Patents

Literature

333results about How to "Improve heating quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

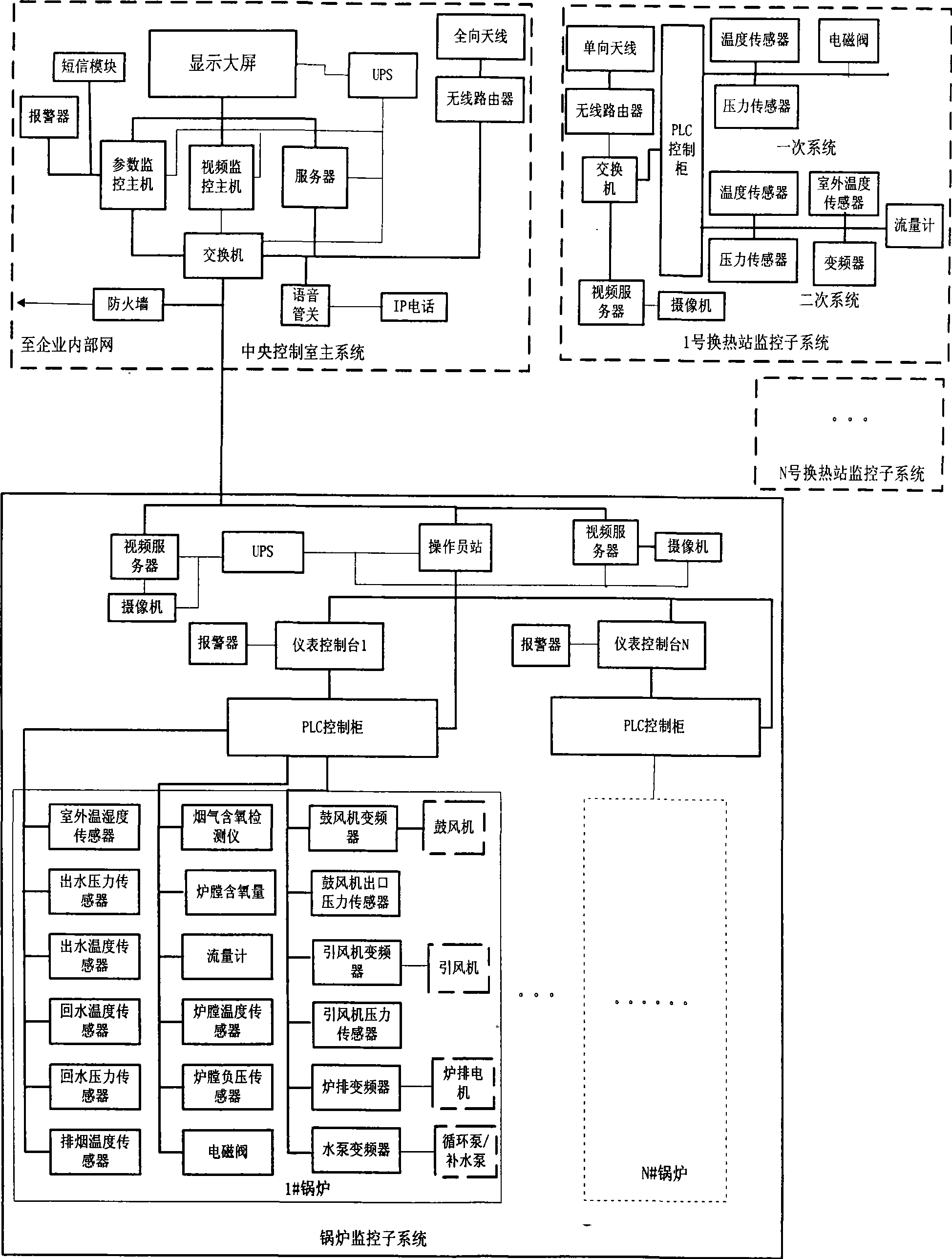

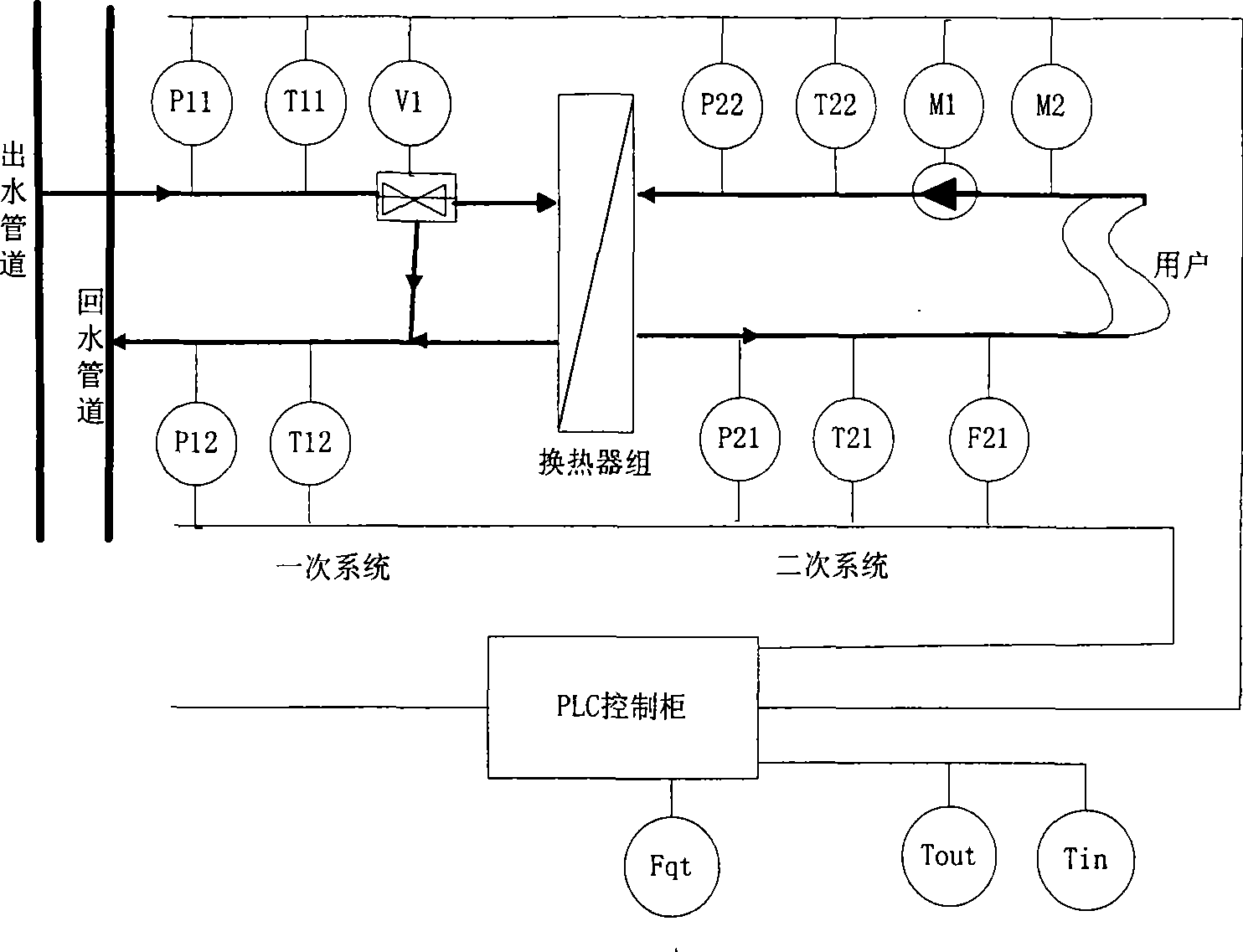

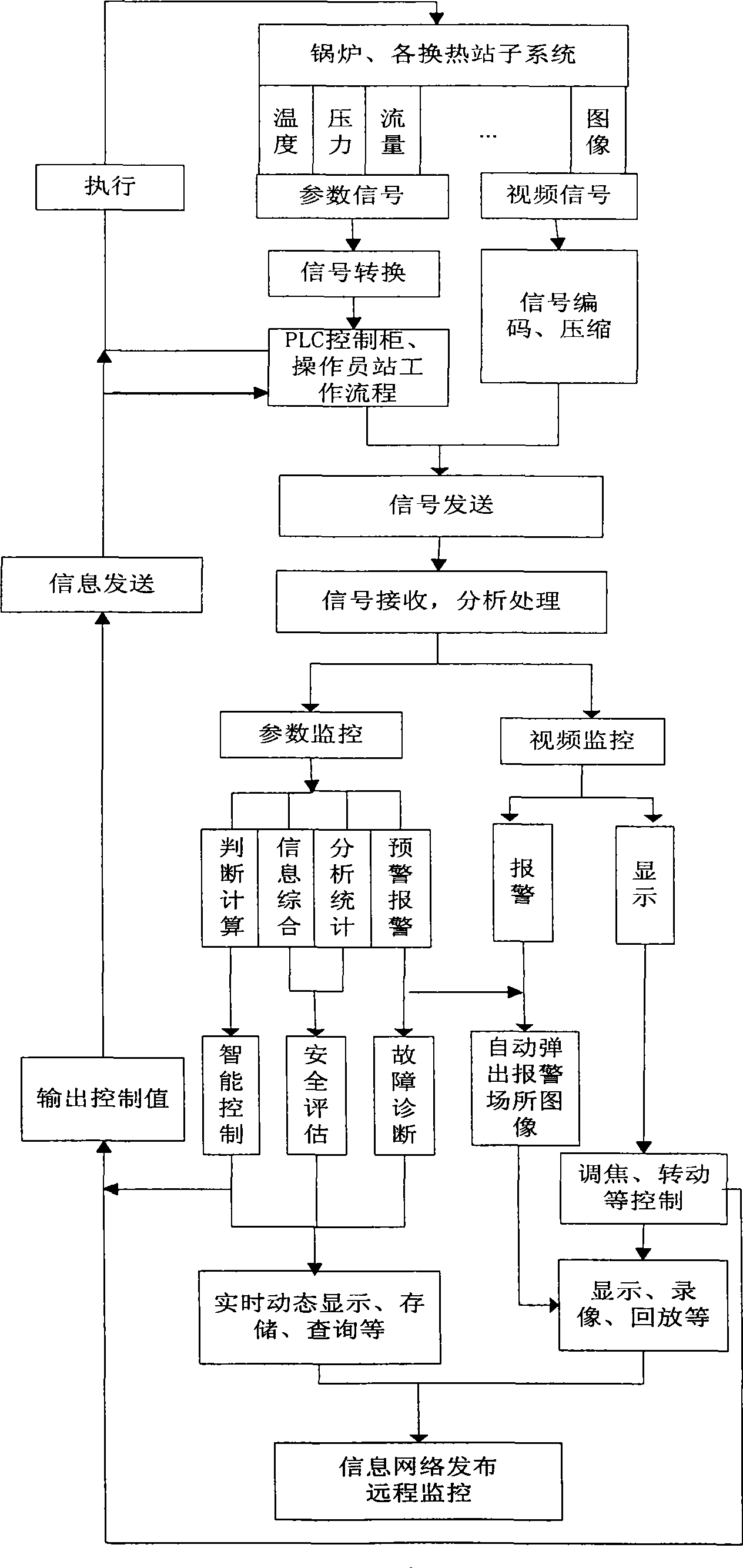

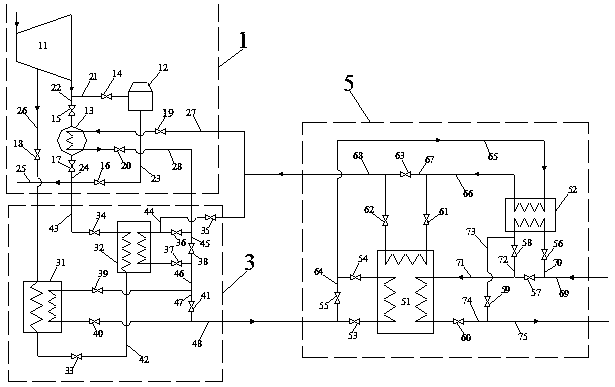

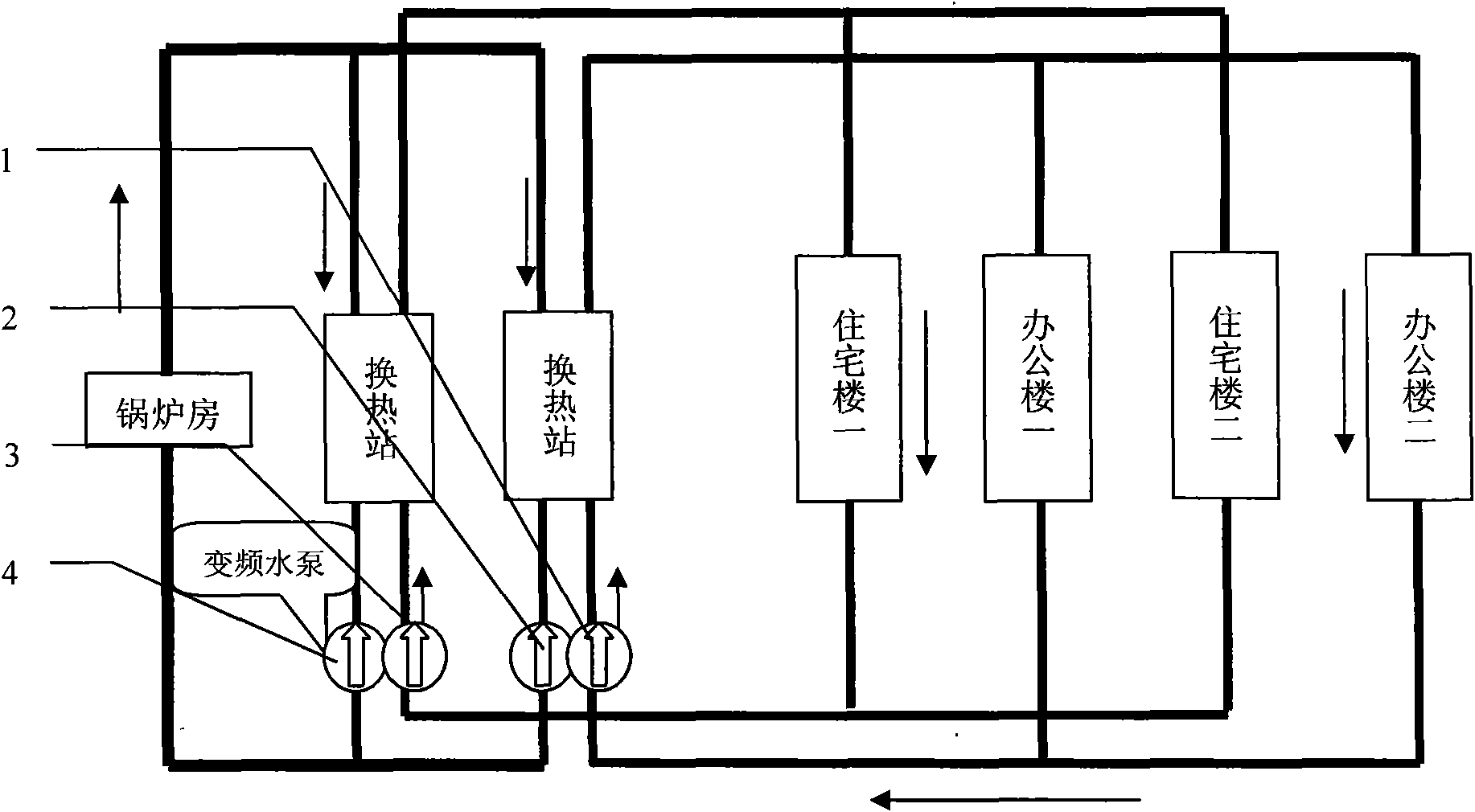

Intelligent monitoring system for boiler and heat exchange station

InactiveCN101498468AImprove operational balance benefitsIncrease the level of automationLighting and heating apparatusSpace heating and ventilation detailsAutomatic controlSignal on

The invention relates to an intelligent monitoring system for a boiler and a heat exchange station and a method thereof, which belong to the technical fields of production monitoring and security management. The system comprises a main system in a central control room, a plurality of boiler monitoring subsystems which are respectively connected with the main system in the central control room and a plurality of heat exchange station monitoring subsystems. The method comprises the following steps: parameters and video signals on site are collected and transmitted in real time and transmitted to a host machine in the central control room after being converted and compressed; the host machine carries out comprehensive processes of intelligent analysis, dynamic display, prewarning and warning and management for the received signals and transmit control commands to the monitoring subsystems to carry out control; and the monitoring subsystems can be cooperated with the central room to carry out monitoring or independently carries out monitoring to realize automatic control. The invention can realize real-time and dynamic intelligent control, prewarning and warning, security management and automatic monitoring for a large boiler or a boiler group and a heating network system and has the advantages of energy saving, consumption reduction, comprehensive analysis, safety, stability and economic operation.

Owner:CHINA ACAD OF SAFETY SCI & TECH

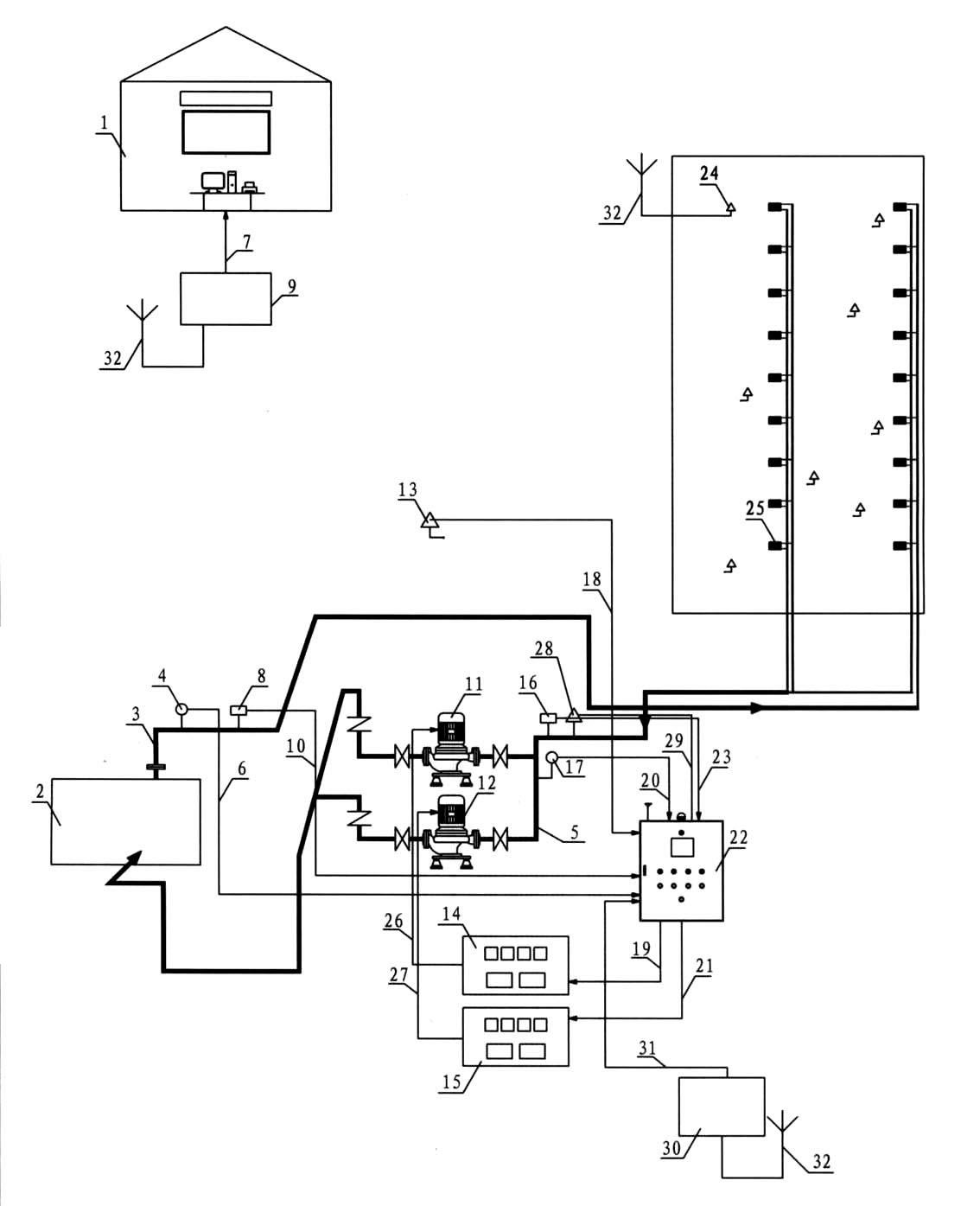

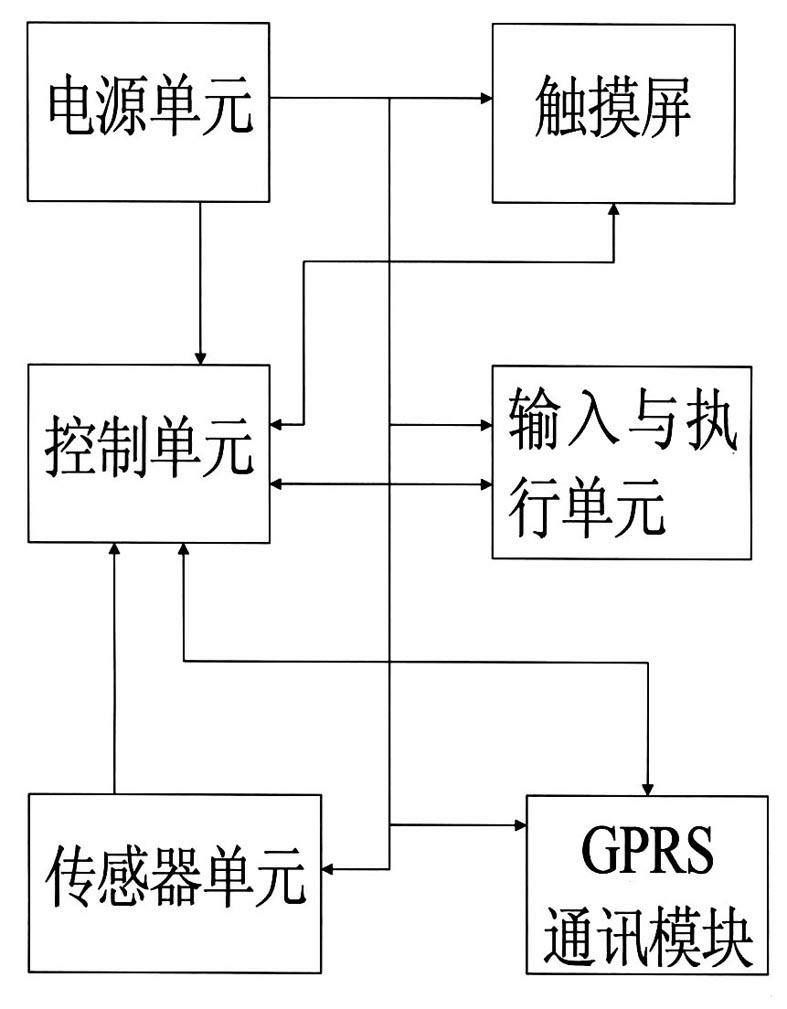

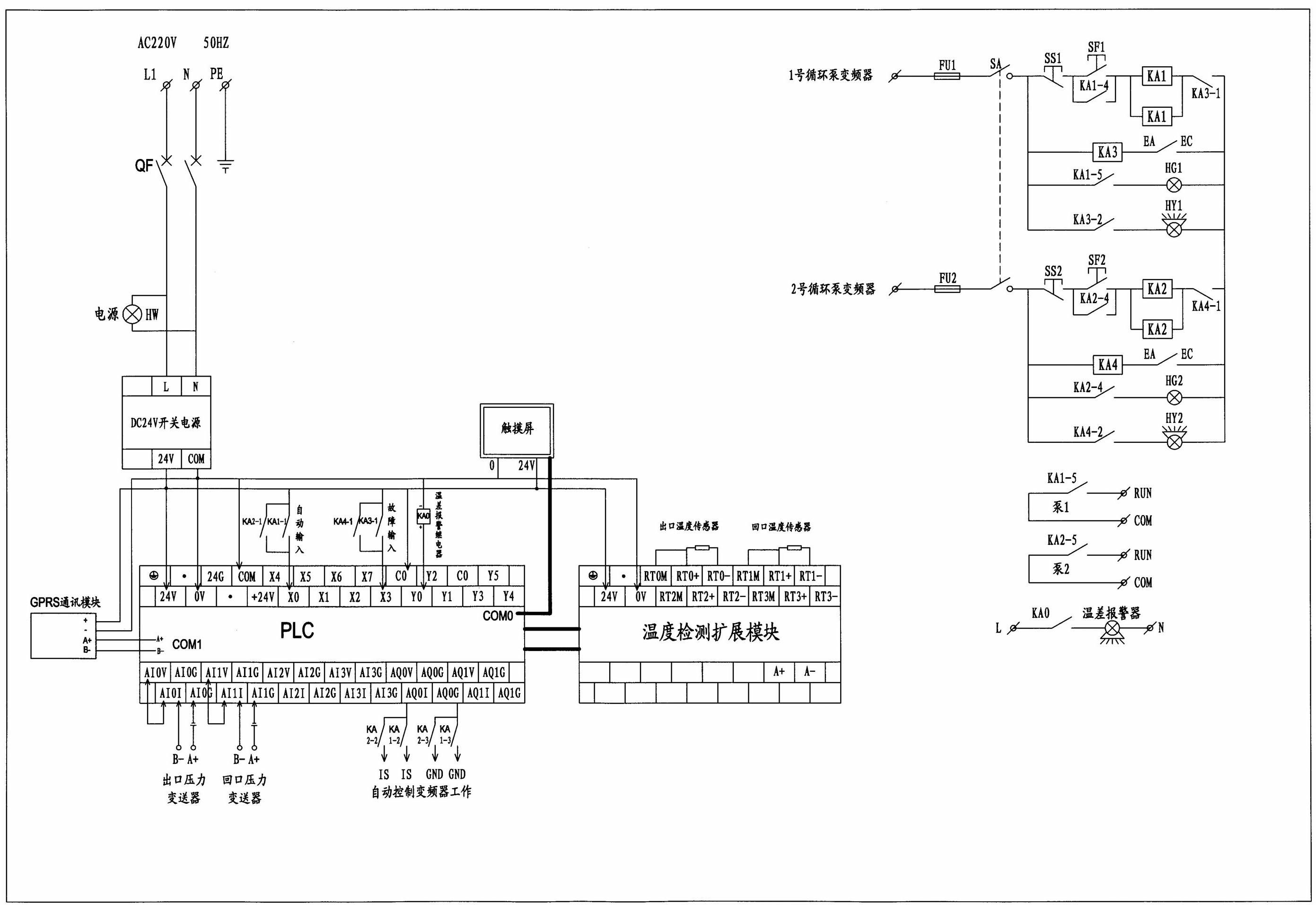

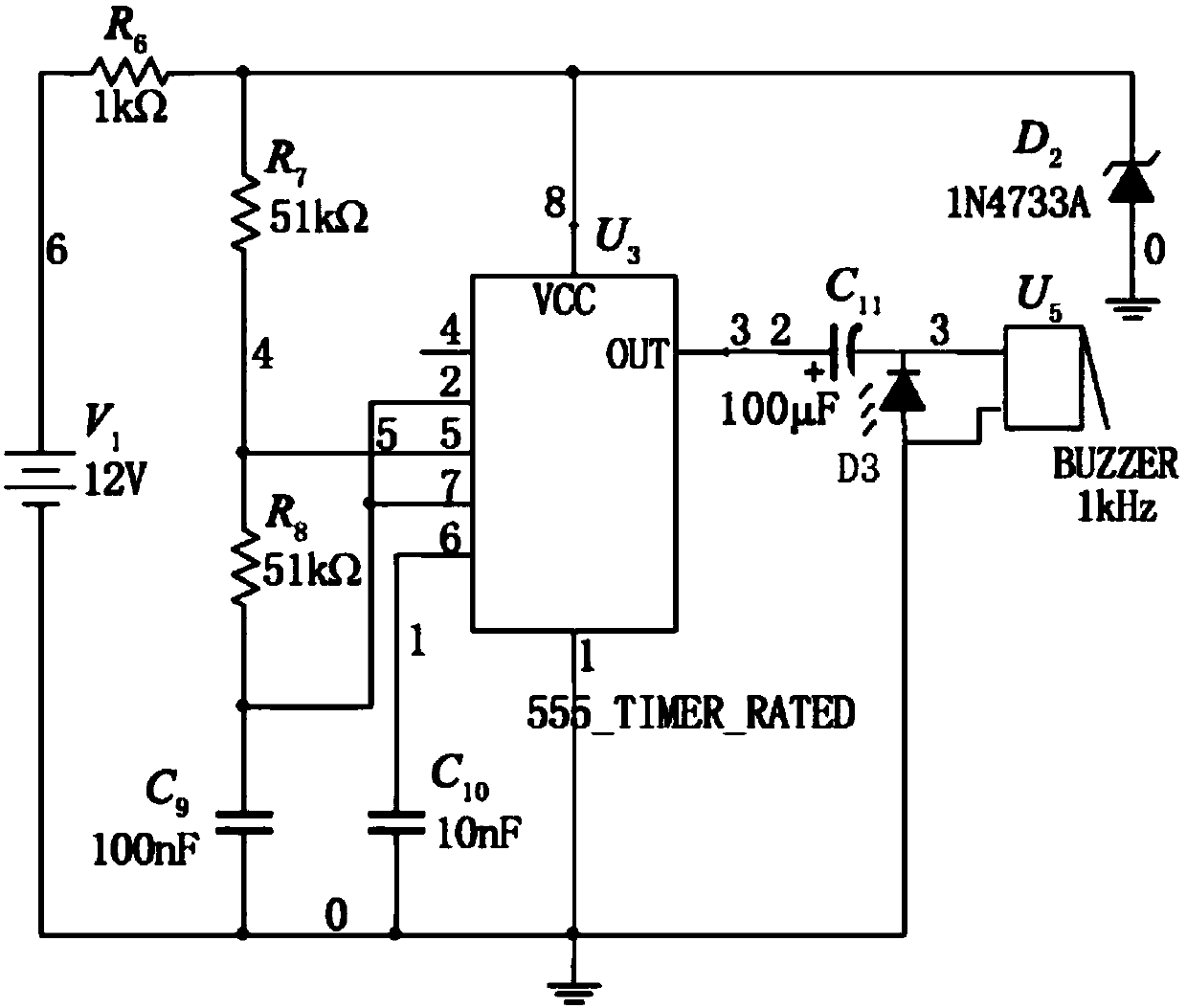

Intelligent controller of heating system network

InactiveCN102207307AImprove coal efficiencyReduce power consumptionLighting and heating apparatusSpace heating and ventilation detailsGeneral Packet Radio ServiceThe Internet

The invention discloses an intelligent controller of a heating system network, which can be used for adjusting and completely recording the running states of a heating system in real time, realizing remote monitoring and control and ensuring the heating system is in a satisfied running state, has a high coal combustion efficiency, less power consumption and improved heating quality. A temperaturesensor and a pressure transmitter are arranged at a heat supply outlet and a heat supply return hole of a heating pipe network of the intelligent controller; the controller is respectively connected with the sensors, the transmitters, a temperature collector and a circulating pump in the heating pipe network; a network management and monitor center internally provided with a computer, a printer and a display screen is connected with a GSM (global system for mobile communications) network through an internet; a GPRS (general packet radio service) communication module is accessed to the internet through the GSM network and connected with controller; the network management and monitor center is connected with a GPRS network temperature collector through an antenna, and the internet is connected with the antenna; the GPRS communication module is connected with a PLC (programmable logic controller); the data in the PLC is transmitted to the network management and monitor center; a touch screen is connected with the PLC; and an alarming short message is sent to a mobile phone through the GPRS communication module to inform the alarming state in a short message manner.

