Patents

Literature

157results about How to "Ensure complete combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

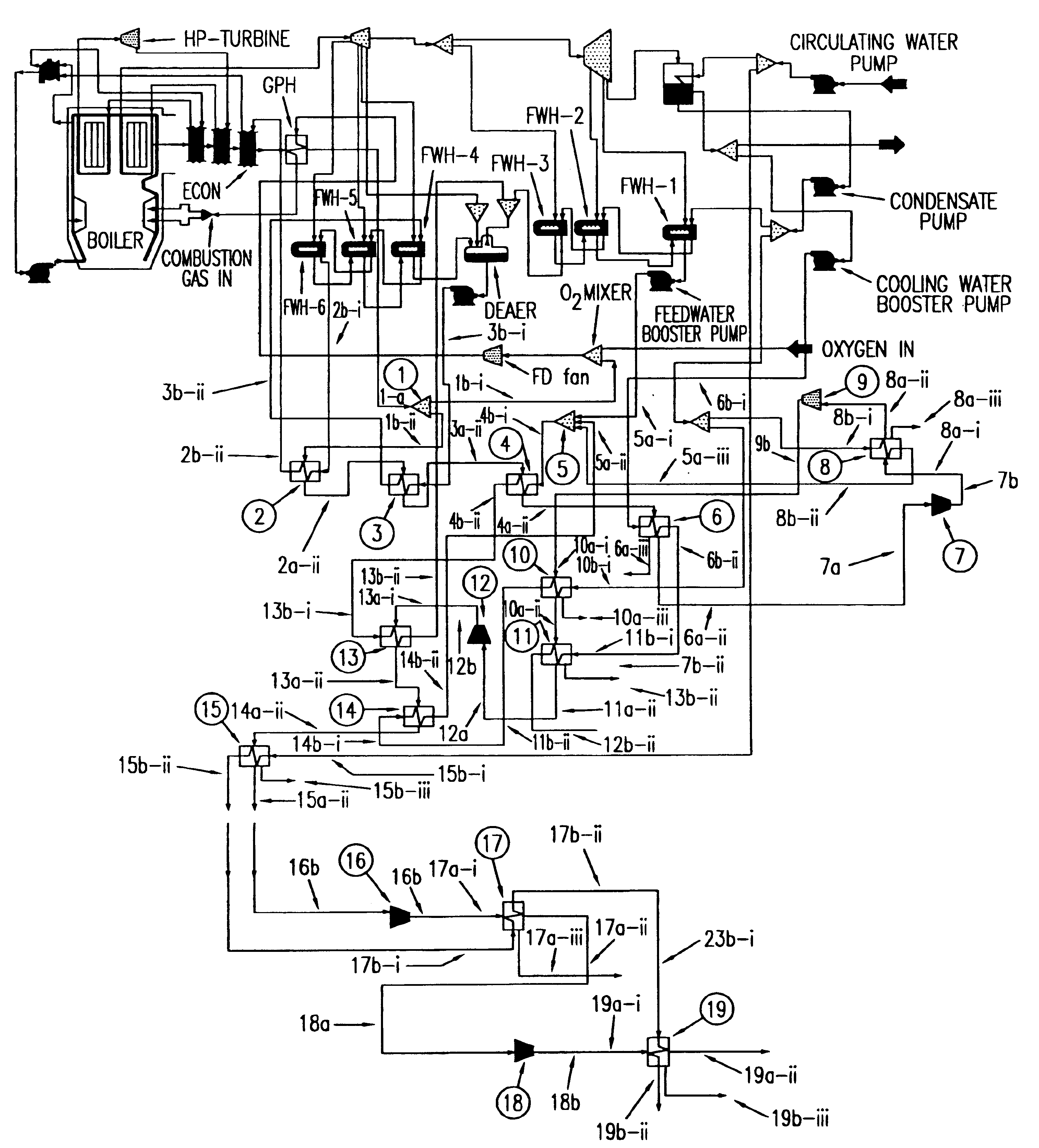

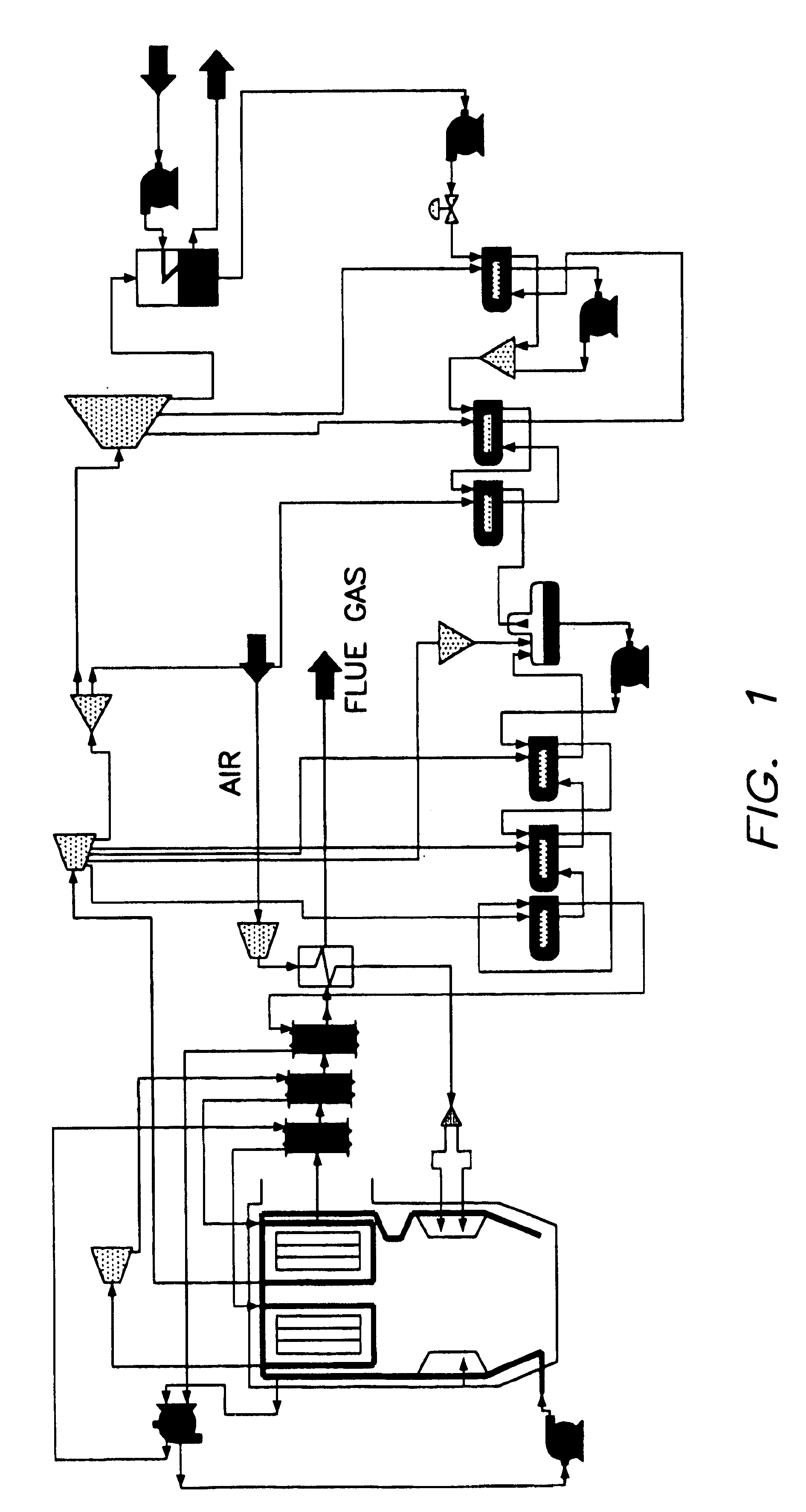

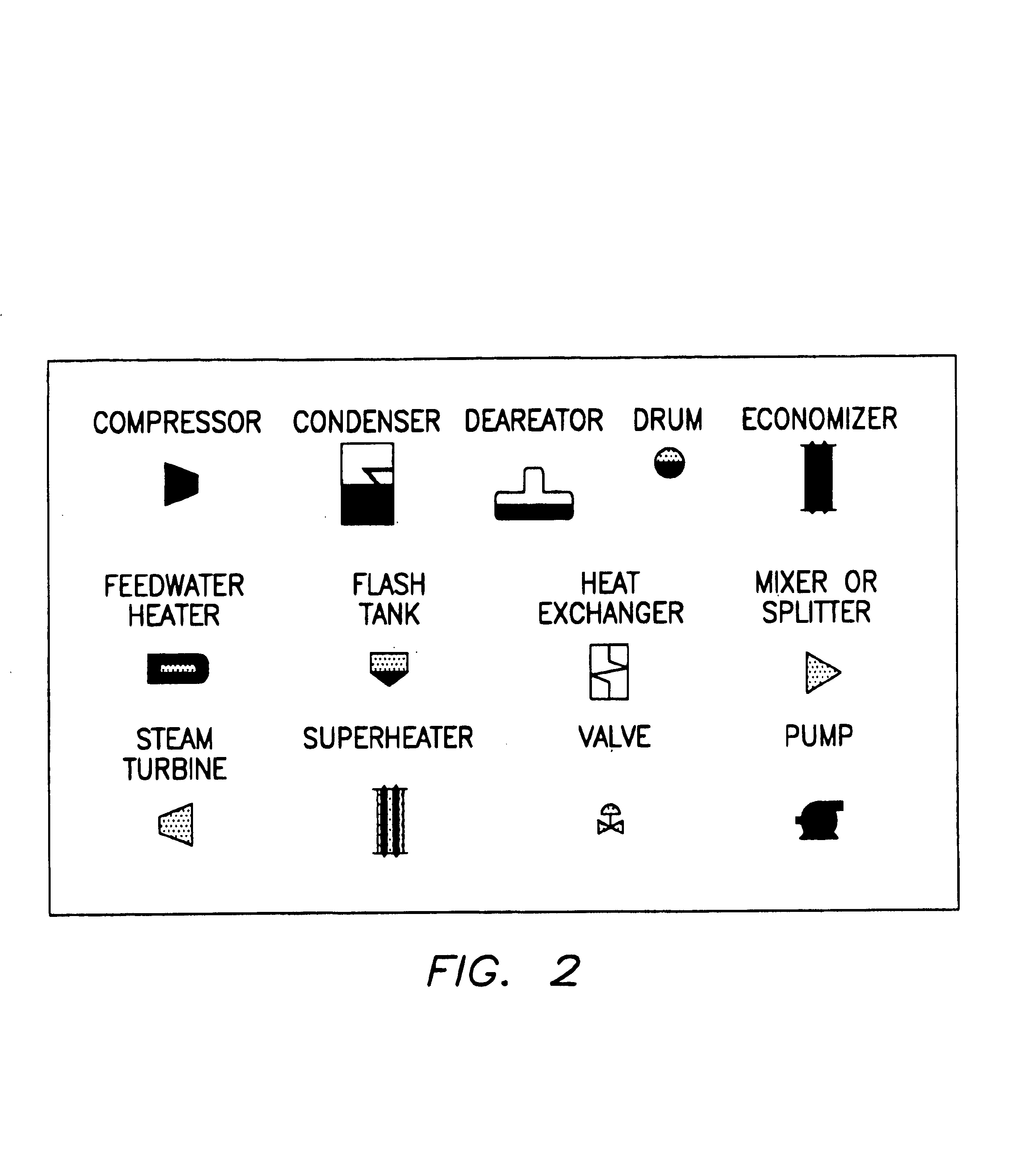

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

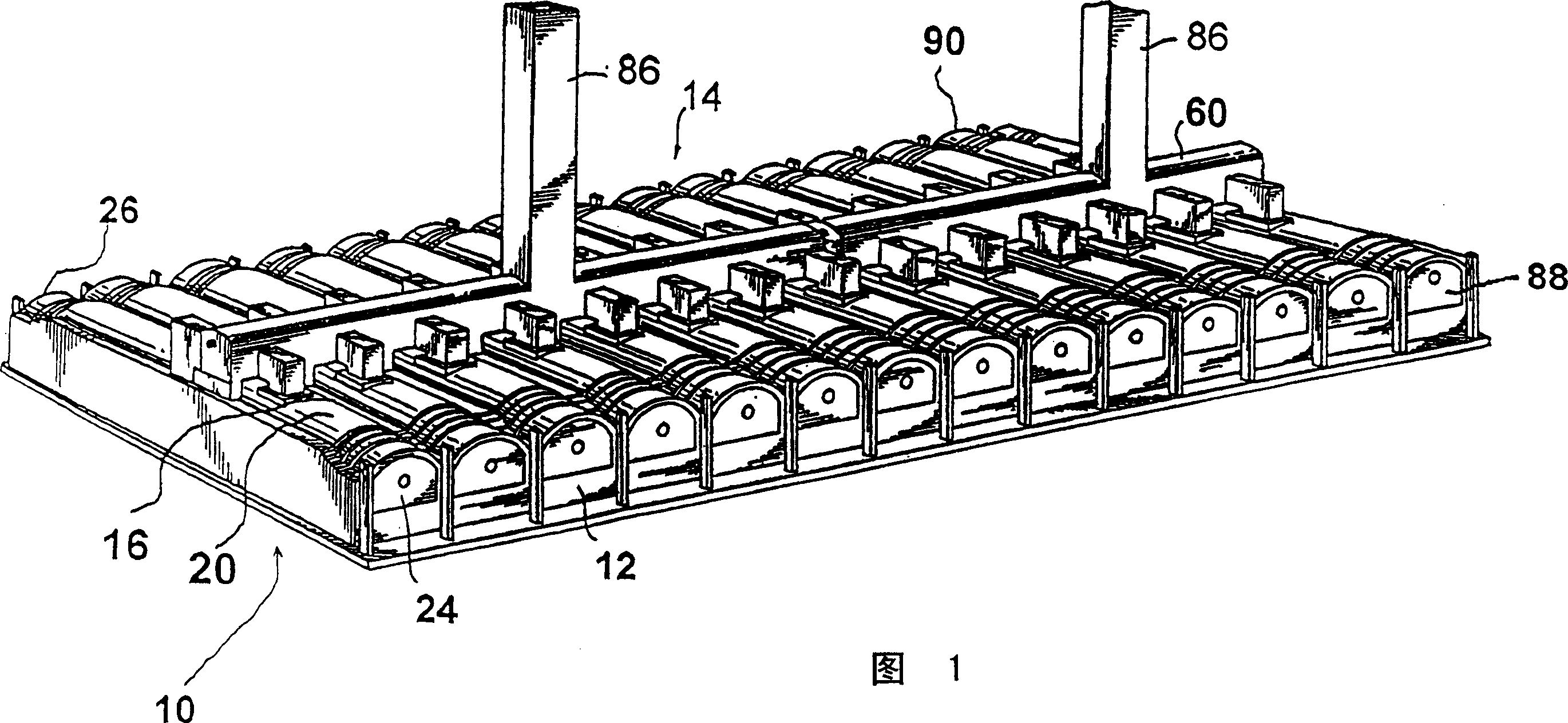

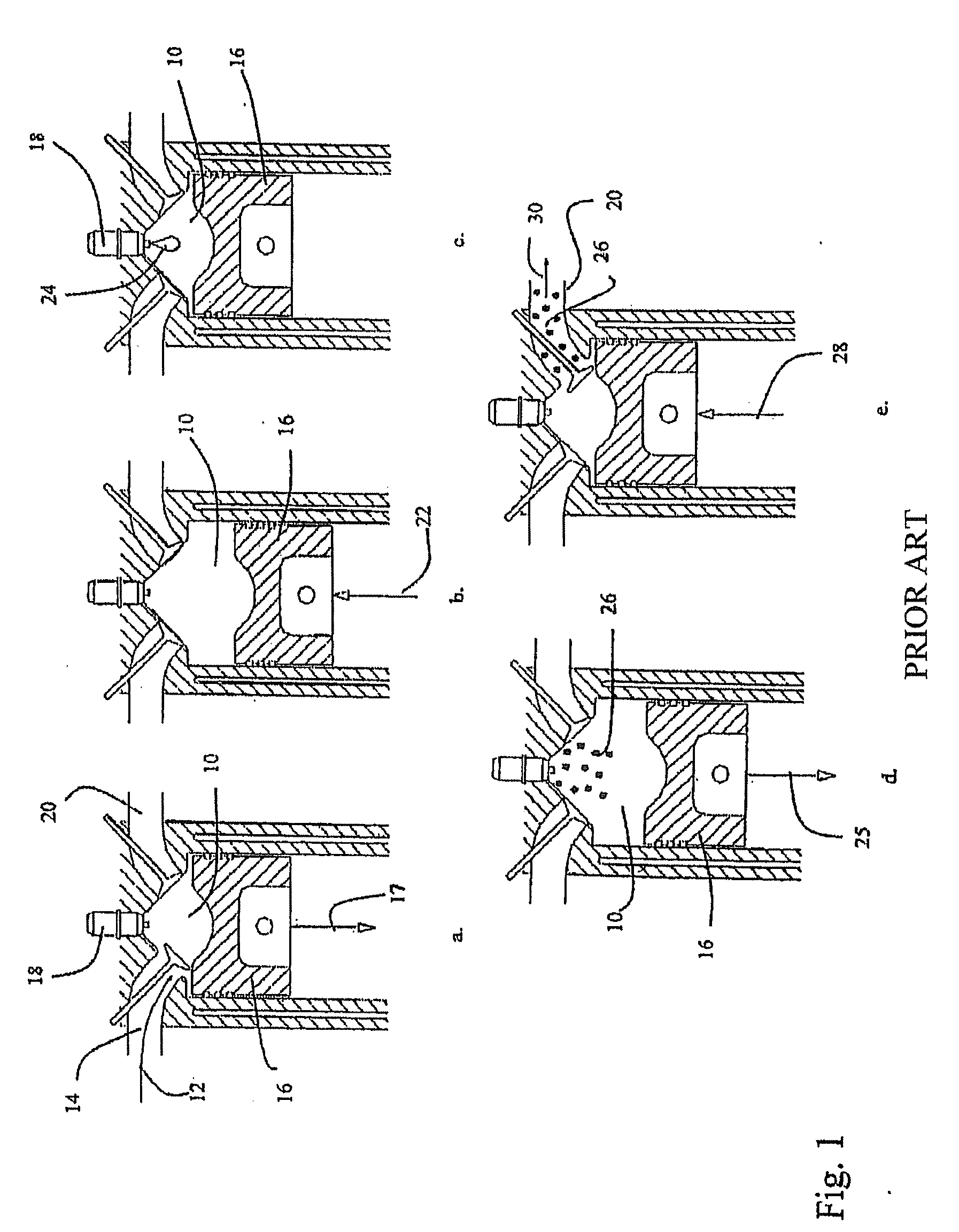

Coke oven flue gas sharing

InactiveCN1527872AExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensFlue gasProduct gas

