Vehicle fuel cell waste heat management system and method

A fuel cell and management method technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of high energy consumption of the whole vehicle in winter, difficult layout of the whole vehicle, exhaust emission noise, etc., and achieve improvement Effects of generating power and efficiency, avoiding temperature lag or advance, and reducing pipeline costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

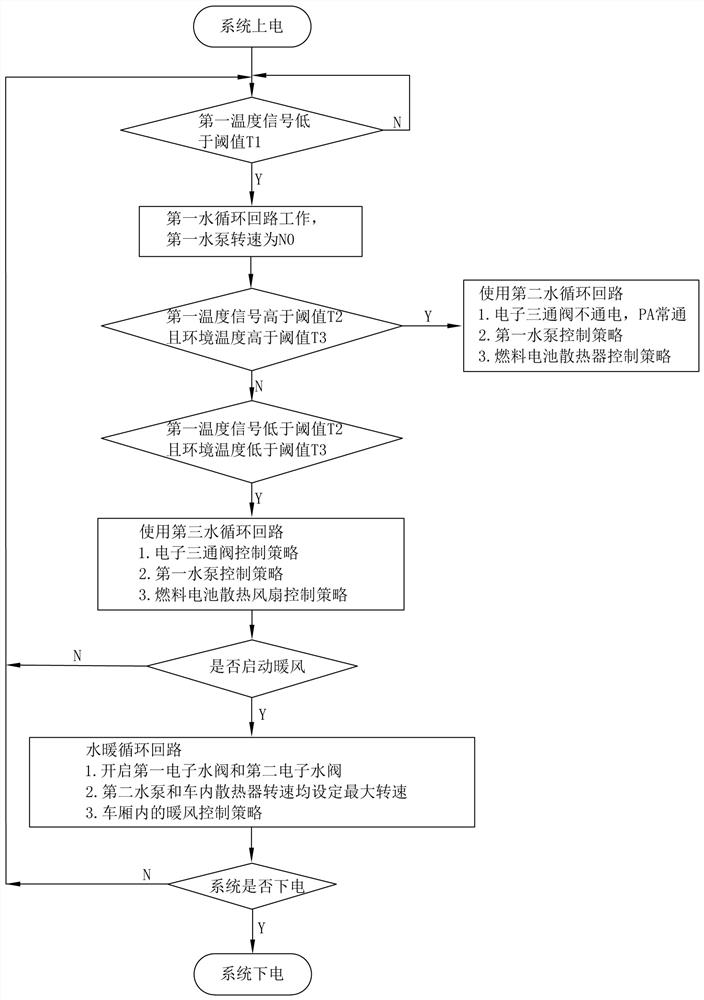

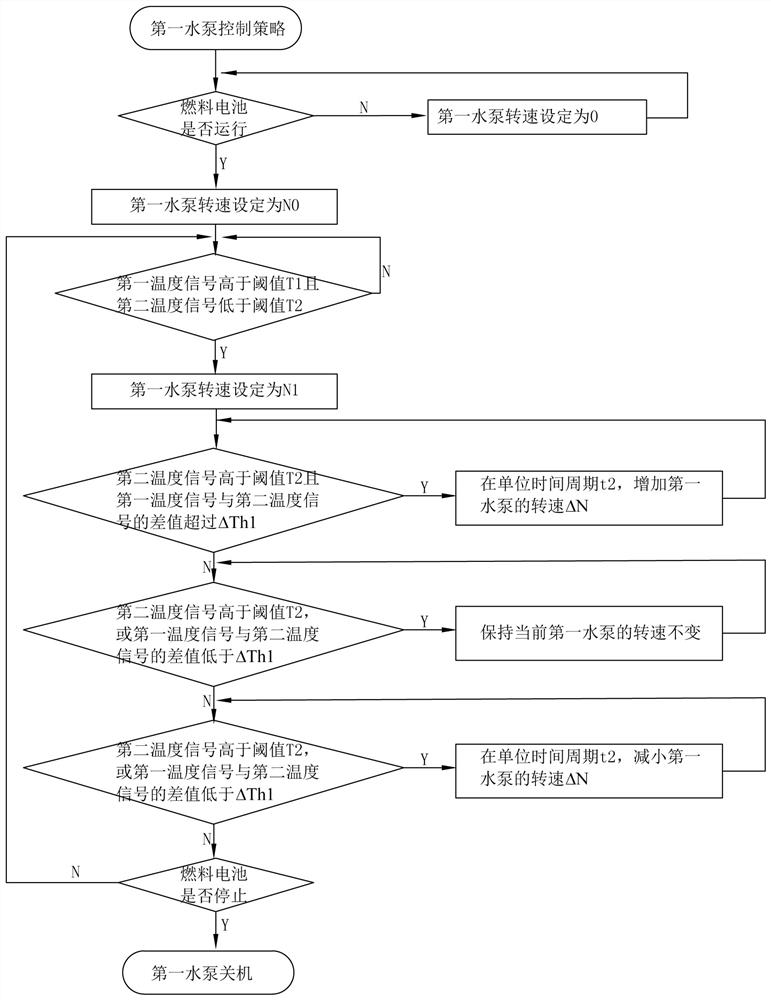

[0027] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

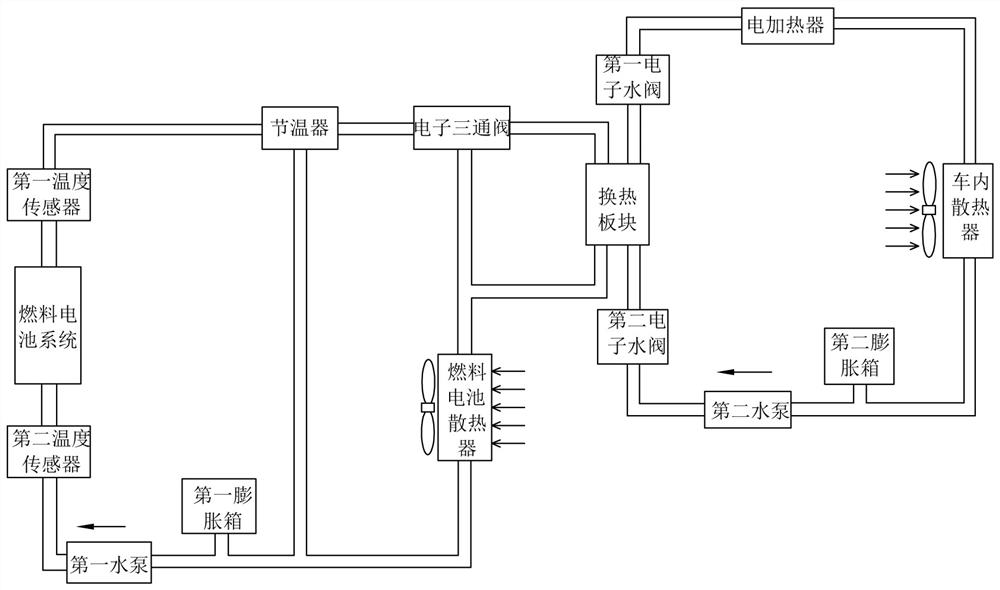

[0028] Such as figure 1 As shown, a vehicle fuel cell waste heat management system includes a cooling system and a water heating system. Wherein, the cooling system includes a first water circulation loop, a second water circulation loop and a third water circulation loop. The plumbing system includes a plumbing loop.

[0029] Such as figure 1As shown, the first water circulation loop includes the fuel cell system, a thermostat, an electronic three-way valve, and a first water pump that are sequentially connected end to end through pipelines. And the water outlet end of the fuel cell system is connected to the water inlet end of the first water pump via the water inlet w of the thermostat and the first water outlet c of the thermostat. Wherein, the thermostat is an existing electronic thermostat or mechanical thermostat, which can be installed not onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com