Owner:CHUANYU ELECTRICAL DANDONG CITY

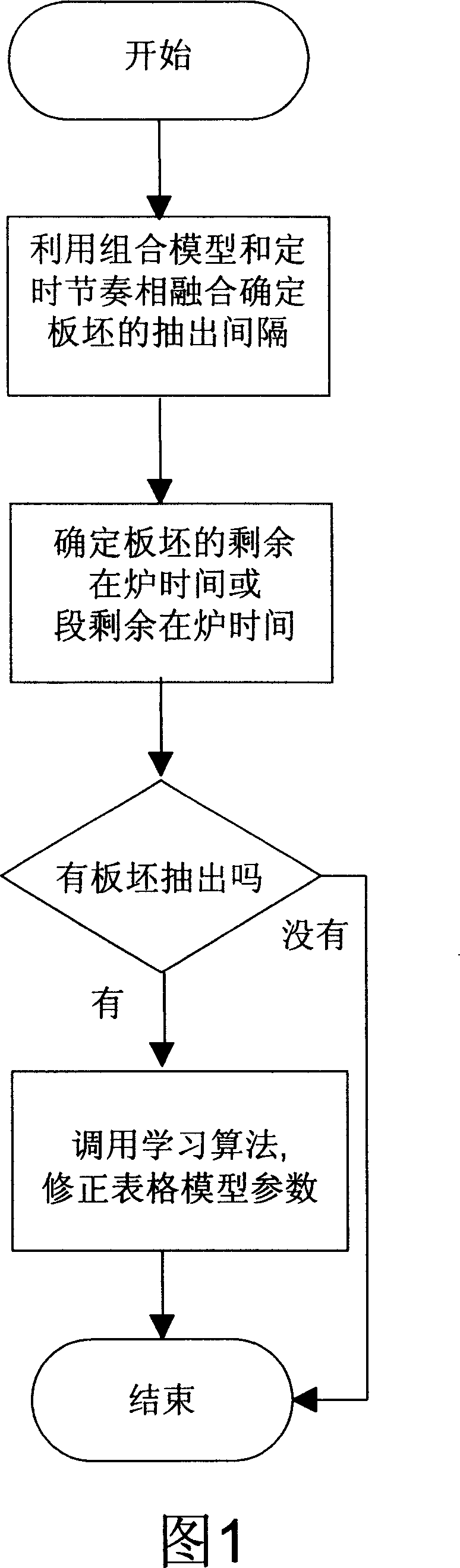

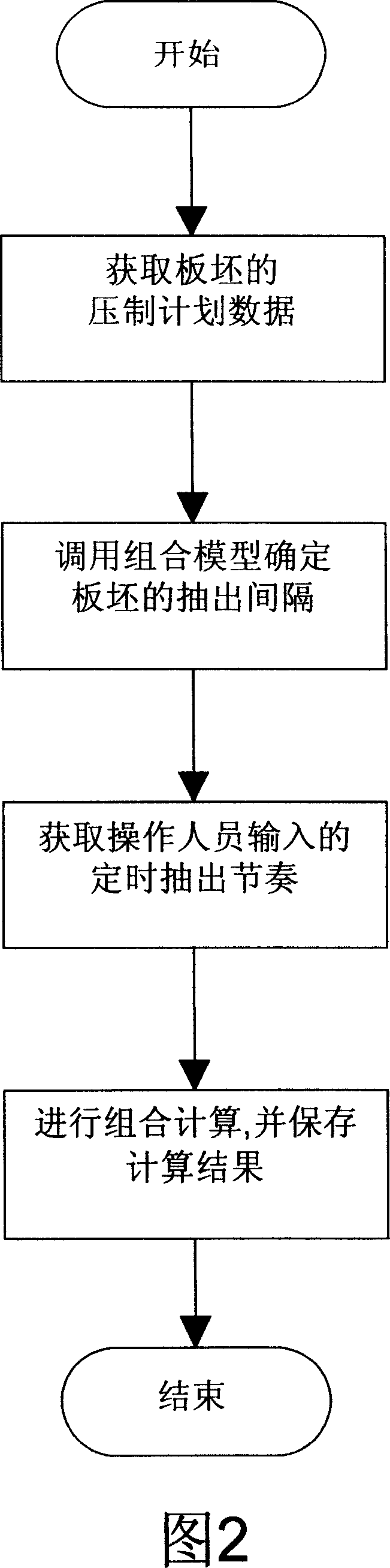

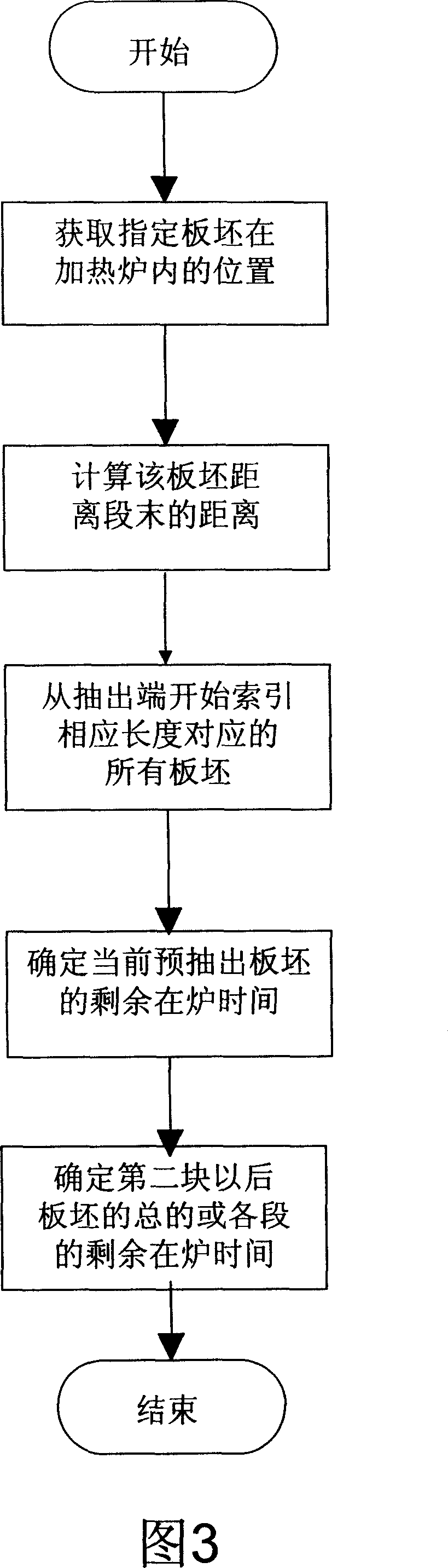

Method for determining the time of hot rolling heating stove bar plate leavings in furnace

ActiveCN101082814AForecast temperatureImprove the level of temperature controlCharge manipulationFurnace typesTemperature controlHardness

The invention discloses an affirming method of residual time of hot-rolled heater slab in the furnace, which comprises the following steps: calculating extracting interval of slab in the furnace through combined prediction model of slab extracting interval according to the length, product breadth and product thickness of slab in the furnace and the length, product breadth, thickness and hardness grade of slab; fusing the extracting time with present timely extracting time; indexing from extracting end according to the present position of each segment length of heater and slab and the length from slab to end; accumulating the extracting interval of slab within index scale to calculate; affirming the residual time of slab in the furnace or segment; fitting automatically; repairing the residual time to predict the temperature of slab precisely. The invention can control the temperature of heater precisely to make the slab reach the regulated goal temperature, which is benefit to improve the temperature control level of slab in the heater and heating quality of slab with low energy consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

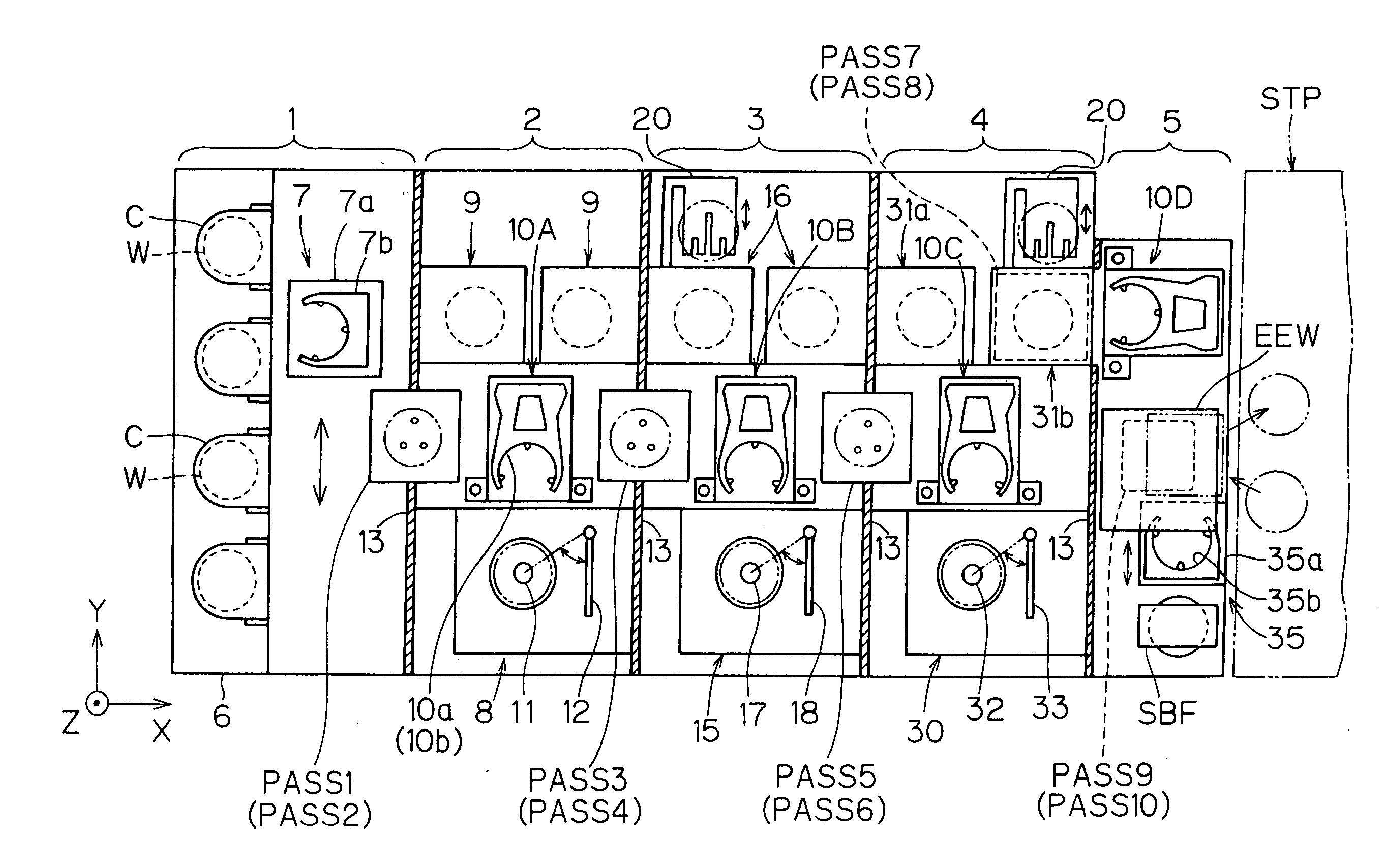

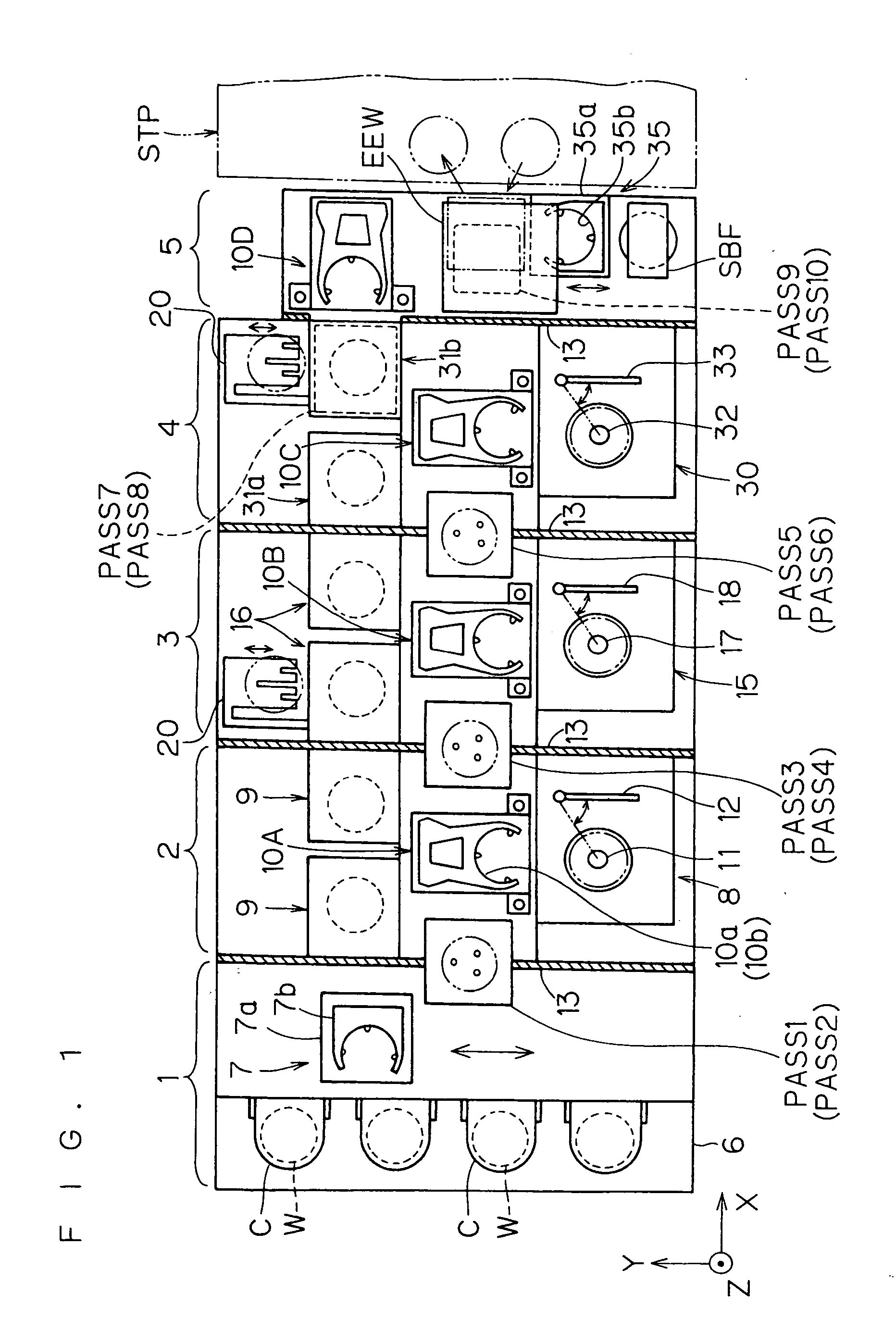

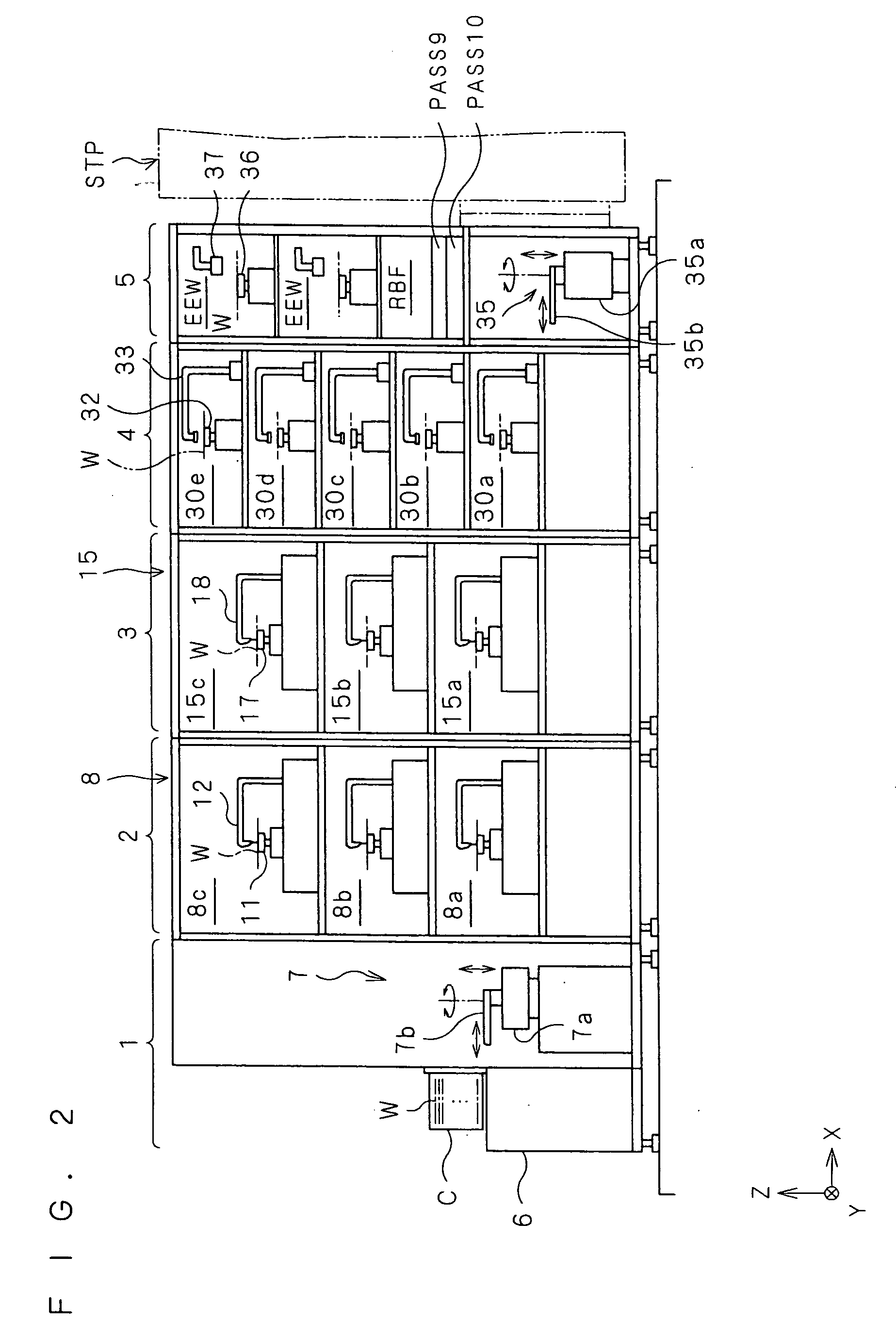

Substrate processing apparatus

ActiveUS20050061248A1Easy to controlReduce failureLiquid surface applicatorsSemiconductor/solid-state device manufacturingCell controllerControl theory

A cell controller controls the operation of a transport robot to keep a substrate belonging to a succeeding lot carried into a heating part in the fourth transport cycle from being transported out of the heating part in the next or fifth transport cycle, thereby preventing interference between the transport of substrates belonging to the succeeding lot and the transport of substrates belonging to a preceding lot. If interference is likely to occur between the transport of the substrates belonging to the succeeding lot and the transport of the substrates belonging to the preceding lot, the cell controller causes the substrates belonging to the succeeding lot not to be transported but to remain in processing units. This allows the transport of the substrates belonging to the succeeding lot in consideration of only the next transport cycle.

Owner:DAINIPPON SCREEN MTG CO LTD

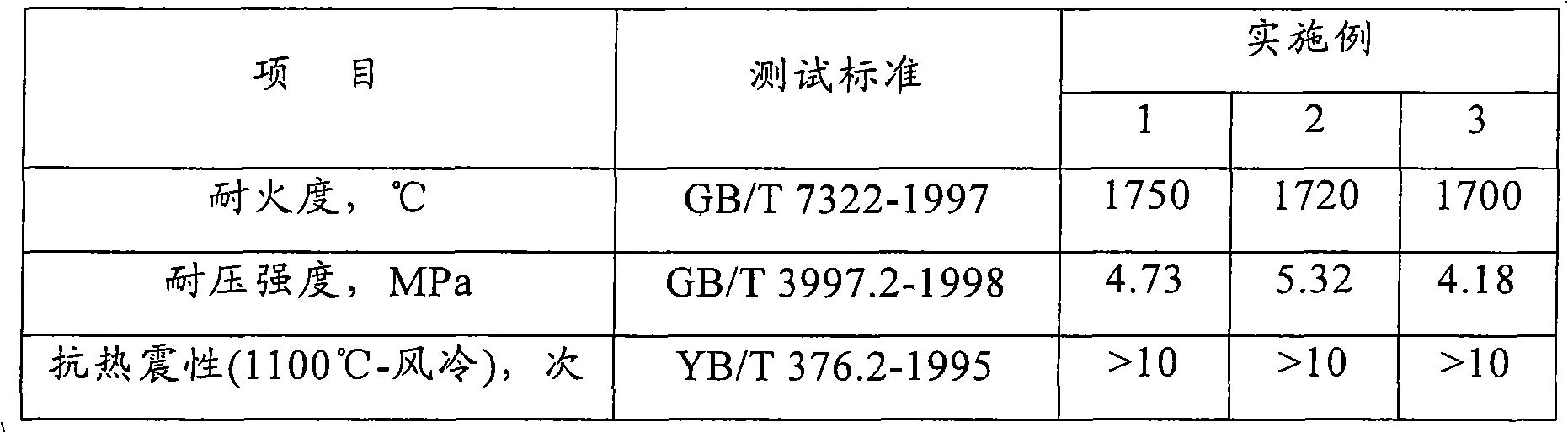

Lightweight high-strength heat-insulation refractory castable

InactiveCN103396141AMake up for the lack of performance degradationAvoid missing gradesFiberDefoaming Agents

The invention discloses a lightweight high-strength heat-insulation refractory castable. The castable comprises the following raw materials by weight: 30 to 40% of lightweight mullite aggregate, 5 to 10% of an aluminum-rich spinel hollow sphere, 5 to 8% of andalusite, 6 to 9% of aluminum-rich spinel powder, 5 to 7% of kyanite powder, 5 to 8% of silicon powder, 5 to 10% of rho-Al2O3 micro powder, 12 to 18% of calcium aluminate cement, 3 to 6% of a refractory fiber, 0.05 to 0.15% of sodium hexametaphosphate, 0.05 to 0.15% of an organic water reducing agent, 0.04 to 0.07% of an organosilicon coupling agent and 0.01 to 0.02% of a defoaming agent. According to the invention, the heat insulation performance of the lightweight refractory castable is guaranteed, close bonding between aggregate and powder in the refractory castable is improved, mechanical strength, capacity of resisting mechanical and thermal shock damage, anti-permeability and comprehensive usage performance at high temperature of the refractory castable are enhanced, and cost for the refractory castable is reduced, thereby finally achieving the comprehensive targets of reduction of heat loss in cooling of furnace beams and columns, prolongation of the service life of a heat insulation lining, improvement of heating quality in a furnace, reduction of energy consumption and maintenance cost, etc.