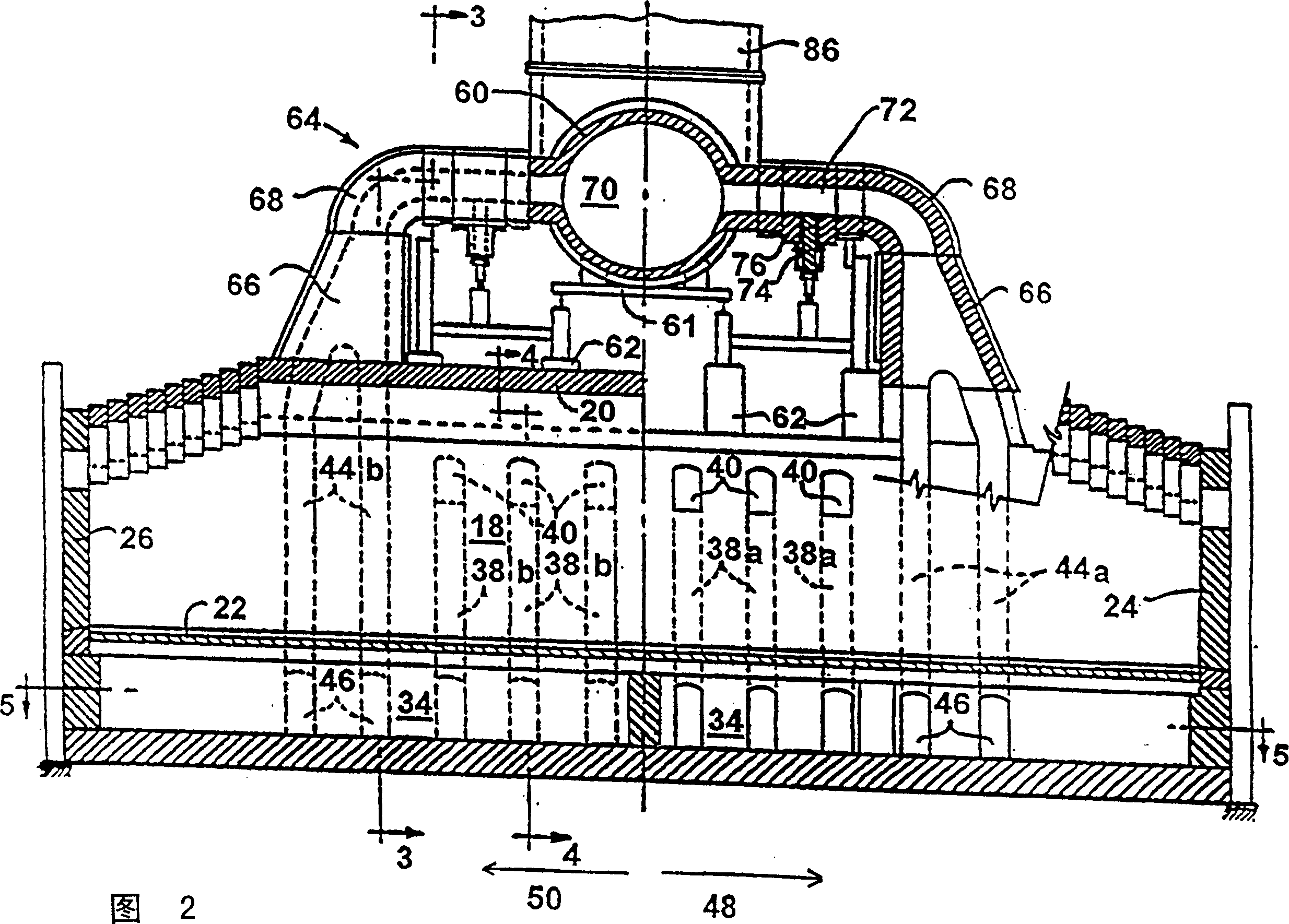

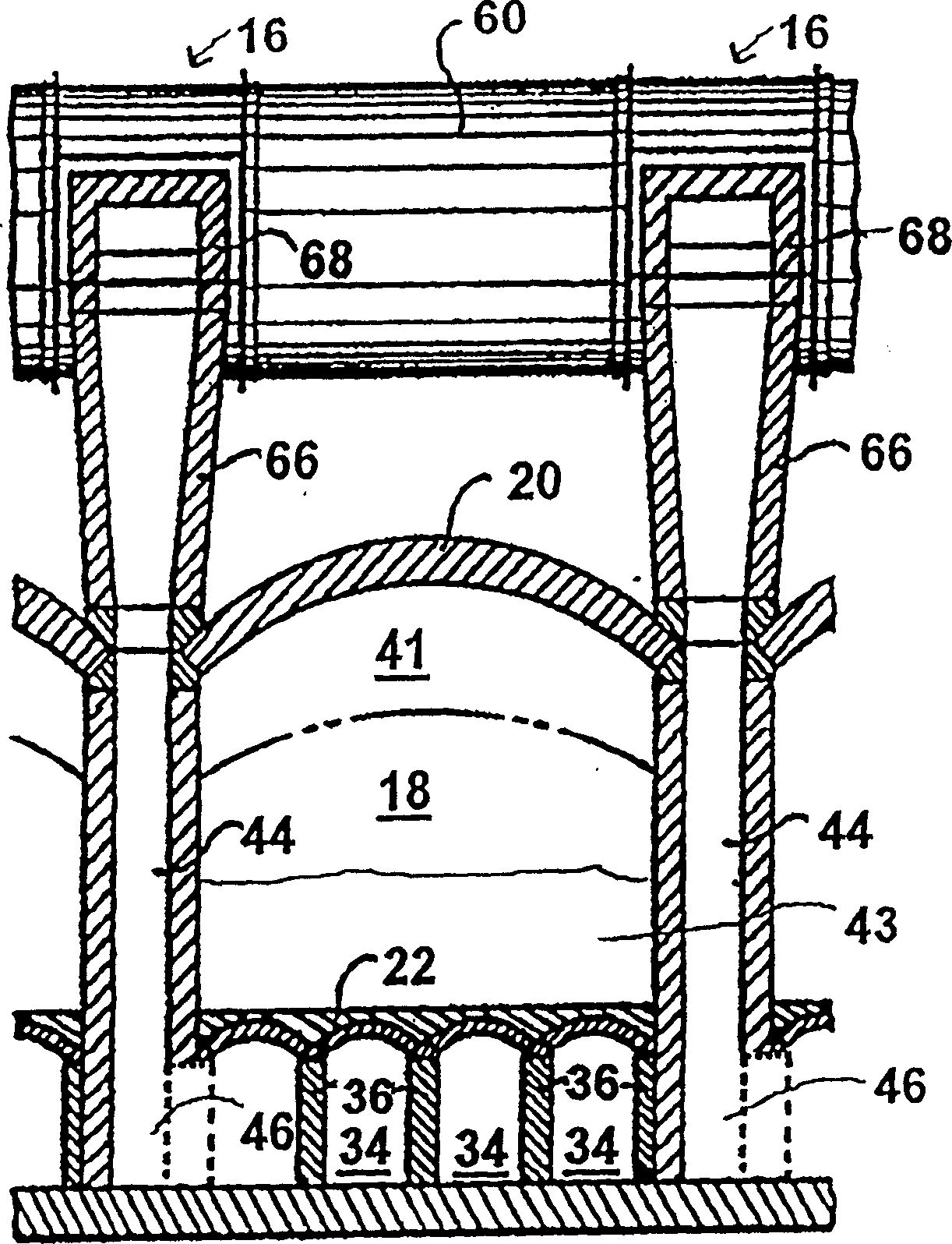

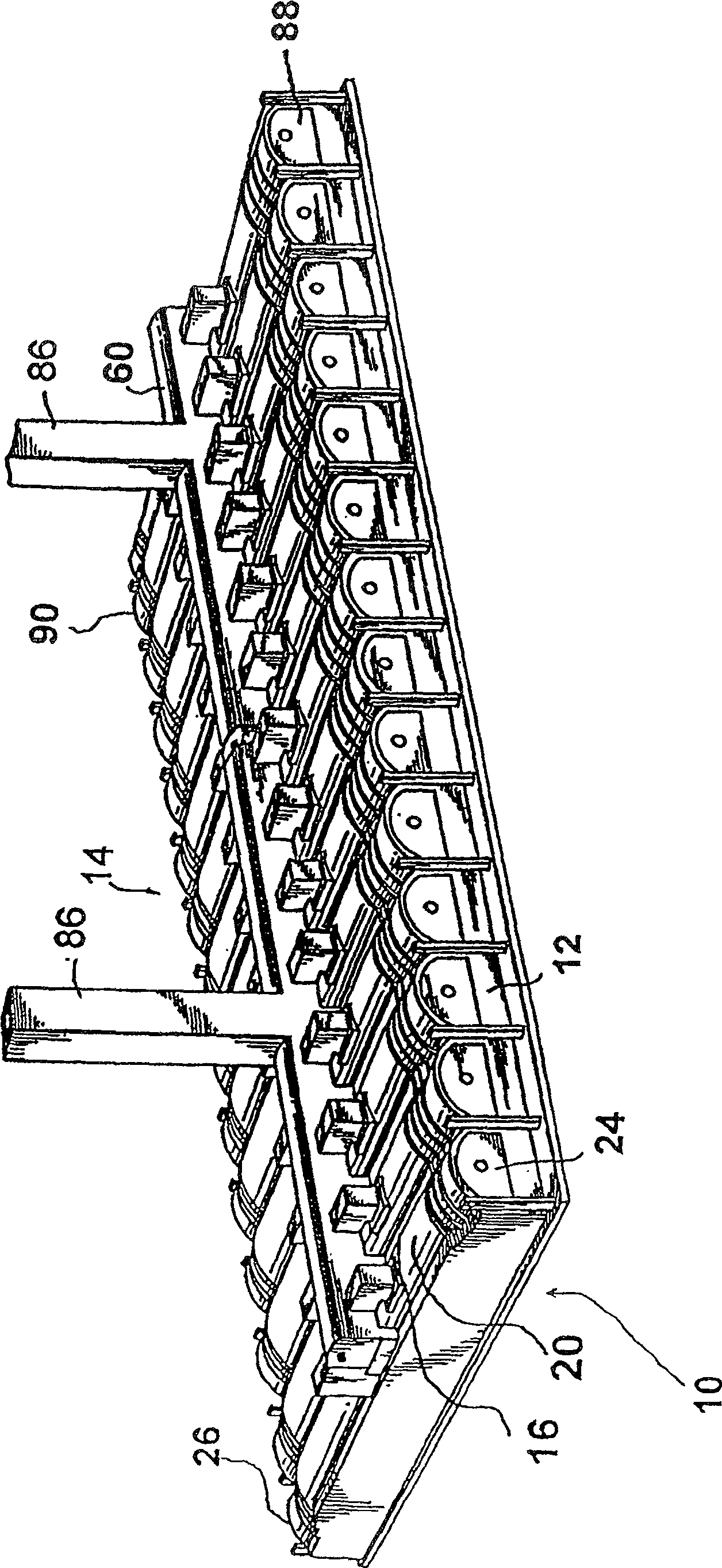

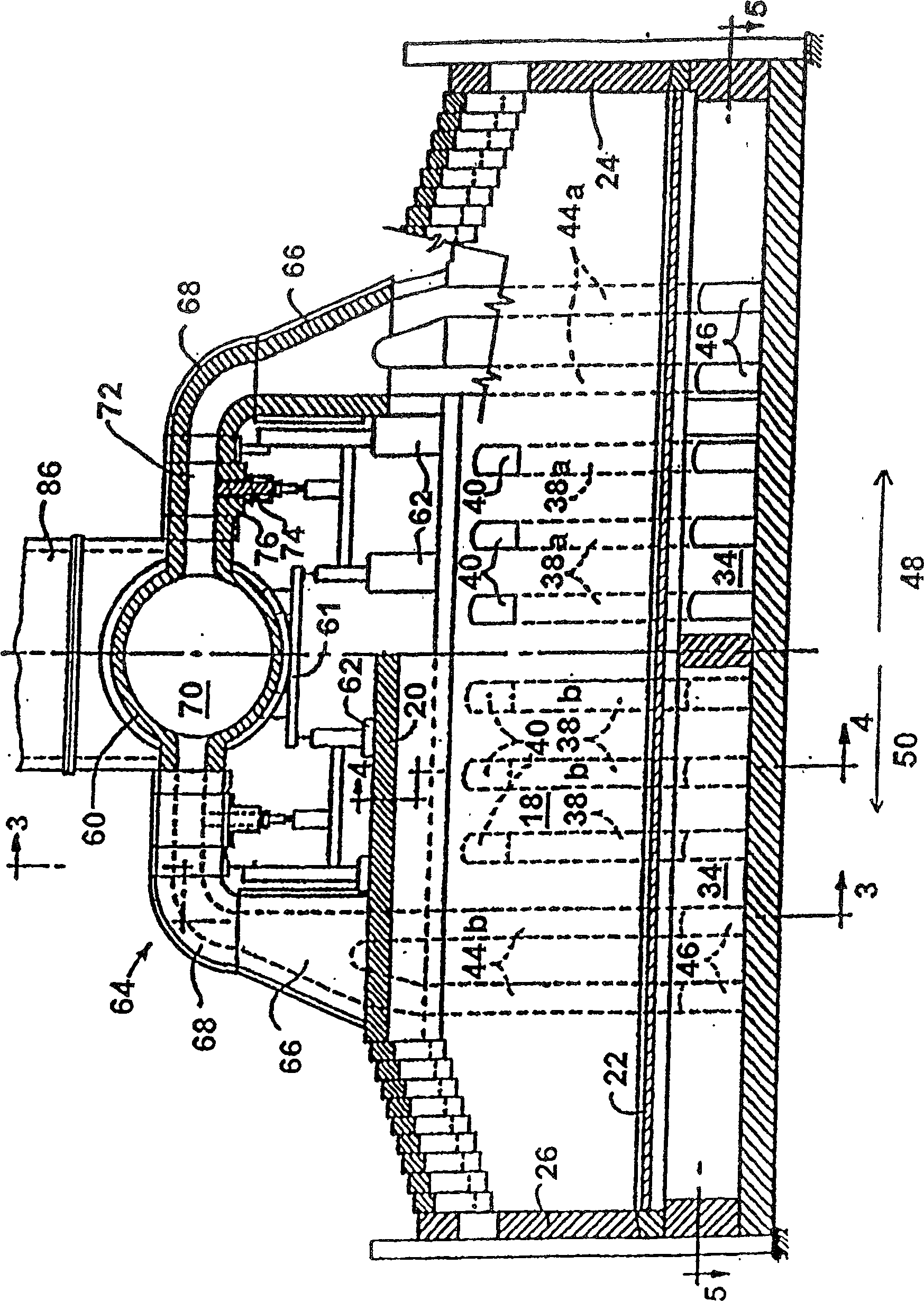

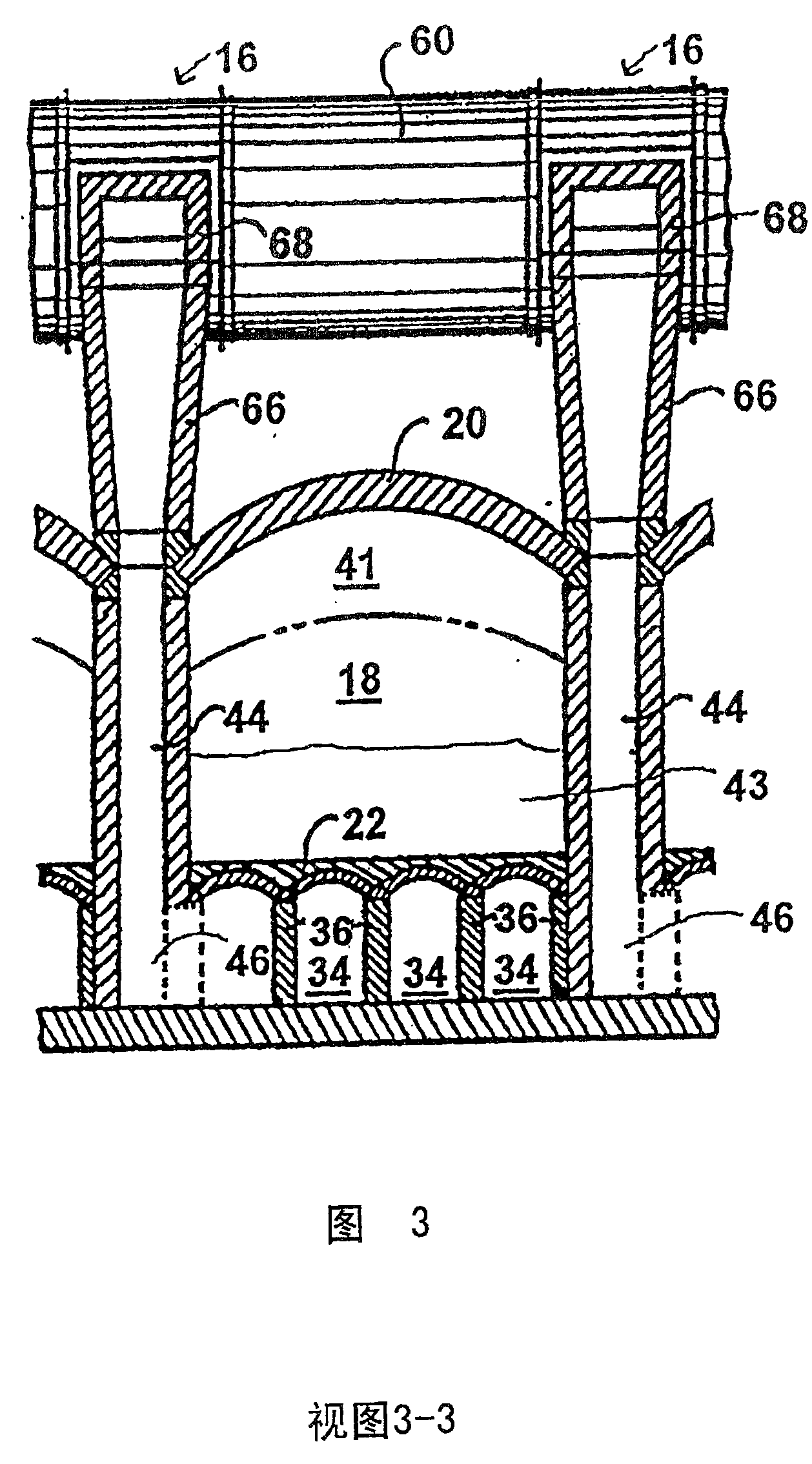

The invention provide a method and apparatus for decreasing gas flow rates in a sole flue gas system for a coke oven during at least an initial coking operation after charging a coking oven with coal (43). The method includes providing a duct system (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) to direct at least a portion of gas from a gas space (41) in first coking chamber (18) to the second coke oven thereby reducing a gas flow rate in the first sole flue gas system of the first coke oven. Reduction in sole flue gas flow rates has a beneficial effect on product throughput, the life of the coke oven and environmental control of volatile emissions from coke ovens.

Owner:SUNCOKE TECH & DEV LLC

Coke oven flue gas sharing

InactiveCN100510004CExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensCoke Oven EmissionFlue gas

The invention provides a method and apparatus for reducing the gas flow velocity in the bottom flue gas system of a coke oven during at least one initial coking operation after the coke oven has been charged with coal (43). The method includes providing a ductwork (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) for transferring at least a portion of the gas from The gas space (41) in the first coking chamber (18) is led into the second coking oven, thereby reducing the gas flow velocity in the first bottom flue gas system of the first coking oven. Reducing the gas flow velocity in the bottom flue has beneficial effects on product yield, coke oven life and environmental control of coke oven volatile emissions.

