Patents

Literature

57results about How to "The production process is compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Co-production of xylose, xylitol and arabinose from agricultural and forestry wastes

ActiveCN102268490AEmission reductionReduce salt contentMicroorganism based processesFermentationChromatographic separationHydrolysate

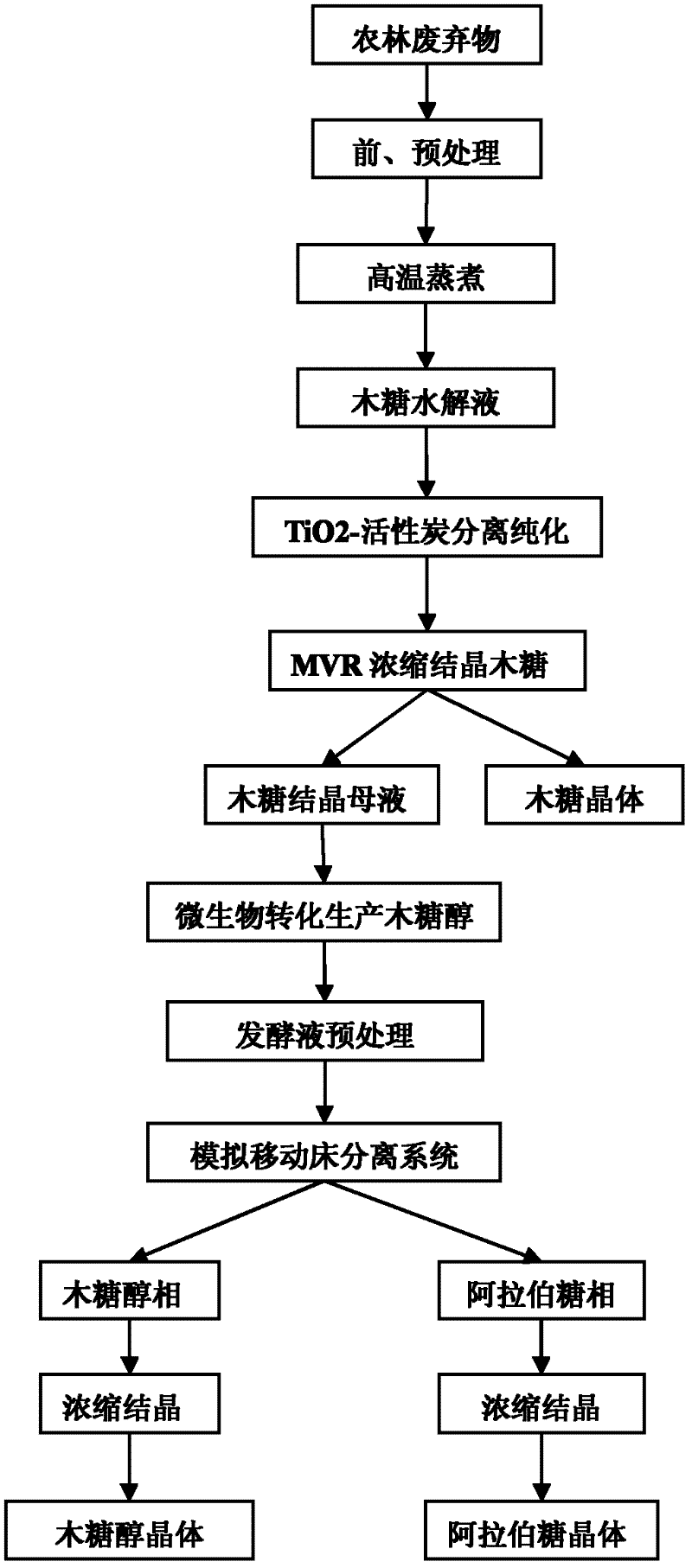

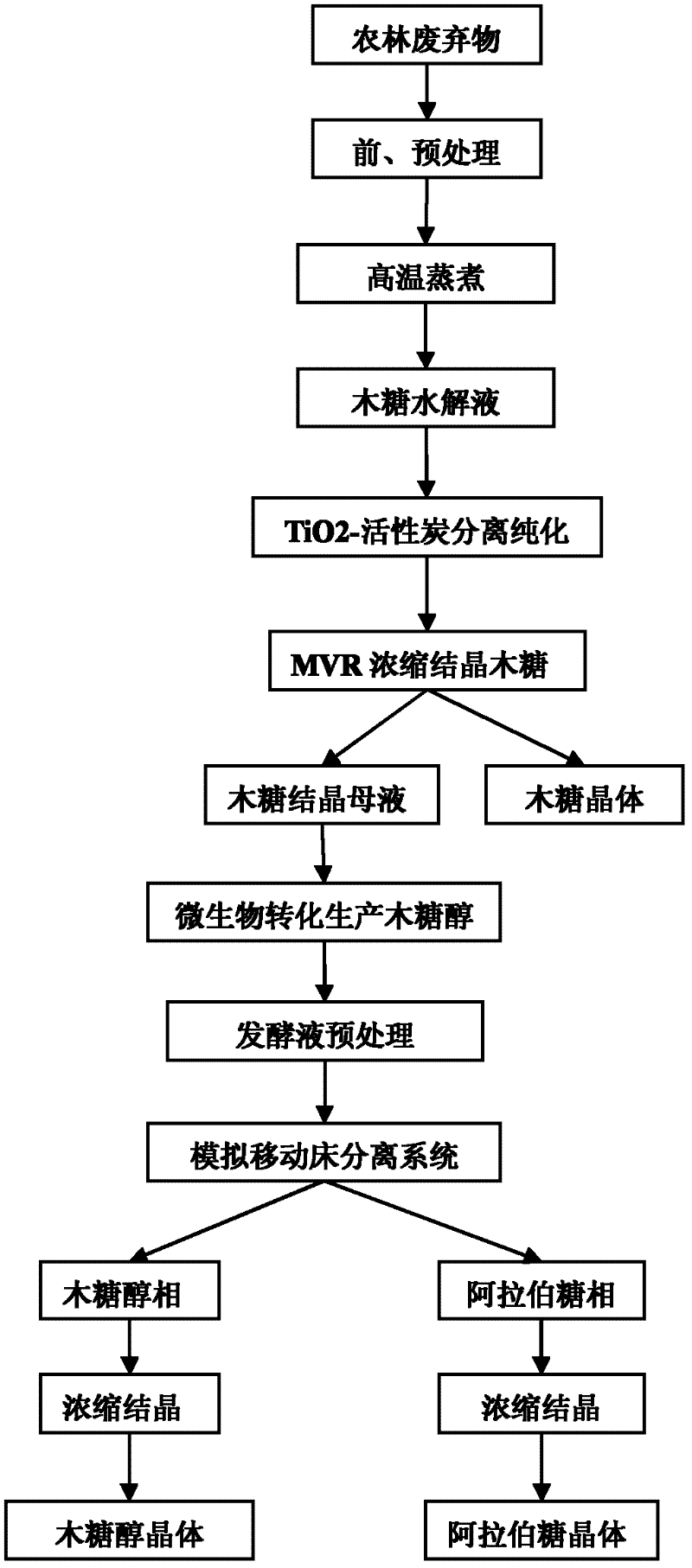

The invention relates to a clean technique for co-producing xylose, xylitol and arabinose from agricultural and forestal waste, belonging to the field of utilization of agricultural and forestal waste. The technique comprises the following steps: pretreating and preprocessing the raw material, and hydrolyzing in a thermophilic digestion mode to prepare a hemicellulose hydrolysate; after centrifugalizing to remove solid residues, carrying out TiO2-loaded activated carbon photocatalysis or ion exchange resin decolorization and detoxification treatment on the hydrolysate; carrying out MVR (mechanical vapor recompression) concentration treatment and gradient-cooling crystallization to obtain a xylose product and a xylose mother solution; fermenting L-arabinose unconverted xylitol fermentationhigh-yield strain xylitol by using the xylose mother solution as the medium to produce the xylitol; centrifugalizing to remove thalli, and carrying out decolorization and desalting treatment by membrane-process or resin adsorption; separating by using a simulated moving bed or chromatographic separation technology to obtain a xylitol phase and an L-arabinose phase; and carrying out MVR or vacuum concentration treatment on the two phases, and crystallizing in a gradient programmed cooling mode to respectively obtaining a xylitol product and an L-arabinose product, wherein the two mother solutions can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

A clean and efficient production process for preparing xylose and l-arabinose

ActiveCN102286571AAddressing the effects of crystallizationHigh yieldSugar derivativesSugar derivatives preparationChromatographic separationYeast

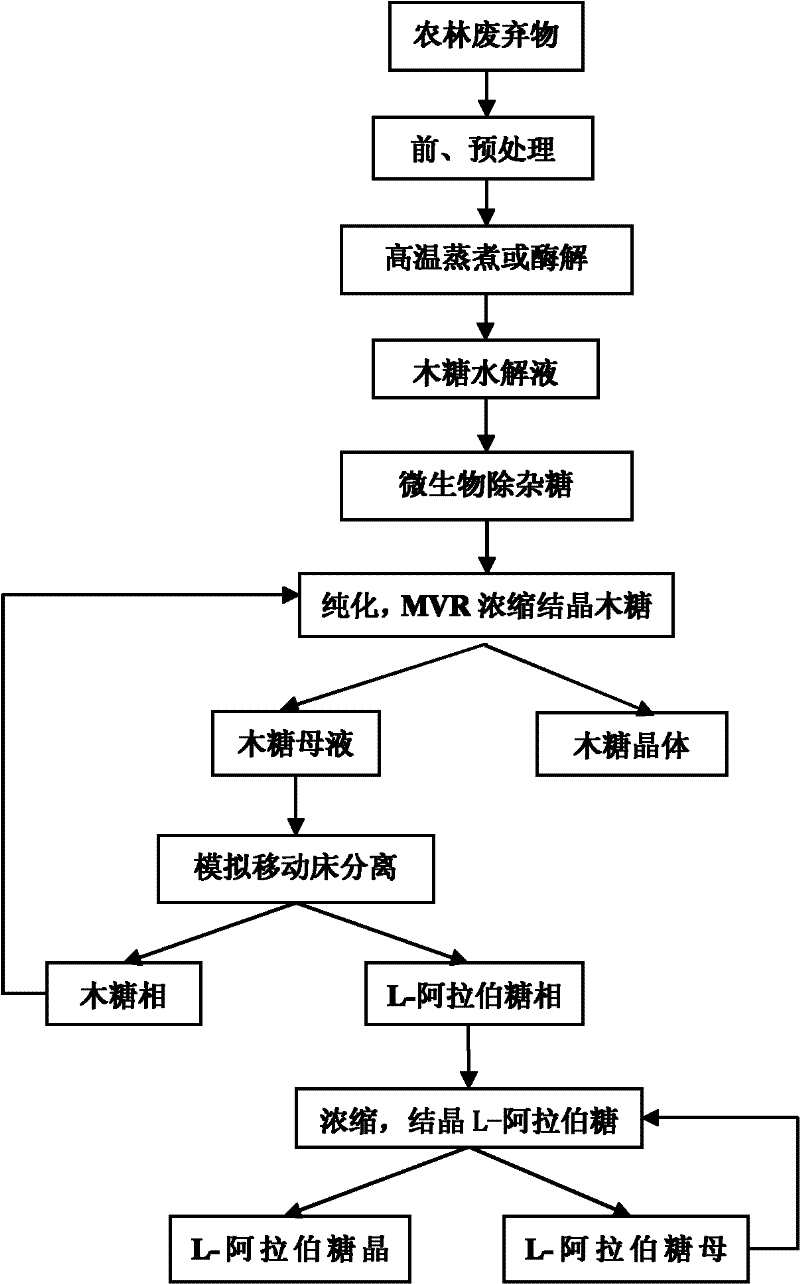

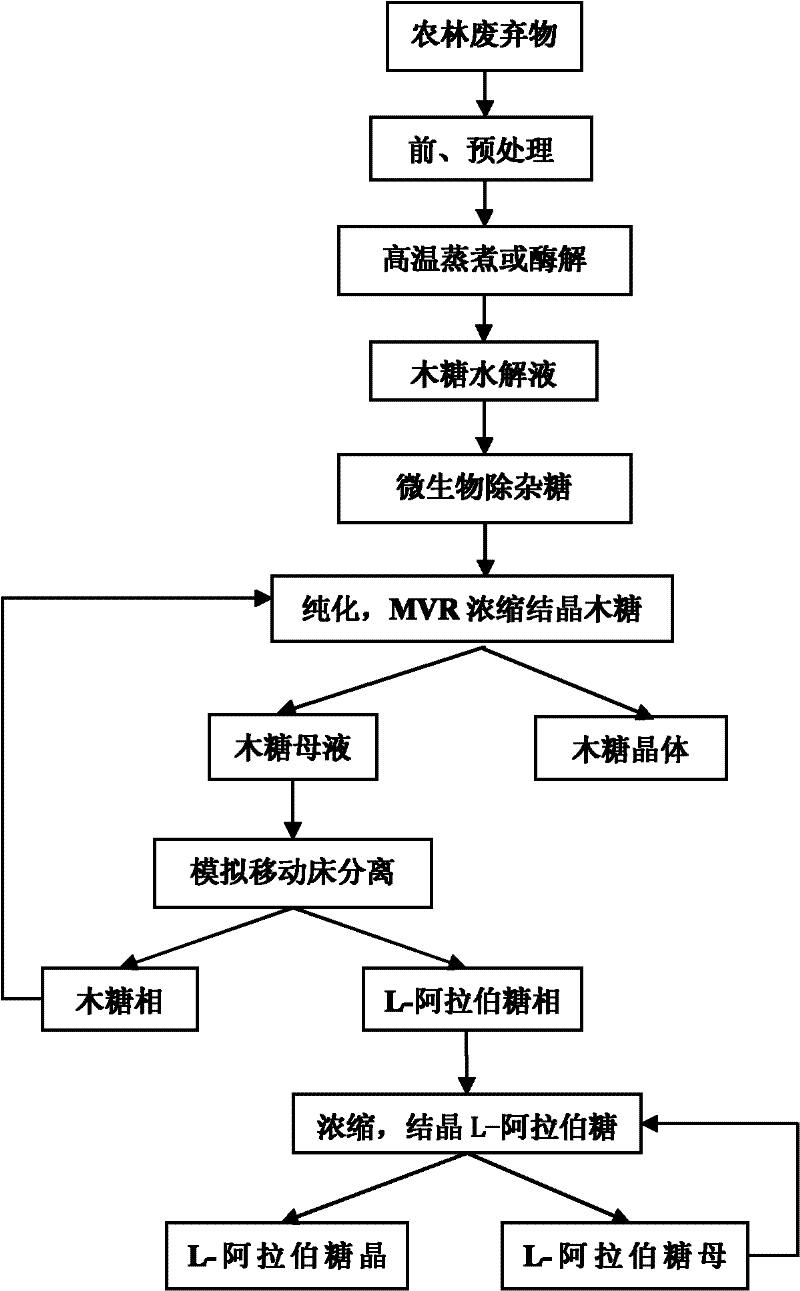

The invention relates to a clean and high-efficiency production process for preparing xylose and L-arabinose and belongs to the field of application of wastes of agriculture and forestry. The production process comprises the following steps of: performing pretreatment on raw materials; hydrolyzing the raw materials in a high-temperature cooking mode; performing neutralizing treatment and performing centrifugal separation on solid slag to obtain xylose or xylooligosaccharide hydrolyzate; adding coarse enzyme solution into xylooligosaccharide solution to hydrolyze to obtain xylose solution; treating the hydrolyzate by Angle yeast; purifying by using active carbon and resin; performing recompression and concentration treatment on the purified hydrolyzate by using a mechanical vapor recompression (MVR) machine; crystallizing the concentrated solution in a gradient program cooling mode to obtain xylose products and xylose mother solution; separating the xylose mother solution by a simulated moving bed or a chromatographic separation technology to obtain a xylose phase and an L-arabinose phase; returning the xylose phase to the xylose solution to concentrate and recrystallize; reusing the xylose mother solution; performing MOVR concentration treatment on the L-arabinose phase and crystallizing in a gradient program cooling mode to obtain L-arabinose products; and reusing the L-arabinose mother solution.

