A kind of sludge carbonization method

A sludge and carbonization device technology, applied in chemical instruments and methods, sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of large investment in incineration process, complex disposal process, complex product components, etc., and achieve the suppression of harmful gases Leakage and disposal process are simple to operate and the effect of saving land and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

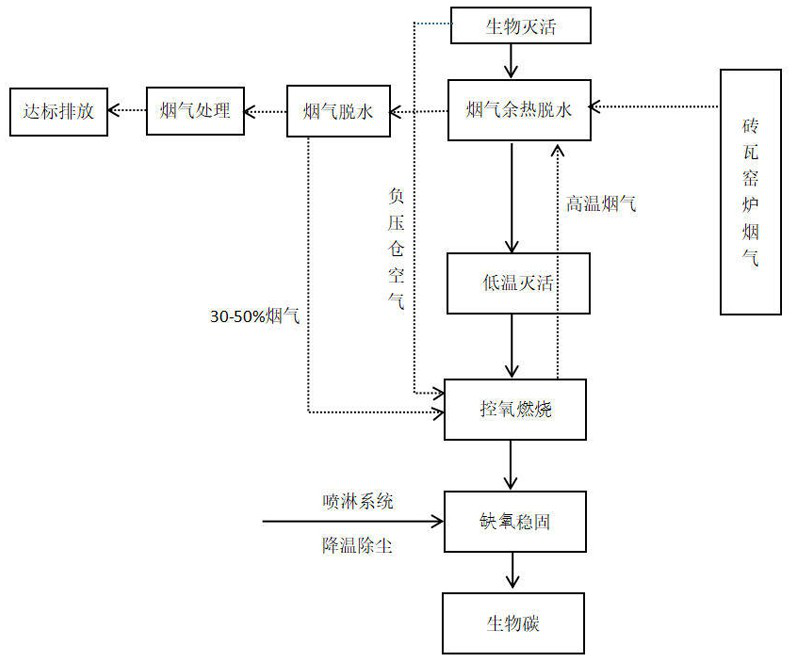

[0076] A sludge carbonization method, comprising the following steps:

[0077] Use chemicals to inactivate the sludge in the negative pressure chamber, extract the air in the negative pressure chamber, and send it to the oxygen-controlled combustion area;

[0078] The first dehydration: use the high-temperature flue gas from the sludge oxygen-controlled combustion area and the brick and tile production line to dehydrate the sludge to reduce the water content of the sludge by 10-20%; extract the exothermic flue gas and dehydrate it. After the water vapor in the flue gas is removed, part of the flue gas is sent to the oxygen-controlled combustion area, and the remaining flue gas is treated and discharged up to standard;

[0079] Low-temperature inactivation: the dehydrated sludge is dehydrated and inactivated for the second time at a temperature of 150-300°C, so that the water content of the sludge after the second dehydration is less than 10%;

[0080] Oxygen-controlled combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com