A nitriding furnace system

A technology of nitriding furnace and nitrogen gas, which is applied in the field of nitriding furnace system and ferroalloy nitriding furnace, can solve the problems of inability to realize continuous production, unstable nitrogen content of products, long production cycle and low efficiency, and facilitate large-scale promotion The use, the overall structure design is ingenious, and the production process is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

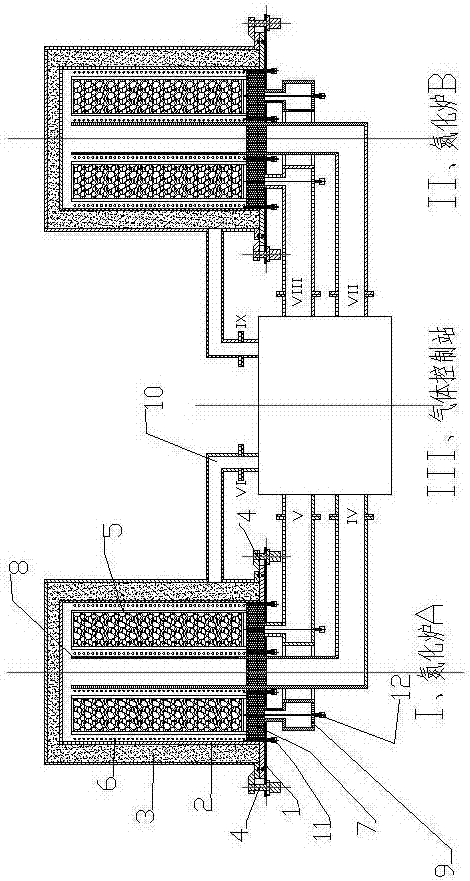

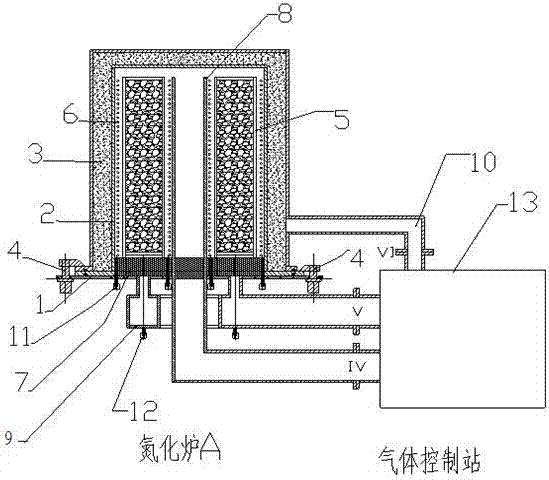

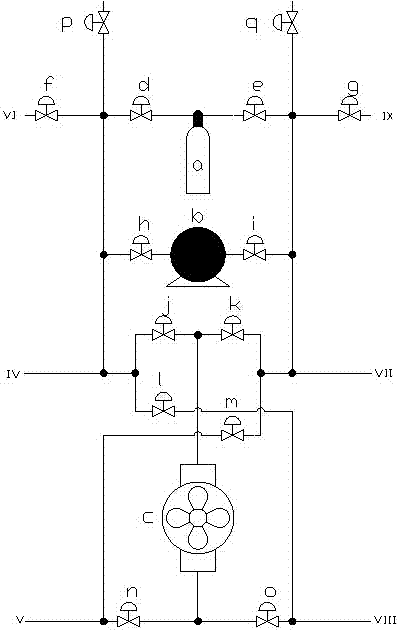

[0028] Embodiment 1: see figure 1 , figure 2 , a nitriding furnace system, the nitriding furnace system includes two nitriding furnaces, i.e. nitriding furnace A and nitriding furnace B, the nitriding furnace A and nitriding furnace B are connected to a gas control station 13 , the structure of nitriding furnace A and nitriding furnace B is exactly the same in this technical scheme, and in specific application, the structure of the first nitriding furnace and the second nitriding furnace are not necessarily identical; The nitriding furnace includes nitriding furnace Furnace base 1, material basket 5, liner 2, central air duct 8, heat preservation shell 3, the material basket 5 is hoisted on the base 1, the liner 2 and heat preservation shell 3 are fixedly connected by locking device 4 On the base 1, the central air duct 8 is arranged in the middle of the nitriding furnace A; wherein the material frame 5 is provided with manganese nitride, the heat preservation shell 3 is arr...

Embodiment 2

[0029] Example 2: see figure 1 , figure 2 , Figure 5 , as an improvement of the present invention, a heat-insulating breathable brick 7 is arranged between the base 1 and the material frame 5, and the thickness of the heat-insulated breathable brick 7 is 150-300mm, which can be selected according to the actual situation, preferably 180-260mm, through the 90-degree rotating hydraulic cylinder locking device 4, the inner tank 2 and the outer shell 13 are fixed on the nitriding furnace base 1, and the heat in the material frame 5 passes through the breathable heat insulating brick 7 and enters the return air ring pipe 9 , and then reach the gas control station for heat conversion and transfer. On the one hand, the breathable heat insulation brick 7 blocks heat conduction during the nitriding reaction, and on the other hand, it can exchange the heat inside the nitriding furnace with the cold material when cooling after the nitriding reaction. This system makes full use of the ...

Embodiment 3

[0030] Embodiment 3: see figure 1 , figure 2 , as an improvement of the present invention, a nitrogen pressure balance pipe 10 is also connected to the insulated casing of the nitriding furnace, one end of the nitrogen pressure balance pipe is connected to the nitriding furnace, and the other end is connected to the gas control station 13 through a balance pipe interface. Connection, the nitrogen pressure balance pipe is a metal hose. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com