Owner:SUNCOKE TECH & DEV LLC

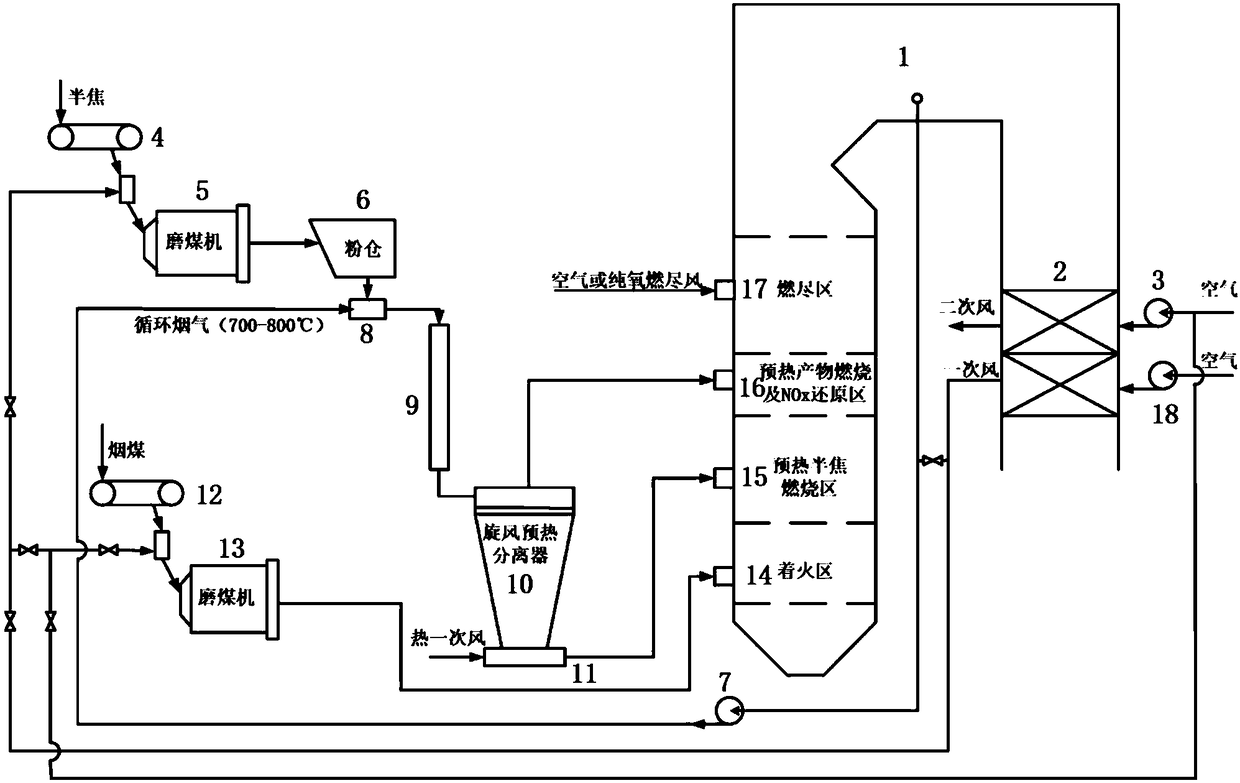

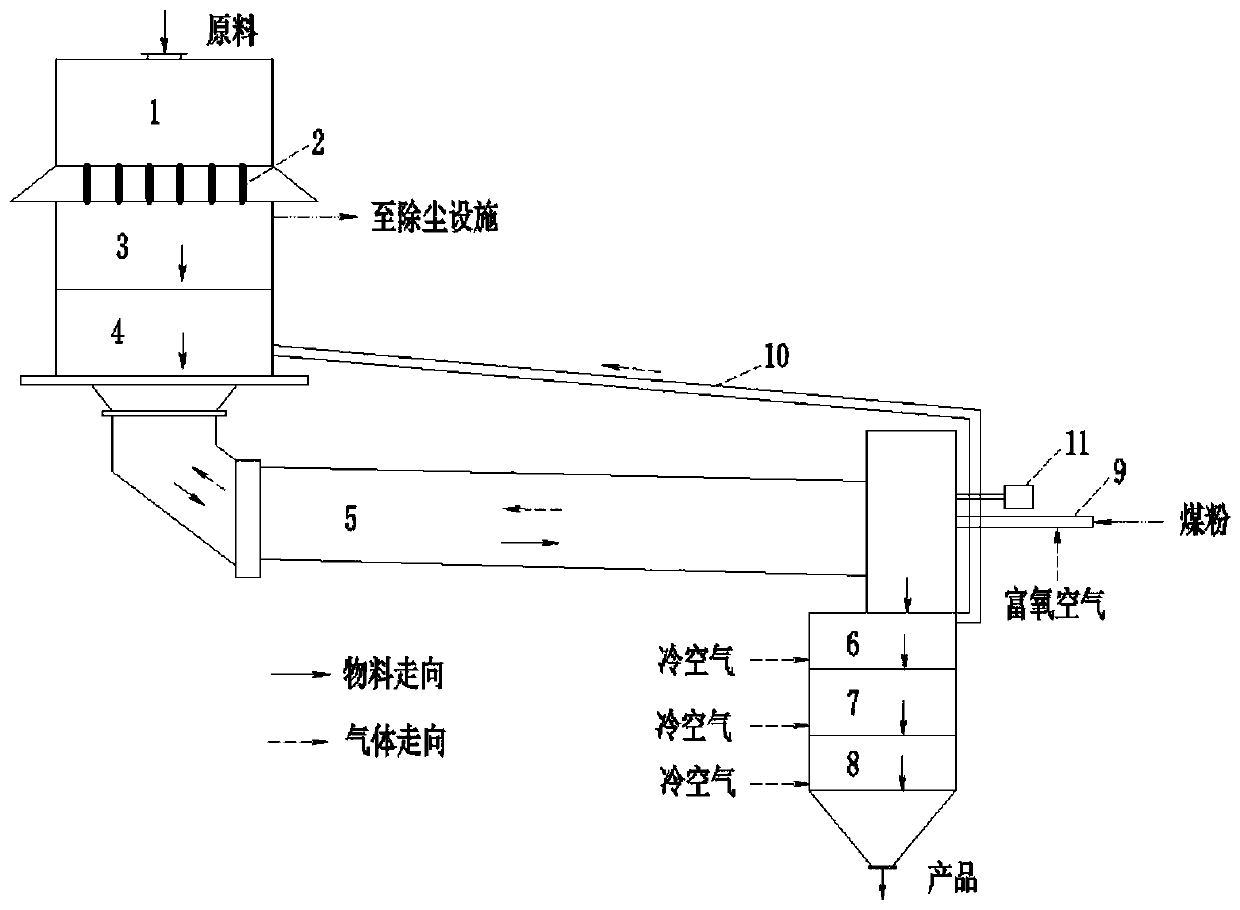

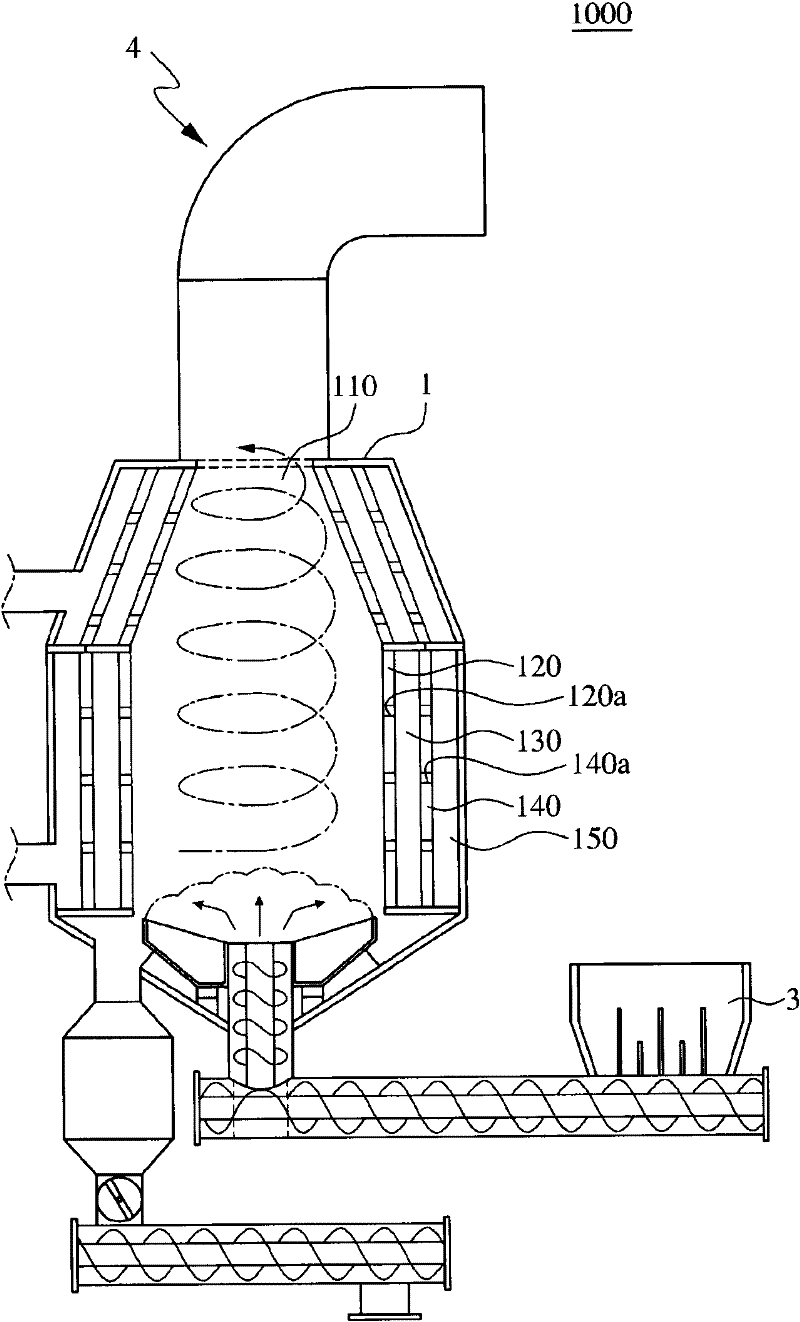

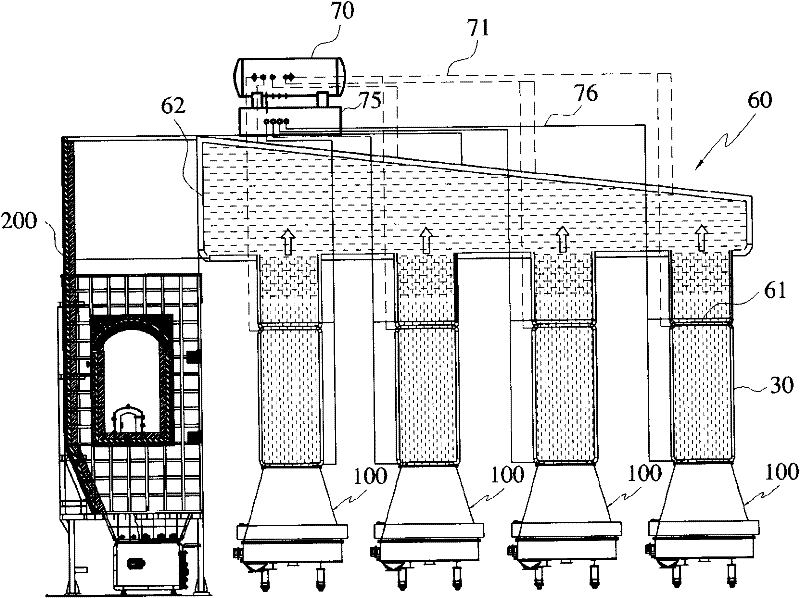

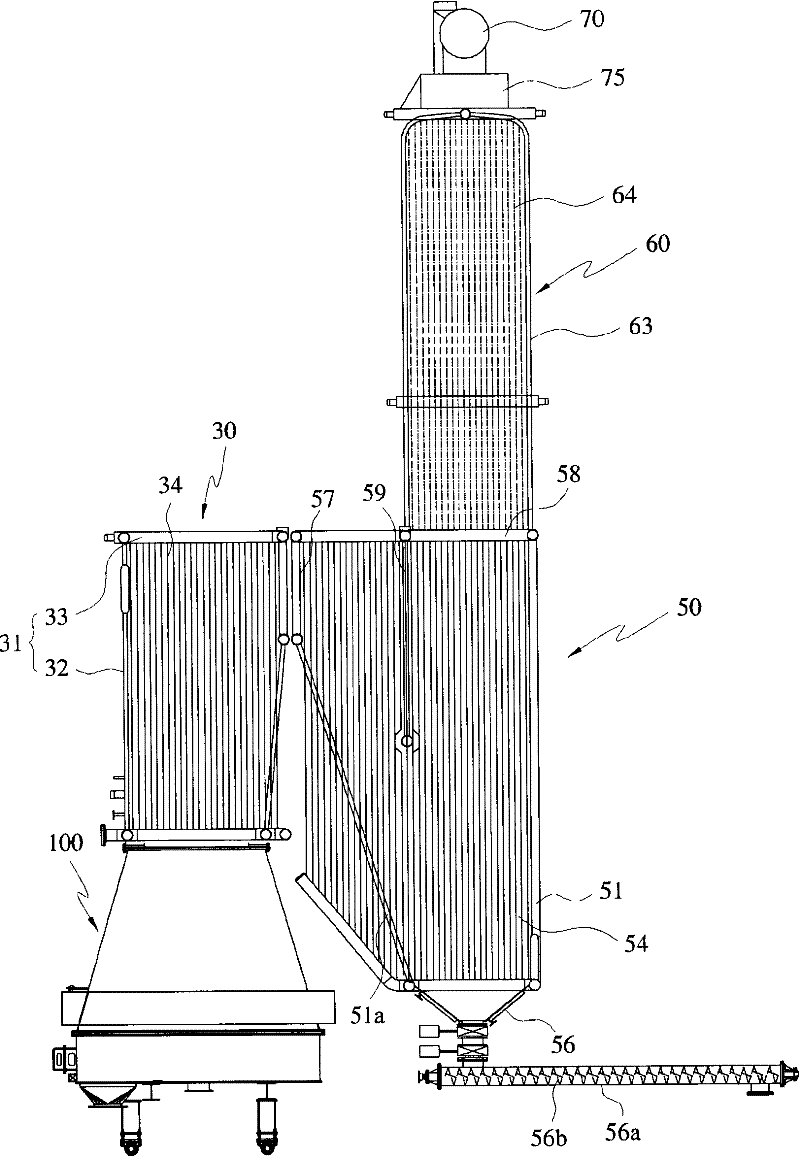

Low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of power station boiler

ActiveCN108151008AIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

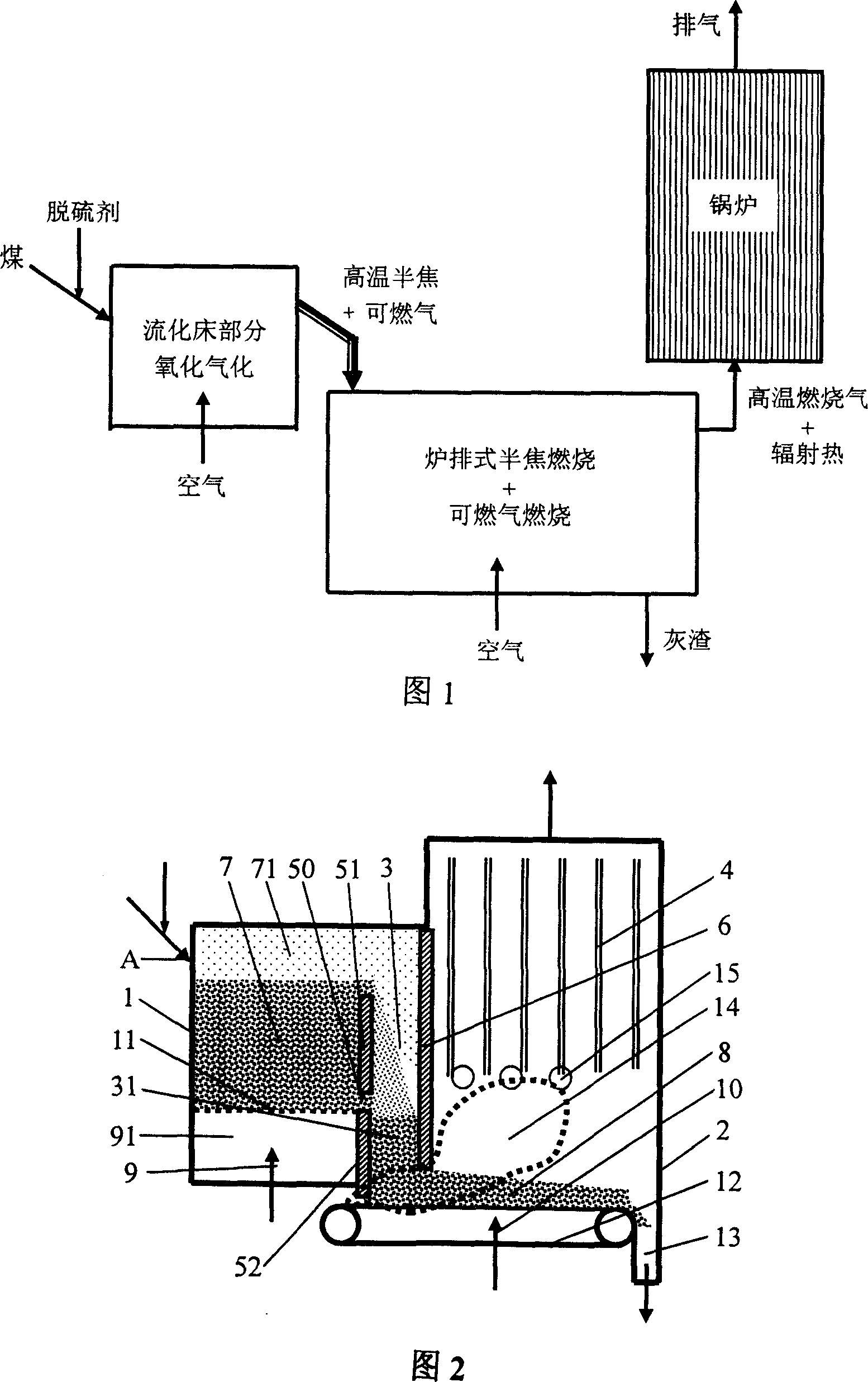

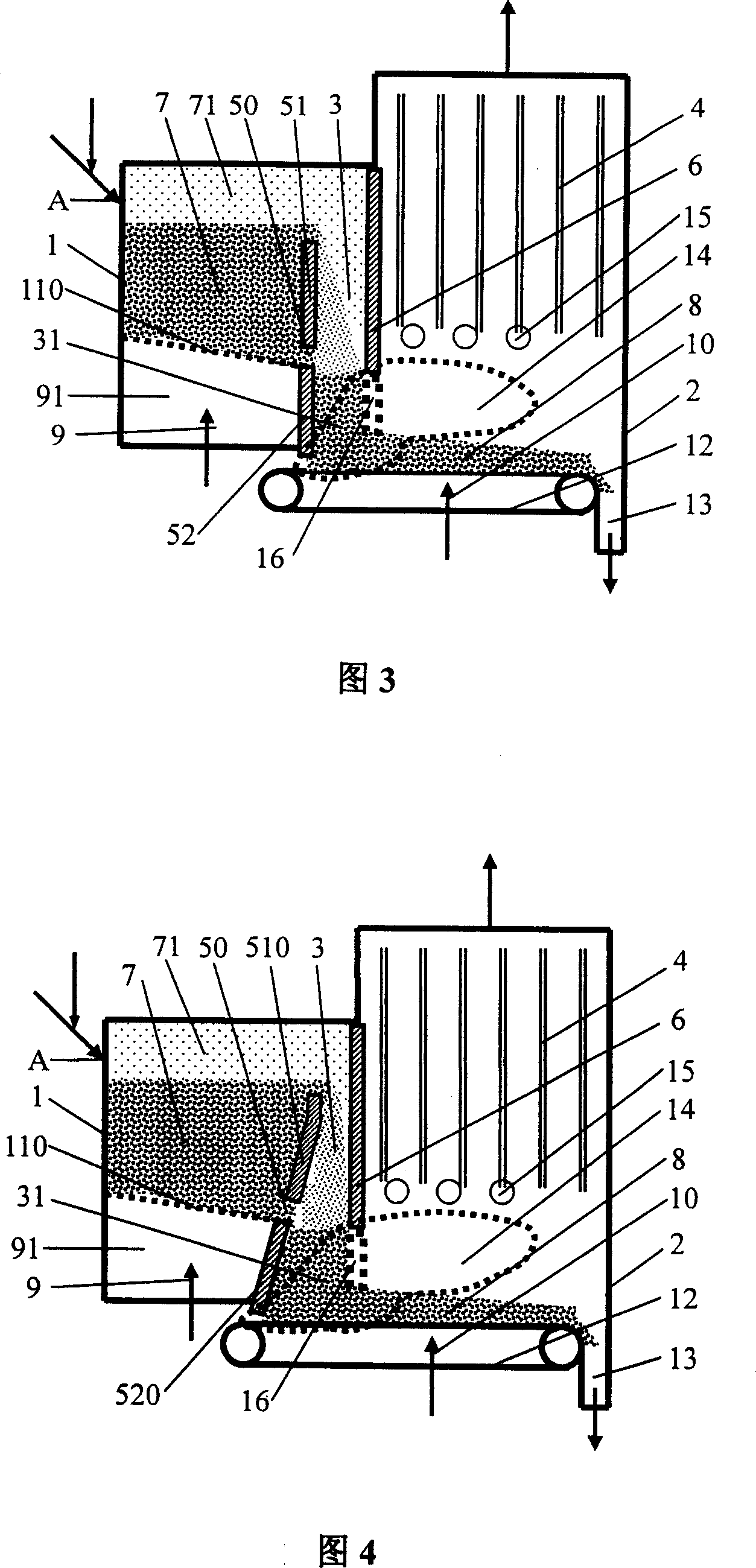

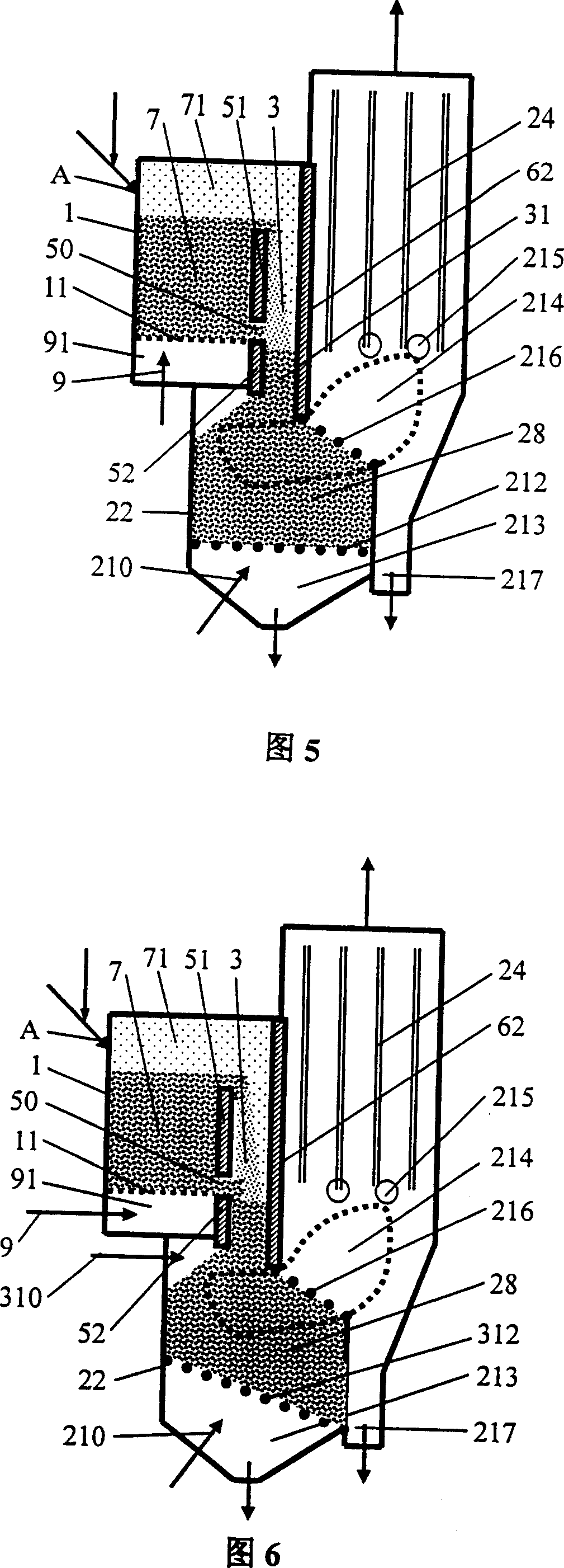

Low-pollution efficient combustion method for coal-burning boiler and combustion apparatus

InactiveCN101025266ASuppress generationEliminate burning black smokeFluidized bed combustionSolid fuel combustionFluidized bedProcess engineering

The invention relates to burning method and the device of low pollution and high efficiency for the coal-burning boiler which divides the burn into two processes. The two processes are the fluidized-bed oxidizing gasification and the burning of the carbocoal and fuel gas in grate burning furnace. The carbocoal and the fuel gas are transferred into the grate burning furnace through the moveable bed channel together; the fuel gas burn at the high temperature carbocoal layer and the carbocoal surface, so it can eliminate the black smoke and NOx; so the carbocoal and the fuel gas can be burned absolutely; the desulfurater added with the coal can remove the sulfide in the fluidized-bed part oxidizing gasification furnace which are dispersed between the carbocoal particle surface and the micropore to remove the oxysulfide sulfoxide of the burning furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

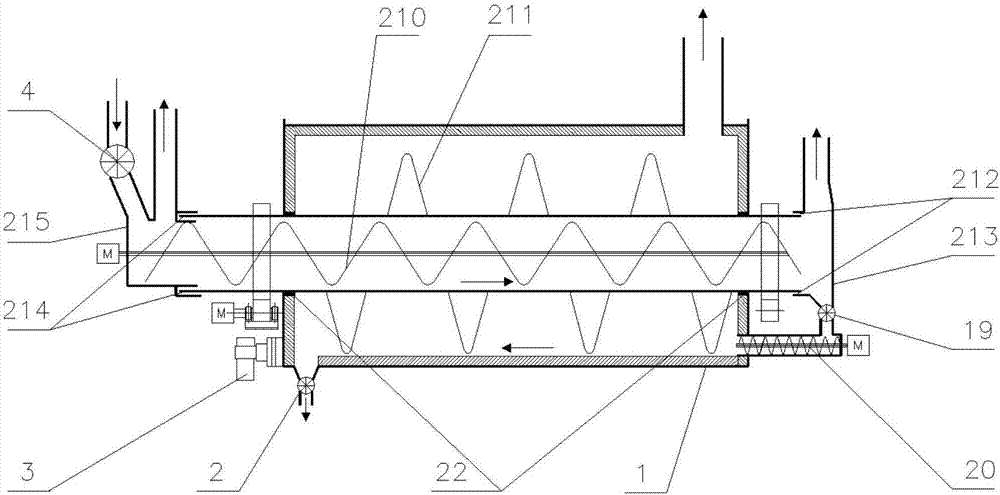

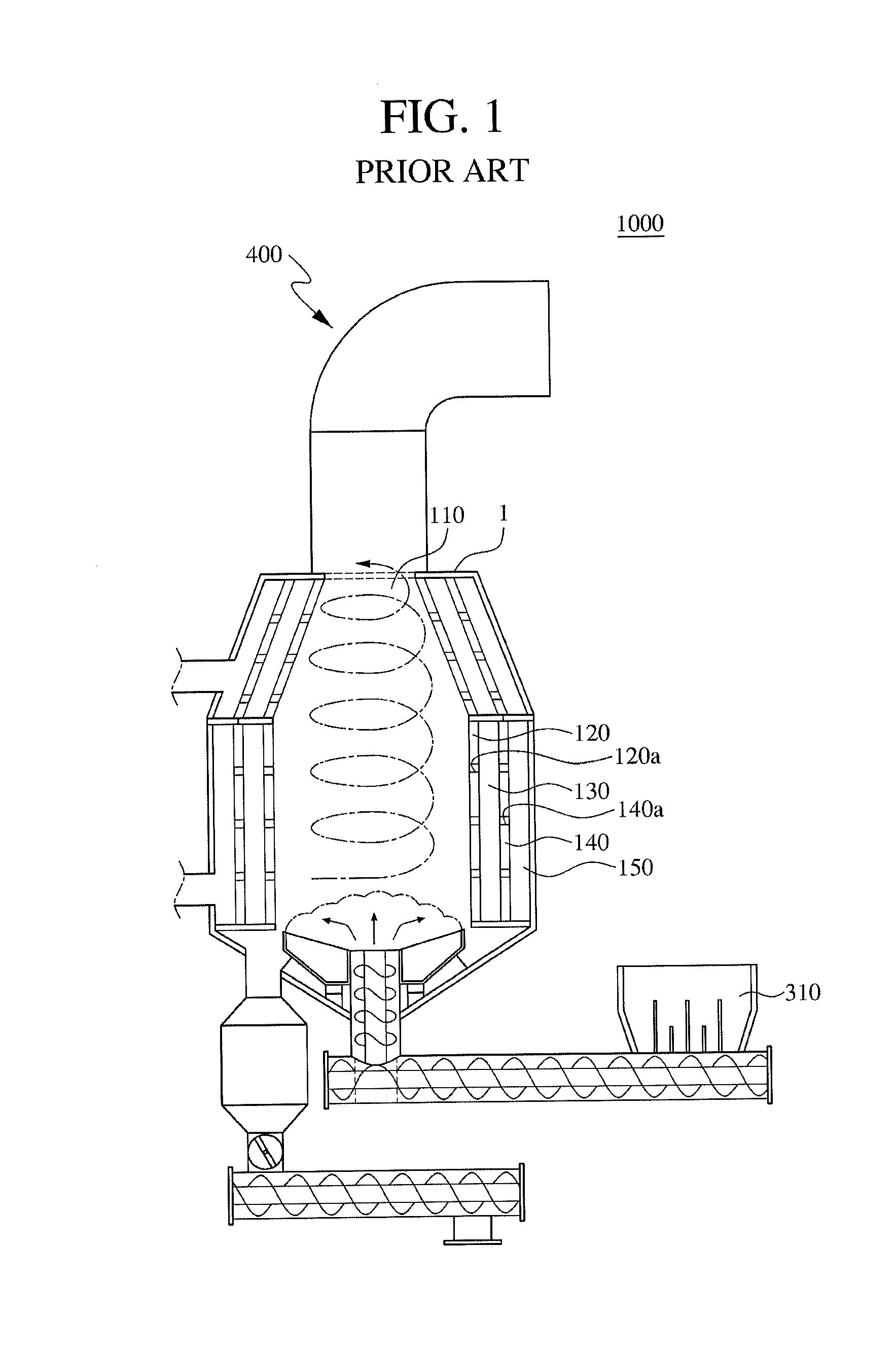

Indirect thermal cracking and ash combustion smelting furnace and treatment method thereof

ActiveCN107120656ASimple structureReduce calorie consumptionIncinerator apparatusCombustion chamberNitrogen gas

The invention belongs to the technical field of organic solid waste treatment, and particularly relates to an efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace with a wide utilization range. The efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace comprises a rotary thermal cracking and ash combustion smelting furnace body and a rotary barrel / rotary kiln sealing device, wherein the rotary thermal cracking and ash combustion smelting furnace body comprises an indirect thermal cracking barrel body with a spiral pushing device in the middle and a spiral inverse pushing ash combustion smelting heating furnace at the outer part of the barrel body; the rotary kiln sealing device comprises a rotary barrel body, a feeding end material collection hood, a discharge end material collection hood, a water seal filling sealing ring, a nitrogen emergency sealing air chamber and scale sealing pieces; the rotary indirect thermal cracking barrel body is lined with a heat-resistant steel barrel made from a silicon carbide material; a rotary screw conveyer is arranged in the heat-resistant steel barrel; and a high temperature resistant ceramic screw conveyer blade is fixed to the outer part of the barrel body. According to the efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace, a cracking furnace, a secondary combustion chamber and a smelting furnace are integrated in one furnace body, noncondensable gas, condensed oil and carbon residues generated after cracking can be utilized as fuel makeup, heat consumption is greatly reduced, and remaining ash is smelted till ash reaches the safe landfill standard.

Owner:无锡爱普特设备科技有限公司

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

Heating method for controlling decarburization in heavy rail billet furnace

InactiveCN101967541AEnsure complete combustionReduce oxidation burnFurnace typesHeat treatment furnacesPollutant emissionsReducing atmosphere

The invention provides a heating method for controlling decarburization in a heavy rail billet furnace in a heat accumulation heating mode. The heating process comprises a pre-heating section, a heating section and a soaking section. A furnace pressure measurement point is positioned at the pre-heating section; the full furnace is controlled at positive pressure; when the billet temperature is controlled to be less than 1,000 DEG C, the atmosphere in the furnace is oxidizing atmosphere, and the air consumption coefficient is between 1.05 and 1.25; and when the billet temperature is controlledto be more than or equal to 1,000 DEG C, the atmosphere in the furnace is weak reducing atmosphere, the air consumption coefficient is between 0.9 and 1.0. Aiming at the operation and decarburizationcharacteristics of the heat accumulation heating furnace different from the traditional heating furnace, the segment control method is adopted on the control aspects of atmosphere in the furnace and temperature, and a limit low-oxygen concentration burning process is realized. The method has the advantages of low heated billet surface decarburization, low oxidized burning loss, high furnace energy utilization, low pollutant discharge, low production cost and the like, is simple, convenient and feasible, and can achieve good effect of saving materials and energy at the same time of improving the heating quality of products.