Owner:武汉钢铁有限公司

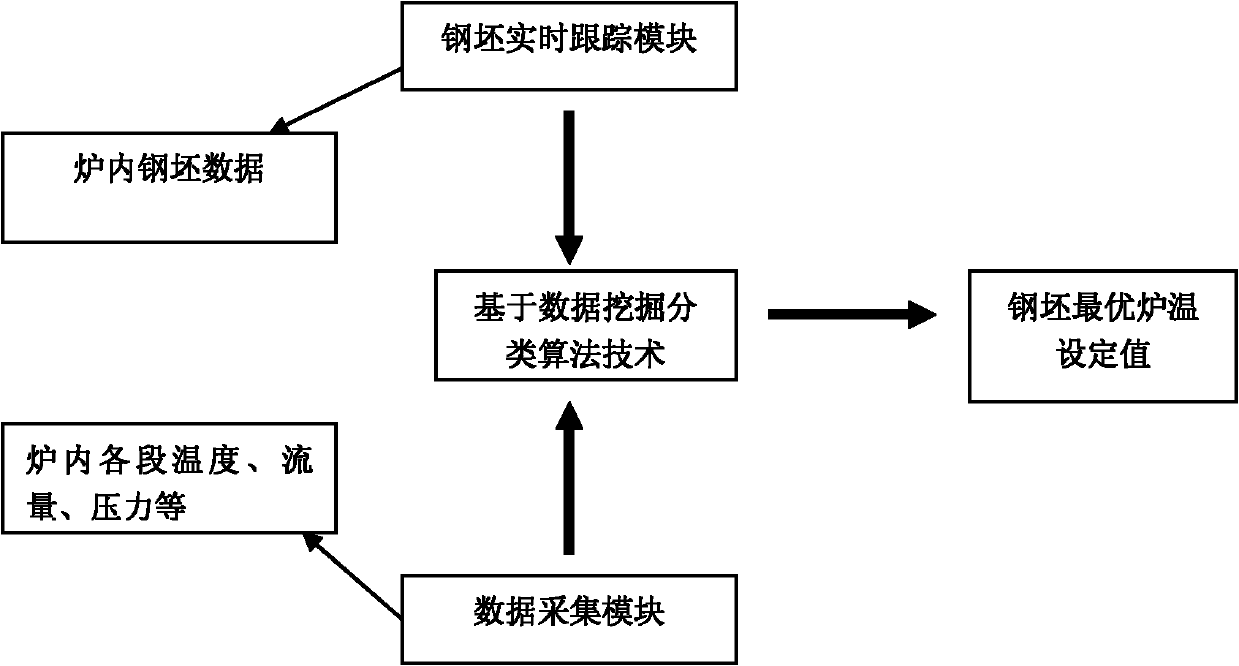

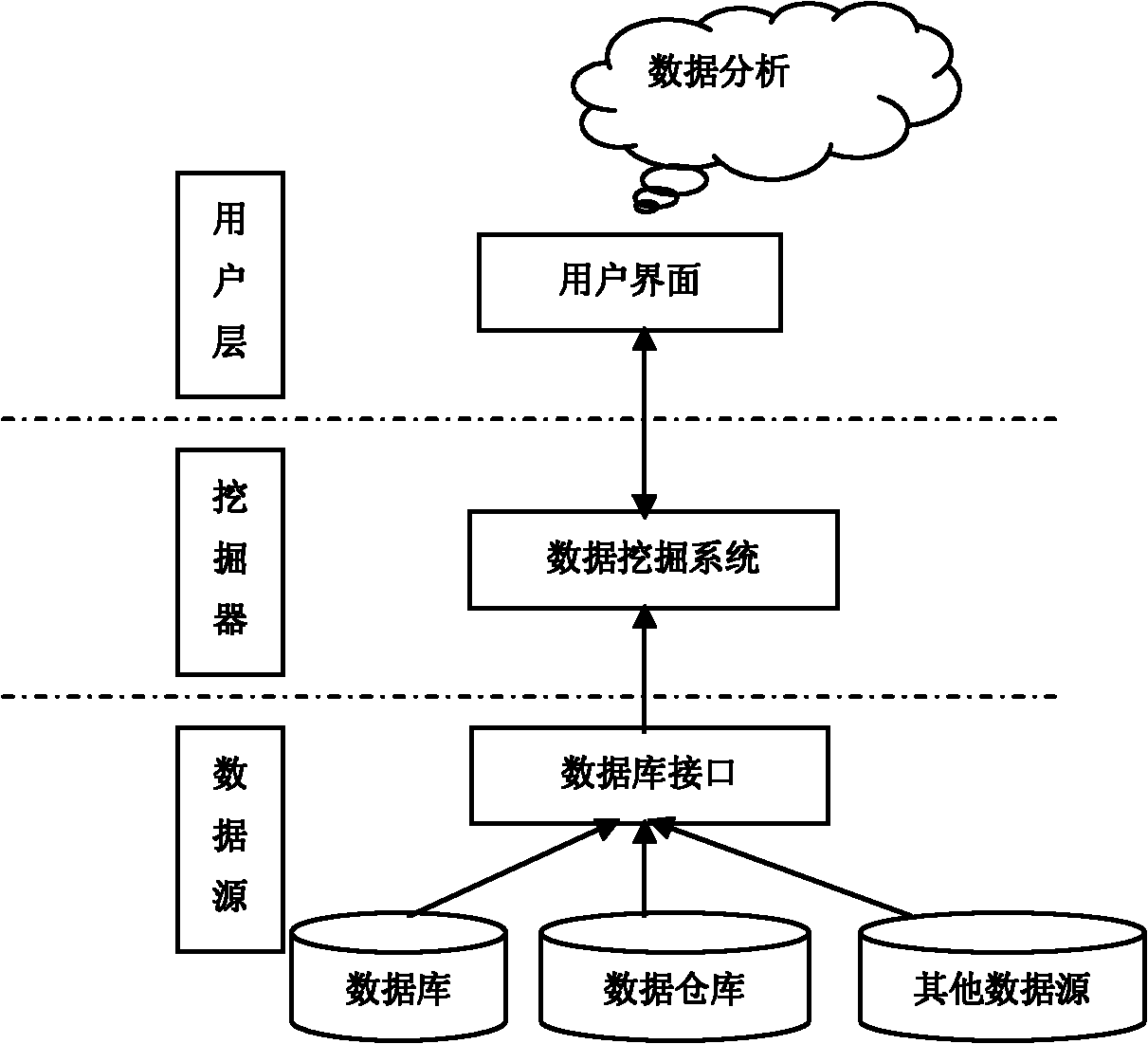

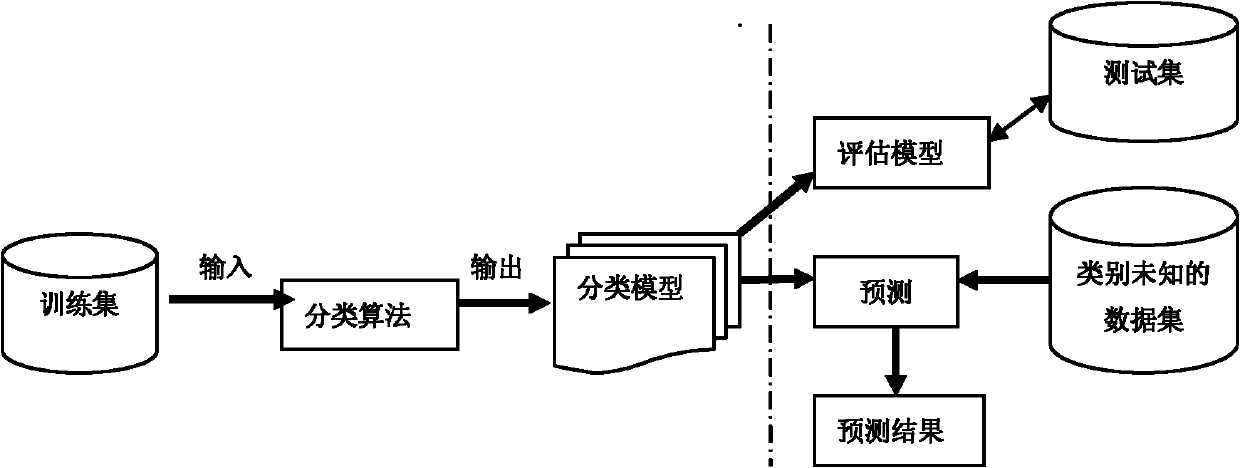

System for optimizing optimal furnace temperature set value based on data mining

ActiveCN102169326AAvoid man-madeAvoid the influence of other factorsAdaptive controlFurnace temperatureData acquisition

The invention relates to the technical field of optimizing a furnace temperature set value of a walking beam type heating furnace in the combustion process, in particular to a system for optimizing the optimal furnace temperature set value based on data mining. The system comprises a data processing module and a data mining analysis module. A data processing process mainly comprises the following steps: acquiring the real-time data, and acquiring the temperature, flow and related production data of each furnace section in the heating furnace; combining the acquired production data and steel billet rolling data into a data mining analysis sample object, and storing a mining result in a background database according to a certain rule model, thereby forming a rule knowledge base; and finally acquiring the optimal furnace temperature set values of different steel billets in each section of the heating furnace from the knowledge base. The system provided by the invention can be used for optimizing and setting an optimal furnace temperature set value curve of the walking beam type heating furnace. For various steel billets, the optimal control guidance can be supplied to the control system, thereby improving the combustion process of the steel billets in the heating furnace, increasing the heating quality and lowering the energy consumption of the heating furnace.

Owner:WISDRI WUHAN WIS IND FURNACE

Method for manufacturing wear-resistant steel pipe by using hot-rolling coiled plate

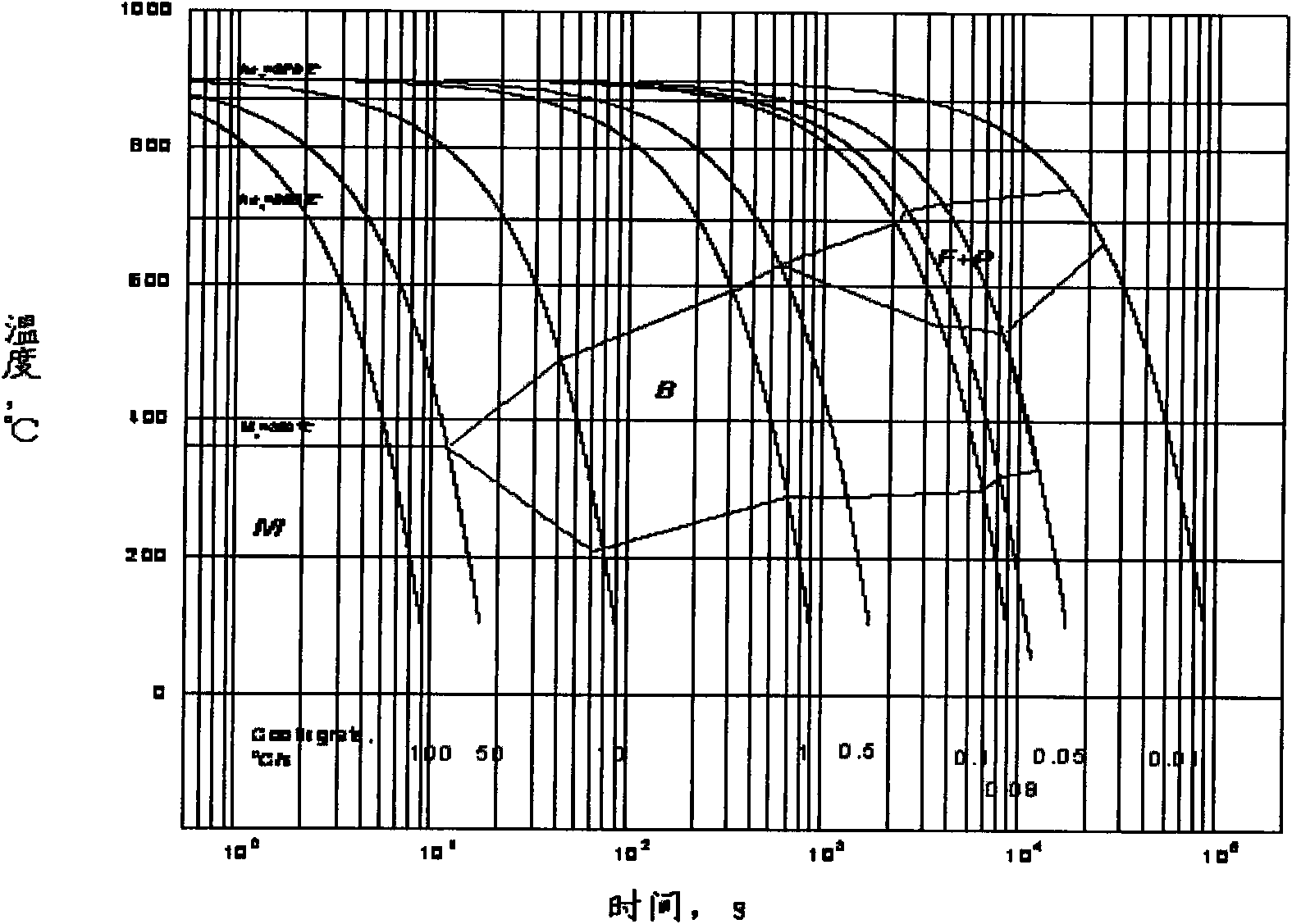

ActiveCN101602079AImprove mechanical propertiesRefined mechanical propertiesFurnace typesIncreasing energy efficiencyWear resistantMartensite

The invention relates to a method for manufacturing a wear-resistant steel pipe by using a hot-rolling coiled plate, comprising a smelting method process, refining outside a furnace and steel blank manufacture. The method is characterized in that a steel blank is rolled and manufactured into a hot-rolling coiled plate blank material by using a hot continuous-rolling machine set or a furnace coiled rolling machine, the hot-rolling coiled plate blank material is rolled and welded into a pipe blank of an ERW steel pipe by using an ERW steel pipe machine set, and heat treatment is carried out after internal and external burrs are removed. The heat treatment method comprises the following steps that: (1) the pipe blank welded into the ERW steel pipe is heated in induction heating equipment to 910 to 960DEG C and austenized, the heating time is 60 to 140s, then the steel pipe with the austenitizing temperature is quenched in a water-cooling or steam-cooling quenching machine set, the quenching and cooling speed is greater than or equal to 10DEG C / S, the steel pipe with a quenched martensite organization is obtained, then induction tempering is carried out, the tempering temperature of the steel pipe is 210DEG C to 320DEG C, the tempering time is 60 to 180s, the quenched martensite is converted into a tempered martensite, and then straightening, flaw detection, surface inspection and sampling inspection are carried out to finally obtain the wear-resistant steel pipe with favorable wear resistance.

Owner:武汉钢实机电设备有限公司

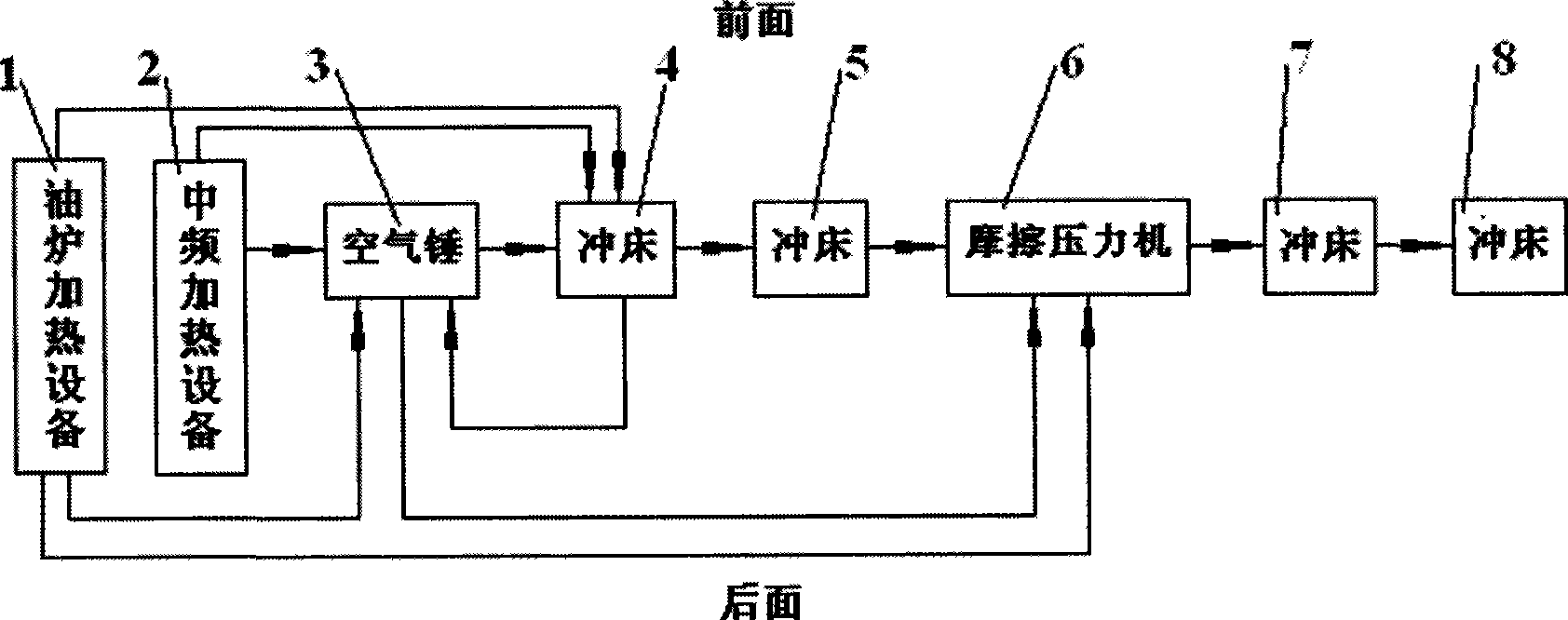

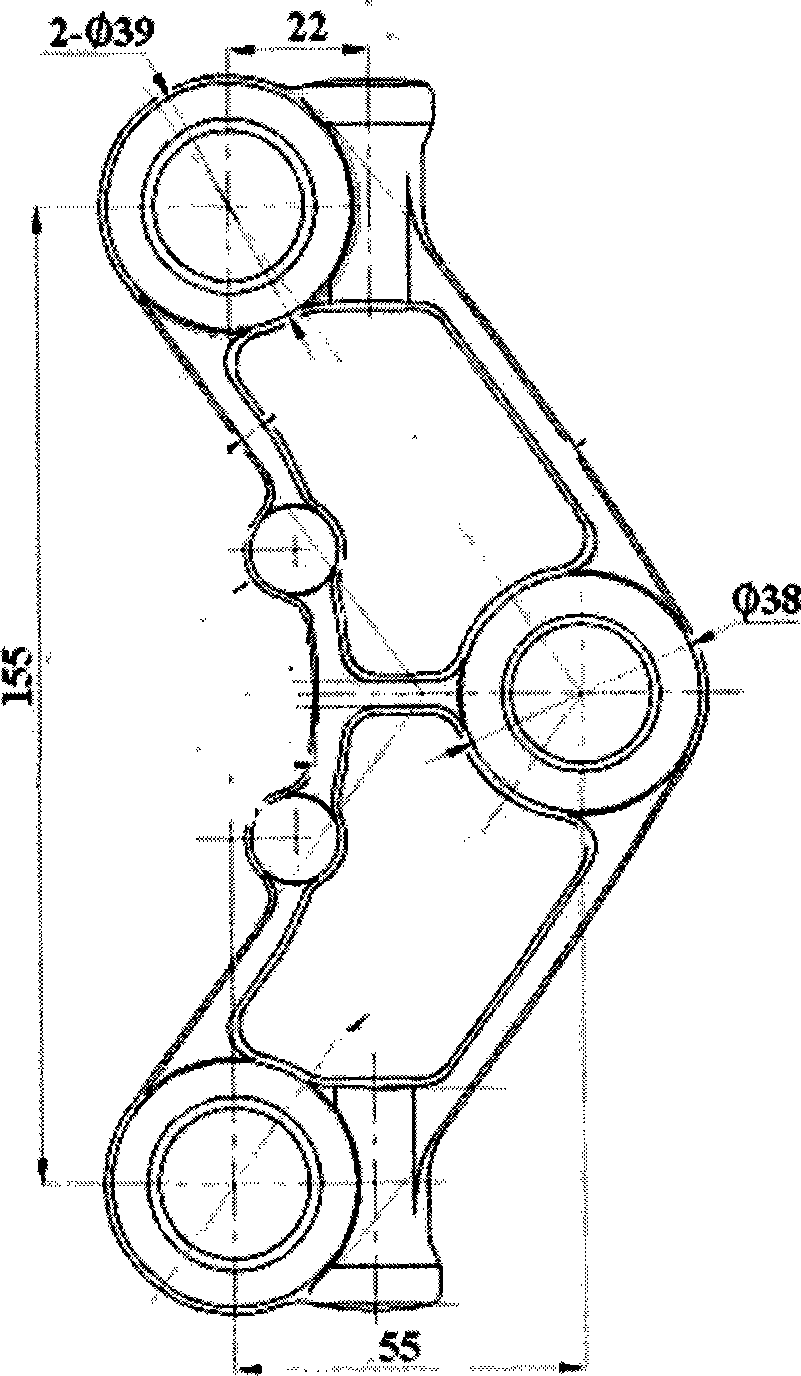

Forging device pipeline of complicated forging piece and forging production technique thereof

InactiveCN101456060AImprove surface qualitySolve billet problemsForging hammersForging press detailsProduction lineEngineering

The invention discloses a forging device production line for a complex forged piece, which comprises heating devices, a forging device and a transfer device. The forging device is a friction press (6) and is arranged according to forging technology, the number of the heating devices is two, and the two heating devices are arranged at two sides of the transfer device of the production line in parallel, wherein one heating device is a main heating device (1), and the other heating device is a double-heating device (2). The invention also provides corresponding forging production technology. The invention adopts a technical proposal to heat the shaped forged piece twice so as to meet the requirement of the forged piece with special request, and solves the repair problem of part of unqualified forged pieces at the same time.

Owner:安徽凯宇机械制造有限公司

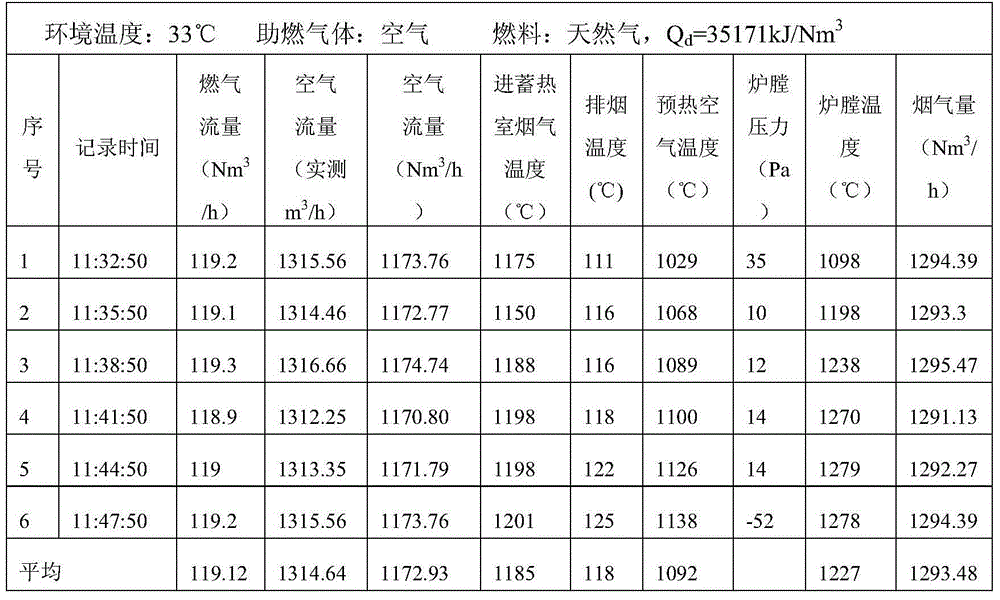

Heating method for controlling decarburization in heavy rail billet furnace

InactiveCN101967541AEnsure complete combustionReduce oxidation burnFurnace typesHeat treatment furnacesPollutant emissionsReducing atmosphere

The invention provides a heating method for controlling decarburization in a heavy rail billet furnace in a heat accumulation heating mode. The heating process comprises a pre-heating section, a heating section and a soaking section. A furnace pressure measurement point is positioned at the pre-heating section; the full furnace is controlled at positive pressure; when the billet temperature is controlled to be less than 1,000 DEG C, the atmosphere in the furnace is oxidizing atmosphere, and the air consumption coefficient is between 1.05 and 1.25; and when the billet temperature is controlledto be more than or equal to 1,000 DEG C, the atmosphere in the furnace is weak reducing atmosphere, the air consumption coefficient is between 0.9 and 1.0. Aiming at the operation and decarburizationcharacteristics of the heat accumulation heating furnace different from the traditional heating furnace, the segment control method is adopted on the control aspects of atmosphere in the furnace and temperature, and a limit low-oxygen concentration burning process is realized. The method has the advantages of low heated billet surface decarburization, low oxidized burning loss, high furnace energy utilization, low pollutant discharge, low production cost and the like, is simple, convenient and feasible, and can achieve good effect of saving materials and energy at the same time of improving the heating quality of products.

Owner:武钢集团有限公司

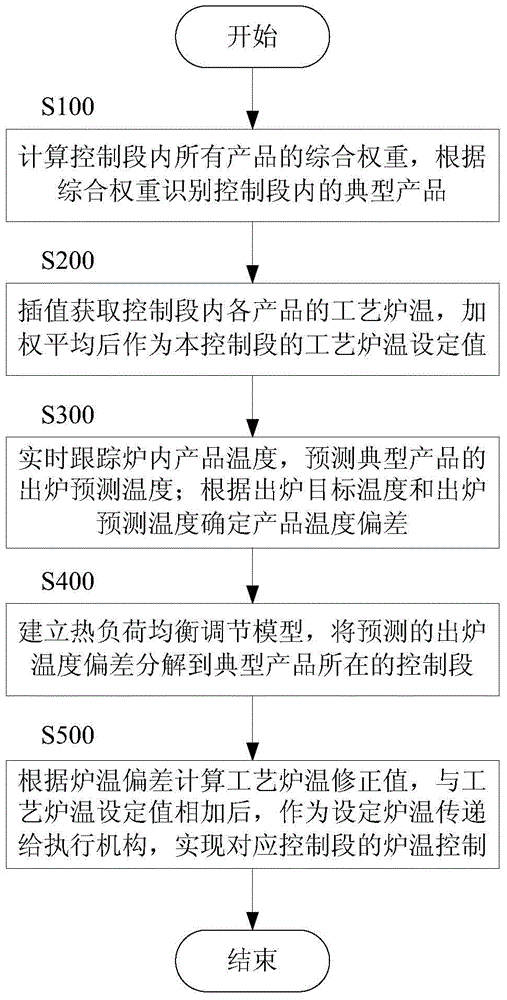

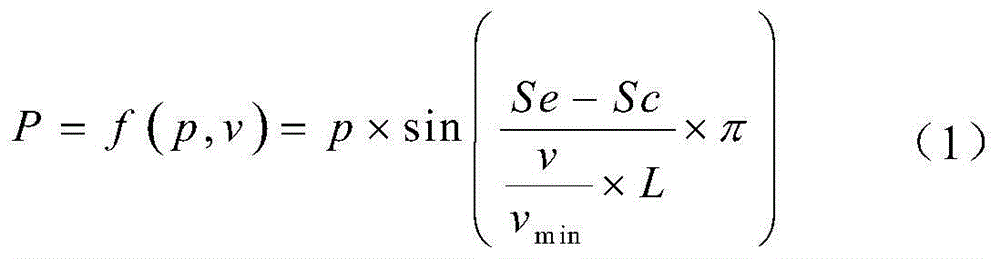

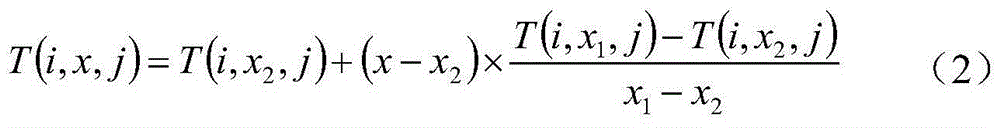

Heating furnace process furnace temperature control method based on thermal load distribution

ActiveCN105018718AHigh control precisionReduce wasteHeat treatment process controlFurnace temperatureCombustion

The invention provides a heating furnace process furnace temperature control method based on thermal load distribution, and relates to control equipment or method specially suitable for a metal rolling mill and processed products thereof. The method comprises the following steps: S100, identifying typical products in a control section according to the comprehensive weight; S200, determining a process furnace temperature set value of the control section according to the production rhythm of the heating furnace; S300, tracking the temperature of the products in the furnace in real time, predicting the furnace discharge predicted temperature of the typical products, and determining product temperature deviations; S400, establishing a thermal load equalizing regulation model, and determining the product temperature deviations corresponding to the control section; and S500, converting the product temperature deviations into process furnace temperature corrected values, and determining the set furnace temperature, thereby realizing the furnace temperature control of the heating furnace corresponding to the control section. By establishing the thermal load equalizing regulation model to distribute the temperature deviations to the control section of the typical products and performing compensation correction on the process furnace temperature for combustion of the heating furnace, the control accuracy of the process furnace temperature is improved, the heating quality of the products is improved, and energy wastes are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

