Patents

Literature

34results about How to "Meet caloric needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for cooperatively producing carbon and heat through gasification power generation of biomass fixed bed

ActiveCN107177381AHigh calorific valueMeet caloric needsSteam generation heating methodsHeat recovery systemsAir preheaterFixed bed

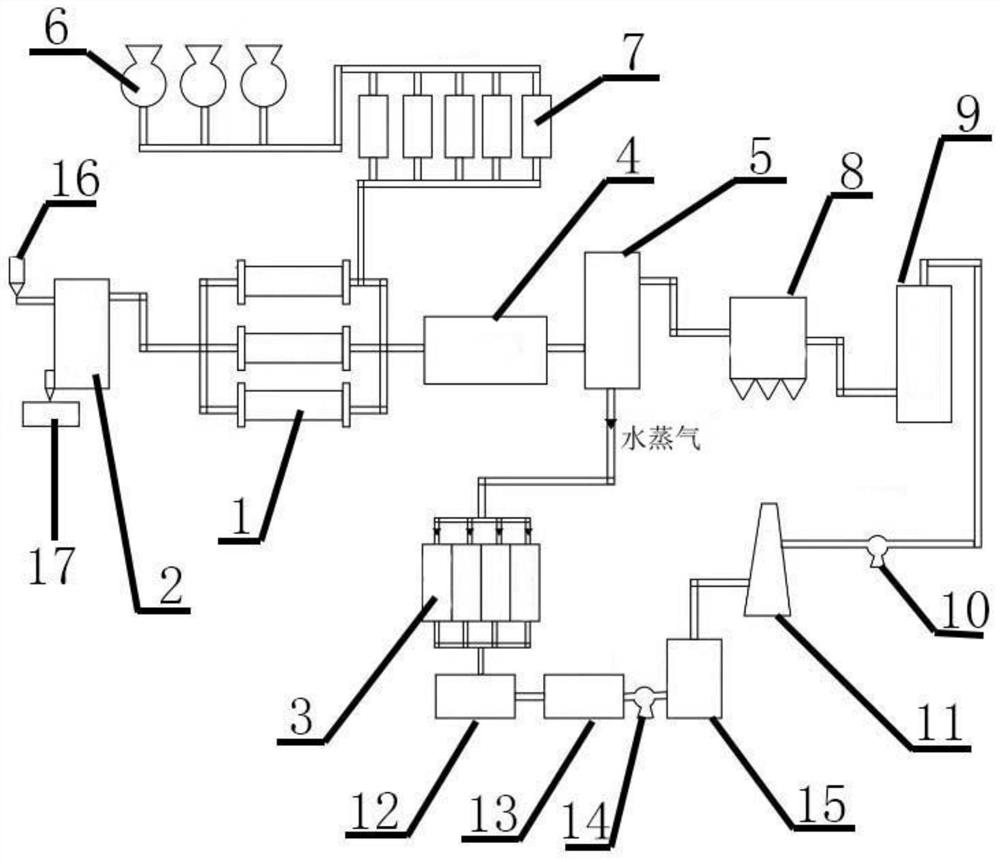

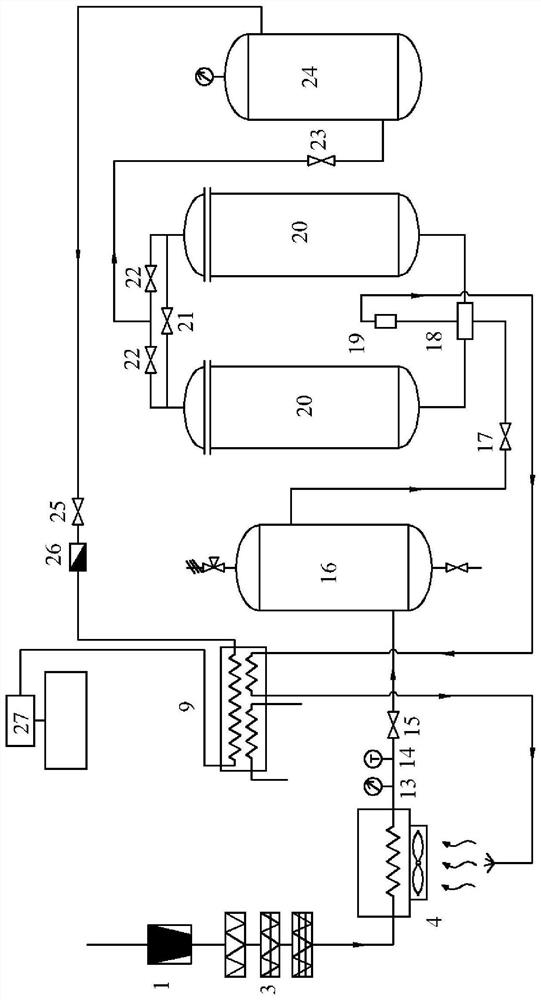

The invention relates to a method for cooperatively producing carbon and heat through gasification power generation of a biomass fixed bed. According to the method, by utilizing middle-heat-value combustible gas, the heat requirement of a high-temperature high-pressure boiler can be met, and the integral power generation efficiency is improved; and nitrogen oxide is low in content and can meet environmental protection requirements, and denitrification is not required. The method comprises the following steps: sending biomass raw materials into a gasification device for preparing middle-heat-value biomass combustible gas, gasifying the biomass raw materials under the action of air-vapor premixed gasifying agent at 700-850 DEG C so as to produce combustible gas, wherein the heat value of the combustible gas is 1600Kcal-1800Kcal, and the temperature is 200-300 DEG C; directly introducing the combustible gas into an environment-friendly combustion cavity for combustion, introducing the combustible gas into the high-temperature high-pressure boiler for combustion to produce high-temperature high-pressure steam so as to push the steam turbine to generate power, and utilizing steam waste heat discharged from the steam turbine; and heating air by virtue of an air preheater through boiler tail gas, respectively introducing hot air into a combustion cavity and the gasification device by virtue of an air blower, and utilizing the waste heat.

Owner:NANJING FORESTRY UNIV

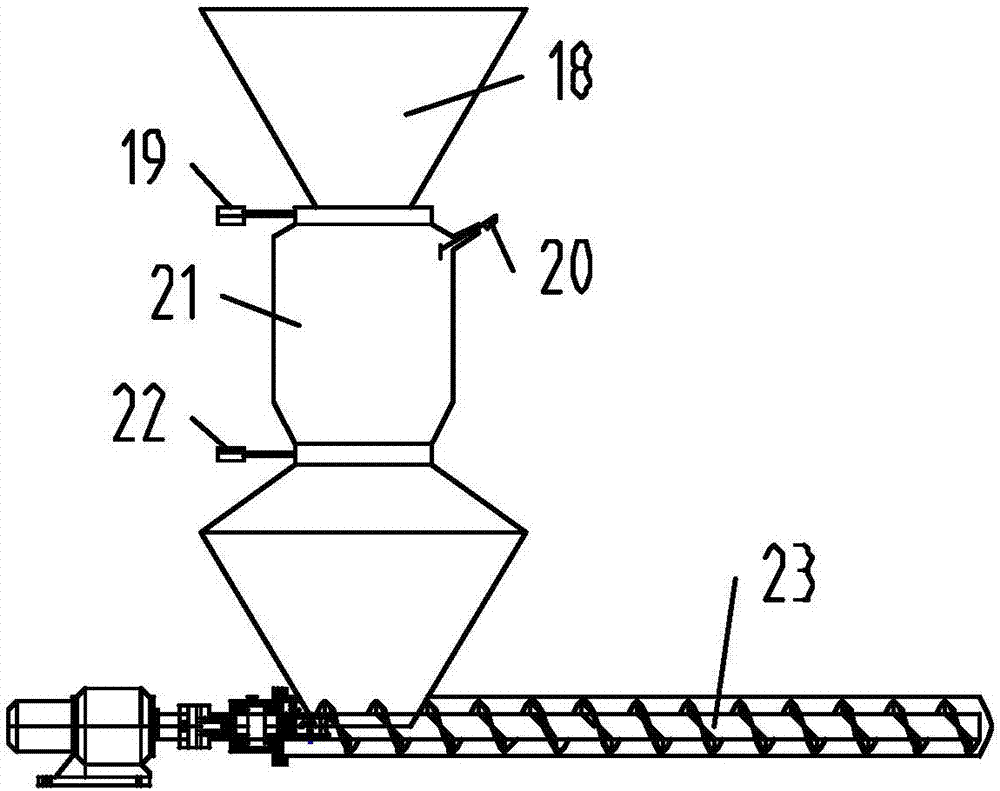

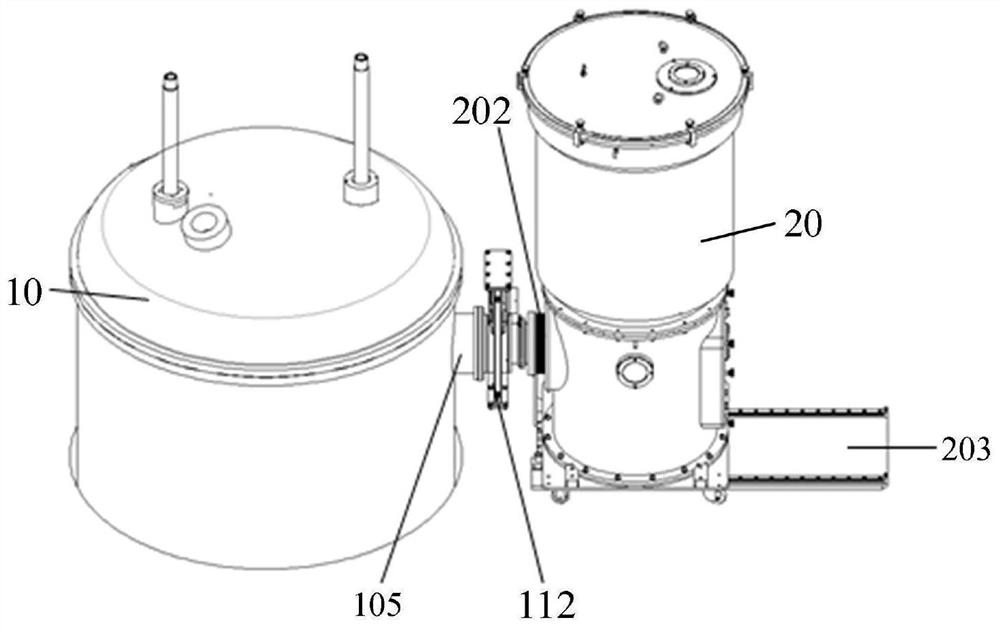

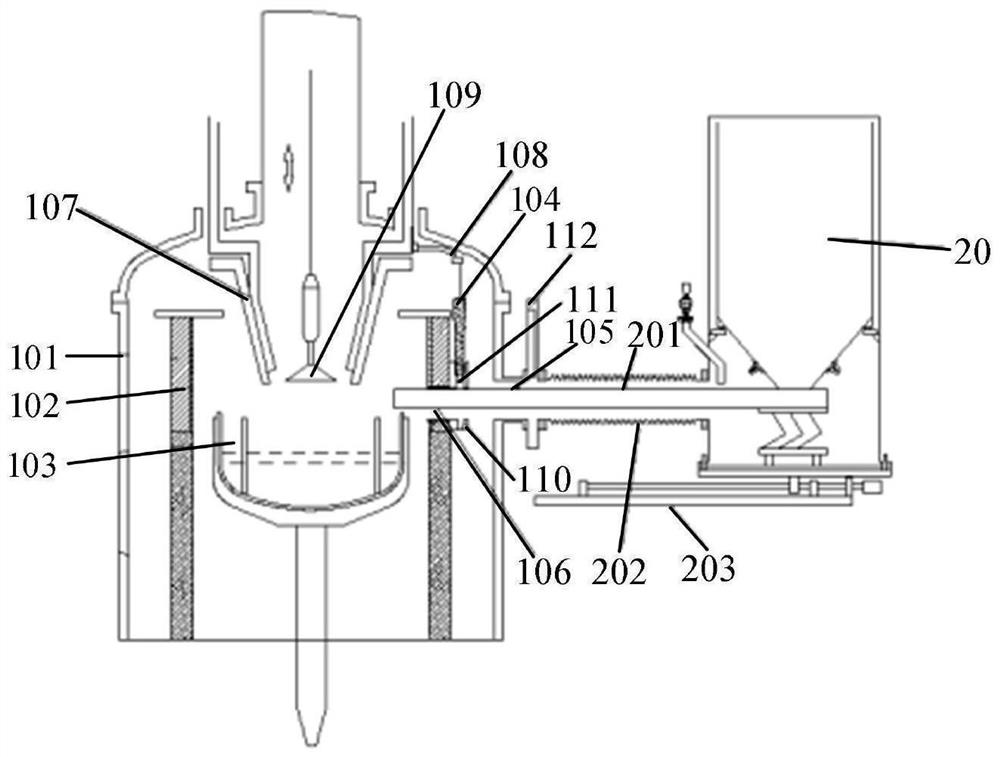

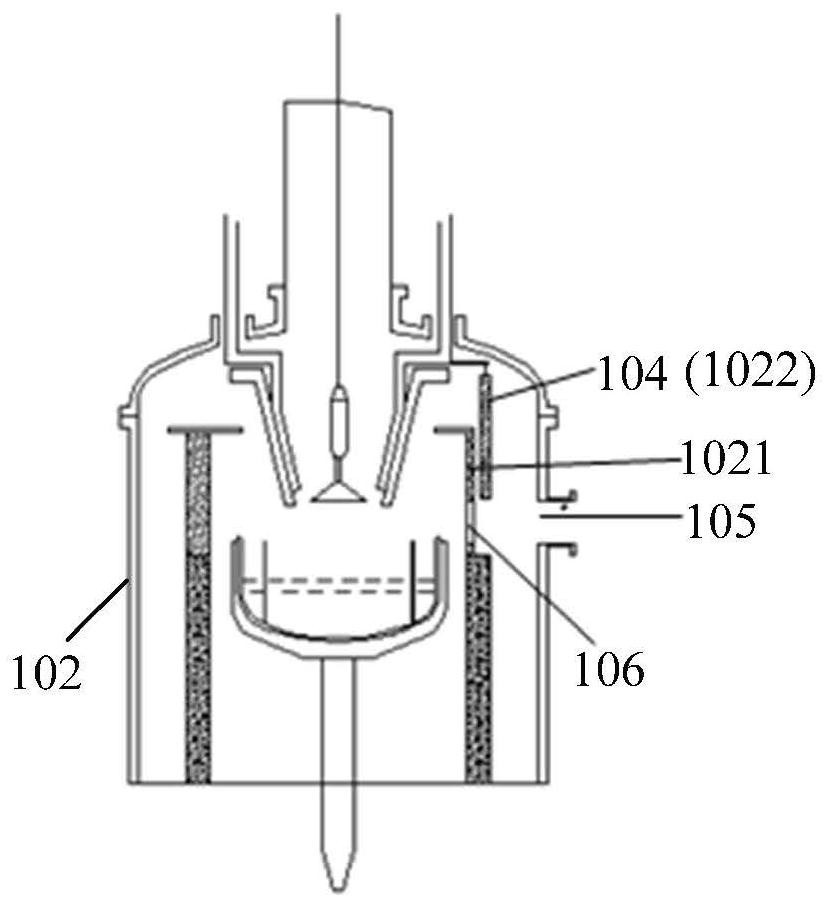

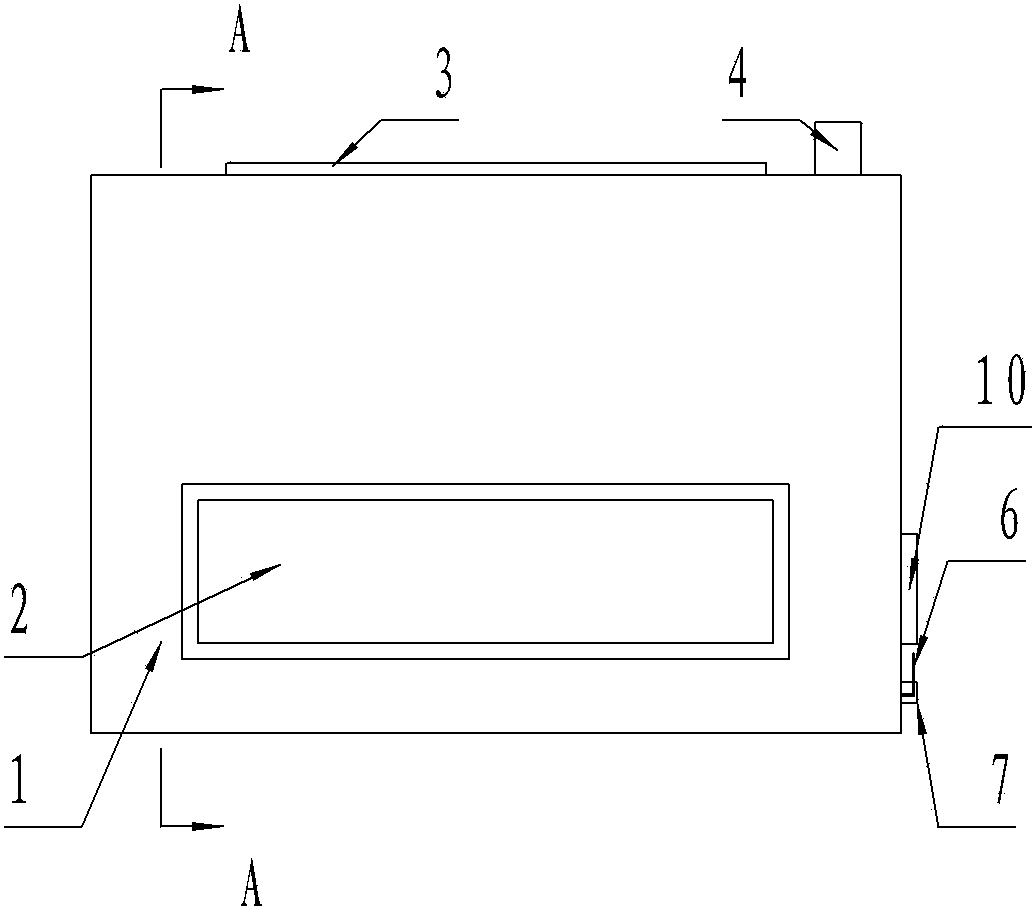

Single crystal furnace charging system

PendingCN113337884AAvoid getting lostEasy to pull crystalPolycrystalline material growthBy pulling from meltInsulation layerThermal insulation

The embodiment of the invention provides a single crystal furnace charging system. The single crystal furnace charging system comprises a single crystal furnace and a charging device, and the single crystal furnace comprises a furnace body, a thermal insulation layer, a crucible and a stopper. A first charging hole is formed in the furnace body, and a second charging hole is formed in a position, opposite to the first charging hole, of the insulating layer; and the charging device comprises a material conveying piece, and the material conveying piece is sequentially and movably arranged in the first charging opening and the second charging opening in a penetrating mode. Moreover, the second charging hole is movably provided with a stop piece for shielding the second charging hole, so that after the charging device finishes charging a crucible, the conveying piece can be drawn out from the second charging hole, and the second charging hole is shielded by the stop piece to prevent the heat in the insulating layer from being lost so as to meet the heat requirement in the crystal pulling process of the single crystal furnace, the crystal pulling process is ensured to be carried out smoothly, and the crystal pulling efficiency is improved.