Owner:武钢集团有限公司

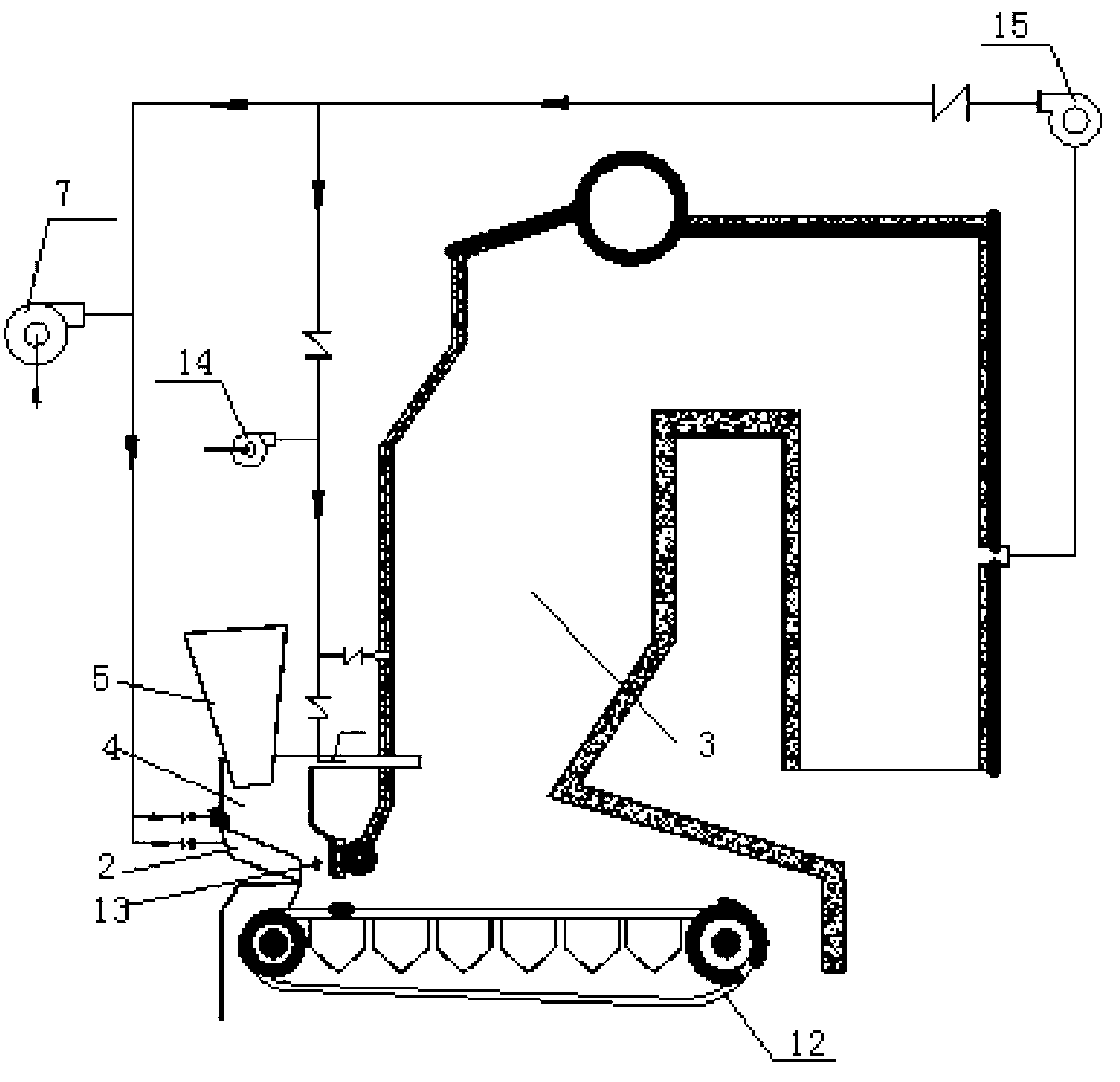

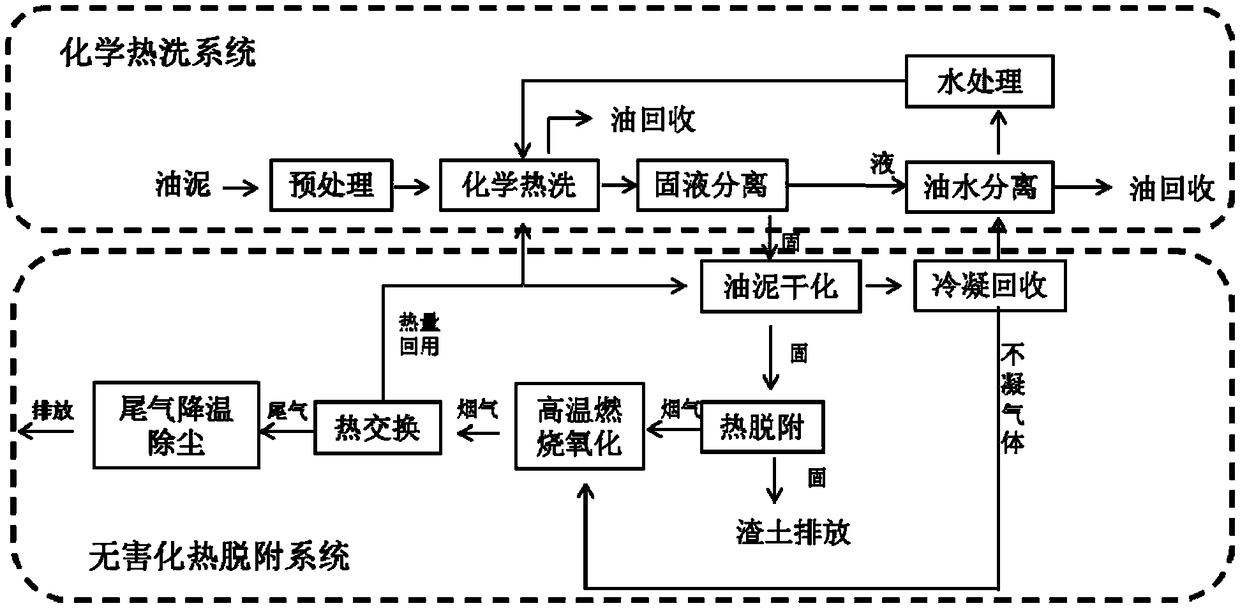

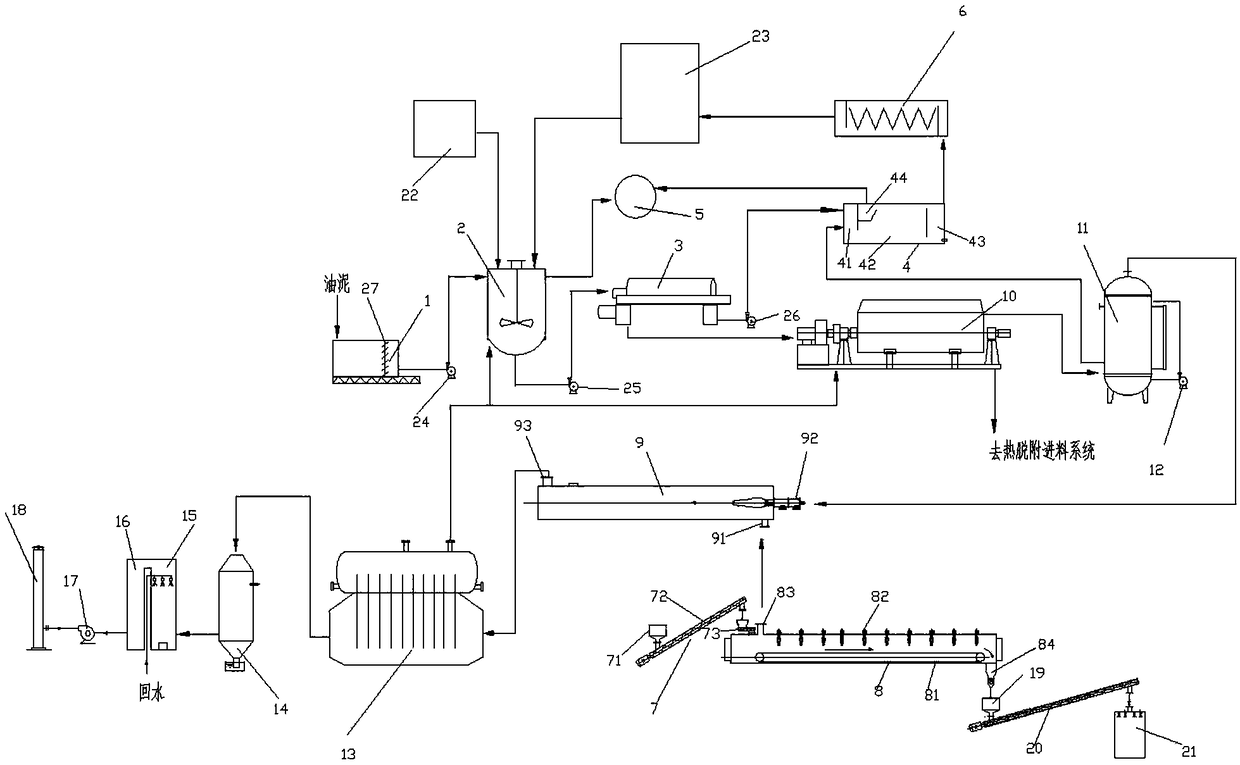

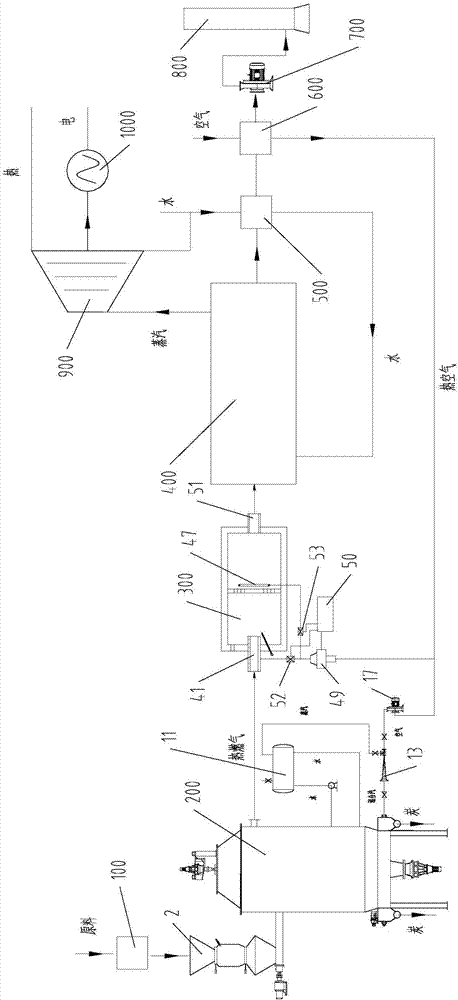

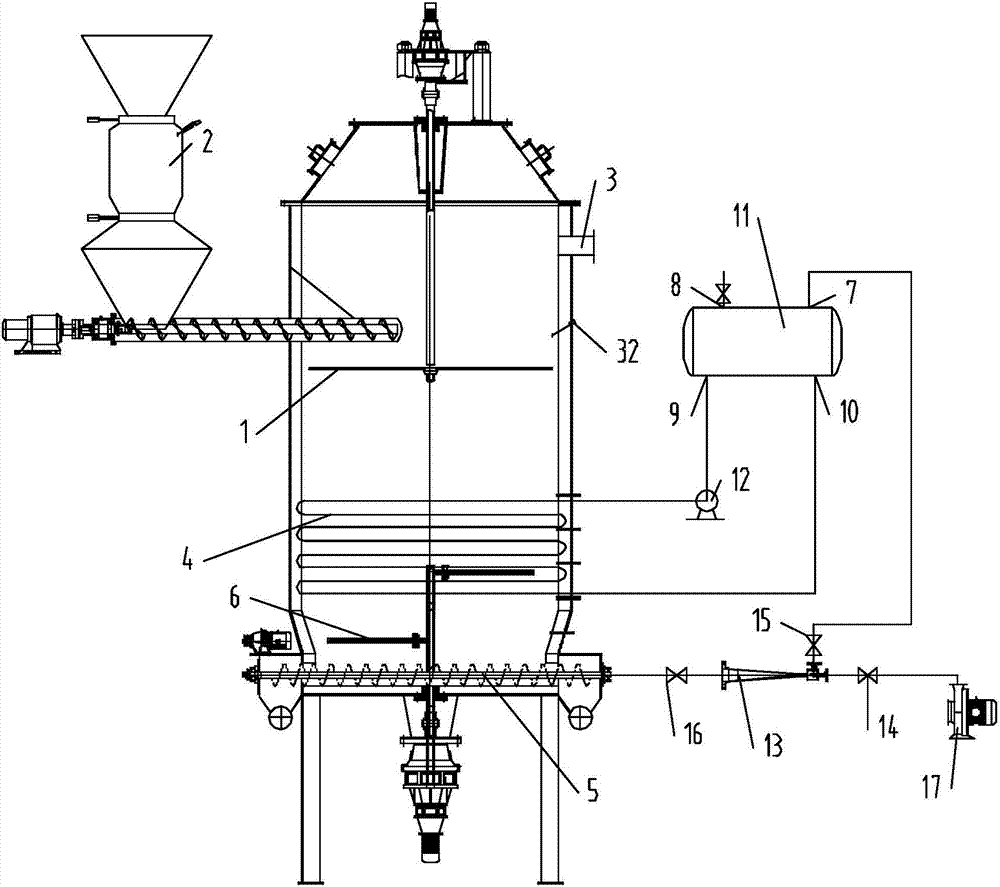

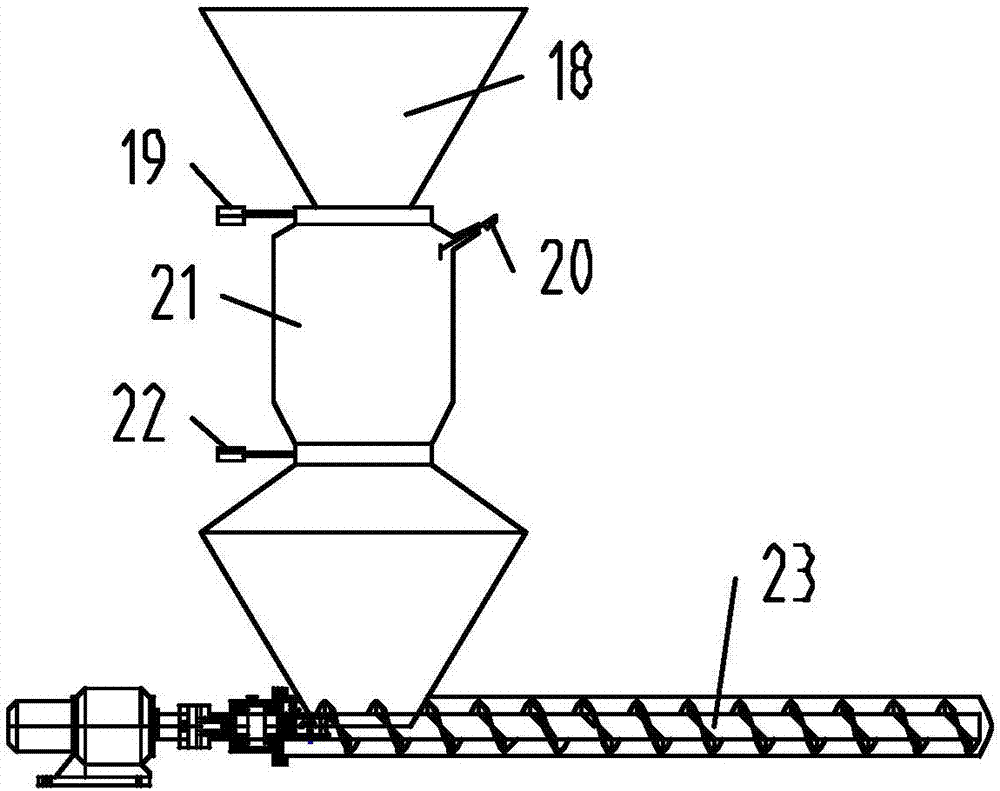

Green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge

ActiveCN108996859ALayering efficiency is fastHigh recovery rateSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesHigh concentrationWater storage tank

The invention discloses a green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge. The treatment method includes the treatment steps of homogeneous impurity removal pretreatment, chemical thermal washing treatment, solid-liquid separation and oil-water separation, oil sludge thermal desorption and high temperature combustion oxidation, heat exchange and tail gas cooling and dust removal. The treatment system includes an oil sludge chemical thermal washing system and an oil sludge harmless thermal desorption system. The oil sludge chemical thermal washing system is formed by connecting an oil sludge homogenization slot, an oil sludge chemical thermal washing tank, a high efficiency solid-liquid separator, an oil-water separator, a sewage integrated treatment system and a water storage tank successively. The oil sludge harmless thermal desorption system mainly consists of a sludge dryer, a condensation recoverysystem, a thermal desorption feeding system, a thermal desorption system, a high temperature combustion oxidation system, a waste heat boiler and a discharging system. With adopting of the combined application of the chemical thermal washing technology and the thermal desorption technology, multiple functions such as resource recovery and utilization of petroleum materials and heat, reduction ofoily sludge, harmlessness and the like can be simultaneously realized.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Process for recovering fluoride salt from aluminium electrolyzing carbon slag

The present invention relates to the treating method of anode carbon slag produced in aluminum electrolyzing process, and is especially the process of recovering fluoride salt from anode carbon slag. The present invention features that anode carbon slag is compounded with alumina as dispersant in the amount of 10-60 wt% of the total material and liquid or gas fuel with ash content less than 1 % is used to roast the carbon slag at 650-930 deg.c for completely burning out carbon material in the carbon slag. The tail gas is adsorbed with alumina and the fluoride salt is recovered. The treated product contains alumina in 15-70 wt%, fluoride salt in 30-85 wt% and few impurity, and may be returned to electrolysis bath for reuse without negative effect on the electrolyte and aluminum liquid quality.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

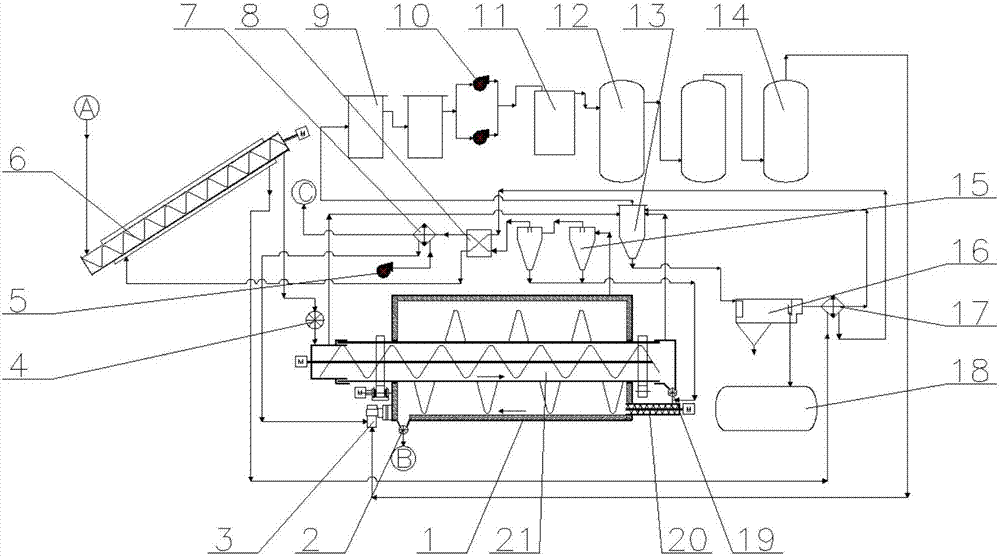

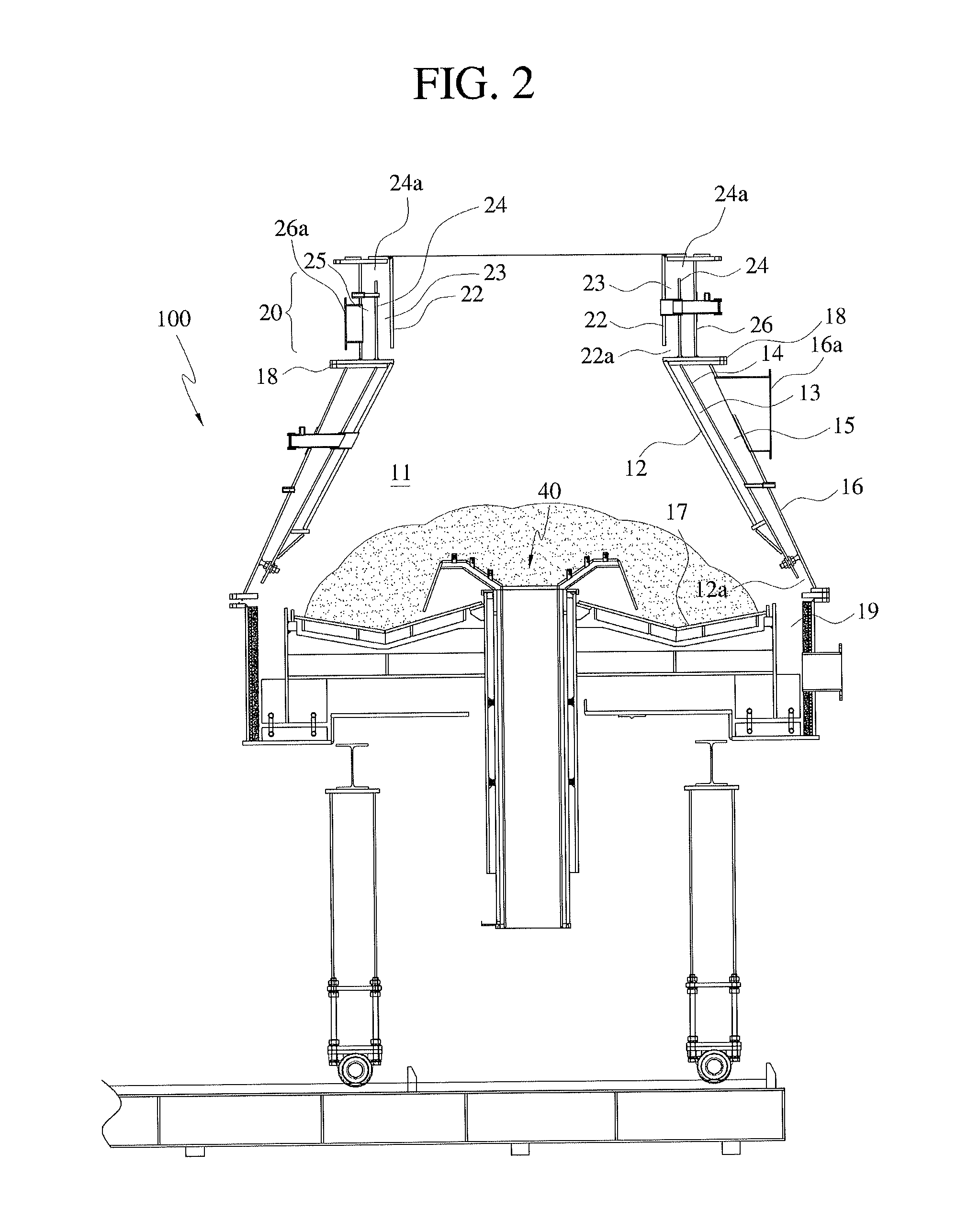

Device and method for cooperatively producing carbon and heat through gasification power generation of biomass fixed bed

ActiveCN107177381AHigh calorific valueMeet caloric needsSteam generation heating methodsHeat recovery systemsAir preheaterFixed bed

The invention relates to a method for cooperatively producing carbon and heat through gasification power generation of a biomass fixed bed. According to the method, by utilizing middle-heat-value combustible gas, the heat requirement of a high-temperature high-pressure boiler can be met, and the integral power generation efficiency is improved; and nitrogen oxide is low in content and can meet environmental protection requirements, and denitrification is not required. The method comprises the following steps: sending biomass raw materials into a gasification device for preparing middle-heat-value biomass combustible gas, gasifying the biomass raw materials under the action of air-vapor premixed gasifying agent at 700-850 DEG C so as to produce combustible gas, wherein the heat value of the combustible gas is 1600Kcal-1800Kcal, and the temperature is 200-300 DEG C; directly introducing the combustible gas into an environment-friendly combustion cavity for combustion, introducing the combustible gas into the high-temperature high-pressure boiler for combustion to produce high-temperature high-pressure steam so as to push the steam turbine to generate power, and utilizing steam waste heat discharged from the steam turbine; and heating air by virtue of an air preheater through boiler tail gas, respectively introducing hot air into a combustion cavity and the gasification device by virtue of an air blower, and utilizing the waste heat.

Owner:NANJING FORESTRY UNIV

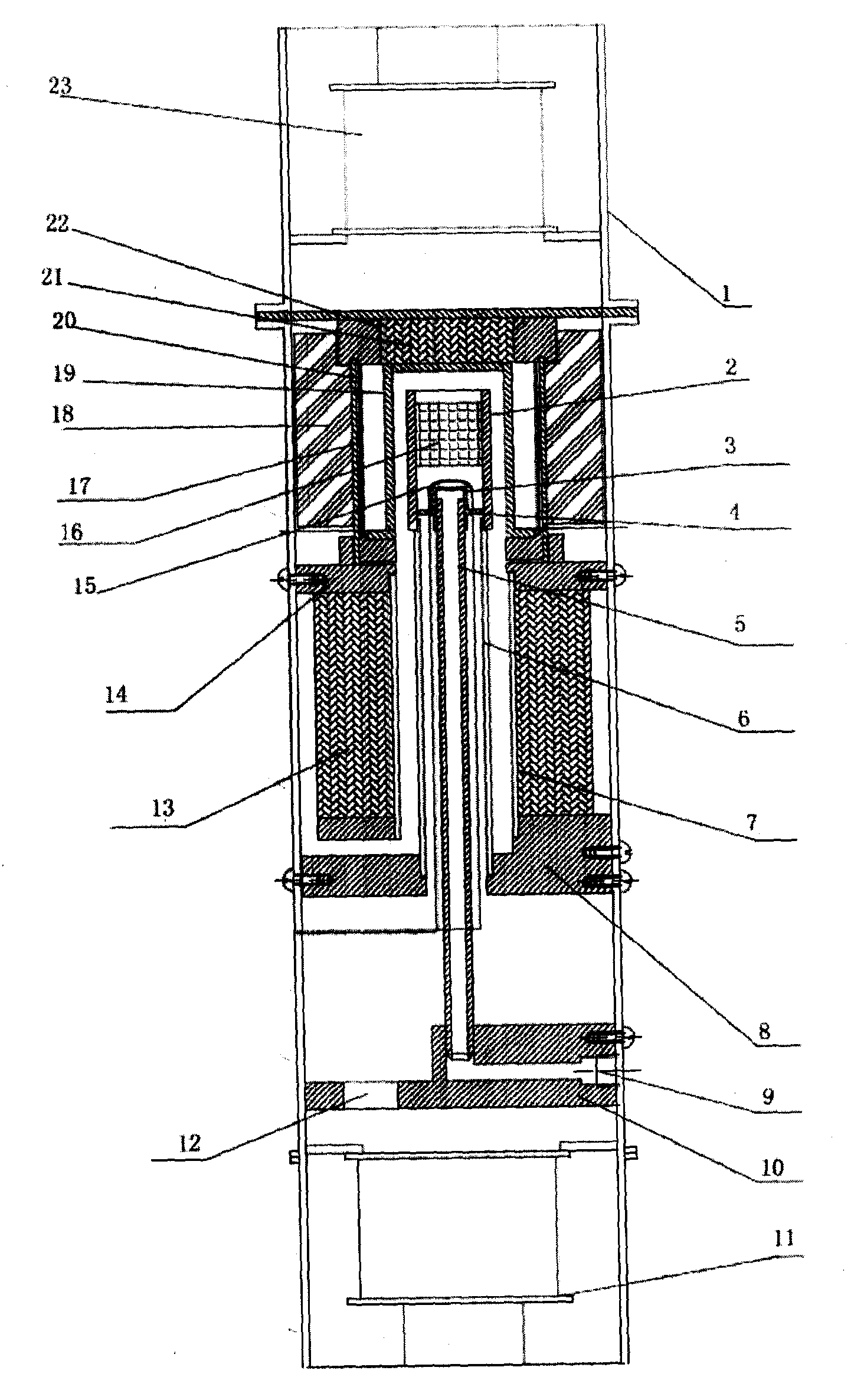

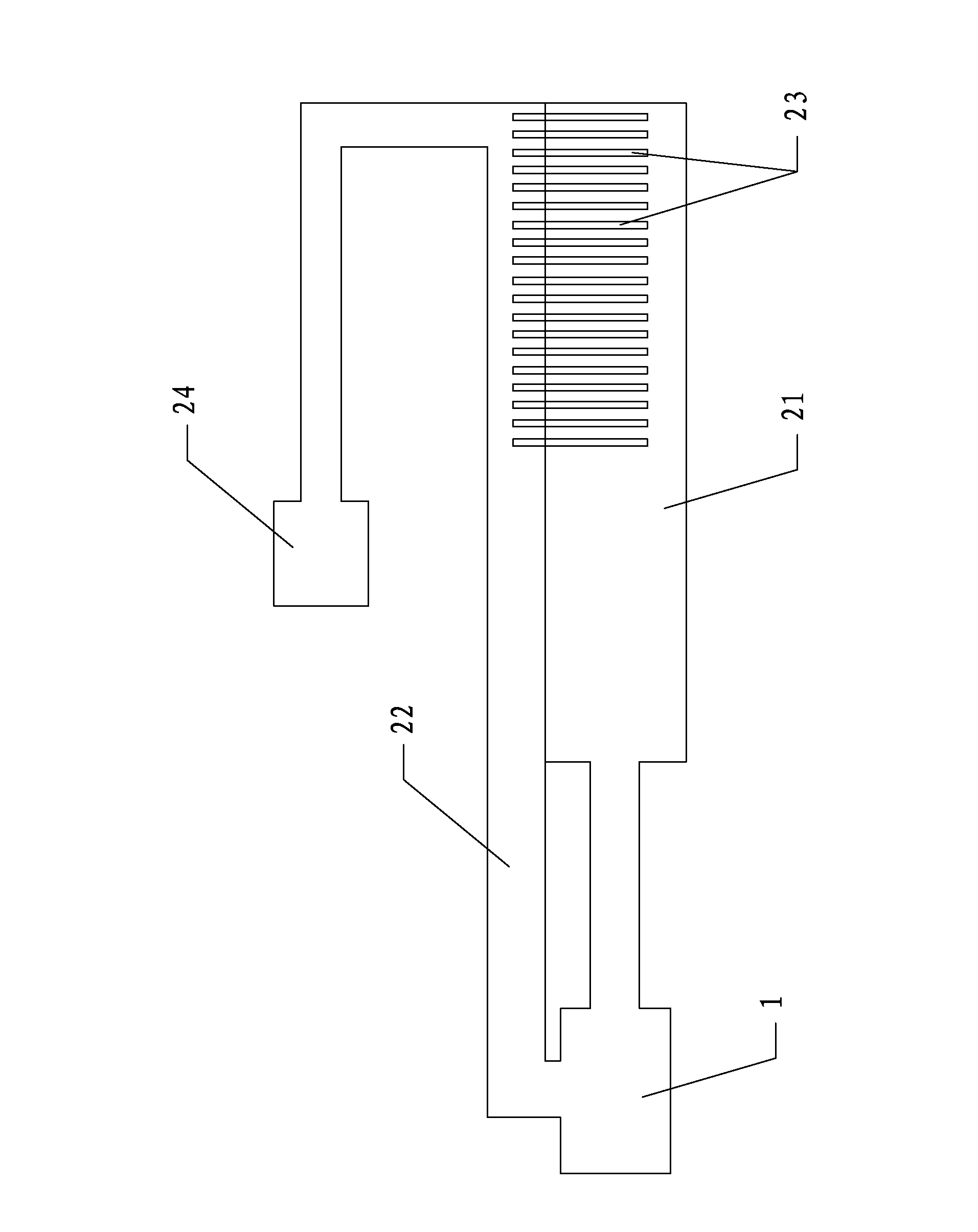

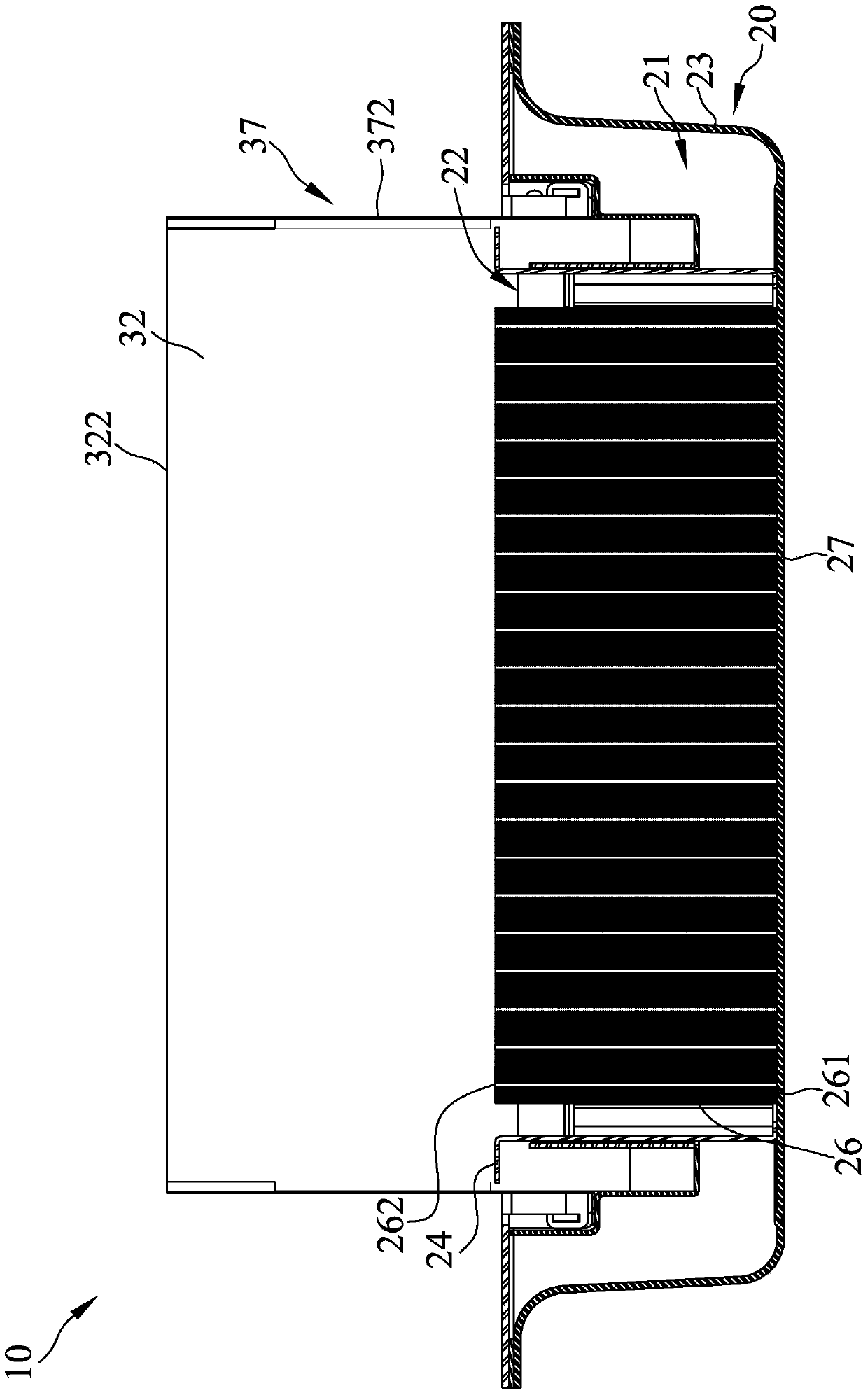

Thermo-photovoltaic direct conversion power generating device

InactiveCN101630926AImprove stabilityPromote heatingPV power plantsPhotovoltaic energy generationThermal radiationElectric energy

The invention discloses a thermo-photovoltaic direct conversion power generating device. In the device, an upper base, a middle base and a lower base are fixed on a shell; one end of a fuel tube vertically passes the upper base and the middle base from the central axis and is vertically connected with the lower base, and communicated with an external fuel inlet arranged on the lower base, and the other end of the fuel tube is connected with a blast cap and an air spoiler; the periphery of the fuel tube is provided with a finned tube; a fume tube is arranged on the periphery of the finned tube; a silicon carbide tube is directly used as a thermal radiation face, and the lower end of the silicon carbide tube is arranged at the upper end of the finned tube; the upper end of a quartz glass tube is closed and covered on the silicon carbide tube, and the lower end of the quartz glass tube is arranged on the upper base; and a battery plate is arranged on the periphery of the quartz glass tube, and the back surface of the battery plate is provided with battery radiating ribs which are arranged between an upper end cover and the upper base. By the device, the heat energy released during combustion of fuel can be converted into the radiation energy, and the radiation energy is further converted into the electric energy by the photovoltaic battery; and the device can effectively improve the stability of flame and ensure complete combustion of flame.