Owner:BEIJING UNIV OF CHEM TECH

Production method of austenitic stainless steel

InactiveCN101928804AHigh yieldAvoid the problem of high loss and low chromium yieldProcess efficiency improvementElectric furnaceNichromeSS - Stainless steel

The invention relates to a production method of austenitic stainless steel, which comprises the following steps of: a, mixing different low-grade nickel-chromium pig iron in an electric furnace, blowing, desiliconizing and decarbonizing to obtain a stainless steel mother liquor; preparing Cr to be about half of a finished product according to the content requirement of a stainless steel finished product, and properly preparing Ni in the stainless steel mother liquor in the electric furnace by using a grade high-carbon ferrochrome; b, adding the stainless steel mother liquor obtained in the step a to an AOD furnace, adding the high-carbon ferrochrome, laterally blasting air, oxidizing by using a gun and flowing out slag; c, adding metallurgical lime, high-carbon ferrochrome, ferronickel and waste steel to carry out primary decarbonization and secondary decarbonization, adjusting carbon content to the level required by the finished product; and e, finely adjusting components and adjusting temperature in an LF furnace to obtain the austenitic stainless steel. The invention has the advantages of low energy consumption, low cost and stable product quality.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

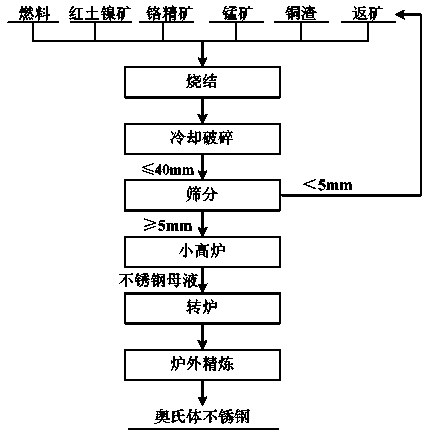

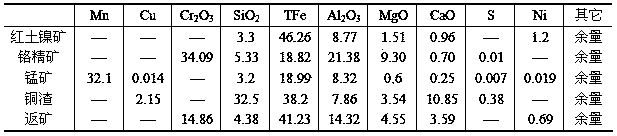

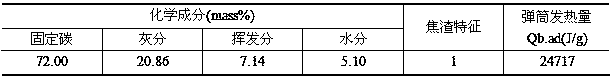

Compact production method of austenitic stainless steel

InactiveCN103866076ASimple processReduce the temperatureManufacturing convertersProduction lineManganese

The invention provides a compact production method of austenitic stainless steel. According to the method provided by the invention, the original four production lines for production of ferronickel, ferrochromium and manganese-iron alloys as well as mixed smelting steel-making are combined into one production flow, and nickel laterite, ferrochromium concentrate, manganese ore and copper slag are directly subjected to mixed sintering and smelting to produce the austenitic stainless steel, thus simplifying the process flow, reducing a sintering ignition temperature and the proportion of carbon, and reducing energy consumption and reducing production cost; and moreover, stainless steel mother solution containing chromium, nickel, manganese and copper is directly obtained by smelting, and the obtained thermal stainless steel mother solution is directly blown in a converter to produce stainless steel, thus further reducing heat loss, decreasing energy consumption, facilitating simplification of a production line of austenitic stainless steel, avoiding the problem of increase of equipment management and maintenance costs due to decentralized flow, and opening up a novel way for a production process of the austenitic stainless steel.

Owner:CHONGQING UNIV

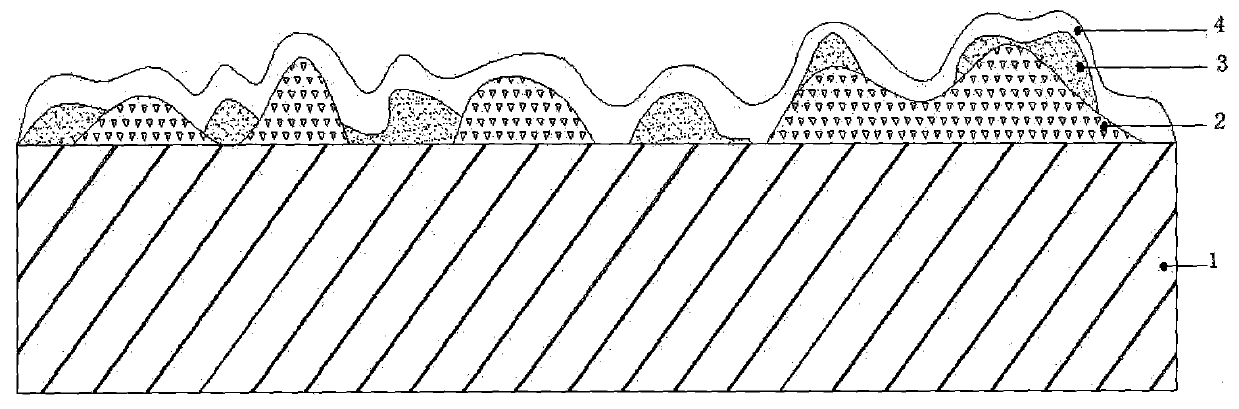

Functional nanocellulose-boron nitride composite film and preparation method thereof

ActiveCN109971020AReduce the number of layersImprove thermal conductivityCoatingsComposite filmFiltration

The invention discloses a functional nanocellulose-boron nitride composite film. A deposition layer is formed after suction filtration of a nanocellulose / boron nitride dispersion liquid on a mixed cellulose ester micro-porous filter membrane, and the deposition layer is hot-pressed and dried to form the inner layer of the composite film; and the inner layer of the composite film is a nanocellulose-boron nitride composite monolayer structure containing 1-7 wt% of boron nitride. The invention also discloses a preparation method of the composite film. The preparation method comprises: (1) mixing,stirring and ultrasonically crushing a nanocellulose dispersion and a boron nitride dispersion to obtain the nanocellulose-boron nitride dispersion; and (2) placing the obtained dispersion on the mixed cellulose ester filter membrane, carrying out vacuum suction filtration to form the deposition layer, removing the mixed cellulose ester filter membrane, and hot-pressing and drying the depositionlayer to obtain the inner layer of the composite film. The composite film provided by the invention has a high heat conduction coefficient and a high hydrophobic insulation performance, and can be widely used in the fields of electronic devices and biomaterials.

Owner:SHANGHAI UNIV

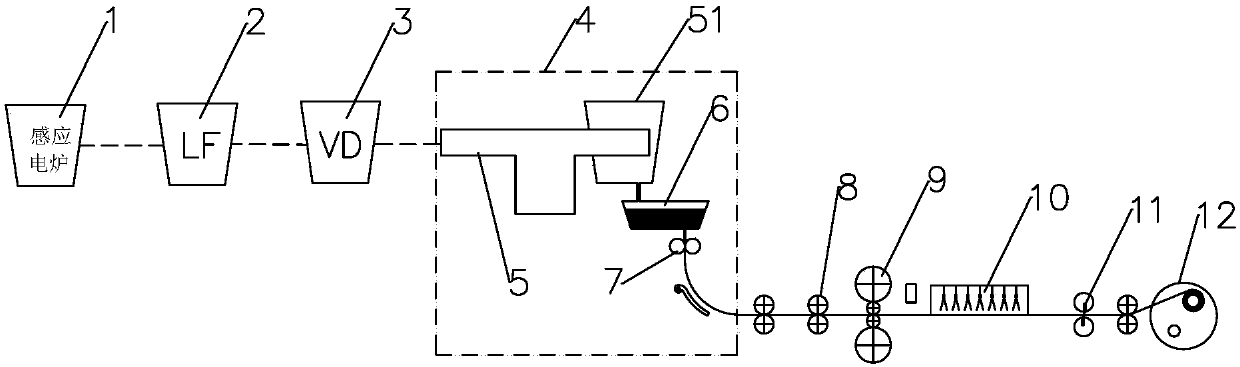

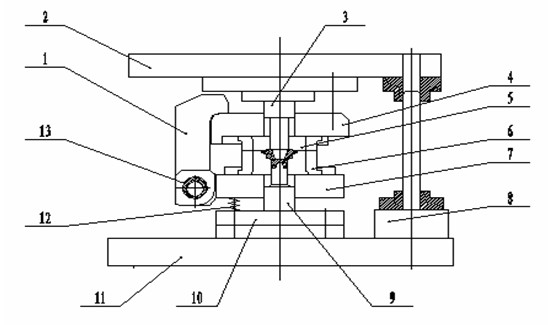

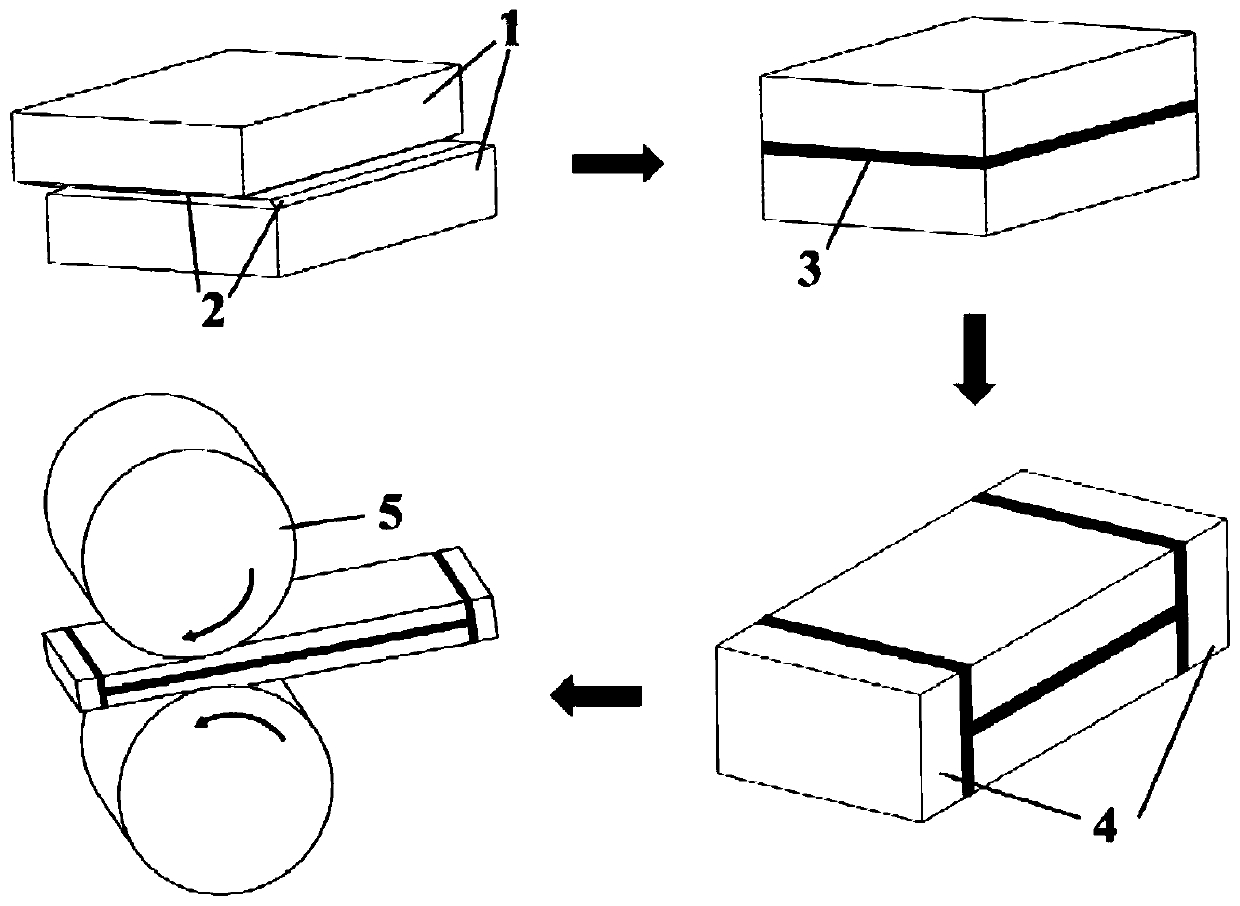

Production method of ultrathin hot-rolled strip steel

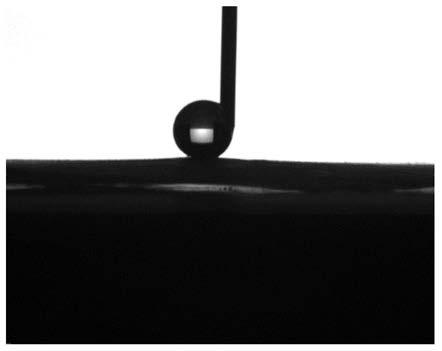

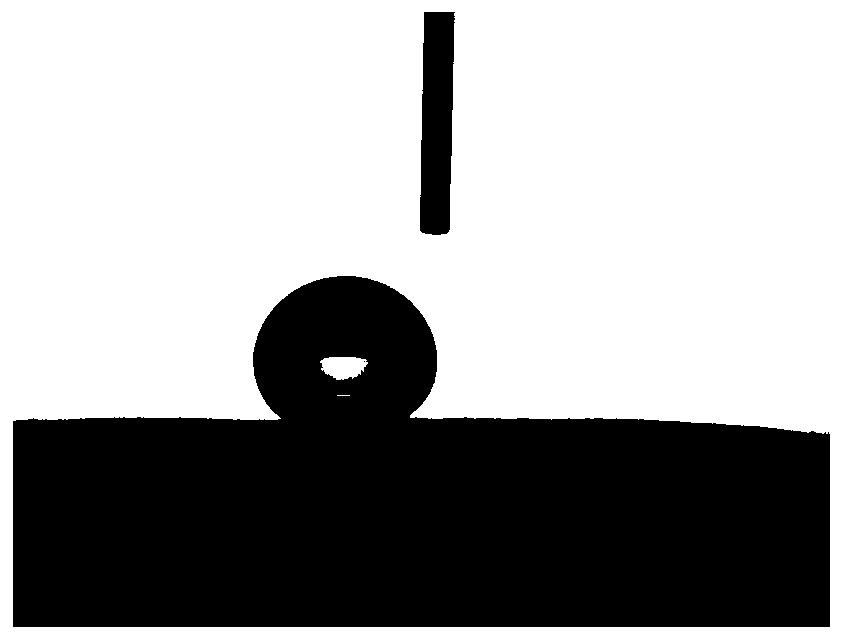

InactiveCN110899644AThe production process is compactEnvironmentally friendly continuous productionMelt-holding vesselsTemperature control deviceTemperature controlStrip steel

