection control apparatus designed to minimize combustion noise of engine

InactiveUS7415964B2Reduce combustion noiseIncrease the number ofElectrical controlInternal combustion piston enginesCombustion noiseCombustion

A fuel injection control apparatus for a diesel engine is provided which works to determine the number of a sequence of injection events to inject fuel into the engine in each operating cycle of the engine and increase it based on the temperature of an injector drive circuit. When the temperature of the injector drive circuit is relatively low, the apparatus increases the number of injection events to decrease the degree of combustion in the engine, thereby reducing the combustion noise of the engine.

Owner:DENSO CORP

Aerodynamic trip for a combustion system

ActiveUS7302802B2Reduce combustion noiseUniform temperature distributionBurnersContinuous combustion chamberCombustion systemCombustion noise

A apparatus and method for improving combustion by improving at least one of temperature distribution in the combustor, pressure distribution around the combustor and combustion noise level in the combustor, by redistributing air around the combustor to modify the structure of the air flow prior to entry into the combustor.

Owner:PRATT & WHITNEY CANADA CORP

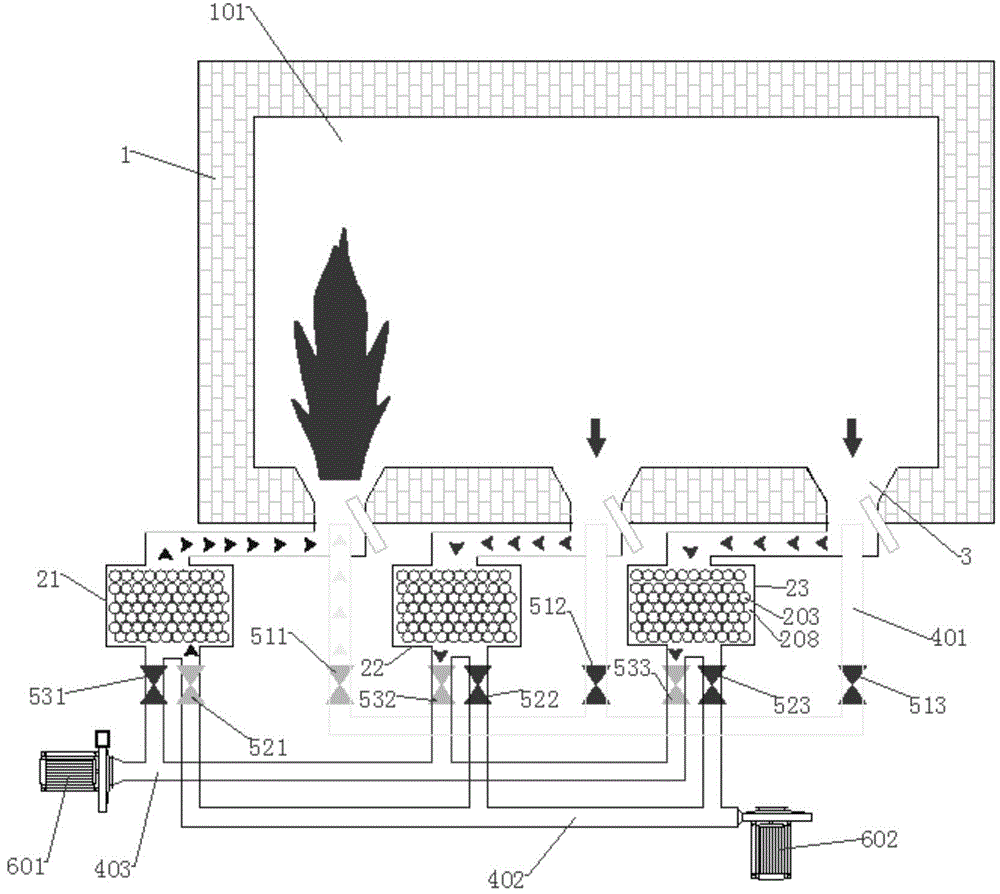

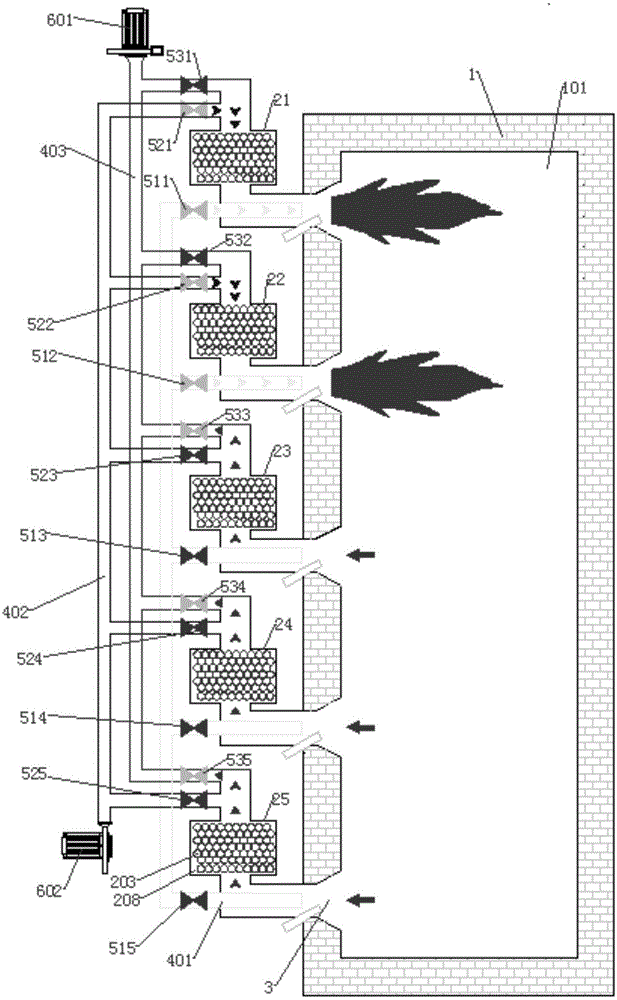

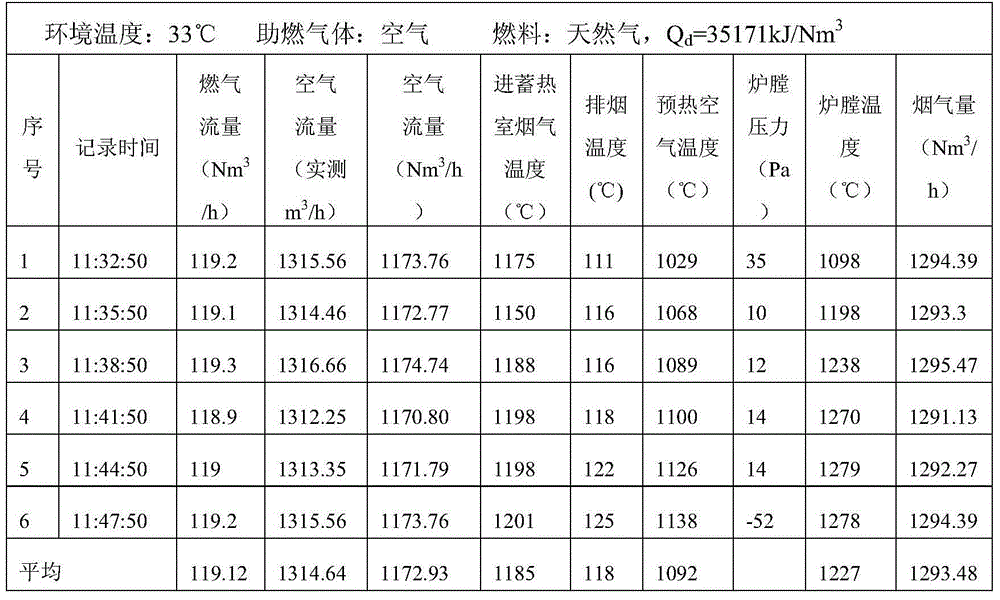

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

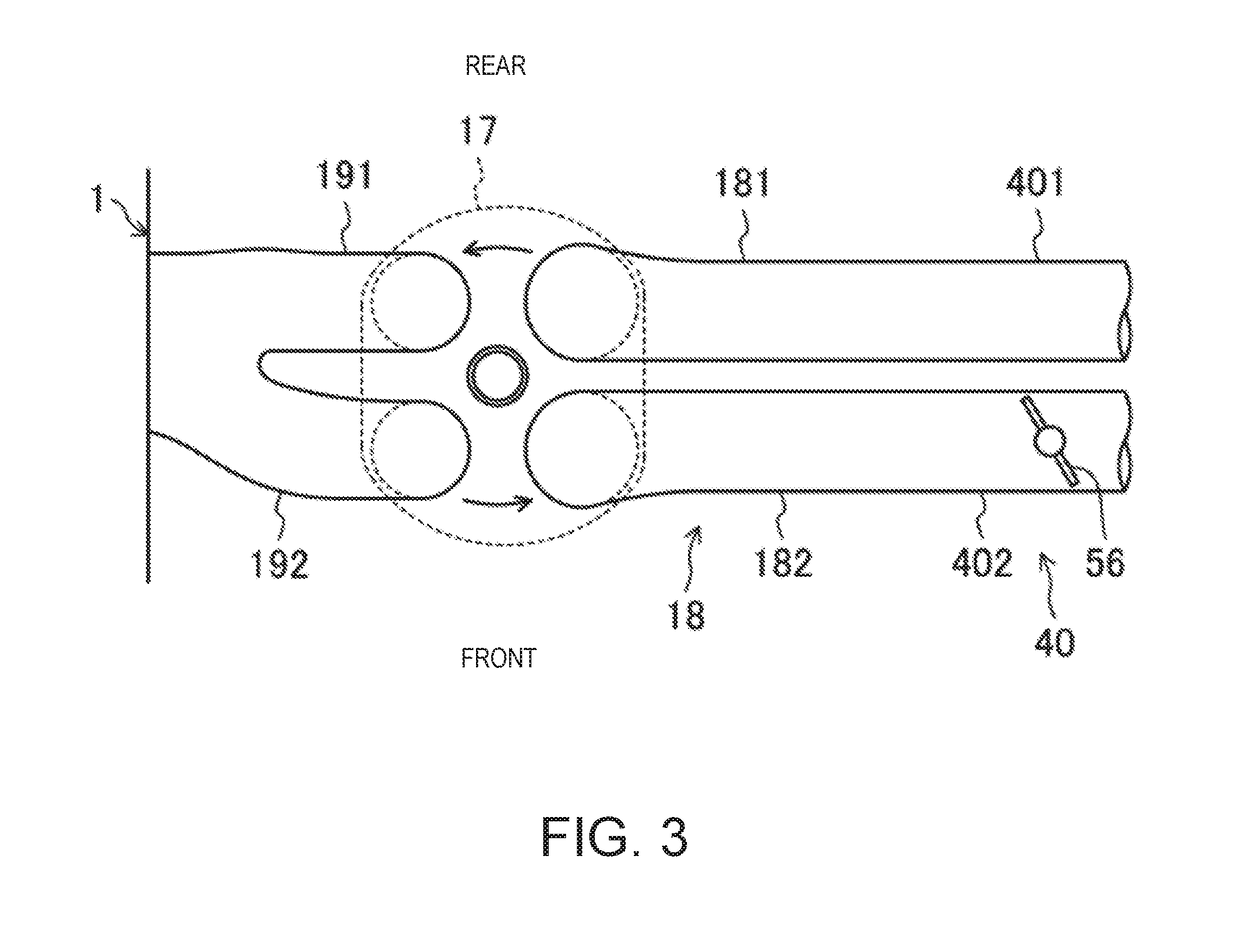

Internal-combustion engine

InactiveCN1928333AEasy to controlEmission reductionInternal combustion piston enginesOutput powerCombustion chamberInlet valve

The invention relates to an internal-combustion engine with piston reciprocating, comprising body, cover, piston, crankshaft and connecting bar. The piston moves advance and return and is connected with crankshaft through connecting bar. The space on the top of piston sealed by cover is formed blast chamber. Intake valve, air outlet valve and spark plug are set in cover at the top of blast chamber. In said body except blast chamber air compressed unit is set, which comprises inhalation valve, air outlet valve, assistant piston, which can move advance and return, and be connected with said crank shaft through assistant connecting bare, and assistant connecting bar. The outlet of air outlet valve is connected to hollow air conversation room withstanding pressure, in which thermal converter, temperature sensor, fuel nozzle and fuel evaporating and mixing room. The outlet of air conversation room is connected to said inlet of intake valve in blast chamber. The invention can decrease harmful gas NOx released largely because of low temperature, improve work efficiency of gas and decrease burning noise.

Owner:袁辉

Gas turbine circulated generation process for combining high (mediate) calorific value gas and low calorific value gas

InactiveCN101169071AImprove combustion thermal efficiencyHigh combustion noiseGas turbine plantsCombined combustion mitigationForced inductionThermal efficiency

The invention relates to a combustion engine combination cycle power plant with low heat value, a co-production of the combustion engine combination cycle thermal power plant, an integrated coal gasification cycle combination (IGCC) power plant, and the like. The invention adopts the new technique of gas turbine combined cycle power generating that the high and intermediate heat value gas cooperate with the low heat value gas, and the invention is a technology with high efficiency and low pollution. A low NOx burner provided with a gas turbine and an afterburner boiler adopt a self-cycle preheating heat-storing volution type low NOx gas burning system, therefore the power consumption of the gas supercharger can be reduced by 10-20 percent and the thermal efficiency of the electricity generating of the combined cycle unit can be increased for 5-15 percent. The invention can also solve the problems of the technology difficulty for reconstructing the system and the project cost. The invention can also provide stable combustion for burning the low heat value gas (blast furnace gas), can enable steam cycle system to have larger installed capacity and higher efficiency, and can lower the kilowatt cost. The invention ensures that the combined cycle thermal efficiency can reach about 60 percent, the electricity generating efficiency of the power plant can reach about 55 percent, and the energy can be saved for above 80 percent. The invention can break through a bottleneck that the investment and the electricity generating cost of the intermediate low heat value gas electricity plant are much higher than that of high heat value combined cycle power plant, namely the economic problem, and then the investment cost of the intermediate low heat value gas power plant (or the IGCC) can be lowered greatly.

Owner:邢一崧

Combustion apparatus

ActiveUS20160377282A1Reduce combustion noiseSignificant differenceBurner safety arrangementsGaseous fuel burnerGas burnerEngineering

A combustion apparatus has a plurality of longitudinally elongated gas burners, each having a burner port on an upper end thereof. A damper is disposed to cover gas inlet ports on an upstream end of an air-fuel mixing tube portion of each of the gas burners. The damper has formed therein ventilation holes for limiting primary air. The ventilation holes overlap, and are smaller than, the gas inlet ports. The damper has #1 ventilation holes having obstacles against which the fuel gas to be ejected from the gas nozzles strike, and #2 ventilation holes without obstacles. Poor combustion such as flame lifting is restricted and combustion noises are reduced.

Owner:RINNAI CORP

High power gas catalytic burner

A catalytic burner of large-power fuel gas type is prepared for connecting gas inlet end of gas transmission pipe to one end of T-joint on pipe, connecting the other two ends in form of 90 degree elbow of T-joint to mixed gas channel, arranging fluid rectifier separately at inlet and outlet of mixed gas channel, connecting one set of catalyst carrier porous module set in frame separately to each of double-surface at burner cavity, packing high-temperature resisting insulation material at peripheral gap of said module and extending temperature transducer into said module through a temperature transducer entrance set on external wall of burner cavity.

Owner:北京建筑工程学院 +1

Fuel injection valve for internal combustion engines

InactiveUS6269795B1Quick closeReduce combustion noiseMachines/enginesFuel injecting pumpsCombustion chamberEngineering

A fuel injection valve for internal combustion engines, having a valve member that is axially displaceable in a valve body and that with a sealing face cooperates, to control an injection opening, with a valve seat face on the valve body. An end of the valve member remote from the combustion chamber is urged in the closing direction by a valve spring disposed in a spring chamber. The valve member has a pressure shoulder acting in the opening direction, which protrudes into a pressure chamber that is filled with high fuel pressure. Via a throttle gap, the spring chamber communicates with the pressure chamber and is sealed off from a fuel return system, so that during the opening stroke motion of the valve member the spring chamber acts as a hydraulic damper.

Owner:ROBERT BOSCH GMBH

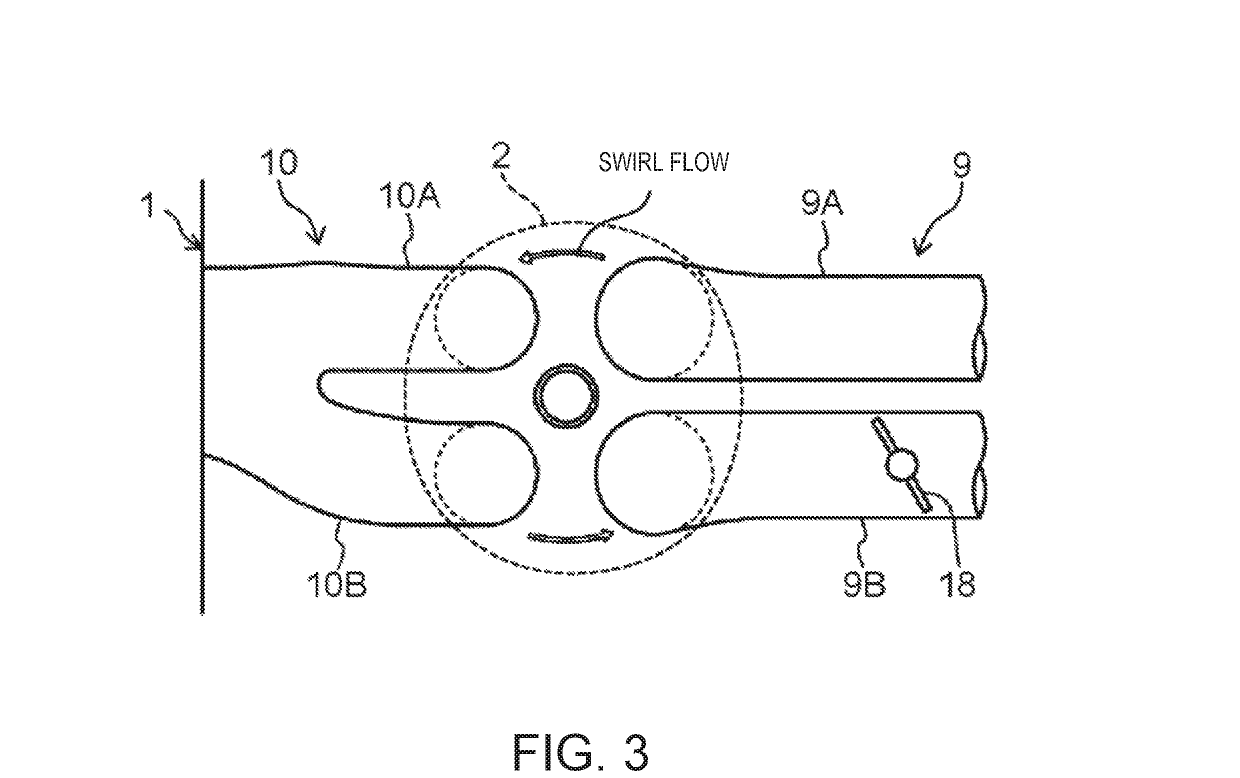

Control device for compression-ignition engine

ActiveUS20190145337A1Raise the ratioHigh reference valueElectrical controlInternal combustion piston enginesCombustion noiseOn board

A control device for an on-board compression-ignition engine in which partial compression-ignition combustion including spark ignition (SI) combustion performed by combusting a portion of mixture gas inside a cylinder by spark ignition followed by compression ignition (CI) combustion performed by causing the rest of the mixture gas inside the cylinder to self-ignite is executed within at least a part of an operating range of the engine, is provided. The device includes a detector configured to detect a parameter related to noise caused by the combustion inside the cylinder, and a combustion controller configured to control the combustion inside the cylinder during the partial compression-ignition combustion based on a combustion noise index value identified by the detected parameter of the detector and a given reference value defined as an upper limit of the combustion noise index value, the reference value increasing as a vehicle speed increases.