Owner:NANJING UNIV OF SCI & TECH

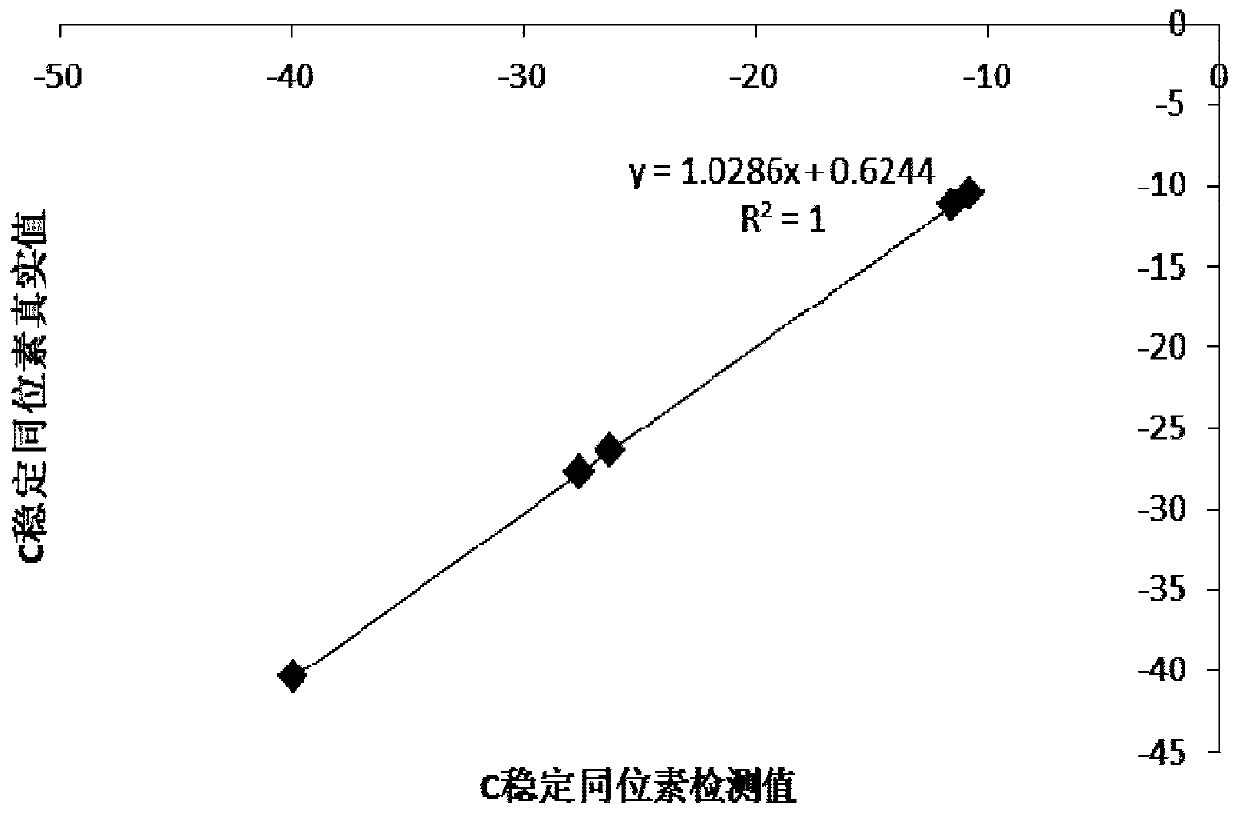

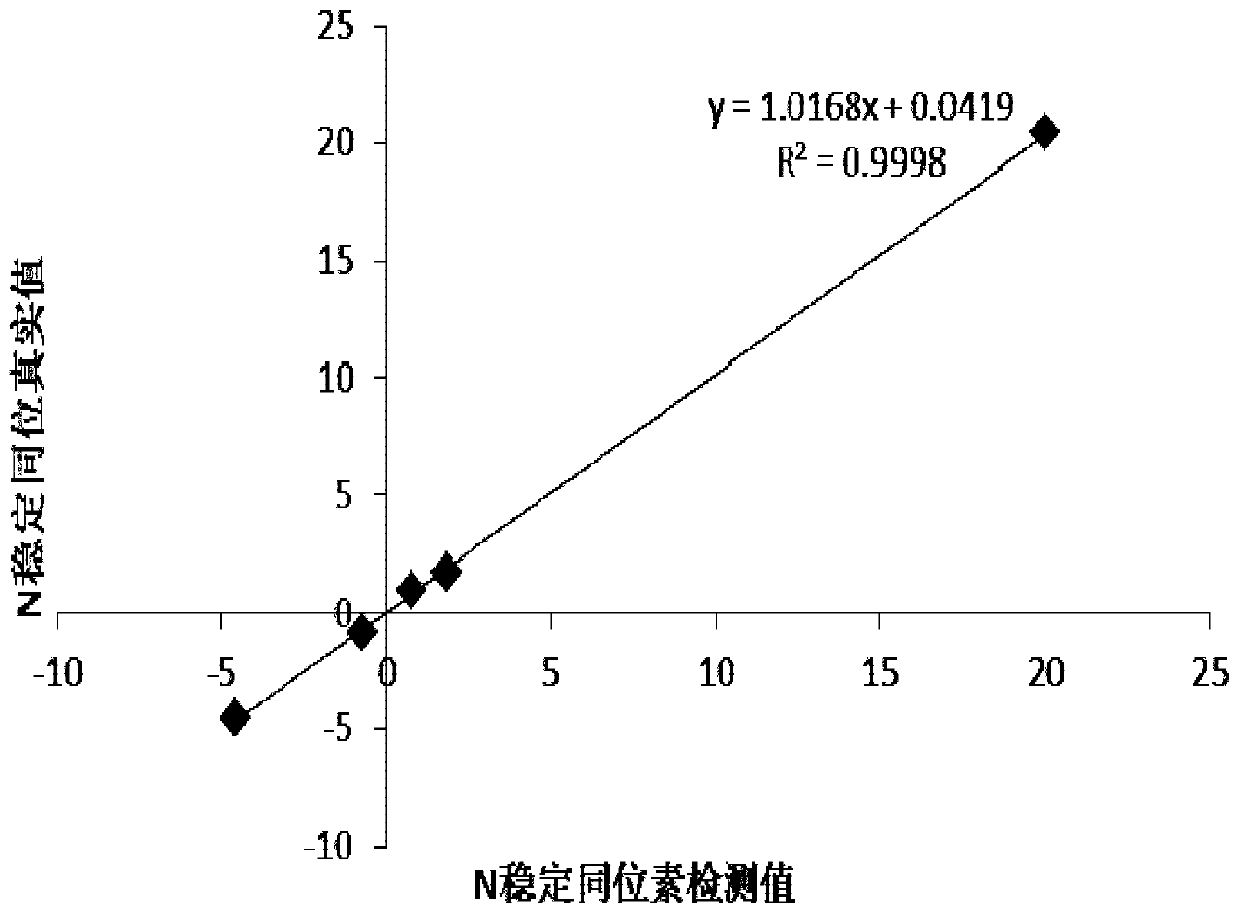

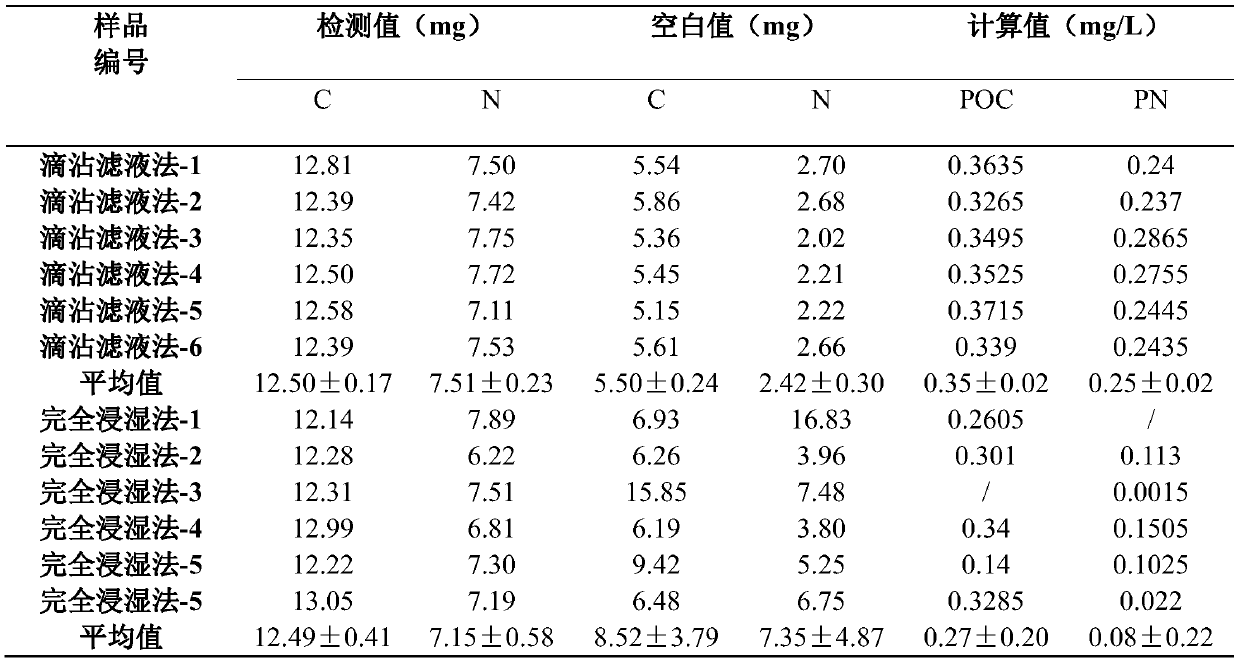

Method for analyzing stable isotopes of granular organic carbon and nitrogen in seawater by using EA-IRMS

ActiveCN110672709AGood removal effectReduce dosageChemical analysis using combustionPreparing sample for investigationElement analysisWater quality

The invention relates to a method for analyzing the stable isotopes of granular organic carbon and nitrogen in seawater by using EA-IRMS, and belongs to the field of water quality detection. The method starts from the whole process of sample collection, storage, treatment and detection; instrument settings and parameters are changed; after a collected sample is filtered, the filtered sample is filtered with 100ml of distilled water; the oxygen adding amount of an element analyzer is set to be 80 s; the temperature of a combustion tube is set to be 700 DEG C; and the filament current of an isotope mass spectrometer is set to be 300-400 microamperes. With the method adopted, detection cost is reduced by 30%, data accuracy is improved, and working efficiency is improved.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

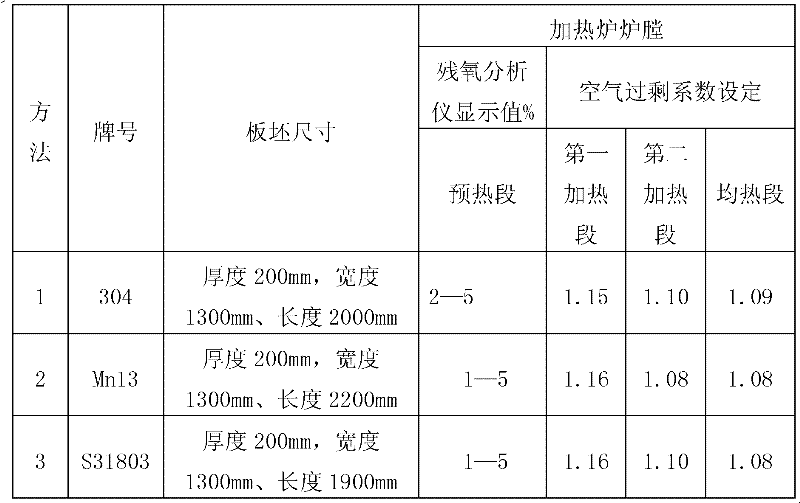

Heating method of weak, micro-oxidation and oxidation combustion for ferrous metal steel slab

InactiveCN102634651ARealize the effect of incomplete combustion + complete combustionTake advantage ofFurnace typesHeat treatment process controlHearthHeating furnace

A heating method of weak, micro-oxidation and oxidation combustion for ferrous metal steel slabs used in industrial furnaces with natural gas as a fuel. Excess air coefficients of a first heating section, a second heating section, and a soaking section of a heating furnace are set; in order to allow a display value of a residual oxygen analyzer to be within 1-4.5%, the excess air coefficients are set to be 1.1-1.2 for the first heating section, 0.96-0.99 for the second heating section, and 0.95-0.98 for the soaking section. The effect is realized that the natural gas combustion in the heating furnace hearth is incomplete combustion and complete combustion. The effect of complete combustion is realized in the first heating section of the heating furnace hearth, and the effect of incomplete combustion is realized in the second heating section and the soaking section. According to the invention, the atmosphere has a characteristic of micro-oxidizability after combustion in the heating furnace; the heating process of ferrous metal steel slabs in the second heating section and the soaking section is reduced; and less oxide scale is generated on the surface; the problem of steel plate surface depression caused by heating factors is reduced; energy saving is realized; the thickness of the oxide scale on the slab surface in the heating furnace hearth is reduced; and the defect of steel plate surface depression caused by heating factors is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

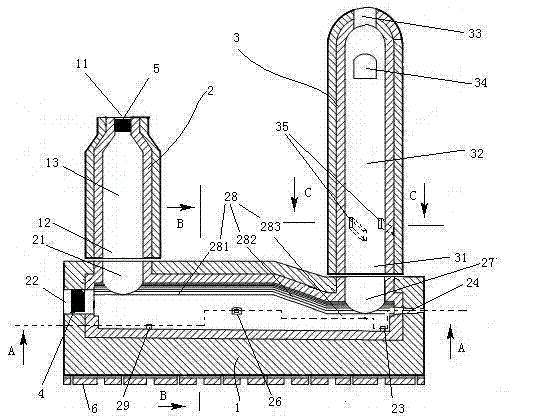

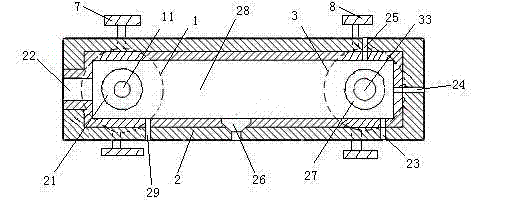

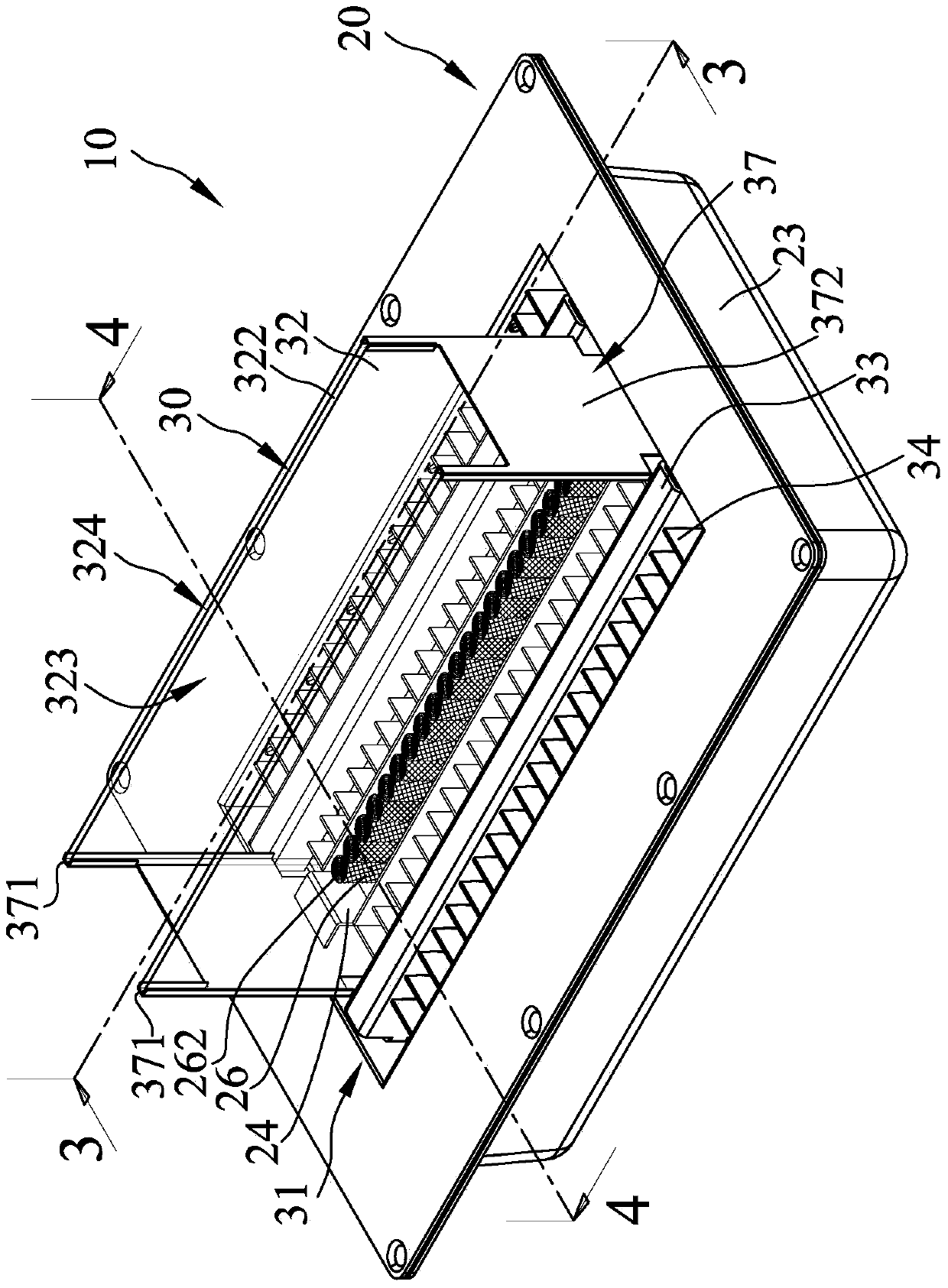

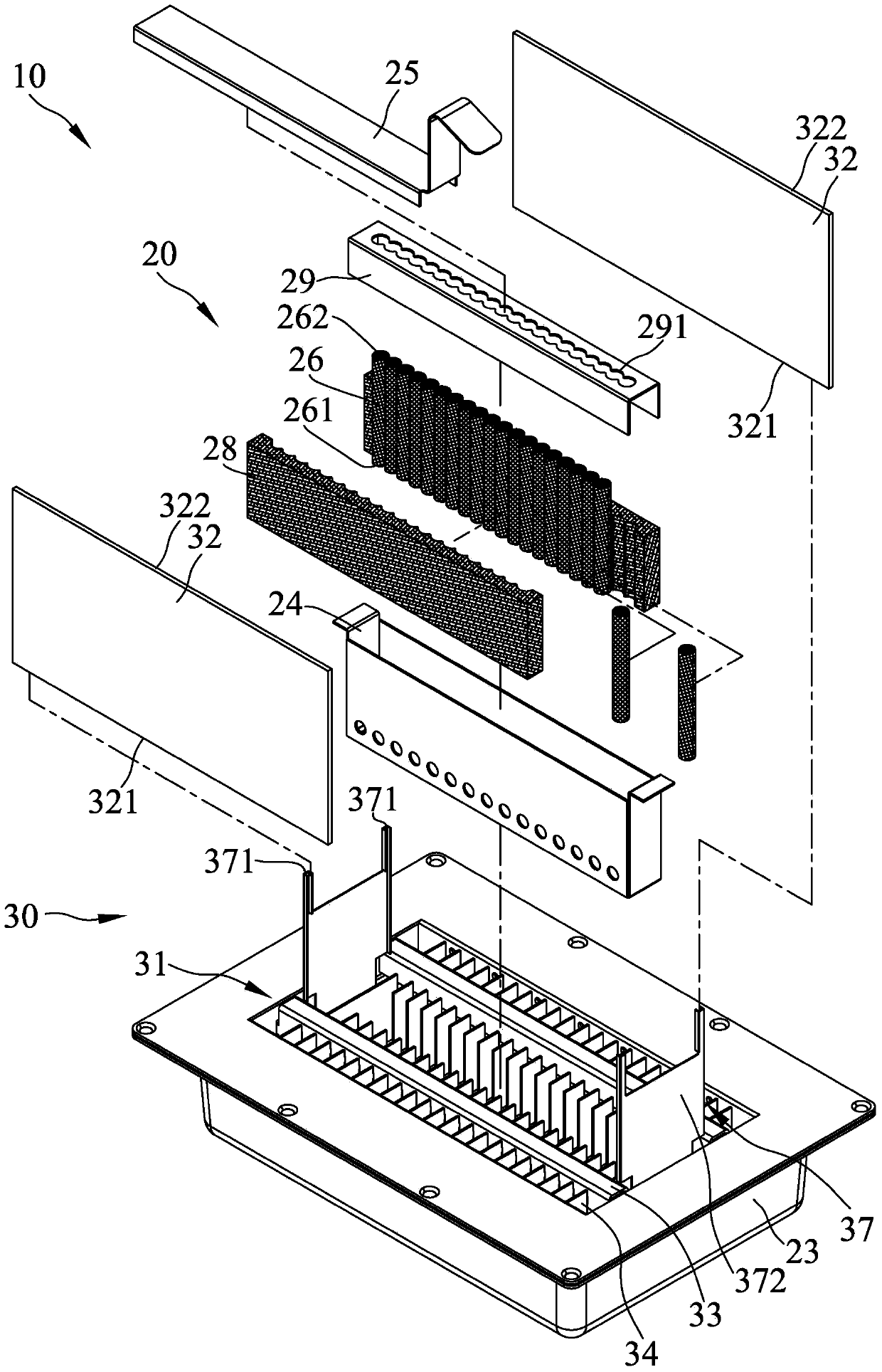

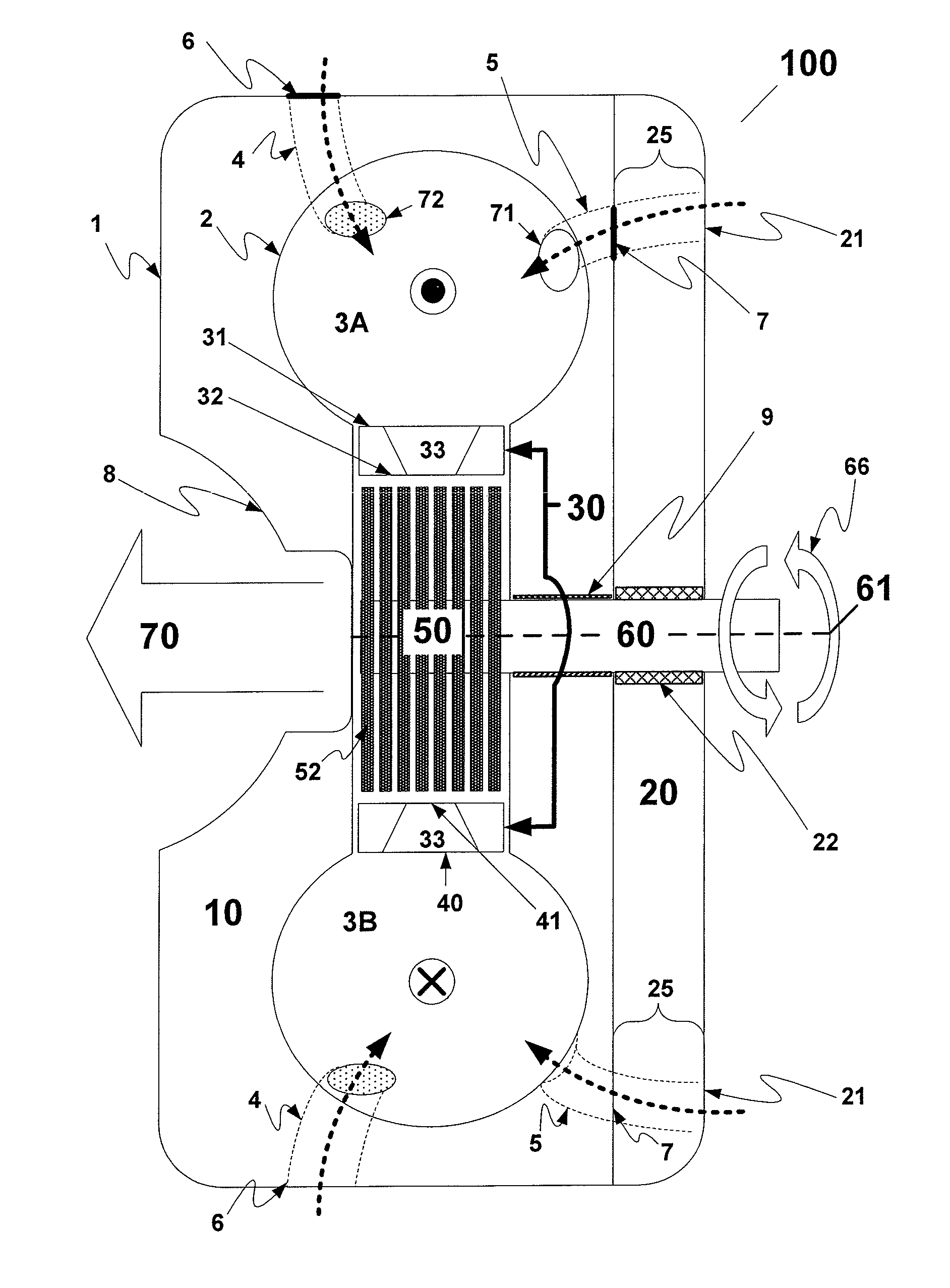

Combustion apparatus with improved thermal efficiency

InactiveUS20120017849A1Reduce lossesImprove thermal efficiencyBurnersBoiler water tubesCombustion chamberWater flow

A combustion apparatus includes a cylindrical combustion chamber surrounded by an inner wall. A cooling chamber comprises an intermediate wall spaced from the inner wall. Cooling water flows in and out lower and upper sides of the intermediate wall, to cool the inner wall by the cooling water that flows into a space formed between the inner and intermediate walls of the cooling chamber. A lateral combustion air supply chamber comprises an outer wall spaced from an outer side of the intermediate wall. Combustion air is supplied at an upper side of the outer wall to thereby make the air in a tangential direction with respect to the cylindrical outer wall turn and fall in a space formed between the intermediate wall and the outer wall, so that the combustion air is supplied to the combustion chamber via an opened lower portion of the lateral combustion air supply chamber.

Owner:KIM SANG KWON

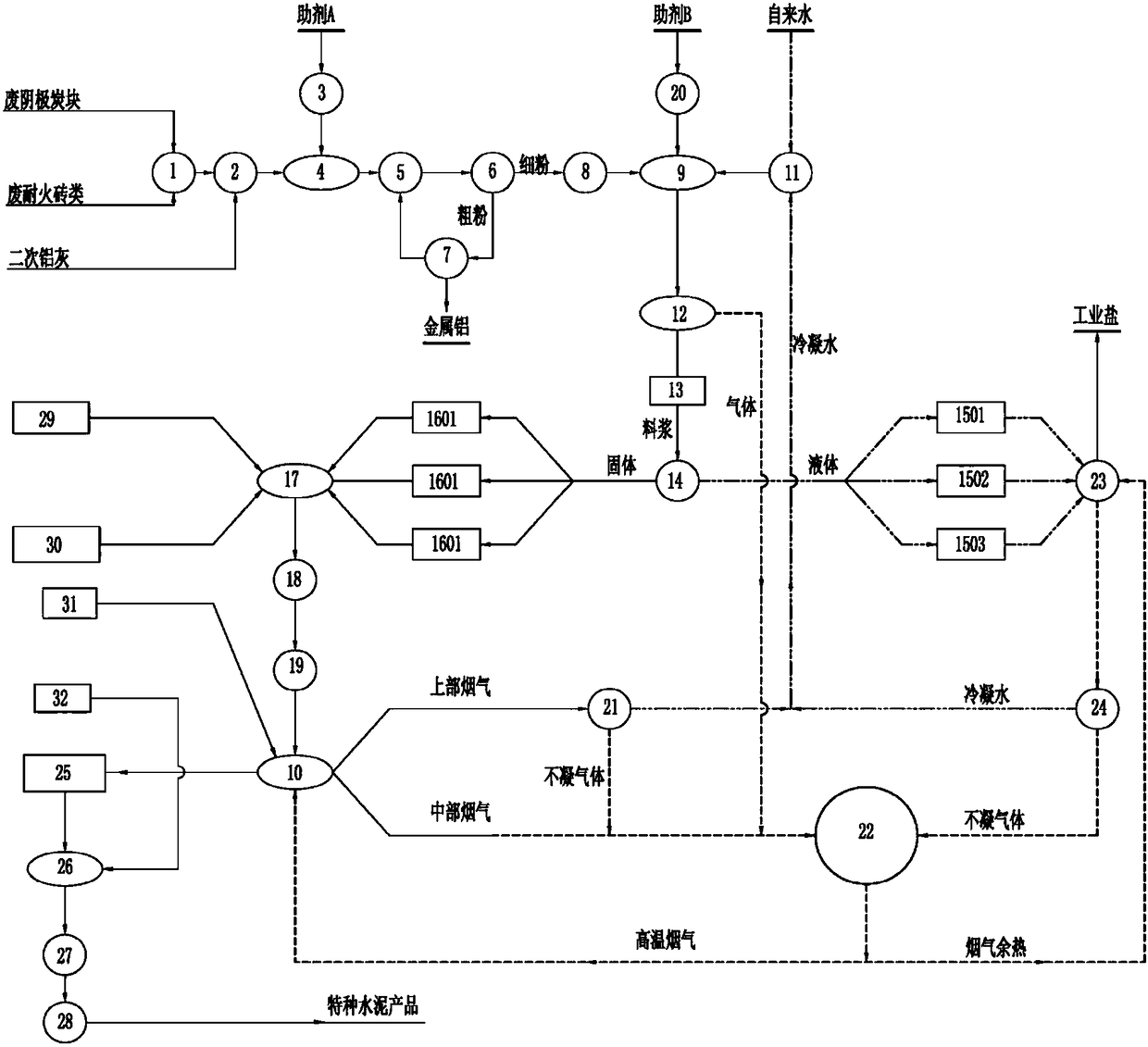

System and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of cement kiln

The invention provides a system and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of a cement kiln, wherein the system comprises a waste residue pretreatment system, a conversion reaction system, an alkaline metal salt extraction system and a cement kiln-based parallel production system of quick-setting quick-hardening cement, which are connected in sequence; all units in the system are hermetically connected, and a suction unit is provided to form micro negative pressure. The method comprises the steps: waste residuepretreatment; conversion reaction; extraction of alkaline metal salts and cement-kiln-based parallel production of quick-setting quick-hardening cement. The system and method herein have the advantages that electrolytic aluminum industrial waste residue can be centrally and uniformly treated at a time to eliminate its toxicity and hazard, and harmless, resourceful and final treatment of the electrolytic aluminum waste residue is achieved. The system and method are also capable of producing special quick-setting quick-hardening cement under low energy consumption and low cost, with no three wastes discharged and no secondary pollution caused.