The invention discloses a production method of ultrathin hot-rolled strip steel. The method comprises the following process steps of A, smelting procedure: feeding scrap steel into an electric induction furnace for smelting such that the scrap steel is smelted into molten steel; B, refining procedure: refining the molten steel by using a ladle refining furnace and a ladle vacuum degassing furnace;C, continuous casting procedure: casting the refined molten steel into a casting strip blank with the thickness of 1.6-2.5 mm through a double-roller thin strip continuous casting system; D, hot rolling procedure: directly sending the casting strip blank formed in the continuous casting procedure into a single-rack hot rolling mill to be rolled to prepare hot-rolled strip steel with the thicknessof 0.8-1.5 mm; and E, cooling and coiling procedure: carrying out atomization cooling treatment on the hot-rolled strip steel, controlling the temperature of the strip steel to be 400-750 DEG C, andcoiling. According to the method, an extremely compact, environment-friendly and economic ultrathin hot-rolled strip steel production process flow is realized, and the environment-friendly and economic continuous production of metal plates and strips is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of production method of austenitic stainless steel

InactiveCN102268593AHigh yieldIncrease productivityProcess efficiency improvementNichromeFerrochrome

The invention relates to a production method of austenitic stainless steel, which comprises the following steps of: a, mixing different low-grade nickel-chromium pig iron in an electric furnace, blowing, desiliconizing and decarbonizing to obtain a stainless steel mother liquor; preparing Cr to be about half of a finished product according to the content requirement of a stainless steel finished product, and properly preparing Ni in the stainless steel mother liquor in the electric furnace by using a grade high-carbon ferrochrome; b, adding the stainless steel mother liquor obtained in the step a to an AOD furnace, adding the high-carbon ferrochrome, laterally blasting air, oxidizing by using a gun and flowing out slag; c, adding metallurgical lime, high-carbon ferrochrome, ferronickel and waste steel to carry out primary decarbonization and secondary decarbonization, adjusting carbon content to the level required by the finished product; and e, finely adjusting components and adjusting temperature in an LF furnace to obtain the austenitic stainless steel. The invention has the advantages of low energy consumption, low cost and stable product quality.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

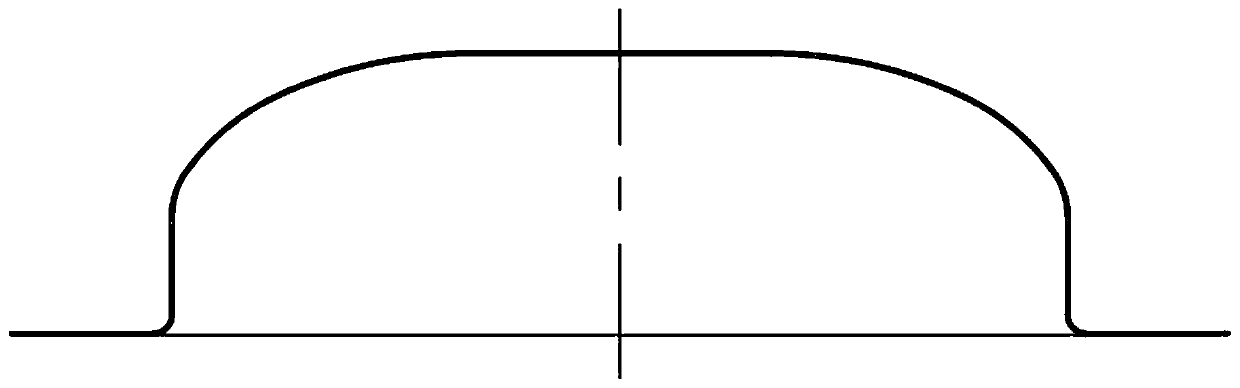

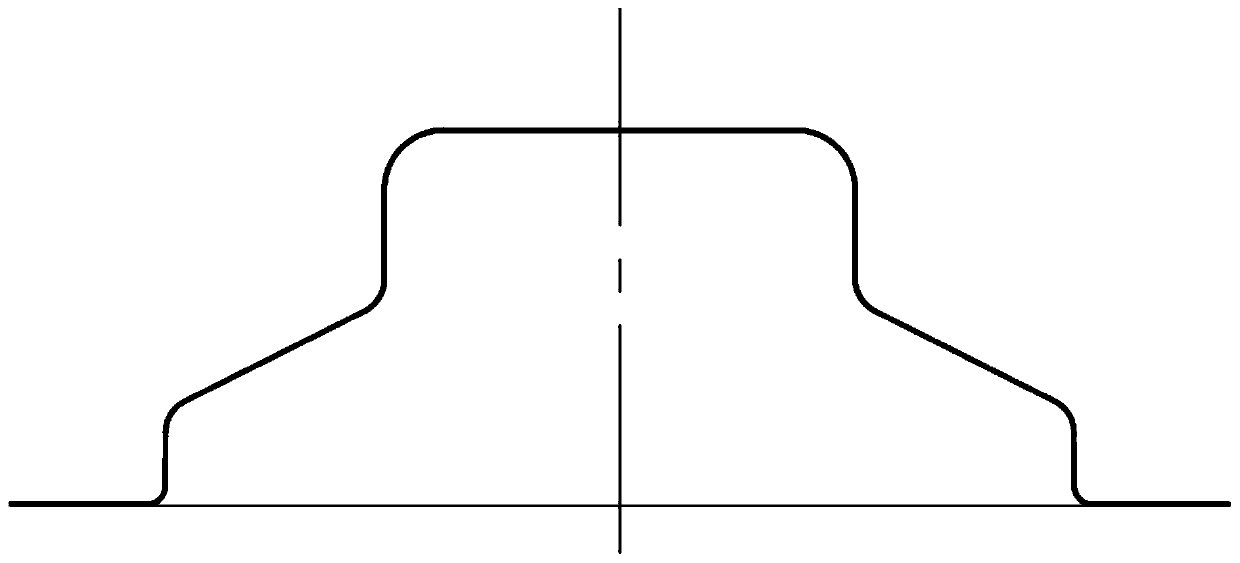

Closed-extrusion and molding method of flange

The invention discloses a closed-extrusion and molding method of a flange and belongs to the technical field of pressure machining of metal. The molding method comprises the specific steps of: firstly, preparing a flange blank; then carrying out induction heating on the flange blank at a temperature in range of 950-1200 DEG C to obtain a flange upset piece with an upset end part; putting the flange upset piece into a closed-extrusion and molding mould and then carrying out primary molding by utilizing a closed radial extrusion method to obtain an extruding piece of the flange; and carrying out shaft neck reverse extrusion and molding on the extruding piece, and punching inner holes and fins, and finally machining to obtain the flange. The closed-extrusion and molding method disclosed by the invention utilizes a double-floating concave mould structure of a belt lock hook mould closing device, and the flange upsetting piece in a closed type cavity can be extruded in a radial direction by upper and lower convex moulds. The method disclosed by the invention has the characteristics of compact production process, high material utilization rate, good flange quality and low production and manufacturing cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High-strength toughening glue, preparation method of high-strength toughening glue and preparation method of A2-level inorganic mineral plate

ActiveCN103965814AExcellent adhesionImprove securityCellulose adhesivesGlass fiberAluminium hydroxide

The invention discloses a preparation method of an A2-level inorganic mineral plate, high-strength toughening glue and a preparation method of the high-strength toughening glue. The preparation method of the A2-level inorganic mineral plate comprises the following steps: selecting the following powder by weight: 15-30 parts of aluminium hydroxide, 10-20 parts of magnesium hydroxide, 40-50 parts of silica powder, 60-70 parts of quartz sand, 10-20 parts of diatomite, 10-20 parts of clay, 10-15 parts of talcum powder, and 2-3 parts of glass fiber; adding the high-strength toughening glue and water for mixing, and gradually increasing the temperature to repeatedly roll and brake after uniformly mixing to obtain the A2-level inorganic mineral plate. The high-strength toughening glue is self-made, so that the sticking of the glue is excellent; the plate is prepared from inorganic minerals, is non-toxic and environment-friendly, and is wide in raw material source, the safety of the plate is improved, and the production cost is reduced; through the repeated braking and rolling, air in the plate is easily discharged from the plate, the rolled plate is compact, the production process is simple, and the production is easy.

Owner:王卫荣

Ultrafiltration/nanofiltration double-membrane high-efficiency pumpkin oligosaccharide purifying method

InactiveCN106799167AEasy to separateImprove production efficiencyMembranesUltrafiltrationInorganic saltsUltrafiltration

The invention discloses an ultrafiltration / nanofiltration double-membrane high-efficiency pumpkin oligosaccharide purifying method. According to the method, an ultrafiltration technology and a nanofiltration technology are applied to a pumpkin oligosaccharide production technology, so that the purpose of purifying pumpkin oligosaccharide in high efficiency is achieved. Macromolecules of protein, polysaccharide and the like are intercepted by an ultrafiltration membrane, and a nanofiltration membrane penetrates through micromolecules of inorganic salt, monosaccharide and the like to achieve a concentrating effect. The method disclosed by the invention achieves separation, refining and concentration of the pumpkin oligosaccharide through the utlrafiltration technology and the nanofiltration technology, has a compact production technology, is convenient to operate and has moderate processing conditions, high preparing efficiency, low energy consumption and a good oligosaccharide separation effect. An ultrafiltration and nanofiltration double-membrane technology is an ideal pumpkin oligosaccharide purifying method, can remove macromolecular impurities and micromolecular impurities in high efficiency and improves concentration and quality of a pumpkin oligosaccharide product.

Owner:CHINA AGRI UNIV

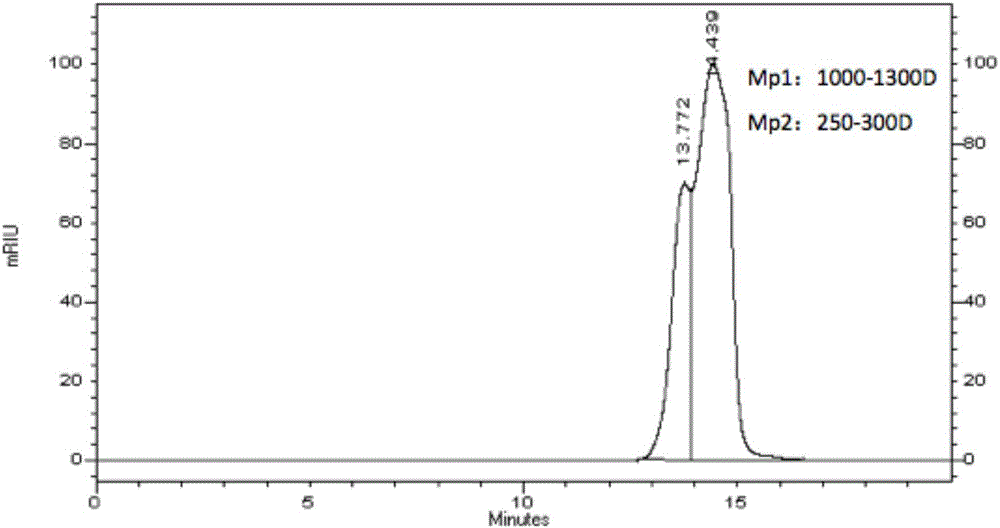

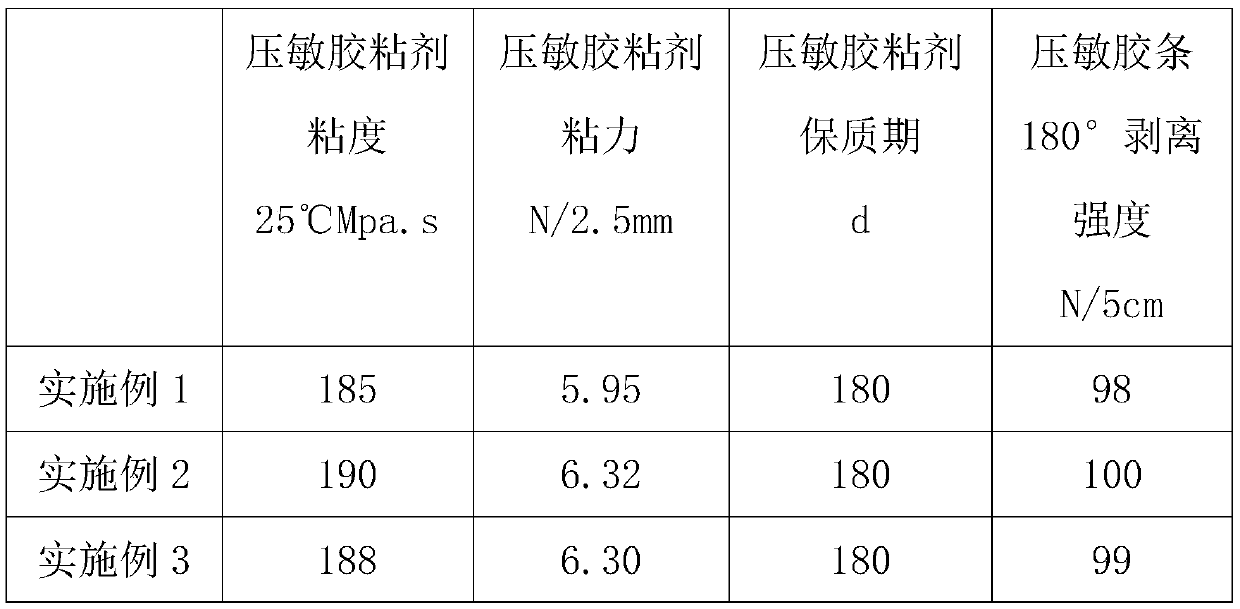

Manufacturing method of environment-friendly pressure-sensitive adhesive material

InactiveCN110551460AImprove securityWill not polluteNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkResource utilization

The invention discloses a manufacturing method of an environment-friendly pressure-sensitive adhesive material, and particularly relates to the technical field of adhesive material preparation. The environment-friendly pressure-sensitive adhesive material comprises a pressure-sensitive adhesive layer, the pressure-sensitive adhesive layer is composed of a base material, a pressure-sensitive adhesive and release paper, the pressure-sensitive adhesive is arranged on one side of the base material, and the release paper is arranged on the side, away from the base material, of the pressure-sensitive adhesive. By using poly(butylene succinate), paraffin, a tackifying emulsion, synthesized plant ester, a PVM / MA decadiene cross-linked polymer, polyoxyethylenealkylphenol ether, alkyl modified organosiloxane and a high-viscosity foam defoamer as production raw materials, a mixed filler and a mixed solvent are added, a little poisonous gas is generated in the pressure-sensitive adhesive production process, the environment is not polluted through purifying treatment in an activated carbon adsorption tower, a pressure-sensitive adhesive cut-off material is put into the filler to continue beingused, thus the resource utilization rate is increased, and the pressure-sensitive adhesive is degradable plastic, safe and environmentally friendly.

