Regenerative combustion device

A combustion device and regenerative technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of large furnace impact, high furnace pressure, poor smoke exhaust, etc., to achieve huge energy saving potential, uniform temperature distribution, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

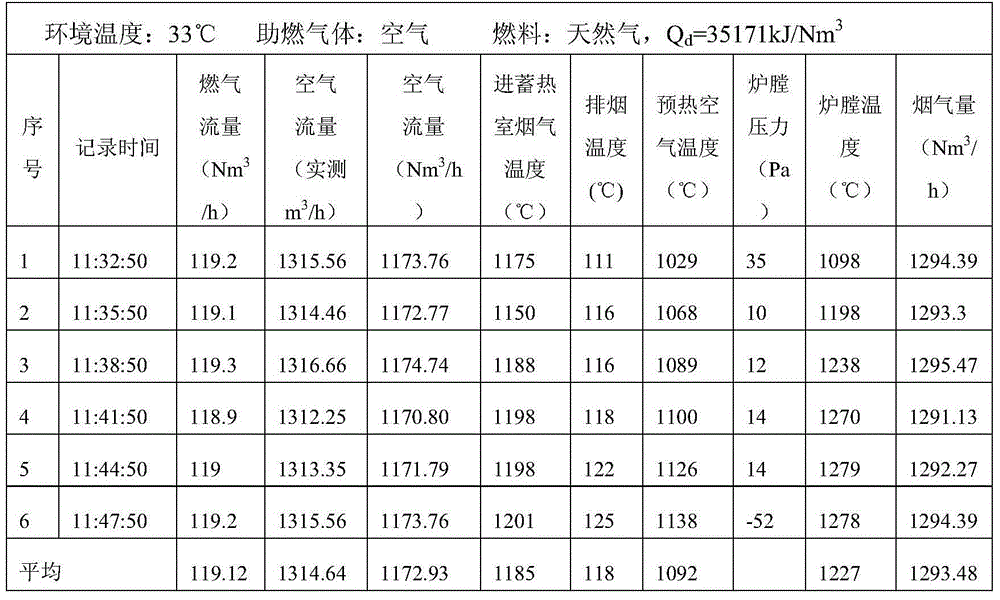

[0063] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

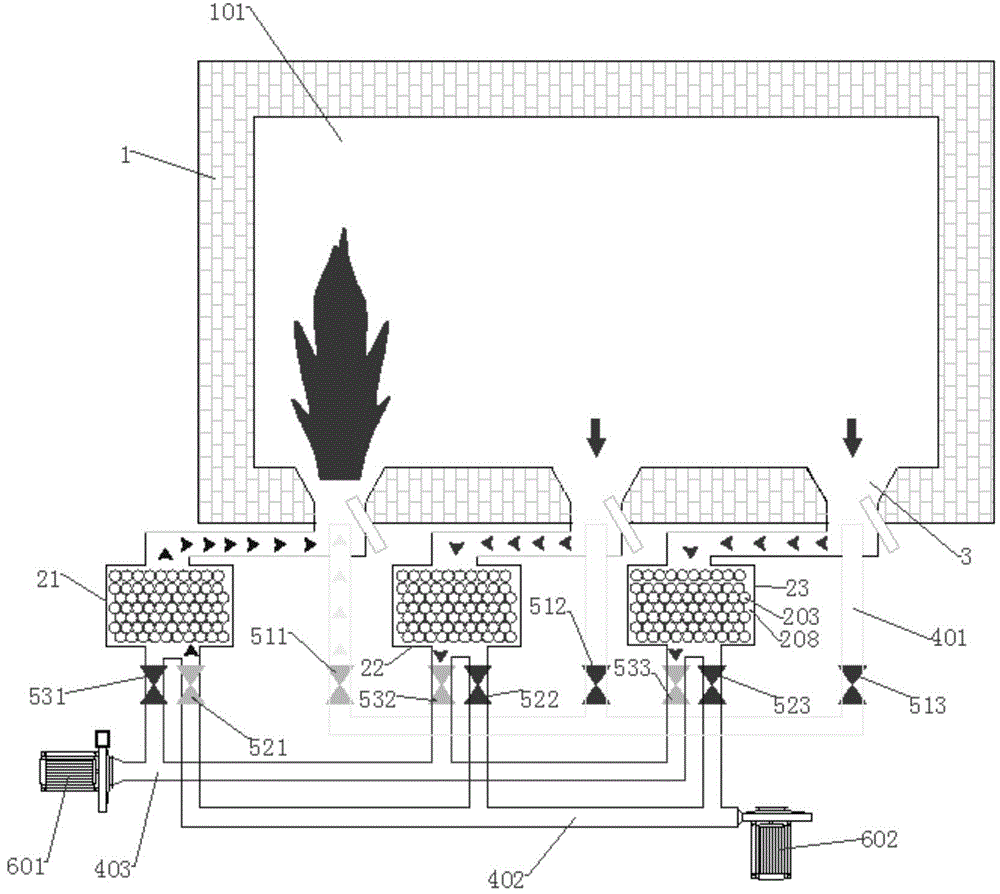

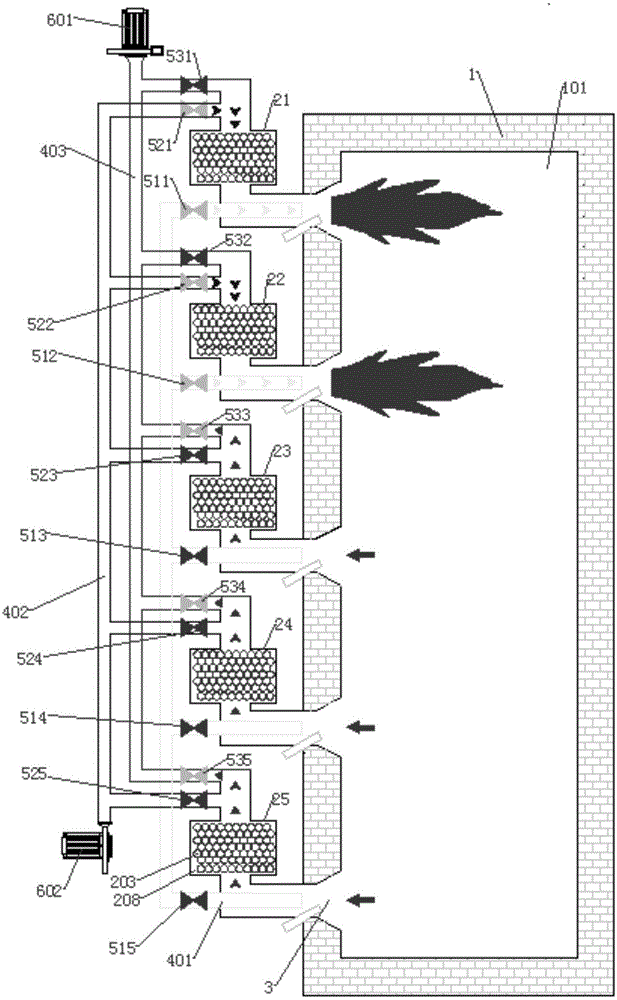

[0064] As a preferred embodiment of the present invention, such as figure 1 As shown, a regenerative combustion device in this embodiment includes a furnace body 1, a furnace 101 set in the furnace body 1, three regenerative burners 2, a gas pipeline 401, a combustion-supporting gas pipeline 402, The flue gas pipeline 403 and the reversing valve 5.

[0065] The furnace body 1 is not provided with an auxiliary pipe communicating with the furnace 101 for directly discharging the flue gas in the furnace, and has strict sealing.

[0066] Holes are opened on the furnace wall of the furnace 101 . The first regenerative burner 21, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com