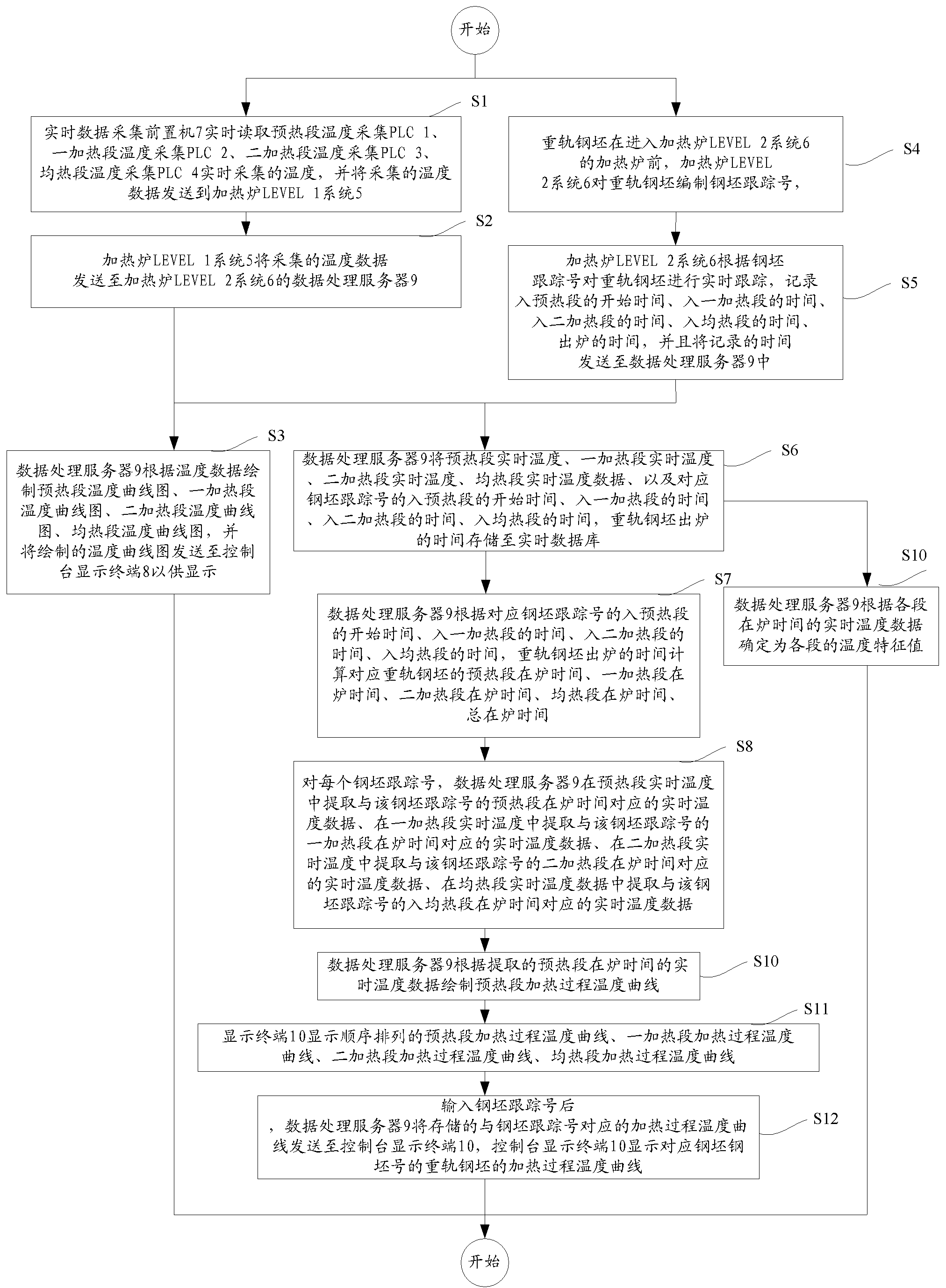

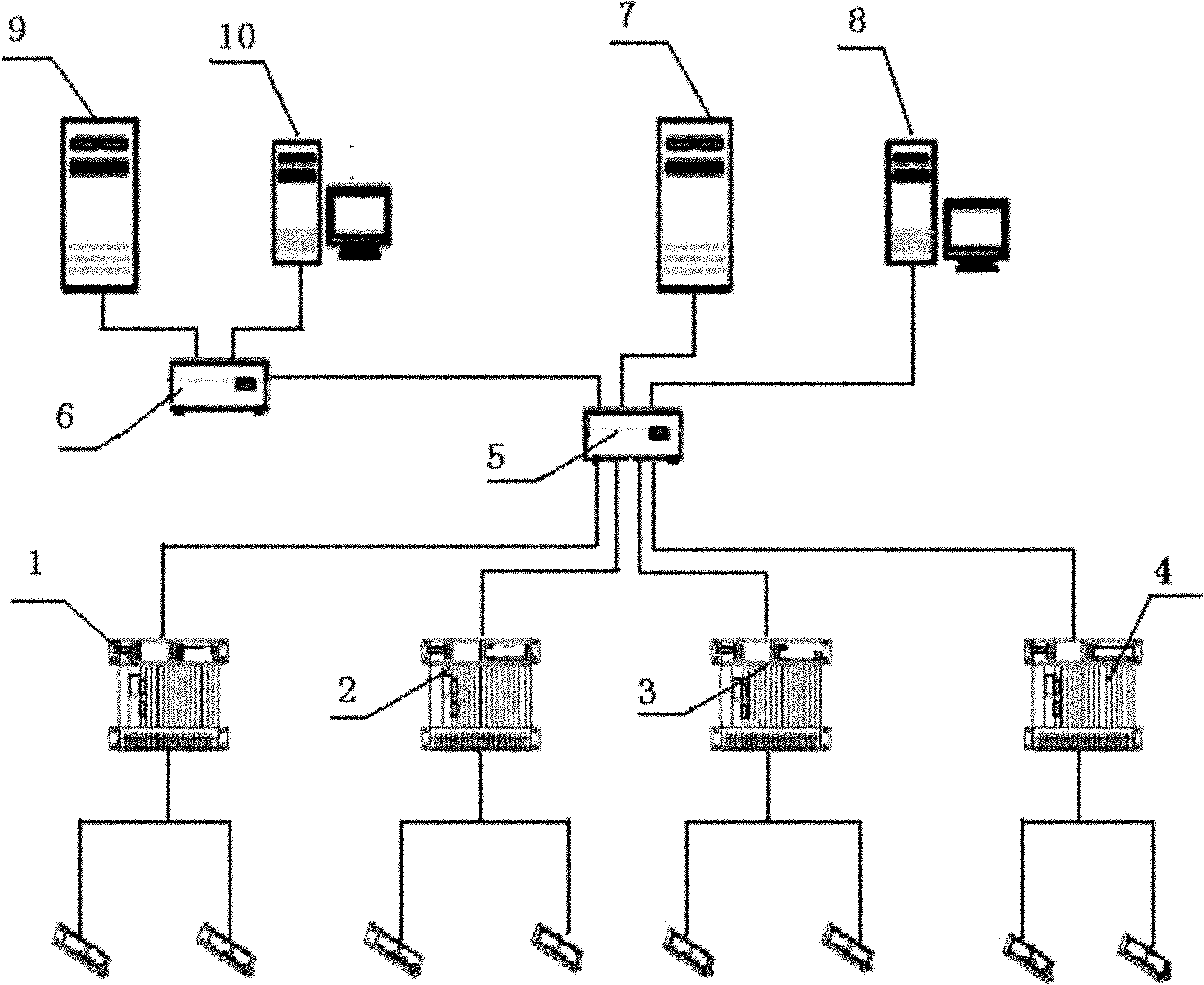

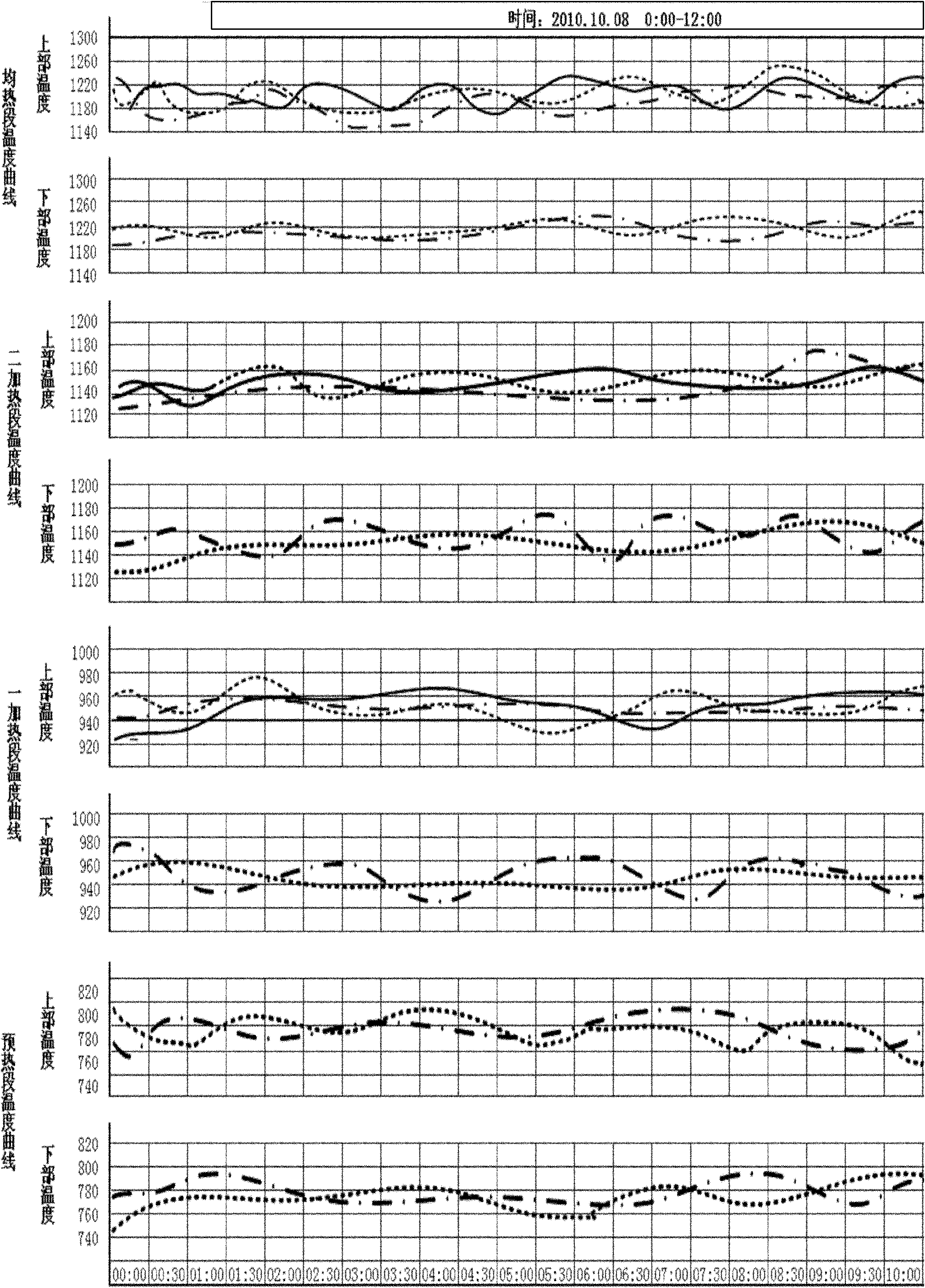

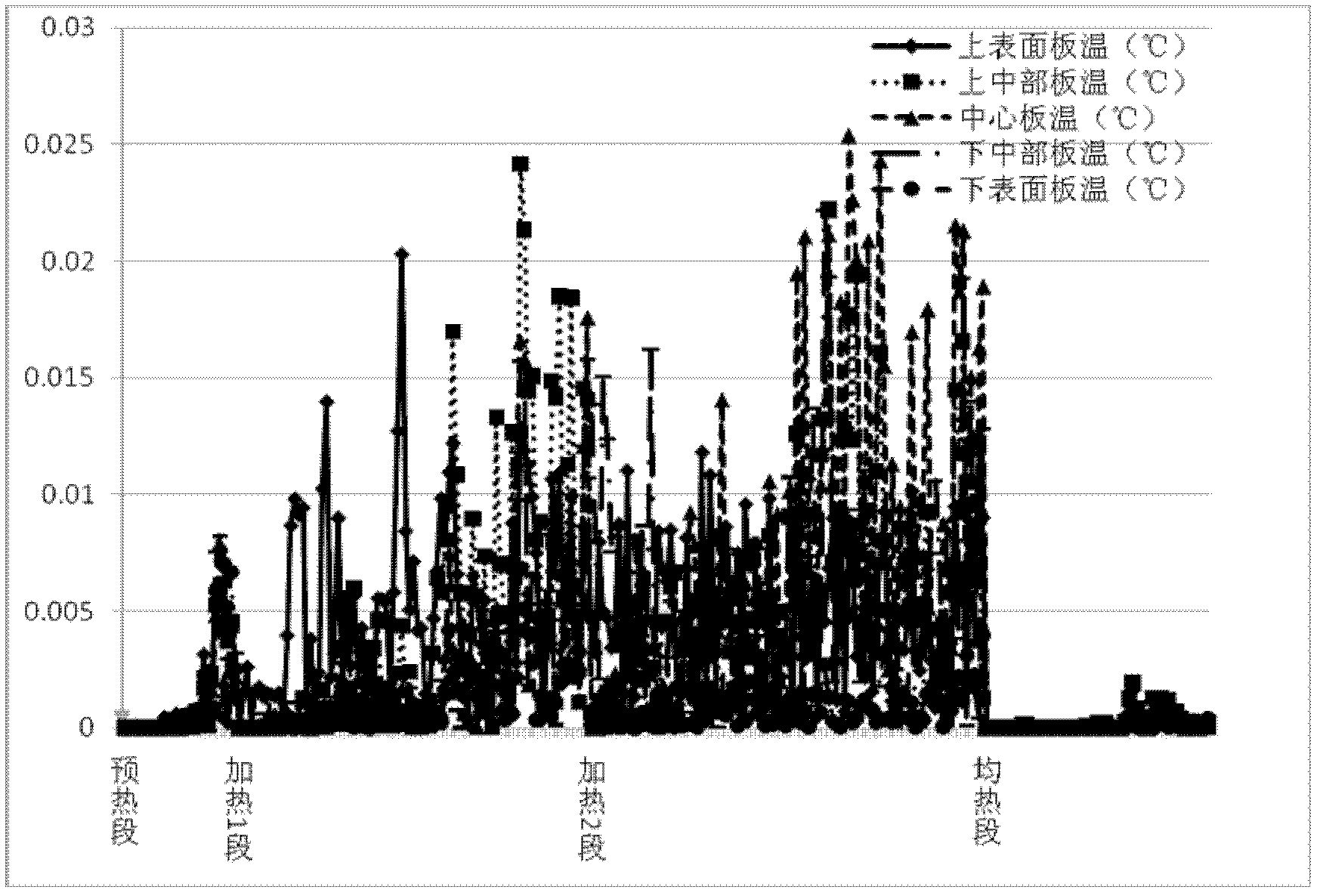

Method for recording temperature curve in heavy rail steel billet heating process

InactiveCN102080155APredicting Rolling EffectsEasy to achieve closed-loop optimal controlThermometer detailsFurnace typesTemperature curveEntry time

The invention provides a method for recording a temperature curve in a heavy rail steel billet heating process, which comprises the following steps: acquiring and storing temperatures of a preheating section, a first heating section, a second heating section and a soaking section of a heating furnace in real time; compiling steel billet tracking numbers for heavy rail steel billets before the heavy rail steel billets enter the heating furnace; after the heavy rail steel billets enter the heating furnace, respectively tracking and storing the preheating section entry time, the first heating section entry time, the second heating section entry time and the soaking section entry time and the discharging time in real time; respectively calculating the holding time of the corresponding heavy rail steel billets at the preheating section, the first heating section, the second heating section and the soaking section; extracting real-time temperature data of each steel billet track number at the preheating section, the first heating section, the second heating section and the soaking section; and drawing and storing a temperature curve in the heating process of each section according to the real-time temperature data of the holding time at each section. In the method, the real-time temperature of the heavy rail steel billets at each section of the heating furnace is converted into the temperature curve of the heating process at each section, thereby facilitating analyzing the temperature distribution of the heavy rail steel billets in the furnace. The invention is also applicable to coal gas flow and pressure alarming.

Owner:武钢集团有限公司

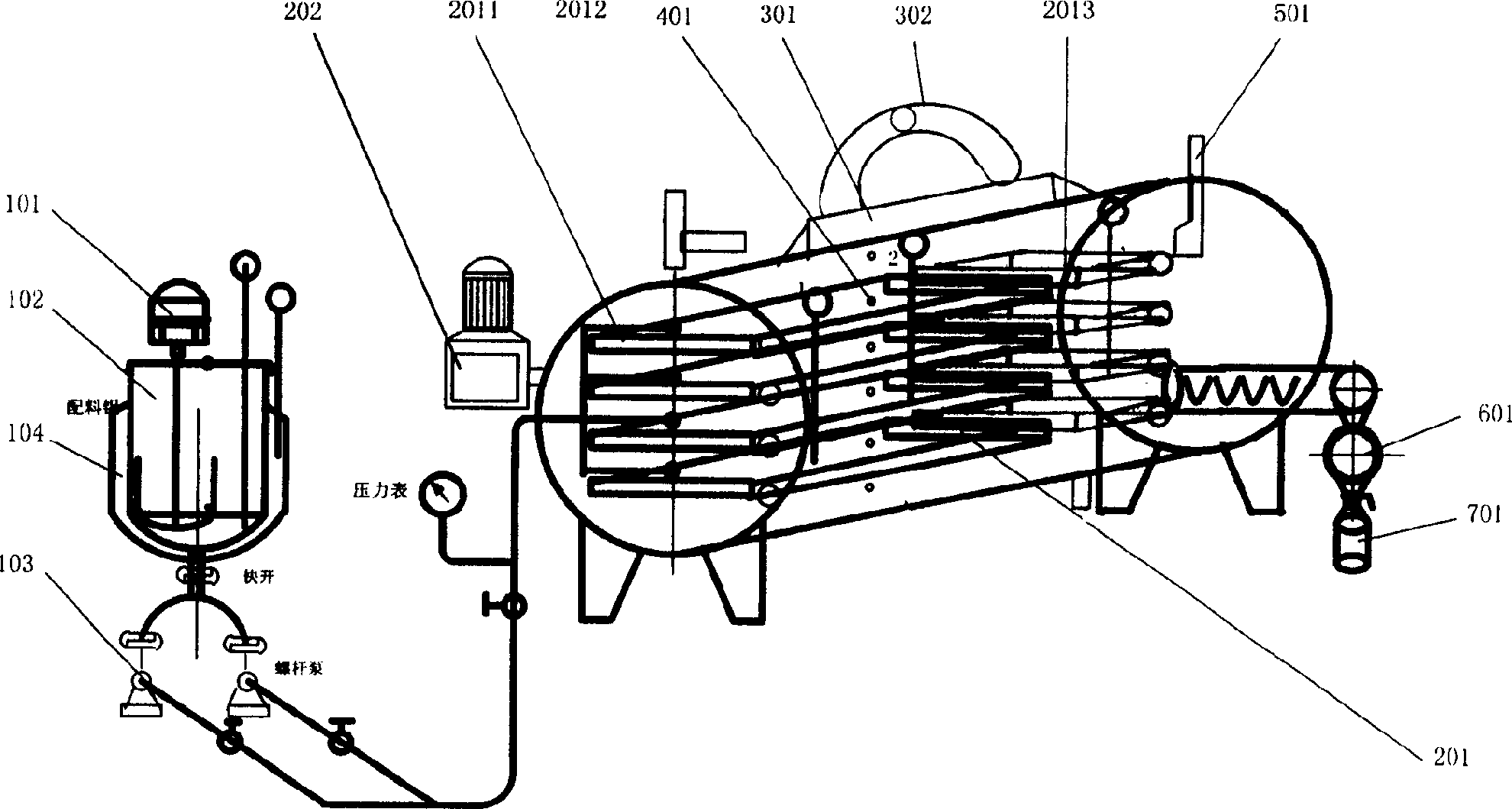

Automatic continuous-band freezing drier at vacuum low temperature

InactiveCN1854657AImprove product qualityPerfect solubilityDrying solid materials without heatDrying machinesEngineeringDistributor

The invention comprises a charging device, a drying belt driving device and a vacuum plant. The charging device includes a charger mixer, a dosage pot and a single-screw pump mounted one by one. The drying belt driving device is disposed in an enclosed vacuum chamber and has several layers of drying belts with the driving device inside. The vacuum plant includes a vacuum distributor and vacuum pipelines.

Owner:上海华琪实业有限公司

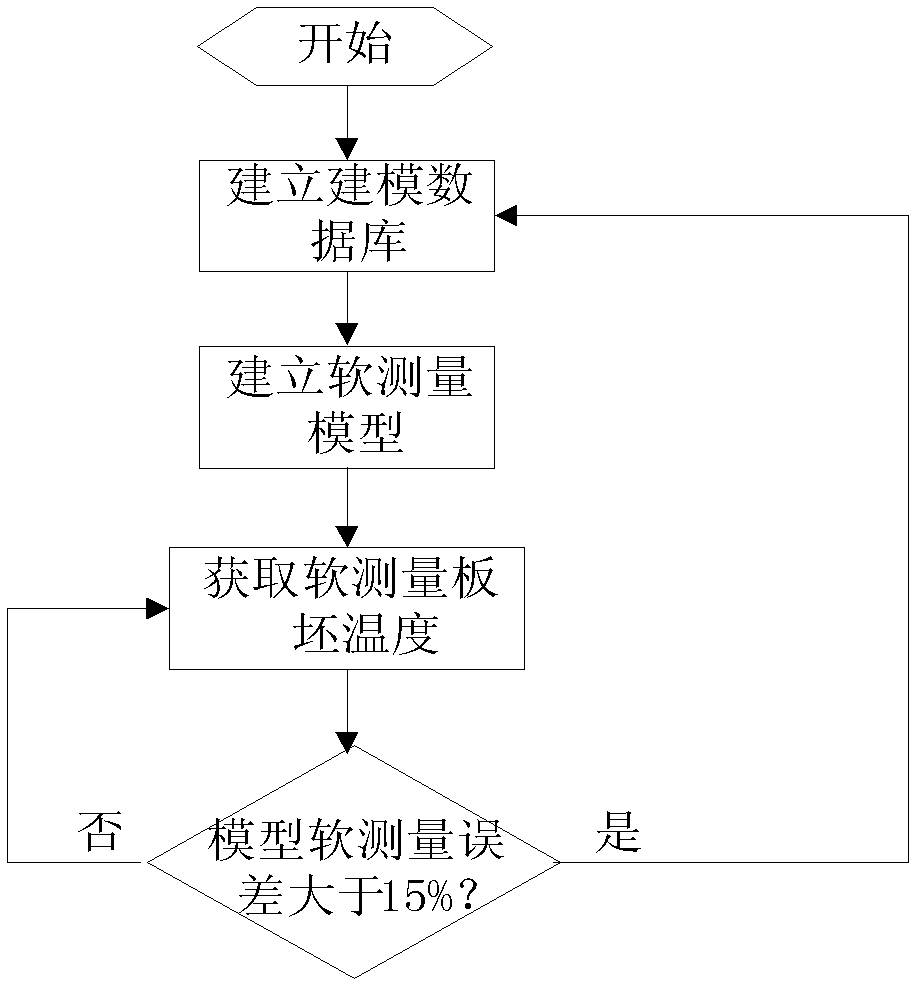

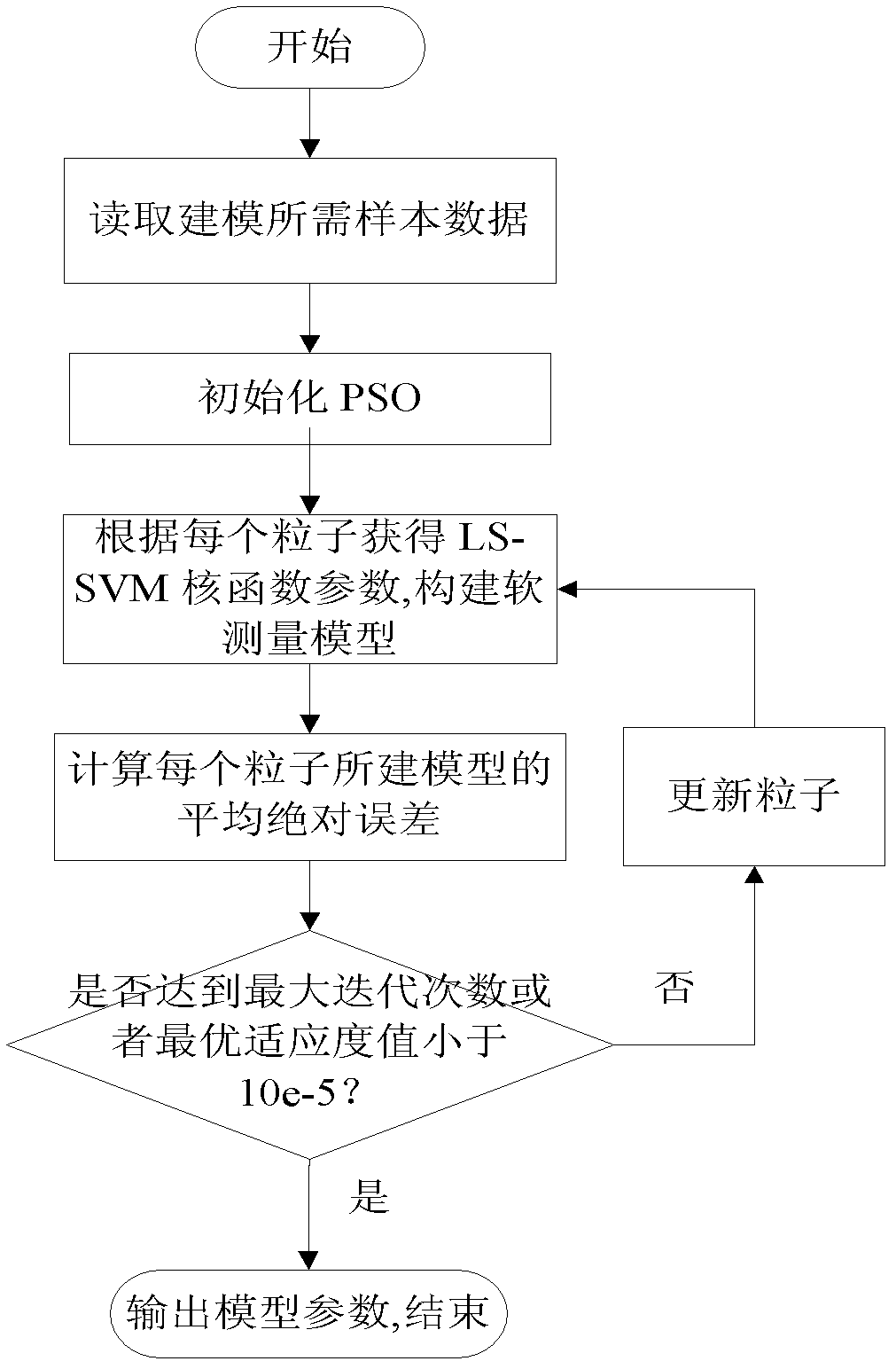

Temperature online measuring method for plate blank in production process of heating furnace

ActiveCN102564644AHigh precisionCalculation speedThermometer applicationsSpecial data processing applicationsData sourceLeast squares support vector machine

A temperature on-line measuring method for a plate blank in the production process of a heating furnace relates to the technical field of temperature online detection of the plate blank in the heating furnace. The temperature online measuring method comprises the following steps: establishing a plate blank temperature soft measurement model of a least squares support vector by using history data; optimizing parameters of an LS-SVM (Least Squares Support Vector Machine) plate blank temperature soft measurement model by adopting a particle swarm optimization algorithm; and after the model is established, calculating the temperature of the plate blank in real time. According to the temperature online measuring method disclosed by the invention, the temperature of the plate blank can be obtained in real time at high precision; high calculation speed and high calculation precision are obtained; the requirement of online production can be met; and the aim of improving the control stability is achieved; the temperature online measuring method can be operated on line to help operators learn about the heating condition of the plate blank in the furnace, thereby guiding the adjustment of the heating system, improving the heating quality and reducing energy consumption; the temperature online measuring method is wide in application range and can be used for determining the temperature of the plate blank or a plate coil in other complex industrial processes by properly modifying a data source; and the temperature online measuring method can conveniently share information with other links and brings convenience to providing reference information for the operation of other links.

Owner:NORTHEASTERN UNIV

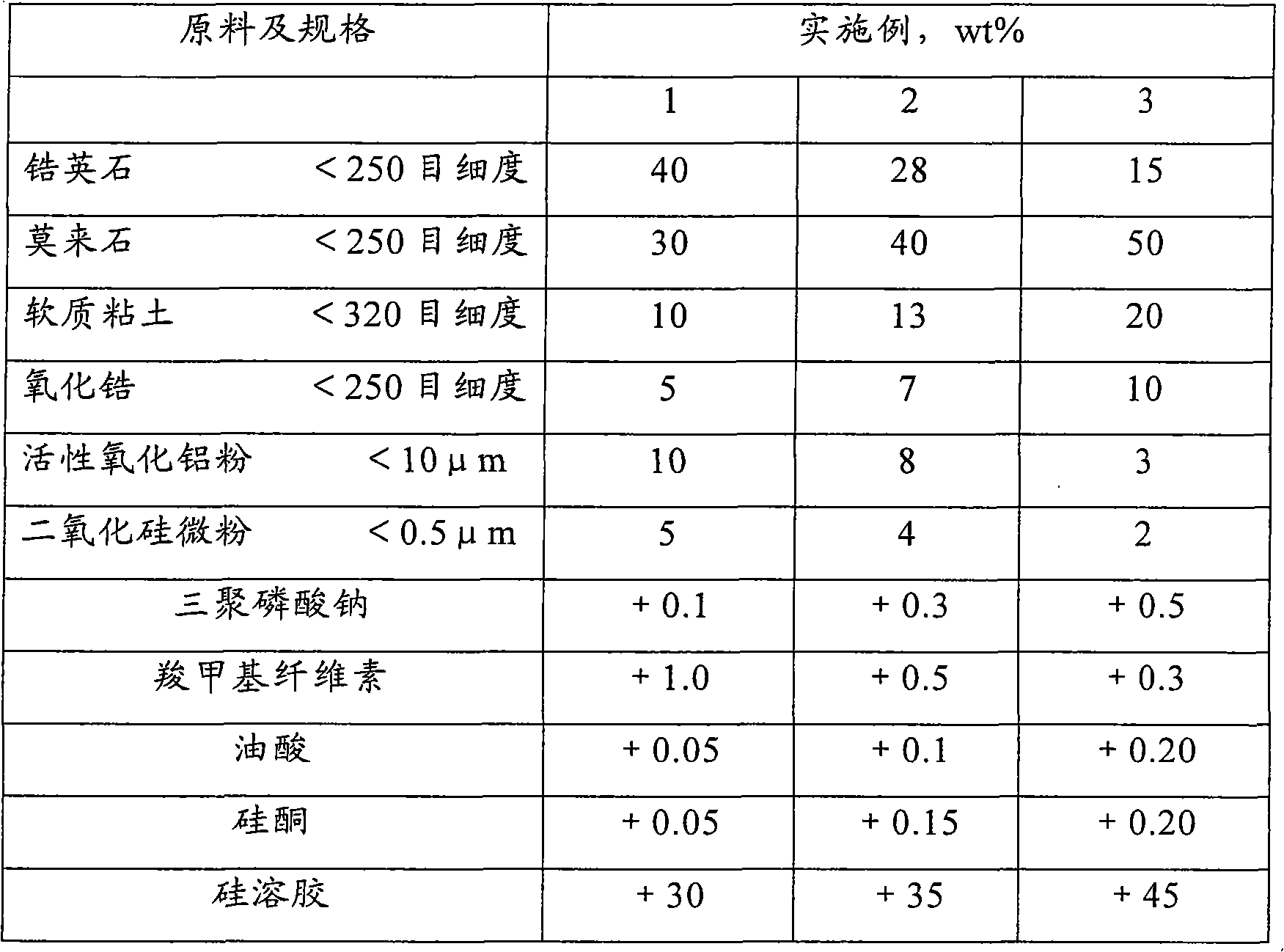

Porous medium burner material and preparation method thereof

InactiveCN101962299AImprove thermal shock resistanceImprove high temperature resistanceCeramicwarePorous mediumMullite

The invention discloses a porous medium burner material. The porous medium burner material comprises ceramic powder, a binding agent, a dispersing agent and a suspending agent, wherein the ceramic powder consists of the following components in percentage by weight: 15 to 40 percent of zirconite powder, 30 to 50 percent of fine mullite powder, 5 to 10 percent of fine zirconium oxide powder, 10 to 20 percent of soft clay, 5 to 10 percent of active aluminum oxide powder and 1 to 5 percent of silicon dioxide micro powder; the binding agent is 30 to 45 percent based on the total weight of the ceramic powder; the dispersing agent is 0.1 to 0.5 percent based on the total weight of the ceramic powder; the suspending agent is 0.2 to 1.0 percent based on the total weight of the ceramic powder; and the particle size of the fine powder is not greater than 250 meshes. The preparation method of the porous medium burner material comprises the following steps of: preprocessing organic foamed plastic; performing ball-milling on the ceramic powder, the additional binding agent, an additive and a proper amount of water; adding an antifoaming agent into the mixture, performing ball milling to obtain uniform paste, and controlling the viscosity to be 1 to 5Pa.s; soaking the preprocessed organic foamed plastic in the paste; repeating the processes for several times until the required density is achieved; removing the excessive paste to obtain the porous biscuit; naturally drying the porous biscuit at the room temperature; drying the biscuit in a drying box of over 90 DEG C to control the moisture to be less than or equal to 1.0 weight percent; and firing the biscuit in a kiln to obtain the porous medium.