Owner:湖南省和祥润新材料有限公司

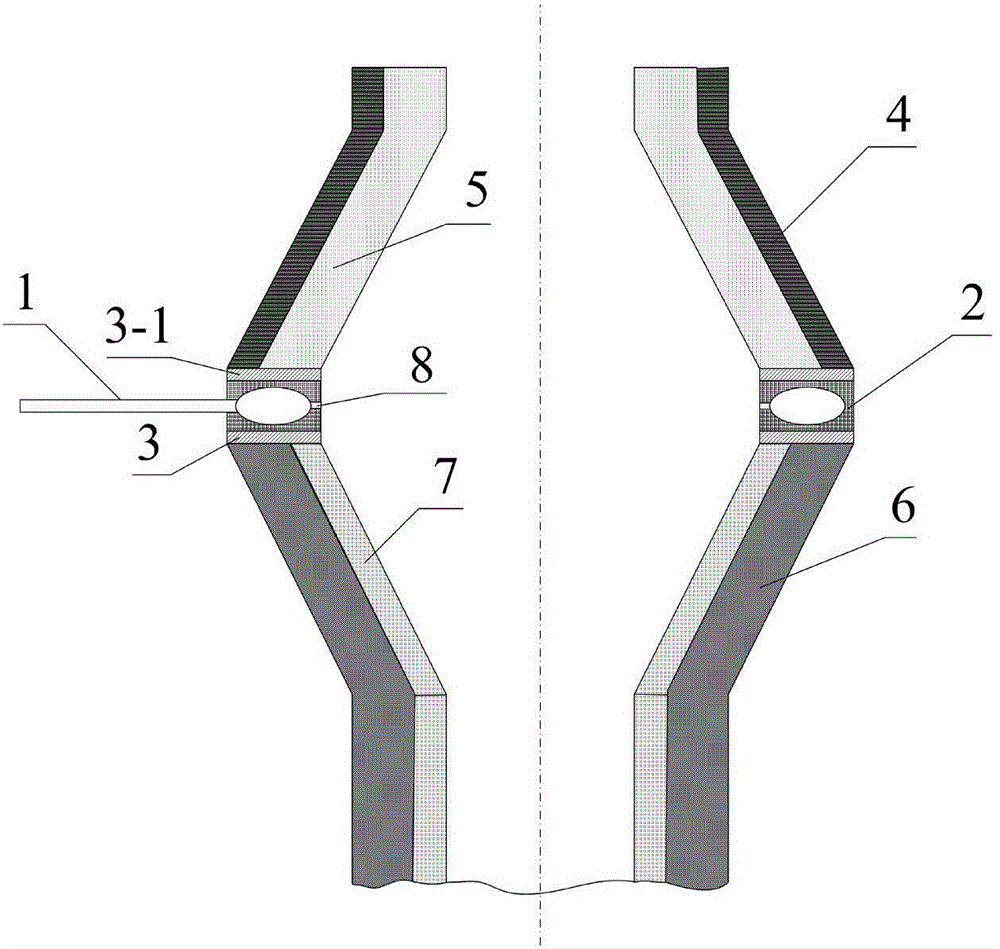

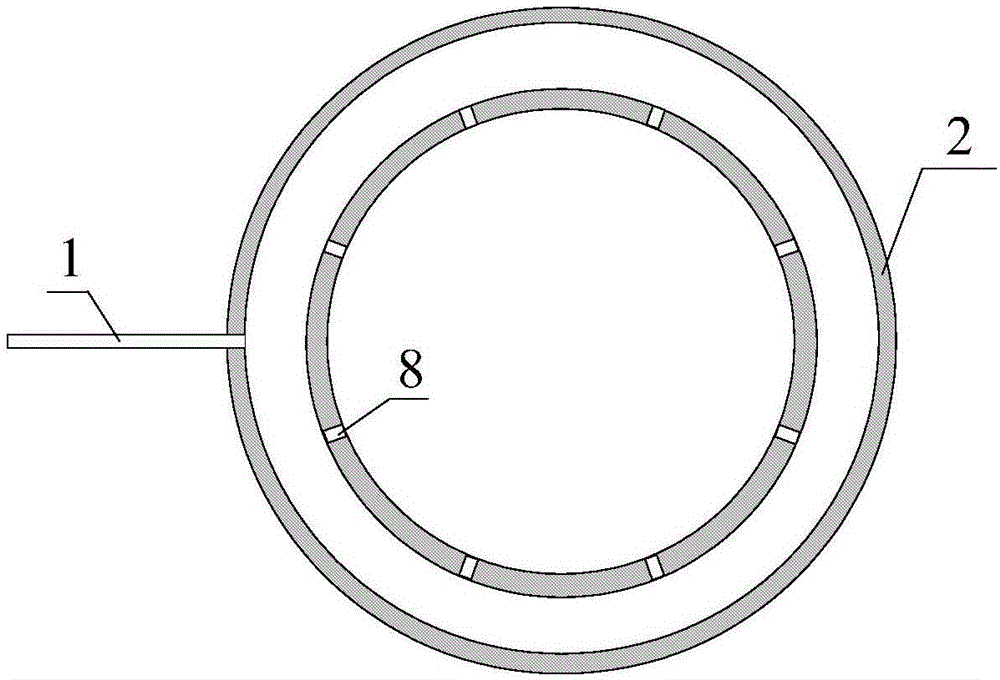

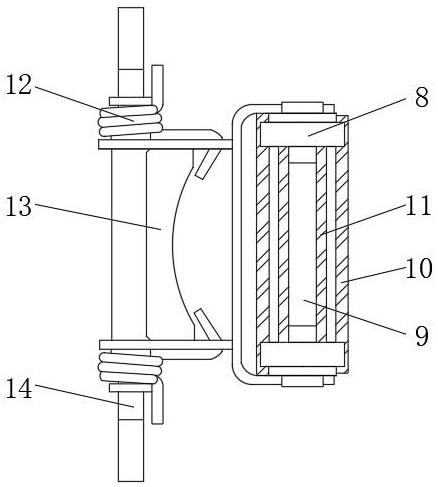

Protecting device for steel ingot pouring and using method of protecting device

The invention relates to a protecting device for steel ingot pouring. The protecting device is used in the pouring process of cast steel ingots in the metallurgical industry. The protecting device comprises an air blowing ring, a protection box, a protection box lining and sealing rings, the air blowing ring is fixed to the upper edge of a middle injection pipe, the protection box is fixed to the upper edge of the air blowing ring, the air blowing ring and the middle injection pipe are sealed through the corresponding sealing ring, and the protection box and the air blowing ring are sealed through the corresponding sealing ring. An inner cavity of the air blowing ring is round or ellipse, the outer side of the air blowing ring is connected with an argon guide-in pipe, the inner side of the air blowing ring is evenly provided with cylindrical air outlet holes, and argon can evenly enter space defined by the protection box and the middle injection pipe through the air blowing ring. The lower portion of the interior of the protection box is in a conic barrel shape, the upper portion of the interior of the protection box is in a straight barrel shape, the argon in the cavity can be upwards sprayed out of an upper port of the protection box at a high speed, and therefore air is effectively prevented from entering the middle injection pipe, secondary oxidation of molten steel is avoided, and the steel ingot quality is improved.