Owner:LONGI GREEN ENERGY TECH CO LTD

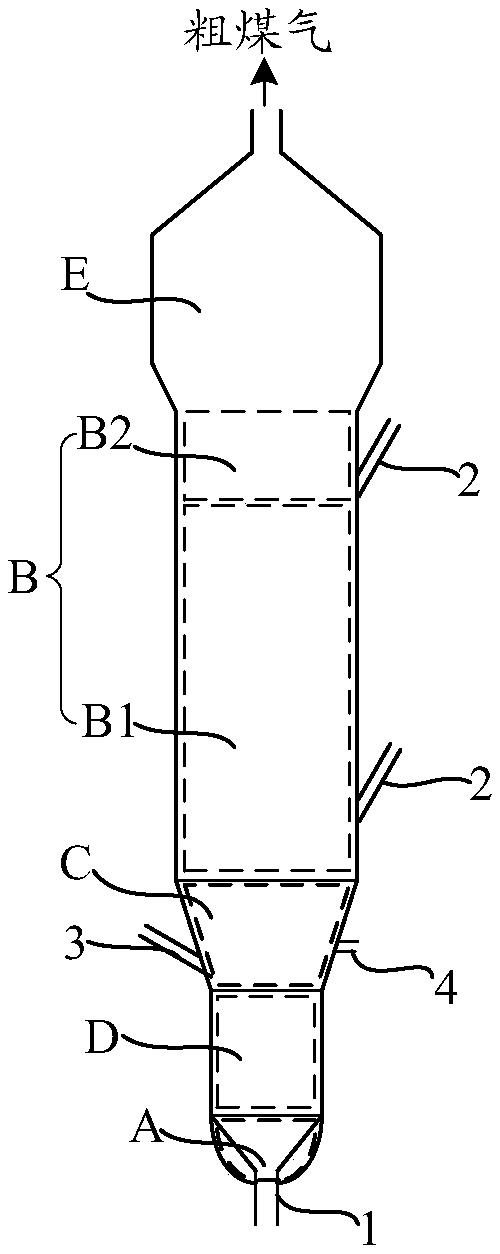

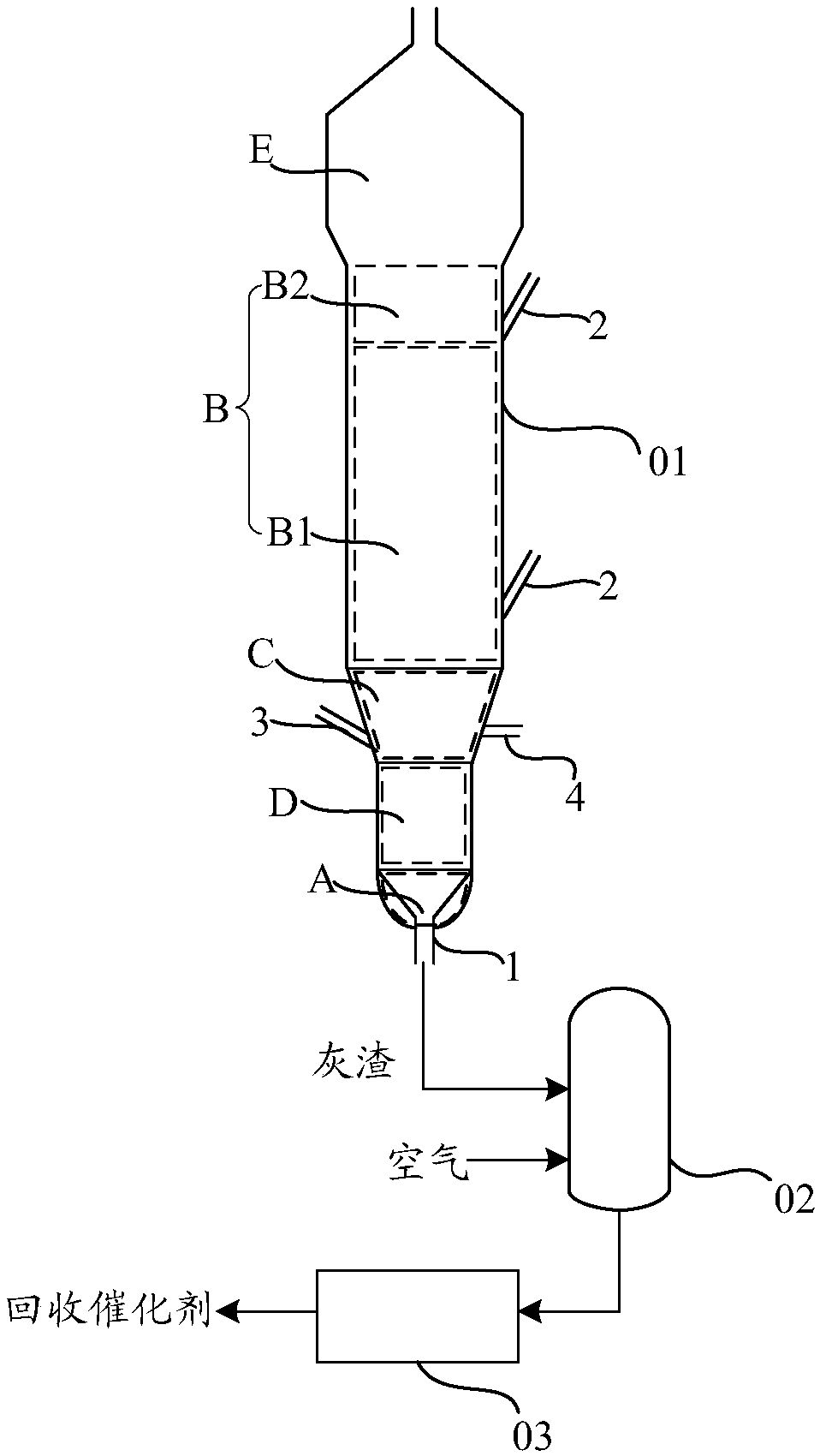

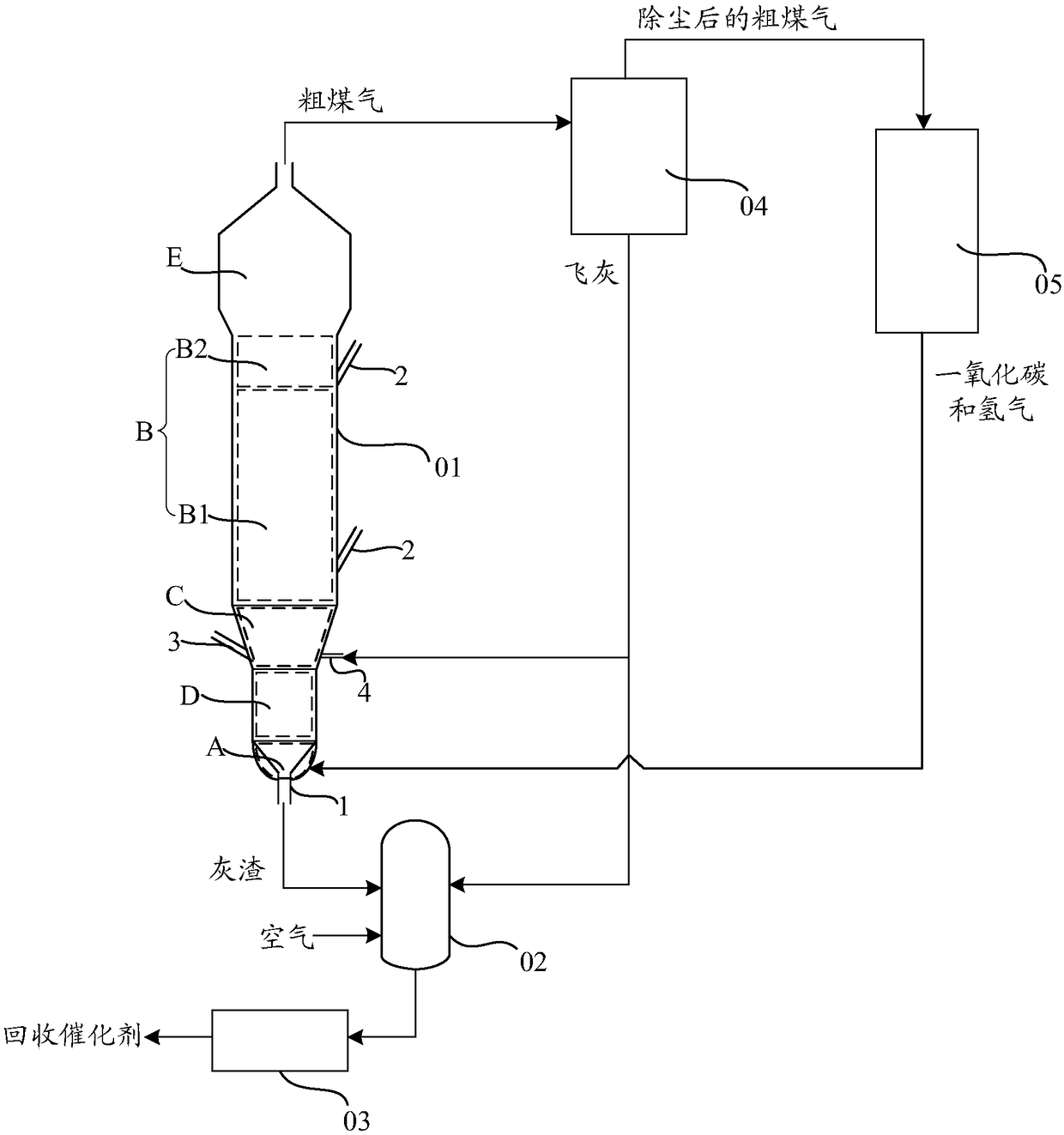

Fluidized bed gasifier, coal gasification system and method

InactiveCN108179032AHigh yieldStable furnace temperatureGasification processes detailsGranular/pulverulent flues gasificationSyngasFluidized bed gasifier

The invention relates to the technical field of coal gasification, in particular to a fluidized bed gasifier, a coal gasification system and a method, can satisfy the heat requirement of overall reaction in the furnace, have no need for introducing oxygen burning coal to provide heat, lower the risk of easy slagging in the gasifier due to introduction of oxygen, at the same time can promote forward overall reaction in the furnace, have no need for returning substantial synthesis gas to the furnace to increase the methane yield, and lower the risk of inhibition on overall reaction in the furnace caused by return of synthesis gas to the furnace. According to the fluidized bed gasifier, the bottom is a gas distribution plate area, a fluidized bed reaction area is disposed above the gas distribution plate area, a variable diameter section with a gradually enlarging inner diameter from the bottom up is disposed between the fluidized bed reaction area and the gas distribution plate area, thebottom of the fluidized bed gasifier is equipped with deslagging port, the side wall of the fluidized bed gasifier corresponding to the fluidized bed reaction area is equipped with coal inlets, and the lower part of the variable diameter section is equipped with a carbon carrier inlet.

Owner:ENN SCI & TECH DEV

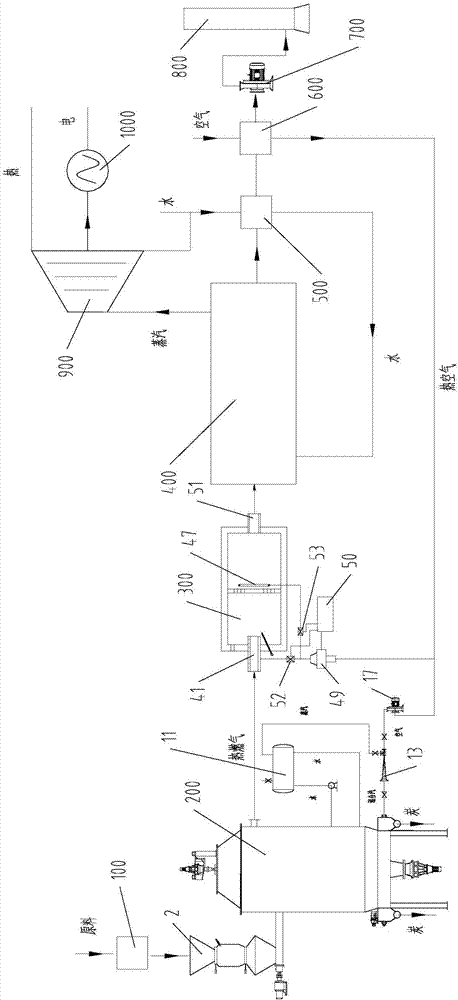

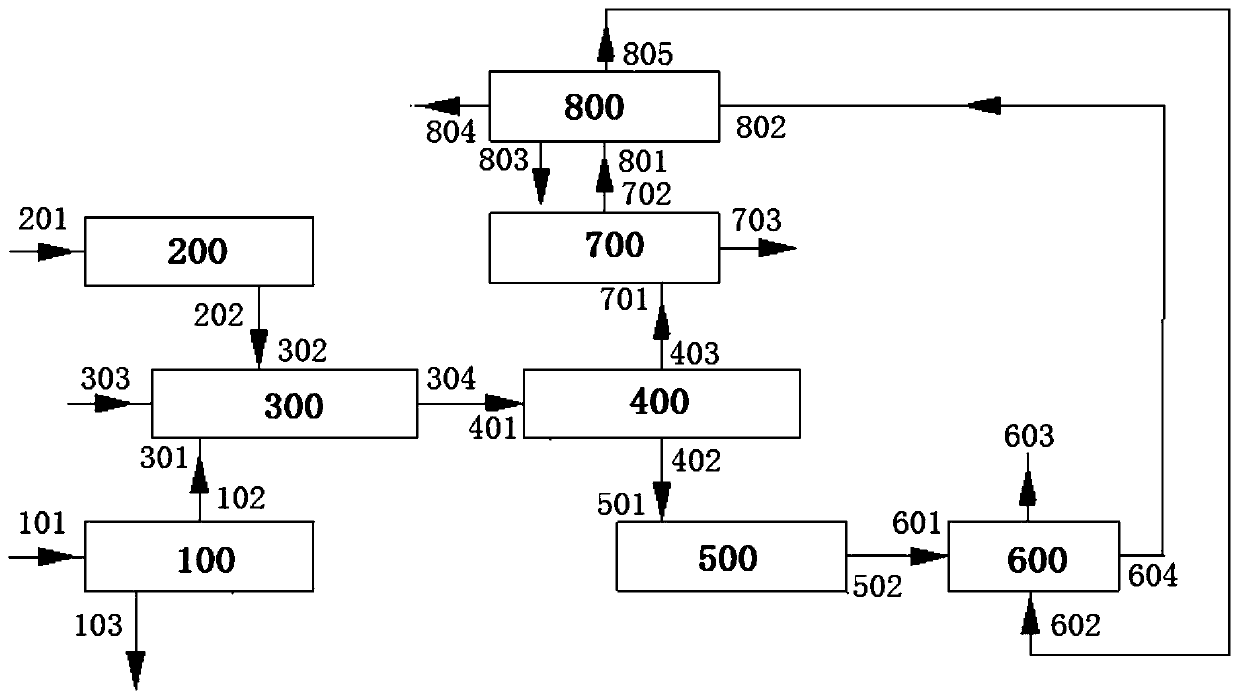

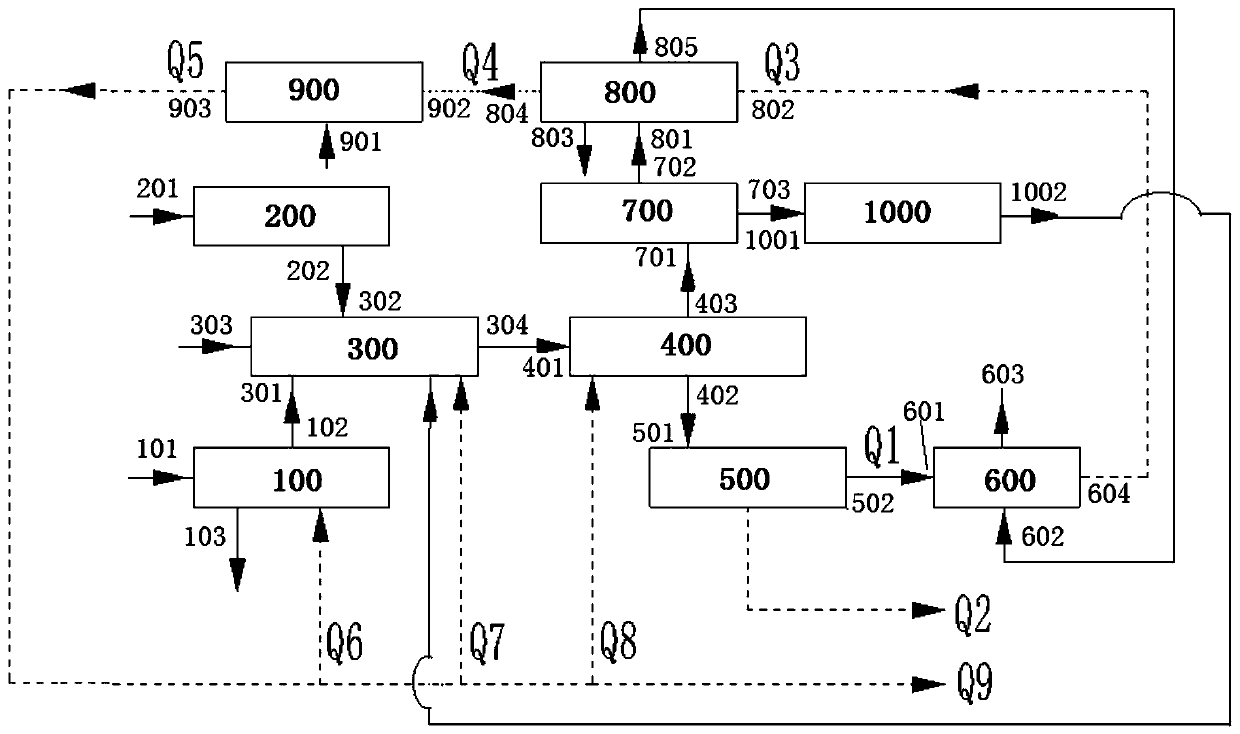

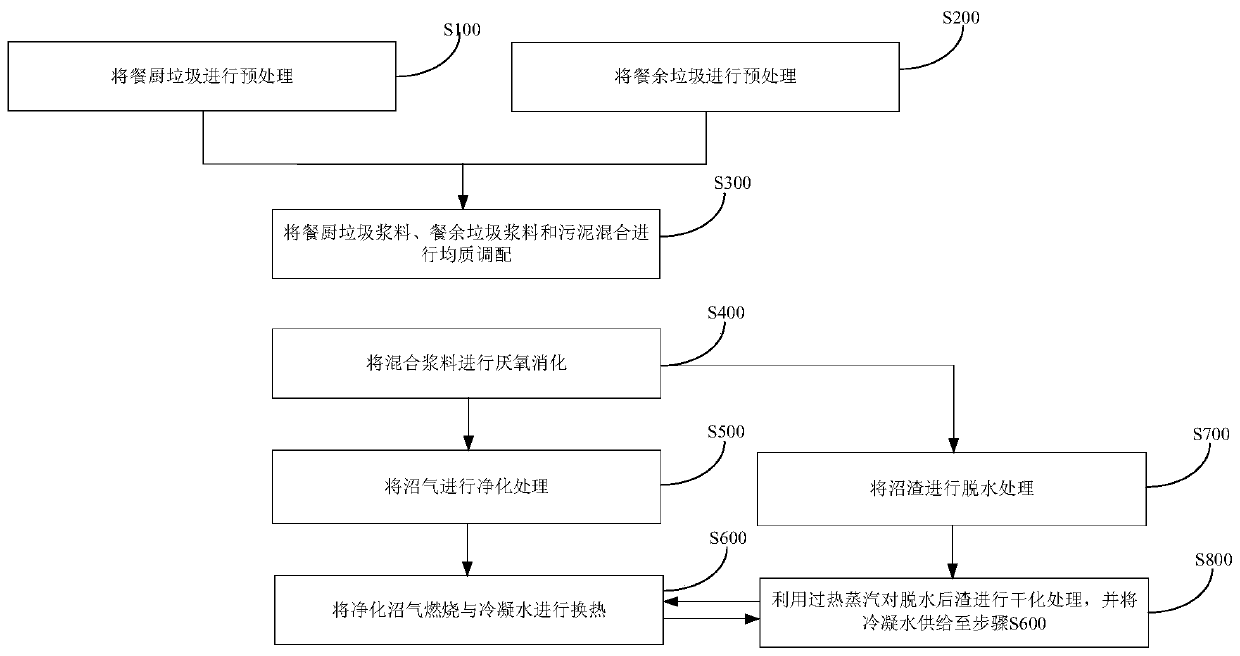

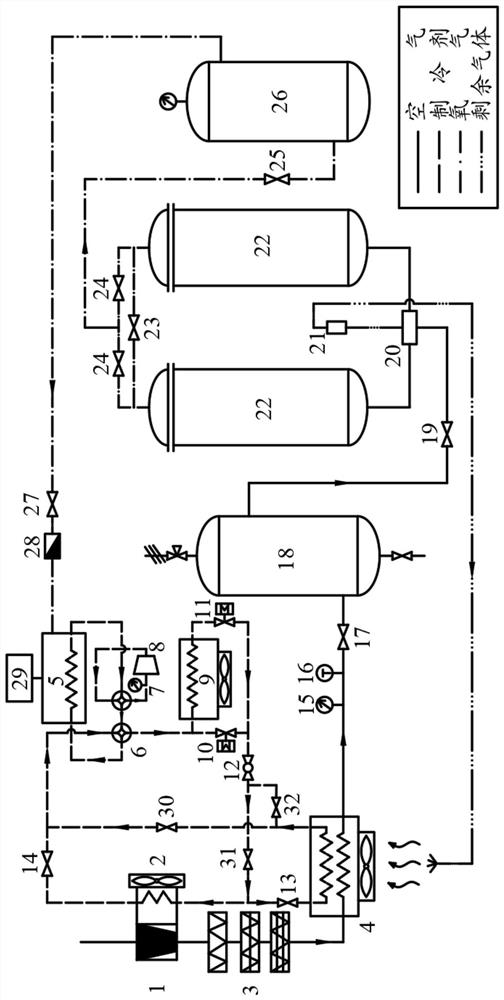

System and method for realizing heat balance of biogas residue drying by synergetically digesting food waste, kitchen waste and municipal sewage sludge

PendingCN110684647AIncrease productionAchieve self-balancingBioreactor/fermenter combinationsSludge treatment by de-watering/drying/thickeningHeat balanceProcess engineering

The invention discloses a system and a method for realizing heat balance of biogas residue drying by synergetically digesting food waste, kitchen waste and municipal sewage sludge. The system for realizing the heat balance of the biogas residue drying by synergetically digesting the food waste, the kitchen waste and the municipal sewage sludge comprises a food waste pretreatment apparatus, a kitchen waste pretreatment apparatus, a homogenizing-blending apparatus, an anaerobic digestion apparatus, a biogas purification apparatus, a combustion boiler, a dehydration apparatus, and a drying apparatus; the food waste pretreatment apparatus comprises a food waste inlet, a food waste slurry outlet, and an oil outlet; the kitchen waste pretreatment apparatus comprises a kitchen waste inlet, and akitchen waste slurry outlet; the homogenizing-blending apparatus comprises a food waste slurry inlet, a kitchen waste slurry inlet, a municipal sewage sludge inlet, and a mixed slurry outlet; the anaerobic digestion apparatus comprises a mixed slurry inlet, a biogas inlet, and a biogas residue outlet; the biogas purification apparatus comprises a biogas inlet, and a purified biogas outlet; the combustion boiler comprises a purified biogas inlet, and an overheated steam outlet; the dehydration apparatus comprises a biogas residue inlet, and a dehydrated residue outlet; and the drying apparatuscomprises a dehydrated residue inlet, an overheated steam inlet, and a dried residue outlet.