Owner:BAOSHAN IRON & STEEL CO LTD +1

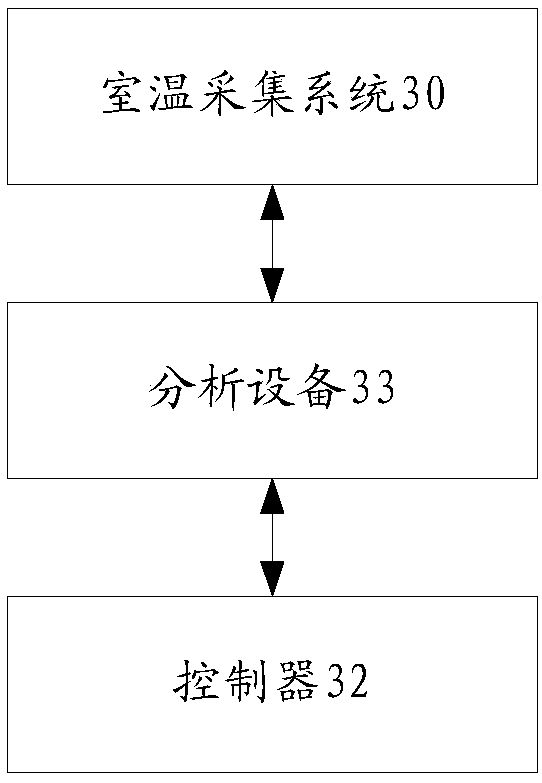

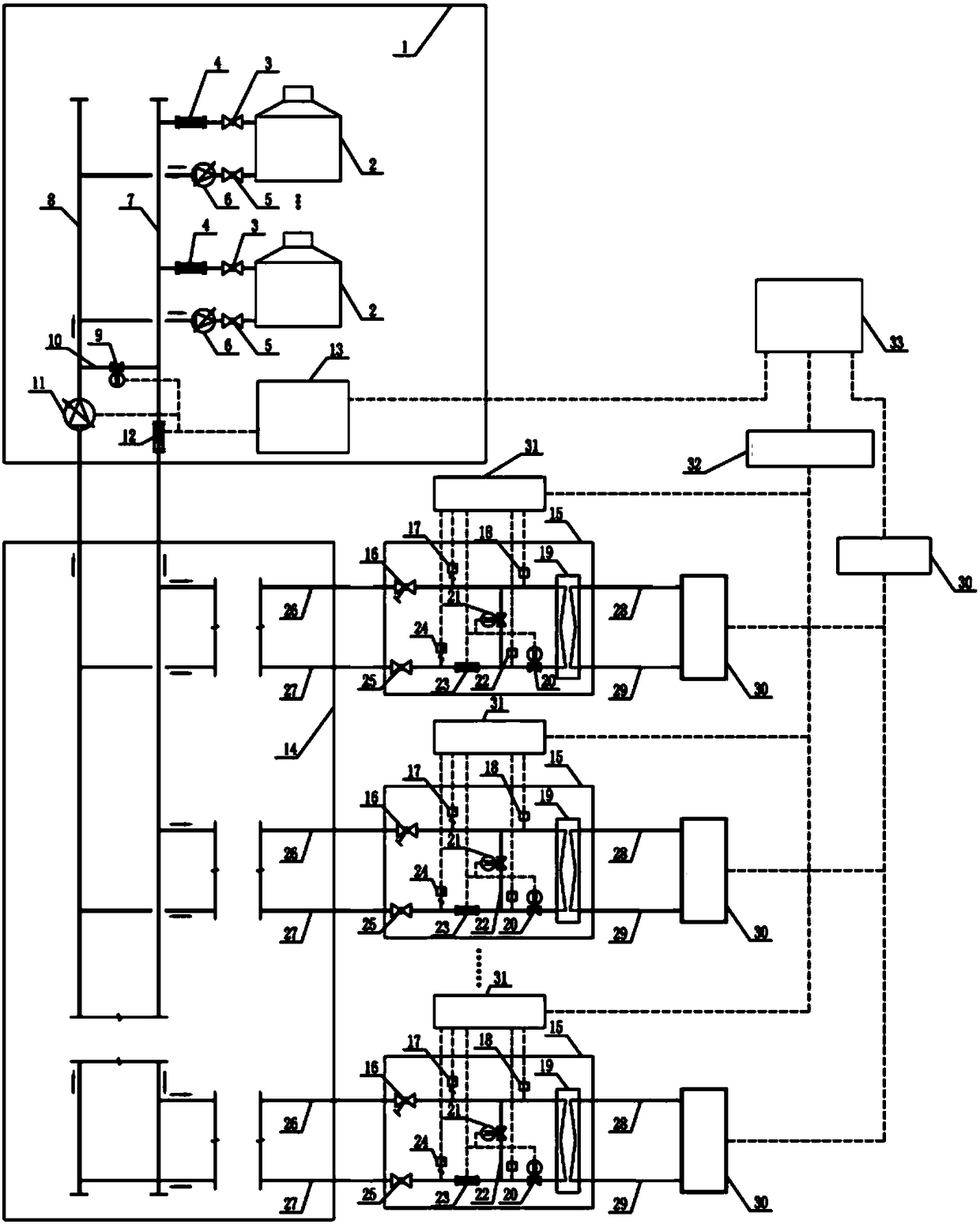

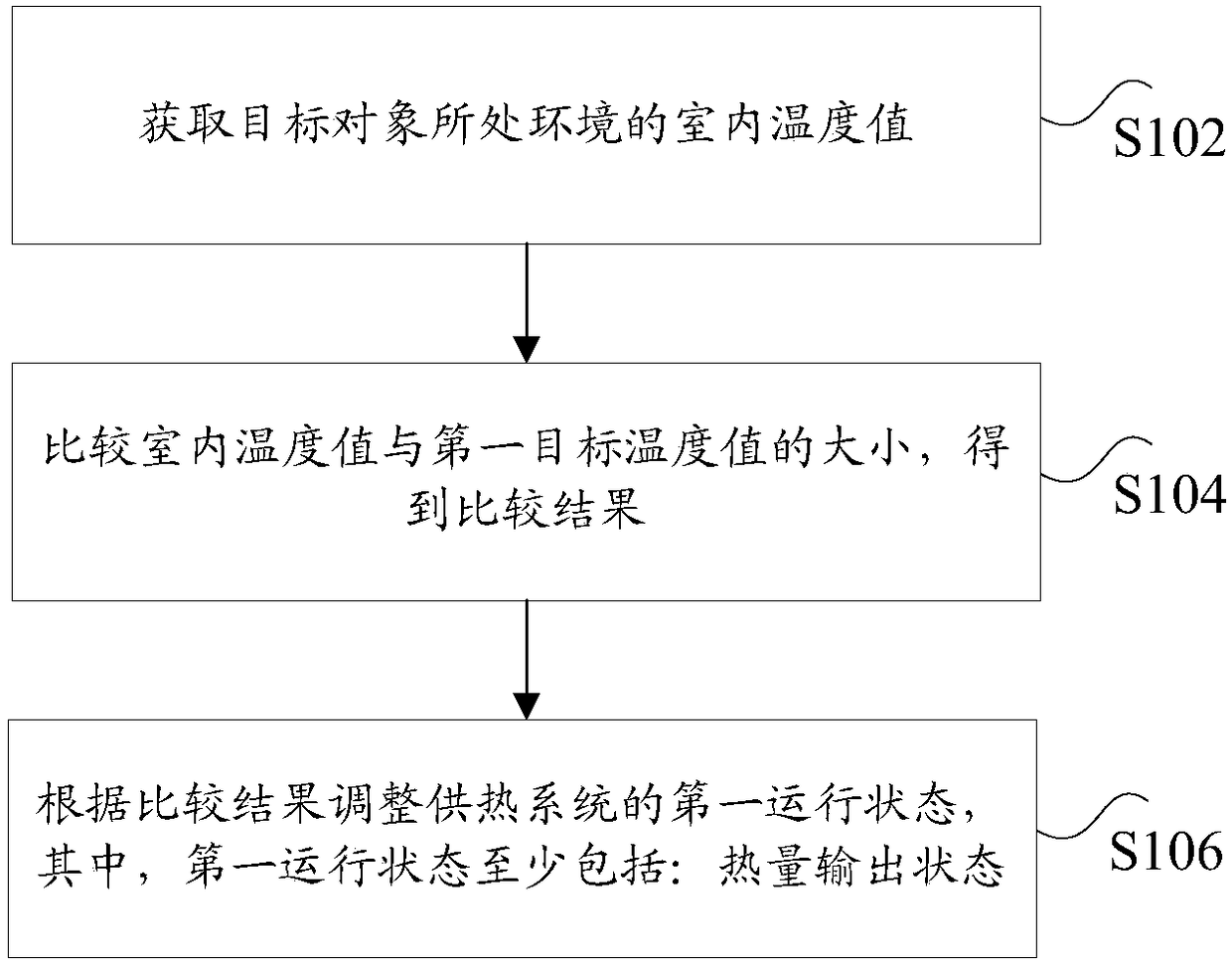

Method and device for adjusting heat supply, heat supply system, storage medium and treatment device

PendingCN108131707AAvoid wastingImprove indoor temperatureLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringProcess measurement

The invention discloses a method and device for adjusting heat supply, a heat supply system, a storage medium and a treatment device. The method comprises the following steps: acquiring an indoor temperature value of the environment of a target object; comparing the indoor temperature value with a first target temperature value to obtain a comparison value; adjusting a first running state of the heat supply system according to the comparison result, at least including a heat output state. According to the method and device for adjusting heat supply, the heat supply system, the storage medium and the treatment device, the technical problem that a heat supply pipeline cannot be subjected full-process measurement and adjustment in an existing heat supply system can be solved.

Owner:沈阳智通工程有限公司

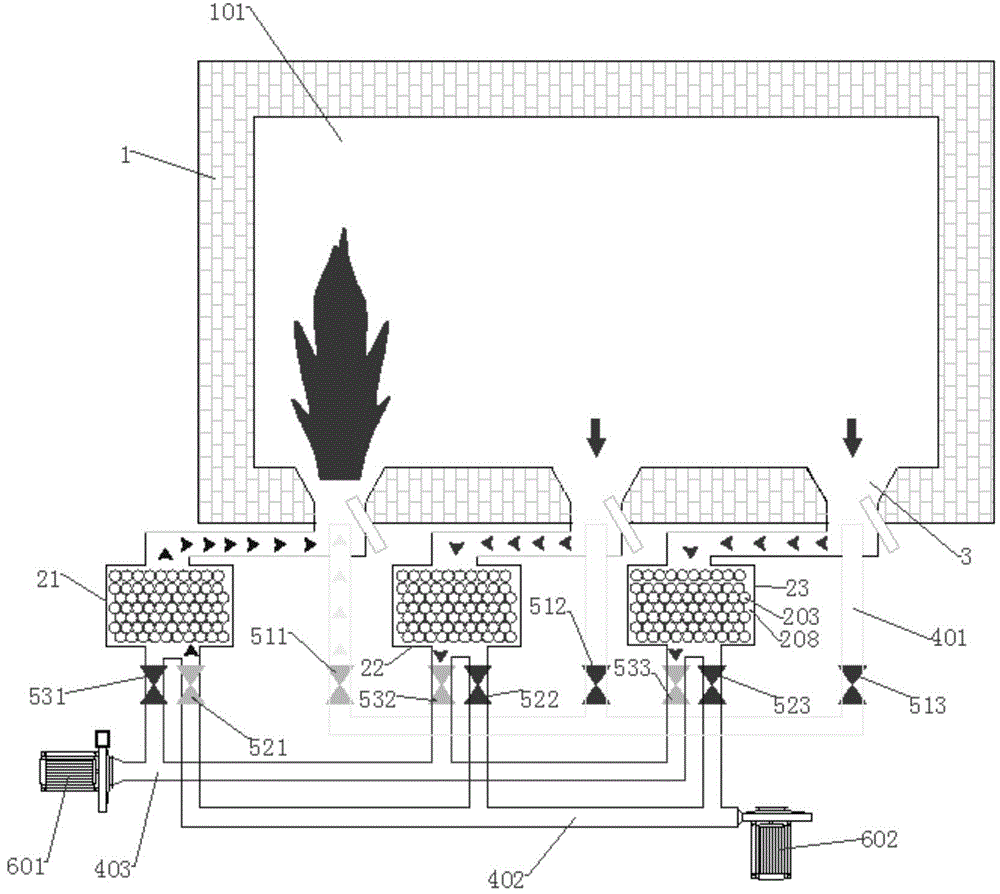

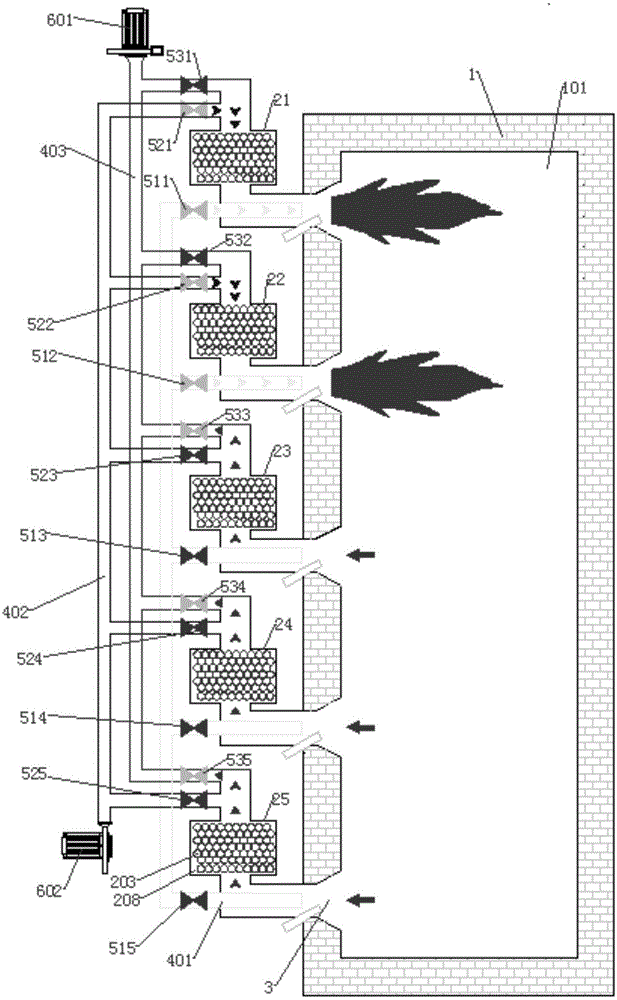

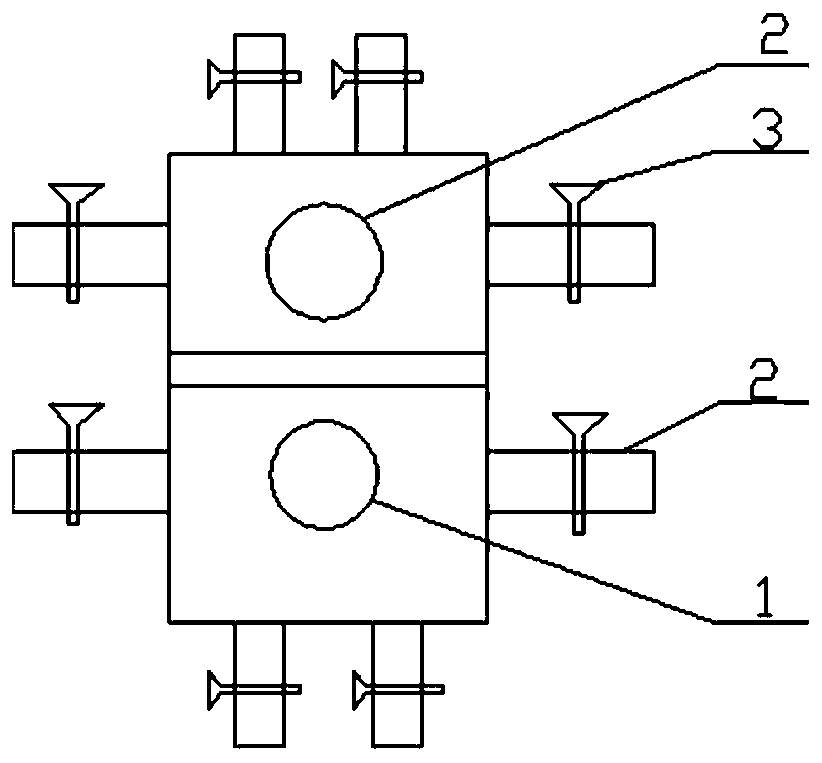

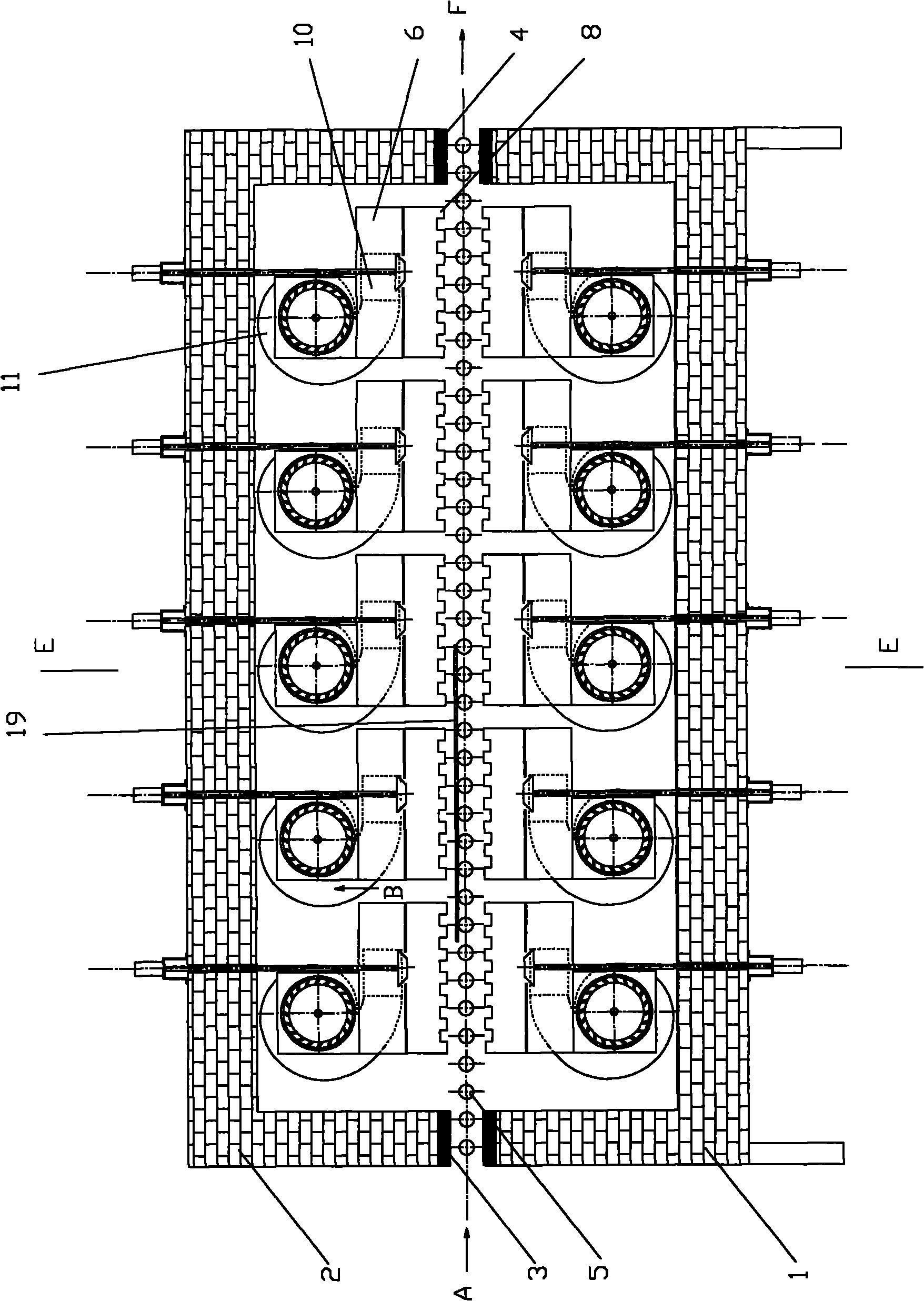

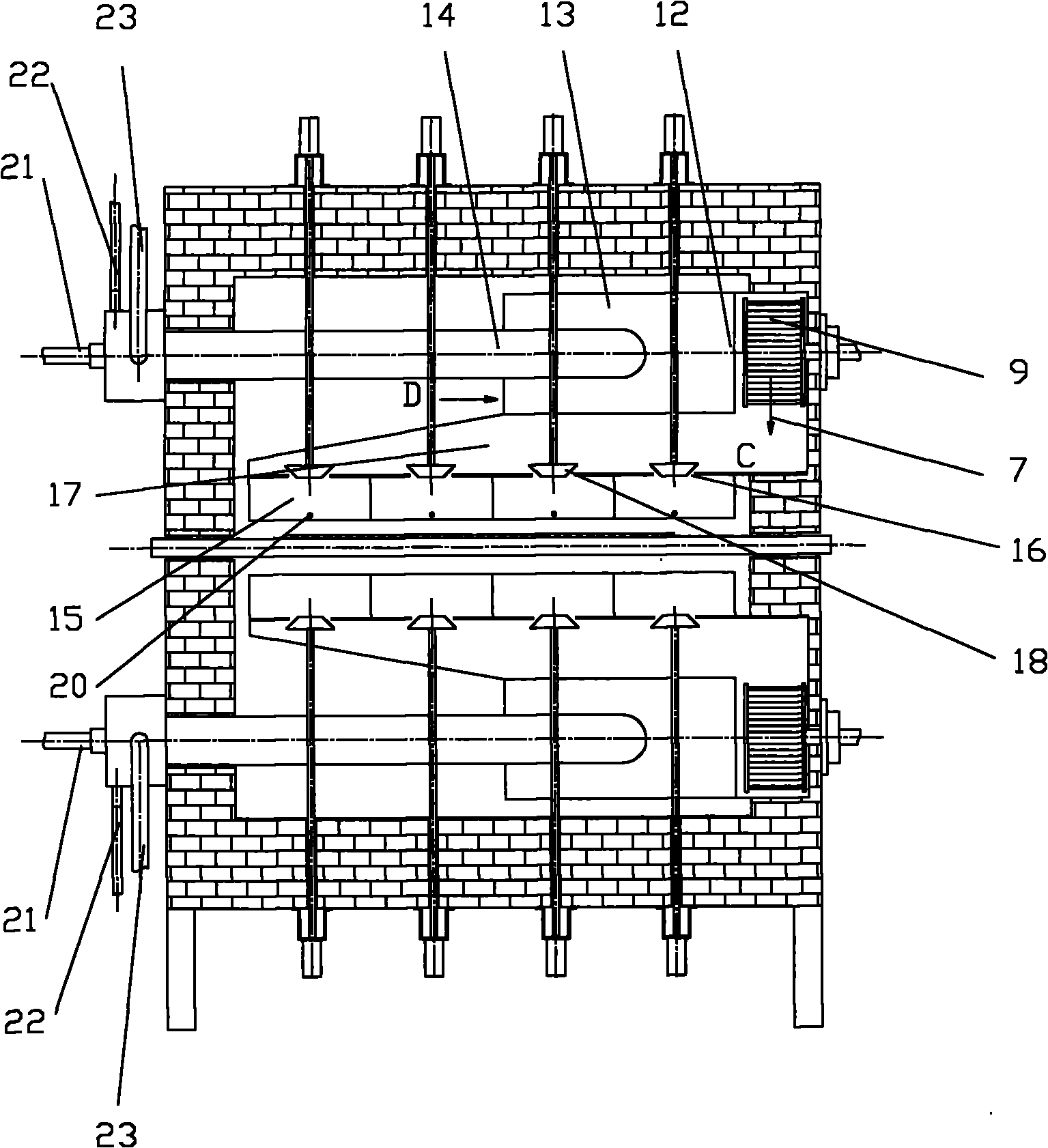

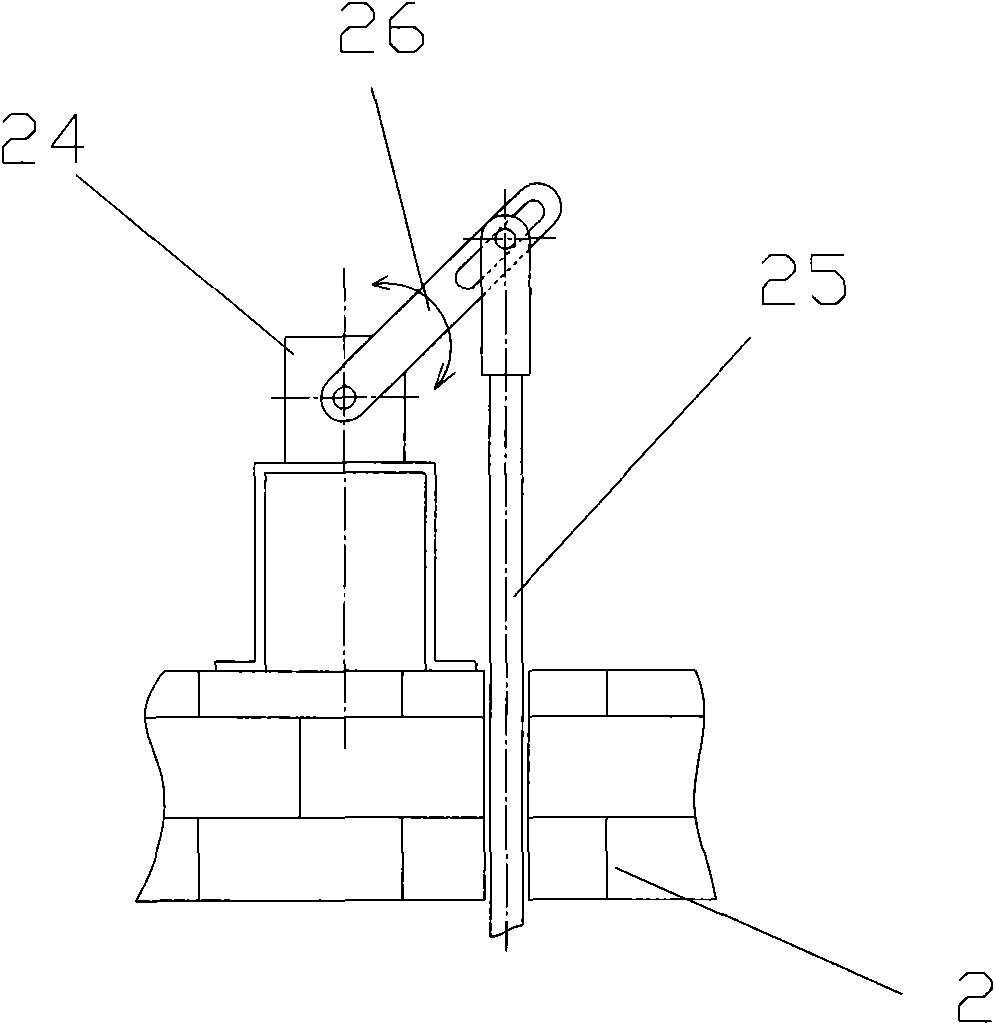

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

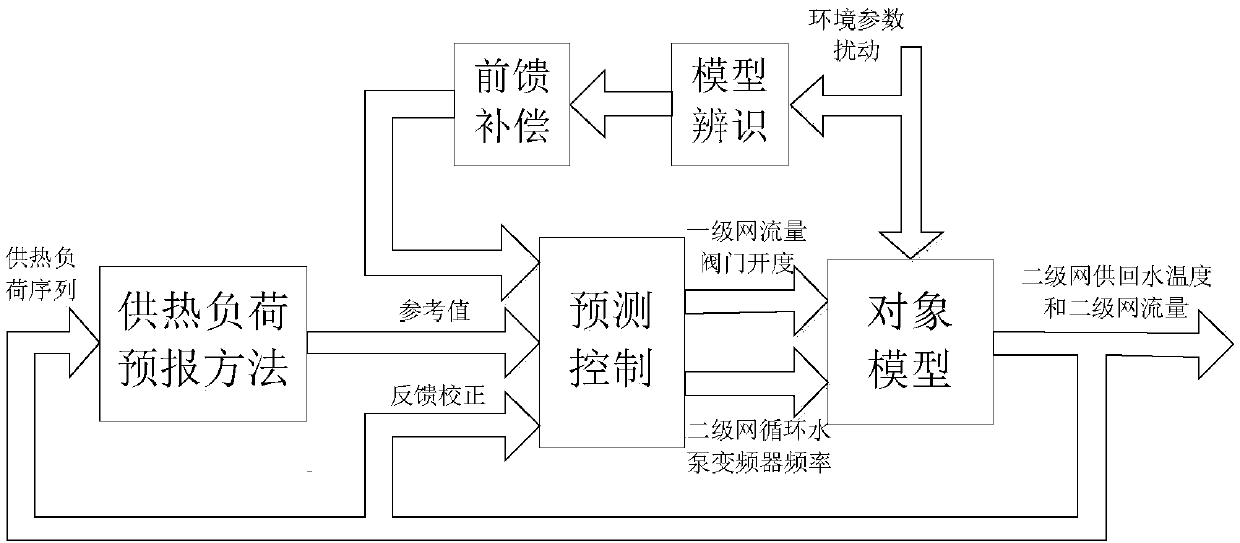

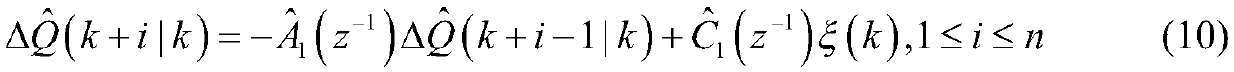

Real-time heating load control method based on environmental parameter compensation

InactiveCN107842908AEliminate the effects of heatingImprove control effectLighting and heating apparatusForecastingEngineeringHeat load

The invention discloses a real-time heating load control method based on environmental parameter compensation. The method comprises the steps that heating load prediction is performed, specifically, aheating load prediction method based on a time sequence is adopted, and a heating system load is predicted; environmental parameter recognition and compensation are performed, specifically, environmental parameters serve as disturbance, and a feedforward compensation loop is arranged so as to eliminate influences of environmental parameter changes on a heating temperature; and prediction controlis performed, specifically, prediction control is adopted, operation is performed according to predicted load demands, and control and regulation operations are performed on a great-inertia heating load system in advance. Compared with the prior art, prediction control is adopted to control the load of a heating system, and the feedforward compensation loop is designed to eliminate the influencesof environmental parameter fluctuation on heating; and the control effect is good, certain disturbance rejection capability is achieved, and the heating quality is effectively improved.