Owner:UNIV OF SCI & TECH BEIJING

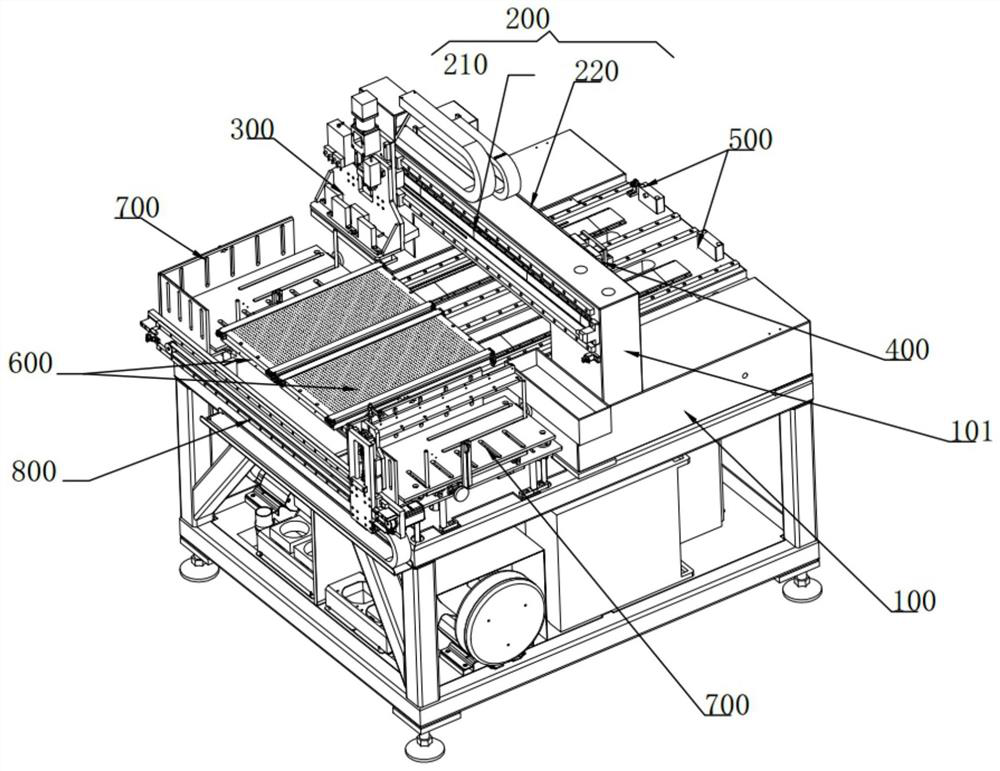

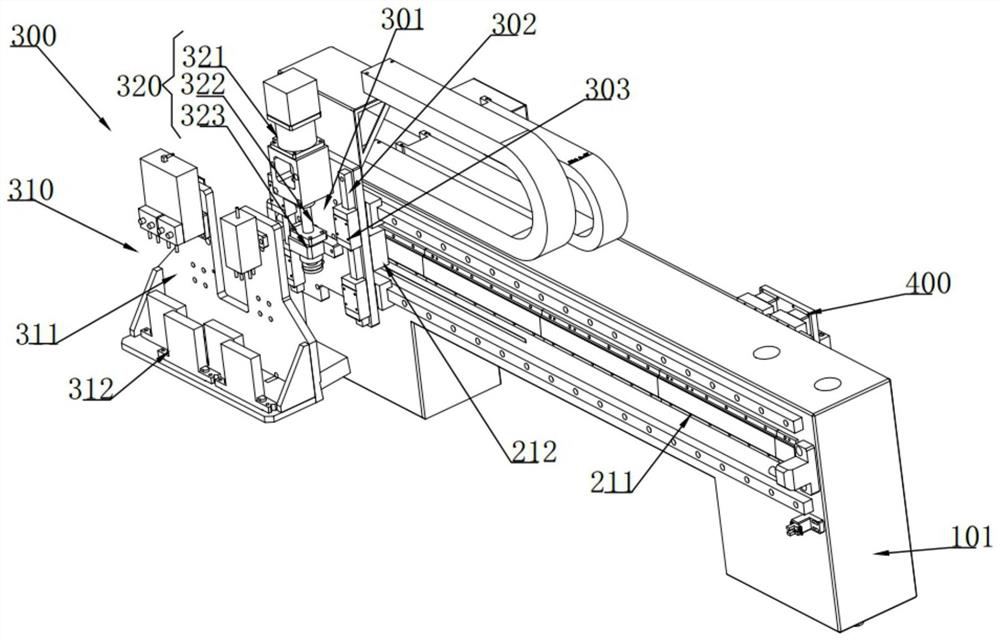

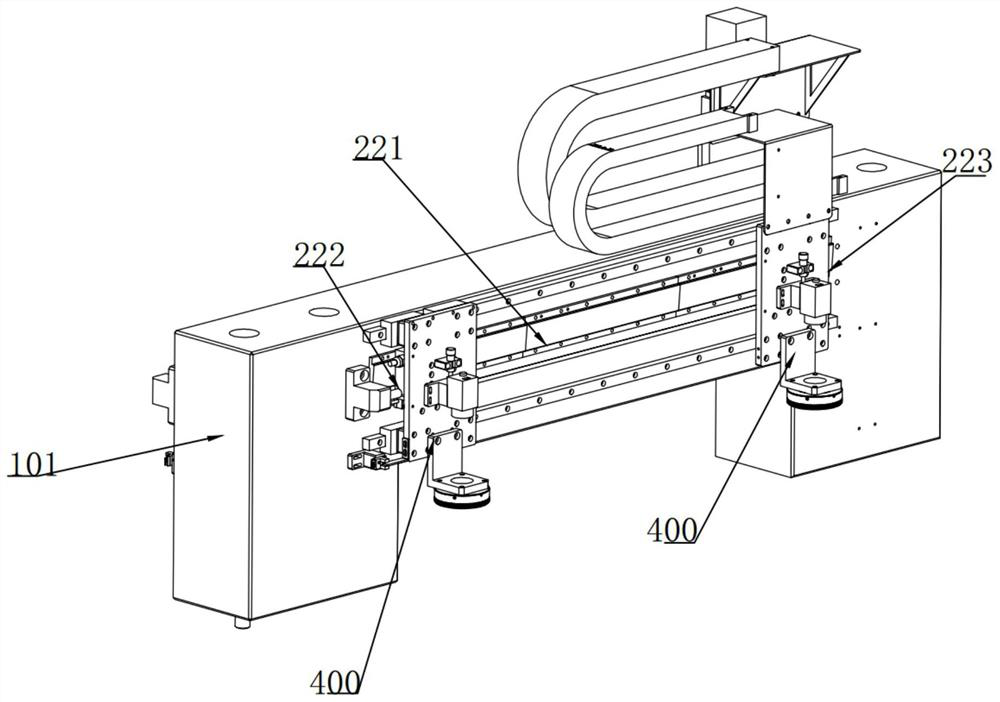

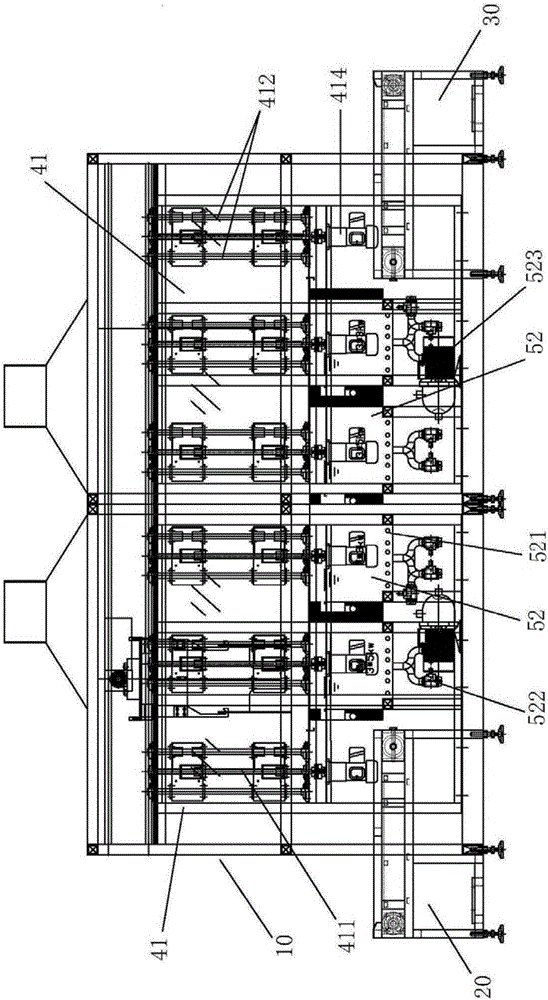

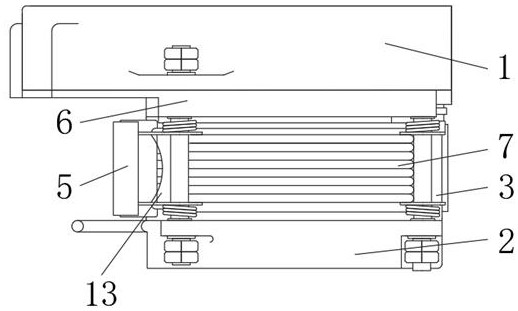

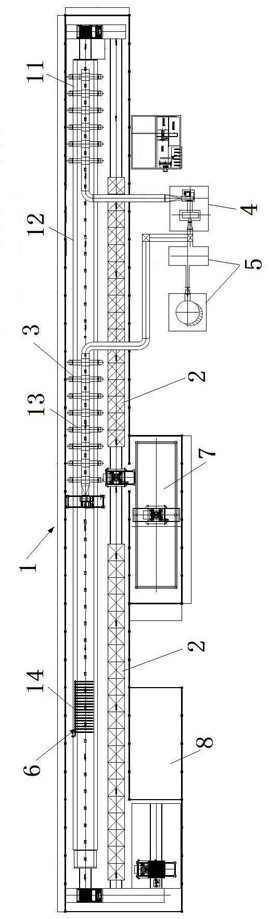

Flat plate solar collector framing and backplate lamination automatic assembling method and system thereof

InactiveCN107553134AReduce the difficulty of productionReasonable designAssembly machinesCollector deviceStacker

The invention discloses a flat plate solar collector framing and backplate lamination automatic assembling method. The method comprises the steps that firstly, workpieces are conveyed to a correctionstation table after a solar collector is preassembled, then the workpieces are conveyed to an automatic framer station, and after short sides of the workpieces are laminated automatically, the workpieces automatically rotate by 90 degrees and then are conveyed to a long-side backplate lamination press; secondly, a robot automatic gluing system performs gluing on gaps of the connecting position ofa frame and a bottom plate; thirdly, a dynamic logistics line is adopted for conveying; fourthly, a full-automatic gluing machine automatically performs gluing on a glass contact surface of the frame;fifthly, glass is positioned at a glass stack and then mounted to the solar collector frame through a glass mounting system; sixthly, depression bars are laminated through a depression bar laminationdevice after being pre-assembled manually; seventhly, the workpieces are packaged through an automatic packaging system; and eighthly, the workpieces are stacked through an automatic stacker crane. The flat plate solar collector framing and backplate lamination automatic assembling method is high in production efficiency, the manufacturing difficulty of the flat plate solar collector frame is lowered, the labor intensity is relieved, and the product quality is guaranteed.

Owner:JINAN XINWUYUE PHOTOVOLTAIC TECH

Graphene disinfectant and preparation method thereof

ActiveCN111470502AImprove the bactericidal effectLong antibacterial timeBiocideGrapheneDaily livingFood grade

The invention discloses a graphene disinfectant and a preparation method thereof. The method comprises the following steps: 1, preparing a water-soluble graphene dispersion; 2, preparing a water-soluble graphene dispersion liquid; 3, adding a dispersing agent into the water-soluble graphene solution obtained in the step 2, and uniformly stirring; 4, continuously adding a surfactant into the solution, continuously stirring until the solution is uniform, and defoaming; and step 5, standing and cooling to room temperature, and filling into a container to obtain the graphene disinfectant. The invention also provides the graphene disinfectant prepared by the method; the main components adopted by the invention comprise water-soluble graphene, a food-grade dispersing agent, a food-grade surfactant and deionized water. The disinfectant has the characteristics of environmental protection, good sterilization effect, long antibacterial time, no pungent smell, low production cost and the like, and can be applied to daily life areas or public places.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Method for distributing materials on surface of microcrystalline glass-ceramic composite brick

The invention relates to the technical field of the production of microcrystalline glass-ceramic composite bricks, and especially relates to a method for distributing materials on the surface of a microcrystalline glass-ceramic composite brick. The method mainly comprises the steps of distributing a template, distributing a silk screen and distributing a belt. The method realizes the stable and unique pattern, good fluency, stable quality and elegant appearance of the materials distributed on the surface of the microcrystalline glass-ceramic composite brick, and also realizes a high artistic decoration effect; and the method has the advantages of simple production process flow, simplicity and low cost of a tool used in the method, and easy operation.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Preparation method of dendrobium nobile stem drink

InactiveCN106923126AGuaranteed freshnessGuaranteed dissolution rateNatural extract food ingredientsFood ingredient as mouthfeel improving agentDissolutionBULK ACTIVE INGREDIENT

The invention provides a preparation method of dendrobium nobile stem drink. The method comprises the following steps: 1) freezing dendrobium nobile stems; 2) performing wall breaking treatment on the frozen dendrobium nobile stems to obtain crushed dendrobium nobile stems; 3) mixing the crushed dendrobium nobile stems with a solvent, and performing wet-type superfine crushing to obtain dendrobium nobile stem liquid; 4) precipitating the dendrobium nobile stem liquid and conducting filtering to obtain dendrobium nobile stem juice; and 5) blending the dendrobium nobile stem juice into dendrobium nobile stem drink. The preparation method provided by the invention has the advantages that the dissolution rate is high, the effective active ingredients are easily absorbed by the human body, the utilization degree is high, the cost is relatively low, etc.

Owner:钟才珍

Method for weakening hydration repulsive force among coal slime particles to promote agglomeration by alternating electric field

InactiveCN102887573AReduce hydrationImprove efficiencyWater/sewage treatment by magnetic/electric fieldsCLARITYCoal

The invention discloses a method for weakening hydration repulsive force among coal slime particles to promote agglomeration by an alternating electric field, and is characterized in that the alternating electric field is applied to coal slime water, so that the hydration repulsive force among the coal slime particles is weakened to promote the agglomeration of the coal slime particles. By the method to treat the coal slime water, the consumption of a drug is effectively decreased, the occupation space of equipment is effectively reduced, the production cost is reduced, the clarity of obtained circulating water is high, the coal slime water is well controlled not to be exhausted outside, the environment-friendly effect is realized, and the loss and waste of coal resources are reduced.

Owner:ANHUI UNIV OF SCI & TECH

High-strength-toughness high-boron stainless steel thin plate and preparation method thereof