Owner:ANYANG AIERWANG NEW ENERGY ENVIRONMENTAL

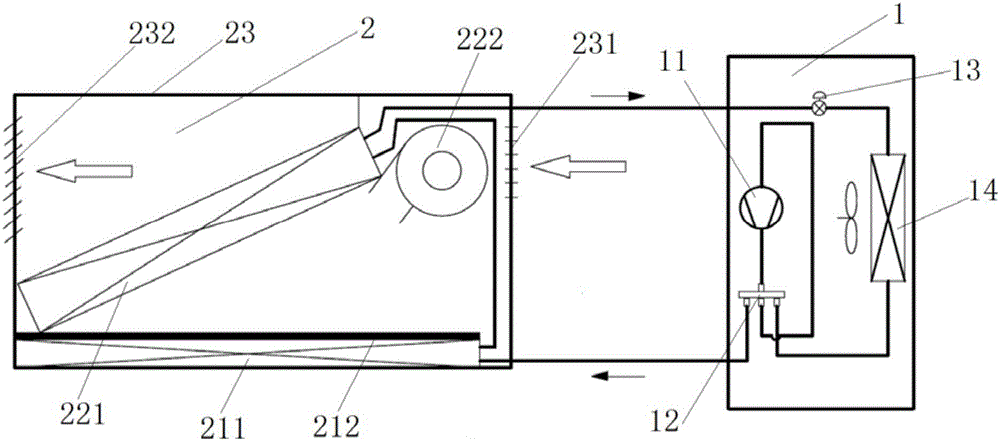

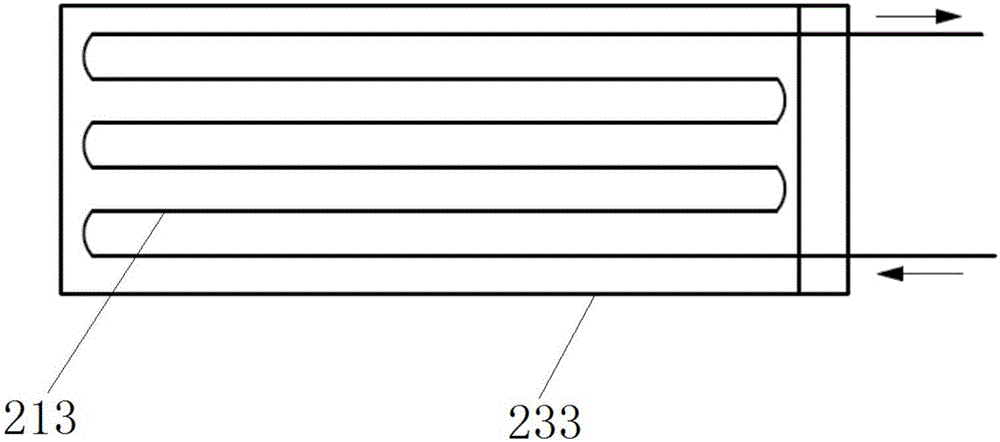

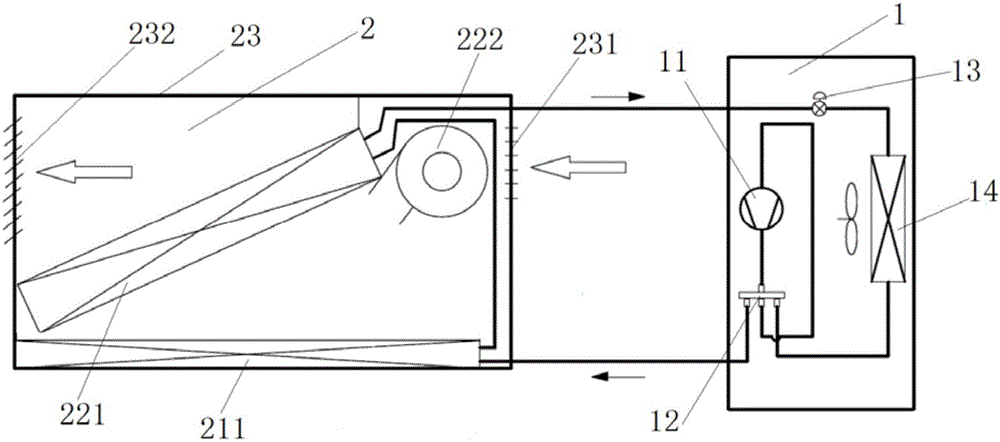

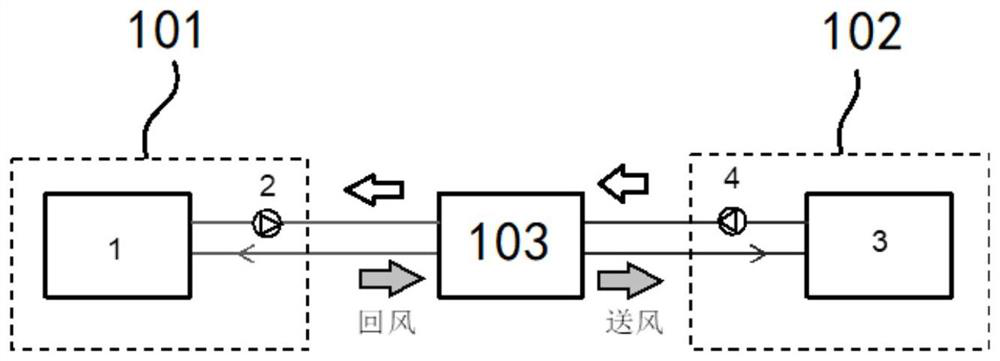

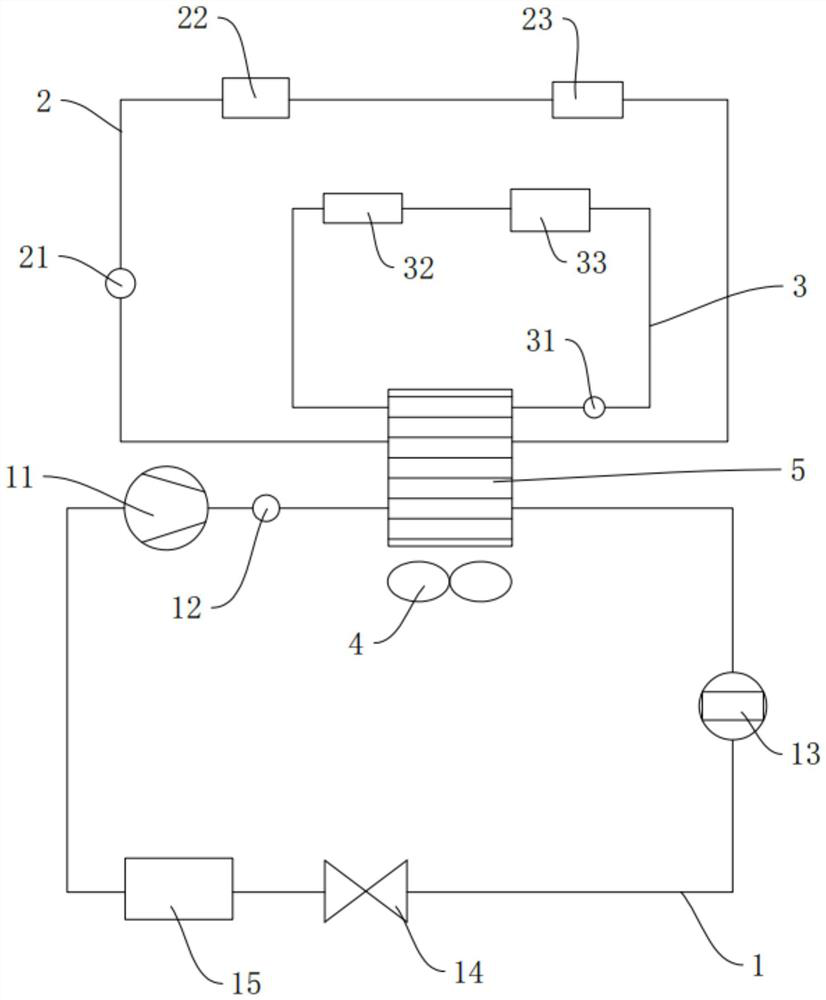

Air conditioner equipment

InactiveCN106678960AImprove thermal comfortReduce energy consumptionLighting and heating apparatusSpace heating and ventilation detailsThermal comfortEngineering

The invention discloses air conditioner equipment, and relates to the technical field of air conditioners. According to the mainly adopted technical scheme, the air conditioner equipment comprises an air conditioner outdoor unit and an air conditioner indoor unit. The air conditioner indoor unit comprises a shell, a radiation heat exchange assembly and a convective heat exchange assembly. The shell is provided with an air inlet and an air outlet. The radiation heat exchange assembly is arranged in the shell, connected with the air conditioner outdoor unit and used for carrying out radiation heat exchange on the interior of a room. The convective heat exchange assembly is arranged in the shell, connected with the air conditioner outdoor unit and used for carrying out indoor convective heat exchange. The air conditioner equipment has a convection heat exchange function and a radiation heat exchange function, the requirements of users for heat are met, and meanwhile the output wind speed can be decreased, so that the user heat comfort is improved, and the energy consumption of a fan is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