Owner:HANGZHOU POWER SUPPLY COMPANY OF STATE GRID ZHENGJIANG ELECTRIC POWER +4

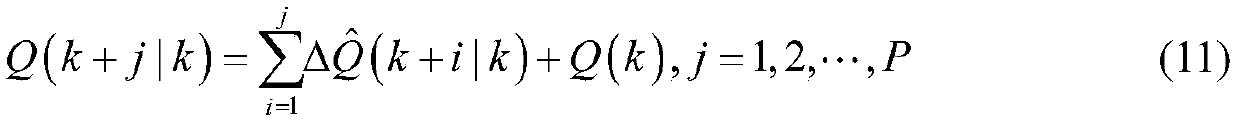

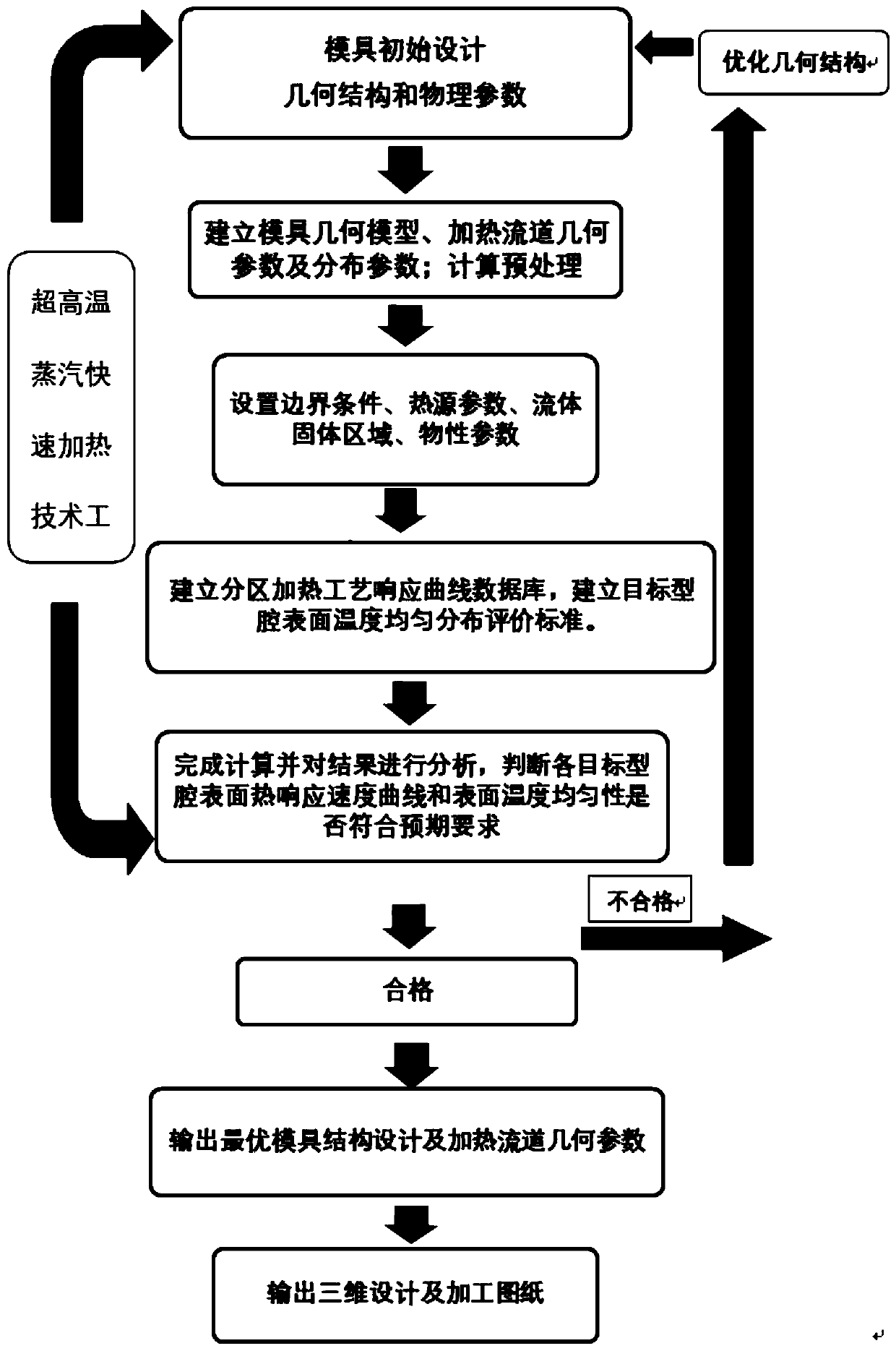

Mould preparation method, mould, mould heating system and heating controlling method

ActiveCN110027139AUniform temperatureMeet the needs of fast-changing mold temperatureThermometers using electric/magnetic elementsUsing electrical meansHot runnerModular unit

The invention discloses a mould preparation method, a mould, a mould heating system and a heating controlling method. The method comprises the following steps: S1, dividing heating areas; S2, pre-setting at least one heating flow channel in each of the heating areas, and the method for determining structural parameters of the heating flow channels comprises the following steps: S21, pre-setting the structural parameters of the heating flow channels; S22, obtaining an actual heating curve of each of the heating areas and actual temperature of each of position points of a mold cavity surface; S23, carrying out deviation analysis and adjusting the structural parameters of the heating flow channels according to a deviation analysis result; S24, repeatedly carrying out the steps S22 and S23; and S3, carrying out processing according to the structural parameters of the heating flow channels to form flow channels. The mould is heated in subareas, and the structural parameters of the flow channels are determined separately in each of the heating areas, so that the phenomena that the overall heat response speed of the mould and the temperature uniformity of the whole mold cavity can meet the requirement can be ensured, and by adopting the method, the requirement on quick change of the mould temperatures of complicated modular unit structures can be met, and subarea heating can be conveniently carried out.

Owner:宁波柚贝儿童用品有限公司

Method for setting high temperature gas spout in convection type glass plate heating furnace and application thereof

ActiveCN101767927AGuaranteed uniformityImprove heating qualityGlass reforming apparatusGlass tempering apparatusEngineeringProduct gas

The invention discloses a method for setting a high temperature gas nozzle in a convection type glass plate heating furnace, and also discloses the convection type glass plate heating furnace designed according to the method. In the invention, all gas nozzles on a whole heating work surface in a furnace chamber are divided into units arranged in matrix, and the temperature of the gas ejected by the nozzle of each unit and / or the gas ejection amount are enabled to be adjustable and the regional control of the high temperature gas convection heating in the furnace chamber is realized; only a cell corresponding to the size of a glass plate can be started to work when a small glass plate is processed, thereby avoiding the waste of energy; and the heating uniformity of the whole glass plate can be ensured by respectively adjusting the heat of different parts of the glass plate applied by each unit when a glass plate with a bigger size is processed, thus the property of the heating furnace is greatly improved, and the technical support is provided for improving the heating quality of the glass plate and reducing the glass processing cost.

Owner:LUOYANG LANDGLASS TECH CO LTD

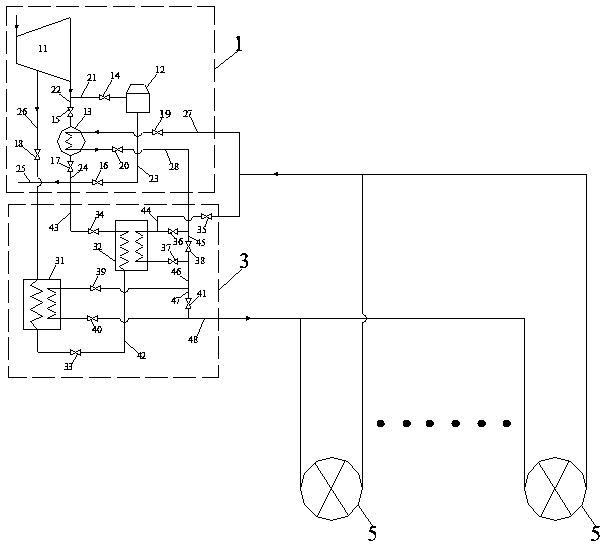

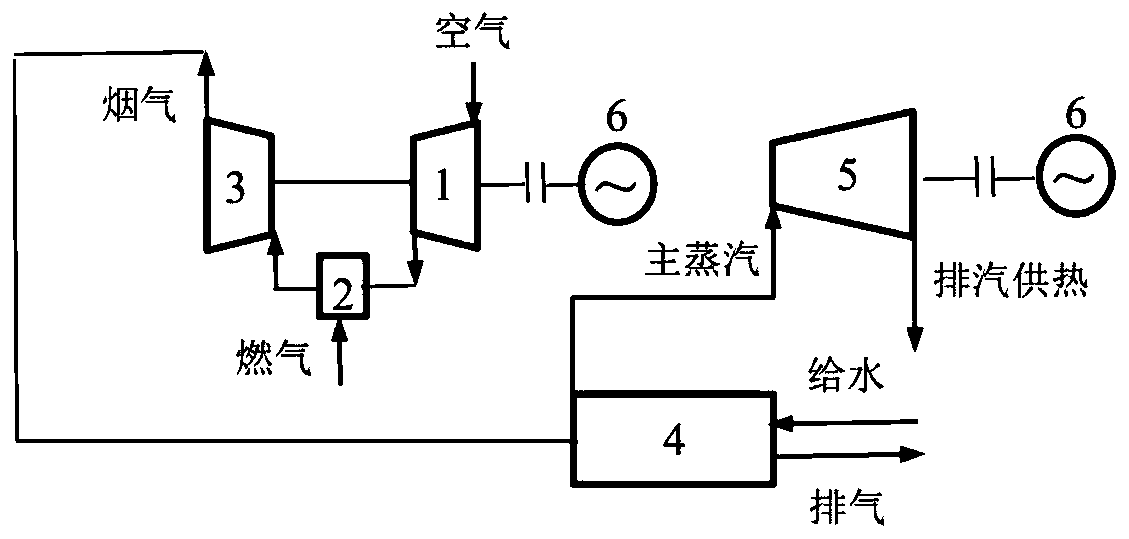

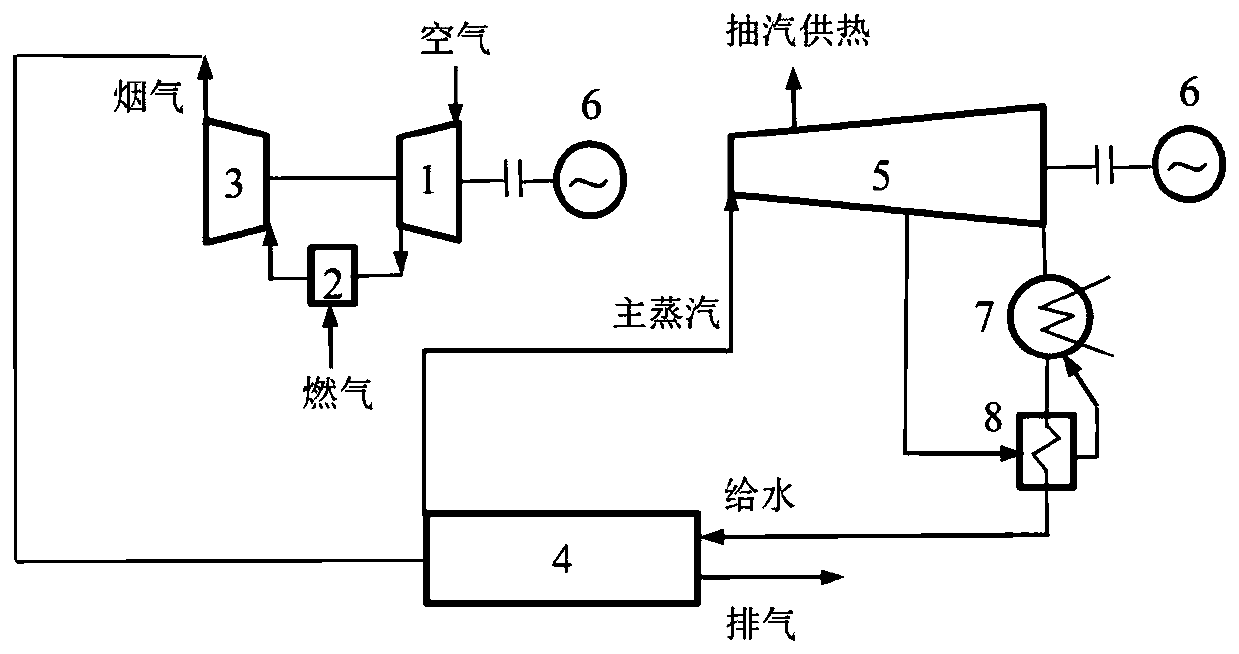

High back pressure coupling large temperature difference heating supply system for air cooling unit and operation method

PendingCN109579108AFlexible adjustmentImprove delivery capacityLighting and heating apparatusSteam usePipingCogeneration

The invention relates to a high back pressure coupling large temperature difference heating supply system for an air cooling unit and an operation method, and belongs to the technical field of combined heat and power generation energy conservation. The high back pressure coupling large temperature difference heating supply system for the air cooling unit comprises a combined heat and power generation unit, a heating network origin station and a secondary heat exchanging station, the combined heat and power generation unit comprises a turbine, an air cooling island and a back pressure condenser, the heating network origin station comprises a heater for heating networks and a hydrophobic heat exchanger, and the secondary heat exchanging station comprises a hot water type absorbed type heat pump and a water-water heat exchanger. The back pressure condenser, the hydrophobic heat exchanger, the heater for the heating networks, the absorbed type heat pump and the water-water heat exchanger are sequentially mounted on a primary network water pipe loop, corresponding valves are opened or closed to realize primary network-water side switching connection in series and in parallel of the backpressure condenser and the hydrophobic heat exchanger and secondary network-water side switching connection in series and in parallel of the hot water type absorbed type heat pump and the water-waterheat exchanger. According to the high back pressure coupling large temperature difference heating supply system for the air cooling unit and the operation method, stepped warming and heating of primary network-water and secondary network-water is realized, the irreversible loss in the heat exchanging process is effectively reduced, and higher practical application value is achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Thermoelectric load optimization scheduling system for multiple sets of gas-steam combined cycle units

InactiveCN110070460AMeet production needsImprove heating qualityData processing applicationsSteam engine plantsNatural gasEnergy balanced

Based on big data analysis and energy balance principles, the invention provides a thermoelectric load optimization scheduling system for multiple sets of gas-steam combined cycle units. The system obtains and uploads operating parameters of the gas-steam combined cycle unit measured and uploaded by field measurement instruments from a power plant DCS system; analyzes the operation parameters to obtain an actual operation trend curve of the equipment; combines the thermal demand and the power generation load demand as the total energy demand of the unit; the method aims at minimizing the totalconsumption of natural gas, thermal power and power generation load requirements of the thermal power plant are optimally distributed in all units through an optimization method, and the purposes that under the condition that the same thermal power and power generation load conditions are met, the comprehensive energy consumption of power generation and heat supply of the thermal power plant is the lowest, and the energy efficiency level is the optimal can be achieved. The system can effectively guide operating personnel to reasonably adjust the operating state, meet the production requirement, improve the heat supply quality, reduce the operating cost, achieve economic operation and improve the overall operating benefit of the thermal power plant.

Owner:SOUTHEAST UNIV

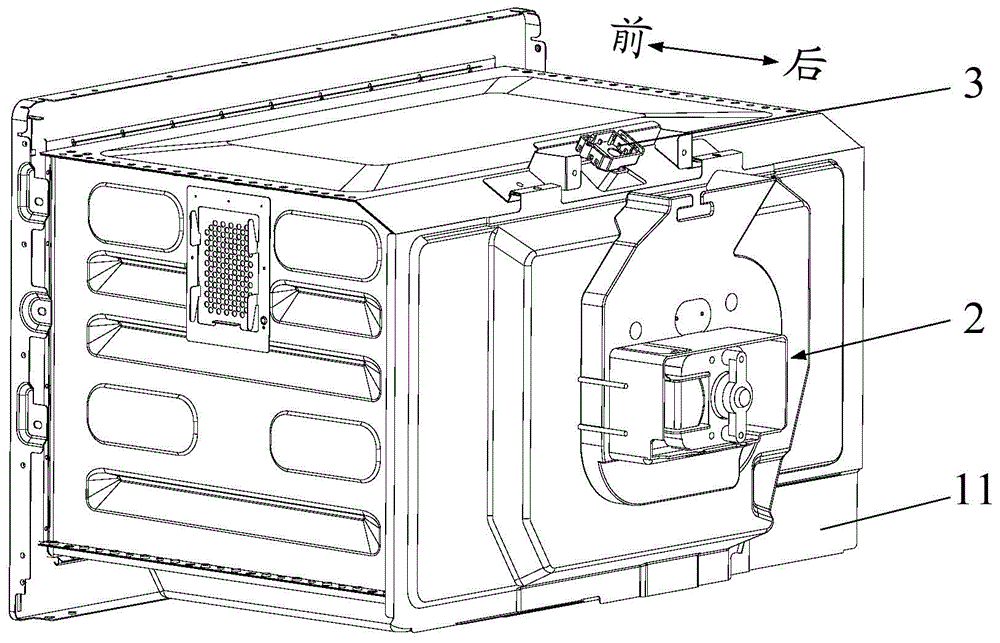

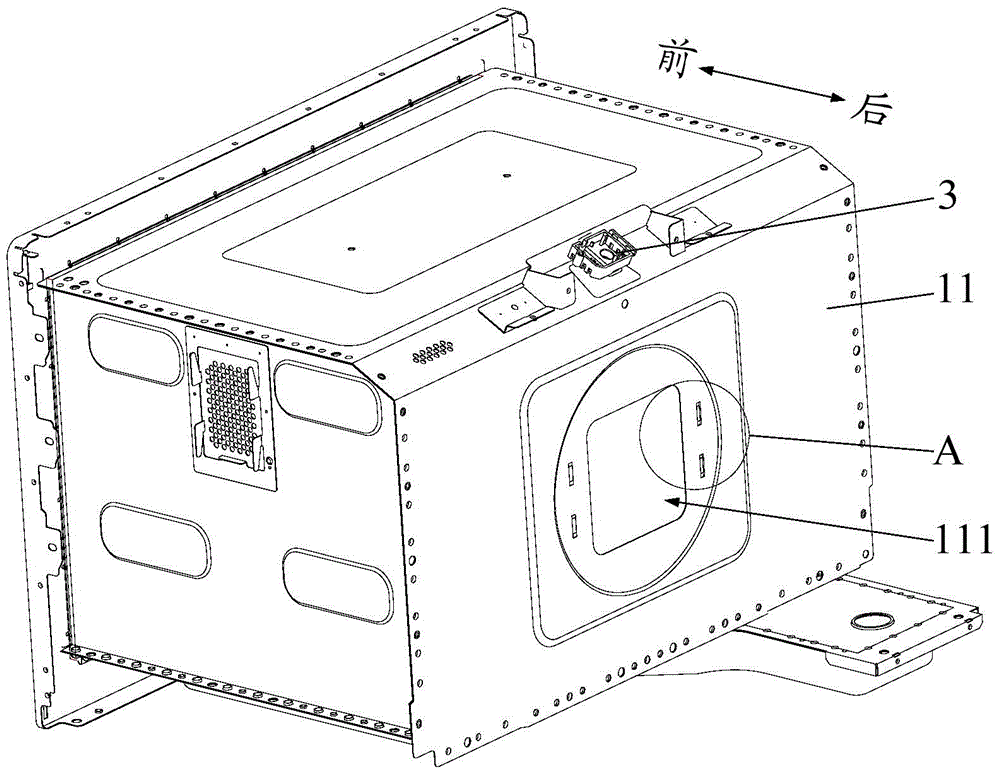

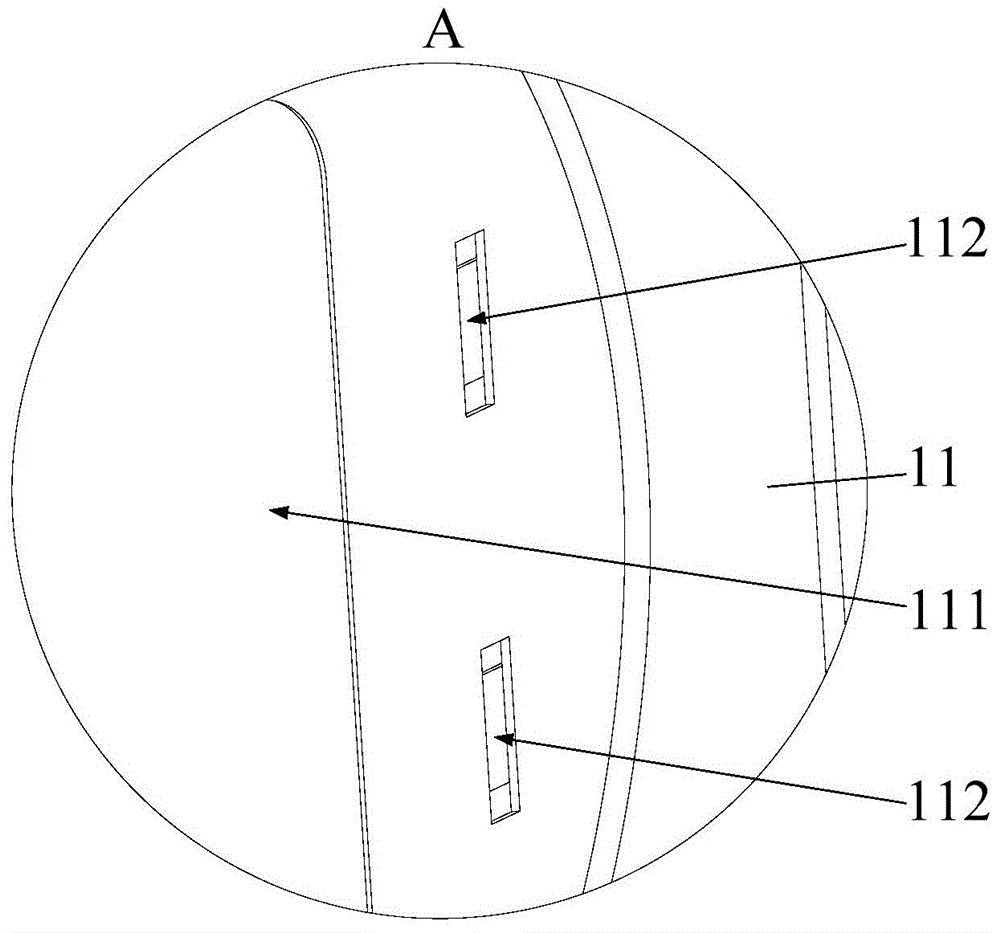

Microwave oven

ActiveCN104456648AEffective stirringEffective reflectionDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention provides a microwave oven which comprises an oven cavity, a first stirring device and a second stirring device, wherein a microwave-transmitting hole is formed in a rear plate of the oven cavity; the first stirring device is fixed below the bottom plate of the oven cavity; microwaves enter the oven cavity after being stirred by the first stirring device; the second stirring device is fixed on the rear plate and positioned on the rear side of the rear plate; stirring blades of the second stirring device are made of microwave-proof materials; turbulent microwave holes are formed in the stirring blades; microwaves can penetrate through the microwave-transmitting hole and are reflected back into the oven cavity after being stirred by the stirring blades. According to the microwave oven provided by the invention, microwaves can be effectively stirred and reflected through rotating stirring blades, when passing through the wave-transmitting hole, the microwaves in the oven irradiate to the second stirring device to be stirred by stirring blades and then reflected back into the oven cavity, so that microwaves in the oven cavity can be distributed more uniformly, the heating efficiency and the heating quality of food in the microwave oven can be improved, the usage performance of the product can be improved, and the microwave oven is more competitive in market.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