Owner:MAZDA MOTOR CORP

Control device for engine

ActiveUS20190063394A1Prevents combustion noiseAvoid noiseElectrical controlInternal combustion piston enginesStart timeCombustion noise

A control device for an engine in which partial compression-ignition combustion including SI combustion performed by forcibly combusting a portion of mixture gas inside a cylinder followed by CI combustion performed by causing the rest of the mixture gas inside the cylinder to self-ignite is executed within a part of an operating range of the engine, is provided. The device includes a detector configured to detect a parameter related to noise caused by the combustion inside the cylinder, a memory configured to store a characteristic defining a relationship between a start timing of the CI combustion and a combustion noise index, and a processor configured to specify a given combustion noise index value based on the detection value of the detector, and control the start timing of the CI combustion.

Owner:MAZDA MOTOR CORP

Control system of compression-ignition engine

ActiveUS10697391B2Small pressure changeReduce combustion noiseElectrical controlInternal combustion piston enginesCombustion chamberLow speed

A control system of a compression-ignition engine is provided, which includes an engine configured to cause combustion of a mixture gas inside the combustion chamber, an injector attached to the engine and configured to inject fuel into the combustion chamber, a spark plug disposed to be oriented into the combustion chamber and configured to ignite the mixture gas inside the combustion chamber, and a controller connected to the injector and the spark plug and configured to operate the engine by outputting a control signal to the injector and the spark plug, respectively. After the spark plug ignites the mixture gas to start combustion, unburned mixture gas combusts by self-ignition. The controller outputs the control signal to the injector so that a fuel injection timing is advanced when the engine operates at a high speed than at a low speed.

Owner:MAZDA MOTOR CORP

Internal combustion engine

ActiveUS20170211499A1Reduce combustion noiseValve arrangementsElectrical controlInjectorIgnition delay

An internal combustion engine comprising the fuel injector arranged in the combustion chamber. The primary fuel injection and the secondary fuel injection from the fuel injector are successively performed to cause autoignition of an injected fuel of the primary fuel injection and autoignition of an injected fuel of the secondary fuel injection. A temperature region suppressing change of an ignition delay time where a change of ignition delay time with respect to a rise in temperature in the combustion chamber is suppressed appears in the compression stroke at a temperature in the combustion chamber of 700K to 900K. The secondary fuel injection is performed if the temperature in the combustion chamber is a temperature within the temperature region suppressing change of the ignition delay time during the compression stroke. The primary fuel injection is performed during the compression stroke or suction stroke before the temperature in the combustion chamber reaches a temperature in the temperature region suppressing change of the ignition delay time at a fuel injection timing at which the injected fuel of the secondary fuel injection is autoignited after the injected fuel of the primary fuel injection is autoignited.