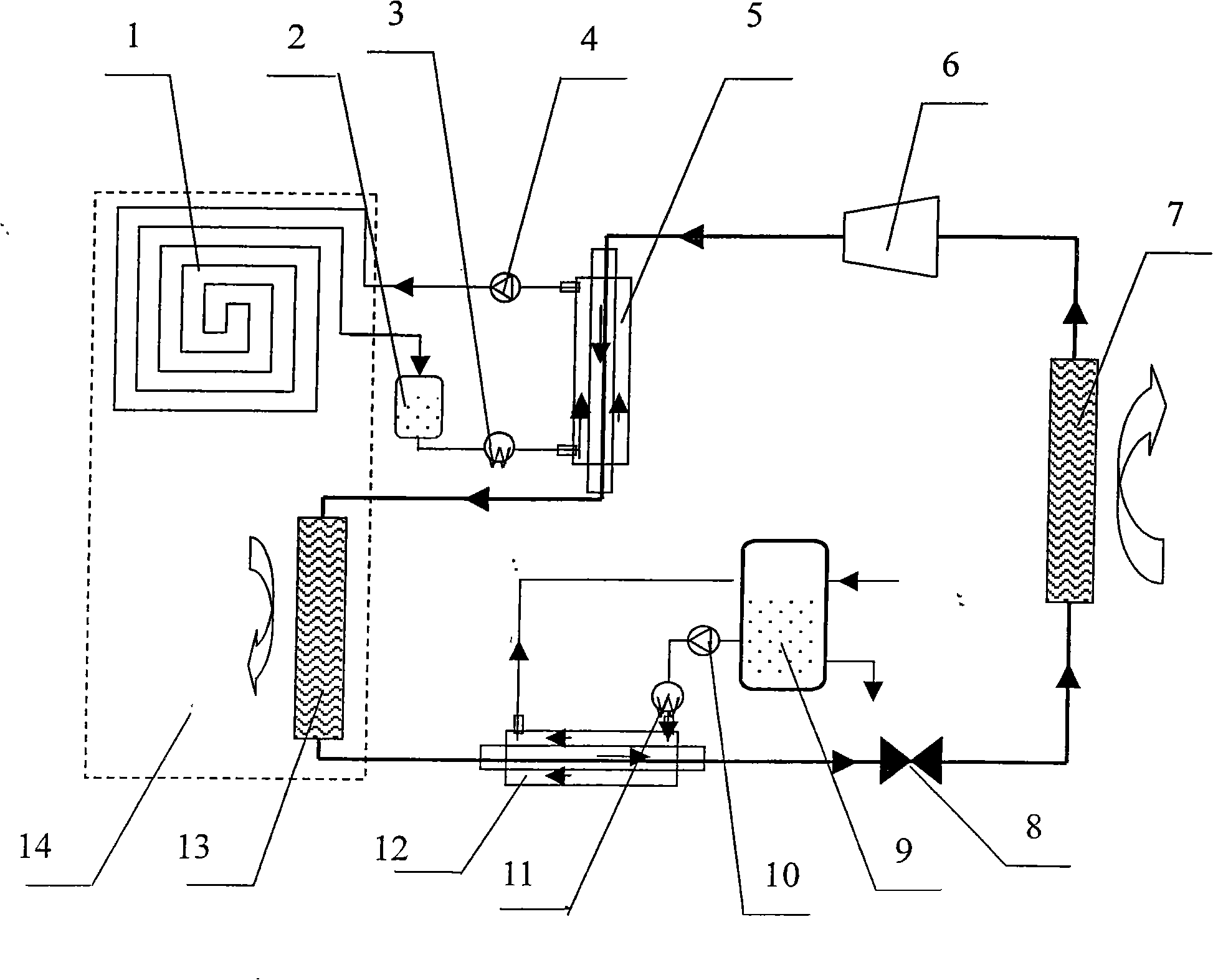

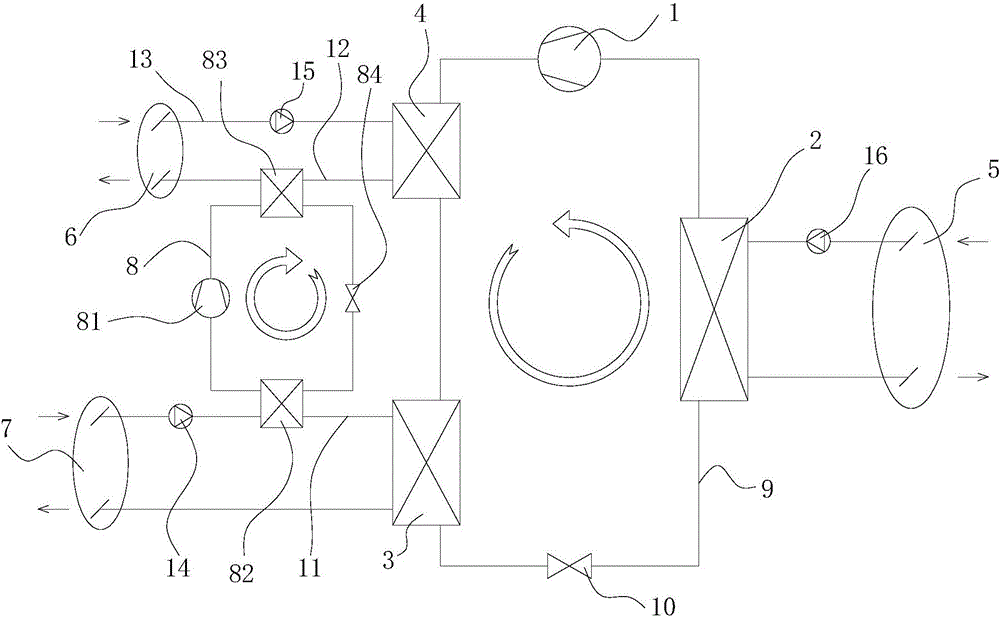

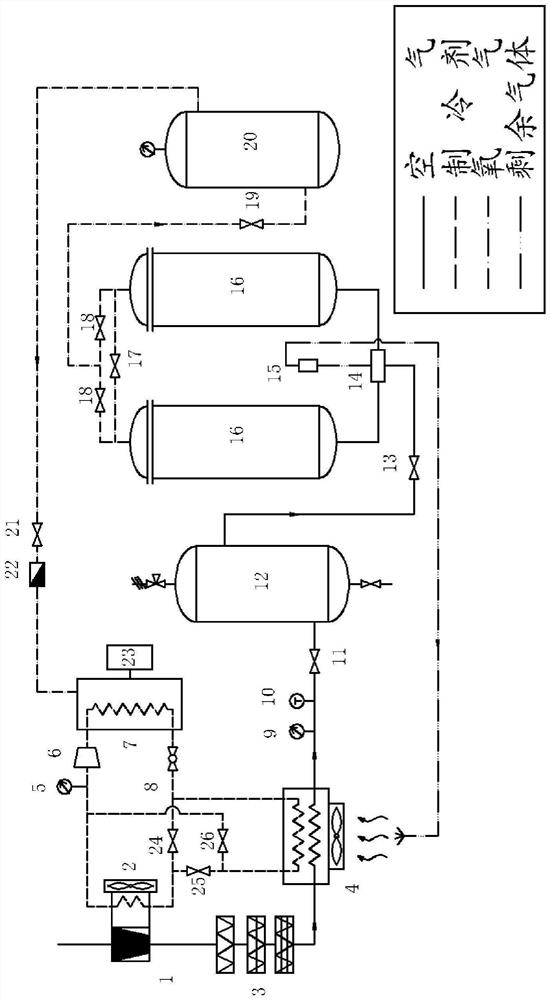

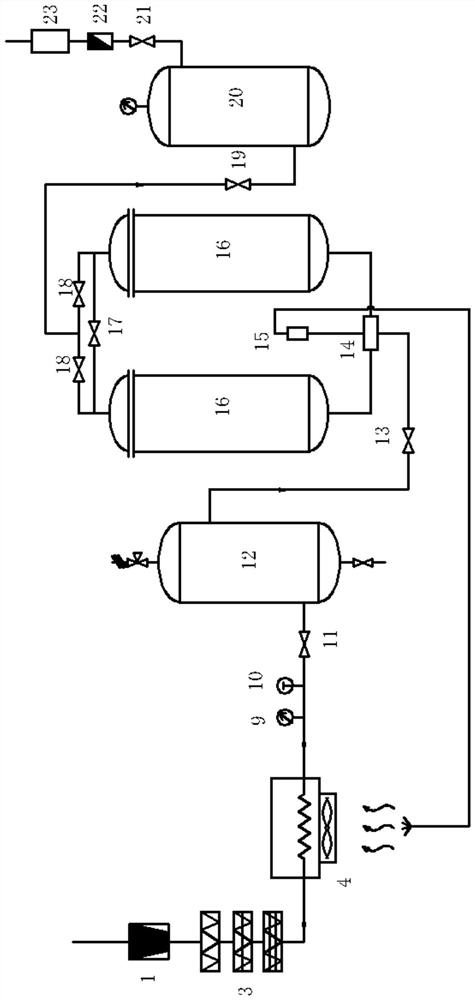

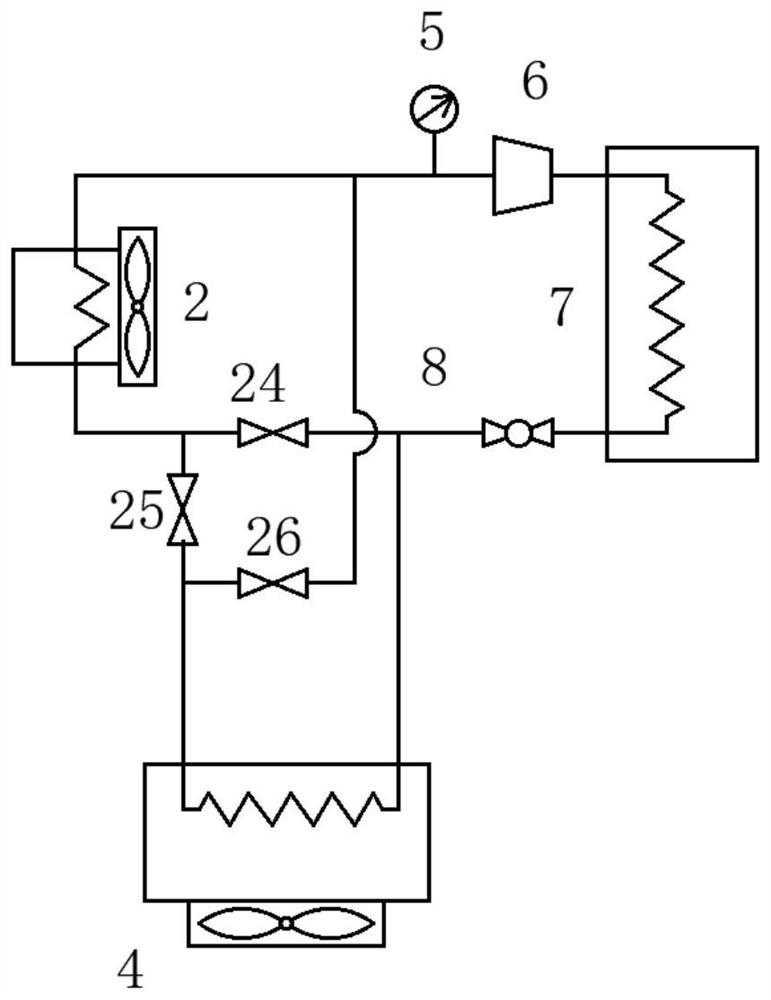

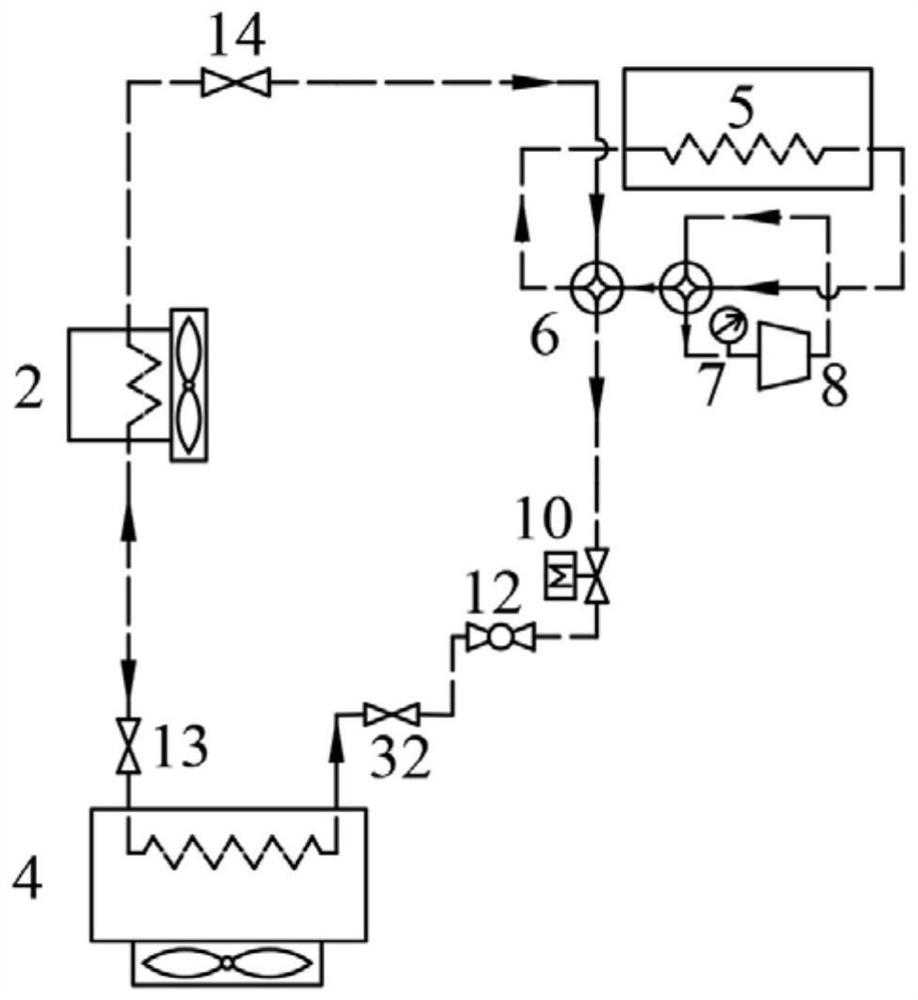

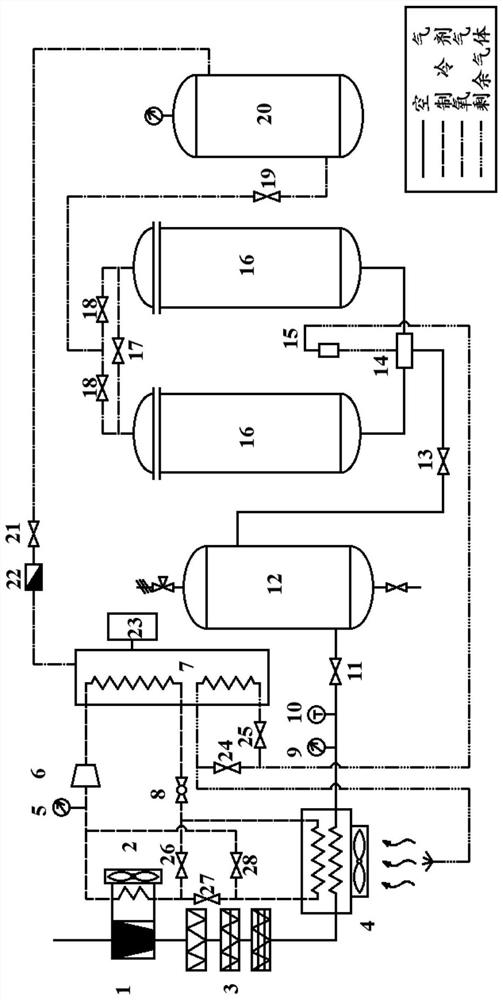

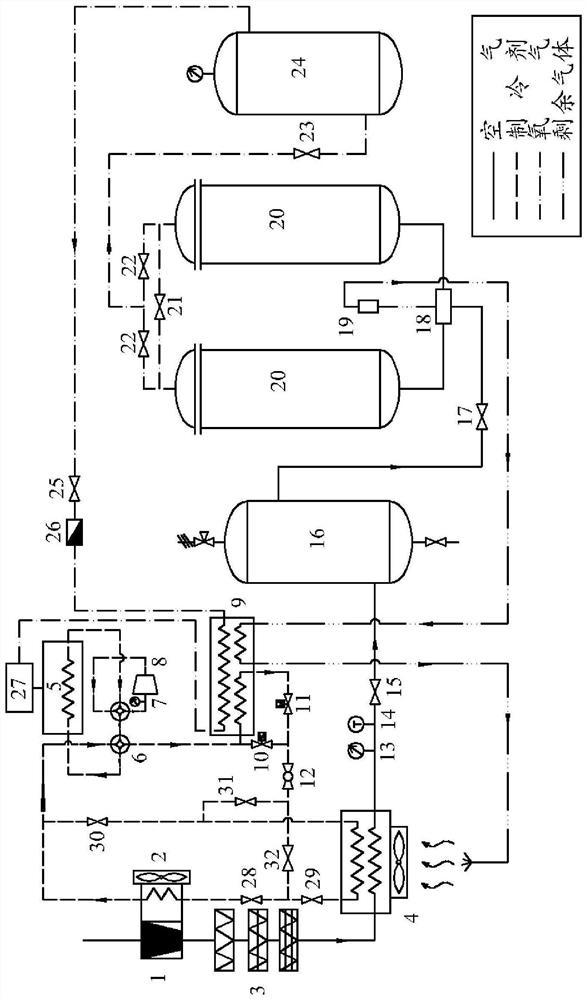

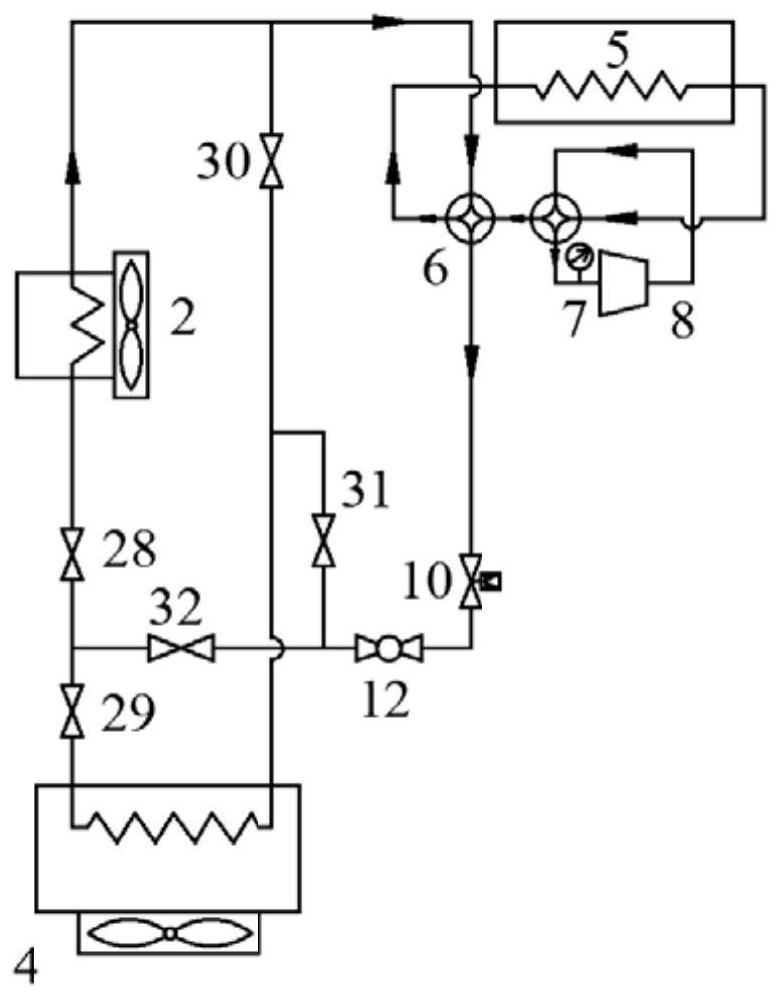

CO2 high-temperature heat pump saunas system

InactiveCN101313879AMeet heating needsMeet caloric needsBathing devicesEngineeringElectronic expansion valve

The invention discloses a CO2 high temperature heat pump sauna system, aiming to provide a CO2 high temperature heat pump sauna system which provides heat for sauna rooms in two modes and has high heat efficiency and low cost. The CO2 high temperature heat pump sauna system consists of a CO2 compressor, a high temperature double-pipe heat exchanger, an indoor wavy finned tube heat exchanger, an intermediate and low temperature double-pipe heat exchanger, an electronic expansion valve and an outdoor heat exchanger; a hot water outlet of the high temperature double-pipe heat exchanger is connected with a hot water inlet of a radiant floor heating system; a hot water outlet of the radiant floor heating system is connected with a water inlet of a high temperature water tank; a water outlet of the high temperature water tank is connected with a backwater port of the low temperature double-pipe heat exchanger through a high temperature water-circulating pump; an outlet of an intermediate and low temperature water tank is connected with a water inlet of the intermediate and low temperature double-pipe heat exchanger through an intermediate and low temperature water-circulating pump; and a water inlet of the intermediate and low temperature water tank is connected with a water outlet of the intermediate and low temperature double-pipe heat exchanger. The CO2 high temperature heat pump sauna system has high heat efficiency, low cost, safe use and large water supply volume and can realize continuous water supply.

Owner:TIANJIN UNIV OF COMMERCE

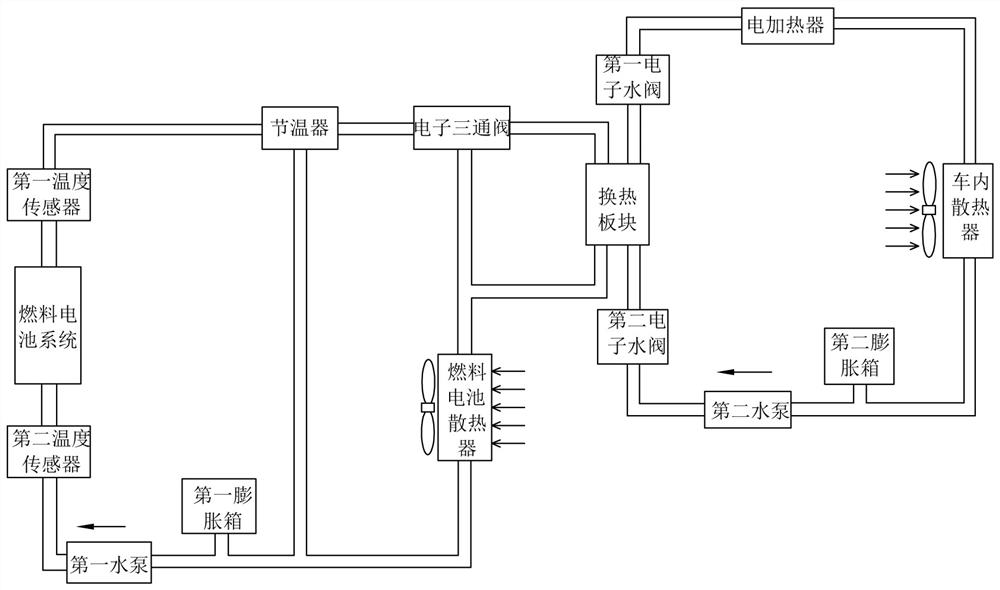

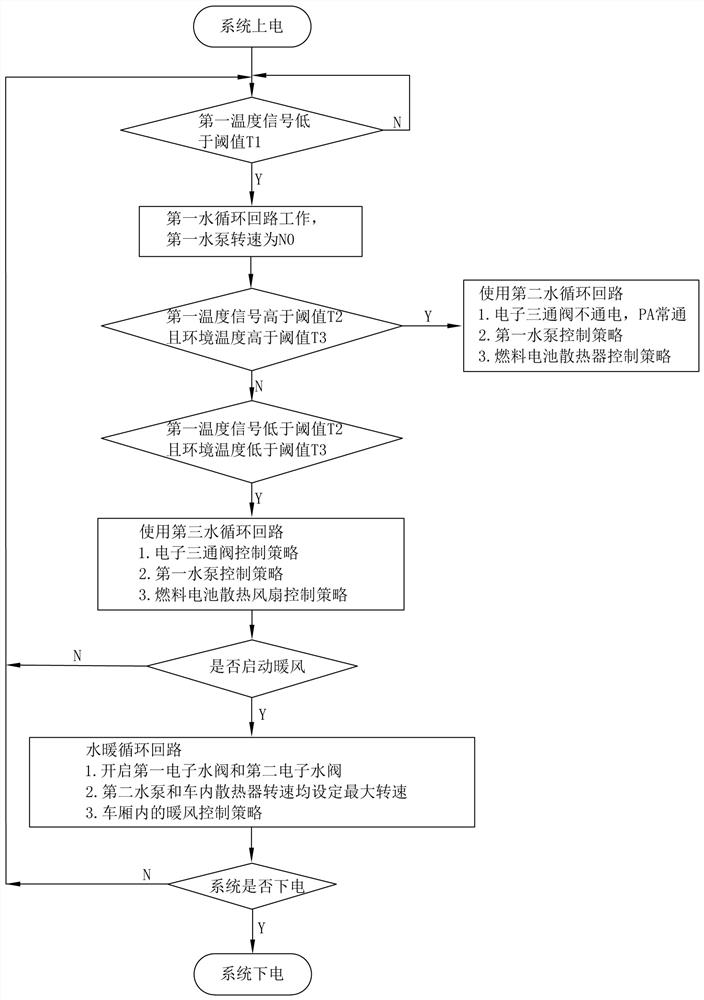

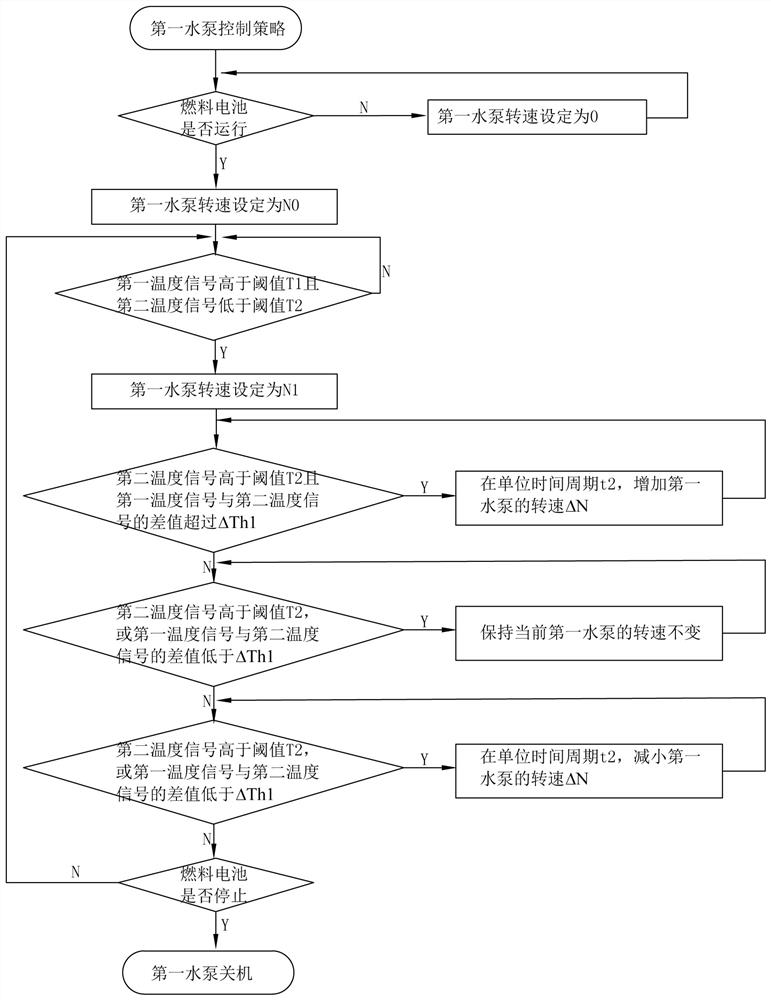

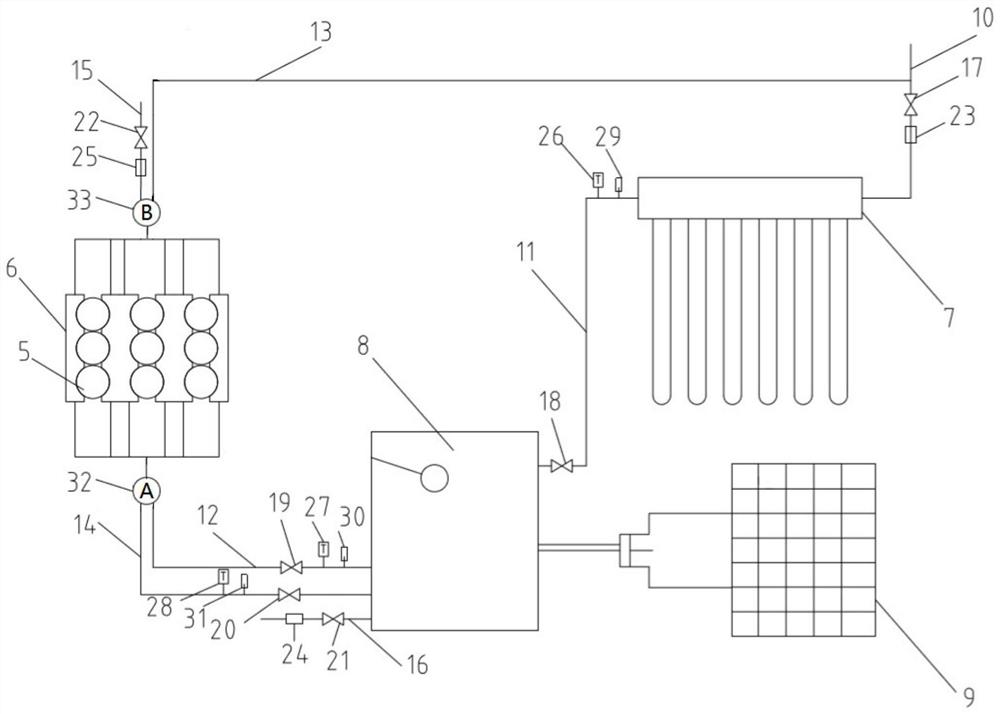

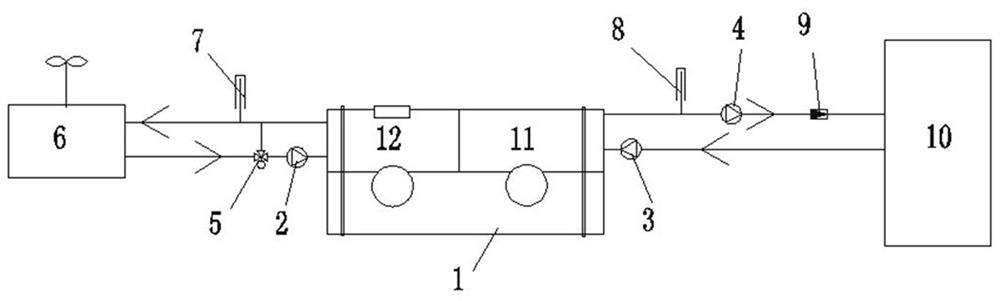

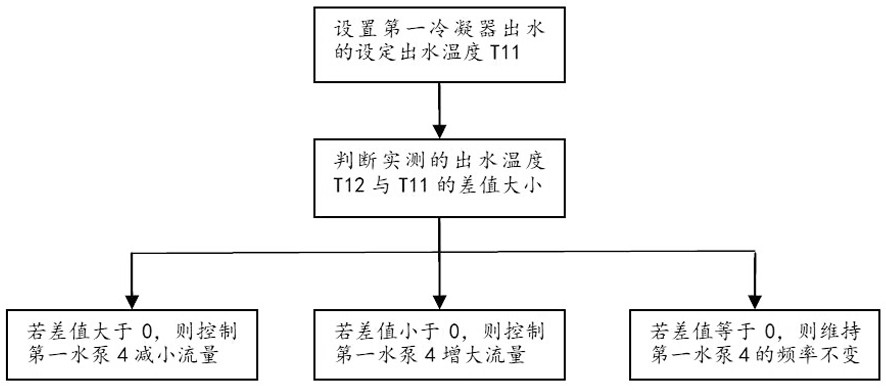

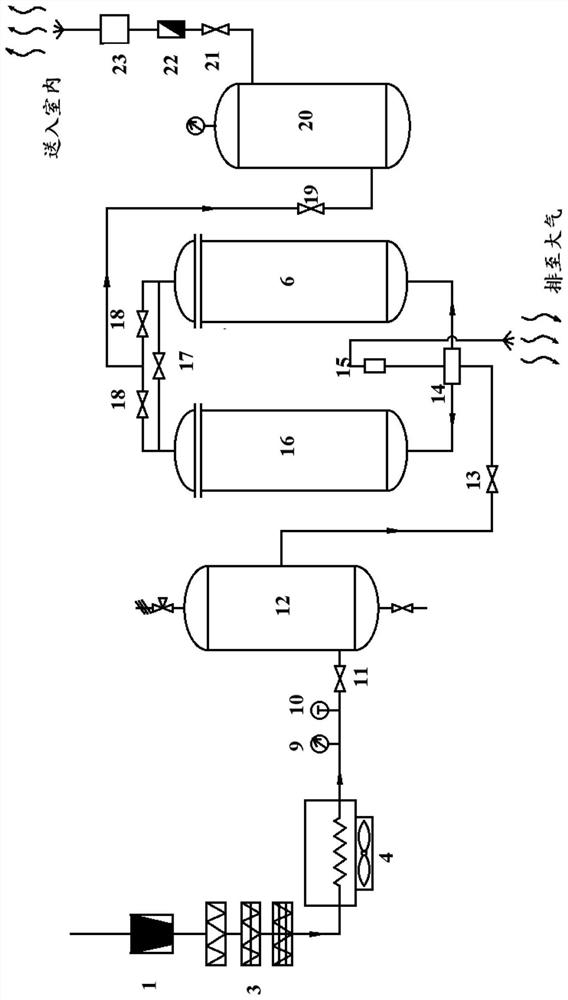

Vehicle fuel cell waste heat management system and method

PendingCN112563533AReal-time intelligent speed adjustmentIntelligent speed adjustmentFuel cell heat exchangePower to electric heating circuitsThermal management systemWater heating

The invention discloses a vehicle fuel cell waste heat management system and method, relates to the technical field of automobiles, and aims to form a vehicle low-cost combined heat and power supply system through special parts such as a heat exchange plate, a three-way valve and an electronic water valve on the basis of meeting the original functions. Waste heat generated by work of the fuel cellsystem is utilized to coordinate and control temperature rise, cooling, water heating in the vehicle and the like of the fuel cell system. Meanwhile, the problems of rapid temperature drop of the cooling medium of the fuel cell system, poor power generation performance, increased refrigeration load in summer and the like caused by large temperature difference of cooling mediums at two sides of the heat exchange plate are solved through the waste heat management system and each control strategy. Through a judgment strategy of signals of a first temperature sensor and a second temperature sensor, a first water pump, a electronic fan of a fuel cell radiator, an electric heater and the like are intelligently adjusted in real time, temperature lag or advanced control can be avoided, and meanwhile electric energy consumption of whole vehicle heat management can be reduced.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

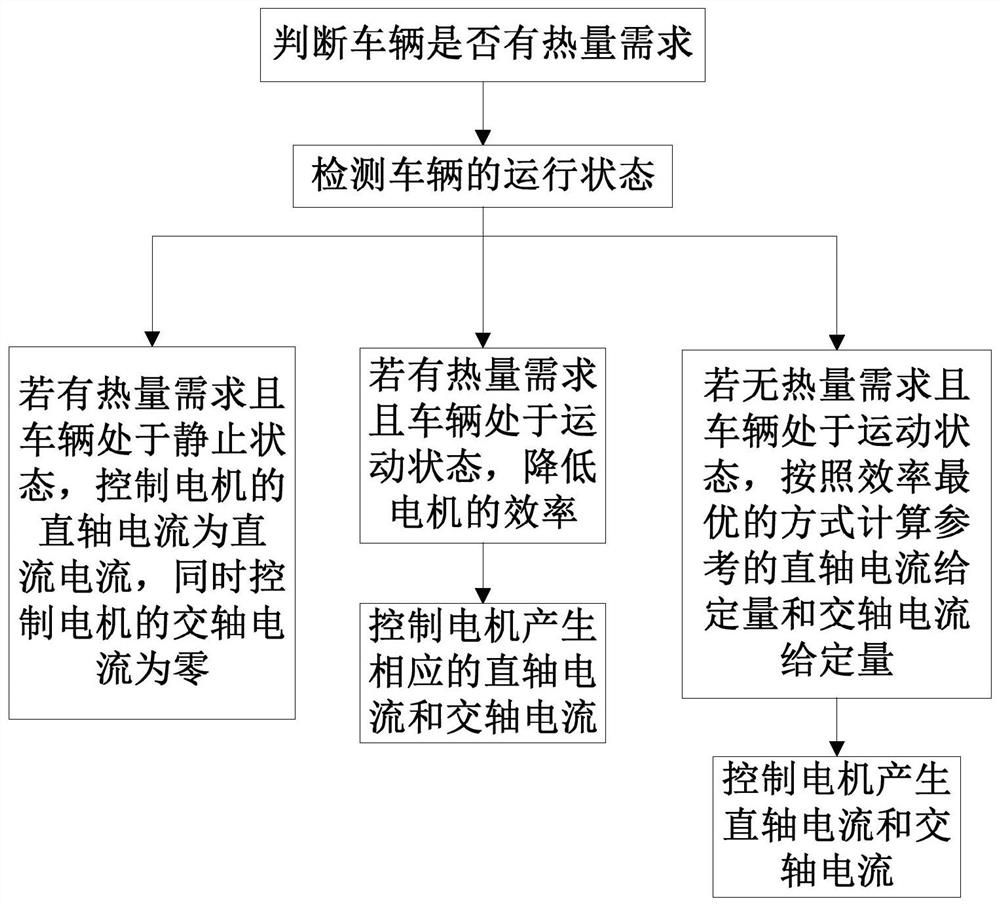

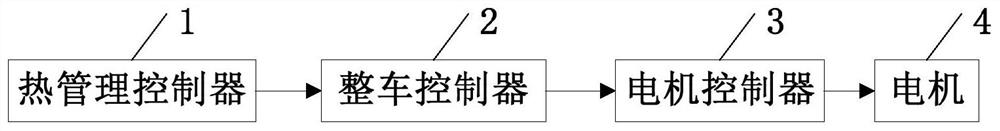

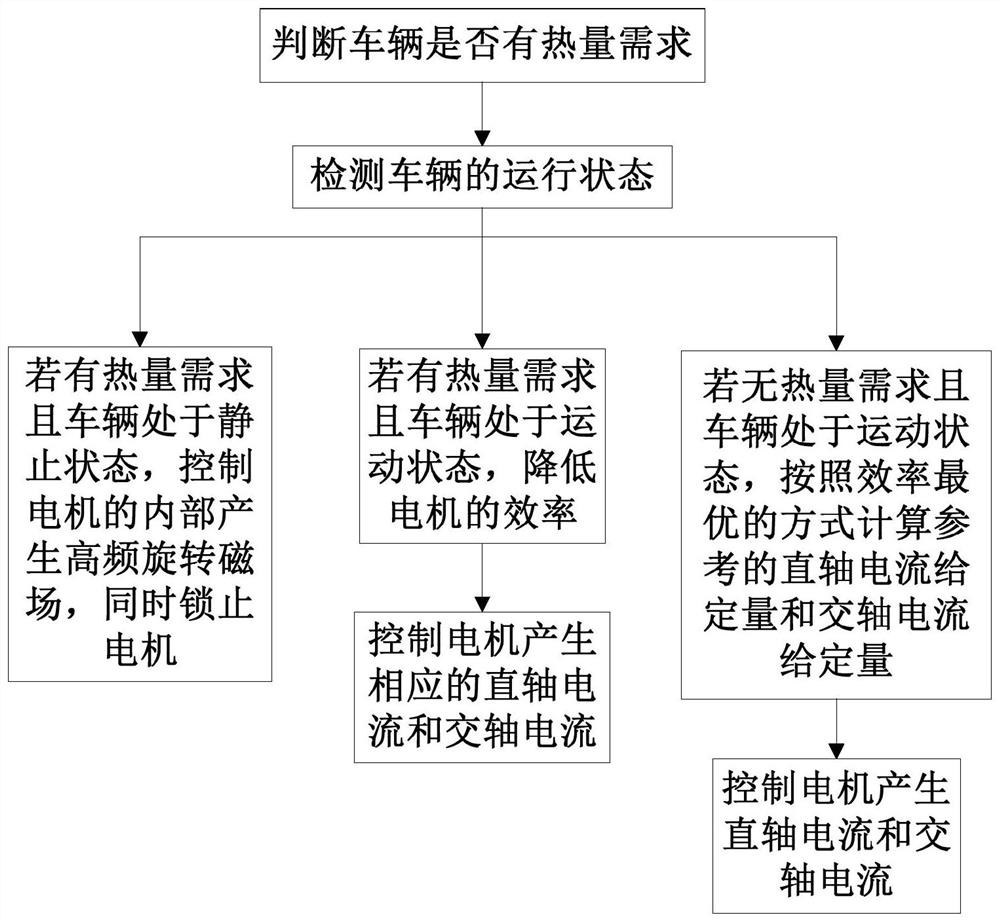

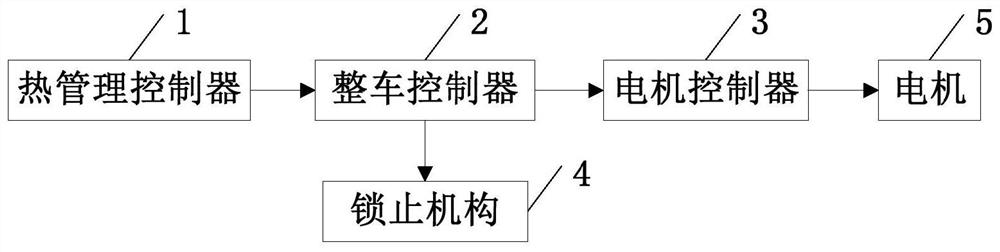

Motor active heating control method and system for vehicle and vehicle

InactiveCN111865185AReduce manufacturing costLight in massElectric motor controlElectric propulsion mountingDC - Direct currentControl system