Owner:长沙中硅环保科技有限公司 +1

Process for recovering fluoride salt from aluminium electrolyzing anode carbon slag

ActiveCN1253369CHigh recovery rateReduce processing costsFluoride preparationElectrolysisAfter treatment

A method for recovering fluoride salt in aluminum electrolysis anode carbon slag, relates to a treatment method for anode carbon slag produced in the process of aluminum electrolysis, in particular to a method for recovering fluoride salt in anode carbon slag. It is characterized in that the process is to add aluminum oxide to the anode carbon slag as a dispersant, and the weight ratio of the aluminum oxide as a dispersant to the total material is 10%-60%, and a liquid or a fuel with ash content of less than 1% is used Gas fuel is roasted at a temperature of 650°C-930°C until the carbonaceous material in the carbon residue is completely burned, the tail gas is adsorbed by alumina, and the fluoride salt is retained and recovered. The processed product contains about 15%-70% alumina and 30%-85% fluoride salt, with very little impurity content, and can be directly and completely returned to the electrolytic tank for use, without adverse effects on the quality of electrolyte and molten aluminum.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

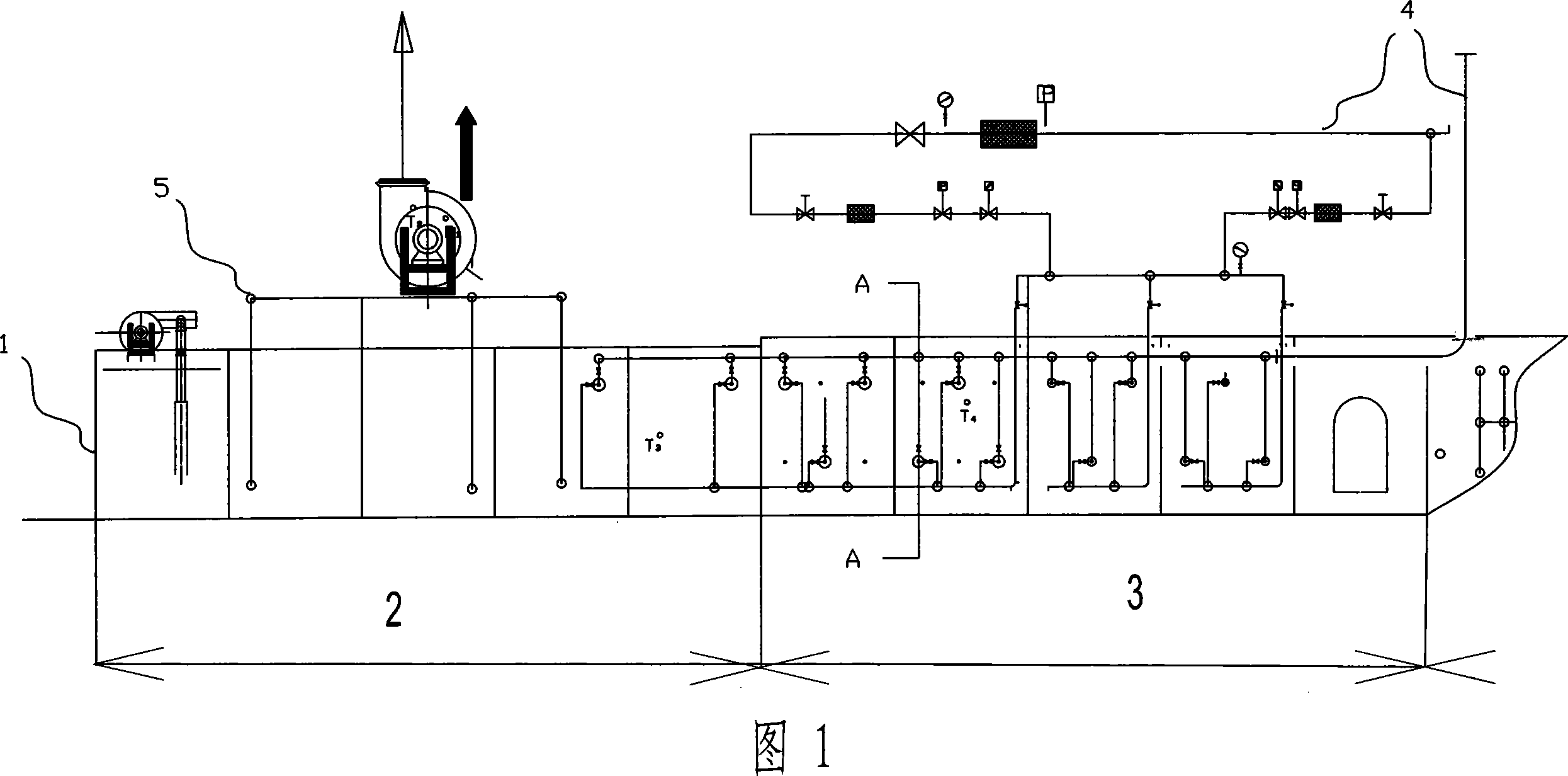

Coal-fired boiler tail gas membrane filtration enriched oxygen recycling method and device

ActiveCN102512920AAvoid dischargeReduce pollutionDispersed particle separationIndirect carbon-dioxide mitigationFiltrationExhaust fumes

The invention relates to the technical field of tail gas recovery, in particular to a coal-fired boiler tail gas membrane filtration enriched oxygen recycling method and a coal-fired boiler tail gas membrane filtration enriched oxygen recycling device. The recycling method comprises the following steps: mixing coal and a desulfurizer to obtain desulfurized coal, feeding the desulfurized coal into a boiler and burning the desulfurized coal; recovering afterheat from the tail gas; layering the tail gas in a pressure regulating device; recovering the layered gas by a recovering device; absorbing the mixed tail gas by an absorbing device; and circulating the tail gas to the boiler to be burnt again, and introducing the afterheat and oxygen passing through the membrane filtering device into the coal-fired boiler for burning. The recycling device comprises a tail gas afterheat recovering device, a pressure regulating device and an absorbing device, which are connected in turn, wherein the pressure regulating device is connected with the recovering device; and the air outlet of the tail gas afterheat recovering device is provided with the membrane filtering device. The method and the device have the advantages of circularly burning all tail gas, preventing pollution by waste gas, avoiding producing particulate matter 2.5 (PM2.5), reducing environment pollution, along with low cost, simple process, high fuel burning efficiency and small fuel consumption.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

hydrogen burner

ActiveCN102297426AEnsure complete combustionSafe and stable operationGaseous fuel burnerCombustorHydrogen

The invention relates to a hydrogen gas combustor, which comprises a central channel, an intermediate channel and an outer ring channel. The hydrogen gas combustor is characterized in that a flame stabilizing disk is arranged at the front part of the outer ring channel; the flame stabilizing disk comprises a closing section and a flaring section; a plurality of ventilation holes are formed at thesmall end part of the flaring section; a plurality of vortex guiding cutting grooves are arranged at the large end part of the flaring section; the central channel and the front end of the intermediate channel are arranged in the flame stabilizing disk and are communicated with the flame stabilizing disk; the front part of the central channel is connected with a plurality of spray pipes; spouts of the spray pipes are attached to the outer wall of the flaring section on the flame stabilizing section; and an ignition device is arranged in the outer ring channel. According to the hydrogen gas combustor disclosed by the invention, by using a flame stabilizing disk structure, small part of hydrogen gas and air transmitting through the ventilation ports of the flame stabilizing disk and the vortex guiding cutting grooves are fully mixed inside the flame stabilizing disk; the most of hydrogen gas is sprayed out through the spray pipe and is paved and dispersed in the flame stabilizing disk; a fluid field structure is reasonably organized; the mixing of air and hydrogen gas is reasonably controlled; the hydrogen gas can be ensured to be completely combusted; the flame length is controlledwithin a reasonable range; and safe and stable operation of the boiler is ensured.

Owner:ZHEJIANG TUFF BOILER

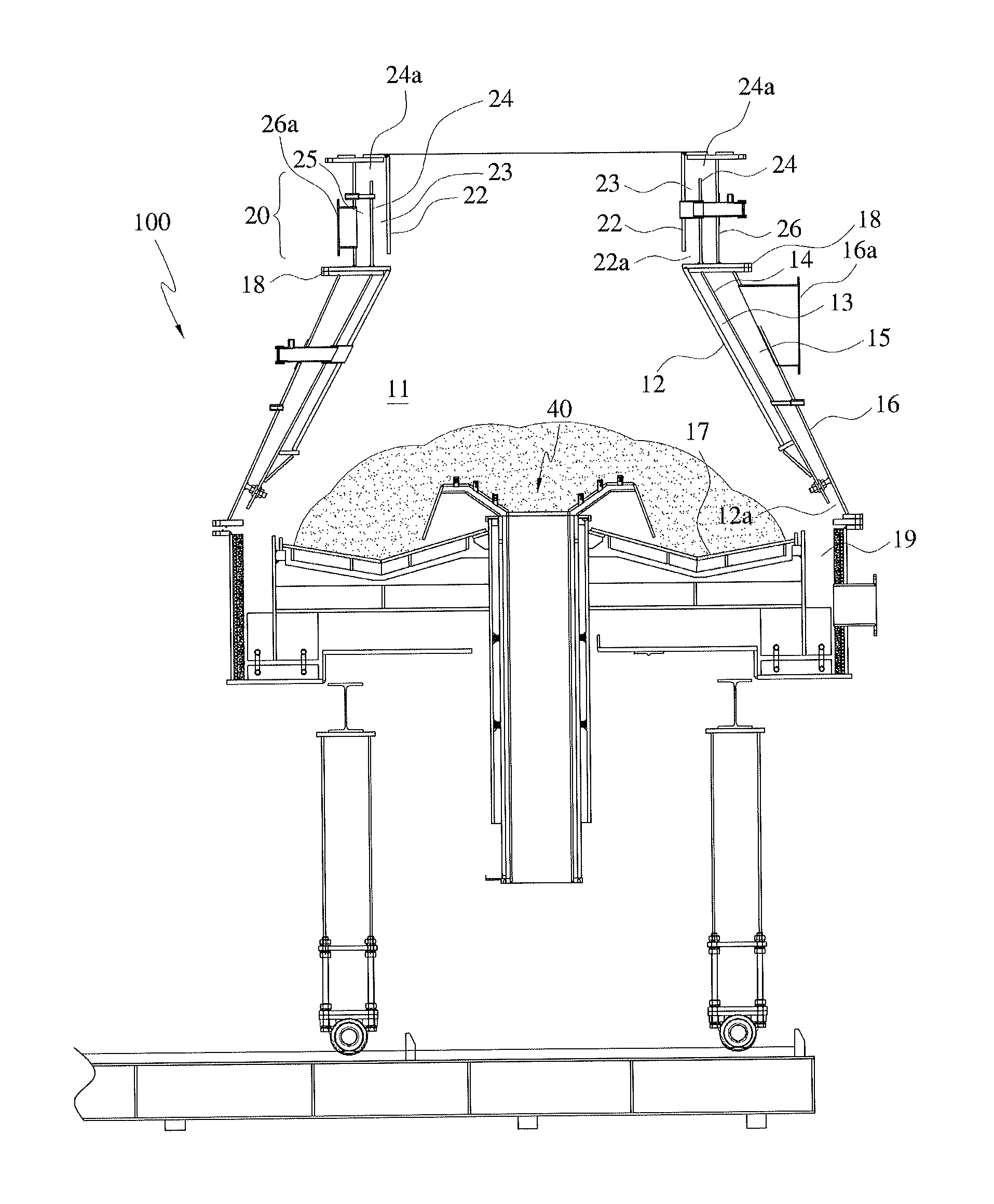

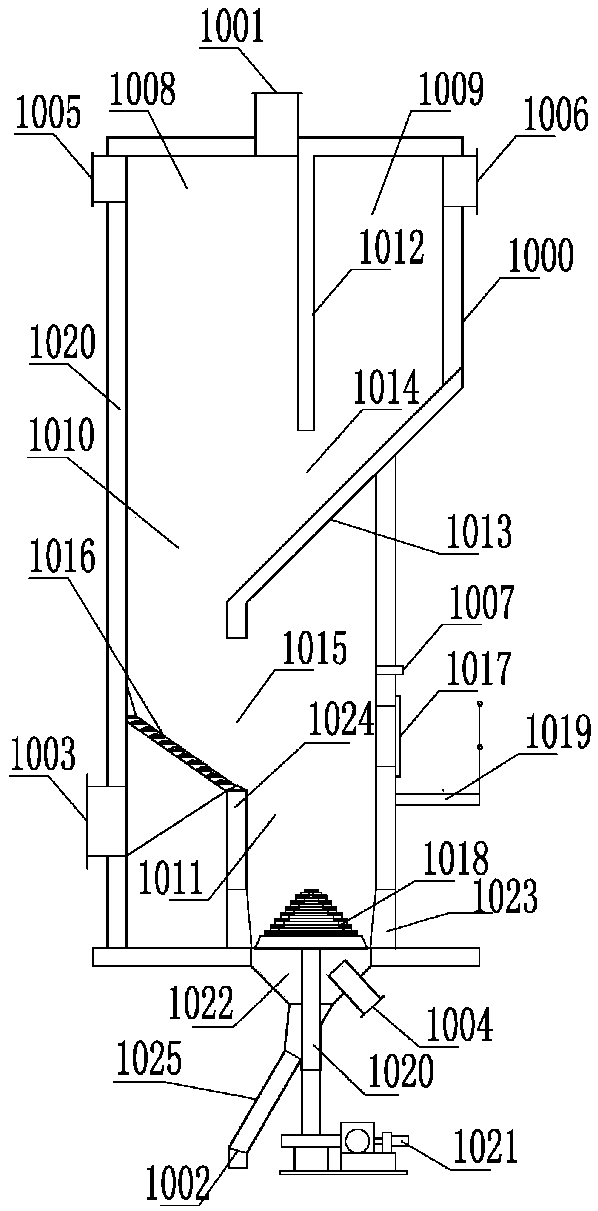

U-shaped high-temperature waste recycling furnace

The invention relates to the field of waste treatment, and provides a U-shaped high-temperature waste recycling furnace, which has the advantages of high treating capacity, environmental friendliness, economic efficiency, high metal recovering rate and high waste suitability. The U-shaped high-temperature waste recycling furnace comprises a vertical combustion tower, a horizontal smelting pond and a vertical disinfecting tower, wherein the top wall of one end of the smelting pond is provided with a first smelting pond inlet hole; the end wall of the smelting pond is provided with a second smelting pond inlet hole; the top wall of the other end of the smelting pond is provided with a smelting pond outlet hole; the top wall of the combustion tower is provided with a combustion tower inlet hole; the bottom wall of the combustion tower is provided with a combustion tower outlet hole; the bottom wall of the disinfection tower is provided with a disinfection tower inlet hole; the top end of the disinfection tower is provided with a smoke outlet; a first turbulent burner is arranged in the combustion tower inlet hole; the combustion tower outlet hole is in butt joint with the first smelting pond inlet hole; the smelting pond outlet hole is in butt joint with the disinfection tower inlet hole; and the side wall of the disinfection tower is provided with at least two air inlet holes. Due to the adoption of the U-shaped high-temperature waste recycling furnace, the problems of poor working condition stability during combustion of wastes and discharge of toxic gases in tail gas out of the standard are solved.

Owner:ZHEJIANG HUANYI TECH

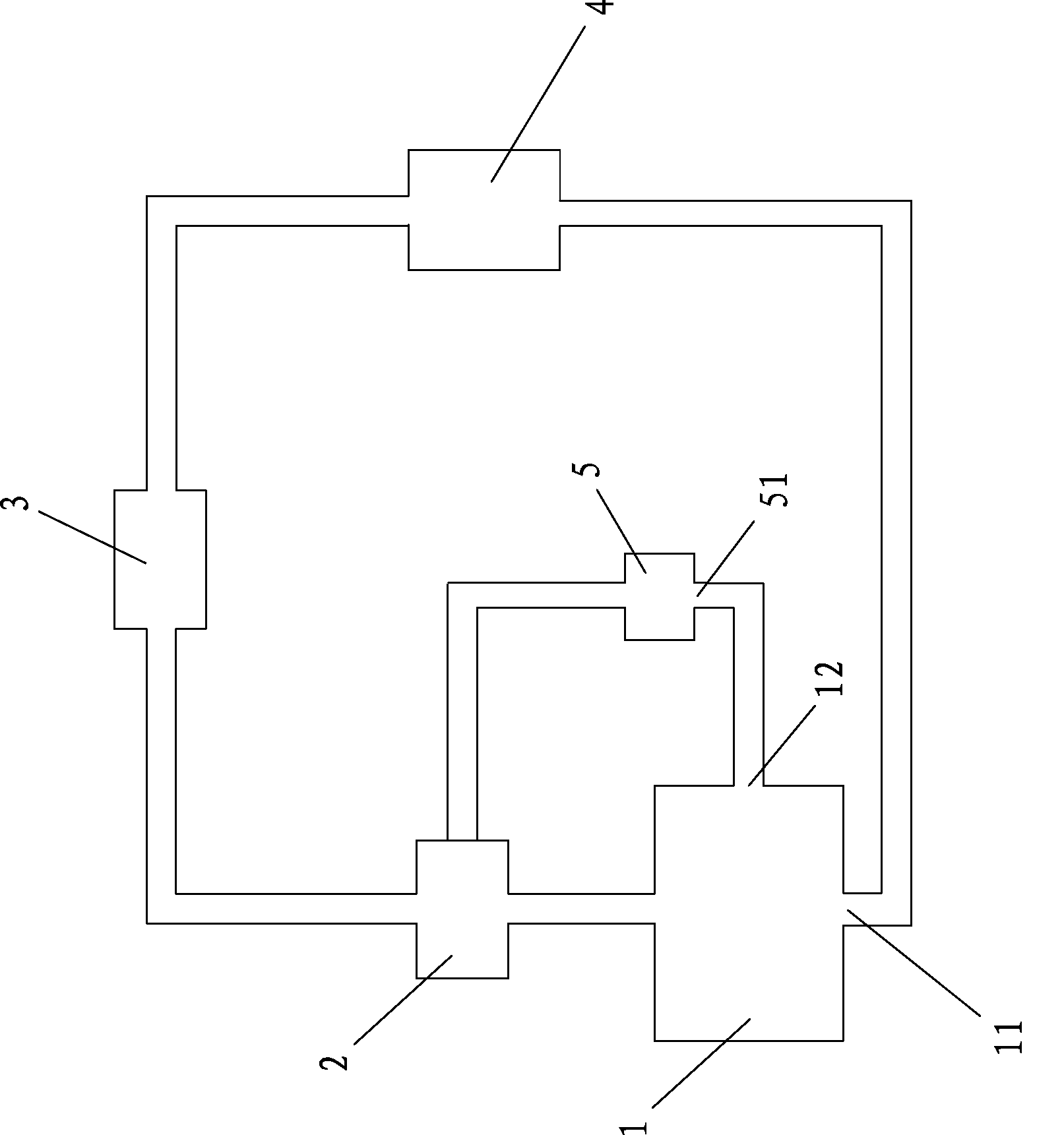

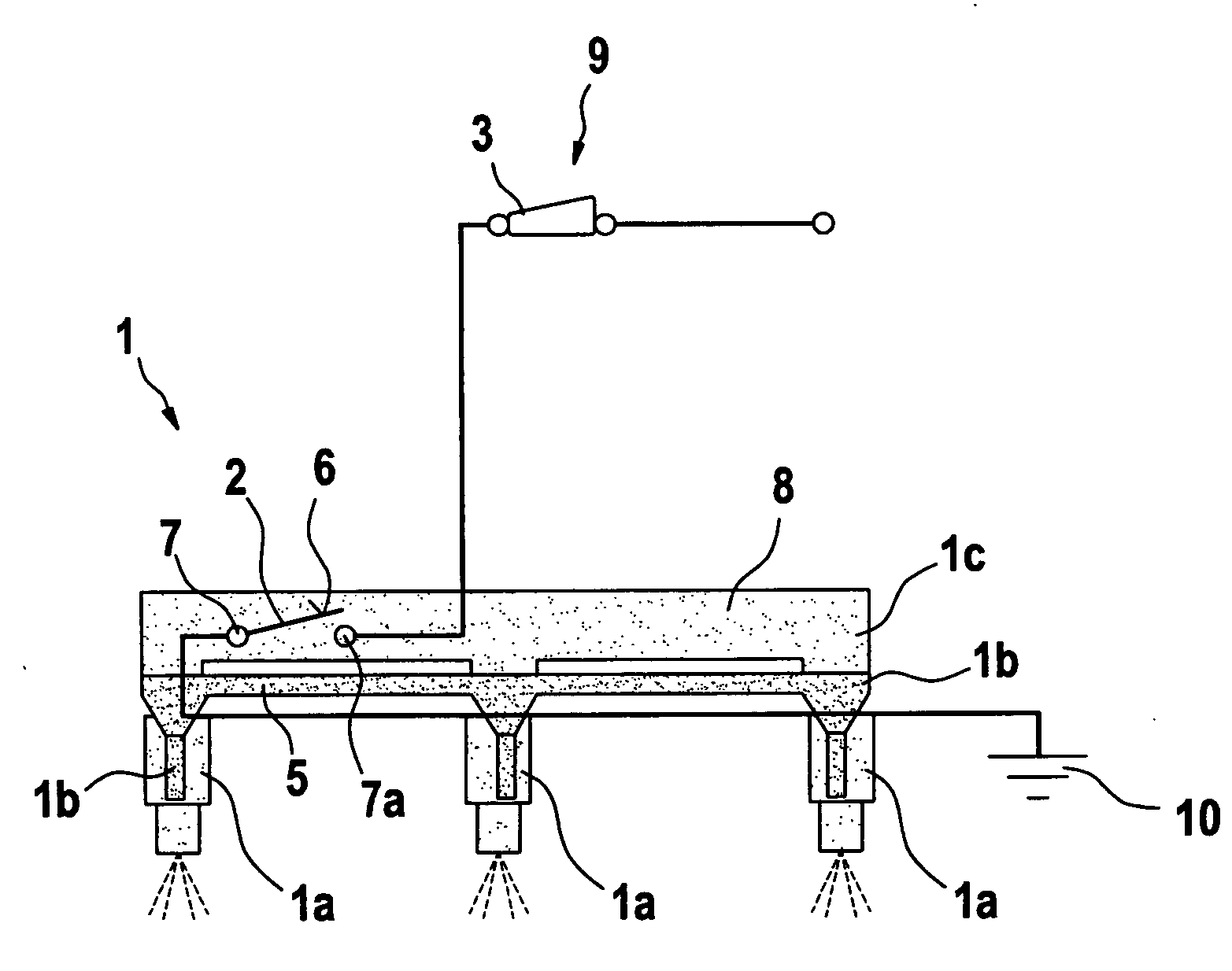

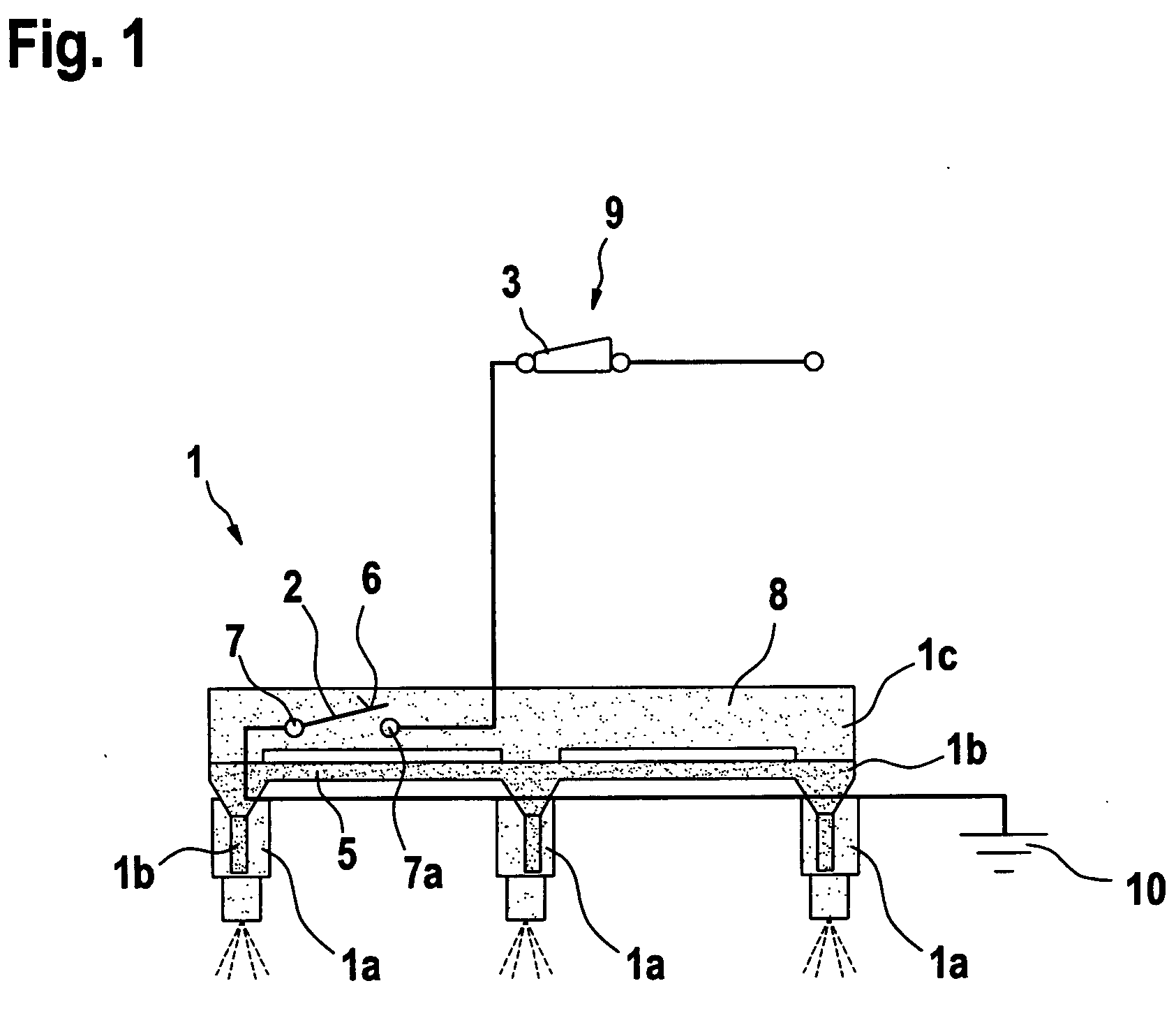

Fuel Injection System

InactiveUS20080251605A1Quality improvementEnsure complete combustionLiquid surface applicatorsInternal combustion piston enginesFuel injectionInjector

A fuel injection system (1) with at least one fuel injector (1a) and a heatable adapter (1b), which is connected to a fuel rail (1c) and to the fuel injector (1a) of the fuel injection system (1); a thermoswitch (2) is provided in the fuel rail (1c), which is connected with an external door contact switch (3) and with the heatable adapter (1b). The thermoswitch (2) includes a thermosensor, so that a reliable cold start is ensured by the fact that, when a previously specified fuel temperature is fallen below, the thermoswitch (2) switches over and causes fuel (8) to be heated.