Owner:TOYOTA JIDOSHA KK

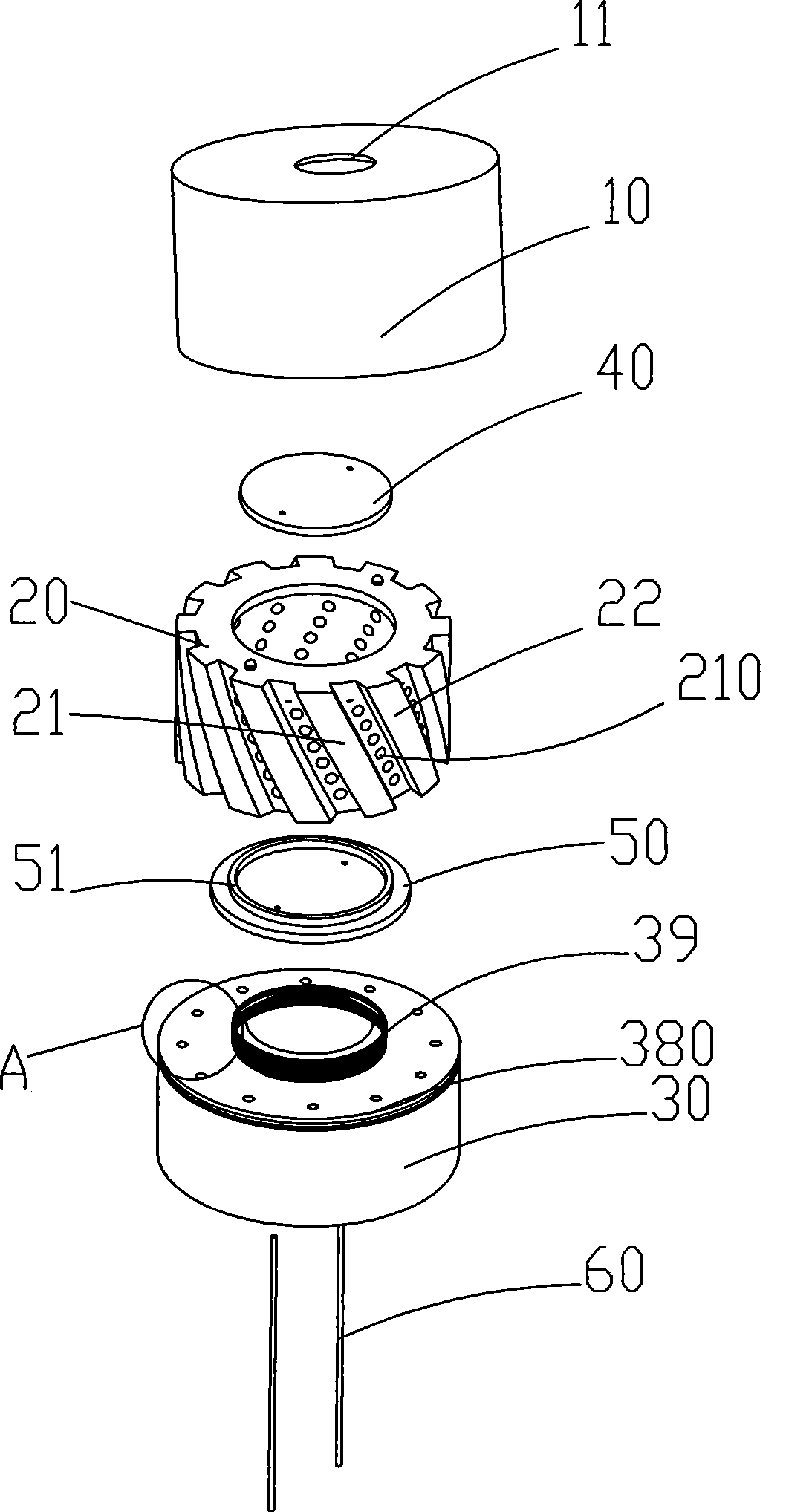

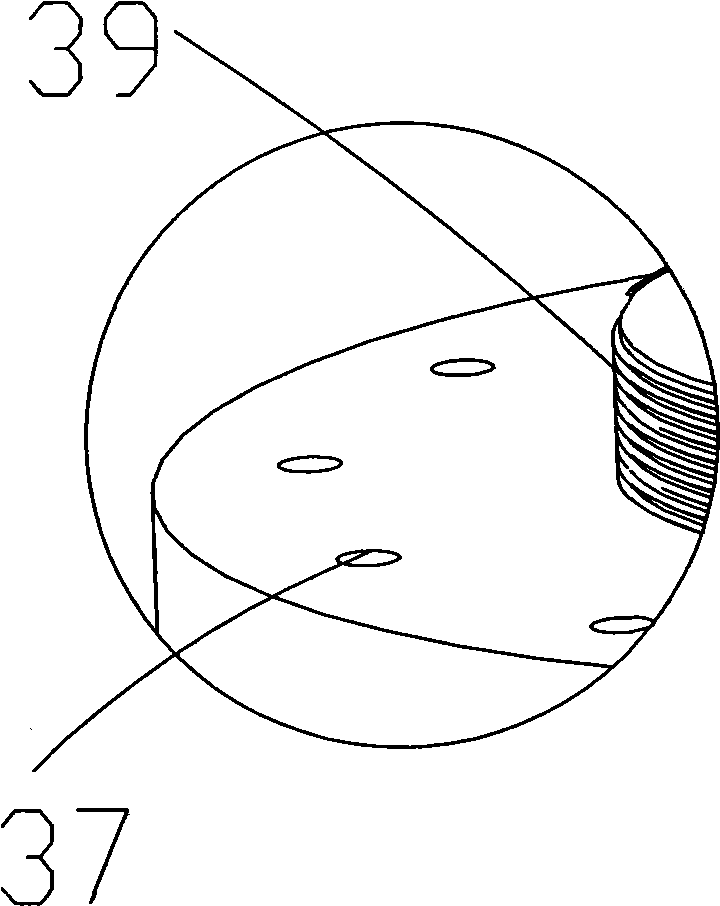

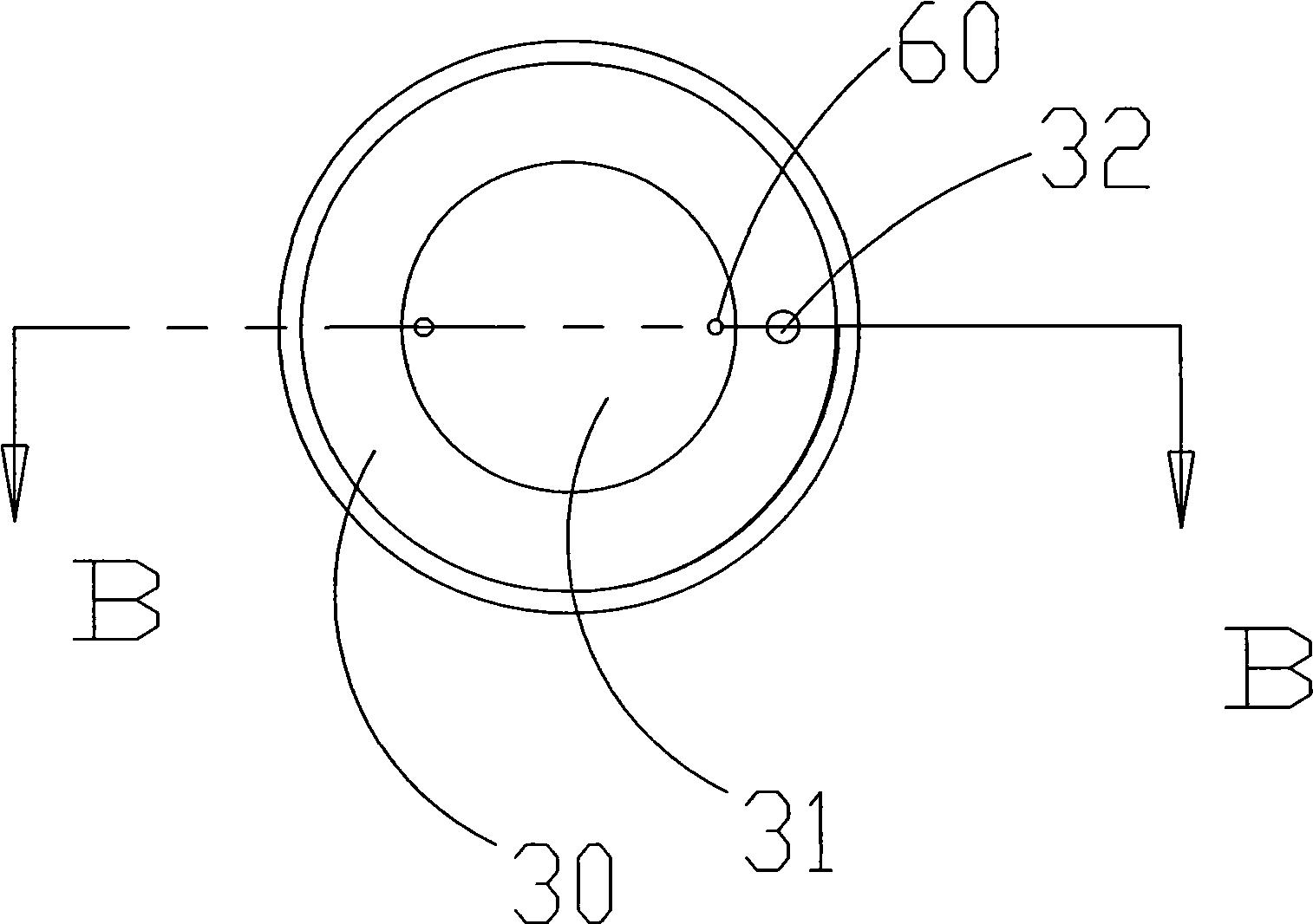

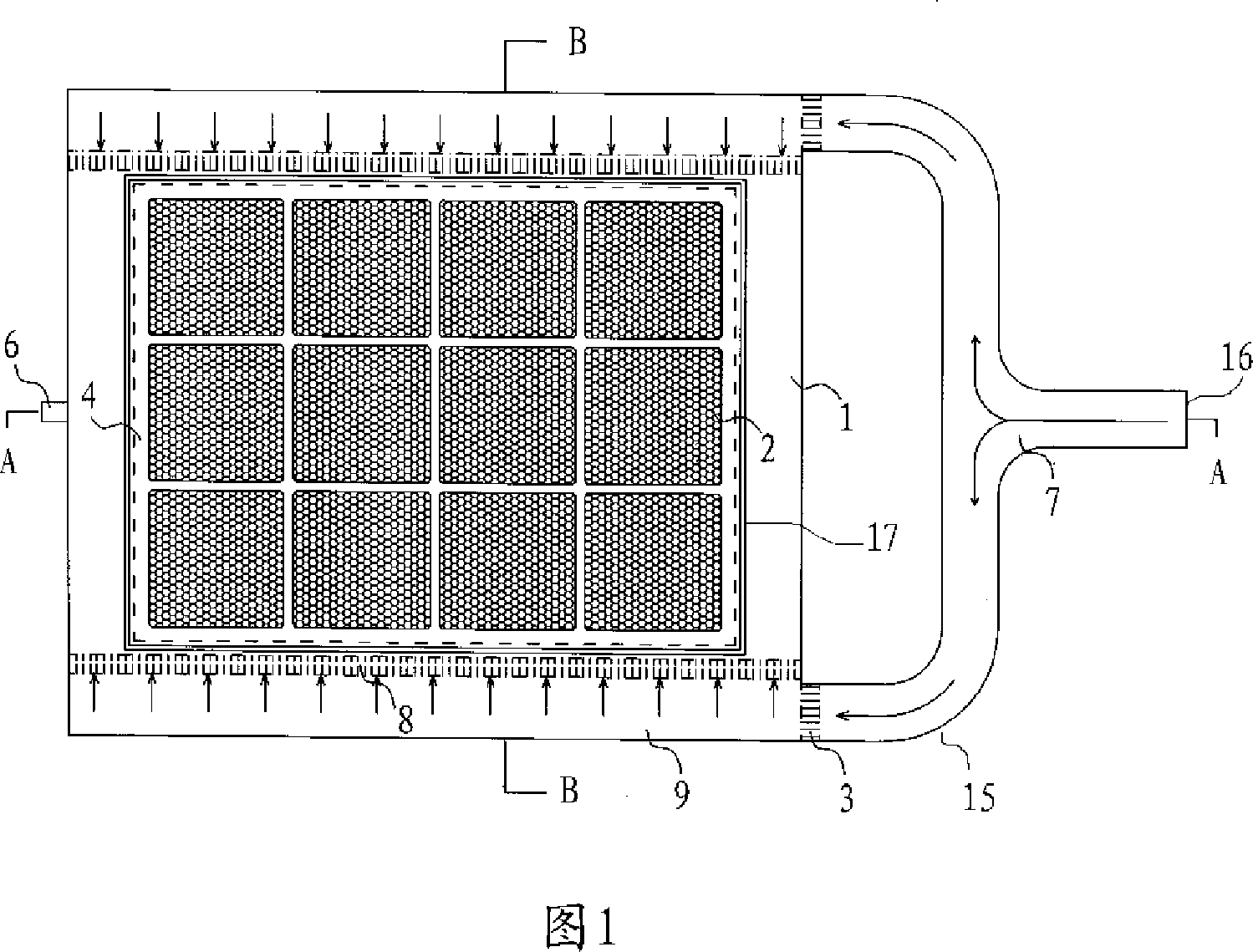

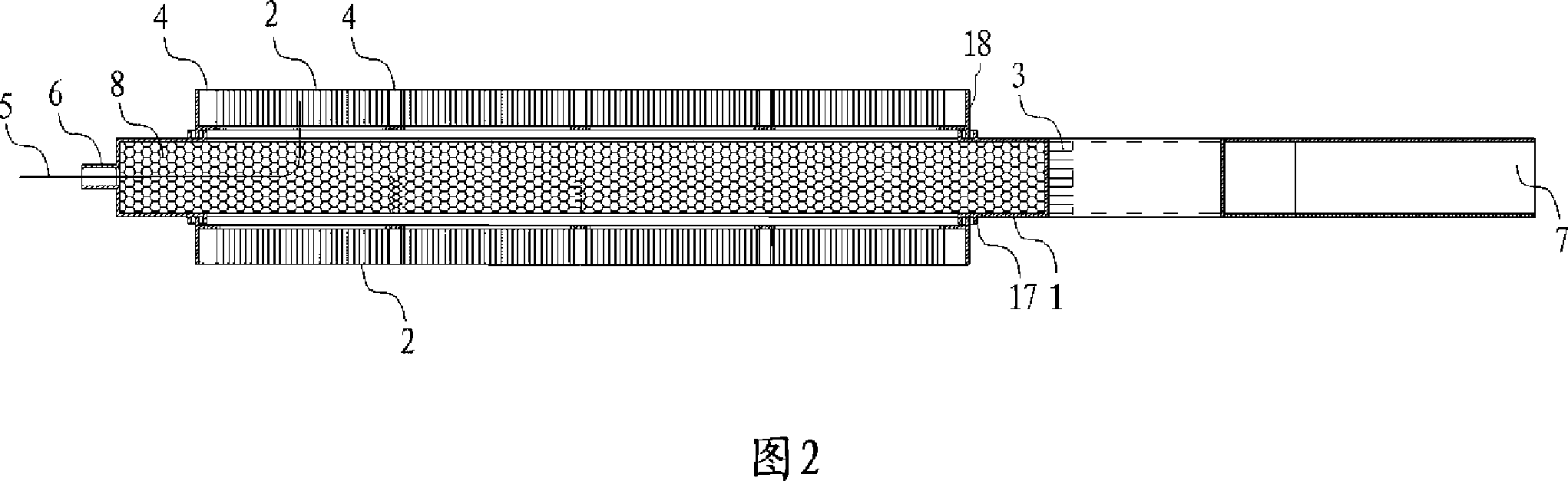

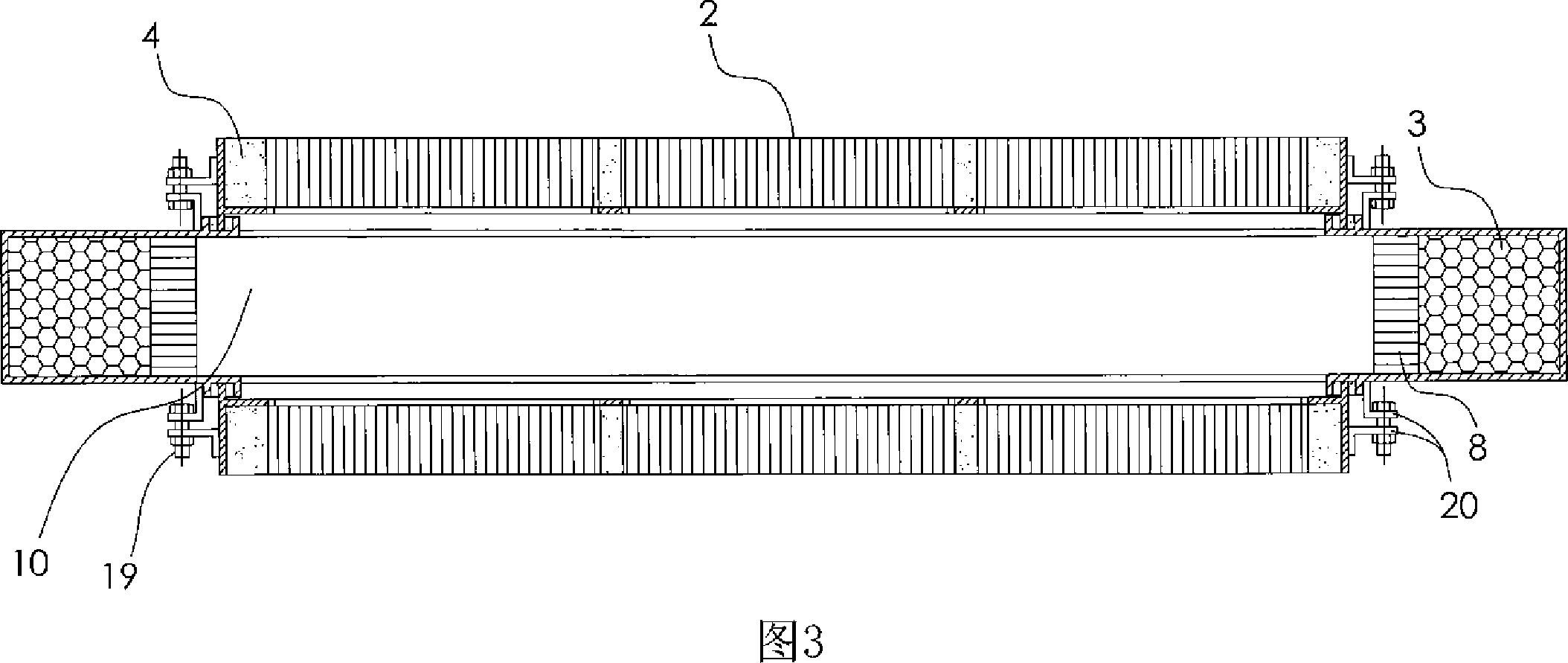

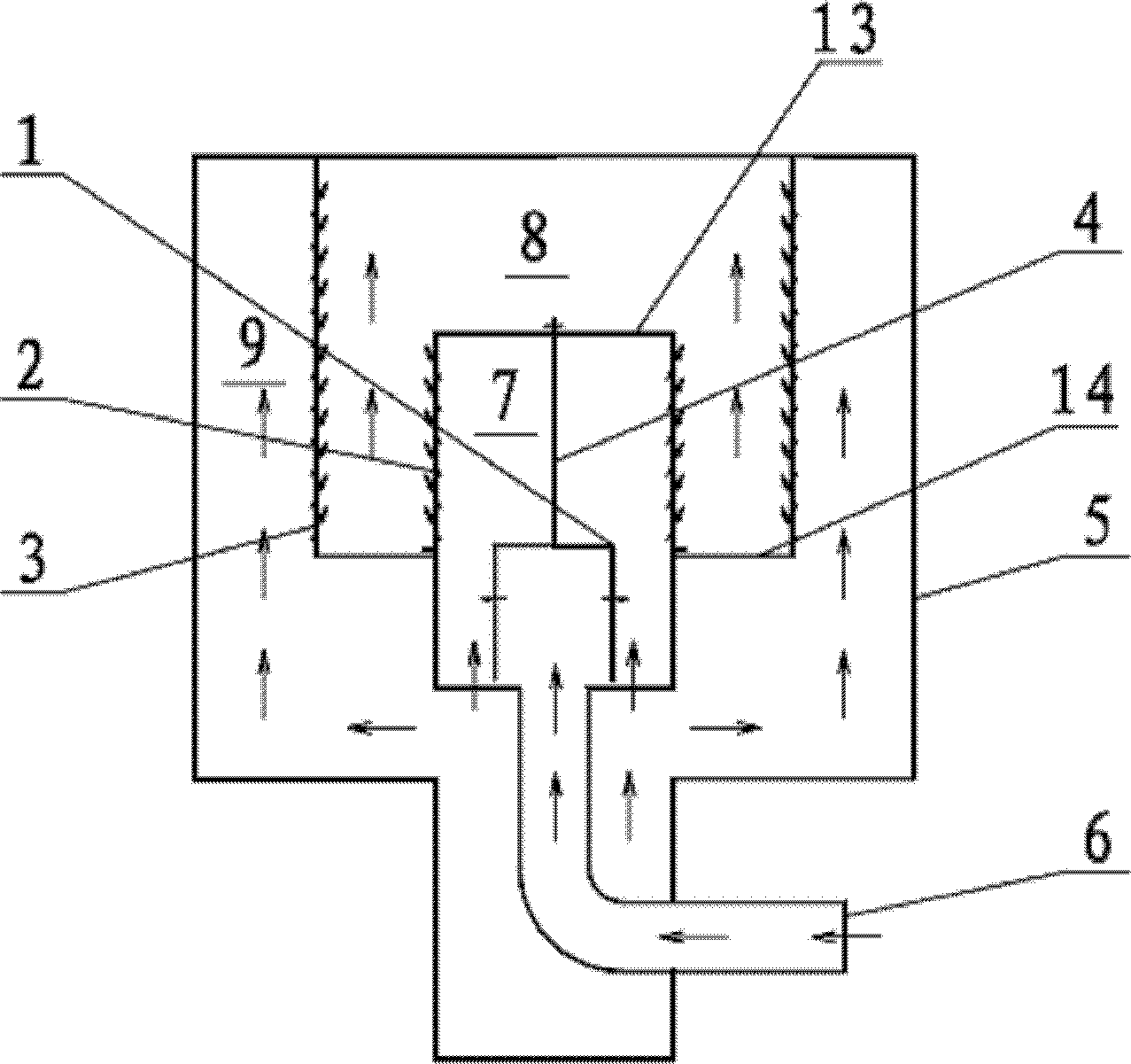

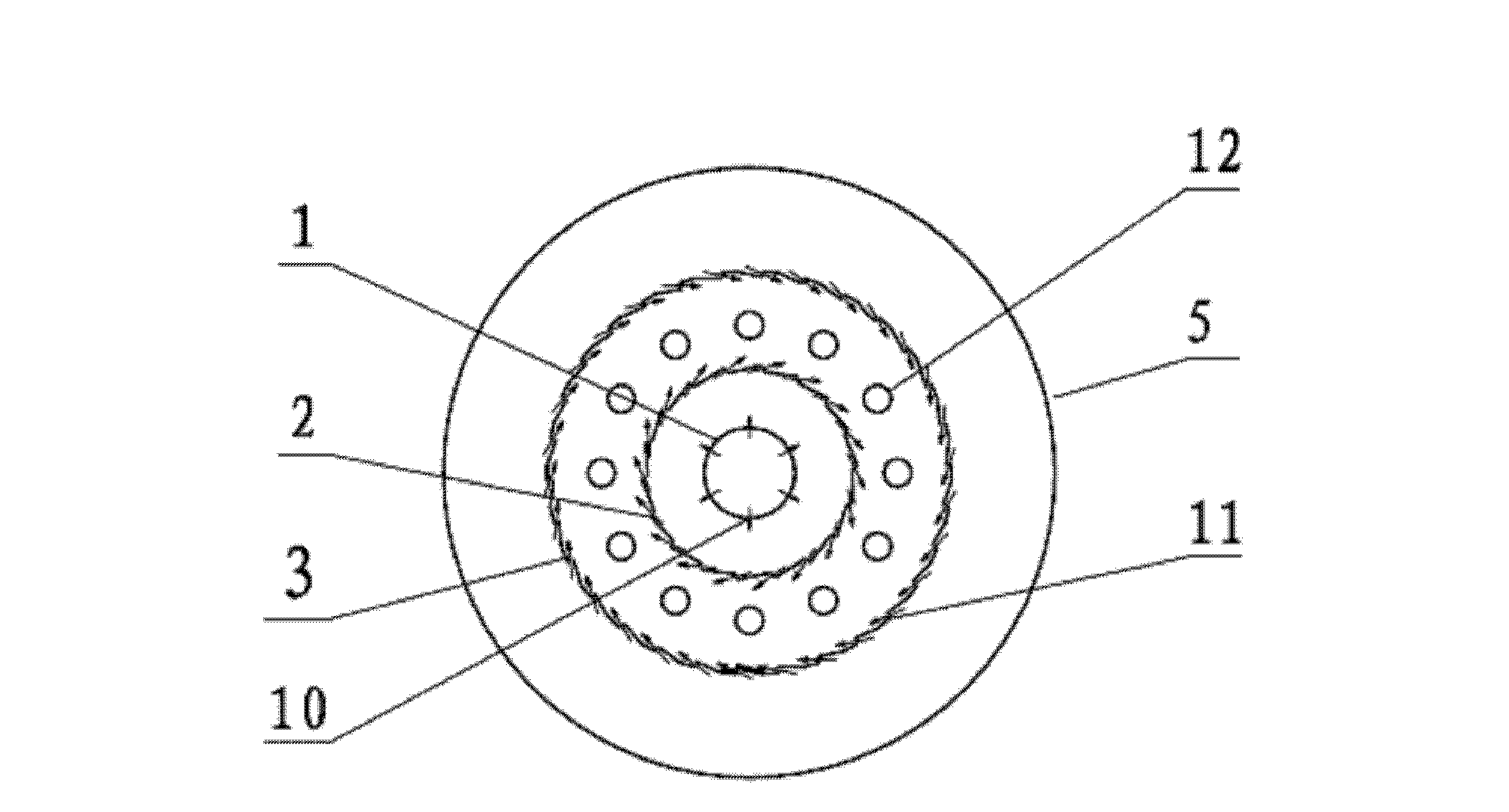

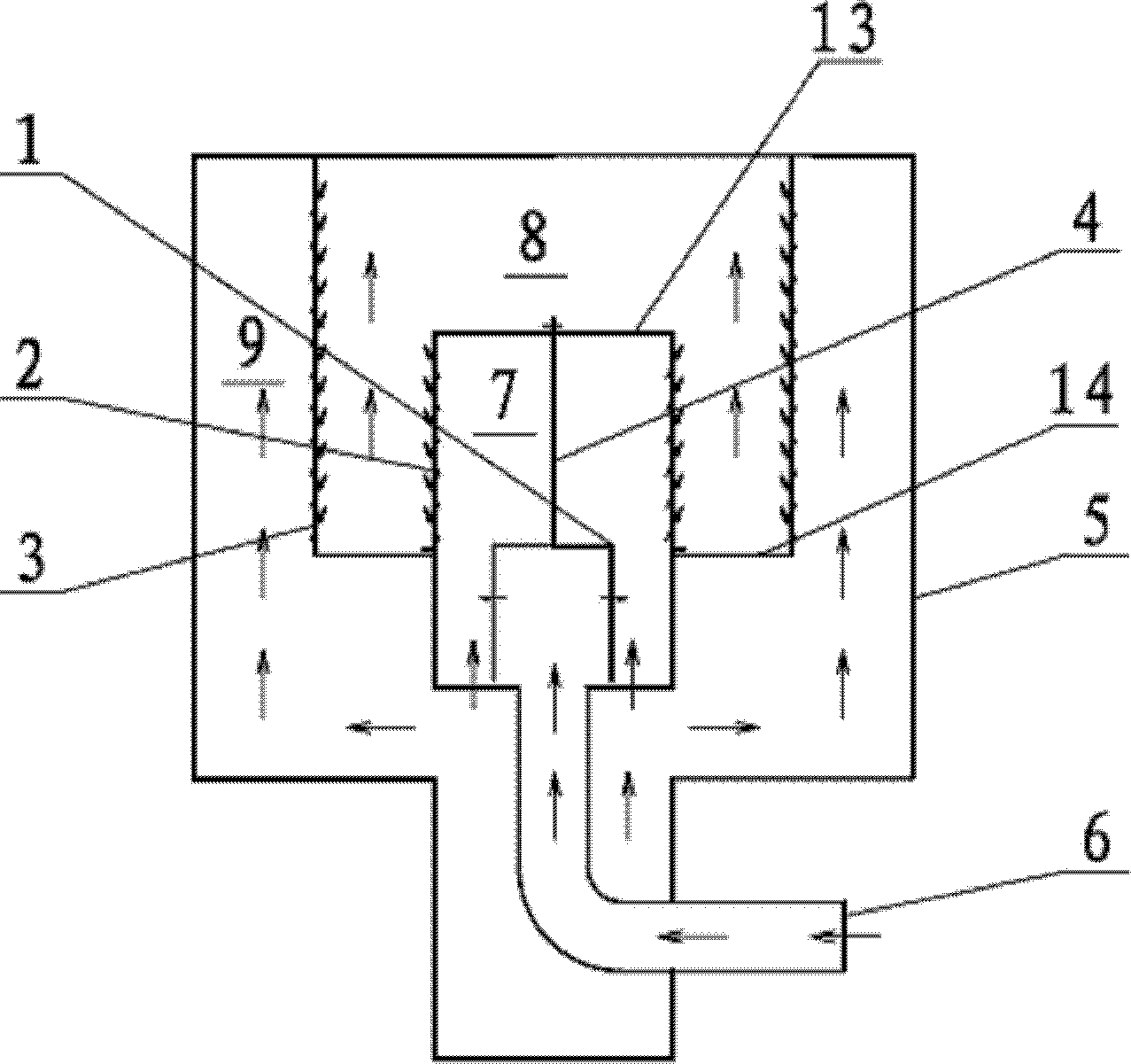

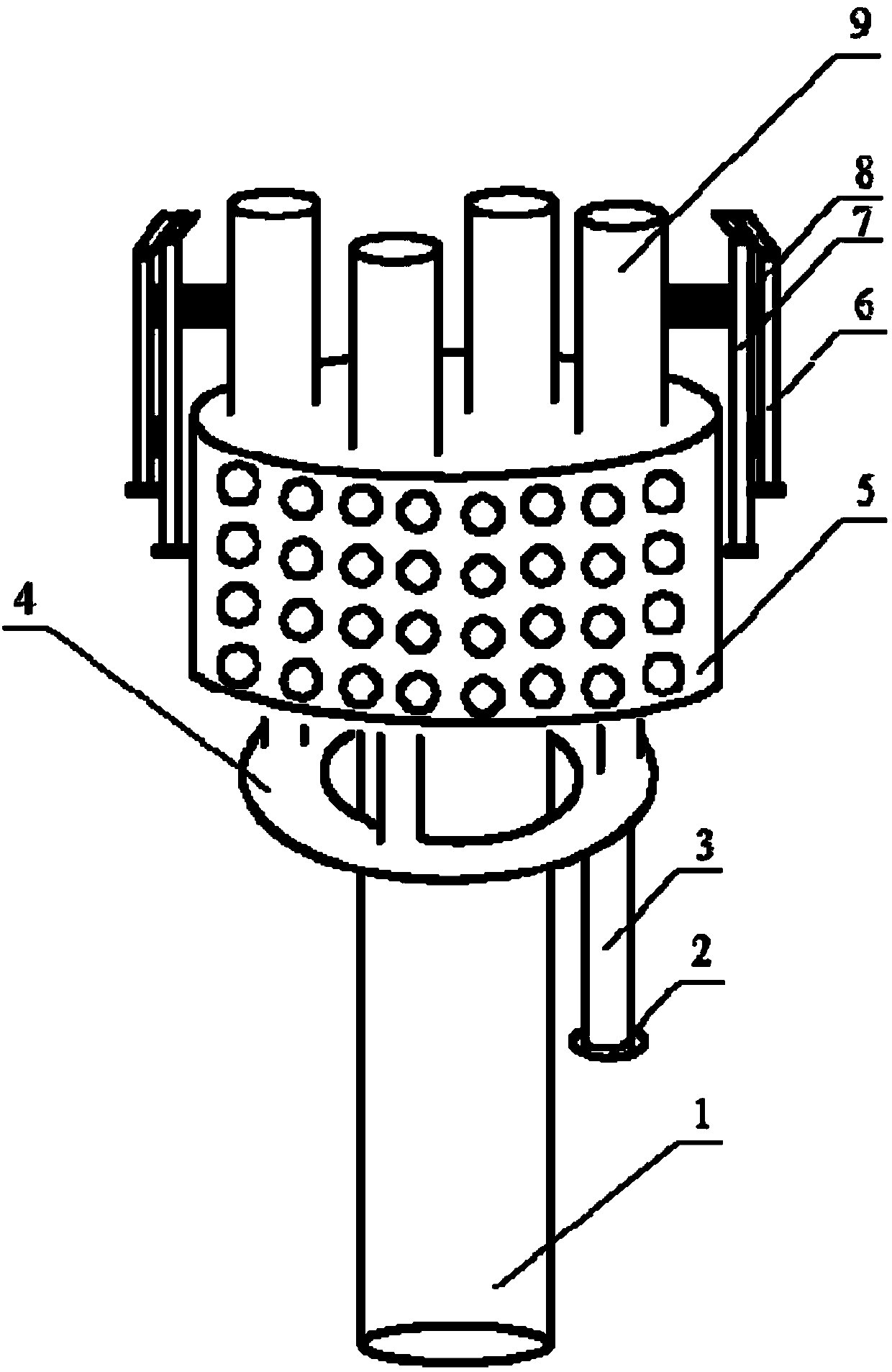

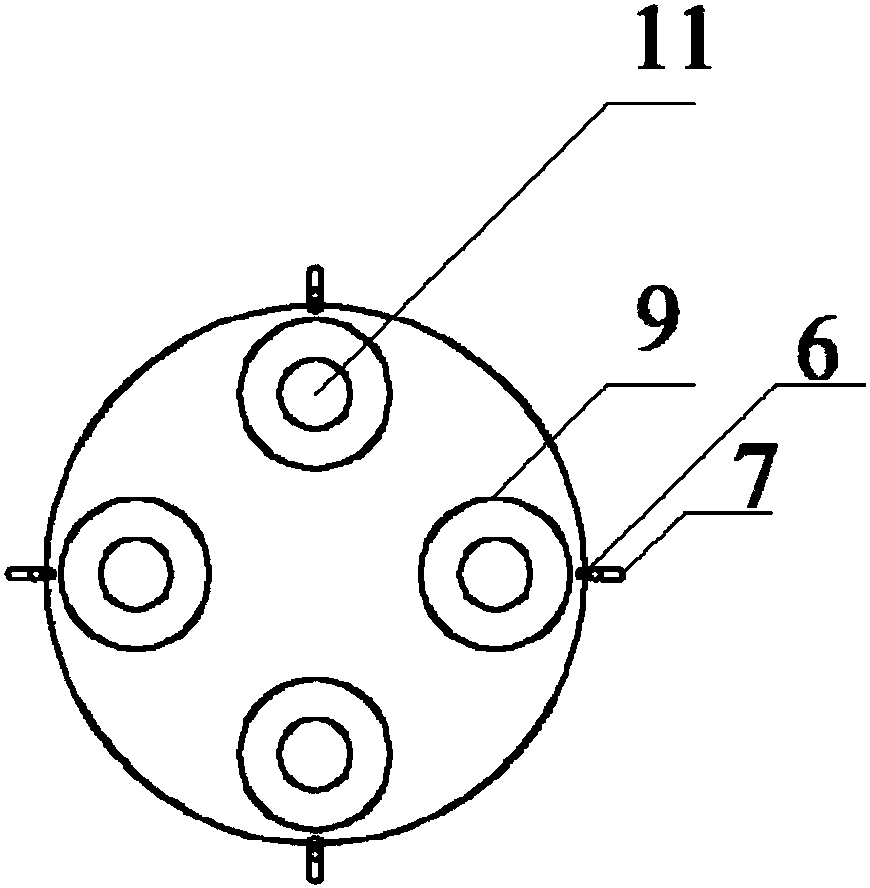

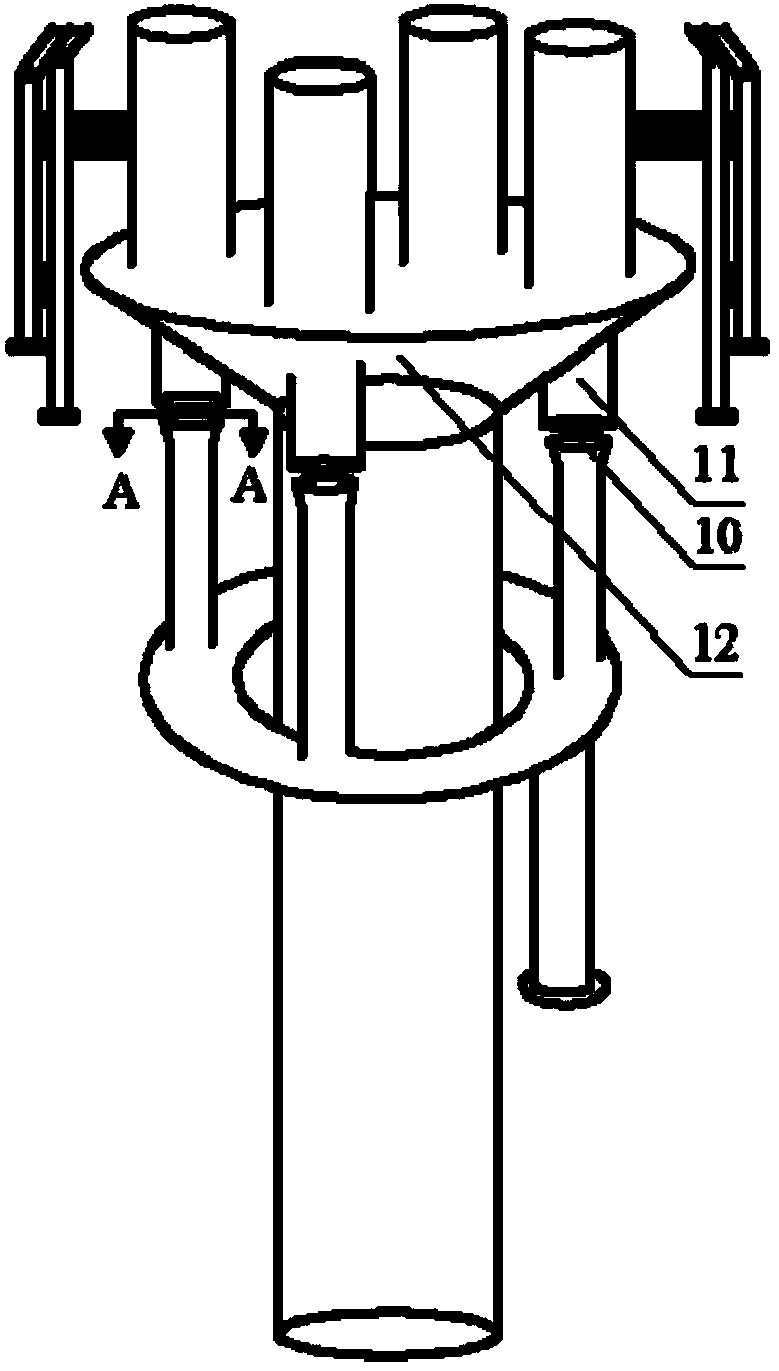

Partial premix combustor

The invention discloses a partial premix combustor, which comprises a jet nozzle (1) and an air inlet tube (6). The jet nozzle (1) is communicated with the air inlet tube (6). The partial premix combustor is characterized by further comprising an inner guide ring (2) and an outer guide ring (3). The inner guide ring (2) surrounds the jet nozzle (1), the outer guide ring (3) surrounds the inner guide ring (2), a first mixing area (7) is formed between the inner guide ring (2) and the jet nozzle (1), and a second mixing area (8) is formed between the outer guide ring (3) and the inner guide ring (2). By adopting the structure, the mixing process of gas and air is strengthened, the gas and the air are mixed completely, combustion noise is small, and the flame adjustment is stable.