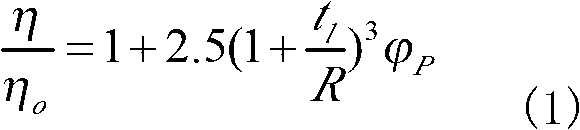

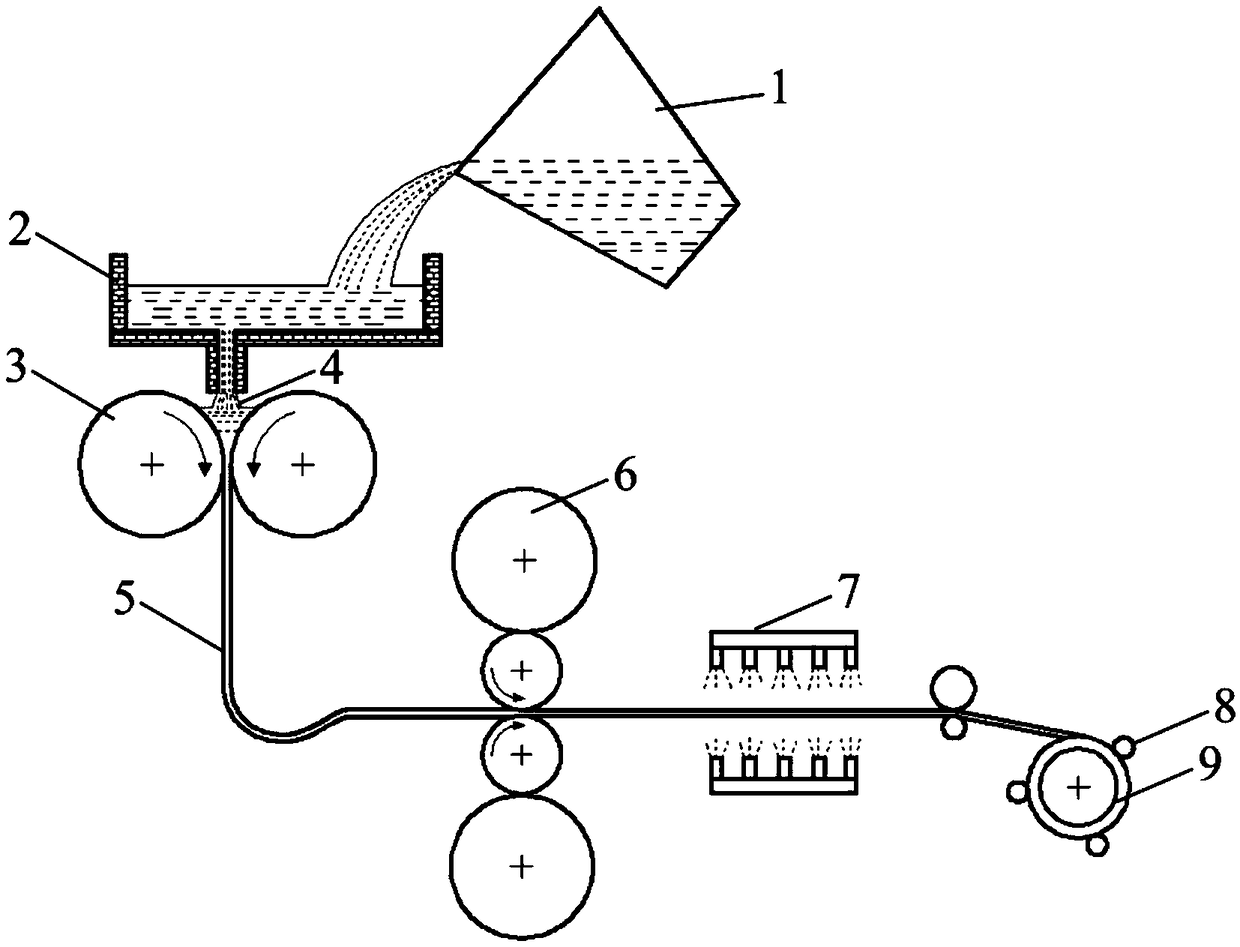

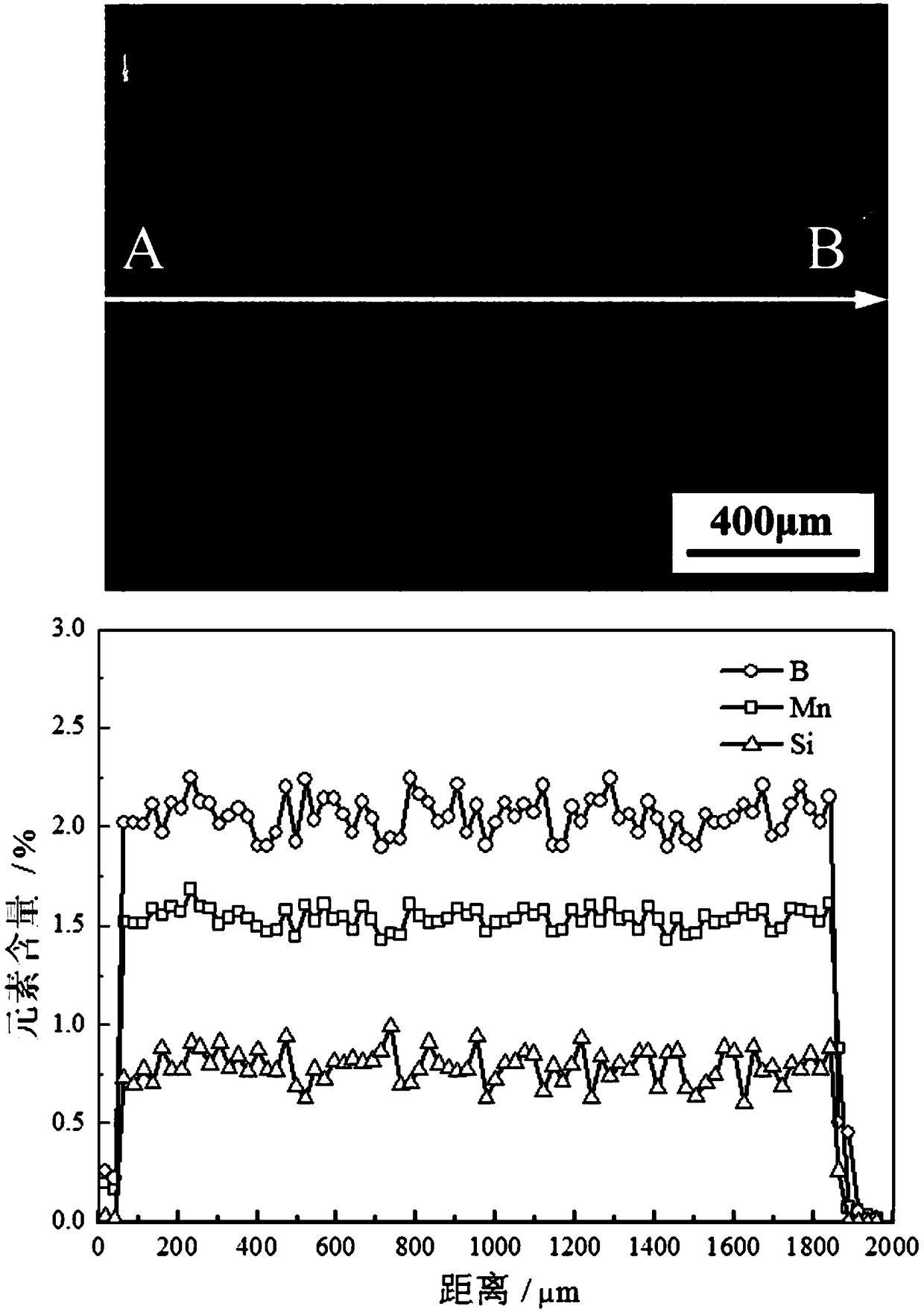

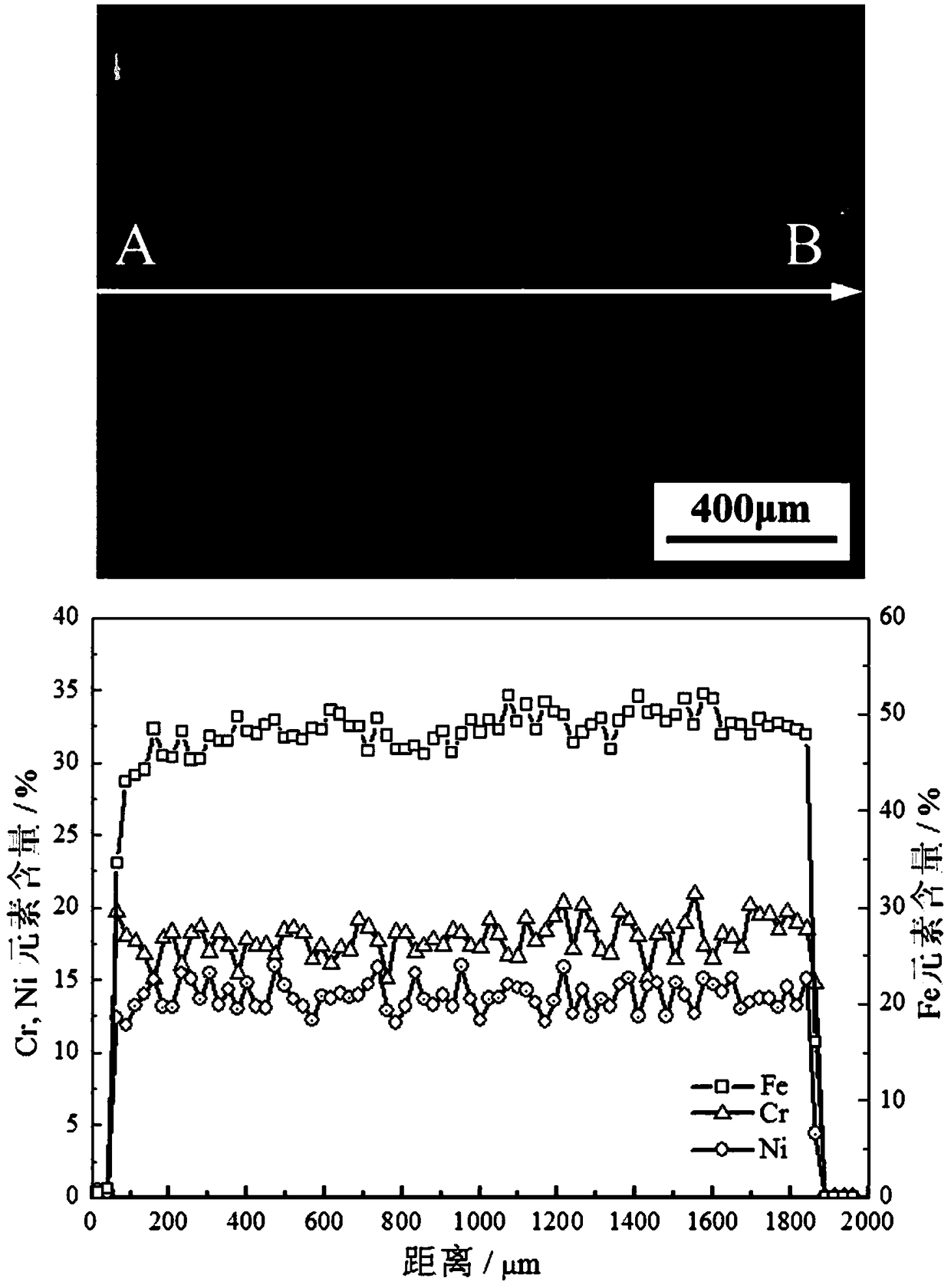

The invention provides a high-strength-toughness high-boron stainless steel thin plate and a preparation method thereof. The stainless steel thin plate comprises the ingredients of, in percentage by mass, 2.0-2.5% of B, less than 0.01% of C, 16.0-18.0% of Cr, 15.5-17.5% of Ni, 1.0-2.0% of Mn, 0.5-1.0% of Si and the balance Fe, wherein Nieq is larger than 1.1 Creq-7.0, the tensile strength is 700-850 MPa, and the room temperature extending rate is 12.5-15.5%. The preparation method comprises the steps that (1), liquid steel smelting is performed; (2), liquid steel enters a tundish to be continuously-cast into thin strips; (3), single pass hot rolling is performed after air cooling is performed to 900-1100 DEG C, and the press down rate is 15-40%; (4), coiling is performed after water cooling is performed to 600-700 DEG C; and (5), annealing treatment is performed under a protective atmosphere condition after uncoiling, and then flattening treatment is performed. By means of the high-strength-toughness high-boron stainless steel thin plate and the preparation method thereof, the alloy element segregation degree is improved, the high-boron stainless steel hot rolled plate with smoothappearance and no edge crack is obtained, the high-strength-toughness high-boron stainless steel thin plate and the preparation method thereof are compact in production procedure and less in fabrication working procedure, and the production cost can be significantly lowered.

Owner:NORTHEASTERN UNIV

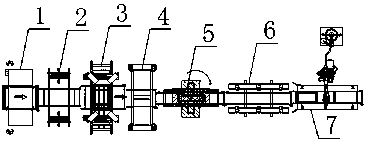

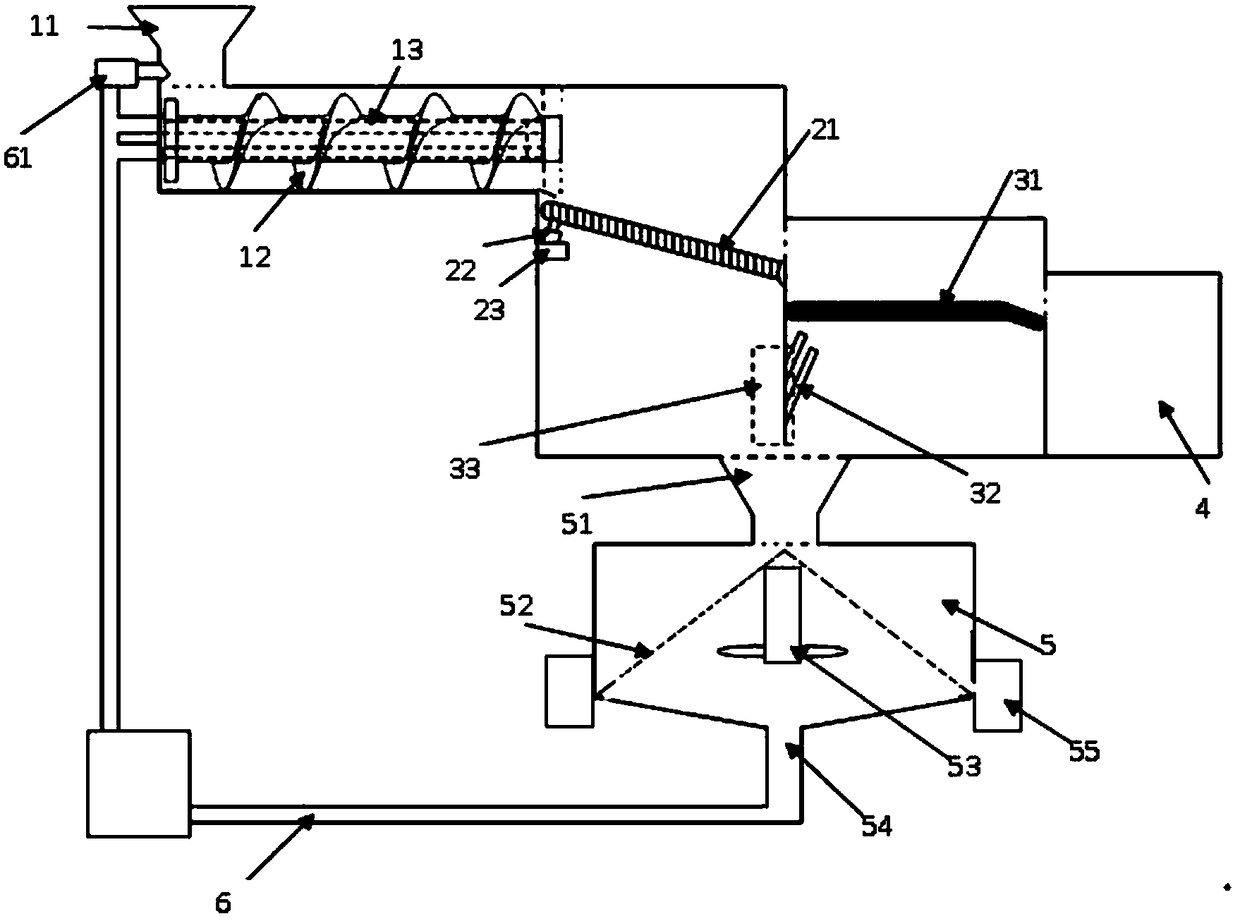

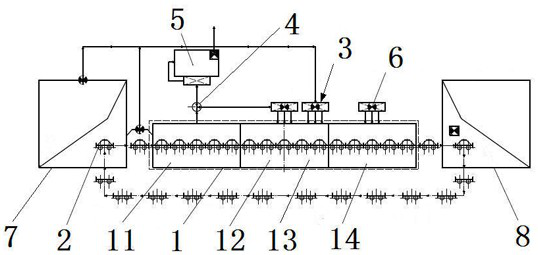

Full-automatic character jet printing machine

PendingCN112976826AThe production process is compactShorten the timeTypewritersEngineeringMechanical engineering

The invention discloses a full-automatic character jet printing machine. The full-automatic character jet printing machine comprises an X-axis driving device, a jet printing device, a CCD detection device, a Y-axis driving device, material loading devices and two material receiving and discharging devices, wherein the jet printing device is arranged on the first X-axis driving device; the CCD detection device can be driven to move along the X-axis direction; the material loading devices are arranged on the Y-axis driving device, and can move in a reciprocating mode in the Y-axis direction; and the two material receiving and discharging devices are located at the end of the Y-axis driving device, located beside the two sides of the Y-axis driving device respectively and used for accommodating materials to be subjected to jet printing or materials subjected to jet printing. According to the full-automatic character jet printing machine, the plurality of material loading devices and the CCD detection device are arranged, so that the production process is more compact, the time is greatly saved in a position information acquisition link, and meanwhile, the time of a jet printing process is greatly reduced.