Owner:ROBERT BOSCH GMBH

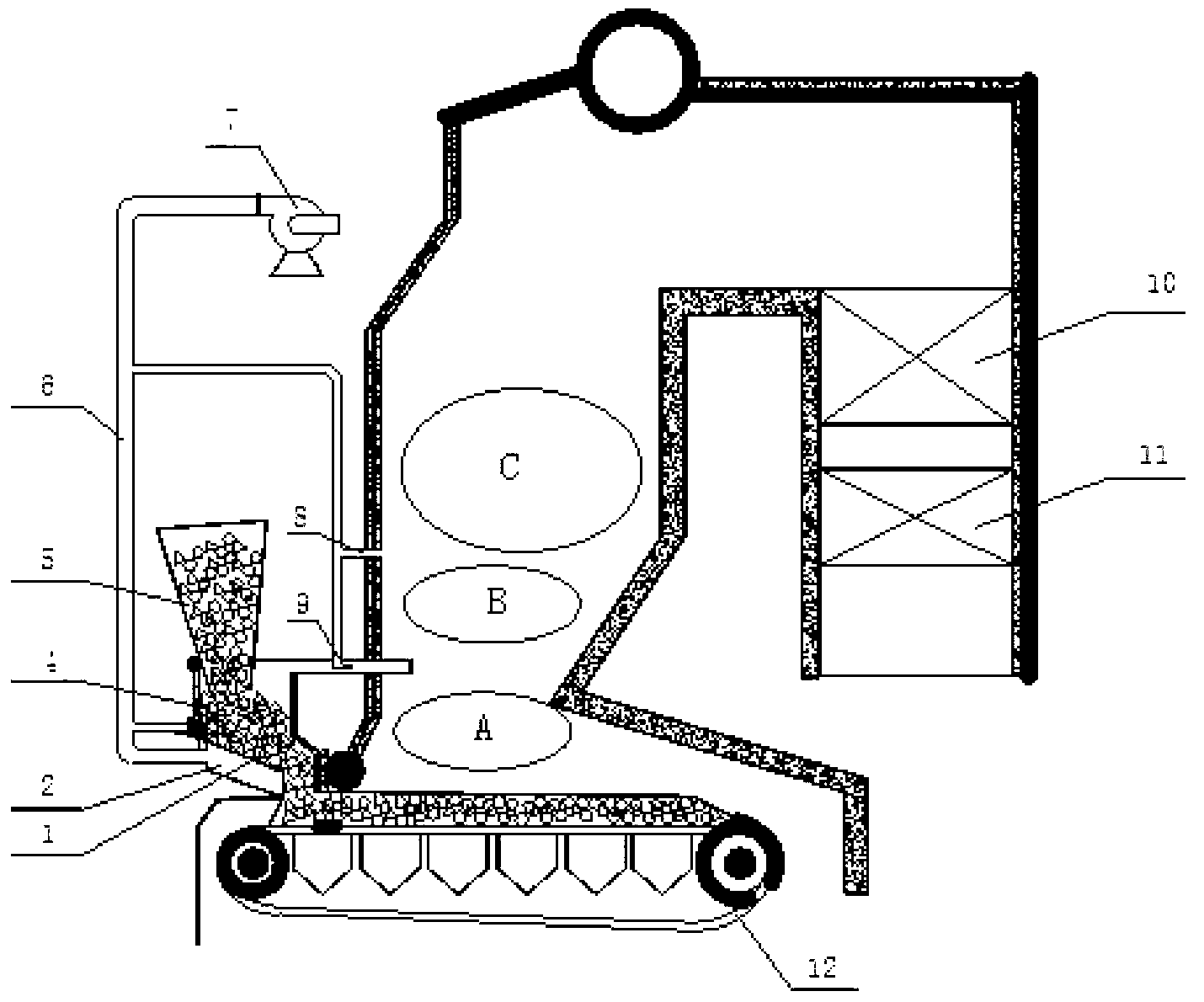

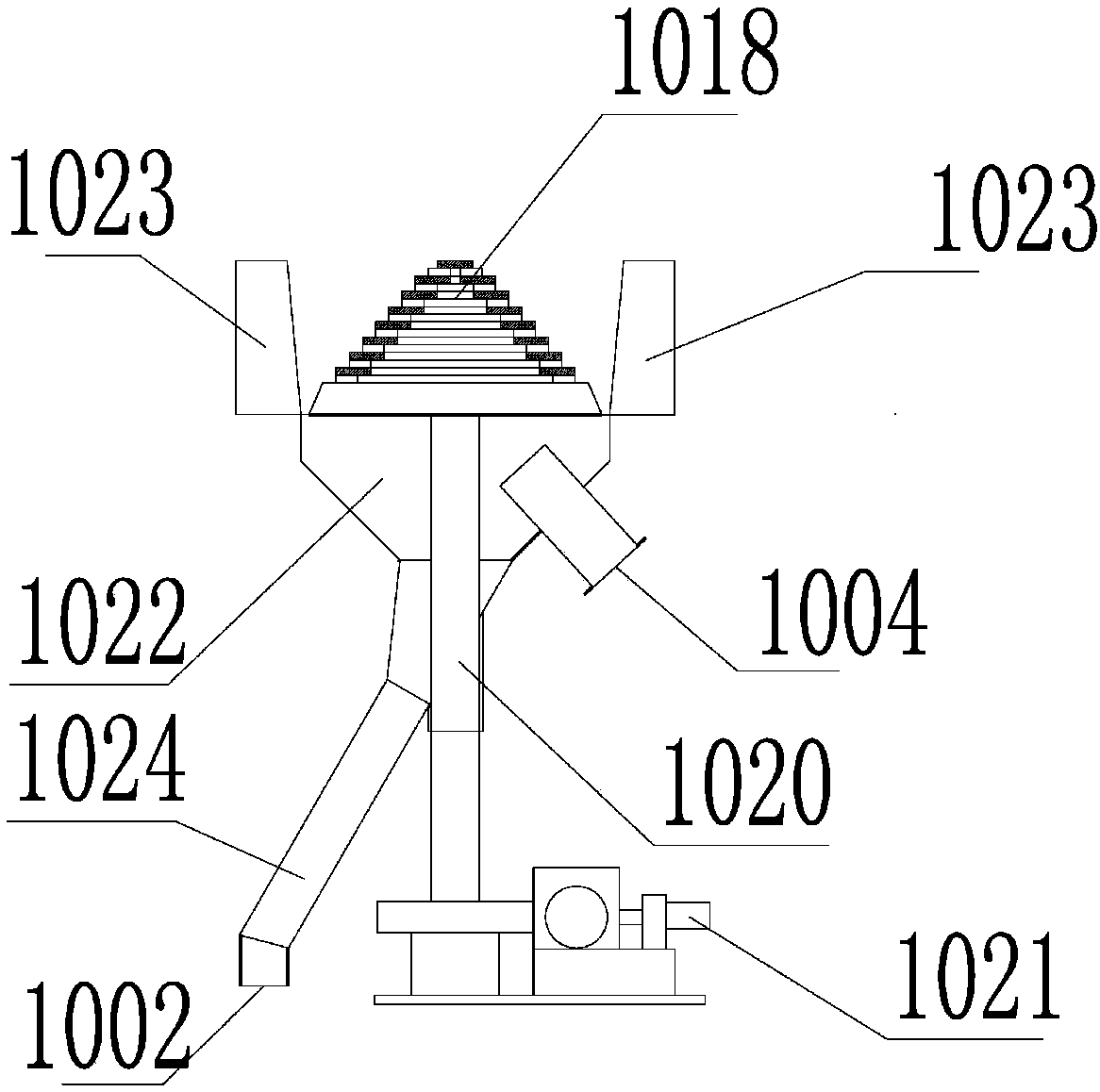

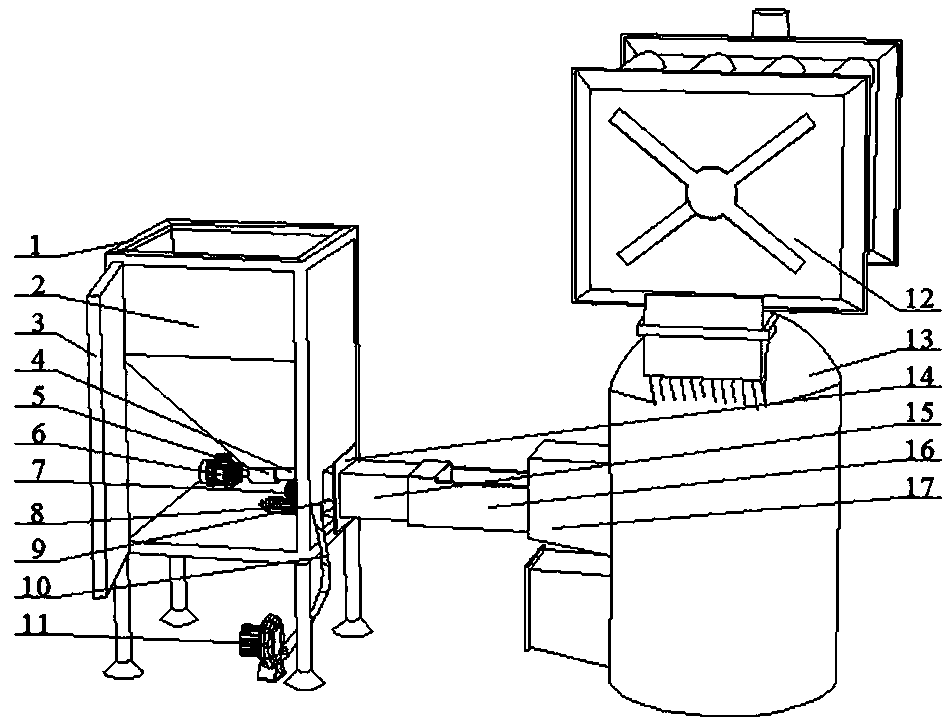

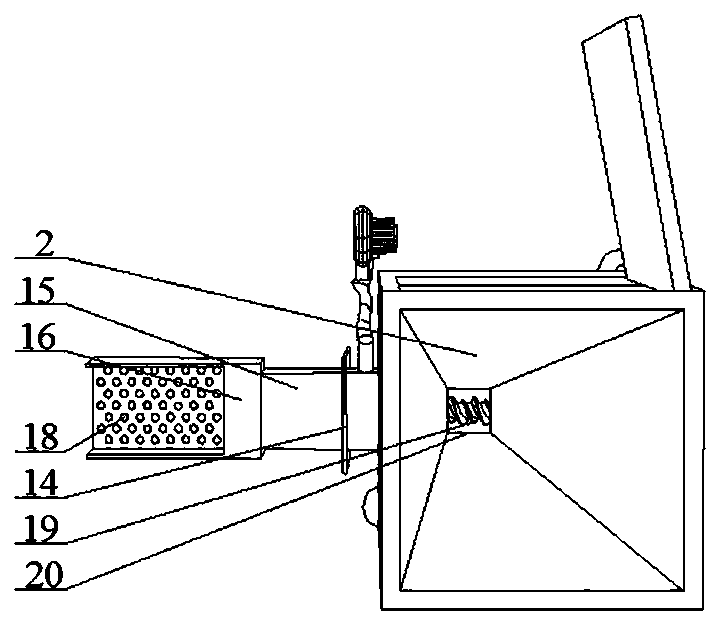

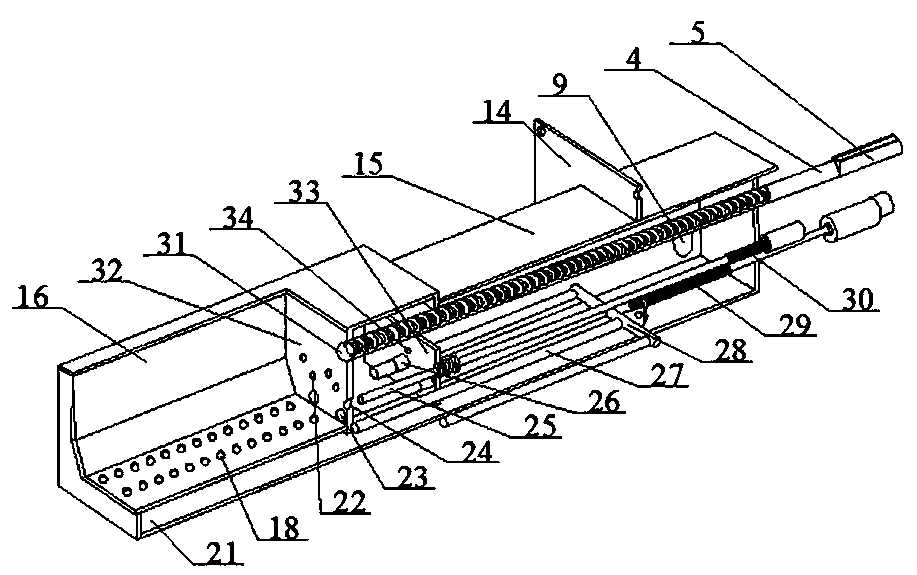

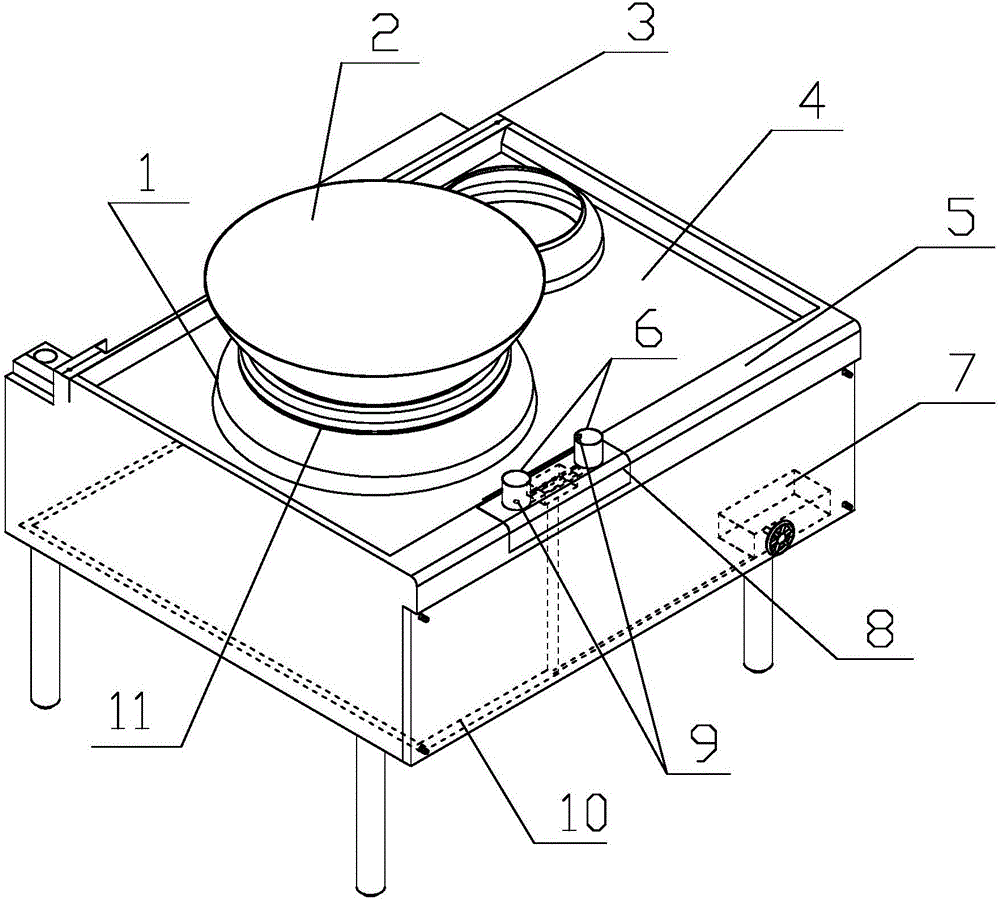

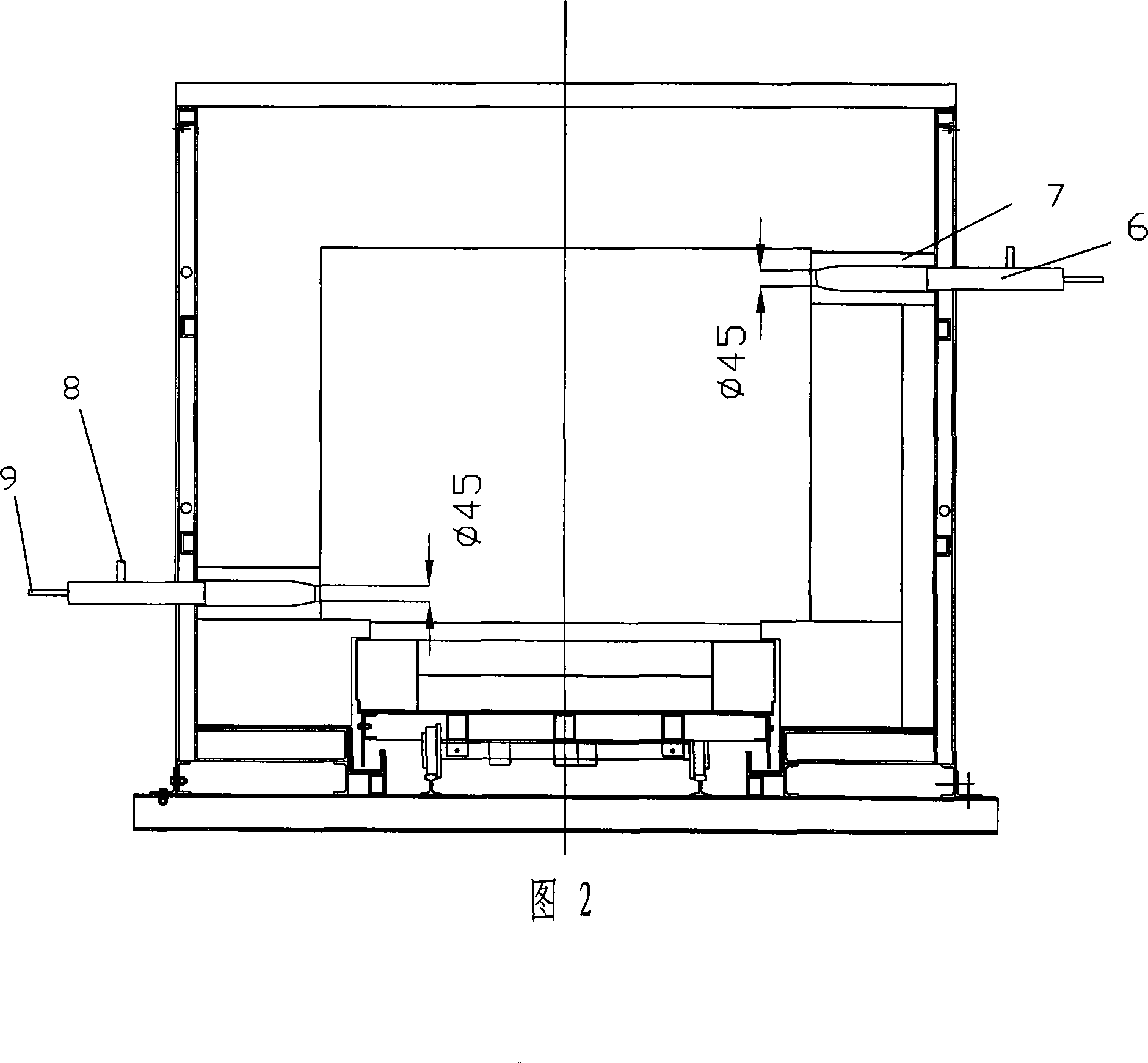

Integrated butt joint furnace of biomass shaped pellet fuel for flue-cured tobacco

InactiveCN110269270APromote secondary complete combustionEnsure complete combustionTobacco preparationCombustorButt joint

The invention discloses an integrated butt joint furnace of biomass shaped pellet fuel for flue-cured tobacco. The integrated butt joint furnace includes a equipment frame and a hopper installed on the top end of the inner part of the equipment frame, a feeding channel is installed at a blanking opening of the hopper, a large and small screw conveyer plate drive bearing is arranged inside the feeding channel in a clamping mode, the head of the large and small screw conveyer plate drive bearing is connected with a feeding power motor, the feeding power motor is fixedly arranged at the bottom end of the inner part of the equipment frame, and the tail portion of the large and small screw conveyer plate drive bearing is placed in a burner, and the burner is installed in an opening hole at the bottom end of the right side face of the equipment frame; the device adopts the large and small double screw conveyer plate drive bearing, the integrity of the biomass particles is improved, an ignition rod and an ignition blow rod in an air chamber blow air to cool the temperature, and the service life of the equipment is prolonged; and horizontal and vertical air-out ensures effective heat transfer and the biomass particles can be fully burned.

Owner:HENAN AGRICULTURAL UNIVERSITY +2

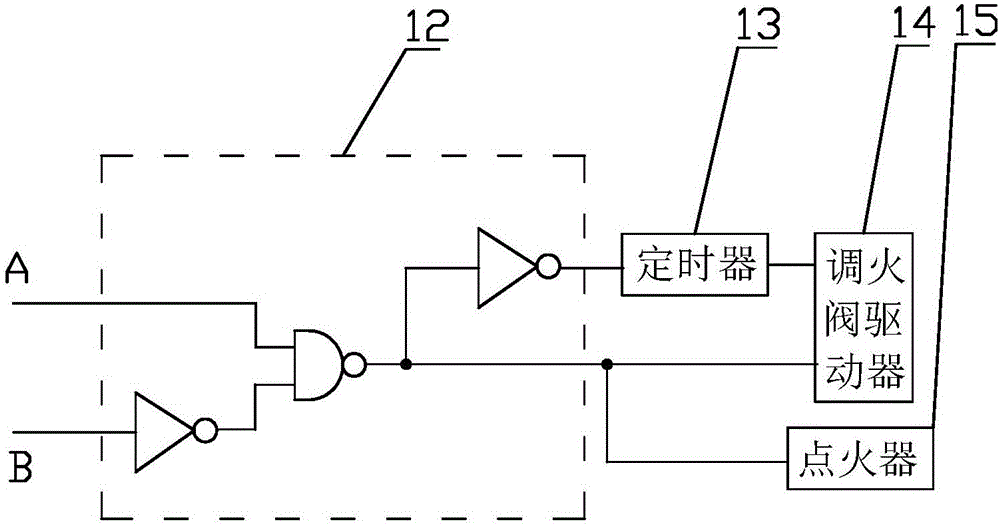

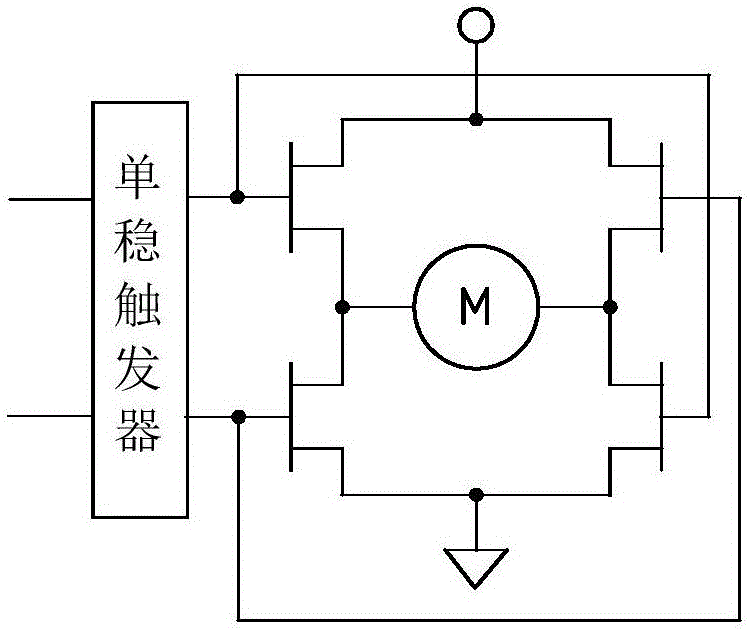

Energy-saving stove with inductive fire-control pot frame and fire control method

PendingCN106765348AImprove stabilityImprove securityDomestic stoves or rangesLiquid heating fuelFire controlFresh air

The invention relates to an energy-saving stove with an inductive fire-control pot frame and a fire control method. A fire-side pot frame for temporarily placing a pot in a cooking process is arranged on the edge of one side, close to an operator, of a cooking bench surface and is provided with support legs, and induction facilities for sensing the position of the pot are arranged in the support legs; and the induction facilities include a first pot position sensing facility and a second pot position sensing facility, the first pot position sensing facility is used for sensing the existence of the pot above a hearth, the second pot position sensing facility is used for sensing the existence of the pot on the fire-side pot frame, and the induction facilities are used for lighting furnace fire when sensing that the pot is placed on a stove hole and turning down or quenching the fire when the pot is taken away from the stove hole. A space between a stove cycle and the pot is closed, and fresh air is introduced to cool the fire-side pot frame and a fire controller. Based on the practicality, the inductive fire control and energy saving of the pot capable of stably working for a long time are truly realized, and the working stability and safety of a system are improved.