Owner:上海集焰节能科技有限公司

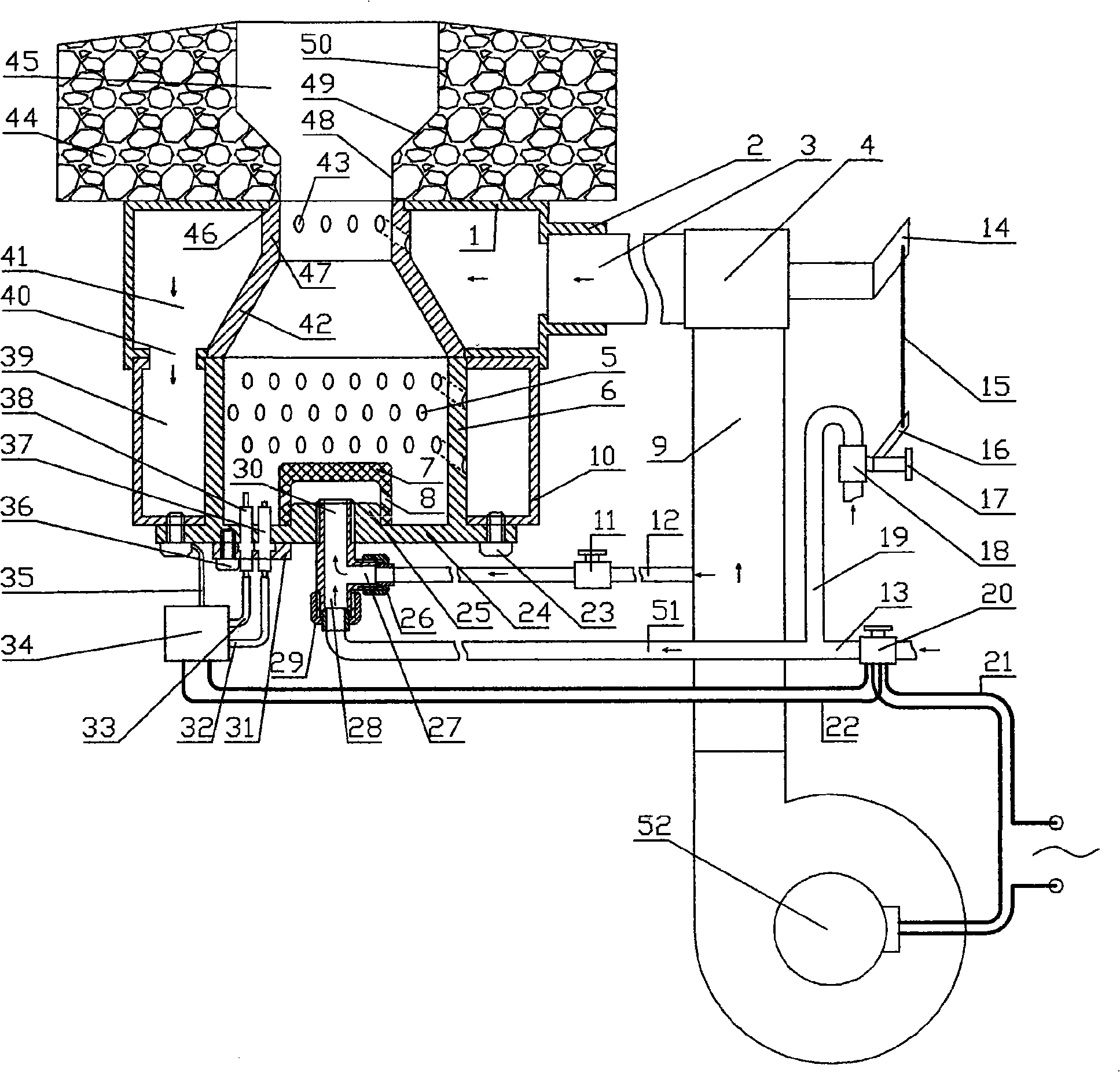

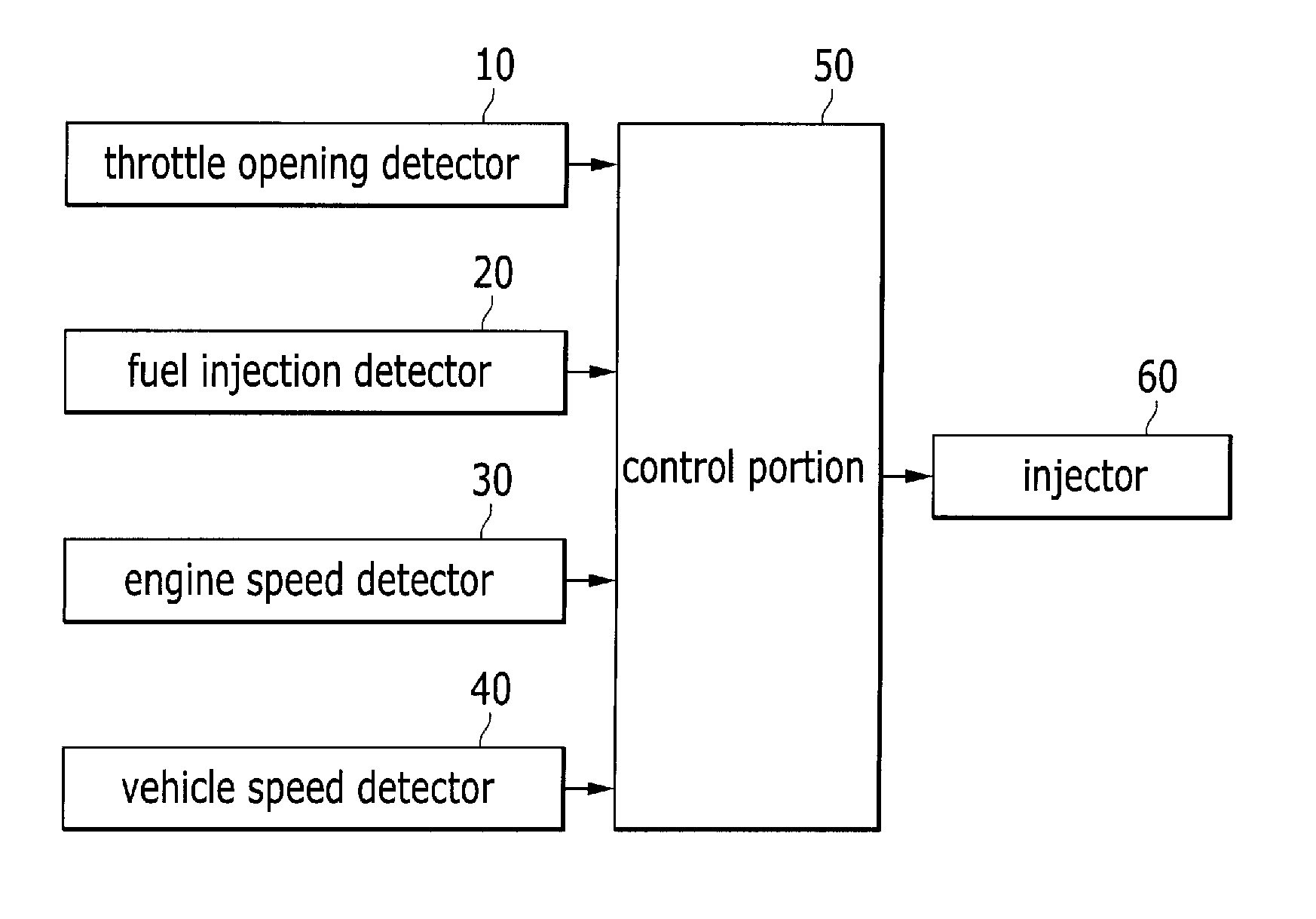

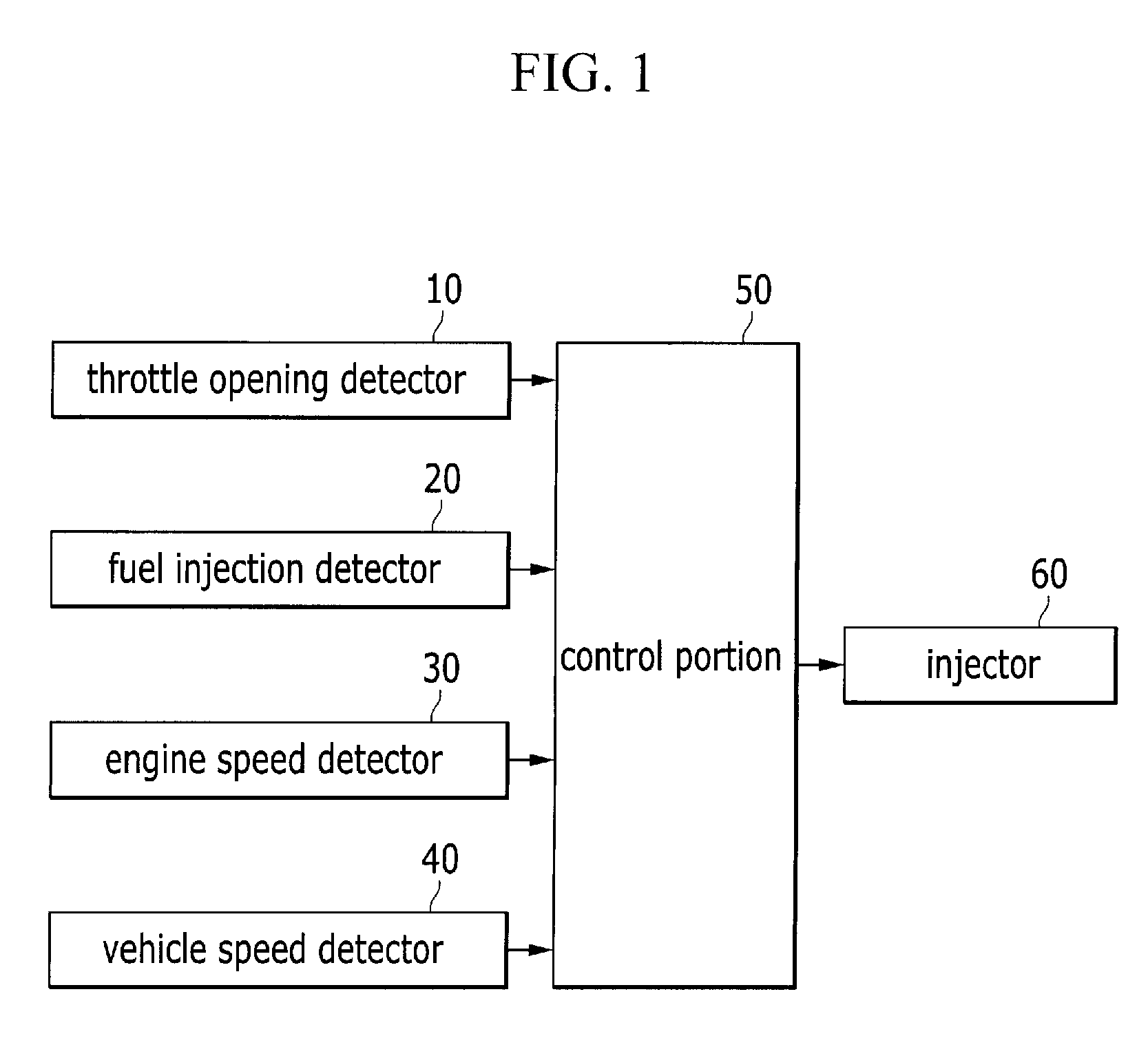

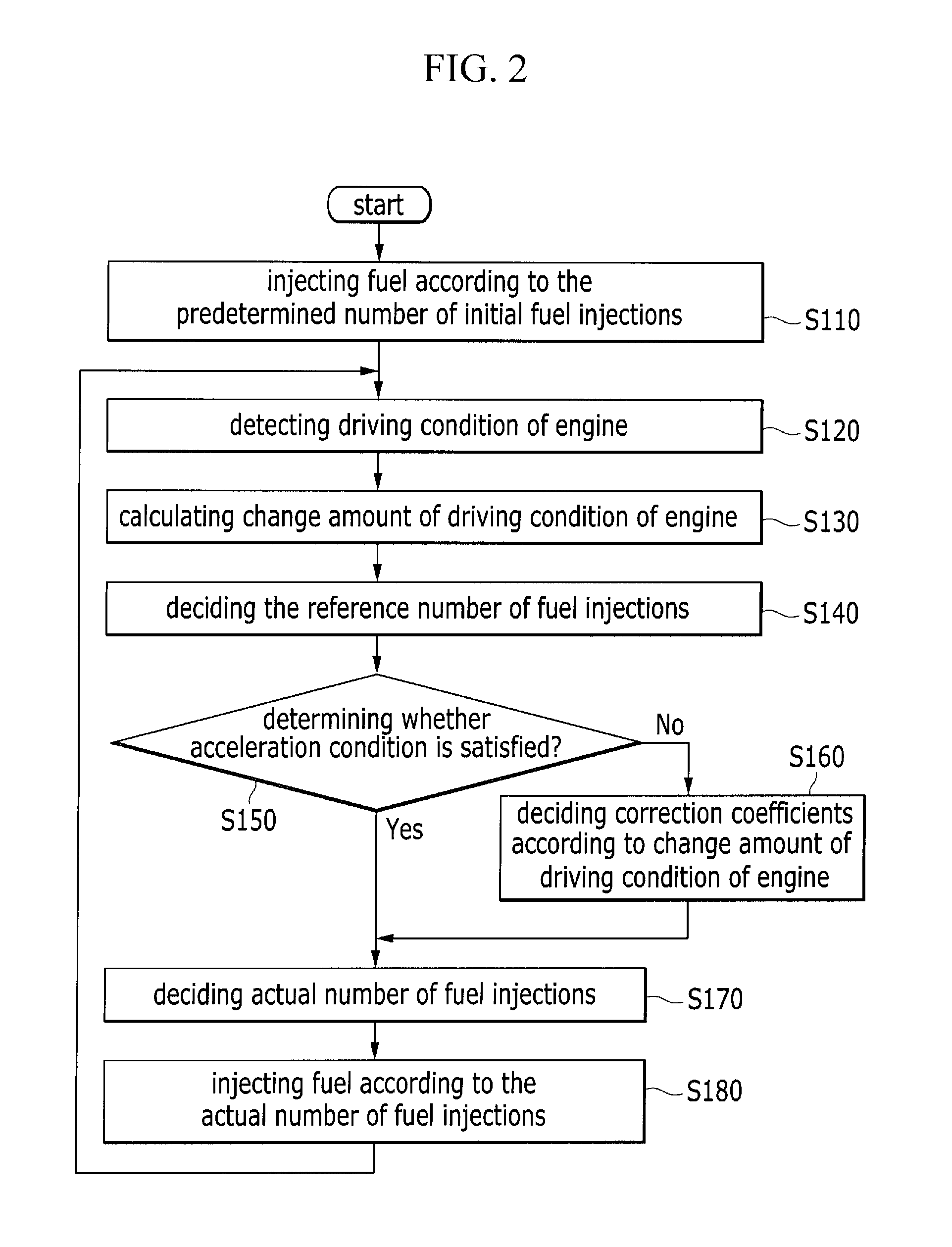

System and Method for Controlling the Number of Pilot Injections

ActiveUS20120065869A1Reduce combustion noiseImprove fuel economyElectrical controlInternal combustion piston enginesCombustion noisePilot injection

A system and a method for controlling the number of pilot injections reduces combustion noise and improves fuel economy by deciding the actual number of the pilot injections based on a change amount of a driving condition and injecting a fuel according to the actual number of the pilot injections in a case of acceleration. The system may include a detecting portion detecting a driving condition of an engine; a control portion calculating a change amount of the driving condition from the driving condition of the engine, and deciding the actual number of the pilot injections based on the driving condition of the engine and the change amount of the driving condition; and an injector injecting a fuel to the engine through a main injection and / or the pilot injections according to the actual number of pilot injections.

Owner:HYUNDAI MOTOR CO LTD

Steam burning supporting type torch burner

InactiveCN110017488AReduce consumptionReduce combustion noiseIncinerator apparatusGaseous fuel burnerCombustorEngineering

The invention relates to a steam burning supporting type torch burner. The steam burning supporting type torch burner mainly solves the problems of high volume of steam consumed in burning, low smokeremoving effect, loud noise and easy generation of black smoke of a steam smoke removing type torch of a torch system in the prior art. The steam burning supporting type torch burner comprises a maintorch gas pipe, a steam inlet, a main steam pipe, a steam coiled pipe, a silencing cover, an ignitor, a pilot burner, a fixed wing plate, a burner, a steam nozzle, a secondary steam pipe and a torch head. The abovementioned problems can be solved by the technical scheme. The steam burning supporting type torch burner is applicable to torch burning.

Owner:CHINA PETROLEUM & CHEM CORP +1

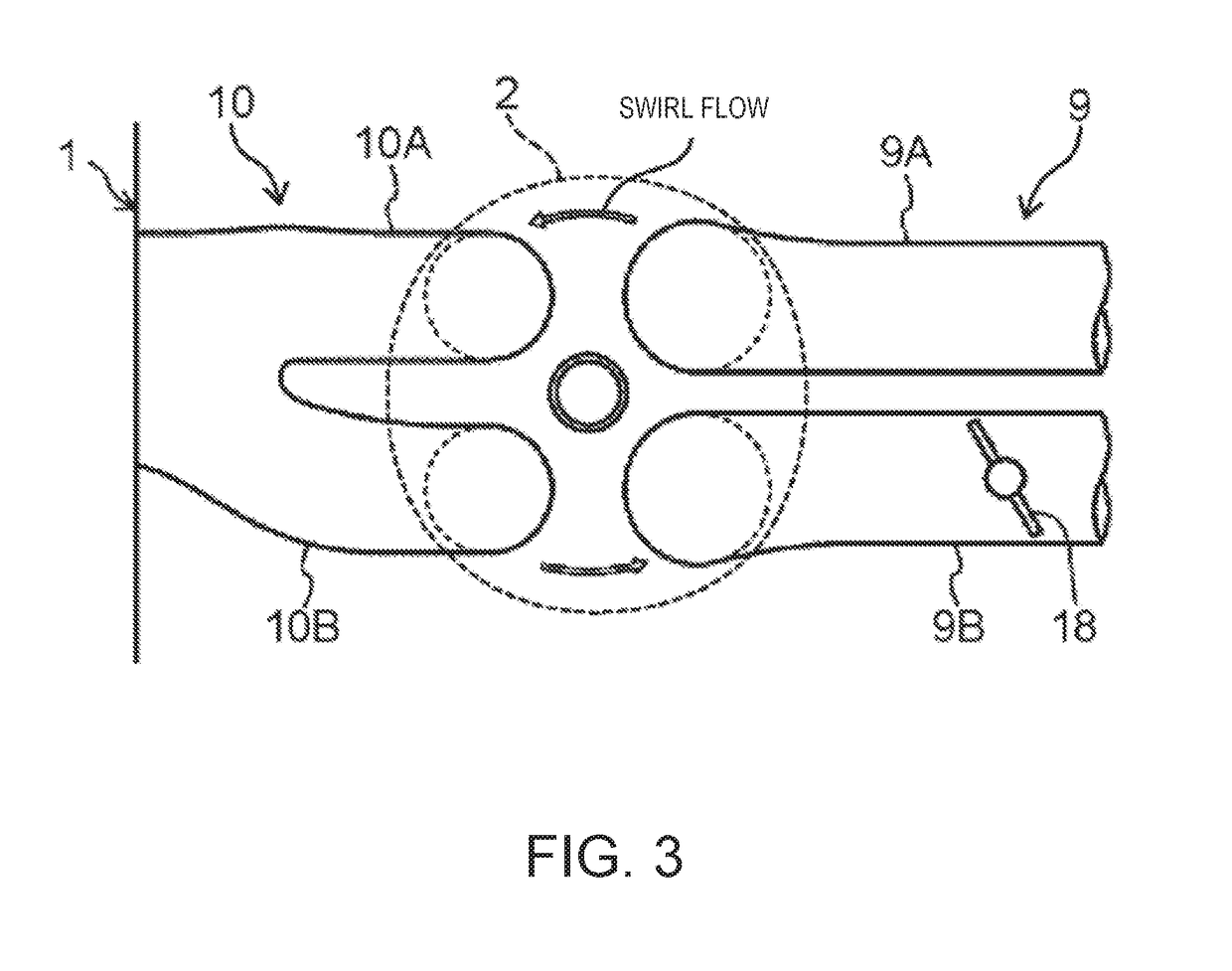

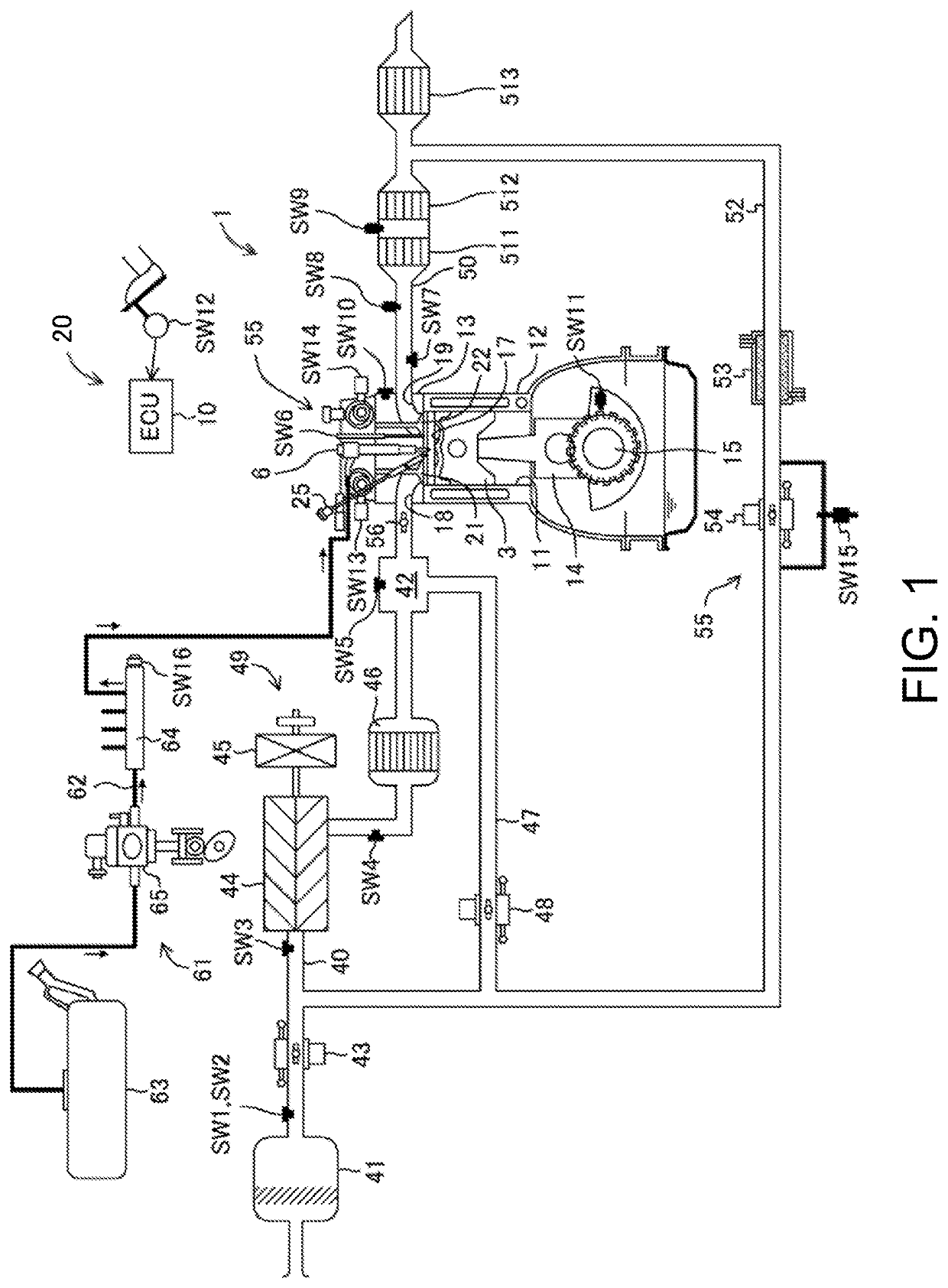

Control system for compression-ignition engine

ActiveUS10767593B2Reduce combustion noiseElectrical controlInternal combustion piston enginesControl systemInlet valve

A compression-ignition engine control system is provided, which includes an intake variable mechanism and a controller. Within a first operating range and a second operating range on a higher engine load side, the controller controls the variable mechanism to form a gas-fuel ratio (G / F) lean environment in which an air-fuel ratio inside a cylinder is near a stoichiometric air-fuel ratio and burnt gas remains inside the cylinder, and controls a spark plug to spark-ignite mixture gas inside the cylinder to combust in a partial compression-ignition combustion. The controller controls the variable mechanism to advance the intake valve open timing on an advancing side of a TDC of the exhaust stroke, as the engine load increases within the first range, and retard the intake valve open timing on the advancing side of the TDC of the exhaust stroke, as the engine load increases within the second range.