The invention discloses a motor active heating control method and system for a vehicle and the vehicle, and relates to the technical field of vehicles. The motor active heating control method for thevehicle comprises the steps of judging whether the vehicle has a heat demand or not; detecting the running state of the vehicle; if the vehicle has a heat demand and is in a static state, controllingthe direct-axis current of the motor to be direct current, and meanwhile, controlling the quadrature-axis current of the motor to be zero, wherein when the direct-axis current of the motor is direct current and the quadrature-axis current of the motor is zero, a constant magnetic field parallel to the rotor magnetic field of the motor is formed in the motor, and the motor has no torque output. Theinvention further provides a corresponding control system. Meanwhile, the invention further provides a vehicle which adopts the control method to control heating of the motor or comprises the controlsystem. When the whole vehicle is static, the motor can generate enough heat to meet the heat requirement of the vehicle.

Owner:ZHEJIANG JIZHI NEW ENERGY AUTOMOBILE TECH CO LTD +1

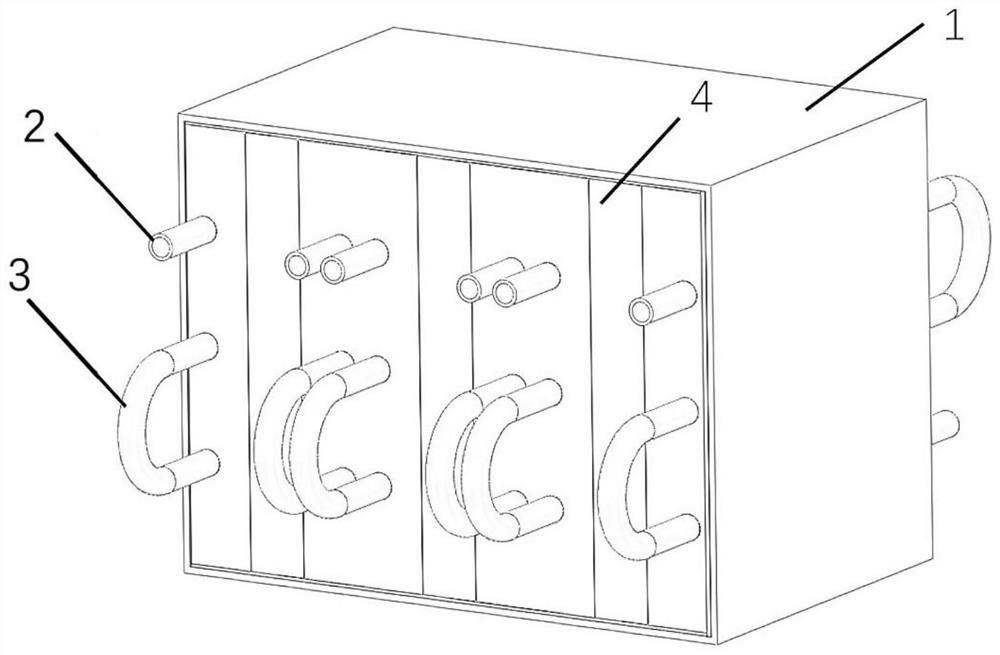

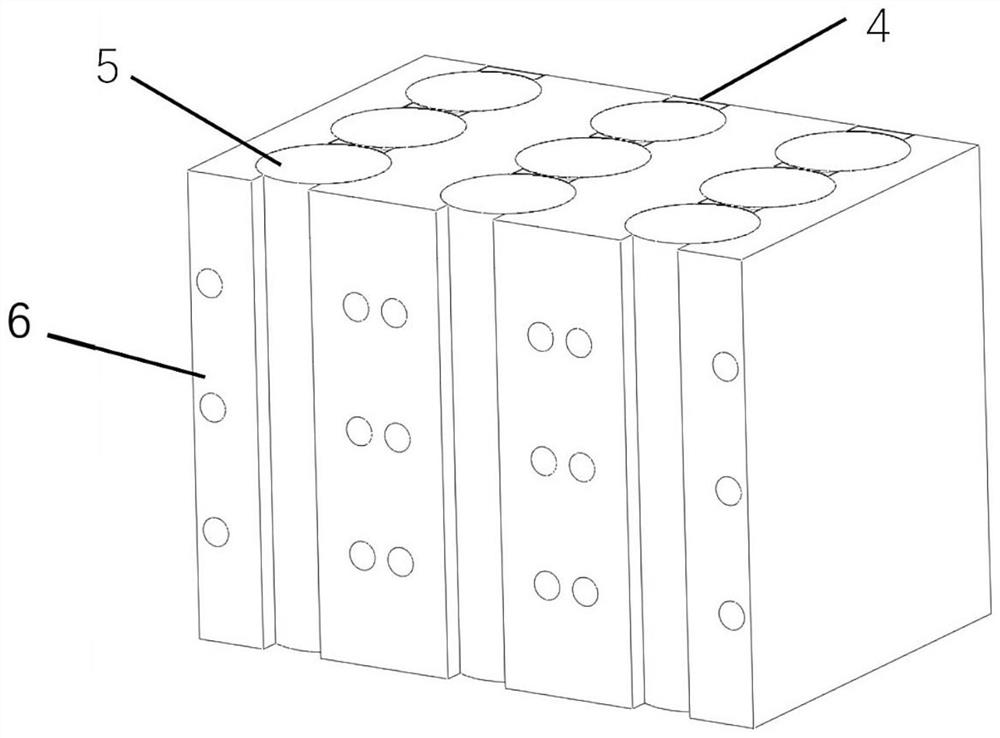

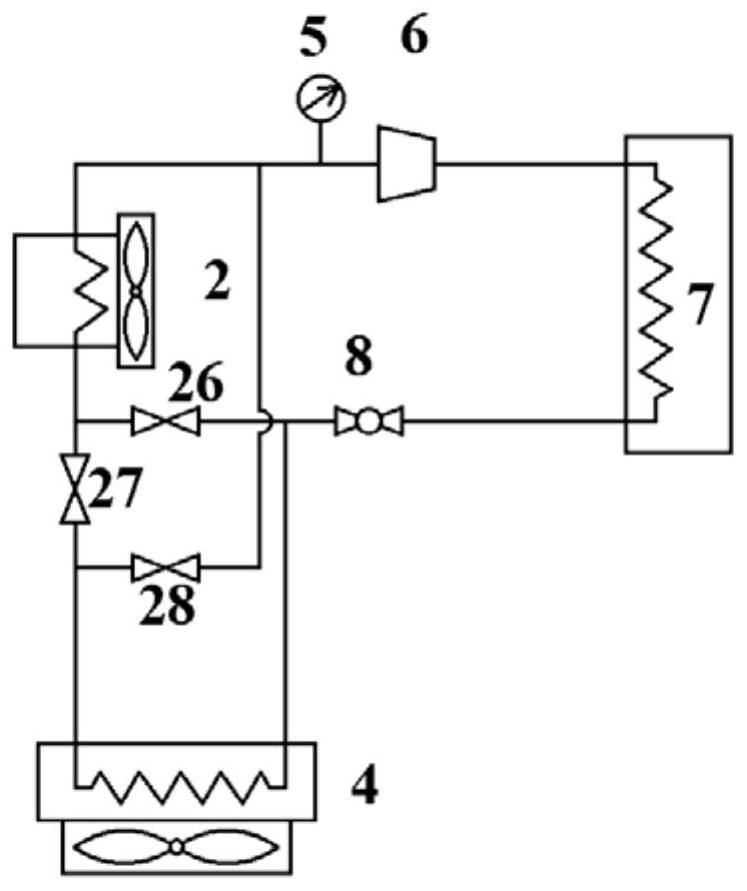

Phase change heat storage device based on solar energy

PendingCN113091330AImprove light-to-heat conversion efficiencyMeet caloric needsSolar heating energySolar heat collector controllersCollector deviceSolar energy conversion

The invention relates to the technical field of heat storage equipment, in particular to a phase change heat storage device based on solar energy. The device comprises a solar vacuum heat collector, a heat storage water tank, a phase change heat storage device, a three-way switching valve A and a three-way switching valve B; the solar vacuum heat collector is provided with a first water inlet pipe; the solar vacuum heat collector is connected with the heat storage water tank through a first connecting pipe; a first outlet of the three-way switching valve A is connected with a first port of the phase change heat storage device, a second outlet of the three-way switching valve A is connected with the heat storage water tank through a second connecting pipe, and a third outlet of the three-way switching valve A is connected with the heat storage water tank through a fourth connecting pipe; and a first outlet of the three-way switching valve B is connected with a second port of the phase change heat storage device, a second outlet of the three-way switching valve B is connected with the outside through a second water inlet pipe, and a third outlet of the three-way switching valve B is connected with the first water inlet pipe through a third connecting pipe. The technical problem of low solar energy conversion and utilization efficiency in the prior art is solved.

Owner:GUANGDONG UNIV OF TECH

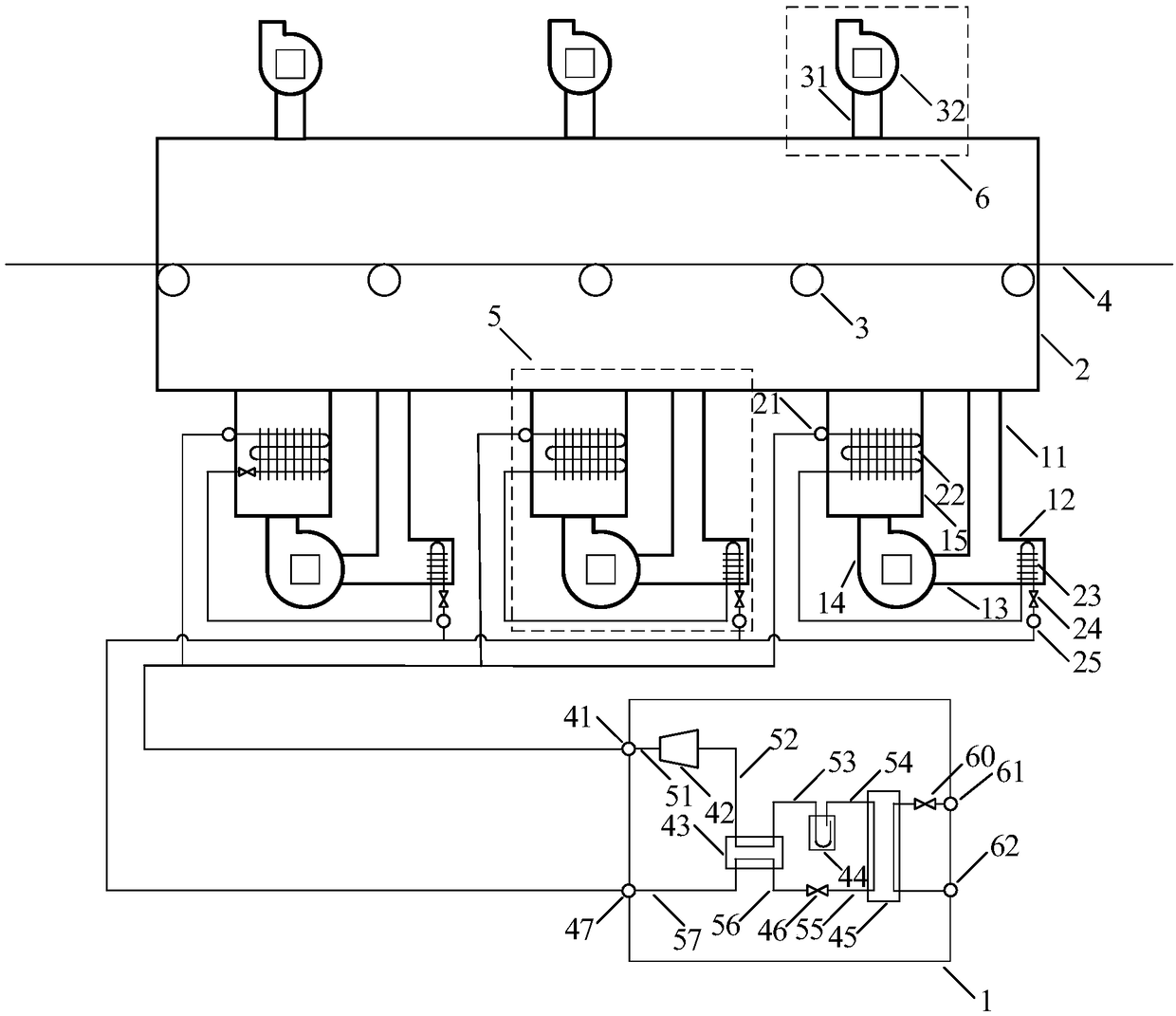

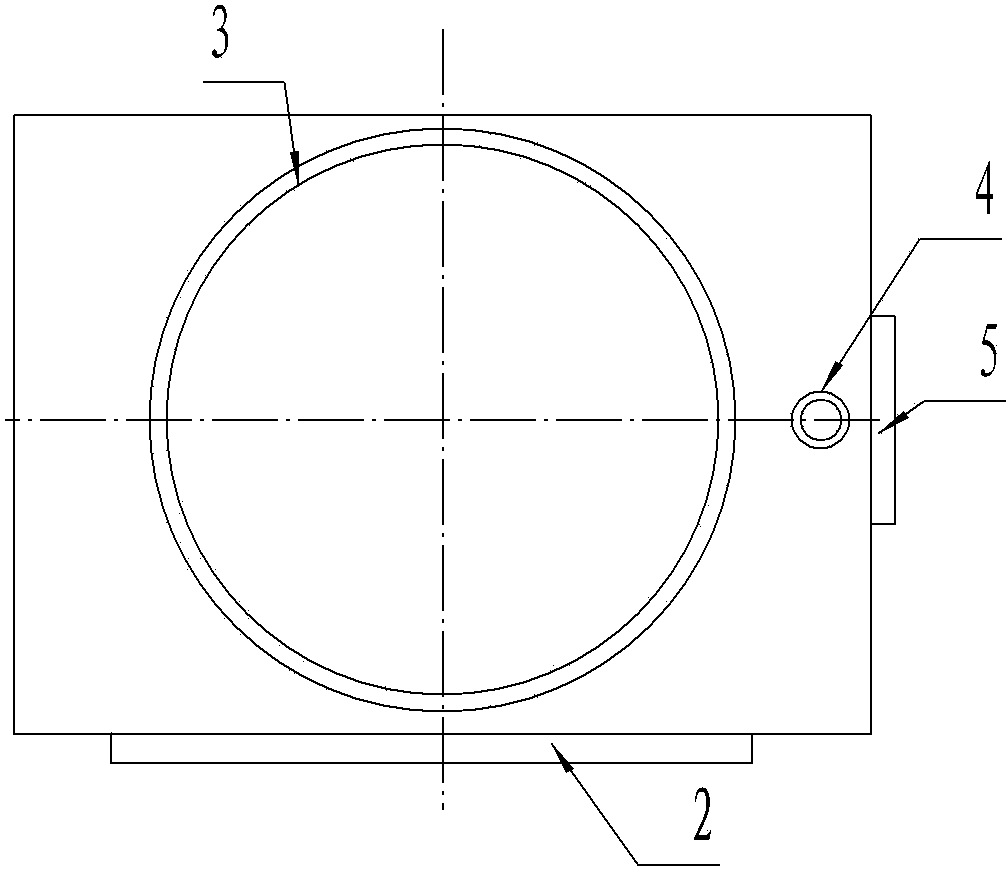

Cool storage type low energy consumption airplane ground air conditioner

PendingCN110371315ACompact structureReasonable structureGround installationsPlate heat exchangerCool storage

The invention relates to a cool storage type low energy consumption airplane ground air conditioner. The cool storage type low energy consumption airplane ground air conditioner comprises a condenser,a first compressor set and a second compressor set which are connected with the condenser simultaneously, a plate heat exchanger which is connected with the condenser, the first compressor set and the second compressor set simultaneously, a primary evaporator and a secondary evaporator which are connected with the condenser respectively, a circulating water pump and an air blower, wherein the circulating water pump is used for conveying cooling capacity to a cool storage box through the plate heat exchanger during cool storage and conveying cooling capacity to a surface air cooler through thecool storage box during cool discharge; an exhaust inlet of the air blower is formed in the lower part of the primary evaporator, an air outlet is connected with an inlet of an air flue, the surfaceair cooler, the secondary evaporator and a heater are arranged inside the air flue along the direction of an air flow in sequence, and an air outlet of the air flue is connected into the interior of an airplane through an air hose and a standard joint. Peak shaving is realized, cool storage and cool discharge are carried out according to practical situation, airplane high-power cooling capacity requirement can be met by using the two compressor sets, and the effects of saving energy and reducing energy consumption are reached.

Owner:无锡雪鸥移动空调有限公司

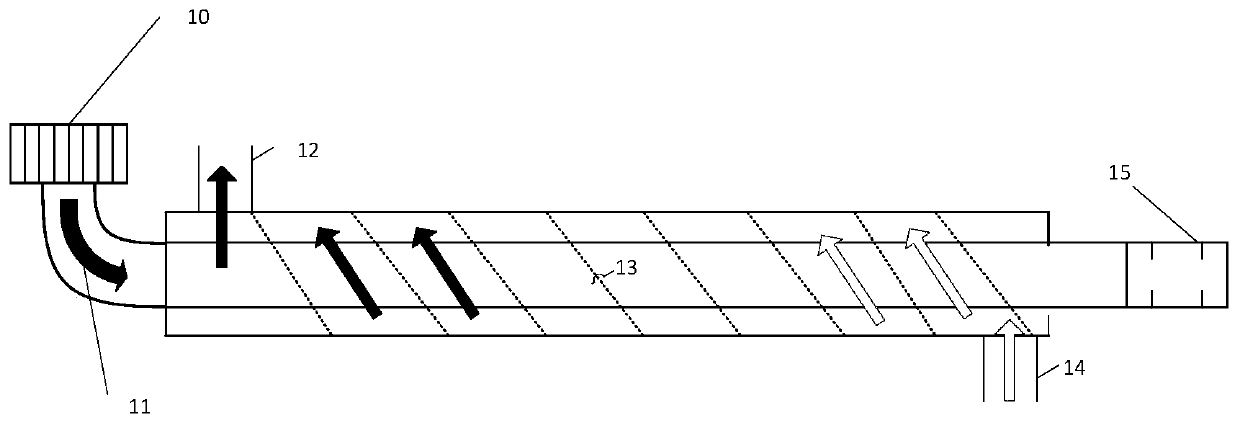

Lithium battery gravure coating machine drying system using multiple heat pumps

InactiveCN108144818AImprove heating energy efficiencyReduce manufacturing costPretreated surfacesCoatingsProcess engineeringEnergy conservation

The invention relates to a lithium battery gravure coating machine drying system using multiple heat pumps. The system comprises a drying way, heating modules, exhaust modules and a heat pump main machine; the multiple heating modules are arranged in the length direction of the drying way, and are used for providing hot air to the drying way; the multiple exhaust modules are arranged in the lengthdirection of the drying way, and are used for exhausting air of the drying way; and one heat pump main machine is provided, is connected with each heating module, and supplies heat to each heating module. Compared with the prior art, on the basis of adopting a heat pump cycle as a heat source, heat exchange parts are arranged nearby each air port in a scattering manner, so that the gravure coating machine drying system can achieve higher-range energy conservation.