Owner:HUBEI ZHONGRUITIANHENG ENERGY SAVING TECH DEV

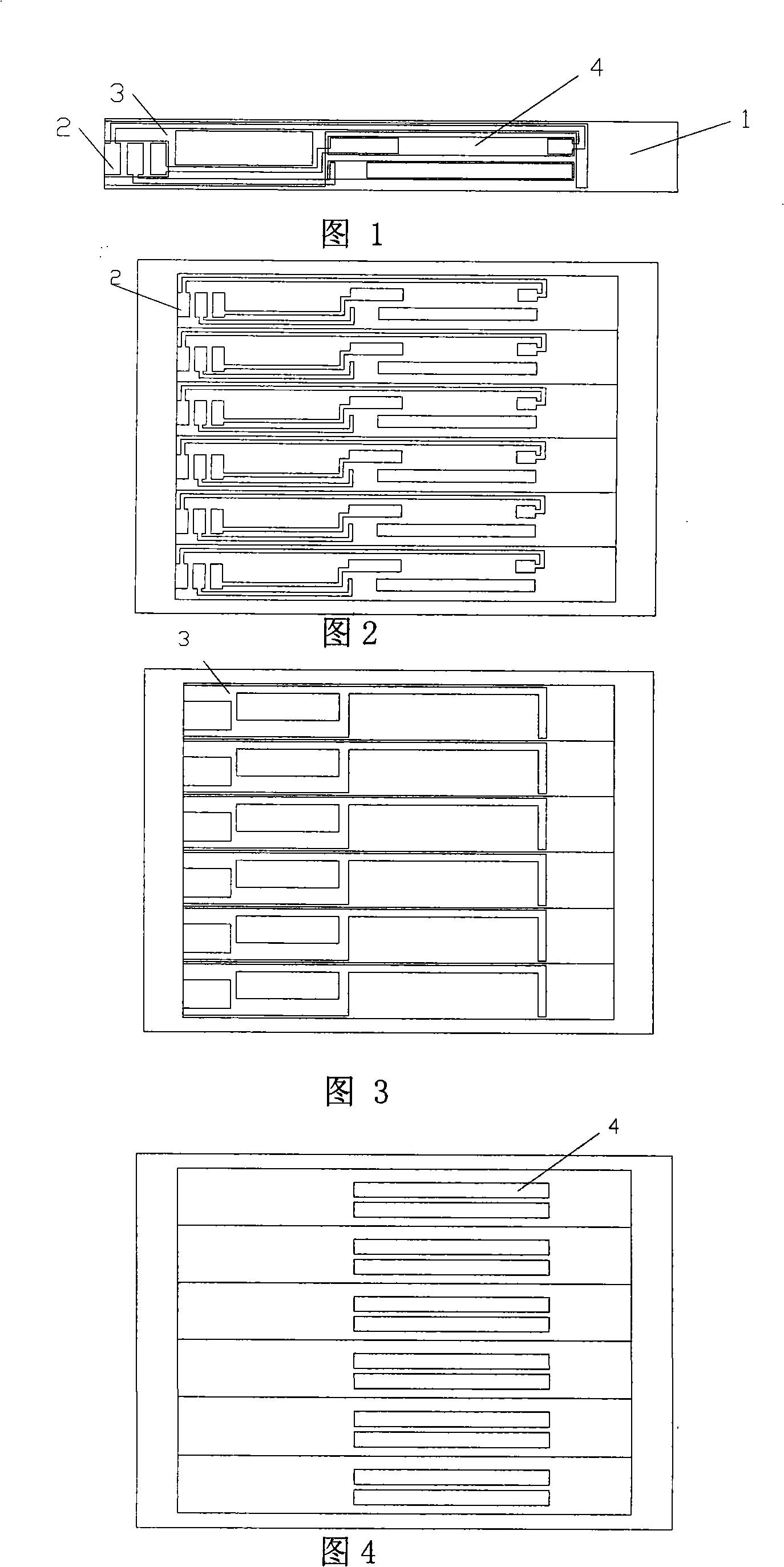

Manufacturing process of resistor plate, obtained resistor plate and application thereof

ActiveCN101291564AEmission reductionGood flatness and wear resistancePrinted electric component incorporationConductive pattern formationSurface electrodeSizing

The invention relates to a method for producing a resistance board, the resistance board and application of the same. In the method, a substrate is taken as a base and attached with a surface electrode film and a resistance film; A. an electrode wire screen is placed on a polyimide film substrate, a layer of electrode sizing agent is printed in the recession of the wire screen by a screen printing method, thereby forming the surface electrode film; B. the resistance film is formed through printing resinous electrode slurry by the screen printing method on the surface electrode film which is the product in step A; and the product with the two films is put into a tunnel kiln for curing, and is divided into a plurality of units along the electrode contraposition line. The resistance board comprises the substrate, the surface electrode film and the resistance film from the inside to the outside, wherein, the substrate is the polyimide film substrate; the surface electrode film is in an open but semienclosed state and the electrode film is cut off with each other; and the resistance film is lapped on the surface electrode film. The resistance board has long service life due to wear resistance and high linearity when used in a throttle position sensor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

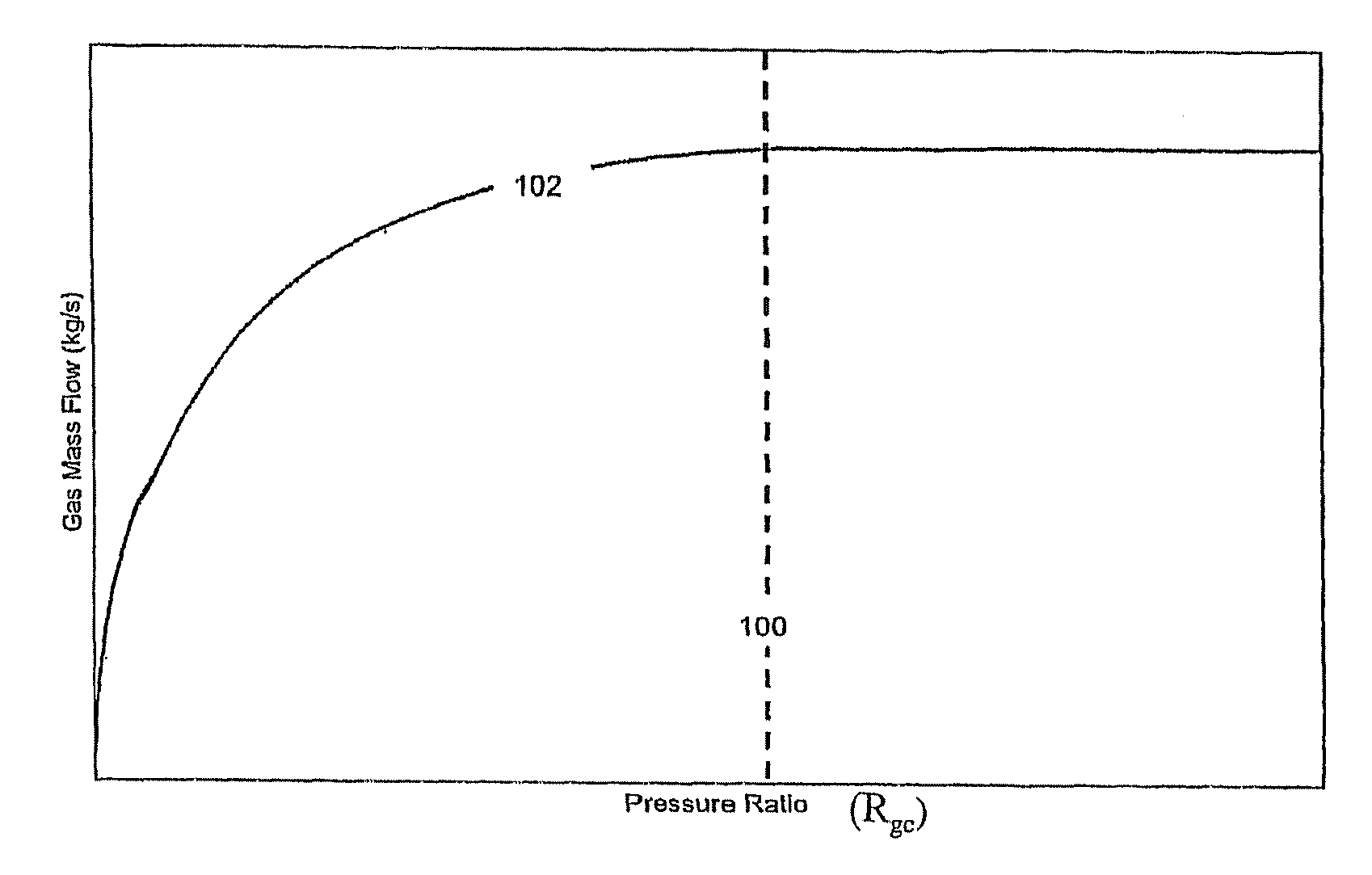

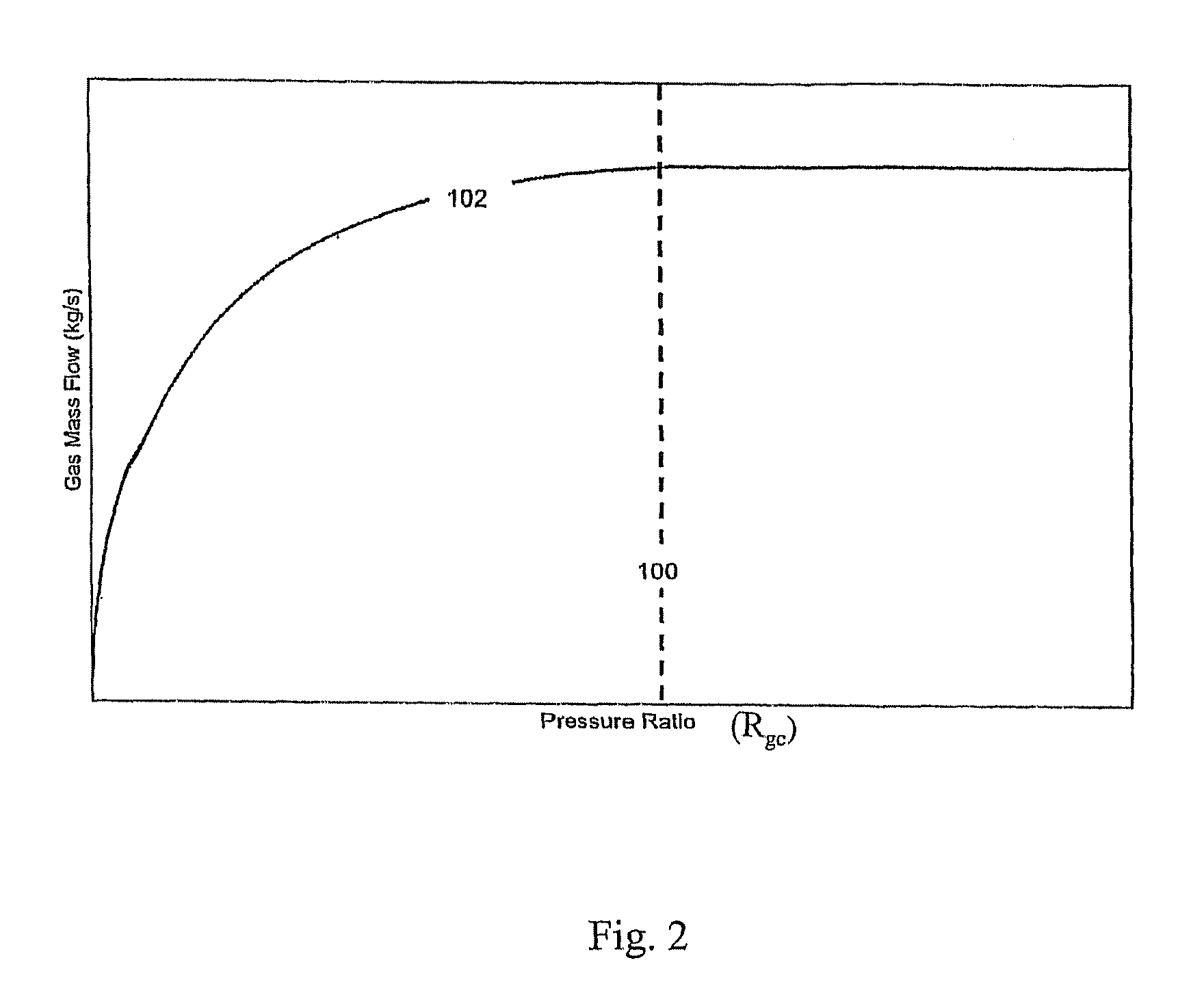

Method for injecting gaseous fuels into an internal combustion engine at high pressures

ActiveUS20060236975A1Promote combustionWell mixedInternal combustion piston enginesFuel supply apparatusShock waveCombustion

A method directly injects gaseous fuel into the combustion chamber of an internal combustion engine. The compressibility of the gaseous fuel is used to provide a fuel to the combustion chamber that is injected over all engine operating conditions at pressures that result in fuel jet speeds beyond the injector nozzle in excess of sonic speeds as determined in reference to the combustion chamber environment. The resulting fuel injection speed results in the fuel passing through shock waves within the combustion chamber, which, in turn, promotes combustion of the fuel by promoting turbulence and mixing of the fuel and intake charge within the combustion chamber where fuel burns in a non-premixed combustion mode.

Owner:WESTPORT FUEL SYST CANADA INC

Combustion device with safety

The invention discloses a combustion device with safety. The combustion device comprises a body and a flow guiding device, wherein the body is provided with a containing space and a group of lampwick; the lampwick is arranged in the containing space; the body is provided with a bottom surface; the lampwick comprises a top end; a first distance is arranged between the top end and the bottom surface of the lampwick; the flow guiding device is connected to the body and comprises a first shielding part which comprises a bottom side and a top side; a second distance longer than the first distance is arranged between the bottom side and the bottom surface of the first shielding part; a third distance longer than the first distance is arranged between the top side and the bottom surface of the first shielding part; the flow guiding device also comprises a first airflow channel for communicating the inner side and the outer side of the first shielding part. The combustion device disclosed by the invention has the advantages that in combustion, air is sucked through the airflow channel, and not only is the combustion provided, but also the airflow is controlled to pass through the surface of the combustion device so as to provide cooling; the shape of flame is controlled and stabilized by a first flow guiding part.

Owner:PRO IRODA INDS

Rich-oxygen and pure oxygen burning tunnel kiln

InactiveCN101182218AReduce total powerEmission reductionFurnace typesCeramic materials productionTunnel kilnHigh concentration

The invention provides an oxygen-enriched and total-oxygen burning tunnel kiln, comprising a preheating area (2), a sintering area (3), a fuel and combustion-supporting medium feeding system (4), a smoke exhaust system (5), a quench area, a cooling area, a temperature control system, a burning system and a waste heat system. The tunnel kiln is used for a combustion-supporting medium with the volume concentration of at least 21 percent of oxygen and the fuel to burn together inside a burner (6), no air combustion-supporting fan is required, the burner (6) is installed at the position of a burner brick (7). In order to solve the problem that the exhaust emission quantity of a ceramic tunnel kiln is large, the invention adopts the high concentration oxygen burning tunnel kiln which has high thermal efficiency, so compared with the combustion which considers the air as the combustion-supporting medium, the burning product quantity is reduced more than 50 percent, the nitrogen oxide produced by the invention is reduced greatly, the invention can reduce the energy consumption more than 10 percent, and the harmful substance emission can be reduced to the minimum.

Owner:WUHAN UNIV OF TECH

Process method for preparing active calcium oxide through oxygen-enriched calcination

InactiveCN110627384AHigh activityLow ignition pointCalcium/strontium/barium oxides/hydroxidesDecompositionHeat transfer efficiency

The invention discloses a process method for preparing active calcium oxide by oxygen-enriched calcination. The process method the following steps of firstly crushing and sieving raw limestone to enable the particle size of the raw limestone to be 10-55 mm, conveying the raw limestone into a stock bin with a circular cross section, wherein the stock bin is arranged at an upper part of a vertical preheater; then, uniformly conveying the raw materials in the stock bin into the vertical preheater through a blanking pipe, and preheating the raw materials by using high-temperature kiln gas and cooling gas of a vertical cooler; then, feeding the materials into a rotary kiln, and importing oxygen-enriched air from a kiln head to perform oxygen-enriched calcination; and then, feeding the calcium oxide obtained after calcination and decomposition into the vertical cooler to be cooled by air, namely, obtaining the active calcium oxide. According to the process method disclosed by the invention,through the integration of the processes of graded preheating, oxygen-enriched calcination, graded cooling, dynamic temperature monitoring and the like, and the raw materials are preheated by combining the high-temperature kiln gas and the high-temperature gas discharged from the cooler, the heat transfer efficiency of the system is greatly improved, the activity of calcium oxide is obviously improved, the energy consumption is reduced, and the energy conservation and emission reduction are realized.

Owner:HUBEI UNIV

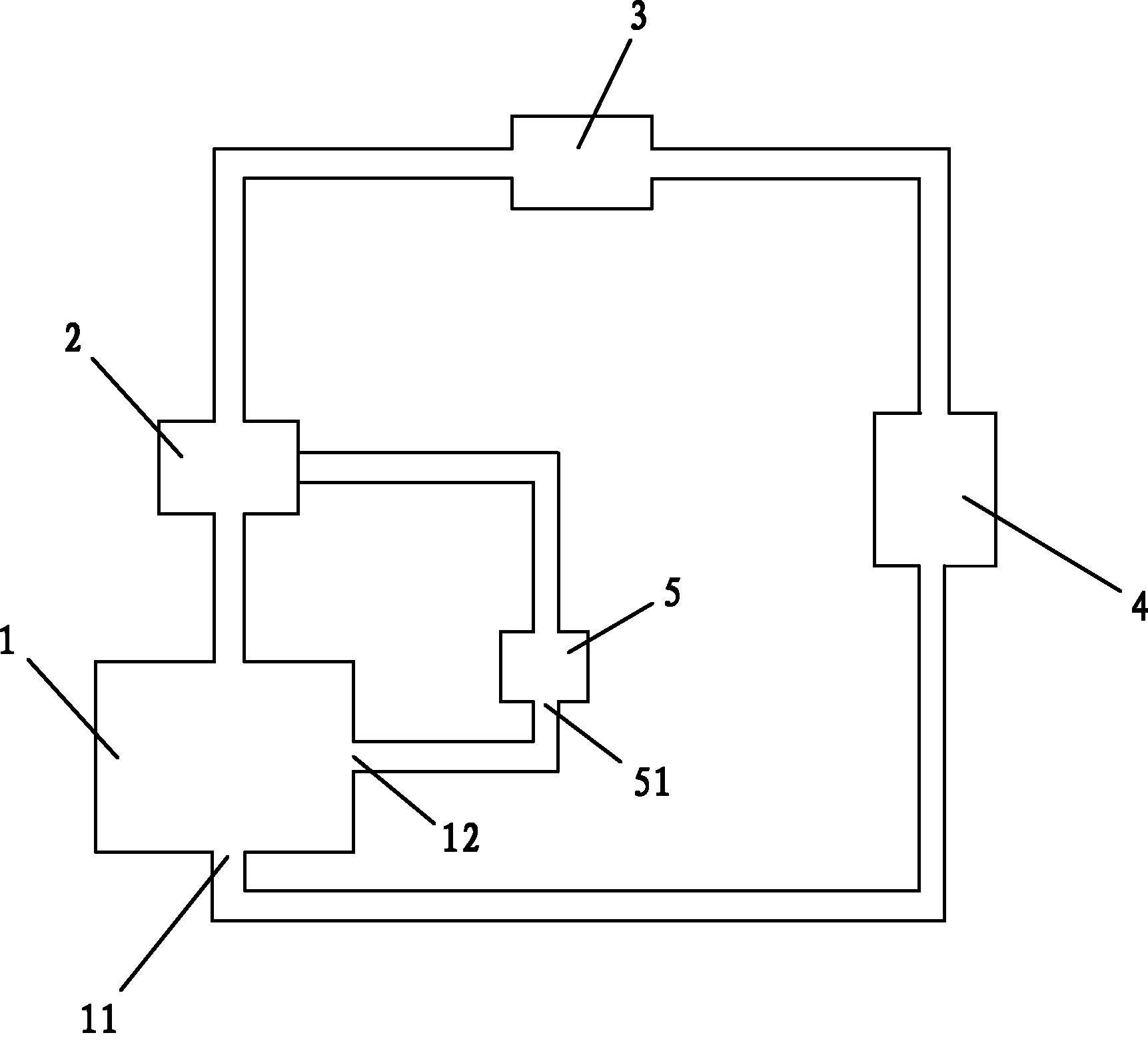

Thermal recovery system with improved thermal efficiency and thermoelectric combined production system equipped with the thermal recovery system

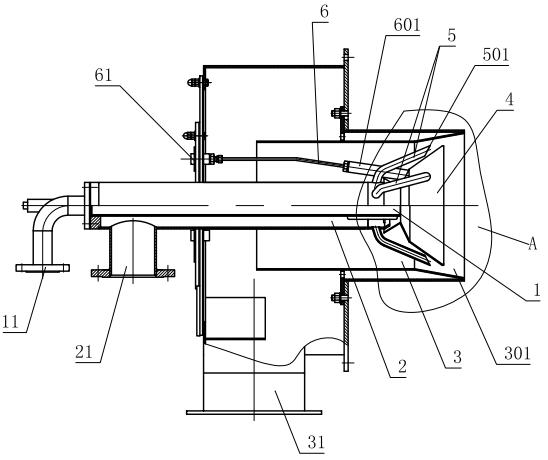

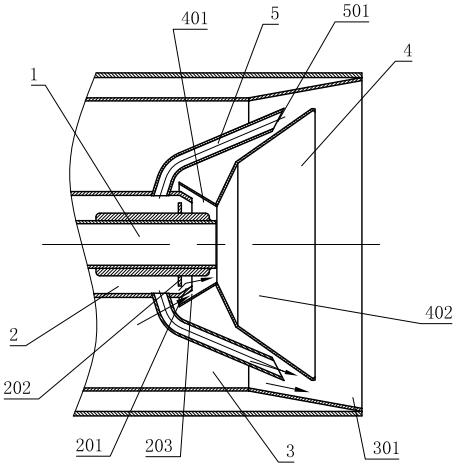

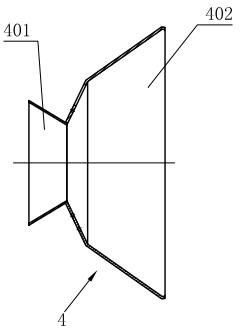

ActiveCN102345850AEnsure complete combustionReduce lossesMachines/enginesSteam generation plantsCombustion chamberCogeneration

The invention provides a thermal recovery system with improved thermal efficiency and a thermoelectric combined production system equipped with the thermal recovery system. A combustion apparatus includes a cylindrical combustion chamber surrounded by an inner wall. A cooling chamber comprises an intermediate wall spaced from the inner wall. Cooling water flows in and out lower and upper sides of the intermediate wall, to cool the inner wall by the cooling water that flows into a space formed between the inner and intermediate walls of the cooling chamber. A lateral combustion air supply chamber comprises an outer wall spaced from an outer side of the intermediate wall. Combustion air is supplied at an upper side of the outer wall to thereby make the air in a tangential direction with respect to the cylindrical outer wall turn and fall in a space formed between the intermediate wall and the outer wall, so that the combustion air is supplied to the combustion chamber via an opened lower portion of the lateral combustion air supply chamber.

Owner:创意能源控股有限公司

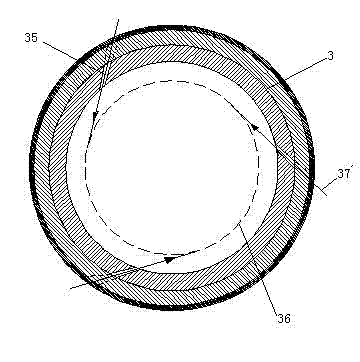

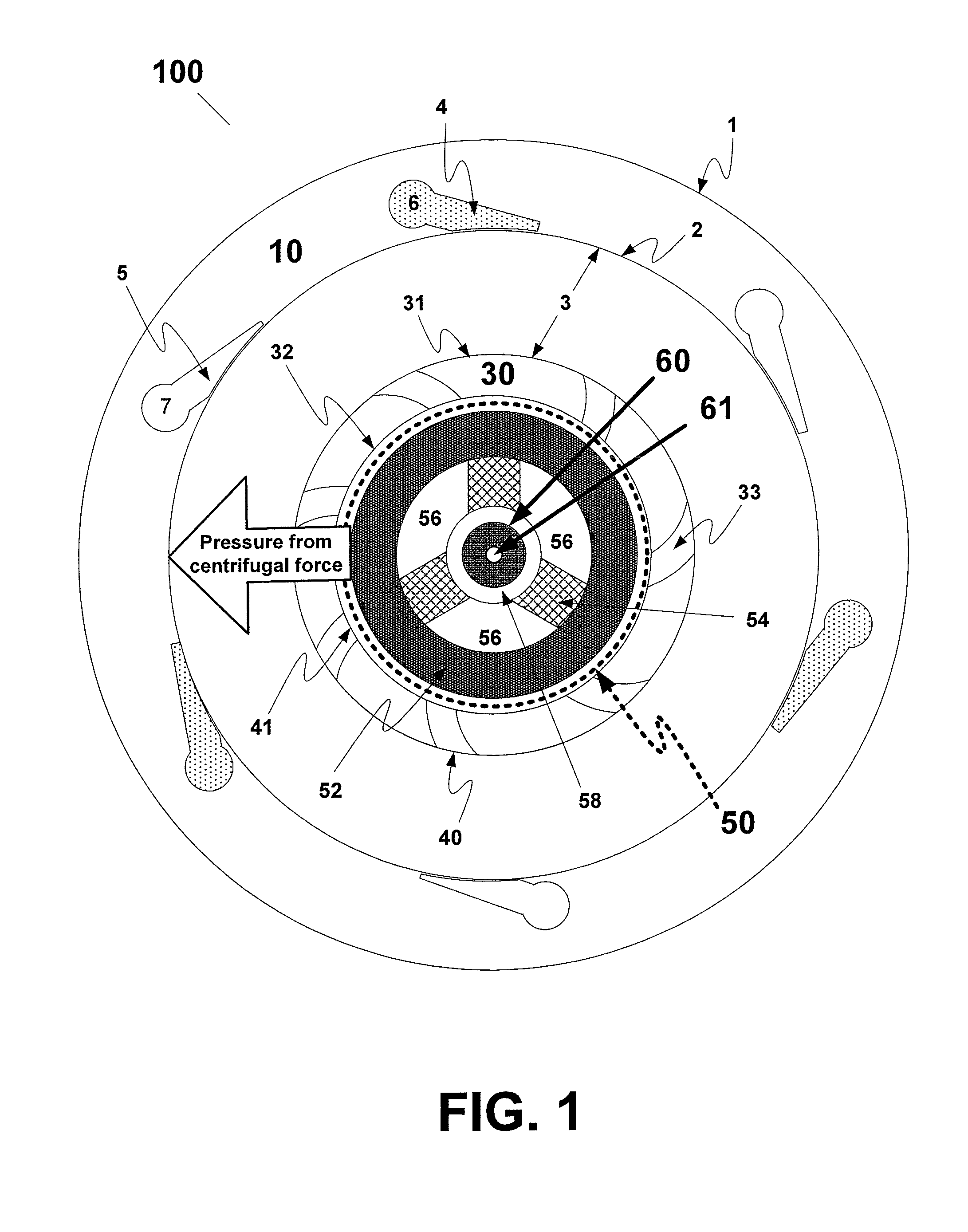

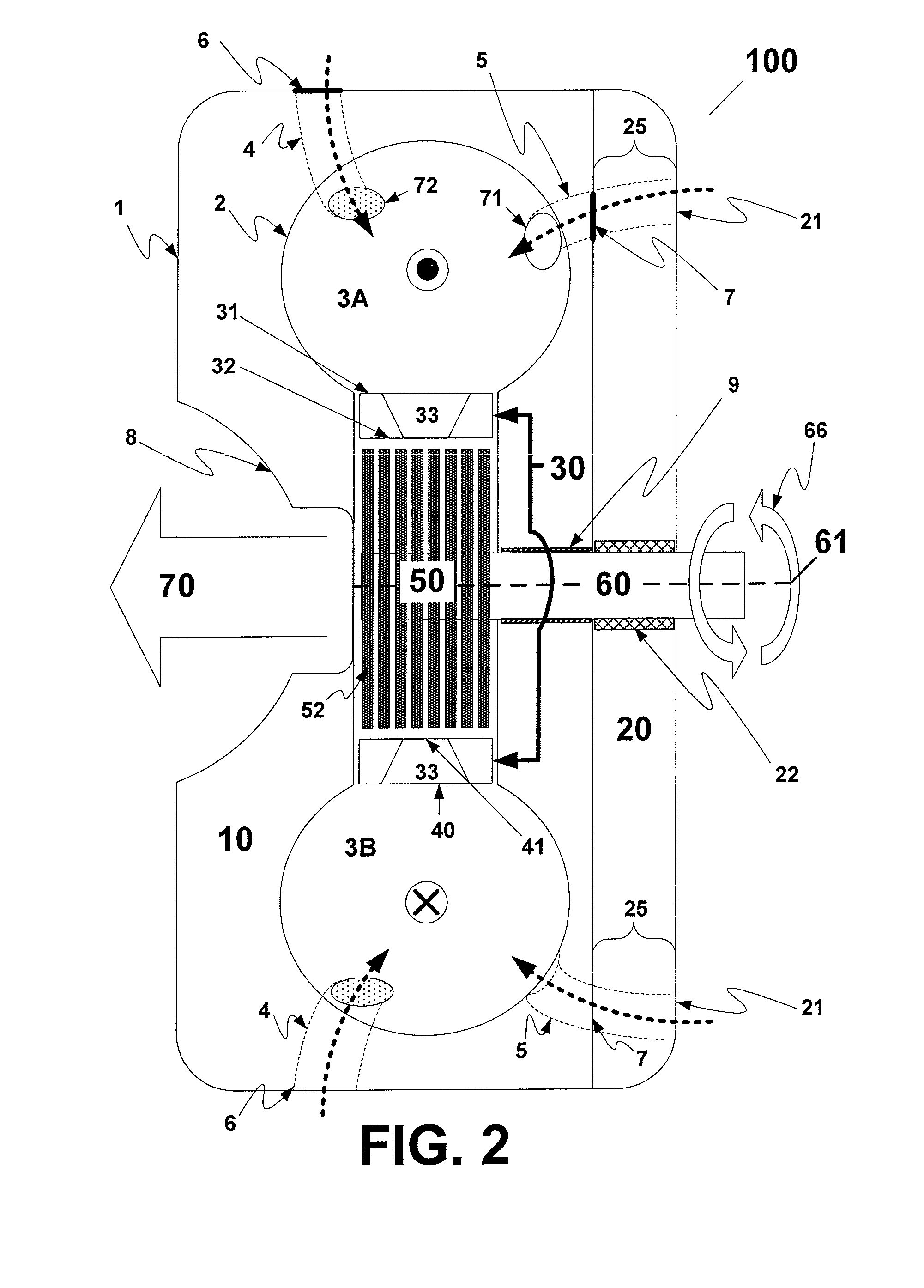

Toroidal boundary layer gas turbine

InactiveUS8863530B2Easy constructionConsiderable efficiencyContinuous combustion chamberTurbine/propulsion engine coolingCentrifugal forceGas turbines

A device comprising a combustion toroid for receiving combustion-induced centrifugal forces therein to continuously combust fluids located therein and an outlet for exhaust from said combustion toroid.

Owner:C6 COMBUSTION TECH LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com