Owner:MAZDA MOTOR CORP

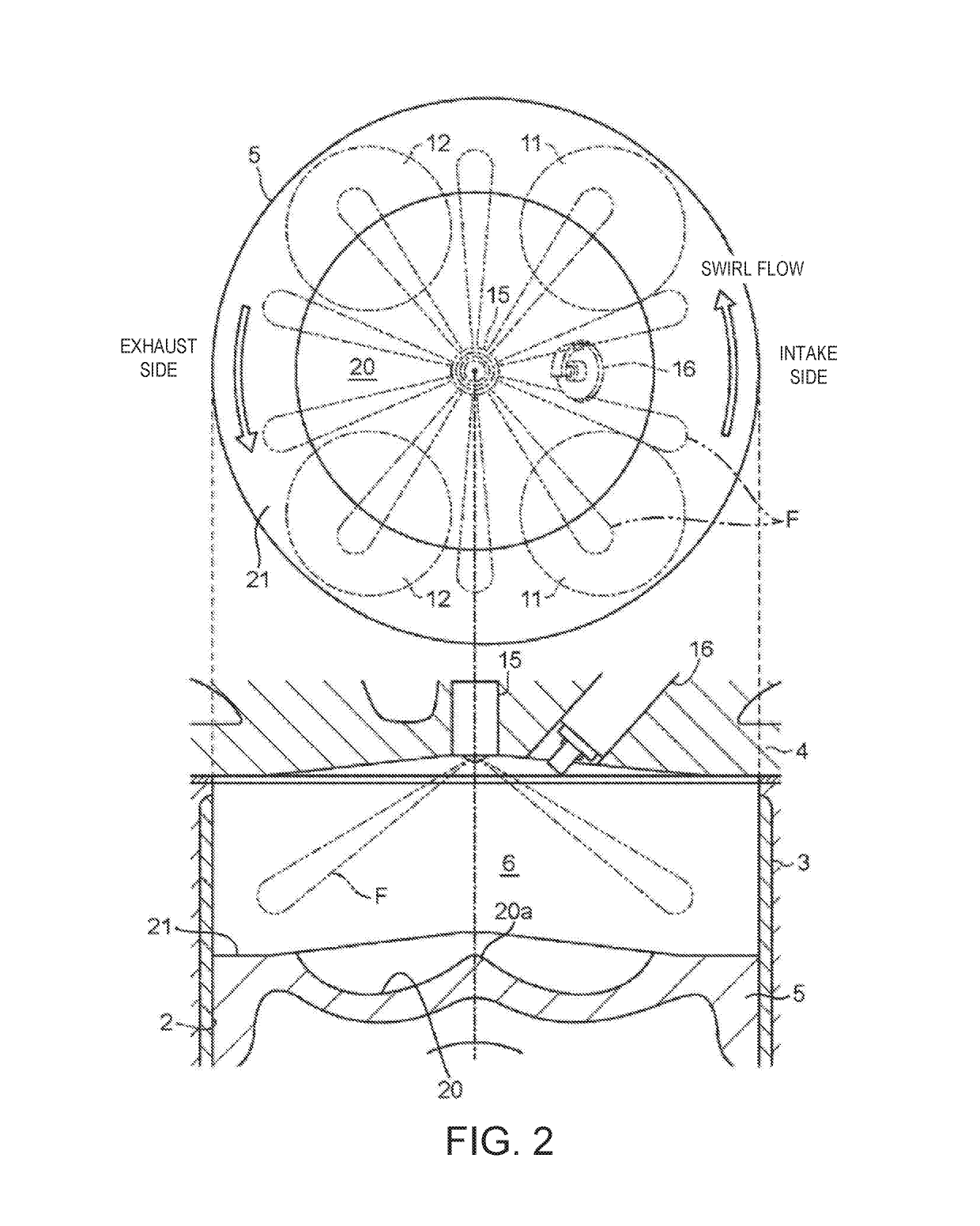

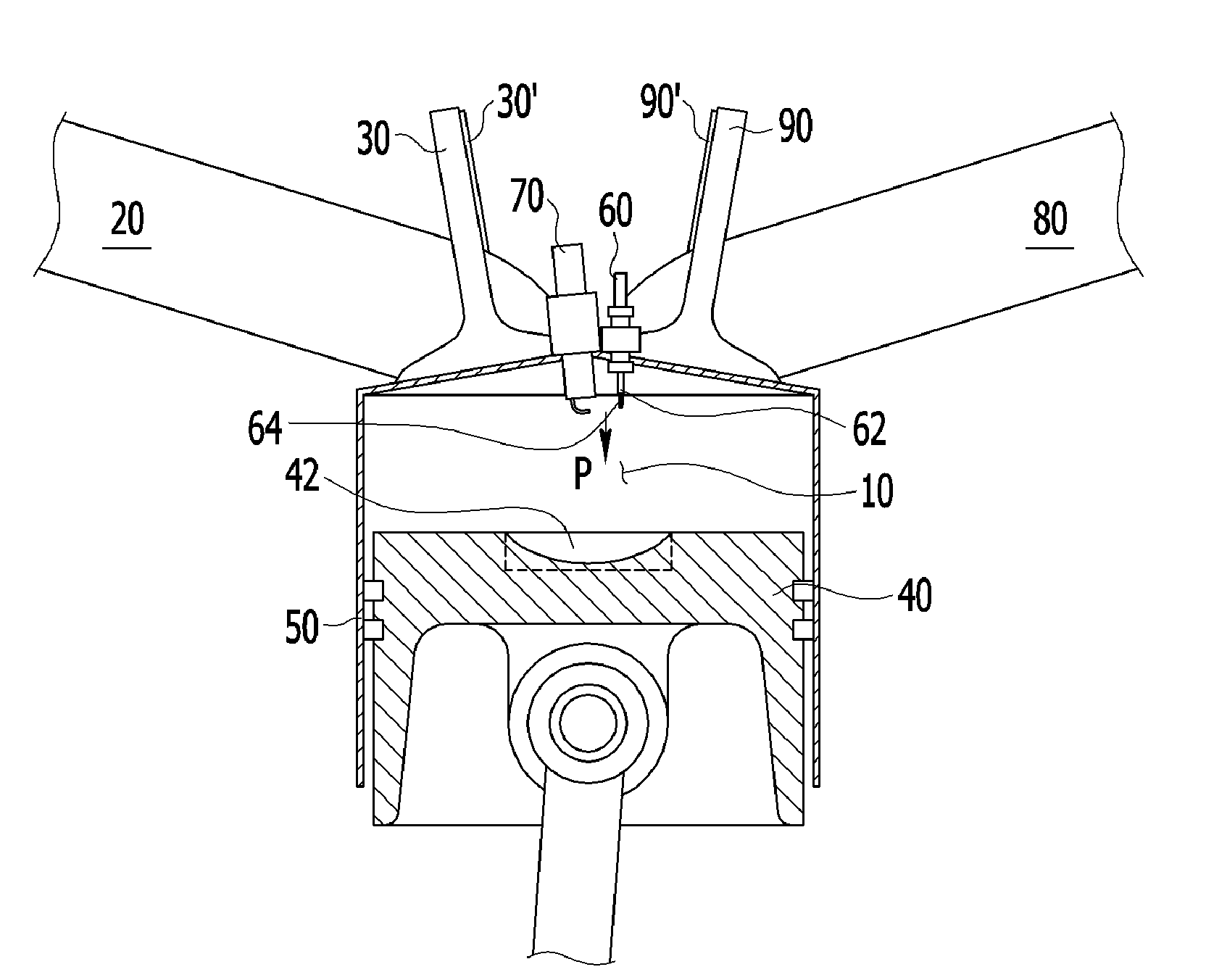

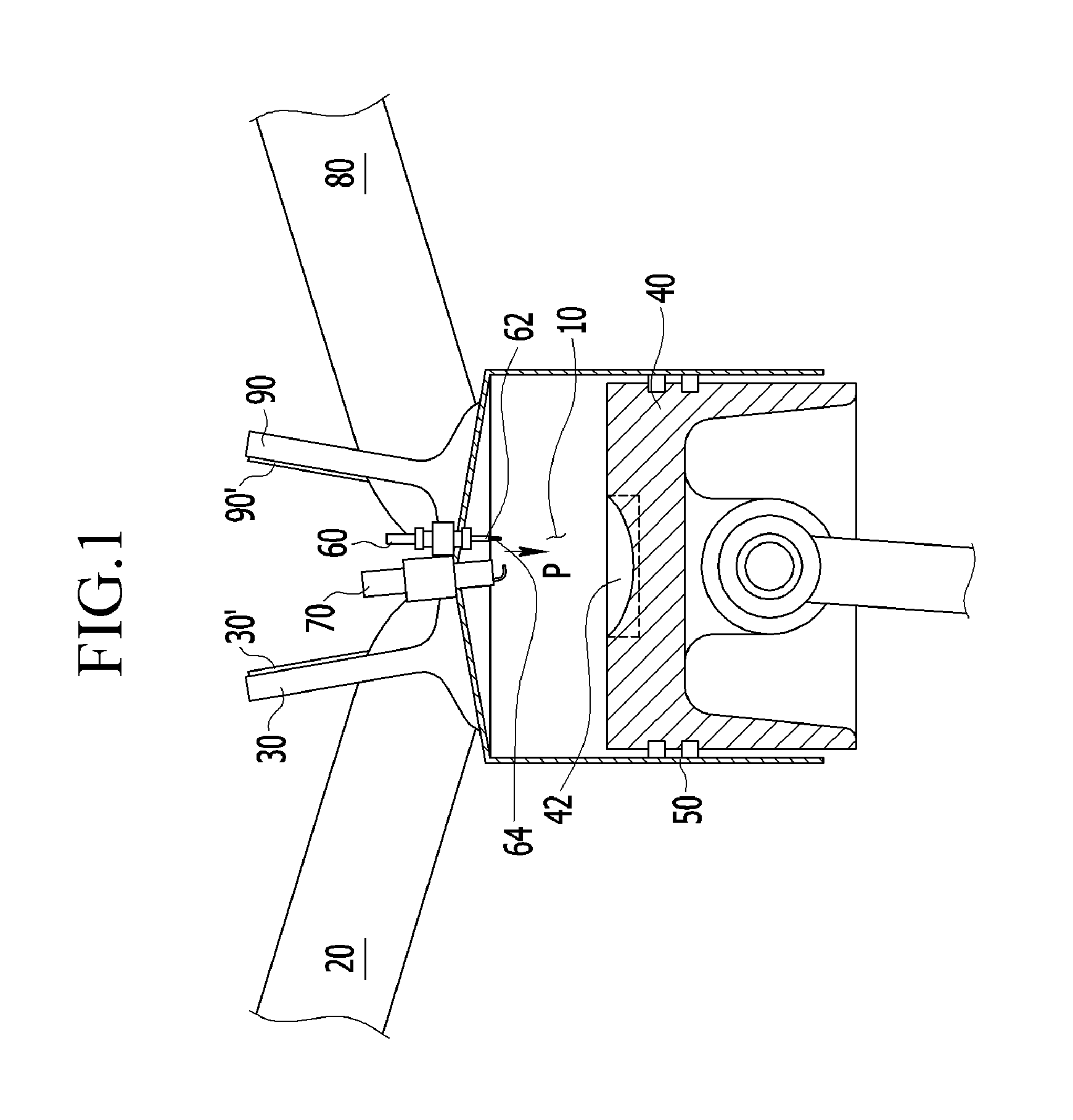

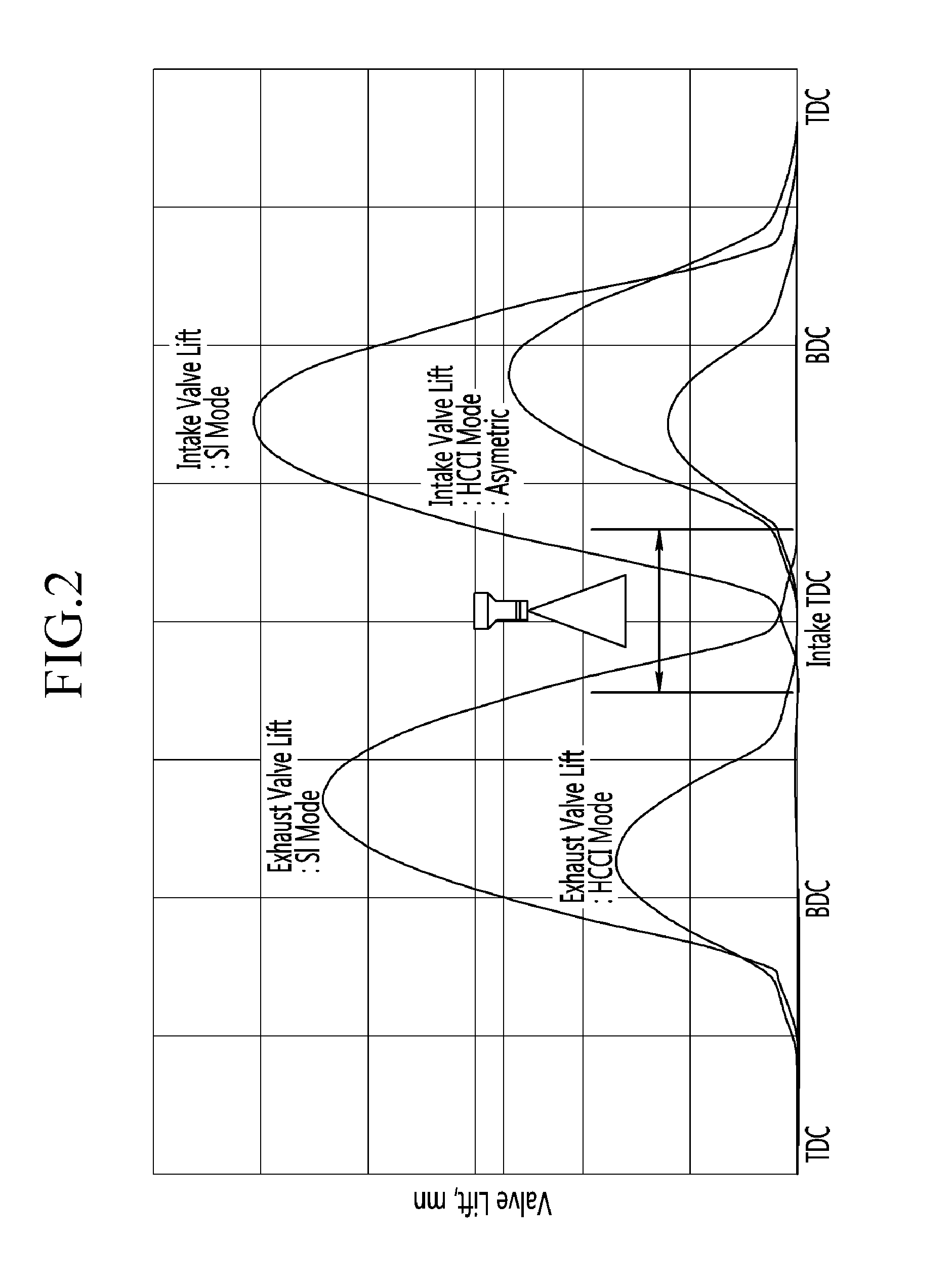

Compression ignition gasoline engine

ActiveUS8590506B2Stable ignitionReduce combustion noiseValve arrangementsElectrical controlExhaust valveCombustion chamber

A compression ignition gasoline engine uses low-cetane number fuel, such as gasoline. The engine includes a combustion control device having an injector directly injecting fuel into a combustion chamber, intake and exhaust valves, and a variable valve device changing a valve timing, in which the compression ignition gasoline engine includes: at least two intake valves and two exhaust valves; a spark plug positioned at the center portion of the combustion chamber; and an injector positioned adjacent to the spark plug toward the center portion of the combustion chamber, in which the exhaust valve is a symmetric valve lift in which the lift and the opening section of the tow exhaust valves are the same in low lift, and the intake valve is an asymmetric valve lift in which the lift and the opening of the two intake valves are different in the low lift.

Owner:HYUNDAI MOTOR CO LTD

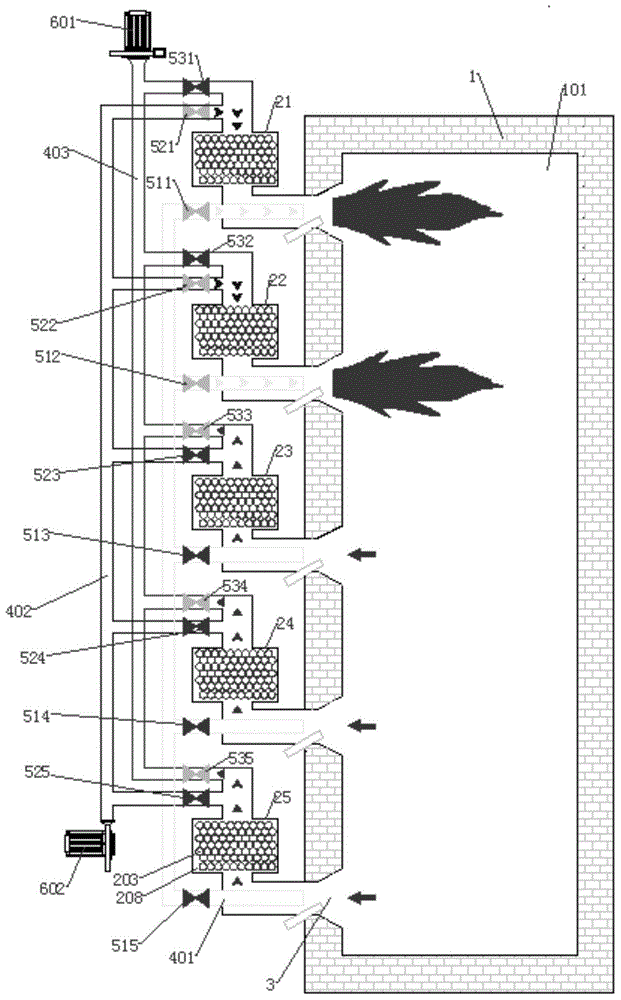

Progressive switchover heat storage type combustion device

InactiveCN104456569ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustor

The invention relates to a progressive switchover heat storage type combustion device. The progressive switchover heat storage type combustion device comprises at least five heat storage type combustors connected with a hearth and a controller capable of controlling the heat storage type combustors. The controller switches over the heat storage type combustors, so that the heat storage type combustors are alternately used for combustion or smoke exhaust, and the number of the heat storage type combustors used for smoke exhaust is made to be larger than that of the heat storage type combustors for combustion at any moment; in combustion production, when the controller switches over any heat storage type combustor, at least another heat storage type combustor maintains combustion work. Compared with the prior art, in the steering process of the device, the phenomena of detonation and furnace blast are effectively avoided, the safety performance is better, and the energy-saving effect is more obvious.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