Owner:深圳市鼎晖伟业自动化设备有限公司

A rare earth ore crushing and screening device

ActiveCN107583741BAvoid cloggingFully dry operationDrying gas arrangementsGrain treatmentsWater resourcesRare earth

Owner:北京安康科创节能环保科技有限公司 +1

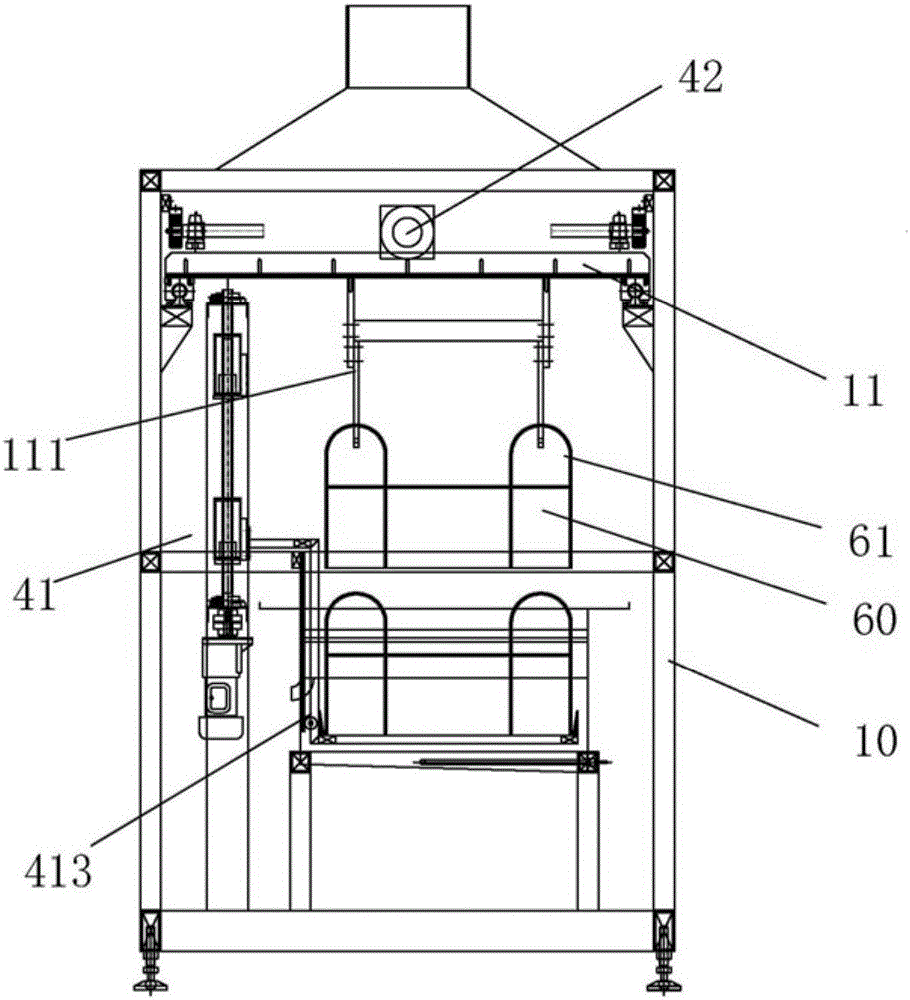

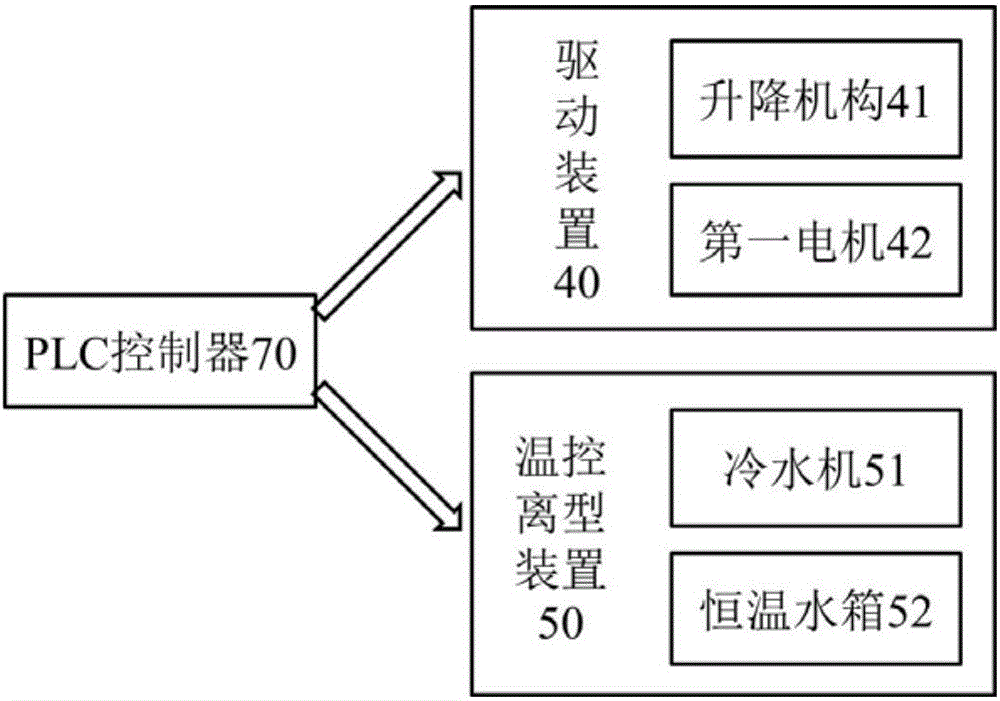

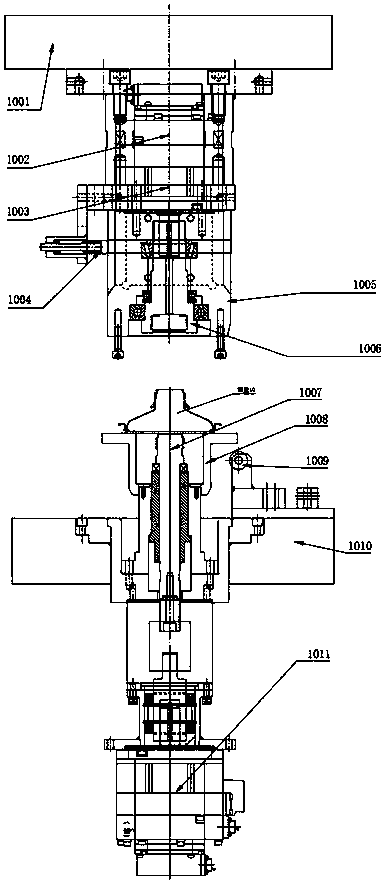

Automatic release appliance for optical lens

ActiveCN106477856AAccurate temperatureReduce lossGlass pressing apparatusTemperature controlControlled release

The application aims at providing an automatic release appliance for an optical lens. The automatic release appliance for the optical lens comprises a frame, a charging platform and a discharging platform, wherein the charging platform and the discharging platform are arranged on two sides of the frame respectively; the automatic release appliance for the optical lens also comprises a temperature-controlled release device; the temperature-controlled release device comprises a water cooler and a constant-temperature water tank which is arranged at the bottom of the frame; the water cooler is mounted outside the frame; a circulating water pump used for circulating cold and hot water is arranged between the water cooler and the constant-temperature water tank. Compared with the prior art, the automatic release appliance for the optical lens has the advantages that the temperatures of a heat source and cold water can be controlled precisely and in time, the release rate of the optical lens is high, the loss of a mold is low, a water source is wasted little, the structure is compact, the floor area is less, and the like.

Owner:上海银杉工业品销售有限公司

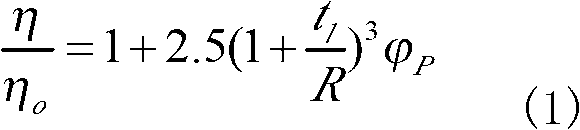

Method for preparing high-strength polyacrylonitrile-based precursor for carbon fiber

ActiveCN101724922BEffective filteringGuaranteed neatnessArtificial filament washing/dryingArtificial filament heat treatmentCarbon fibersAcrylonitrile

The invention discloses a method for preparing a high-strength polyacrylonitrile-based carbon fiber precursor. The method comprises the steps of: using azodiisobutyronitrile to trigger acrylonitrile and a comonomer to perform homogeneous solution polymerization in dimethyl sulfoxide to obtain spinning solution, and controlling the temperature of the spinning solution to be between 40 and 70 DEG C and the solid content to be between 18 and 24 percent; performing monomer removal on the spinning solution under the pressure of between -60 and -78KPa, and performing deaeration treatment under the pressure of between -78 and -97KPa; then extruding the spinning solution into a spin duct in a coagulation bath with a temperature of between 35 and 65 DEG C and a dimethyl sulfoxide concentration of between 50 and 70 percent for molding through a spinneret, and obtaining PAN-based as-spun fiber through 45 to 75 percent of minus stretch in the coagulation bath; then molding and stretching through a secondary coagulation bath, a third coagulation bath, a fourth coagulation bath and a fifth coagulation bath; and obtaining the high-strength polyacrylonitrile-based carbon fiber precursor through solvent removal by water scrubbing, hot water stretch, oiling, drying and densification, steam stretch, and hot air setting. The tensile strength of the high-strength polyacrylonitrile-based carbon fiber precursor reaches 10.2cN / dtex.

Owner:ZHONGFU SHENYING CARBON FIBER

Molding process of beer can screw cap

ActiveCN110576116AEmission reductionProduction process is environmentally friendlyShaping toolsClosure capsPunchingEngineering

The invention aims to provide a molding process of a beer can screw cap. In the process, a laminated film is used as a raw material, and according to the characteristics of the material, through a lotof experiments, a production process for preparing the beer can screw cap from the laminated film as the raw material can be obtained. The molding process adopting the technical scheme comprises thefollowing steps of 1, stretching a sheared blank into a beer can screw cap blank; 2, stretching the beer can screw cap blank for multiple times to form a semi-finished product; 3, trimming the semi-finished product and punching; 4, preliminarily curling the edge contour of the bottom of the semi-finished product and the circumferential edge of a punched hole; and 5, curling the edge contour of thebottom of the semi-finished product and the circumferential edge of the punched hole; and 6, flattening the curled parts, and tapping the surfaces, thereby obtaining the beer can screw cap.

Owner:广东韩江轻工机械有限公司

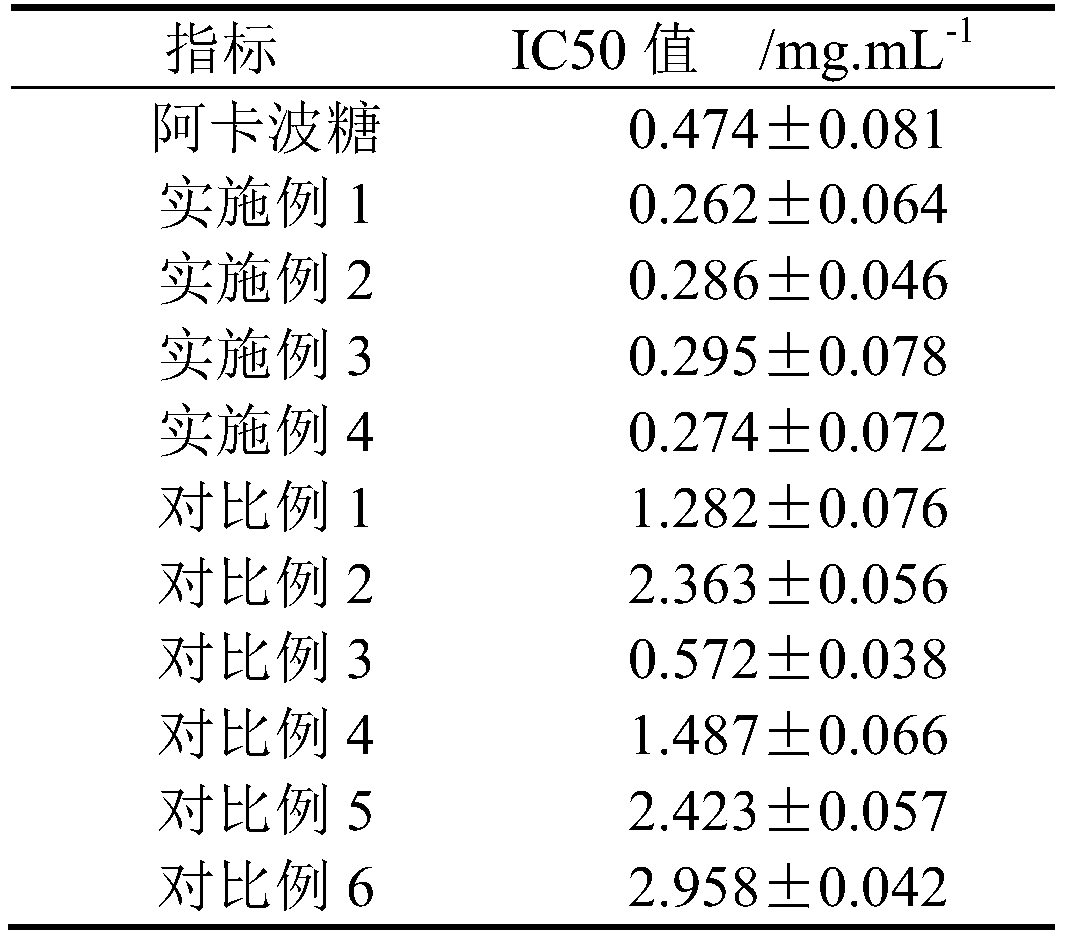

Soybean peptide with alpha-glucosidase activity inhibition function, preparation method and application

PendingCN111088310AEfficiently obtainedProduction process scienceChemical industryPeptide preparation methodsSeparation technologyAlkaline proteinase

The invention discloses a soybean peptide with an alpha-glucosidase activity inhibition function, a preparation method and application. Soybean protein isolate powder is taken as a raw material, and the soybean peptide with the strong alpha-glucosidase activity inhibition function is prepared through alkaline protease enzymolysis, isoelectric point enzyme deactivation centrifugal separation, pepsin enzymolysis, ultrafiltration, nanofiltration and drying. The technology aims at preparing the soybean peptide with the strong alpha-glucosidase activity inhibition function, the target peptide is efficiently obtained by fully utilizing an enzyme combination technology and integrating separation technologies such as isoelectric point centrifugal separation, ultrafiltration and nanofiltration, theproduction technology process is scientific, compact and energy-saving, the preparation method is easy to operate, and the soybean peptide with the alpha-glucosidase activity inhibition function issuitable for industrial production.

Owner:广州合诚实业有限公司

Double-roller rope pressing mechanism for winch rope arrangement

InactiveCN112062020AReduce frictional resistanceNot easy to wearCleaning using toolsWinding mechanismsWire ropeIndustrial engineering

The invention relates to the technical field of hoisting and lifting machines, and discloses a double-roller rope pressing mechanism for winch rope arrangement. The problems that rope disorder, rope pressing and rope biting are easily caused for winch rope arrangement in the current market, a steel wire rope is large in friction resistance, is easily abraded by rollers, is short in service life, complex in structure, not convenient to disassemble, not convenient to maintain, complex in process, unfavorable to producing and purchasing, high in cost and not convenient to popularize, dirt removalcannot be achieved, steel wire rope corrosion is serious, the winding space is influenced, and winding is not convenient are solved. The double-roller rope pressing mechanism comprises a base, a front support is installed at the top of the base, and a right steel rope pressing device is installed on one side of the front support. The double-roller rope pressing mechanism has the advantages of being reasonable in design, capable of achieving orderly rope arrangement and preventing rope loosening at the same time, simple and compact in equipment structure, convenient to disassemble and assemble, convenient to maintain, small in steel wire rope resistance, not prone to abrasion, long in service life, low in production cost, convenient to apply and popularize, capable of removing dirt on a steel wire rope and reducing surface corrosion of the steel wire rope and stable in steel wire rope winding space, and convenient to wind.