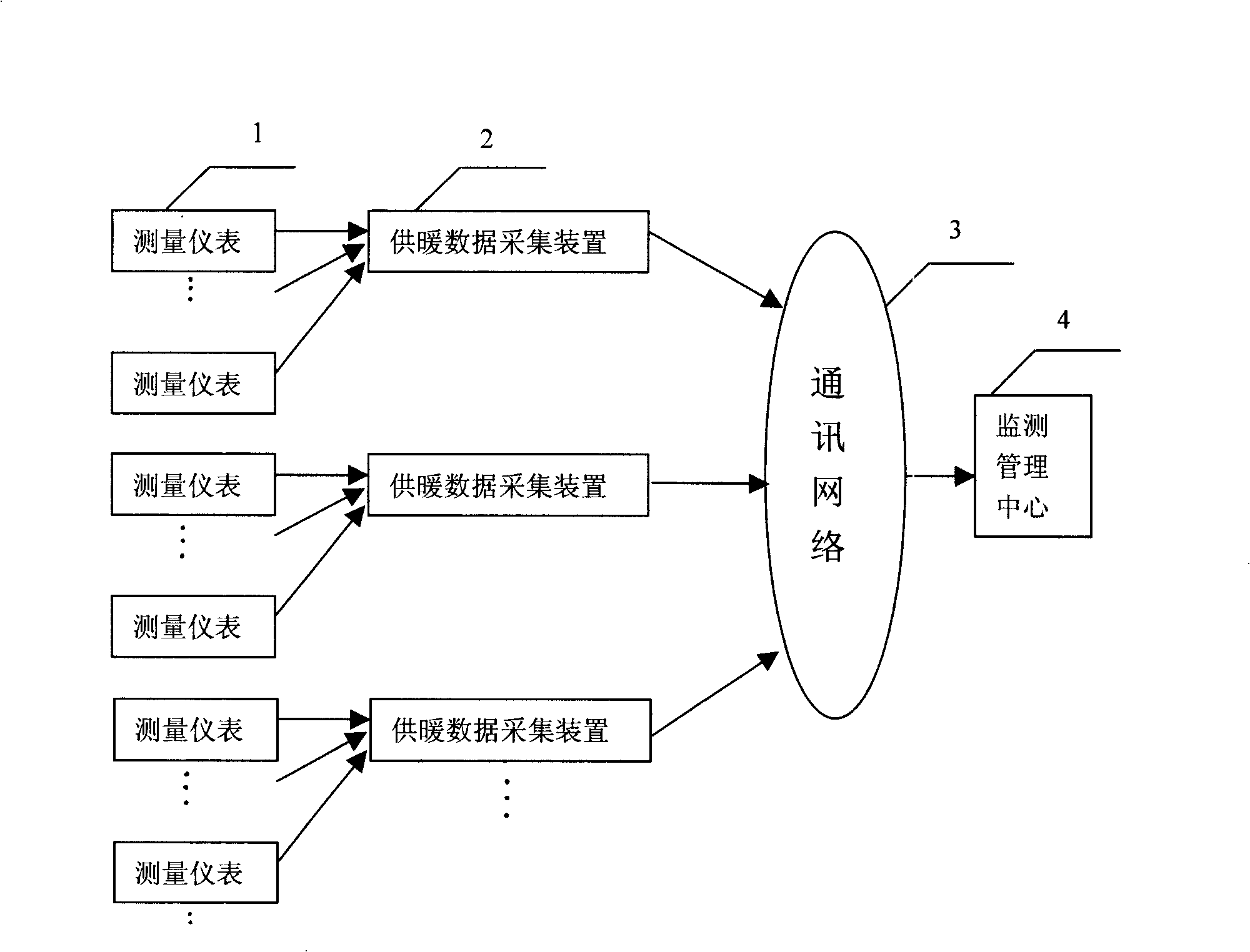

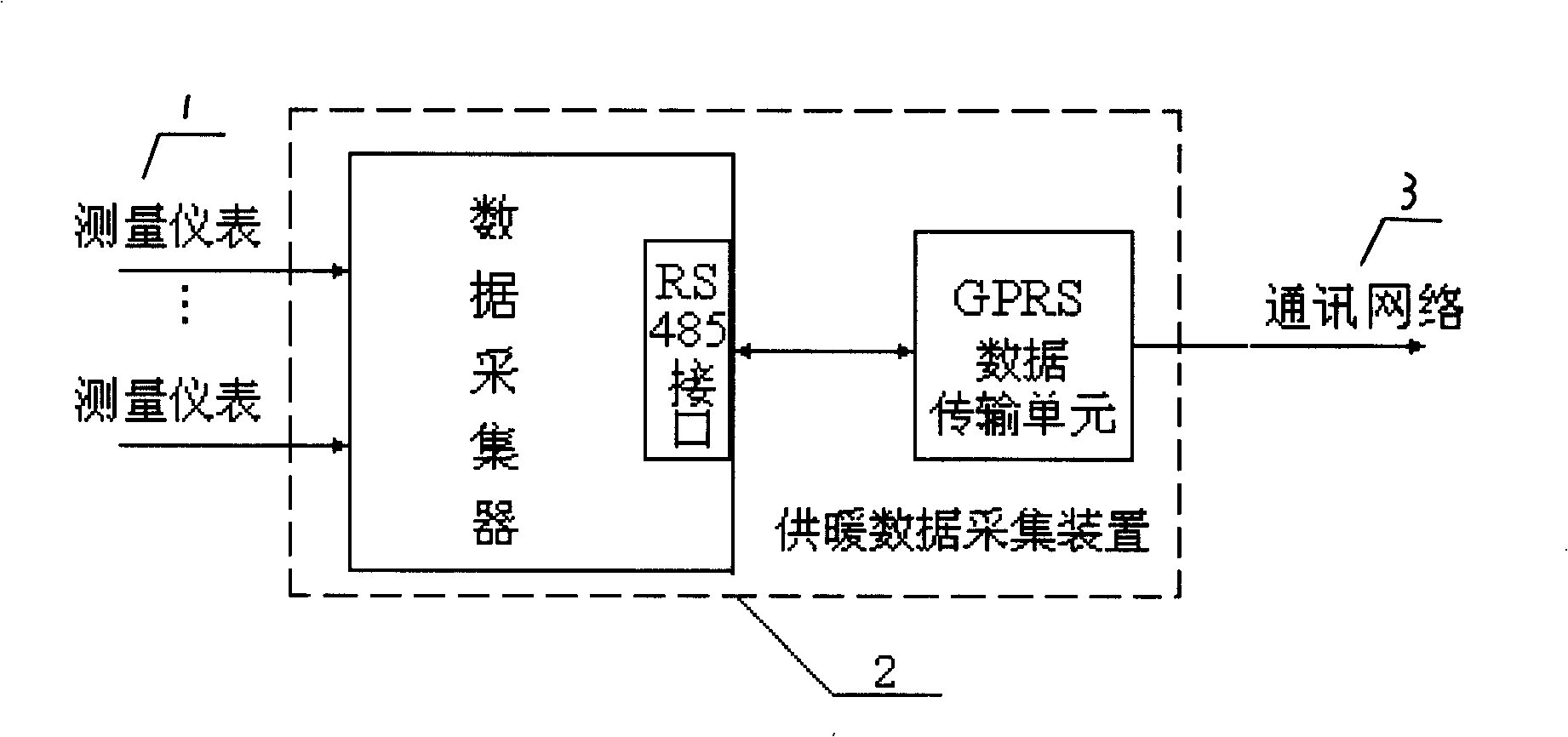

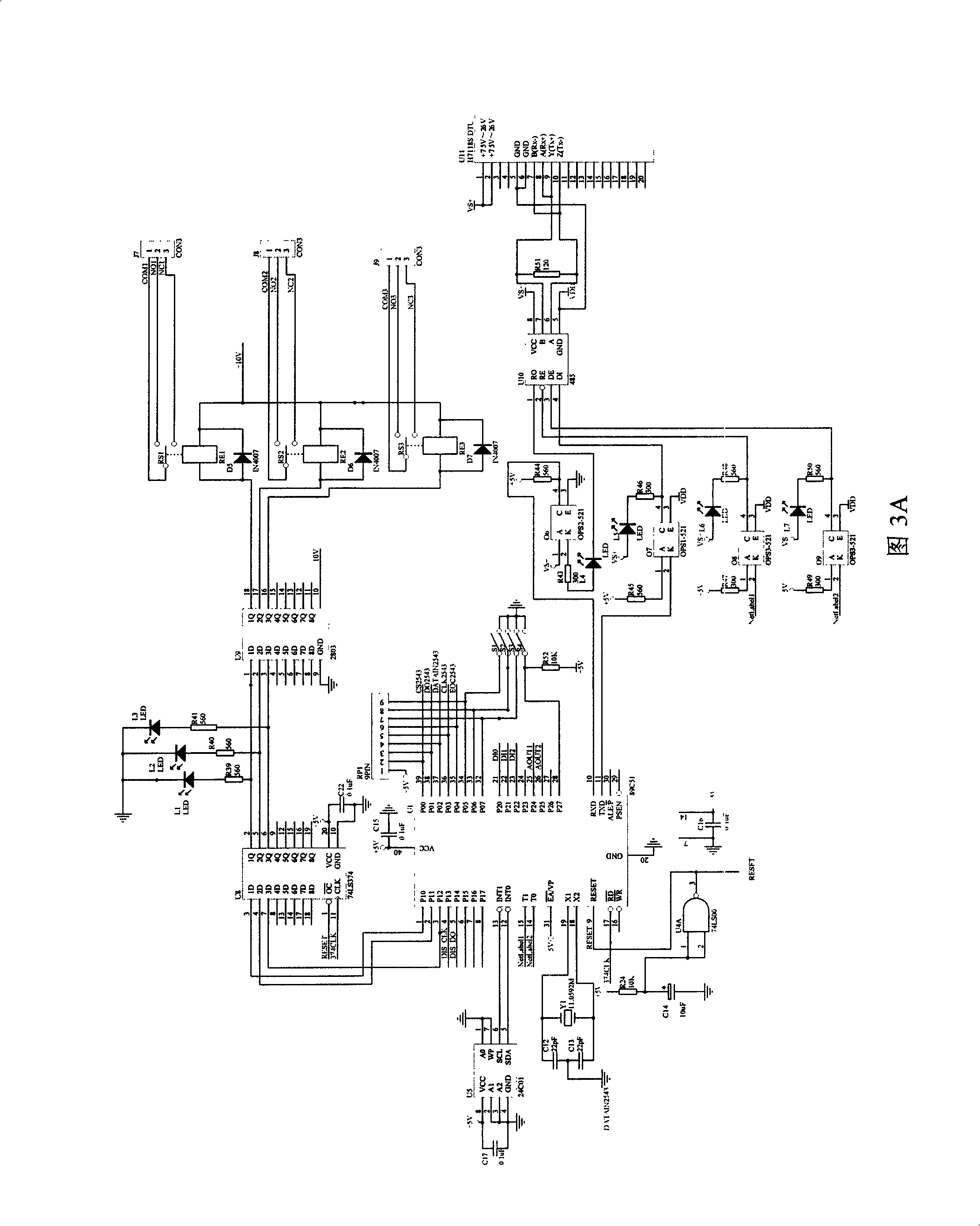

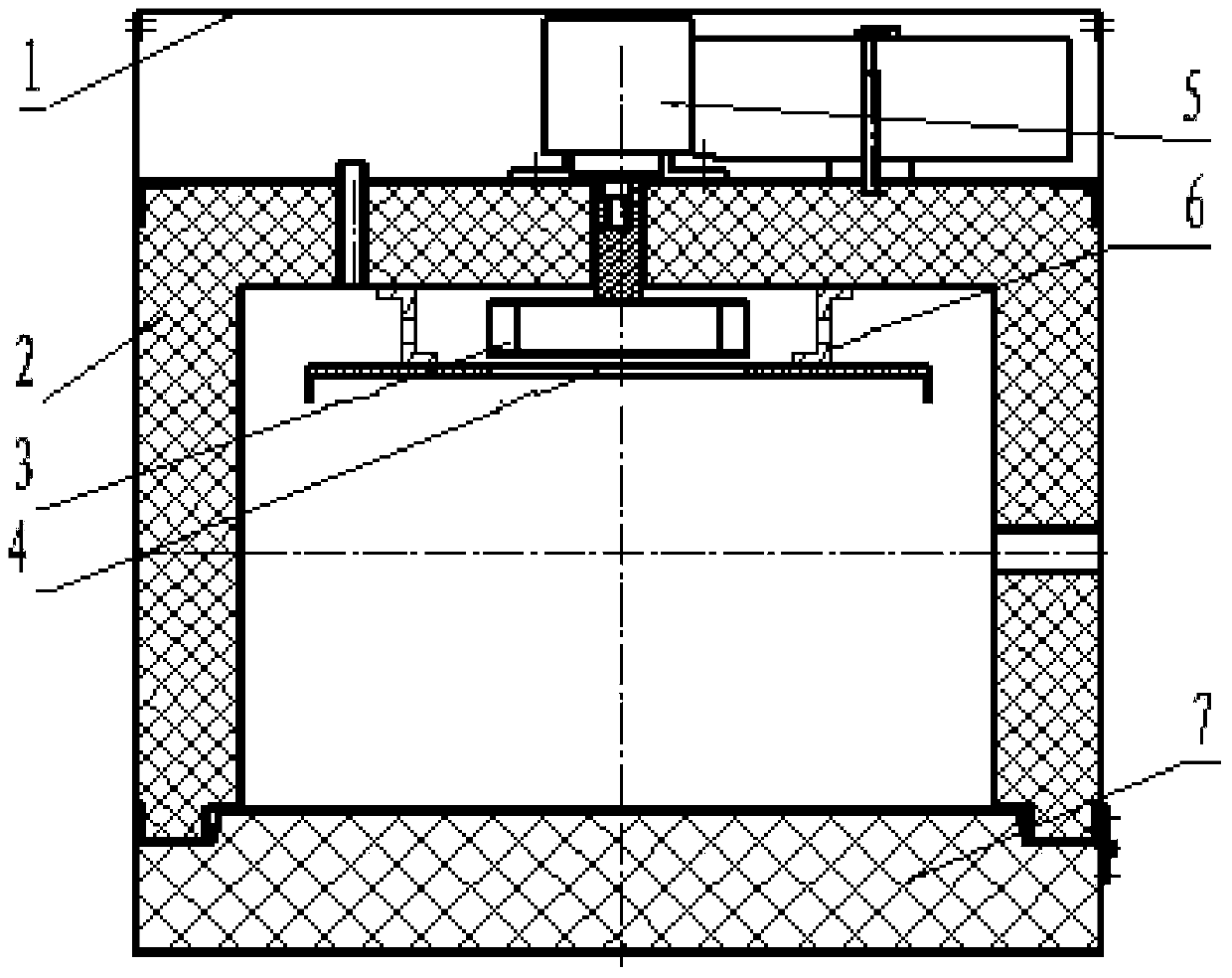

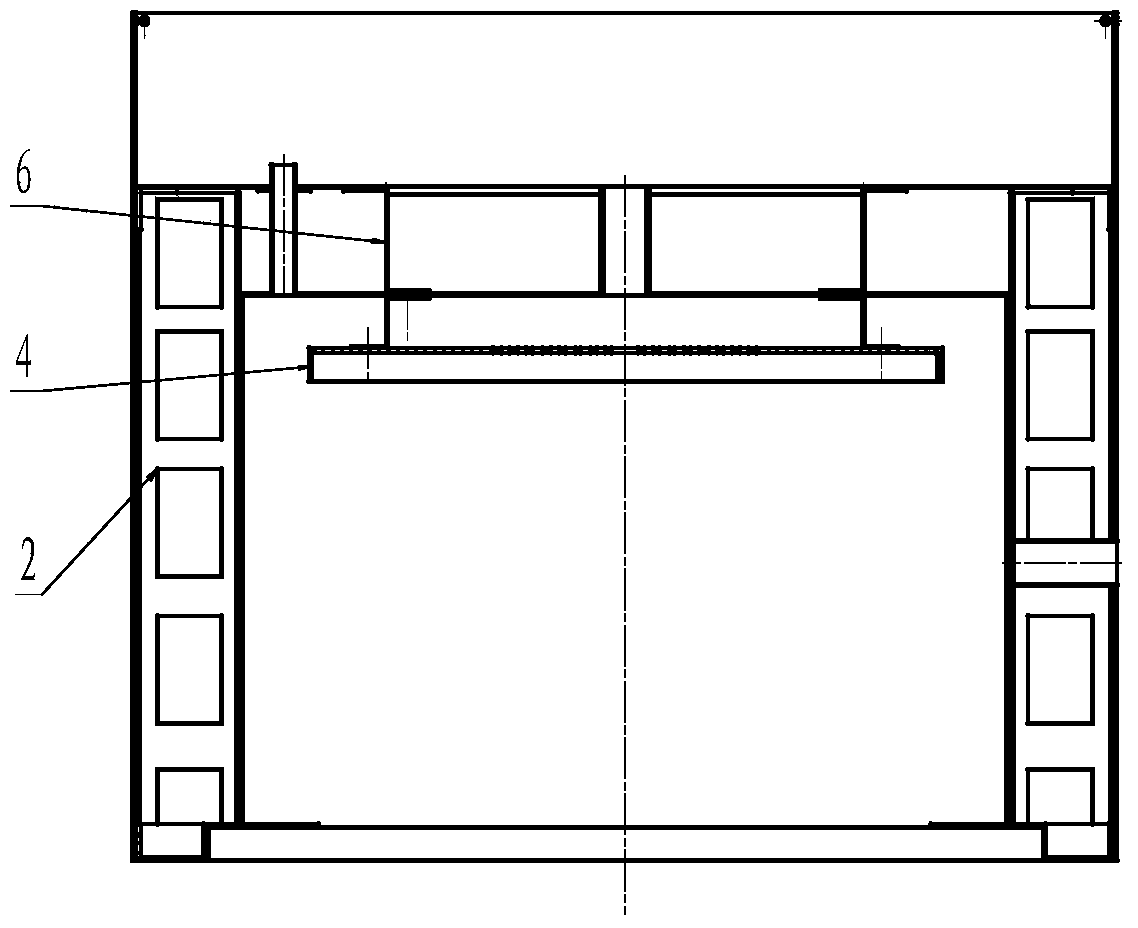

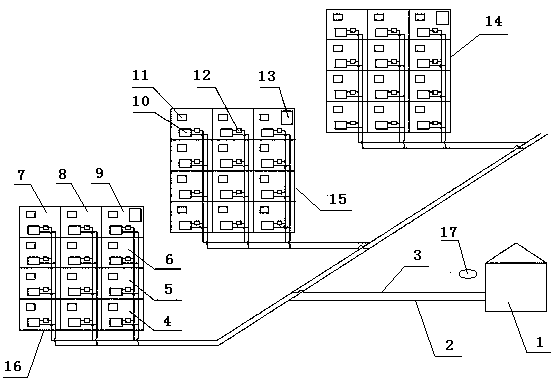

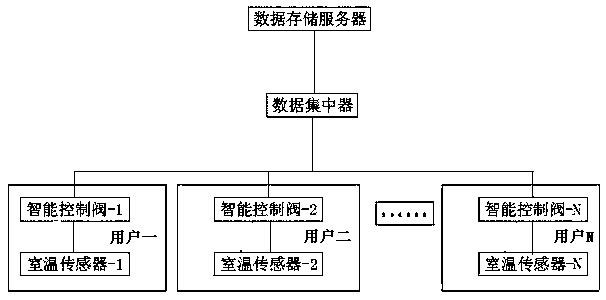

Urban heat supply data acquisition unit and heat supply centralized control method

InactiveCN101261022AEasy to manageReal-time monitoring of heatingLighting and heating apparatusSpace heating and ventilation detailsMeasuring instrumentData store

The invention relates to an urban heating data collecting device and a heating centralized monitoring method. The urban heating data collecting device is provided with a data collector; an input terminal receives and stores heating detection data from a measuring instrument and is connected with a wireless data transmission unit by a communication interface; the wireless data transmission unit sends the data stored by the data collector to a monitoring management center by a radio communication network; the heating centralized monitoring method comprises the following steps that: the heating data collecting device detects heating data of a heating unit by the measuring instrument; the heating data is collected by the heating data collecting device; according to a communication protocol, the heating data collecting device receives a command from the monitoring management center and sends the heating data to the monitoring management center by the radio communication network; the monitoring management center receives the heating data and outputs analytical results. The urban heating data collecting device and the heating centralized monitoring method can carry out real-time and on-line collection of operating data of the heating unit, improve the heating quality, carry out scientific examination on a heating enterprise and provide an effective scientific basis and a management platform for government sectors.

Owner:刁树杰 +1

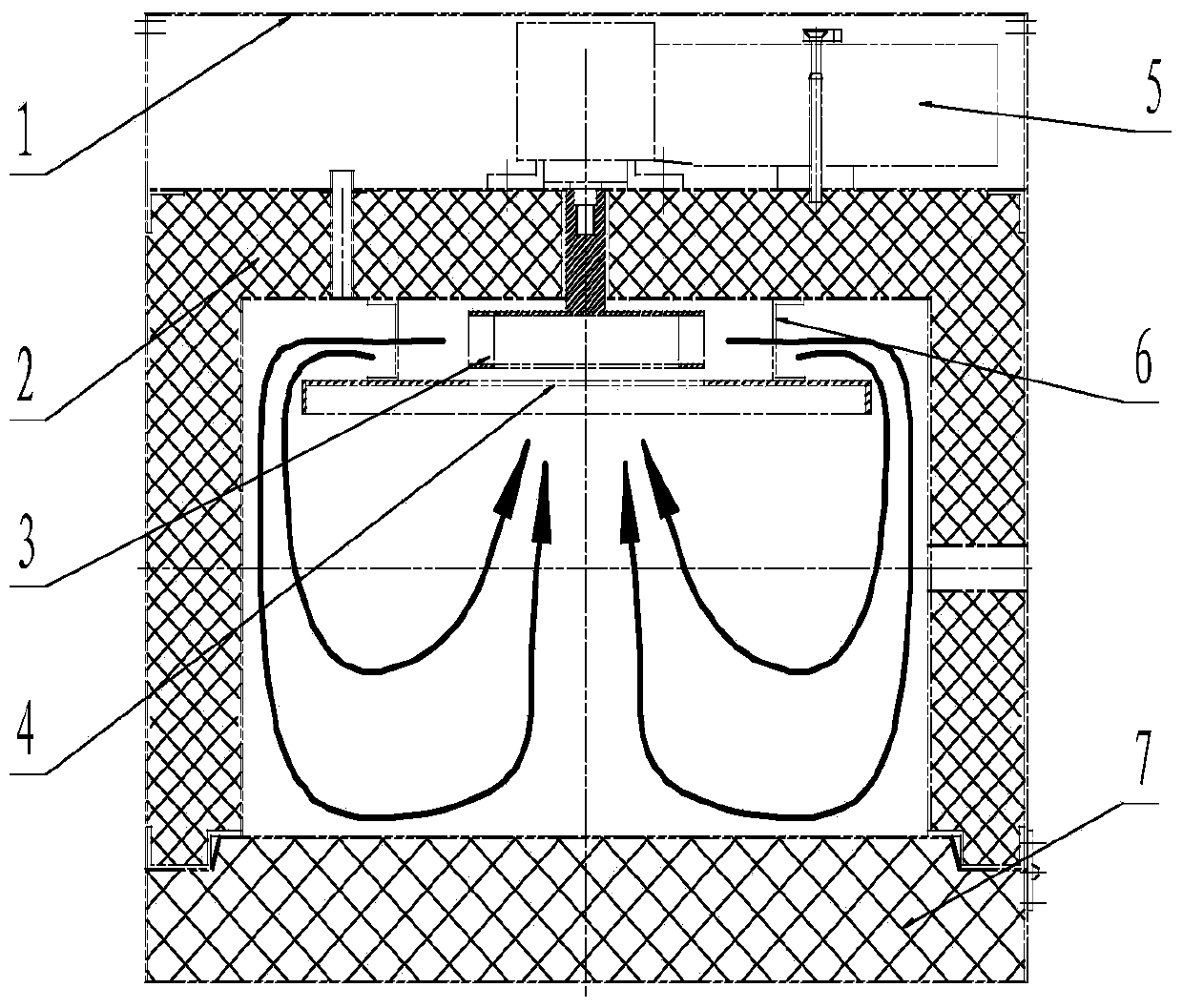

Aerodynamic heating furnace

InactiveCN103629838AAchieving High UniformityReduce consumptionOther heat production devicesThermal energyEngineering

The invention provides an aerodynamic heating furnace. An impeller is located in a furnace body. A guide plate is installed in the furnace body through a guide plate support and is fixed to the inner surface of a rear wall plate of the furnace body. Two surfaces, adjacent to the impeller, of the guide plate are spaced. An air inlet hole is formed in the center of the guide plate, and the air inlet hole and the center of the impeller are concentric. A plurality of airflow holes are evenly distributed in the circumference of an annular impeller support. The sum of the sectional areas of the airflow holes is 1-2 times the circumference area of the impeller. A guide edge protruding in the axial direction is arranged on the outer circumference of the guide plate and the guide edge faces towards an inner wall of the furnace body. Turbulence is increased by the right-angled guide edge and heating uniformity and the heating depth are improved by the right-angle guide edge. According to the aerodynamic heating furnace, wind energy is used as a heating medium, the impeller is driven by a motor, so that the wind energy is converted into thermal energy, high-uniformity of a temperature field is achieved through flowing of the wind energy, heating elements such as a heating tube can be omitted, the number of parts used for keeping the uniformity of the temperature field is reduced, the number of partial high temperature points is reduced, the furnace body heat capacity is reduced, the number of furnace body heat bridges is reduced, and therefore the purposes that energy consumption is reduced and the energy-saving effect is achieved are achieved.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

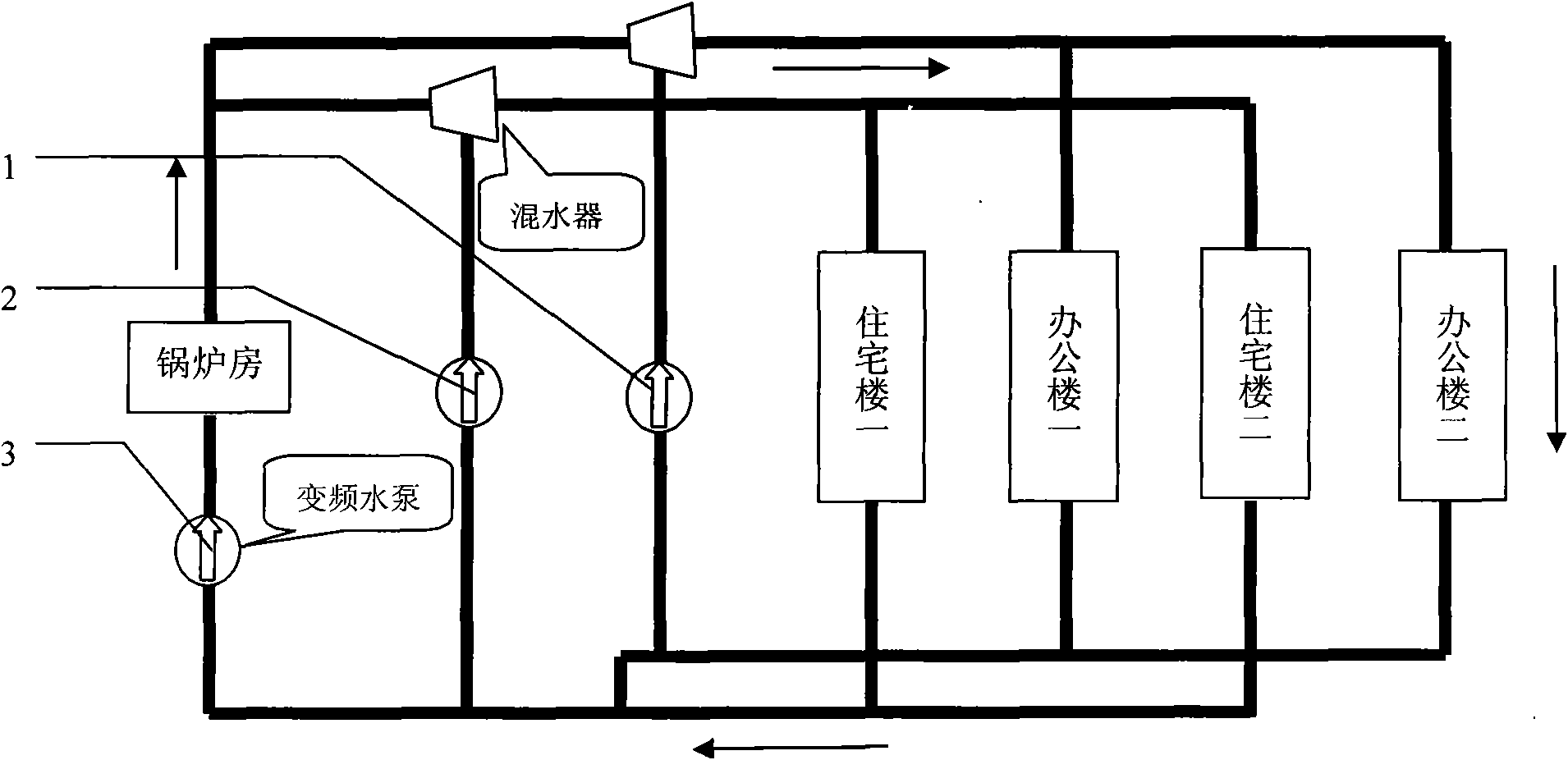

Energy-saving and emission-reducing regulation and control method for urban region boiler room central heating system

InactiveCN101571298AImprove heating qualityGood energy saving and emission reduction effectLighting and heating apparatusTemperatue controlUrban regionBoiler furnace

The invention belongs to the technical field of urban central heating, in particular to an energy-saving and emission-reducing regulation and control method for urban central heating. On the premise that a frequency converter pump is installed first for flow control, the regulation and control method adopts the following technical measures: 1) limiting the fluctuation range of the temperature in a boiler furnace to less than 20 DEG C and ensuring that the temperature of the inlet and outlet water of the boiler is a rated temperature of between 60 and 130 DEG C; 2) adopting 'high flow and small temperature difference' for a pipeline system, wherein in the pipeline at user end, the flow is 1.1 to 1.25 times as much as calculated circulating flow, and the temperature difference is reduced by one fifth to one third; and 3) separately heating according to the functions of buildings, quantitatively predicating the change of heating load, and regulating heating according to an optimal regulating method. The regulation and control method has the advantages of realizing the regulation of the temperature of conventional heat source outlet water, regulating system temperature and flow, effectively improving heating quality and reducing the energy consumption of unit area.

Owner:NORTHEASTERN UNIV

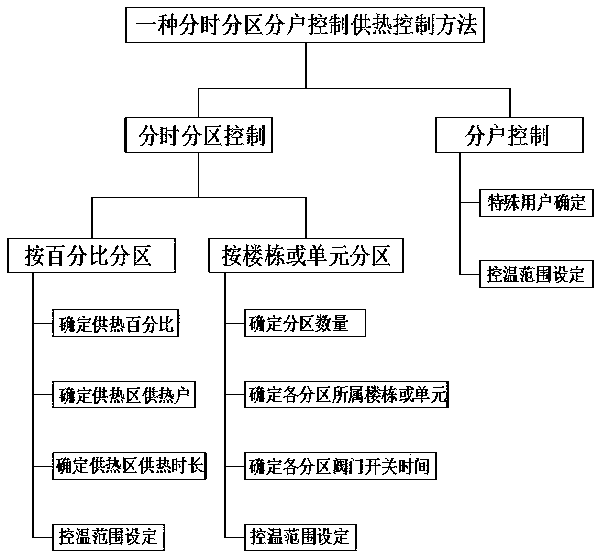

Time-sharing area-sharing user-sharing controlled heat supply device and control method

ActiveCN108644886AMeet needsSave energyLighting and heating apparatusSpace heating and ventilation detailsTemperature controlTime-sharing

In order to solve the problems in the prior art, the invention creatively discloses a time-sharing area-sharing user-sharing controlled heat supply control method. The heat supply control method is scientific and reasonable, is strong in applicability and is good in effect; according to the advanced electromechanical control technology, the invention also provides a time-sharing area-sharing user-sharing controlled heat supply device, and the heat supply device is combined with multi-disciplinary knowledge, is reasonable in structure, is convenient to use, and is advanced in control means. Theheat supply device realizes indoor temperature control of an end user by virtue of flow control over warming equipment in the end user, so that the hydraulic disorder problem is avoided, and balancedheat supply and precise heat supply can be realized; and the time-sharing area-sharing user-sharing method is adopted for heat supply, so that total flow of a heat supply system can be remarkably reduced, electric energy consumption of a heating station is reduced, and energy is effectively saved.