Owner:TONGJI UNIV

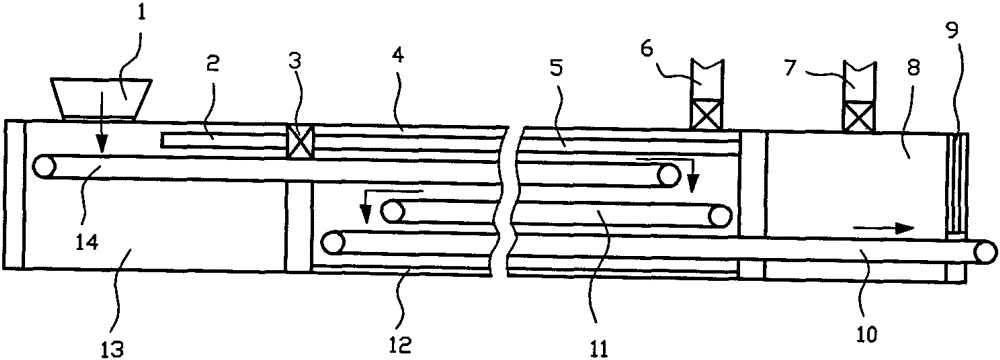

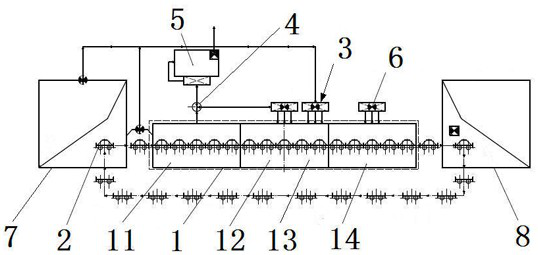

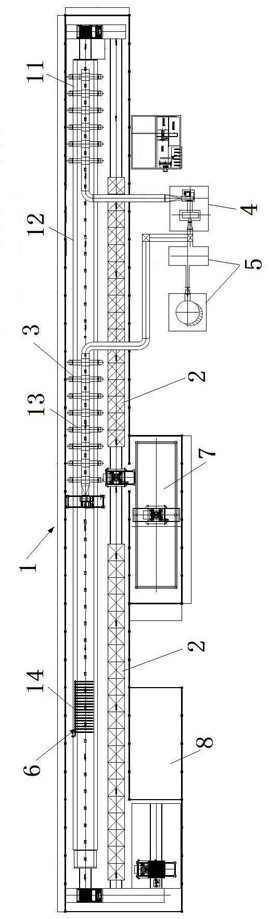

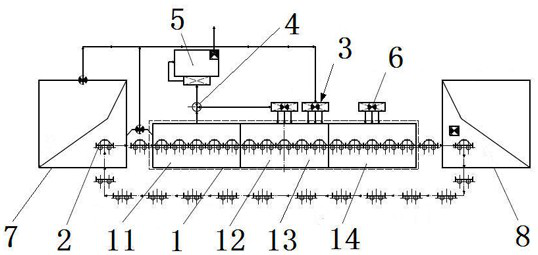

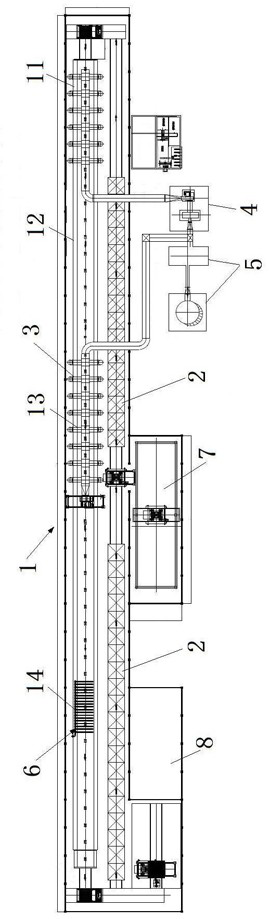

Honeysuckle flower drying production line

InactiveCN105276946AMeet the heat demand of dryingMeet caloric needsDrying machines with progressive movementsDrying solid materialsWork periodDry heat

A honeysuckle flower drying production line is composed of a preheating compartment, a drying compartment, an air-drying compartment, a heat distribution tube, a first conveying belt, a second conveying belt and a third conveying belt. Fresh honeysuckle flowers enter the first conveying belt via material distribution port and are conveyed to the second conveying belt and the third conveying belt. Finally, the obtained dried honeysuckle flowers are conveyed to the interior of equipment for the next processing procedure through the third conveying belt. During the period, a drying heat source arranged at the bottom of the drying compartment aims to enable the temperature inside the drying compartment to reach proper temperature so that the heat requirement of honeysuckle flower drying can be satisfied. Redundant heat is conducted into the preheating compartment through a heat conduction tube under the action of a heat converter. In this way, the temperature in the preheating compartment can meet the preheating requirements of the honeysuckle flowers. Moisture produced during the drying work period of the drying compartment is discharged through a moisture discharge tube. An exhaust tube arranged on the top of the air-drying compartment further dries the honeysuckle flowers through air convection so that the purpose of reaching the commercial grade can be achieved.

Owner:周高超

Refrigeration host system of water-cooled air conditioner

InactiveCN106196531AMeet caloric needsIncrease temperature gradeEnergy recovery in ventilation and heatingFluid heatersCold sideCooling tower

The invention discloses a refrigeration host system of a water-cooled air conditioner. The refrigeration host system comprises a main compressor, a main evaporator, a main condenser, a heat recovery heat exchanger, an air conditioning client, a hot water client, a cooling tower and an auxiliary heat pump device, wherein cold side channels of the main compressor and the main evaporator are connected with a hot side channel of the main condenser in sequence end to end; a hot side channel of the main evaporator is connected with the air conditioning client, and a cold side channel of the main condenser is connected with the cooling tower; and a cold side channel of the heat recovery heat exchanger is connected with an inlet of the hot water client, and both ends of the auxiliary heat pump device are respectively connected with an outlet of the hot side channel of the main evaporator and an outlet of the cold side channel of the heat recovery heat exchanger. Thus, the heat recovery temperature grade of the heat recovery heat exchanger is increased, the total heat supplied to the hot water client is increased, the heat requirement of the hot water client is satisfied, the temperature of cooling water of the main condenser is reduced, the refrigeration energy efficiency ratio of the whole refrigeration host system of the water-cooled air conditioner is increased, and energy consumption is reduced.

Owner:海南唯视雅科工程服务有限公司

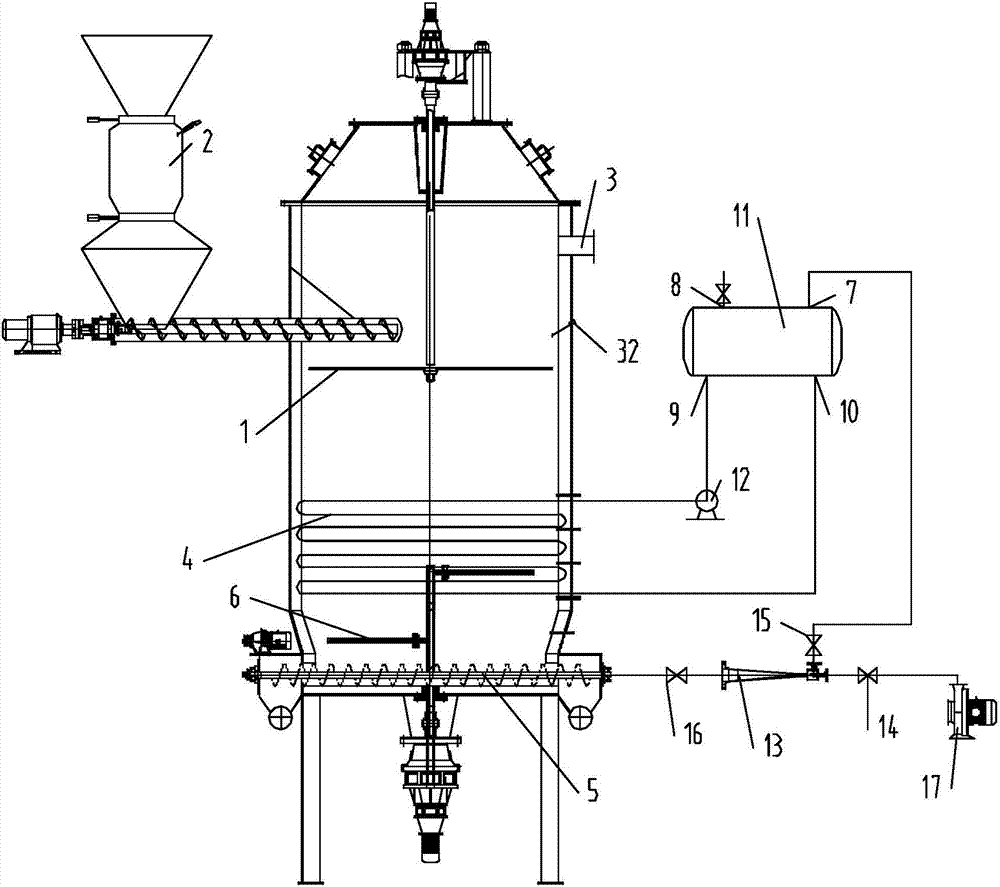

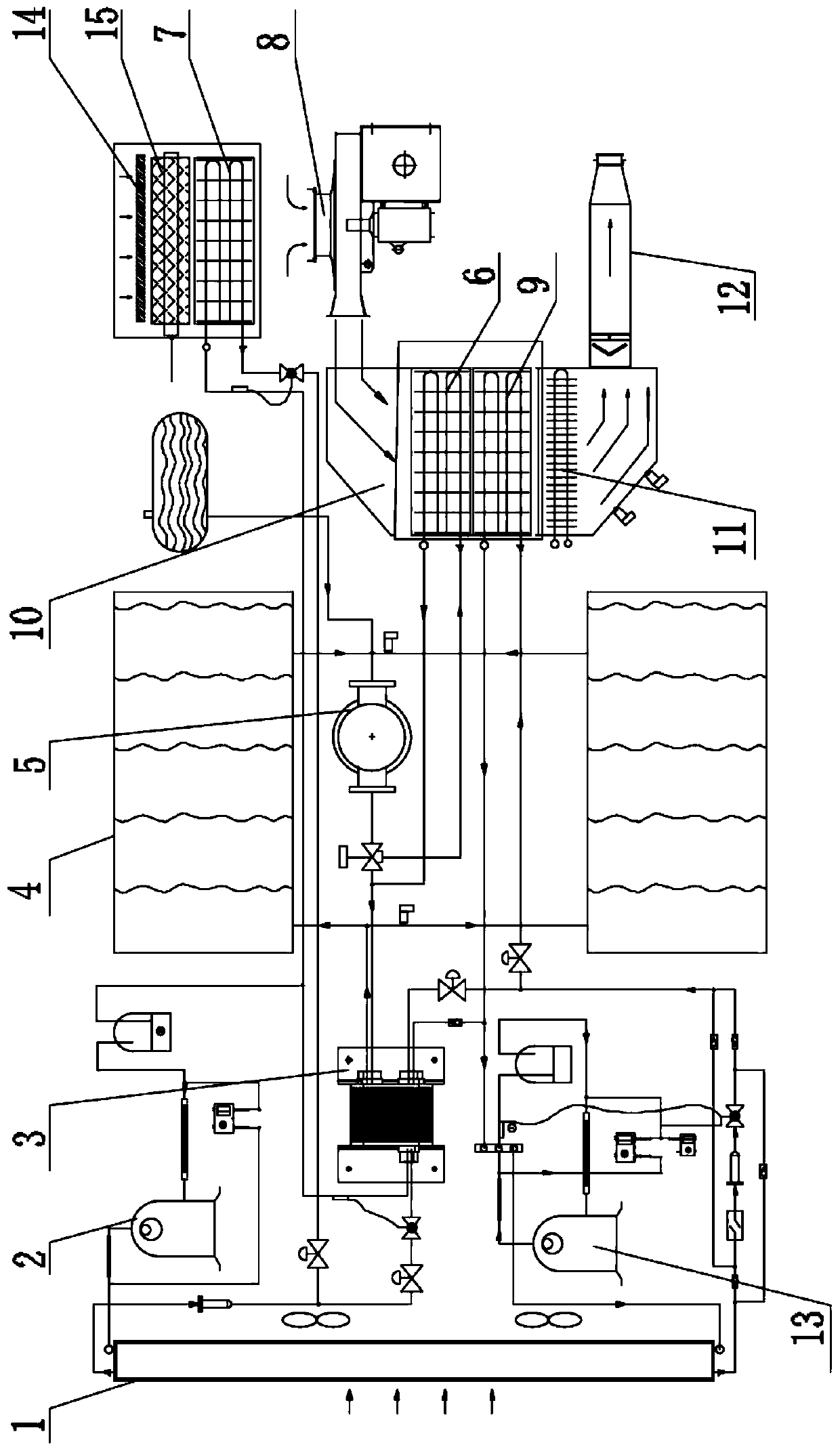

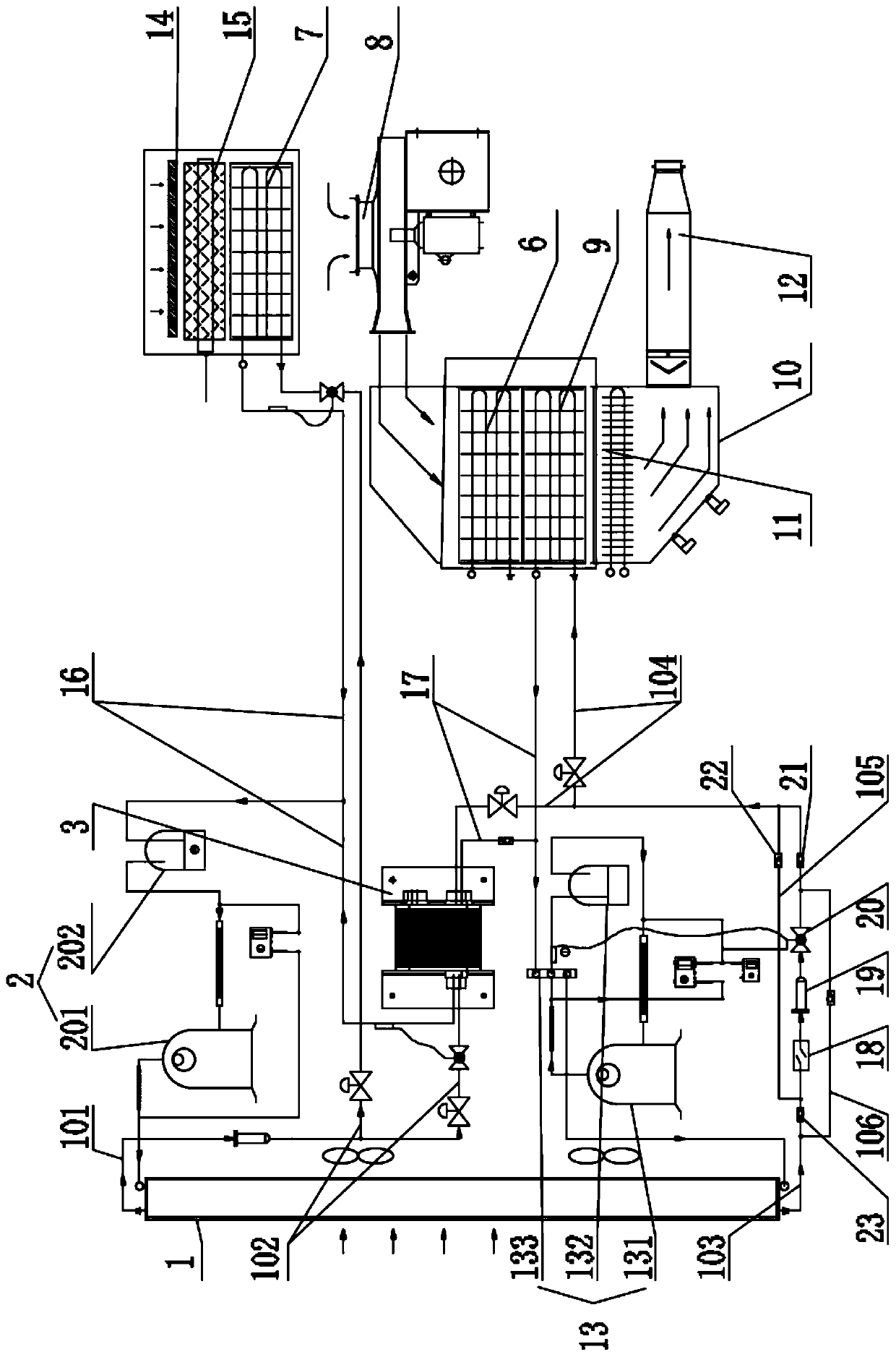

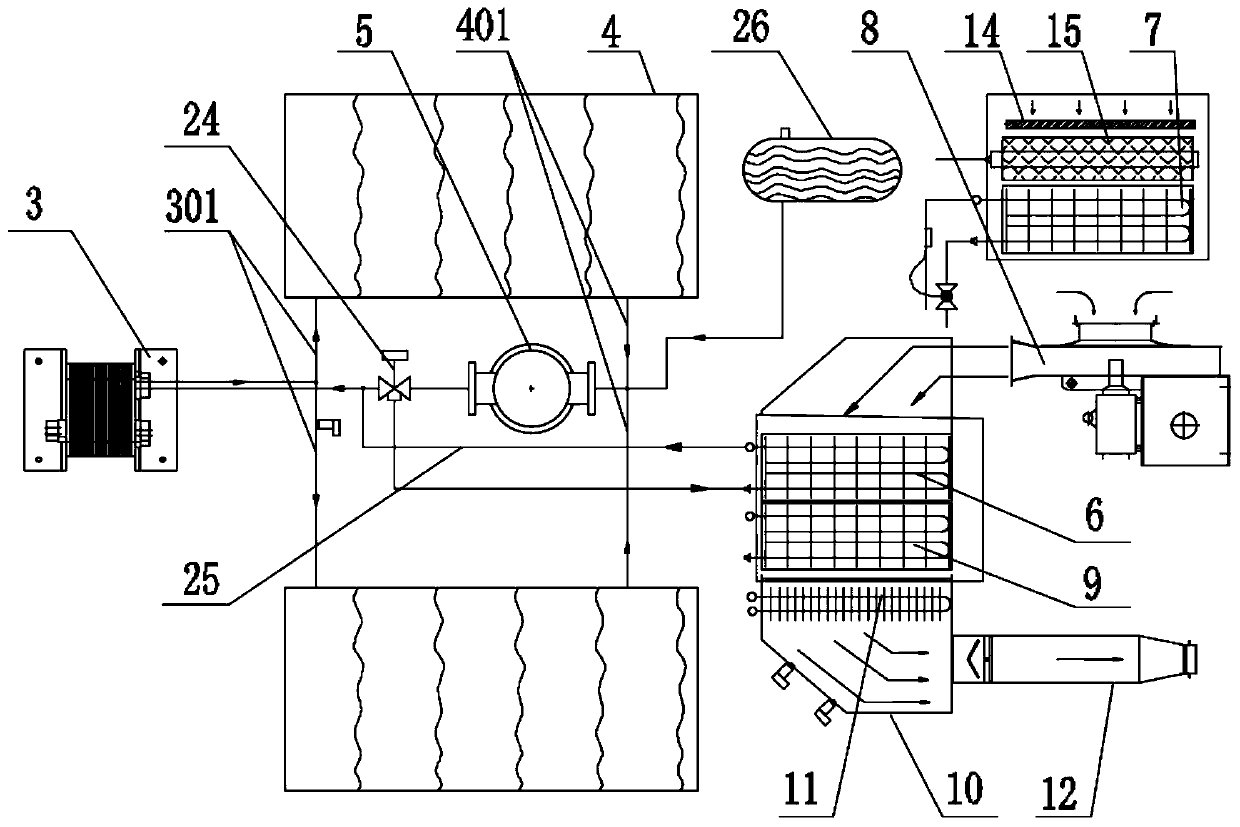

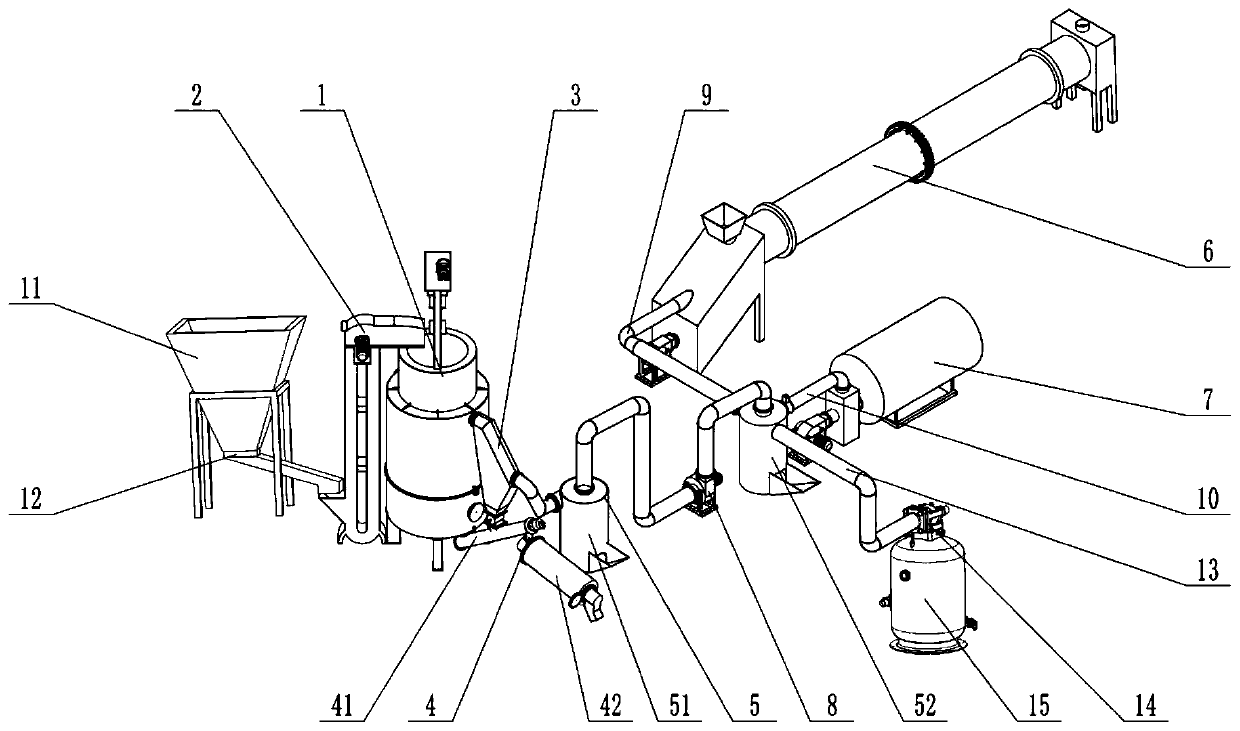

Production line for co-production of gas and charcoal from biomass fuel

PendingCN111500301ALower acquisition costsMeet caloric needsBiofuelsSpecial form destructive distillationEnvironmental engineeringClean energy

The invention provides a production line for co-production of gas and charcoal from a biomass fuel, mainly belonging to the field of biomass fuel production and utilization in wood board manufacturers. The production line comprises: a gas-charcoal co-production furnace; a feeding device, which is matched with a filling opening; a gas-dust separator, wherein one side of the top of the gas-dust separator is connected with a gas outlet; a charcoal powder collector, which is connected with a charcoal outlet; and a tar filter, wherein a gas outlet end, away from the gas-dust separator, of the tar filter is provided with a sucking pump, the gas outlet end of the tar filter is connected with a first branch and a second branch, and the first branch is connected with the second branch in parallel.The production line has the beneficial effects that the biomass fuel is used for preparing the biomass gas and the charcoal; the biomass gas is used as clean energy and is environmentally friendly incombustion and high in heat value; and products including charcoal powder and tar produced by gas-charcoal co-production can also be used as byproducts to be sold, and therefore, income is created forenterprises.