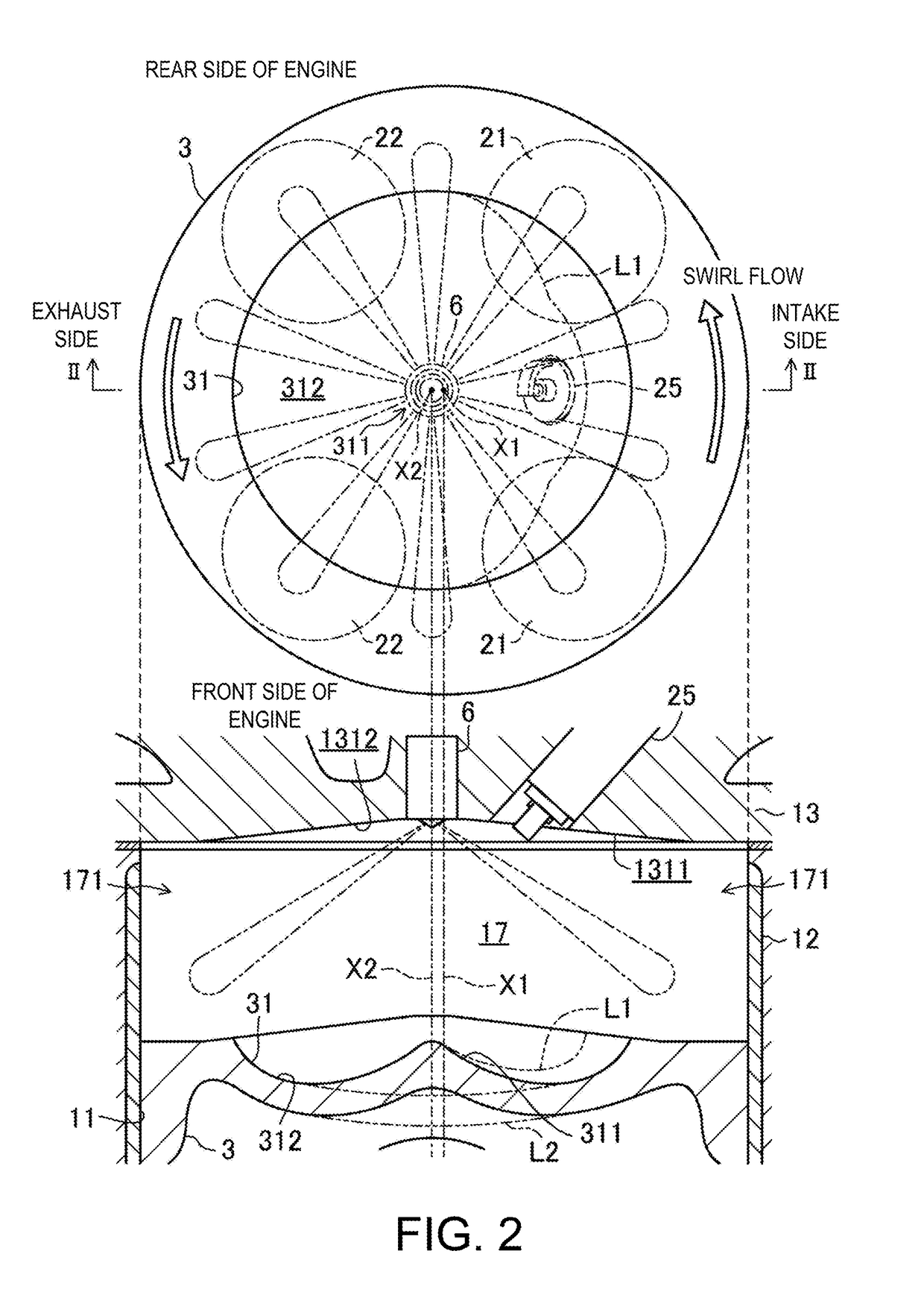

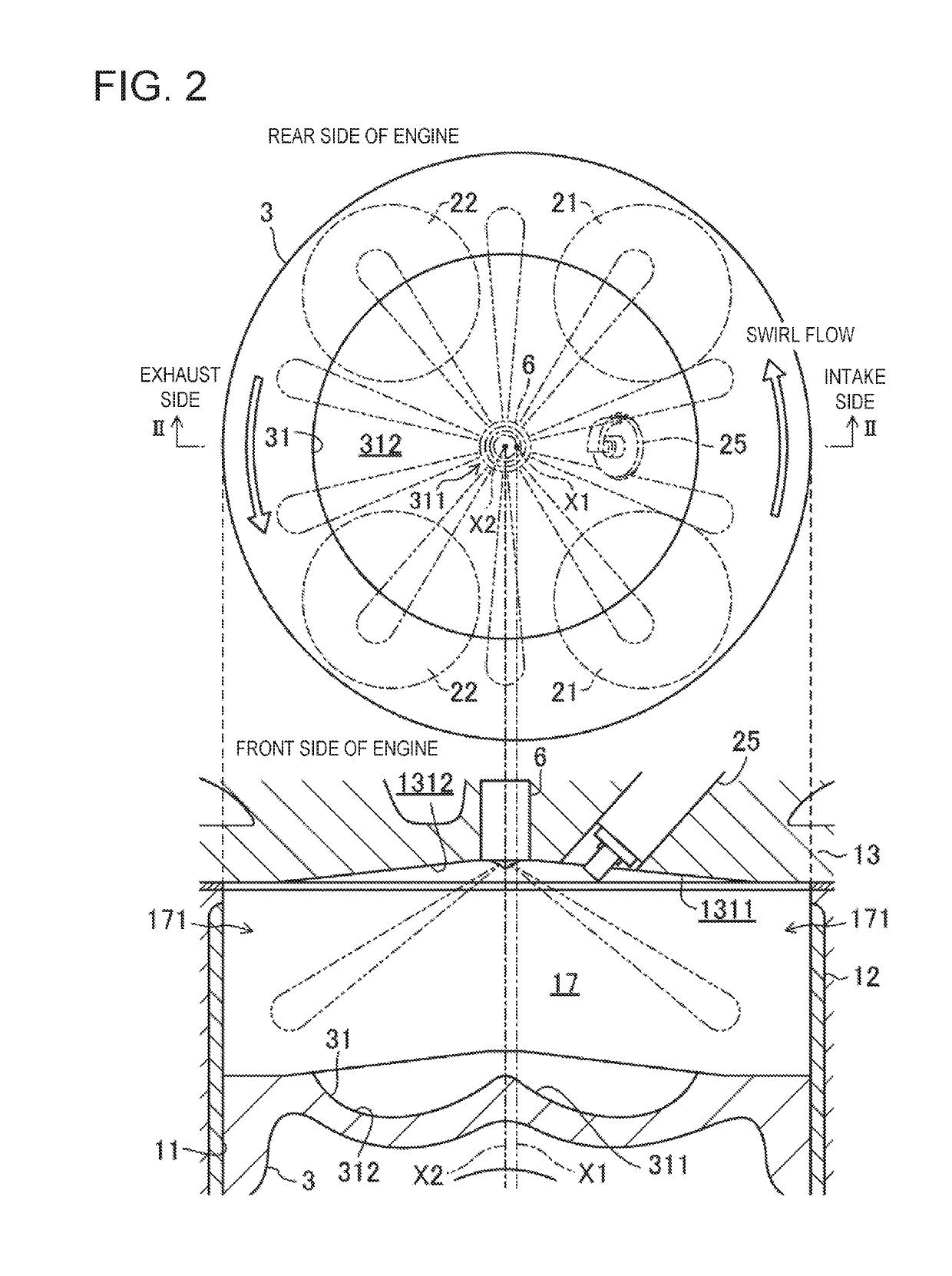

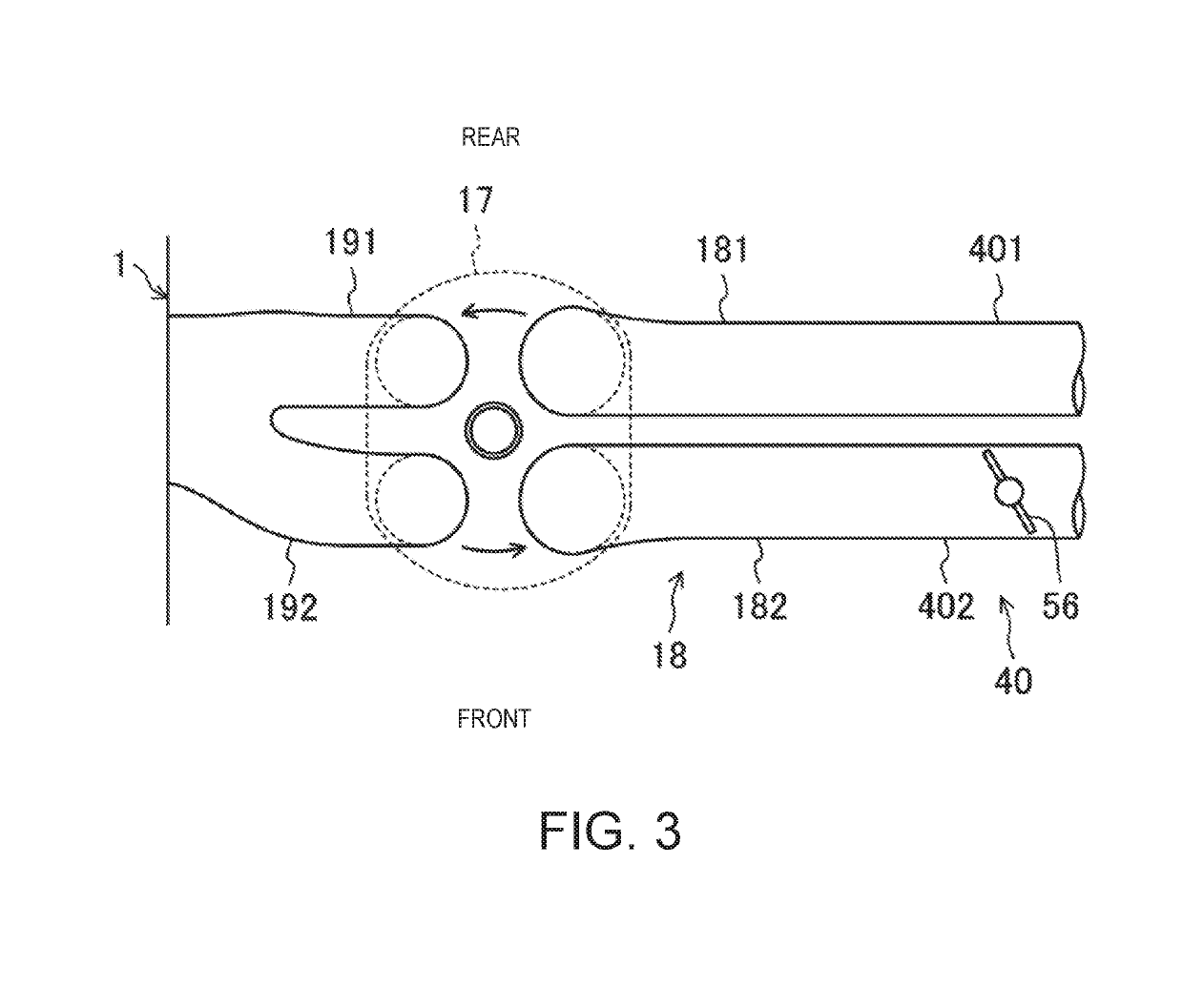

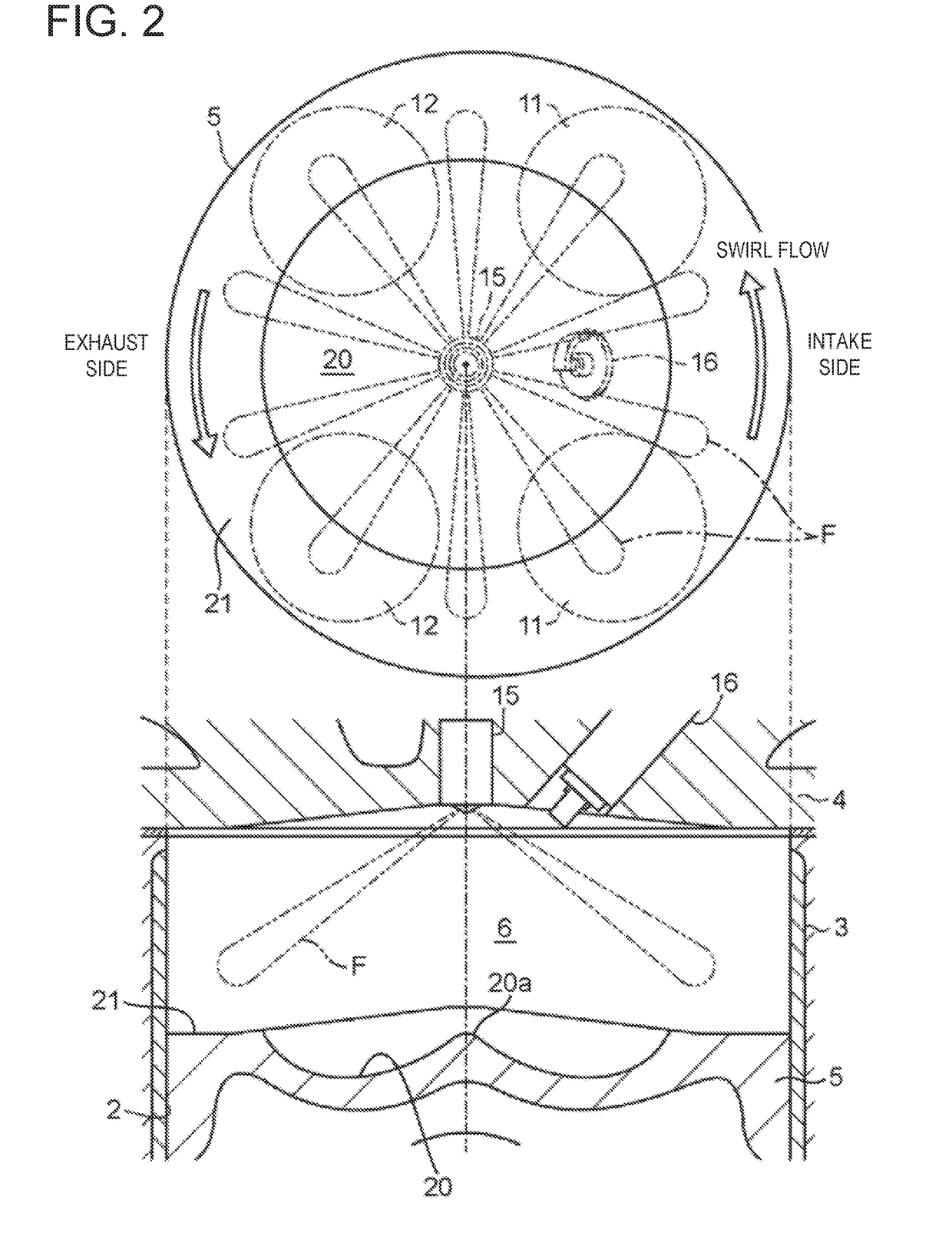

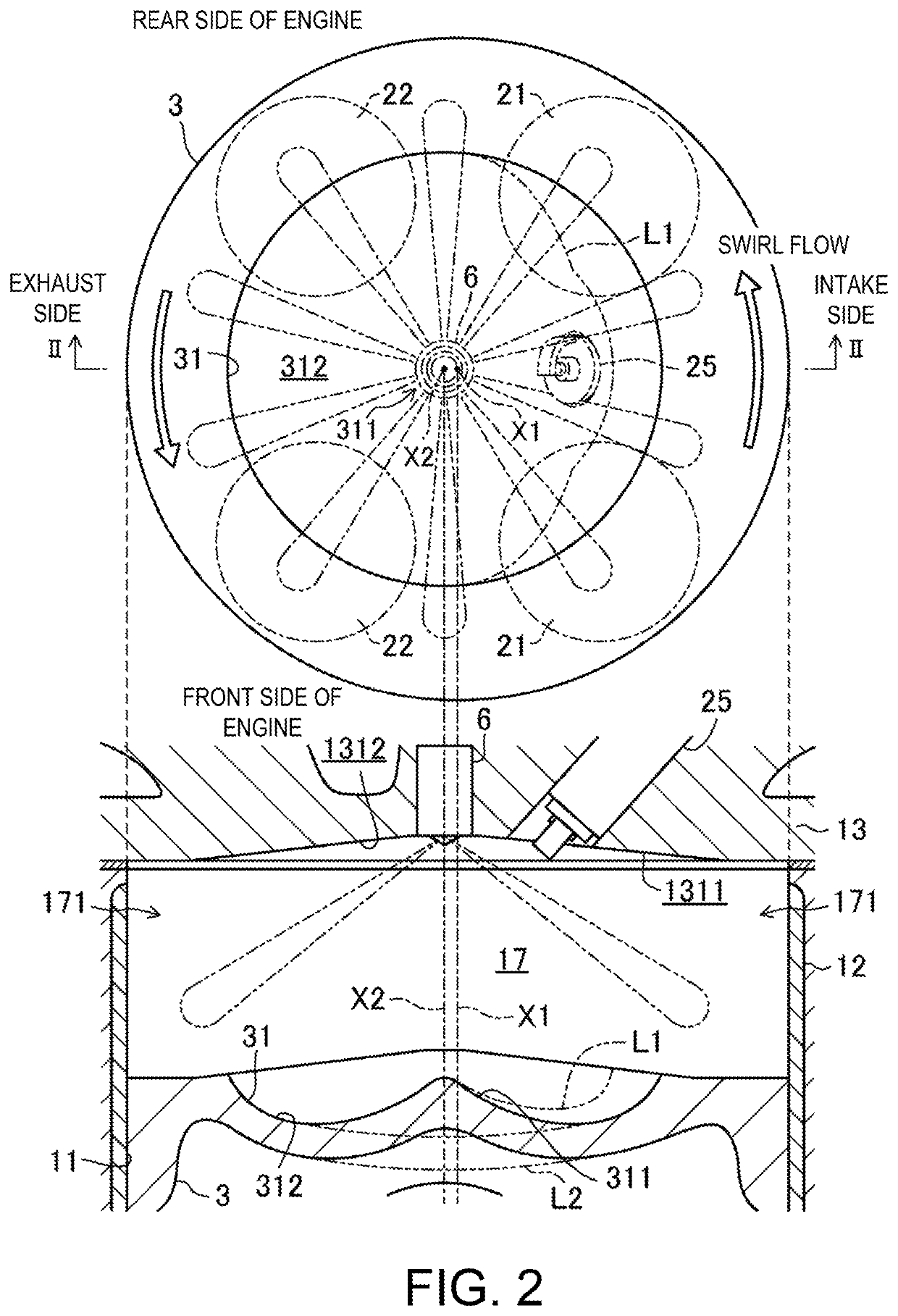

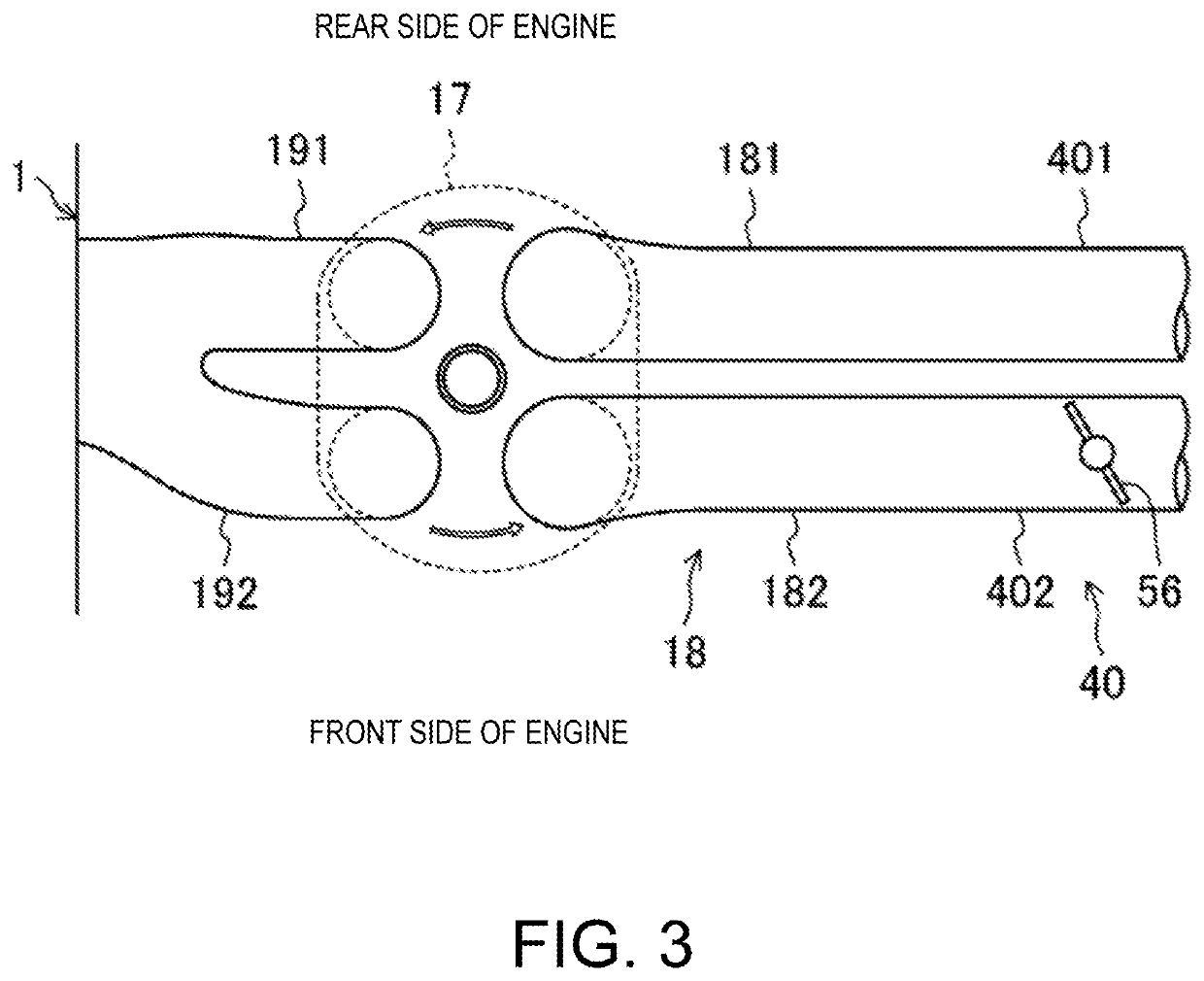

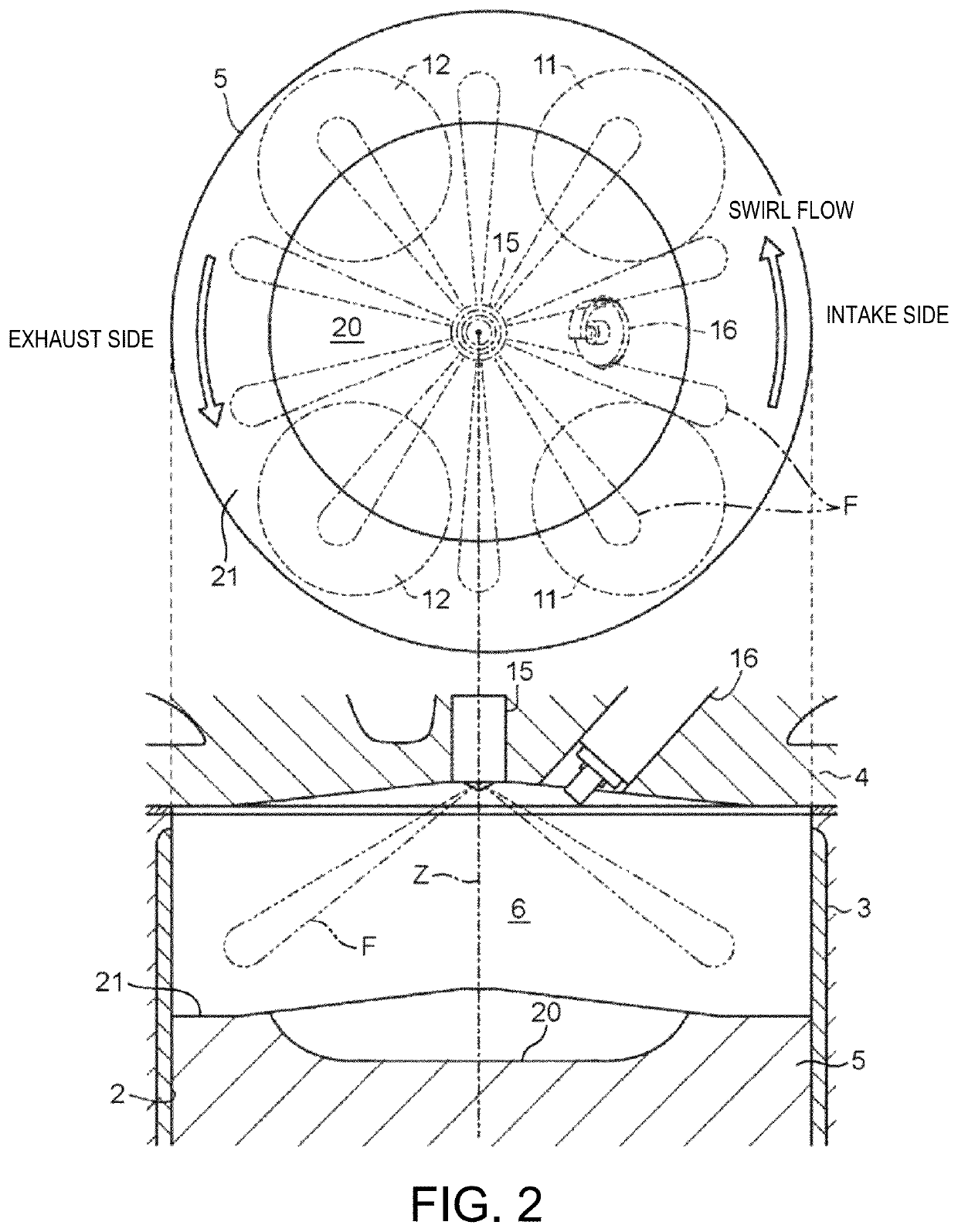

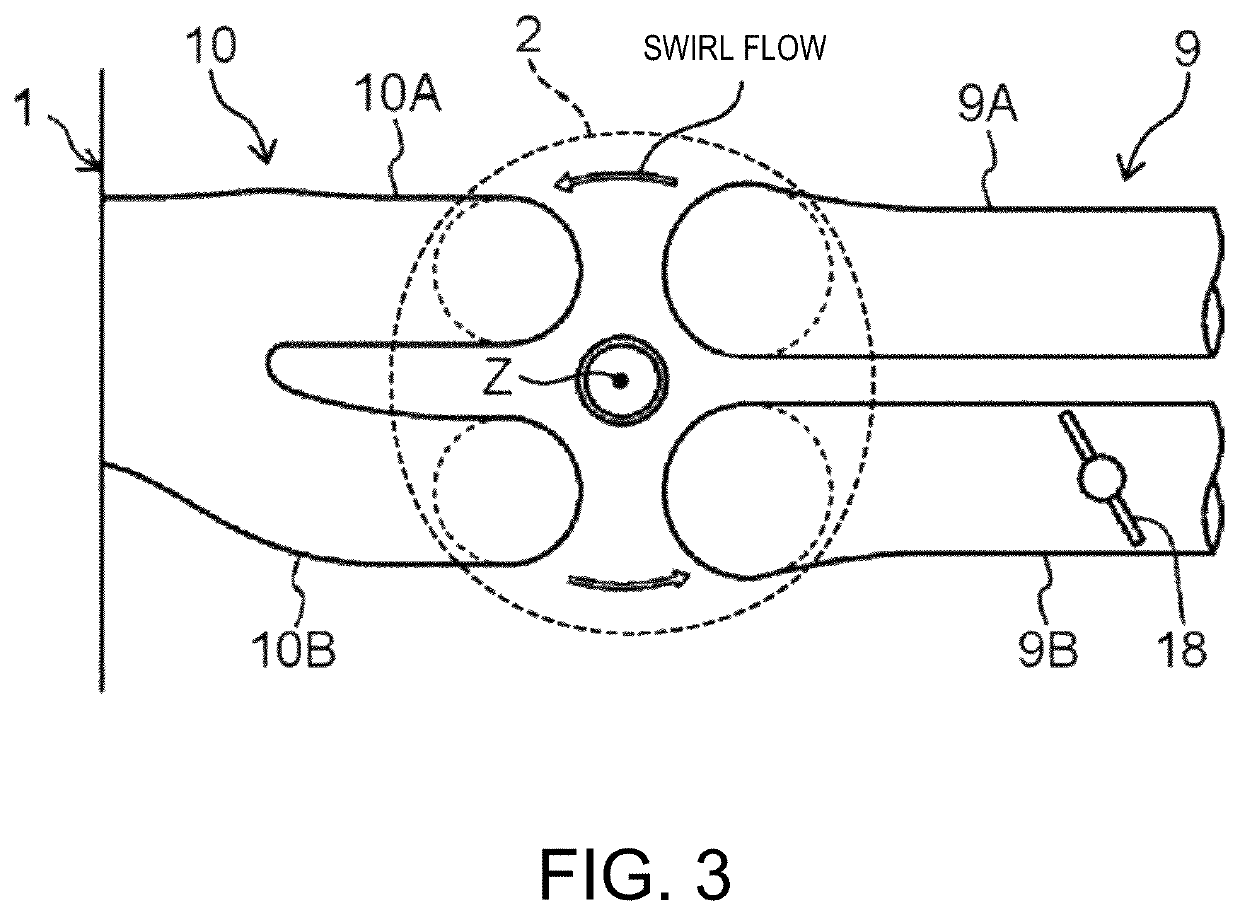

Control system for pre-mixture compression-ignition engine

ActiveUS20190063361A1Reduce combustion noiseReduce variationElectrical controlInternal combustion piston enginesCombustion chamberControl system

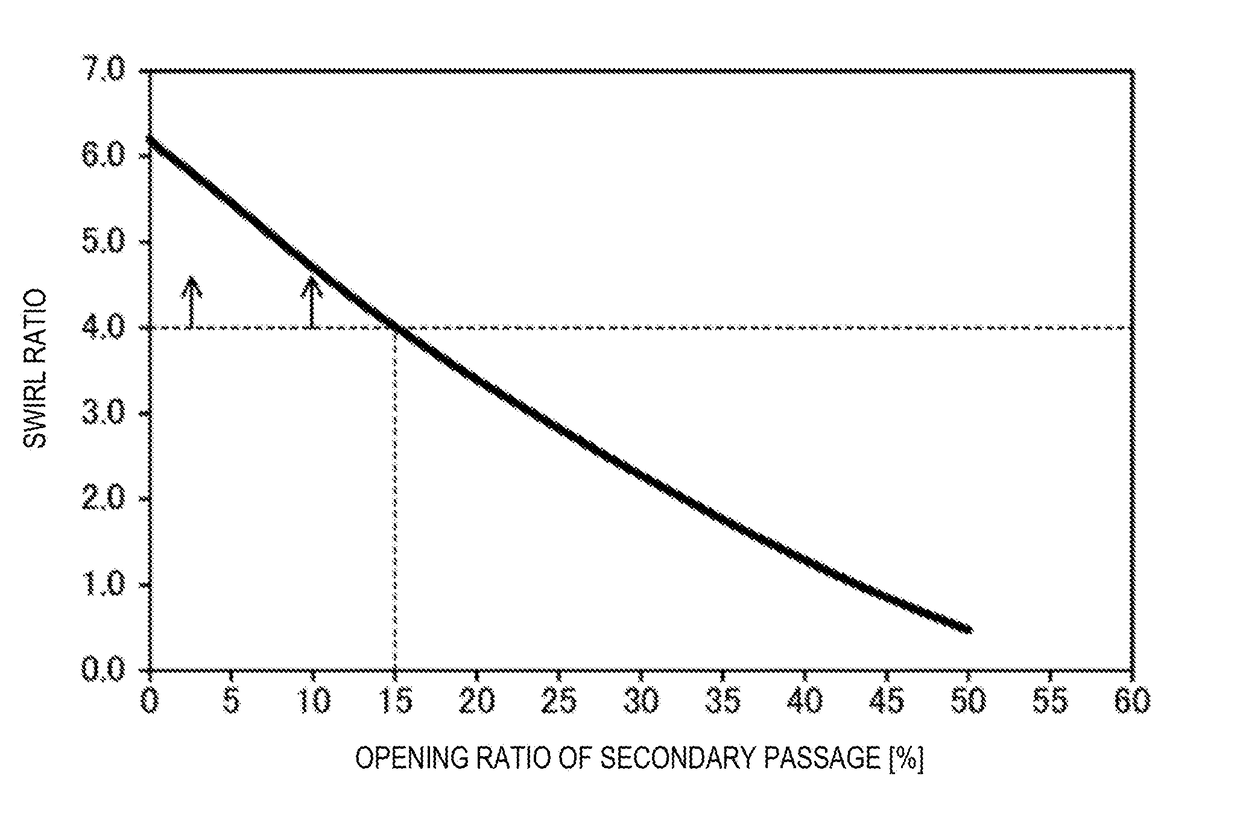

A control system for a pre-mixture compression-ignition engine is provided, configured such that in a first combustion mode, the control unit controls the fuel injection valve to have a fuel amount within a mixture gas in an outer circumferential portion of the combustion chamber larger than in the center portion, the swirl generating part to generate a swirl flow in the outer circumferential portion, and the spark plug to ignite the mixture gas in the center portion. In a second combustion mode, the control unit controls the fuel injection valve to start a fuel injection on intake stroke so that the mixture gas is formed in the entire combustion chamber, the swirl generating part so that a swirl flow becomes weaker than in the first combustion mode, and the spark plug to ignite the mixture gas before CTDC.

Owner:MAZDA MOTOR CORP

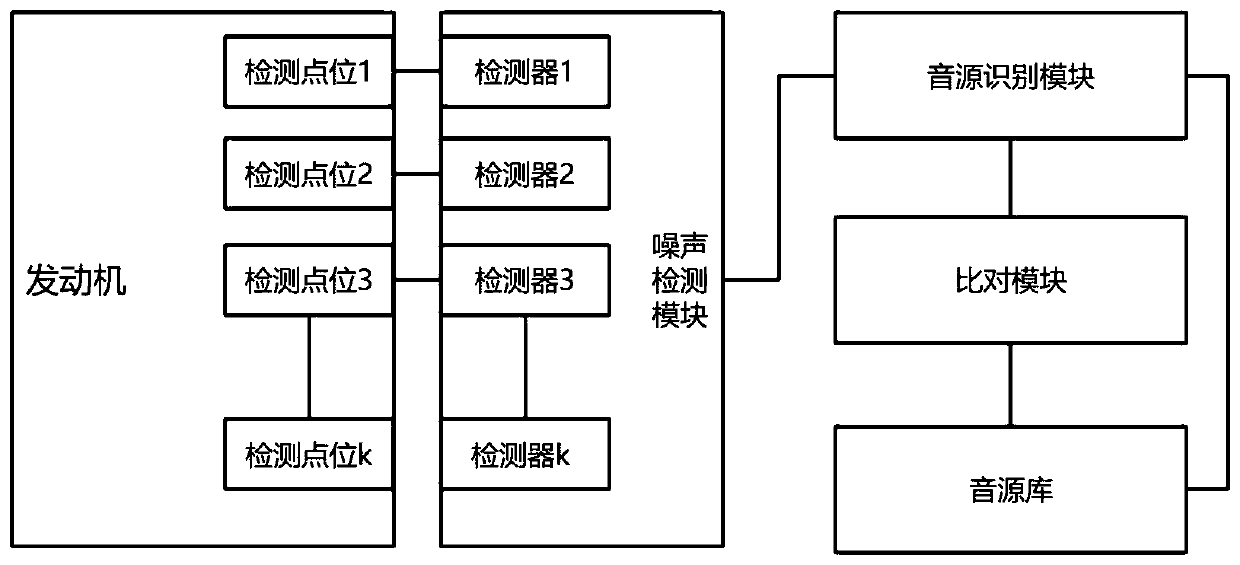

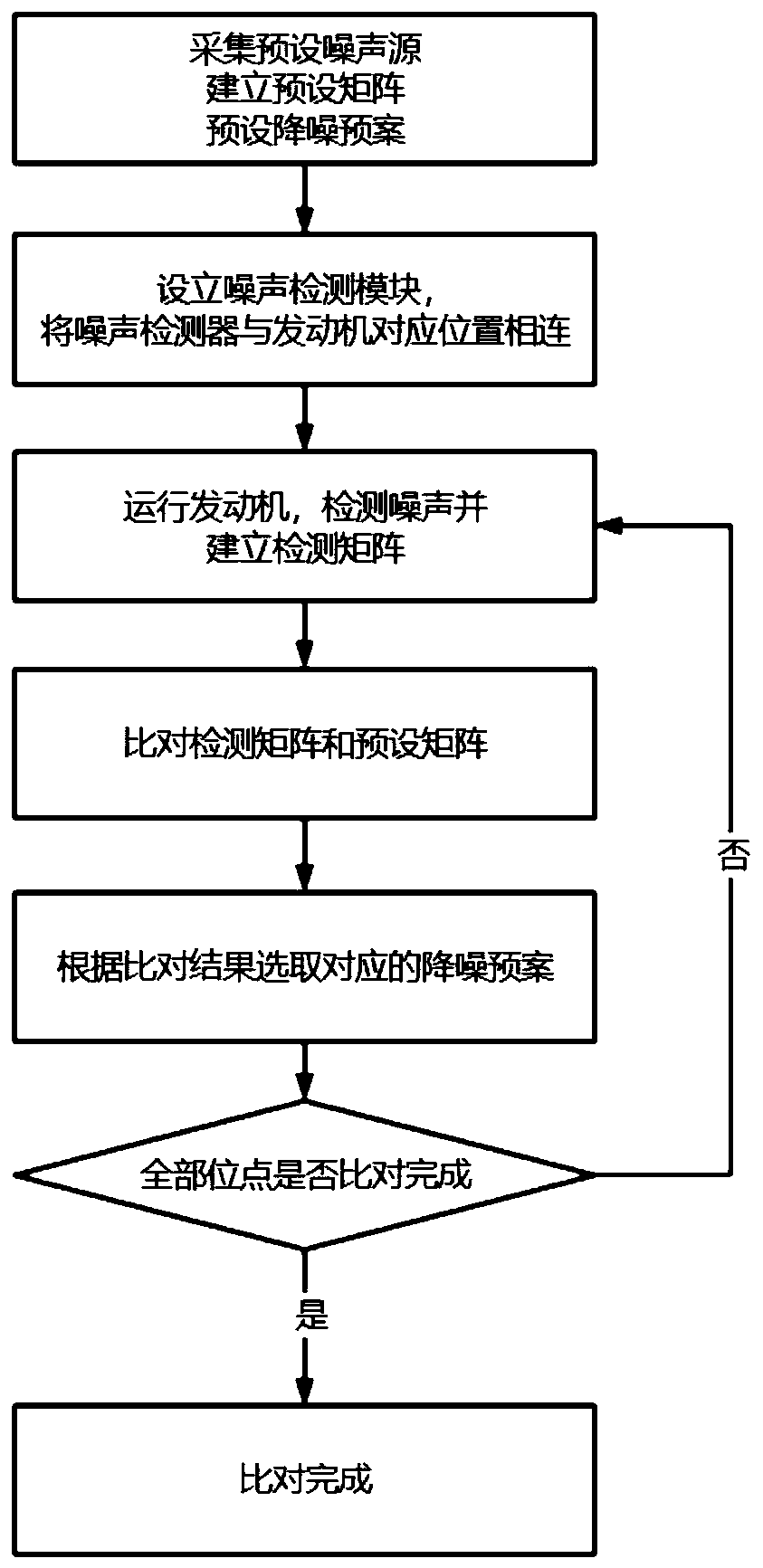