Owner:JILIN HONGSHEN TECH +1

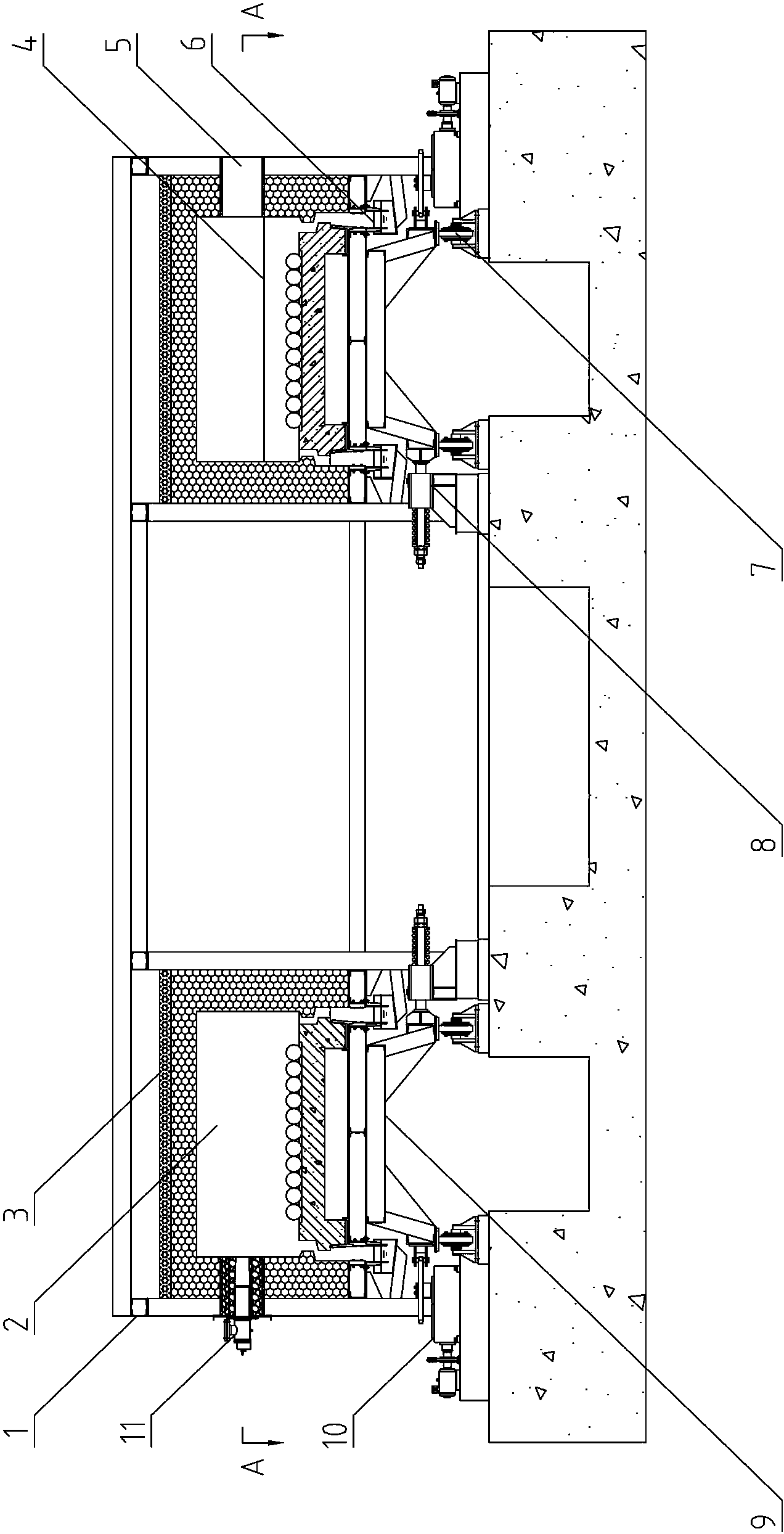

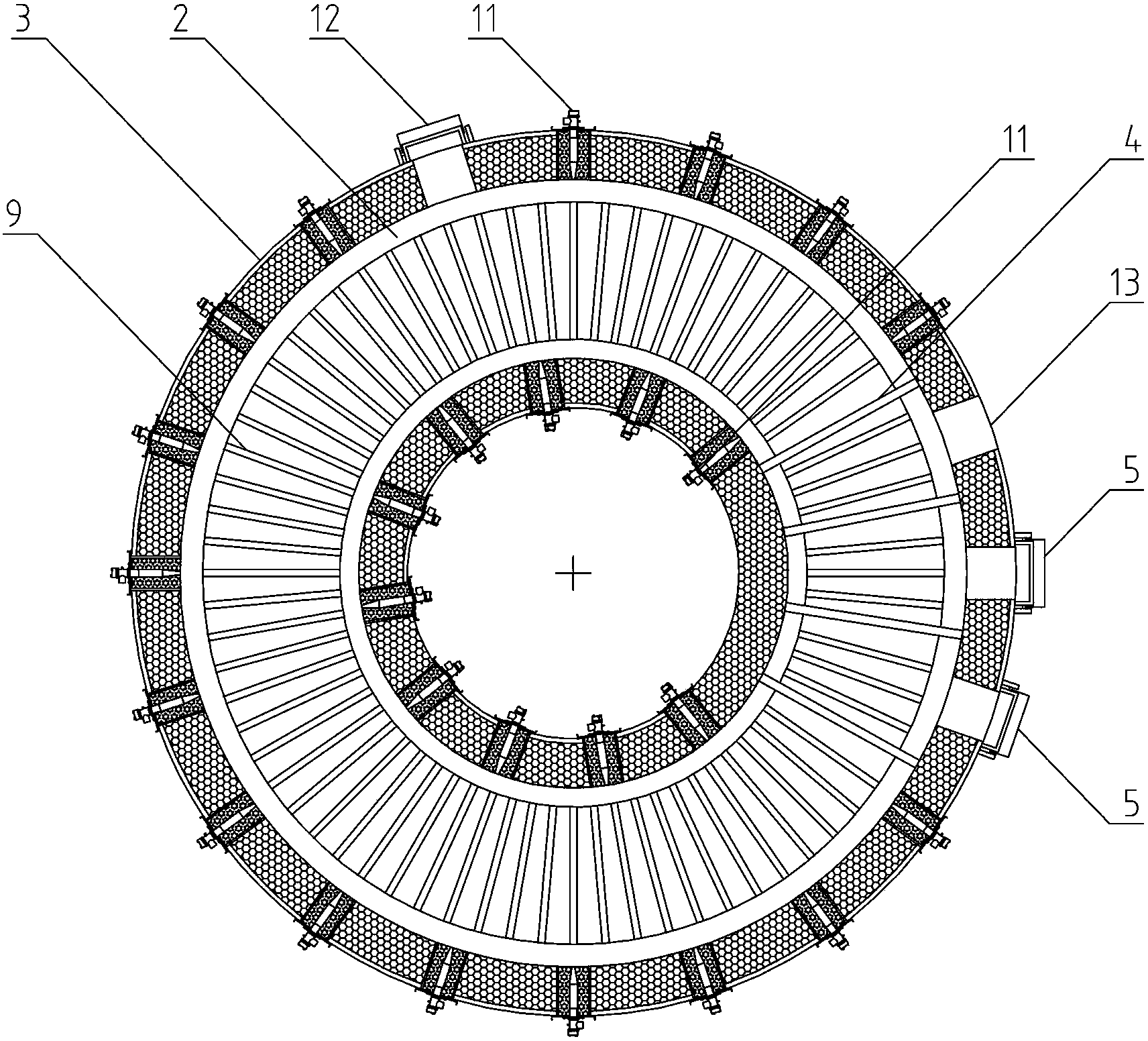

Annular heating furnace with rotary furnace bottom

InactiveCN103773922AImprove heating qualitySolve the labor-intensiveFurnace typesCombustorHigh energy

The invention relates to an improvement of a wear resistant steel ball heat treatment heating furnace, and concretely relates to an annular heating furnace with a rotary furnace bottom. The annular heating furnace is provided with a furnace body, feeding and discharging ports, combustors, a maintenance furnace gate and a smoke outlet; and the bottom of the furnace body is respectively provided with a rotary driving mechanism, a lateral positioning mechanism and a support raceway; a hearth has an annular structure, the bottom of the hearth is a water seal tank provided with a furnace bottom, and the furnace bottom is composed of a heat insulation panel, a skirt rim sealing plate, a structural support, a tooth ring, an annular rail surface and a baffle ring. The problems of large labor intensity of an operator, low work efficiency, large hidden safety trouble, unstable heating quality and high energy consumption per unit output of present wear resistant steel ball quenching treatment heating furnace with inclined-bottom hearths are solved, and present wear resistant steel ball heat treatment heating furnaces are mainly improved in the invention.

Owner:湖北中冶窑炉有限公司

Method for manufacturing cast-iron radiator without sand inside cavity

A technology for manufacturing the heat radiator with cast iron, which has no sand in its internal cavity, includes preparing sand core, modelling, loading sand core in mould, and casting. Said steps for preparing sand core includes preparing resin sand from sand, resin, dibutyl ester, calcium stearate, urotropine and silane as coupling agent through mixing, preparing sand core by moulding, solidifying, demoulding and trimming.

Owner:董立春

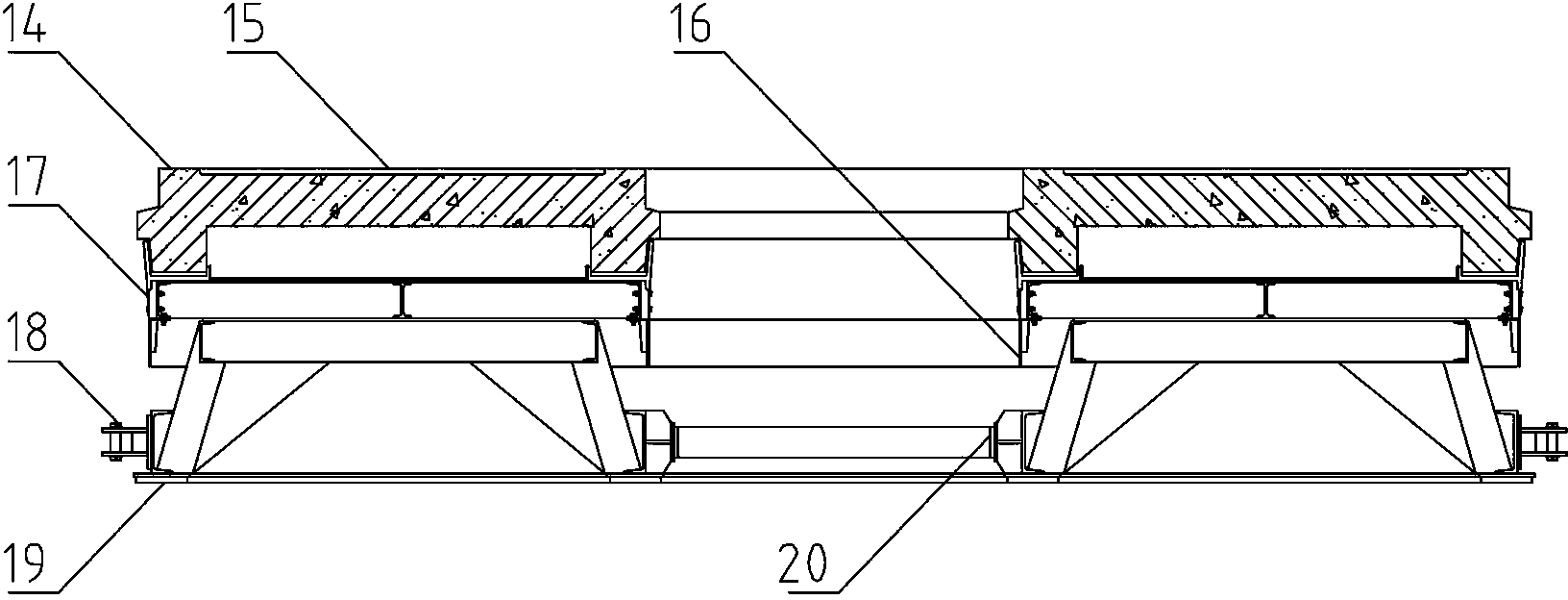

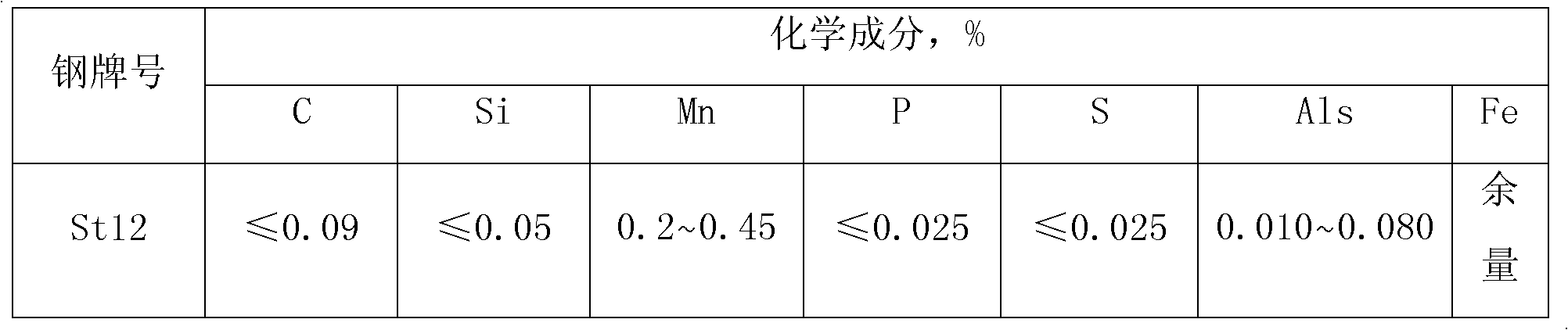

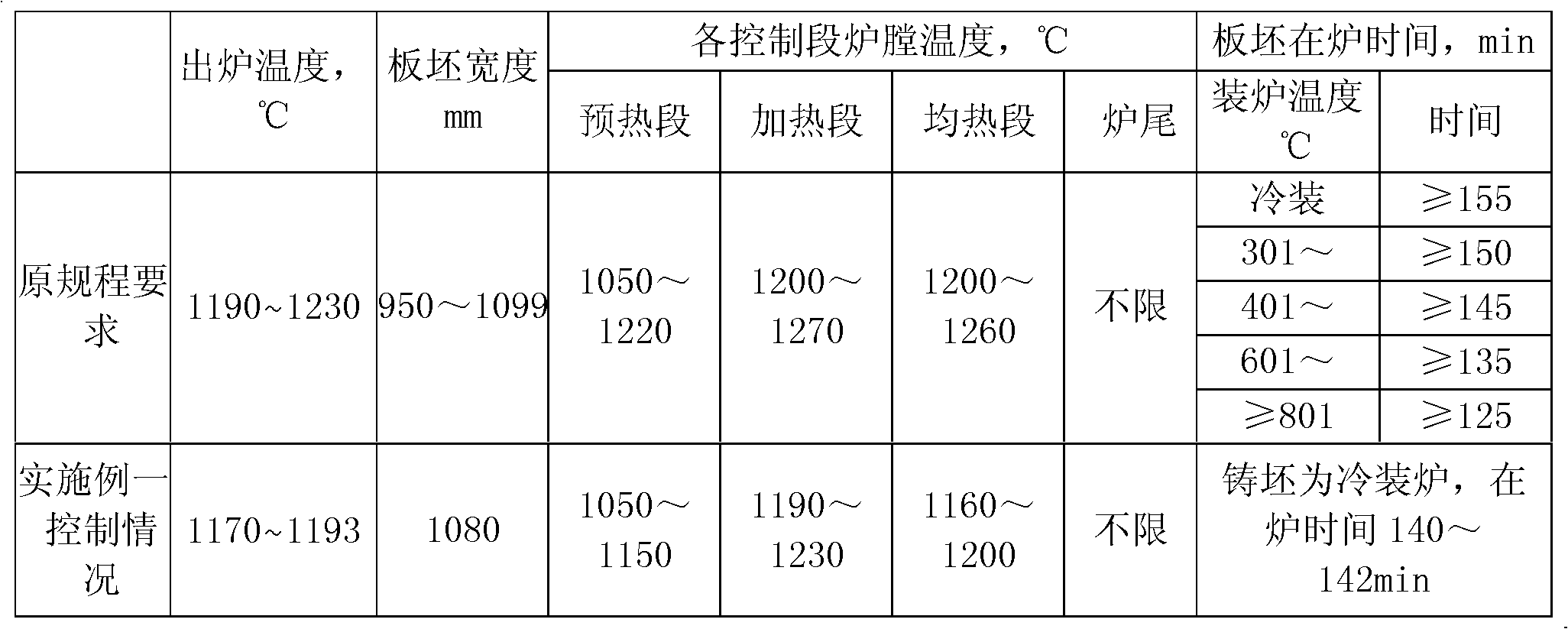

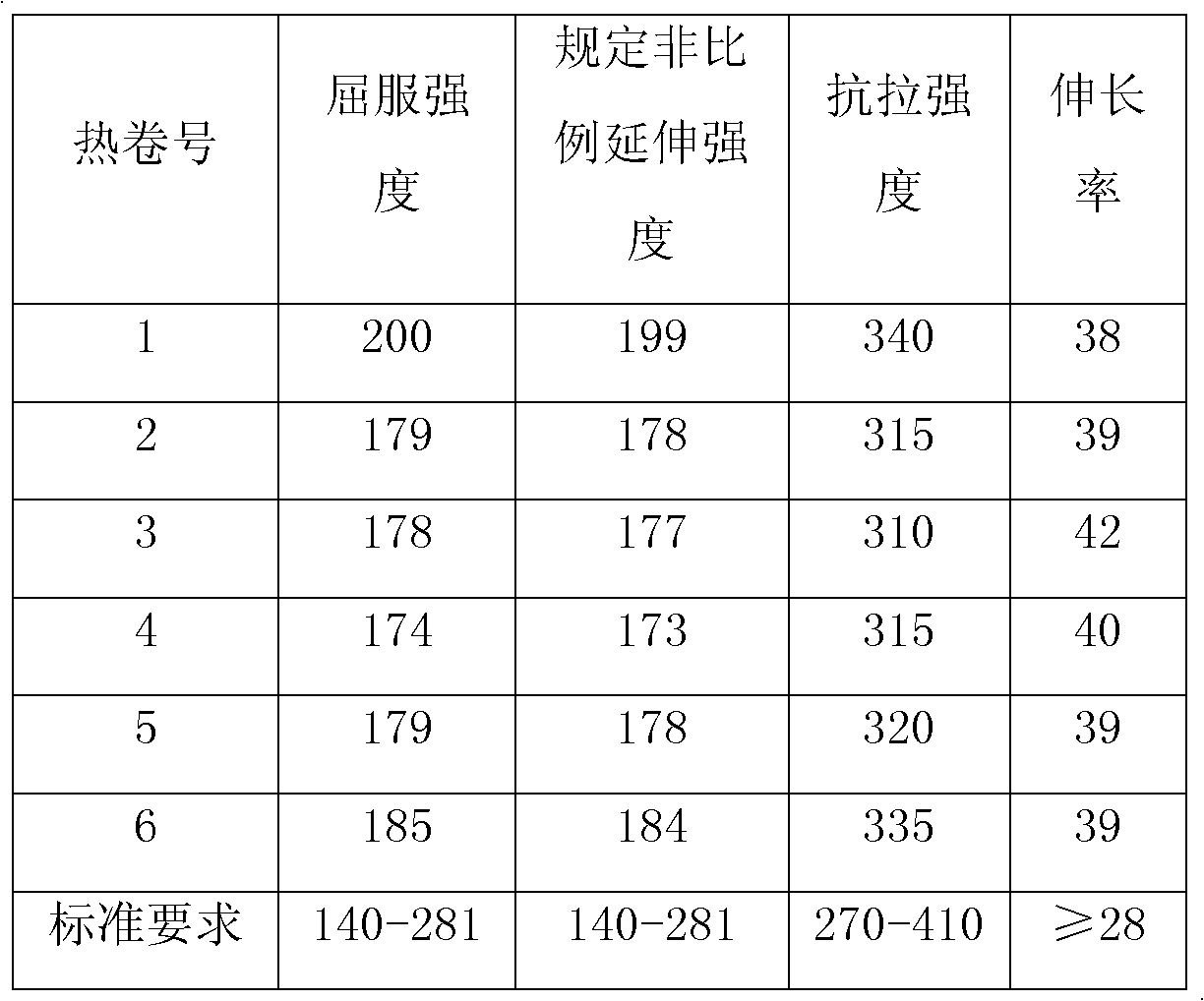

Hot rolling heating method for low-carbon aluminum killed steel casting blank

The invention belongs to the technical field of production of hot rolling strip steel, and in particular relates to a hot rolling heating method for a low-carbon aluminum killed steel casting blank. The invention aims to solve the technical problem of providing a hot rolling heating method for the low-carbon aluminum killed steel casting blank, and the hot rolling heating method has low heating temperature and short heating time. To solve the technical problem, the invention uses the technical scheme that the temperature of a preheating section of a heating furnace is 1050-1150 DEG C, the temperature of a heating section is 1185-1230 DEG C, the temperature of a holding section is 1160-1200 DEG C, and the heating time of the heating furnace is 135-147min. By adopting the method of the invention for heating the low-carbon aluminum killed steel casting blank, the uniformity of the heating temperature of the low-carbon aluminum killed steel can be improved, the rolling process requirement is met, the heating temperature of the low-carbon aluminum killed steel casting blank is reduced by 40 DEG C averagely, low temperature heating is realized, the heating time is reduced by 10 minutes averagely, the yield and the heating quality of the heating furnace are improved, the fuel consumption of the heating furnace is reduced, and the comprehensive effects of increasing yield, guaranteeing quality, saving energy and reducing consumption are obtained.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

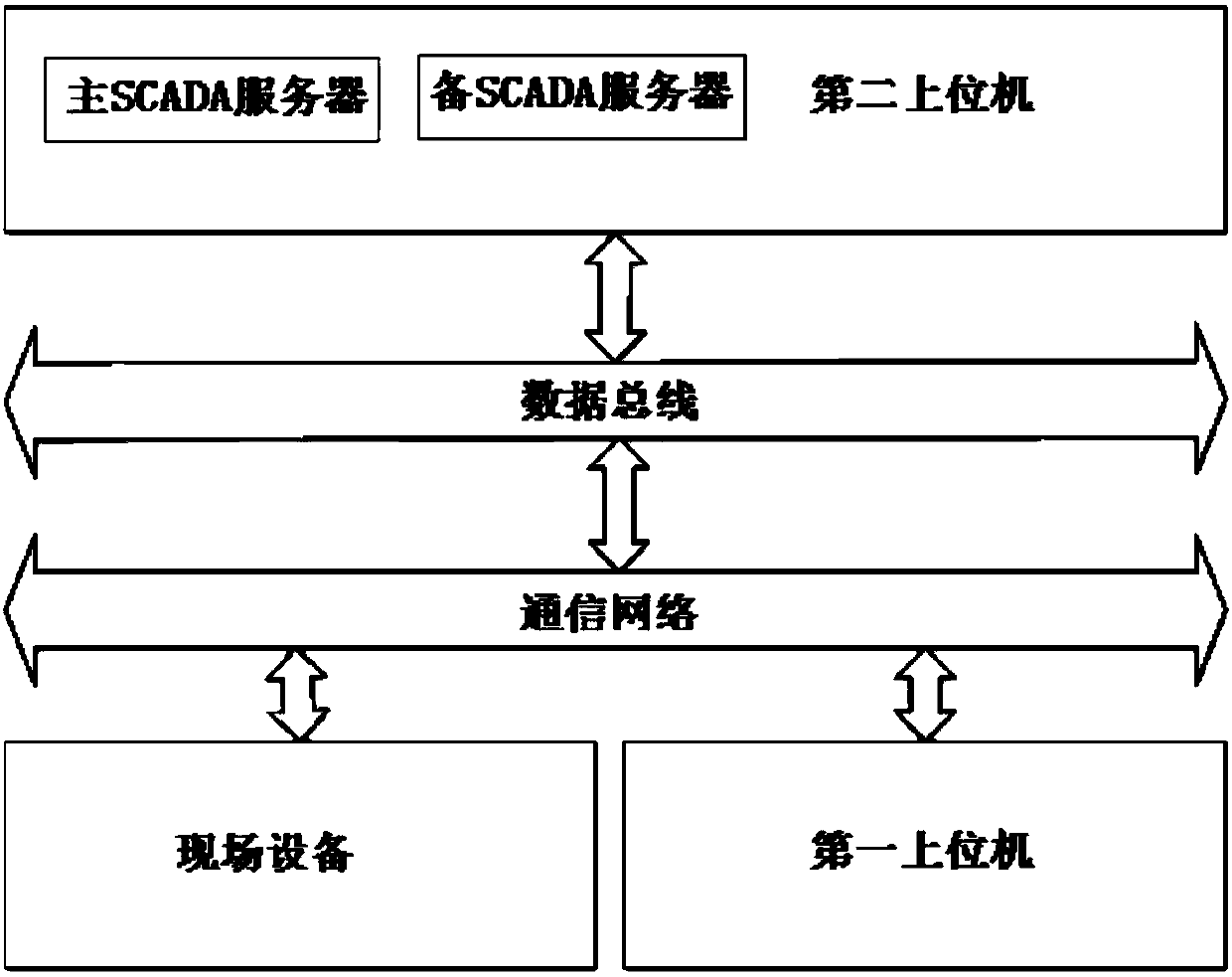

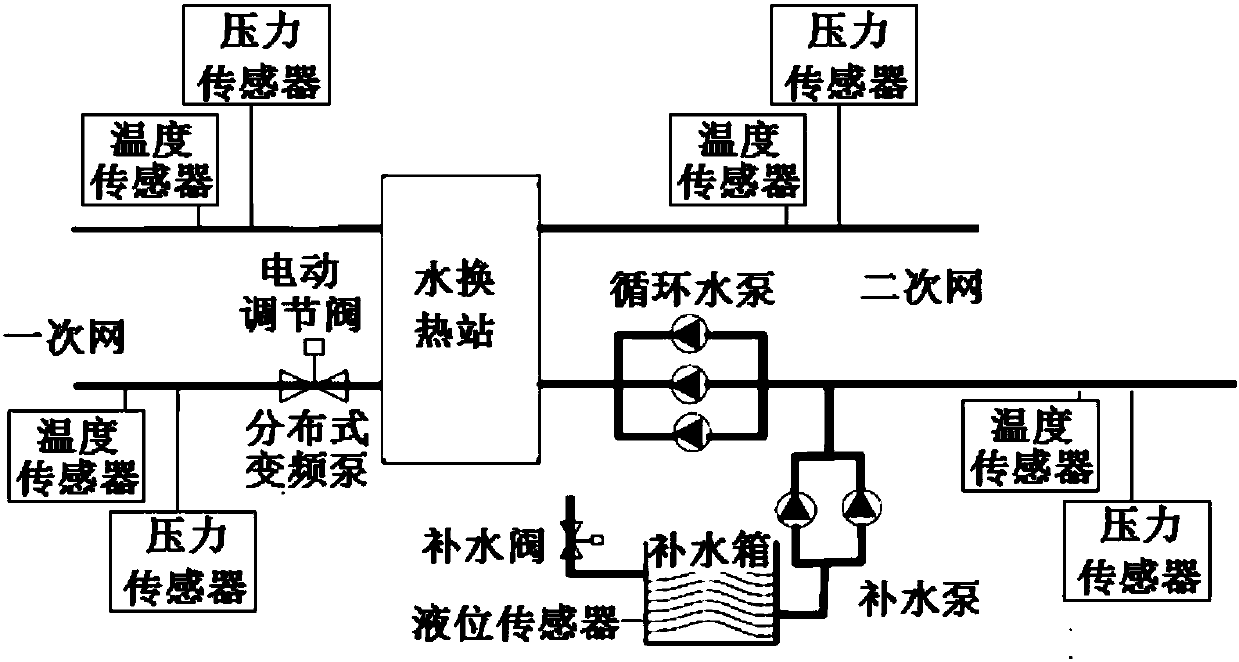

Heat supply network balance control system

PendingCN107588453ASolve the problem of horizontal hydraulic imbalanceSolve the long-standing problem of uneven heating and coolingLighting and heating apparatusSpace heating and ventilation detailsControl systemComplement system

The invention relates to a heat supply network balance control system. The technical problems that hydraulic imbalance is not completely solved and interfere of outdoor temperature changes exists aresolved. The heat supply network balance control system comprises a site device, a first upper computer and a whole network balance module connected with the site device and the first upper computer sequentially through a communication network and a data bus, and the whole network balance module is arranged in a server located in a second upper computer. The site device comprises a first sensor, anelectric valve, a distributed variable frequency pump, a second sensor, a circulating water pump, a water complementing system and a field controller, wherein the first sensor, the electric valve andthe distributed variable frequency pump are arranged on a primary network; the second sensor, the circulating water pump and the water complementing system are disposed on a secondary network; and the field controller is used for controlling the electric valve, the distributed variable frequency pump and the water complementing system. The first sensor and the second sensor each include an outdoor temperature sensor. Through the technical scheme, the problem is solved well, and the heat supply network balance control system can be used for heat supply network balance control of centralized heating.

Owner:烟台华蓝新瑞节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com