Owner:安徽上元绿能科技有限公司

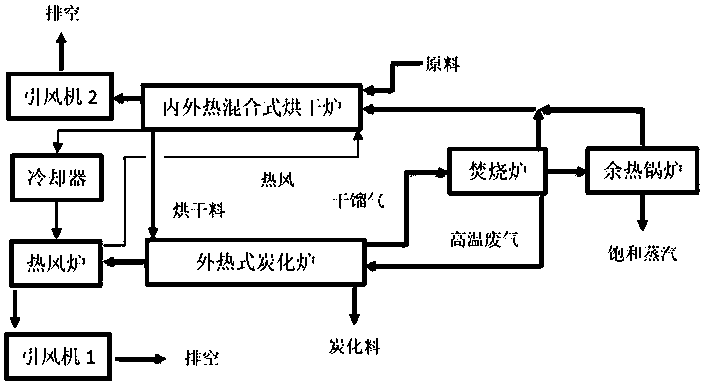

Method for charring biomass and upgrading brown coal

PendingCN108315030AEasy to recycleHigh economic valueDirect heating destructive distillationBiofuelsBiomassDry gas

The invention discloses a method for charring biomass and upgrading brown coal. The method is characterized in that drying and charring procedures are finished in different equipment; the flowing direction of hot waste gas in the drying procedure is the same as that of materials in a drying furnace, hot dry gas and gas generated by drying, the hot dry gas dries the materials by a direct contact mode, and the hot waste gas heats the materials by a heat-radiation mode; the hot waste gas generated in the charring procedure and materials in a charring furnace flow reversely, the materials in the charring furnace and retorting gas flow in the same direction, and the hot waste gas heats the materials by a heat-radiation mode. The method disclosed by the invention has the beneficial effects thatvinegar liquid is purer, the recovery value is high, and the emission of pollutants is reduced; the drying efficiency is improved, the heat loss is reduced, the blockage caused to equipment and pipelines by condensation can be avoided, the reliability is high, the materials cannot be oxidized and ablated, and the materials are high in strength and good in activity; the retorting gas is wholly incinerated, and no waste liquid and waste solid are discharged; latent heat of the retorting gas becomes sensible heat completely, the heat meets the requirements of a whole system, and better economic benefit is realized.

Owner:淮北中清环保科技有限公司

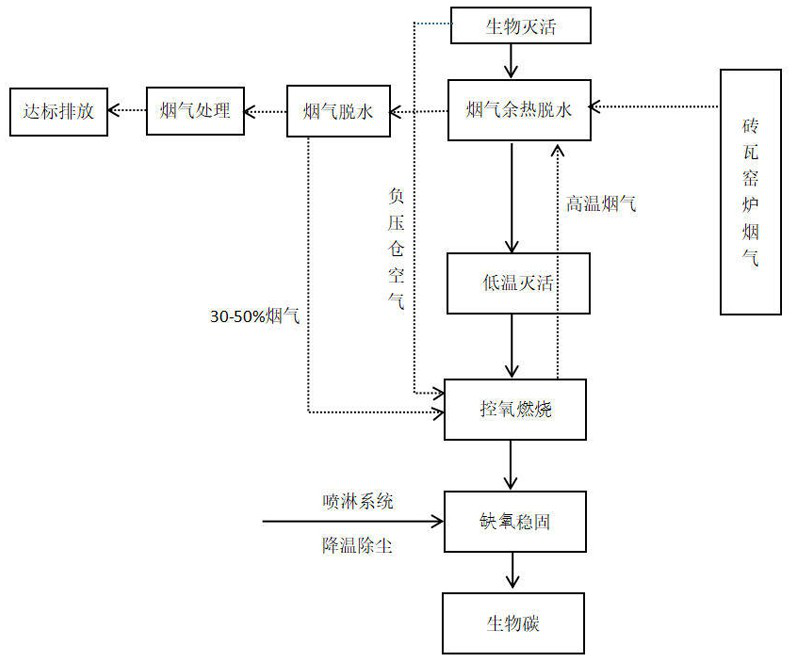

Sludge carbonization method

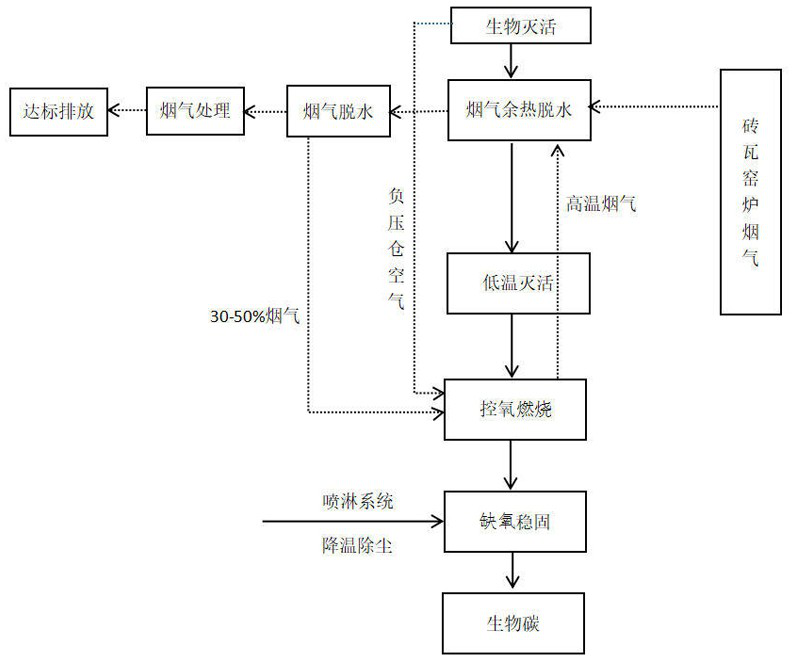

ActiveCN112520968AEasy to operateThe production process is compactSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCombustionSludge

The invention discloses a sludge carbonization method. The method comprises the following steps: 1) first dehydration: reducing the water content of sludge by 10-20% by using hot air; 2) low-temperature inactivation: carrying out second dehydration inactivation on the sludge subjected to the first dehydration at the temperature of 150-300 DEG C, so that the water content of the sludge subjected tothe second dehydration is less than 10%; 3) oxygen-controlled combustion: under an oxygen-controlled condition, combusting the sludge subjected to second dehydration at a temperature lower than 600 DEG C; and 4) oxygen deficit stabilization: sending the product obtained by combustion into an oxygen deficit link for carbonization stabilization, cooling to a temperature lower than 40 DEG C, and discharging to obtain the final product. The sludge carbonization method provided by the invention has the advantages of small investment, realization of sludge burning by sludge, reservation of part ofthe heat value, stabilization of sludge carbonization, increase of the added value, change of wastes into valuables, thorough treatment of sludge, no pollution, carrying of sludge by using a carrier loader, and improvement of the work efficiency.

Owner:湖南爵铭环保有限公司

Motor active heating control method and system for vehicle and vehicle

InactiveCN111865184AReduce manufacturing costLight in massElectric motor controlElectric propulsion mountingControl systemElectric machinery

The invention discloses a motor active heating control method and system for a vehicle and the vehicle, and relates to the technical field of vehicles. The motor active heating control method for thevehicle comprises the steps of judging whether the vehicle has a heat demand or not; detecting the running state of the vehicle; and if the vehicle has a heat demand and is in a static state, controlling the interior of the motor to generate a high-frequency rotating magnetic field, and meanwhile, locking the motor. The invention further provides a corresponding control system. Meanwhile, the invention further provides a vehicle which adopts the control method to control heating of the motor or comprises the control system. When the whole vehicle is static, the motor can generate enough heat to meet the heat requirement of the vehicle.

Owner:ZHEJIANG JIZHI NEW ENERGY AUTOMOBILE TECH CO LTD +1

Organic fertilizer and preparation method thereof

InactiveCN104892059AGuaranteed nutritional valueHigh nutritional valueFertilizer mixturesNutritive valuesEdible mushroom

The invention relates to technical field of organic fertilizer manufacturing, in particular to an organic fertilizer and a preparation method thereof. Mixing in proportion is performed through distilled grains, edible mushroom culture medium and chicken manure, so that the nutritive value of the organic fertilizer is guaranteed, the waste chicken manure, edible mushroom culture medium and distilled grains can be utilized, and then the organic fertilizer is produced as a product with a greater added value, the environmental pollution is avoided, and the production cost of the organic fertilizer; moreover, concentrated sulfuric acid is added in the preparation process, and the concentrated sulfuric acid is instantly heated after meeting water, so that the initial fermentation time is shortened in the raw material stockpiling process, the preparation cycle of the organic fertilizer is shortened, particularly heat generated in the heating process through water absorption of the concentrated sulfuric acid meets the heat requirement of the fermentation process, and the energy consumption in the preparation process of traditional organic fertilizers is reduced; and moreover, the heat discharged through the water absorption of the concentrated sulfuric acid is used for performing sterilization treatment on harmful germs in the chicken manure, and the quality of manufacturing the organic fertilizer by the chicken manure is improved.

Owner:ZUNYI JUNYU AGRI SCI & TECH

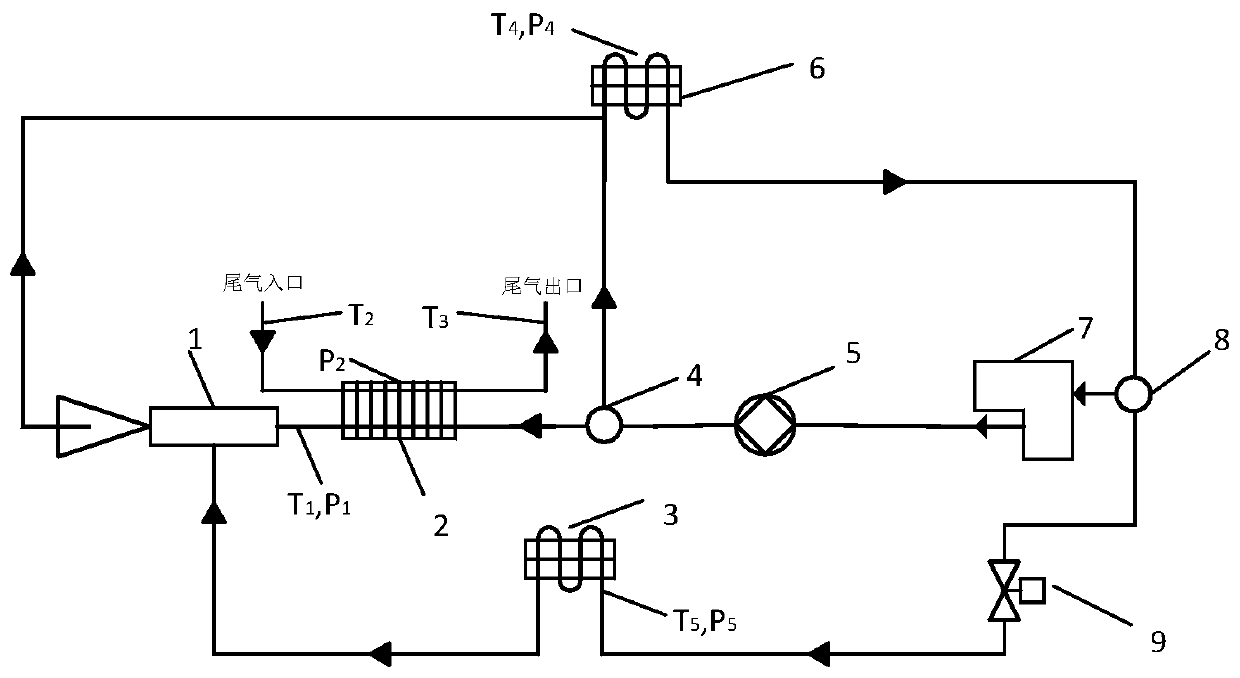

Device and method for driving injection type refrigerating system through automobile waste heat recovery

InactiveCN110017629AMeet low temperature refrigeration needsMeet caloric needsInternal combustion piston enginesClimate change adaptationMixed flowEngineering

The invention provides a device and method for driving an injection type refrigerating system through automobile waste heat recovery. The device comprises an automobile tail gas heat exchanger. The automobile tail gas heat exchanger is used for further heating and pressurizing engine cooling liquid which reaches a set temperature threshold value and is subjected to primary pressurization, dividingthe engine cooling liquid into a first strand of primary flow and a second strand of primary flow and feeding the first strand of primary flow and the second strand of primary flow into an ejector. The first strand of primary flow forms a negative pressure zone in an ejector sucking room so as to inject secondary flow cooling liquid from the interior of an evaporator, the secondary flow cooling liquid is subjected to injection by the first strand of primary flow and is then sucked into a room at the ejector and subjected to heat exchange with the outside in the ejector sucking room so as to conduct refrigeration. The second strand of primary flow is used for injecting a mixed stream of the first strand of primary flow and a secondary flow, and enters an air cooler to be subjected to condensation heat exchange with the outside after being completely mixed with the mixed flow; and after shunting, cooling liquid subjected to condensation heat exchange in one path is used for cooling an engine and is recycled to the automobile tail gas heat exchanger again, and cooling liquid subjected to condensation heat exchange in another path is throttled and then enters the evaporator to form secondary flow cooling liquid.

Owner:SHANDONG UNIV

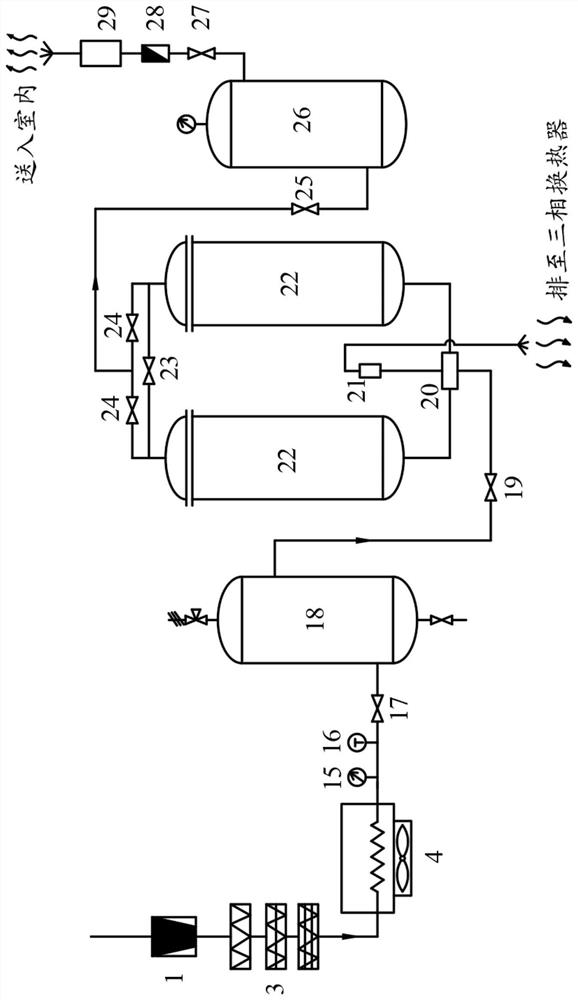

Heat recovery heat supply oxygen making unit for high and cold anoxic environment

PendingCN113251470AReduce energy dissipationEasy renovationMechanical apparatusSpace heating and ventilation detailsOxygen supplyMechanics

The invention discloses a heat recovery heat supply oxygen making unit for a high and cold anoxic environment. The oxygen making unit comprises an oxygen making module and a heat supply module. The oxygen making module comprises an air compressor, a multi-stage high pressure filter, a three-phase heat exchanger, a surge tank, two adsorption towers, an oxygen storage tank and a humidification bottle. The multi-stage high pressure filter, the three-phase heat exchanger and the surge tank are sequentially connected behind the air compressor. A stop valve and an electromagnetic valve are sequentially arranged between the surge tank and the adsorption towers connected in parallel. A pressure equalizing valve and two throttling valves are sequentially connected in parallel between the two adsorption towers and the oxygen storage tank. A one-way valve is arranged between each throttle valve and the oxygen storage tank, and a pressure limiting valve and a flow meter are arranged between the oxygen storage tank and the humidification bottle. The heat supply module is connected with the oxygen making module. A oxygen making system and a heat pump system are fully combined, oxygen supply, humidification and heating can be achieved at the same time, adverse reactions caused by low-pressure oxygen deficit, cold drying and the like in high-altitude areas can be reduced, energy dissipation is reduced, heat recovery and utilization are achieved, and the actual requirements of high-altitude areas are met.

Owner:四川零碳工程科技有限公司

Heat recovery type heat pump oxygen generation air conditioning unit

ActiveCN113251699AIncrease oxygen concentrationIncrease humidityHeat pumpsEnergy inputEngineeringAir compressor

The invention discloses a heat recovery type heat pump oxygen generation air conditioning unit. The heat recovery type heat pump oxygen generation air conditioning unit comprises an oxygen supply module and a heat pump module, wherein the oxygen supply module comprises an air compressor, a multi-stage high-pressure filter, a three-phase heat exchanger, a pressure stabilizing tank, two adsorption towers, an oxygen storage tank and a humidifying bottle; the multi-stage high-pressure filter, the three-phase heat exchanger and the pressure stabilizing tank are sequentially connected to the rear of the air compressor, and a second pressure gauge, a thermometer and a check valve are sequentially arranged on a pipeline between the three-phase heat exchanger and the pressure stabilizing tank; a stop valve and an electromagnetic valve are arranged between the pressure stabilizing tank and the two adsorption towers which are connected in parallel; a pressure equalizing valve and two throttling valves are arranged between the two adsorption towers and the oxygen storage tank; a one-way valve is arranged between the throttling valves and the oxygen storage tank, and a stop valve and a flow meter are arranged between the oxygen storage tank and the humidifying bottle; and the heat pump module is connected with the air compressor, the three-phase heat exchanger and the humidifying bottle in the oxygen supply module. According to the heat recovery type heat pump oxygen generation air conditioning unit, an oxygen generation system and a heat pump system are fully combined, so that oxygen generation and humidification can be realized, and meanwhile, heat recovery and utilization can be realized.

Owner:四川零碳工程科技有限公司

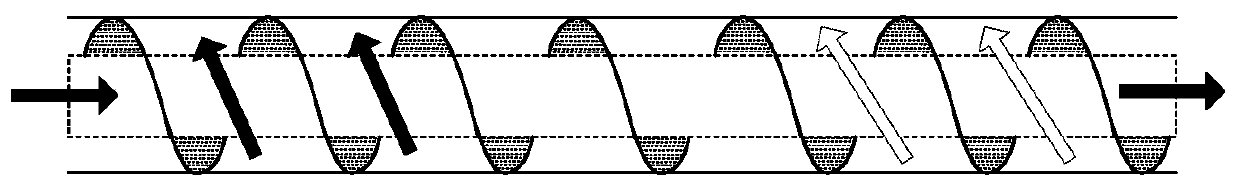

Opening type drying tunnel using multi-connected type heat pump

InactiveCN108507340AReduce lossesReduce energy consumptionDrying gas arrangementsProcess engineeringSmall footprint

The invention relates to an opening type drying tunnel using a multi-connected type heat pump. The opening type drying tunnel comprises a drying tunnel body, heating assemblies, air exhausting assemblies and a heat pump main machine; and the multiple heating assemblies are arranged in the length direction of the drying tunnel body and are used for providing hot air to the drying tunnel body, the multiple air exhausting assemblies are arranged in the length direction of the drying tunnel body and are used for air exhausting of the drying tunnel body, and the heat pump main machine is connectedwith all heating assemblies and supplies heat to all heating assemblies. Compared with the prior art, on the basis that the heat pump is used as a heat source, the multi-connected type heat pump is adopted, heat exchange components can be scattered to the positions nearby all air openings, the air transmission and distribution losses and energy consumption are reduced, meanwhile, only one heat pump main machine is needed for meeting the needs of the overall drying tunnel body, the cost is low, and the floor space is small.

Owner:TONGJI UNIV

A raw coal carbonization activation co-production process and its system

ActiveCN111453728BEfficient use ofImprove adaptabilityCarbon compoundsEnergy inputFluidized bedCarbonization

The invention discloses a raw coal carbonization activation co-production process and a system thereof, and relates to the technical field of coal treatment. The system includes a raw coal carbonization furnace, a fluidized bed activation reactor and a Sleep activation furnace. The raw coal carbonization furnace is respectively connected with The fluidized bed activation reactor and the Sleep activation furnace are co-produced; the raw coal carbonization furnace is sequentially connected with a first incineration chamber and a waste heat steam boiler connected to the Sleep activation furnace. A raw coal carbonization activation co-production system of the present invention includes a raw coal carbonization furnace, a fluidized bed activation reactor and a Sleep activation furnace, and carries out particle size classification on the carbonized material produced by the raw coal carbonization furnace, and sends fine particles into the fluidized bed for activation The reactor is activated, and the large particles are sent to the Sleep activation furnace for activation, which realizes the effective utilization of all carbonized products, diversifies the activated carbon products, covers different markets, improves the adaptability to market fluctuations, and realizes the efficient utilization of raw coal.