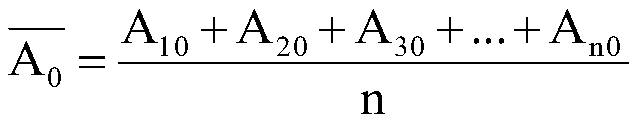

Generator set shock absorption and noise reduction method based on noise source recognition

ActiveCN111243613AImprove shock absorption efficiencyComprehensive detectionSpeech analysisSound sourcesNoise detection

The invention relates to a generator set shock absorption and noise reduction method based on noise source recognition. The method comprises the steps that a preset noise source is collected, a presetmatrix is established, and a noise reduction plan is preset; a noise detection module is arranged, and a noise monitor is connected with the corresponding position of the generator set; operating thegenerator set, detecting noise and establishing a detection matrix; comparing the detection matrix with a preset matrix; and selecting a corresponding noise reduction plan according to the detectionresult. According to the invention, different types of standard noise sources are pre-recorded; taking the noise source as a judgment reference; according to the method, the preset matrix is set to store the specified parameters in the noise into the sound source library, the types of the detected noise can be accurately judged by sequentially comparing the detected noise with the preset noise, the specific noise reduction method is used in a targeted mode according to the types of the noise, and the shock absorption efficiency of the method on the generator set can be effectively improved.

Owner:福建省煜坤强威电机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com