Owner:江西中船航海仪器有限公司

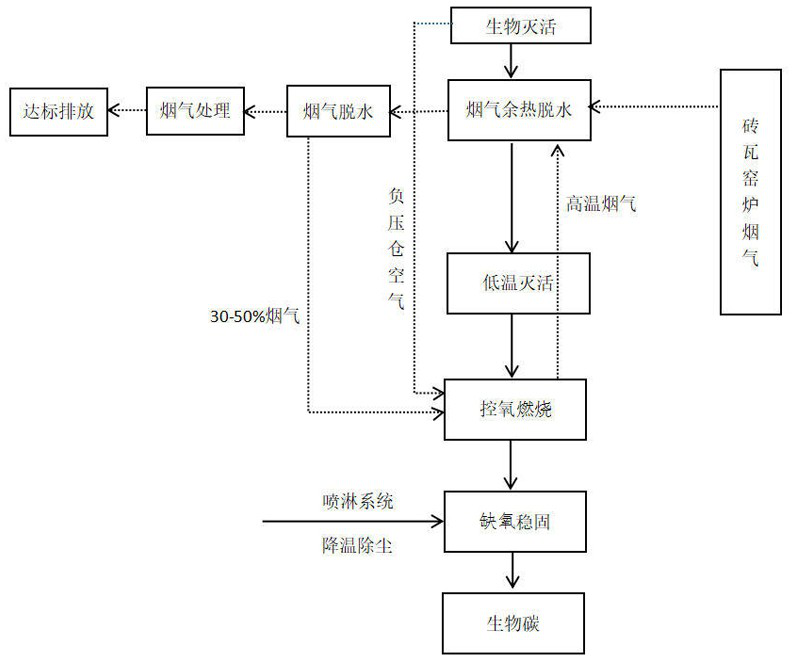

Sludge carbonization method

ActiveCN112520968AEasy to operateThe production process is compactSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCombustionSludge

The invention discloses a sludge carbonization method. The method comprises the following steps: 1) first dehydration: reducing the water content of sludge by 10-20% by using hot air; 2) low-temperature inactivation: carrying out second dehydration inactivation on the sludge subjected to the first dehydration at the temperature of 150-300 DEG C, so that the water content of the sludge subjected tothe second dehydration is less than 10%; 3) oxygen-controlled combustion: under an oxygen-controlled condition, combusting the sludge subjected to second dehydration at a temperature lower than 600 DEG C; and 4) oxygen deficit stabilization: sending the product obtained by combustion into an oxygen deficit link for carbonization stabilization, cooling to a temperature lower than 40 DEG C, and discharging to obtain the final product. The sludge carbonization method provided by the invention has the advantages of small investment, realization of sludge burning by sludge, reservation of part ofthe heat value, stabilization of sludge carbonization, increase of the added value, change of wastes into valuables, thorough treatment of sludge, no pollution, carrying of sludge by using a carrier loader, and improvement of the work efficiency.

Owner:湖南爵铭环保有限公司

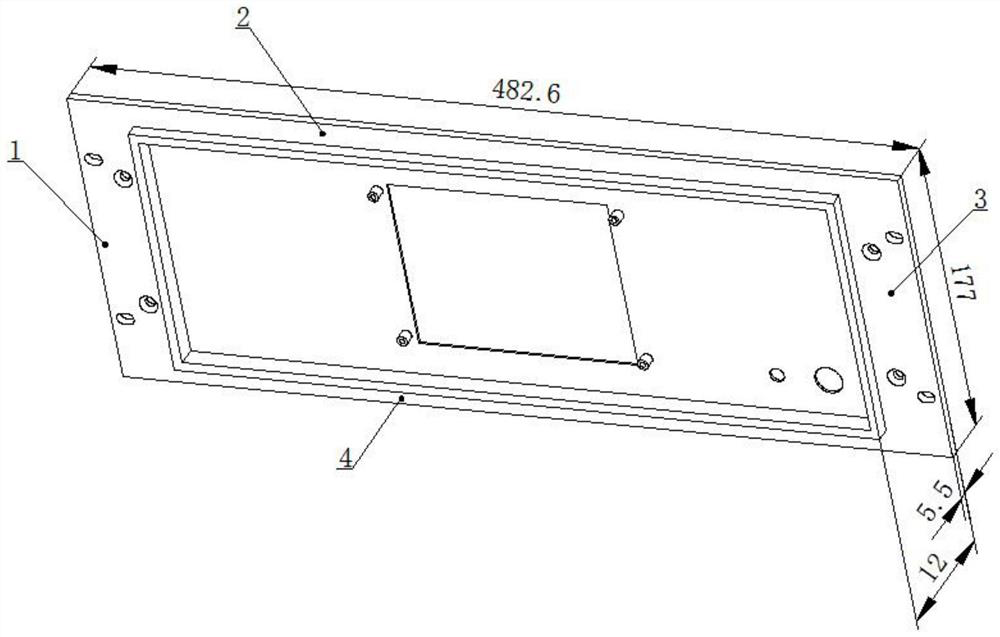

Case panel machining method

ActiveCN112975013ASolve the deformationDimensional accuracy is easy to guaranteeNumerical controlElectric machine

A case panel machining method mainly comprises the technological steps of wire-electrode cutting electric machining blanking and numerical control milling. A universal multi-process and multi-work-type machining technology is changed, a wire-electrode cutting electric machining mode is adopted for blanking, and a plane, a cavity and a rectangular annular flange are milled in a numerical control mode in the length direction for machining, so that the deformation problem in the machining process can be effectively solved, the dimensional precision is easy to guarantee, the quality is stable and consistent, the surface quality is good, the planeness is smaller than 0.1 mm, a heat treatment destressing procedure is not needed, the production process is compact, concentrated and short, the machining cost is low, the production period is short, and safety and reliability are achieved.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

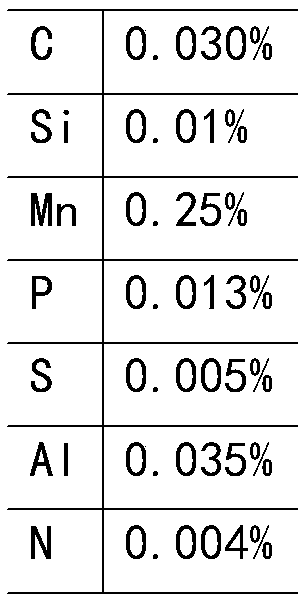

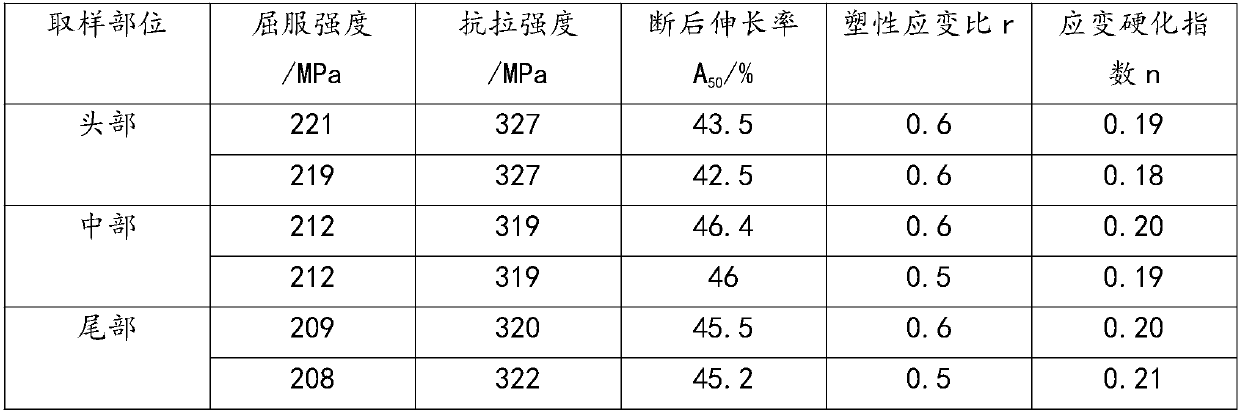

Production process for hot-rolled acid-free acid pickling low-carbon steel plate

The invention relates to a production process for a hot-rolled acid-free acid pickling low-carbon steel plate. The production process for the hot-rolled acid-free acid pickling low-carbon steel platecomprises a low-carbon steel plate production process and an acid pickling process, and is characterized in that the acid picking process comprises the following steps of uncoiling a flattened steel plate, mechanically grinding and acid picking, acid picking mortar, and rolling; and the mortar acid pickling comprises the following steps of mixing water and gravel to obtain mortar, and casting themortar to the surface of the low-carbon steel plate through an impeller head, wherein an included angle between the casting direction of the mortar and the low-carbon steel plate is 0 to 45 degrees. Apure mechanical physical manner instead of a chemical manner is adopted for cleaning, so that no pollution emission is realized, and the operation process is harmless to the environment.

Owner:SICHUAN TIANHONG STAINLESS STEEL

Boron-containing stainless steel thick plate with excellent plasticity and toughness and preparation method thereof

The invention relates to a boron-containing stainless steel thick plate with excellent plasticity and toughness and a preparation method thereof. The boron-containing stainless steel thick plate comprises the following components in percentage by mass: 18.0-20.0% of Cr, 12.0-15.0% of Ni, 0.2-2.0% of Mn, 0.5-1.5% of B, less than 0.5% of Si, less than 0.02% of C and the balance of Fe. The thicknessis 20-80mm, the tensile strength is more than or equal to 550MPa, the room-temperature ductility is more than or equal to 18%, and the room-temperature impact toughness is more than or equal to 200KJ / m <2>; the method comprises the following steps: (1) smelting molten steel; (2) roughly rolling the casting blank after soaking and heat preservation; (3) forming a V-shaped groove in the rough rolling blank to prepare a single body; stacking the plurality of single bodies, and carrying out vacuum welding; (4) welding plain carbon steel plates at the front and rear ends of the composite blank; (5)heating to 1100-1150 DEG C, carrying out heat preservation, and carrying out multi-pass hot rolling; and (6) cutting the end part of the plain carbon steel, carrying out solution treatment, and carrying out air cooling to room temperature. By means of the method, homogenization and fine control over boride in the finished plate are achieved, and the plate shape and the edge cracking degree of theboron-containing stainless steel thick plate are improved; the process production flow is compact, and mechanization and automation are convenient to achieve.

Owner:NORTHEASTERN UNIV

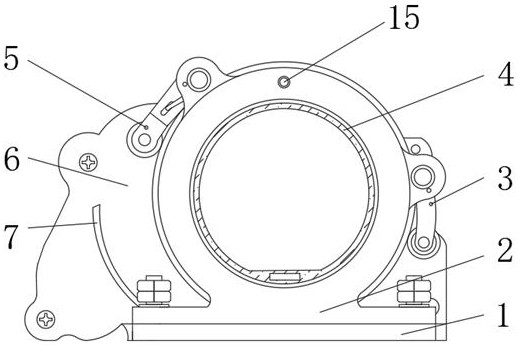

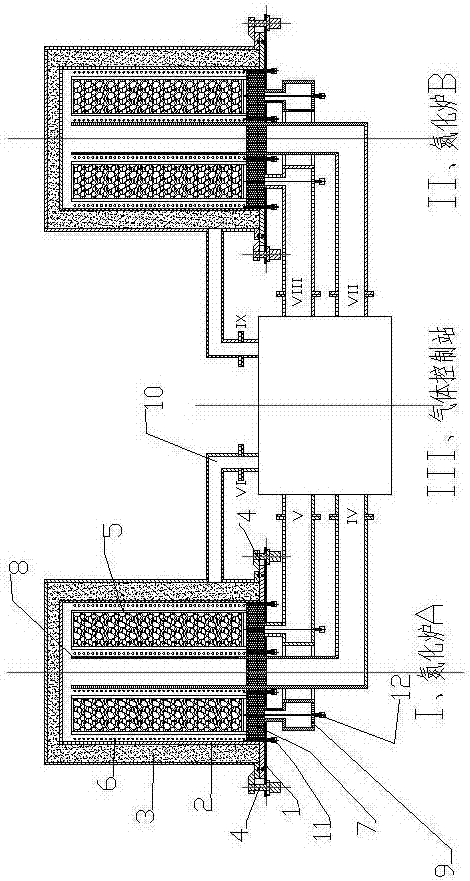

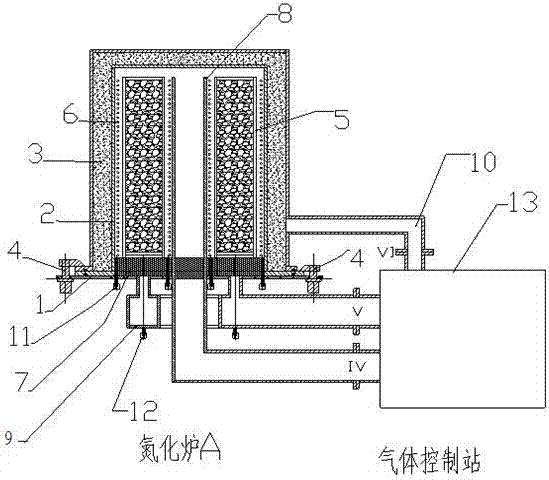

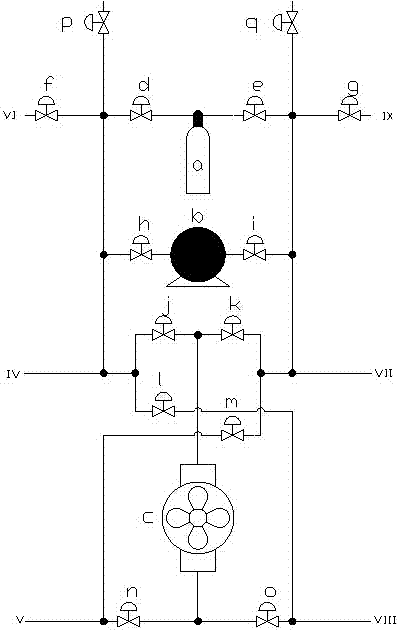

A nitriding furnace system

ActiveCN104294207BImprove uniformityIncrease the amount of participationSolid state diffusion coatingWaste heat treatmentThermal insulationIron nitride

The invention relates to a nitriding furnace system, which comprises a first nitriding furnace and a second nitriding furnace, and a gas control station is connected between the first nitriding furnace and the second nitriding furnace. The first nitriding furnace includes a base, a material basket, an inner tank, a central air duct, and a thermal insulation shell, the material basket is hoisted on the base, and the inner tank and the thermal insulation shell are fixedly connected to the base through a locking device Above, the central air duct is arranged in the middle of the first nitriding furnace. The beneficial effects of the present invention are as follows: 1) The continuous production of iron nitride alloys is realized by switching between two nitriding furnaces, and the efficiency is greatly improved; 2) The heat exchange system is adopted to make full use of the waste heat of materials, and to speed up the cooling speed, which is both environmentally friendly and Economical; 3) The method of heating the material on both sides increases the amount of material added in a single batch, improving the efficiency and the stability of the nitrogen content of the product; 4) The overall structure design is ingenious, and the entire technical solution occupies a small area and is low in cost , which is convenient for large-scale promotion and use.

Owner:江苏江南铁合金有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com