Owner:新疆鑫力环保科技有限公司

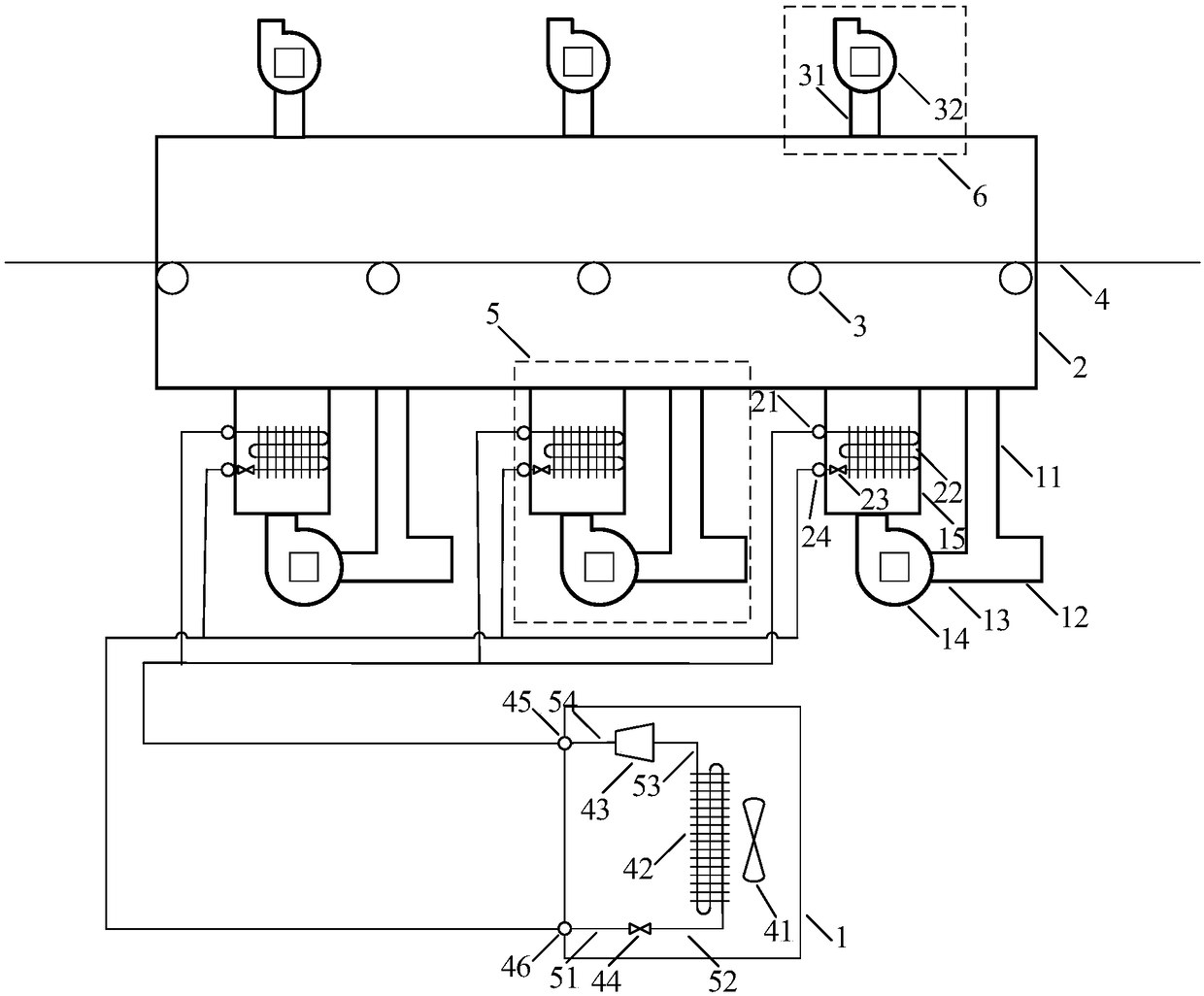

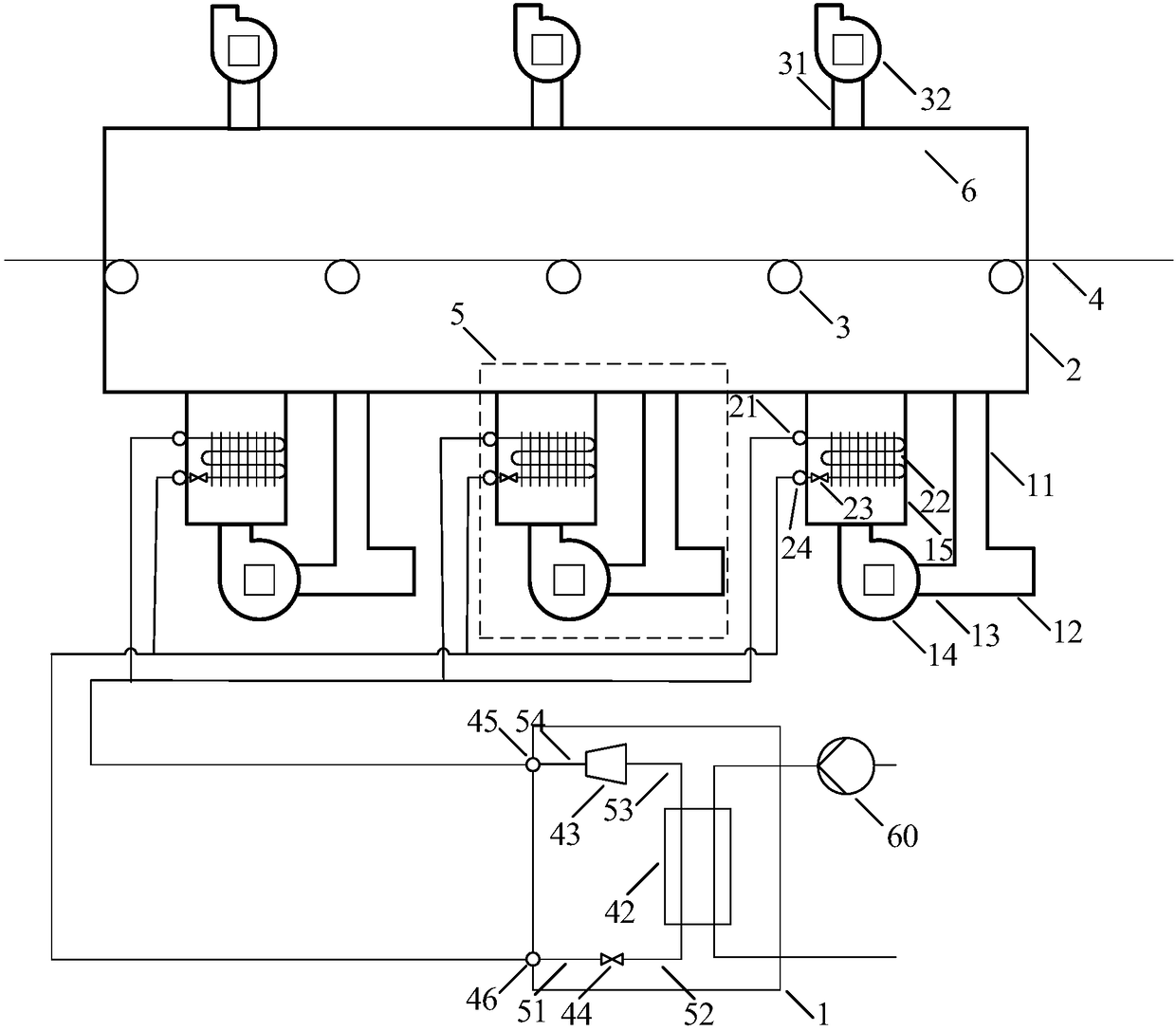

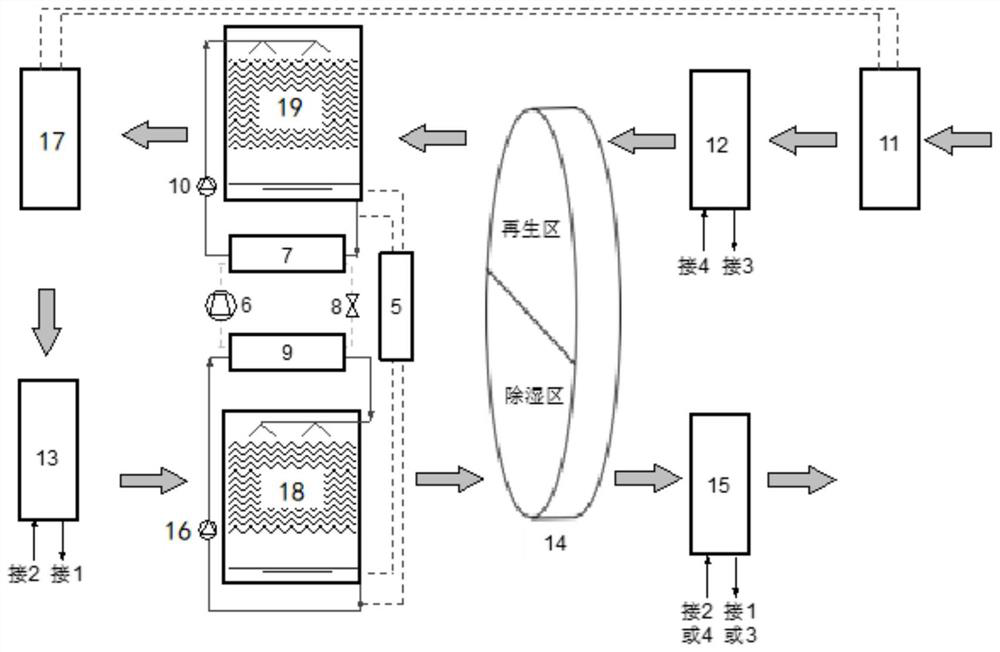

A Cascade Composite Deep Dehumidification Air Treatment System

ActiveCN113432211BMeeting Humidity Handling NeedsRealization of deep dehumidificationEnergy recovery in ventilation and heatingAir treatment detailsThermodynamicsAir treatment

The invention relates to a cascaded composite deep dehumidification air treatment system, comprising: a heating device used for heating indoor return air; a solid adsorption runner arranged in rotation on the air outlet side of the heating device, and the solid adsorption The runner includes a dehumidification area and a regeneration area; a solution regeneration device, used for regeneration of the hygroscopic solution; a cooling and dehumidification device, used for cooling and dehumidification of the return air; a solution dehumidification device, between the solution dehumidification device and the solution regeneration device A solution circulation loop is formed between them, and the dehumidification zone is arranged on the air outlet side of the solution dehumidification device; the terminal sensible heat treatment device is used for temperature regulation of the indoor return air; the indoor return air passes through the heating device and the regeneration area in sequence , solution regeneration device, cooling and dehumidification device, solution dehumidification device and terminal sensible heat treatment device and then discharged into the room. The composite deep dehumidification air treatment system can realize high efficiency and deep dehumidification, and realize efficient independent control of temperature and humidity.

Owner:TSINGHUA UNIV

Fresh tea withering furnace

InactiveCN104381477ASimple structureReasonable cooperationPre-extraction tea treatmentFlueCombustion chamber

The invention discloses a fresh tea withering furnace and relates to the technical field of tea processing equipment. The fresh tea withering furnace comprises a box body with an air inlet and an air outlet. A combustion chamber is arranged at the lower part of the box body. Two exits on the top of the combustion chamber are connected with two flues, outlets of which extend out of the top of the box body. The wall of the box body is provided with ash cleaning doors. In comparison with the prior art, the problem that present fresh tea leaf withering temperature and humidity cannot be controlled and withering quality is not ideal can be solved in the invention.

Owner:三江县陆氏茶叶机械制造有限公司

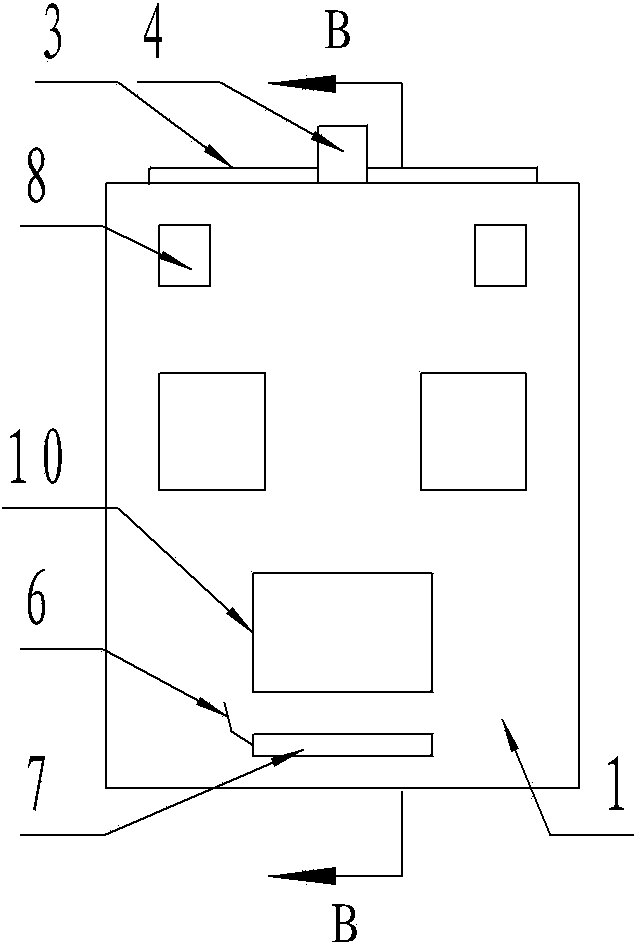

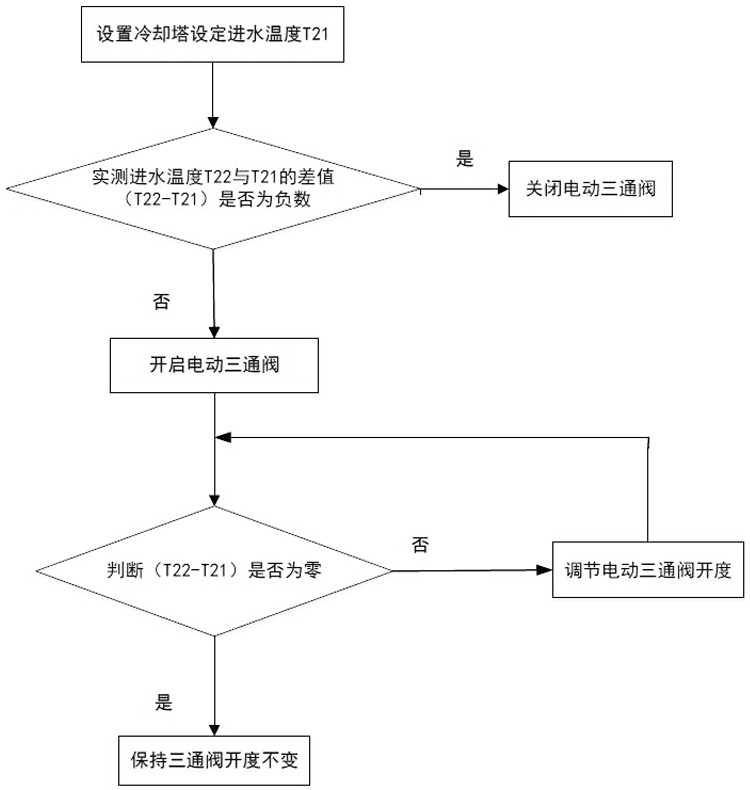

Heat recovery unit and control method thereof

InactiveCN113790487AStable cooling effectAdjustable parametersEnergy recovery in ventilation and heatingMechanical apparatusProcess engineeringMechanical engineering

The invention discloses a heat recovery unit and a control method thereof. The heat recovery unit comprises a first condenser and a second condenser which are connected in series, the first condenser is connected with a user side hot water system, the second condenser is connected with a cooling water system, the heat recovery unit further comprises a first controller used for controlling the water outlet flow according to the user side temperature requirement, and a second controller used for controlling the water inlet temperature of a cooling tower. On the basis that the condenser is used for heat dissipation, the good operation state of the unit is maintained, waste heat is effectively utilized, and energy conservation, emission reduction and carbon emission reduction are really achieved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Multi-stage waste heat recovery heat supply oxygen generation unit

PendingCN113251469AIncrease oxygen concentrationIncrease humidityMechanical apparatusSpace heating and ventilation detailsEngineeringAir compressor

The invention discloses a multi-stage waste heat recovery heat supply oxygen generation unit. The multi-stage waste heat recovery heat supply oxygen generation unit comprises an oxygen generation module, a heating module and an auxiliary heat source module, wherein the oxygen generation module comprises an air compressor, a multi-stage high-pressure filter, a three-phase heat exchanger, a pressure stabilizing tank, two adsorption towers, an oxygen storage tank and a humidifying bottle; the multi-stage high-pressure filter, the three-phase heat exchanger and the pressure stabilizing tank are connected to the rear of the air compressor; a stop valve and an electromagnetic valve are arranged between the pressure stabilizing tank and the adsorption towers connected in parallel; a pressure equalizing valve and two throttling valves are arranged between the two adsorption towers and the oxygen storage tank; a one-way valve is arranged between the throttling valves and the oxygen storage tank, and a pressure limiting valve and a flow meter are arranged between the oxygen storage tank and the humidifying bottle; and the heating module is connected with the oxygen generation module. According to the multi-stage waste heat recovery heat supply oxygen generation unit, an oxygen generation system and a heat pump system are fully combined, oxygen supply, humidification and heating can be carried out at the same time, adverse reactions caused by low-pressure oxygen deficiency, cold drying and the like to people in high-altitude areas can be reduced, energy dissipation is reduced, heat recovery and utilization are realized, and the actual requirements of the high-altitude areas are met.

Owner:四川零碳工程科技有限公司

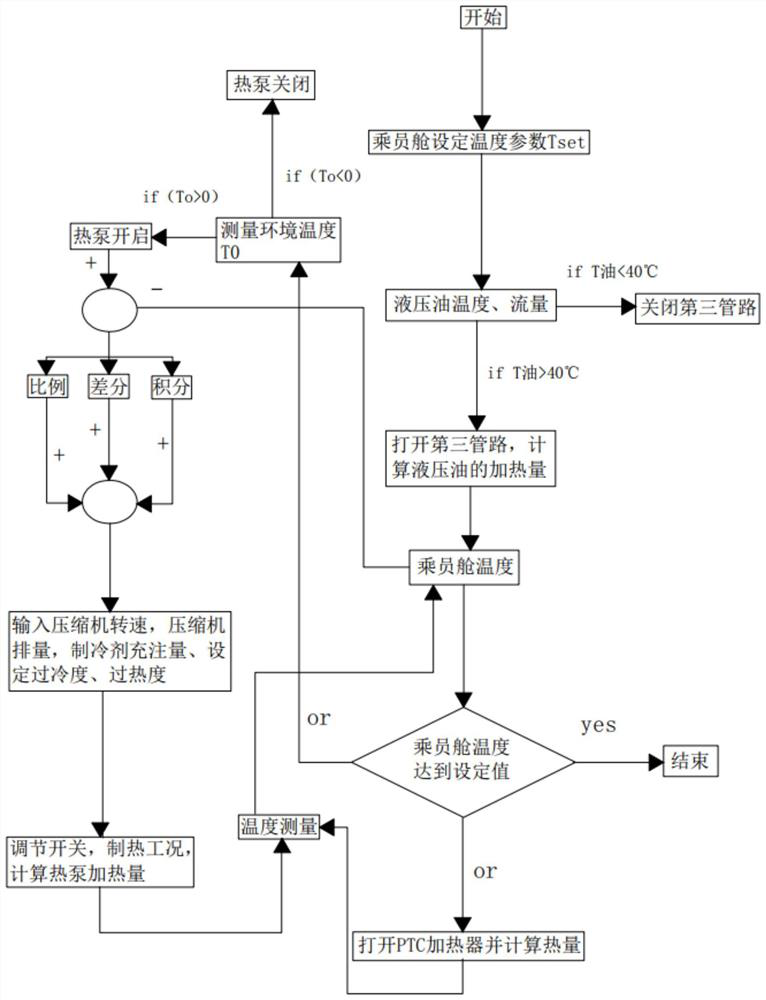

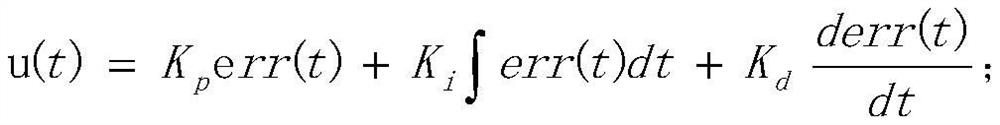

Cab air conditioning system, control method thereof and engineering machinery

PendingCN114435073AMeet caloric needsImprove heating efficiencyAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

The invention provides a cab air conditioning system, a control method thereof and engineering machinery, the air conditioning system comprises a heat pump heating system, a waste heat recovery system and an electric heating system, and the control method comprises the following steps: S1, setting a preset temperature; s2, controlling an electric heating system to be turned on or turned off according to the difference value between the temperature in the cab and the preset temperature; and / or the heat pump heating system is controlled to be turned on or turned off according to the external environment temperature; and / or, the waste heat recovery system is controlled to be started or stopped according to the temperature of the cooling medium, so that the temperature in the cab reaches the preset temperature. According to the control method, the heat pump heating system, the waste heat recovery system and the electric heating system are combined according to the external temperature and the condition of the heating medium, reasonable heat management is carried out while the heat requirement of the cab can be met, the energy utilization efficiency is further improved, and the heating efficiency of the cab is improved.

Owner:SANY HEAVY MACHINERY

Frost-free heat pump oxygen generation air conditioning unit

ActiveCN113251700AIncrease oxygen concentrationIncrease humidityHeat pumpsEnergy inputEngineeringAir compressor

The invention discloses a frost-free heat pump oxygen generation air conditioning unit. The frost-free heat pump oxygen generation air conditioning unit comprises an oxygen generation module, a heat pump module and an auxiliary heat source module. The oxygen generation module comprises an air compressor, a multi-stage high-pressure filter, a three-phase heat exchanger, a pressure stabilizing tank, two adsorption towers, an oxygen storage tank and a humidification bottle. The multi-stage high-pressure filter, the three-phase heat exchanger and the pressure stabilizing tank are connected to the rear of the air compressor. A second pressure gauge, a thermometer and a check valve are sequentially arranged on a pipeline between the three-phase heat exchanger and the pressure stabilizing tank. A stop valve and an electromagnetic valve are arranged between the pressure stabilizing tank and the adsorption towers. The two adsorption towers and a silencer are connected to the rear of the electromagnetic valve. The heat pump module is connected with the air compressor, the three-phase heat exchanger and the humidification bottle. The auxiliary heat source module comprises a pipeline sequentially connected with the silencer, a condensation heat exchanger and the three-phase heat exchanger. According to the frost-free heat pump oxygen generation air conditioning unit, an oxygen generation system and a heat pump system are fully combined, oxygen generation and humidification can be achieved, heating and refrigeration switching can be achieved, and heat recycling and utilization are achieved.

Owner:四川零碳工程科技有限公司

A kind of sludge carbonization method

ActiveCN112520968BEasy to operateThe production process is compactSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCombustionSludge

The application discloses a sludge carbonization method, which includes the following steps: 1) first dehydration: use hot air to reduce the water content of sludge by 10-20%; 2) low-temperature inactivation: the sludge after the first dehydration is ‑300°C for the second dehydration and inactivation, so that the water content of the sludge after the second dehydration is less than 10%; 3) Oxygen-controlled combustion: Under the condition of oxygen control, the sludge after the second dehydration is at a temperature lower than 600°C 4) Oxygen-deficient stabilization: send the product obtained from the combustion to the anoxic link for carbonization and stabilization, lower the temperature to below 40°C, and discharge to obtain the final product. The sludge carbonization method provided by this application has a small investment and can realize "sludge burning sludge", while retaining part of the calorific value, making the sludge carbonization stable, increasing added value, turning waste into treasure, and thoroughly disposing of sludge , No pollution, use the truck to carry the sludge, improve work efficiency.

Owner:湖南爵铭环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com