High-strength-toughness high-boron stainless steel thin plate and preparation method thereof

A high-strength, toughness, stainless steel technology, applied in the field of metallurgical materials, can solve the problems of low production efficiency, long and complex process flow, complex chemical composition, etc., and achieve the effect of fewer manufacturing processes, lower production costs, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

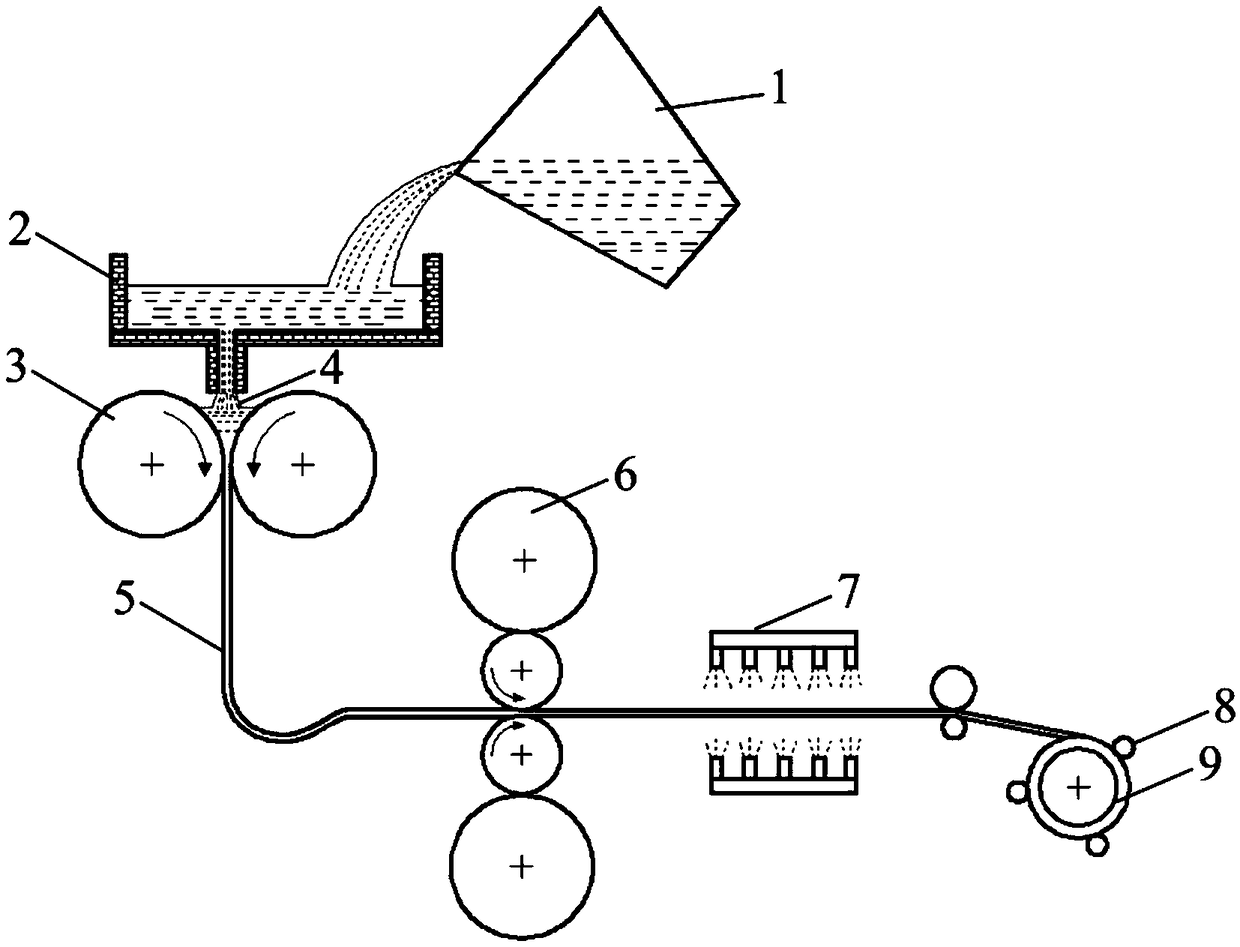

Method used

Image

Examples

Embodiment 1

[0036] The composition of molten steel for smelting is: B 2.5%, C 0.006%, Cr 17.9%, Ni 15.8%, Mn 1.5%, Si 0.8%, the rest is Fe and unavoidable impurities, and the element composition meets Nieq>1.1Creq -7.0, where Nieq=15.8+30×0.006+0.5×1.5=16.73, Creq=17.9+1.5×0.8=19.1;

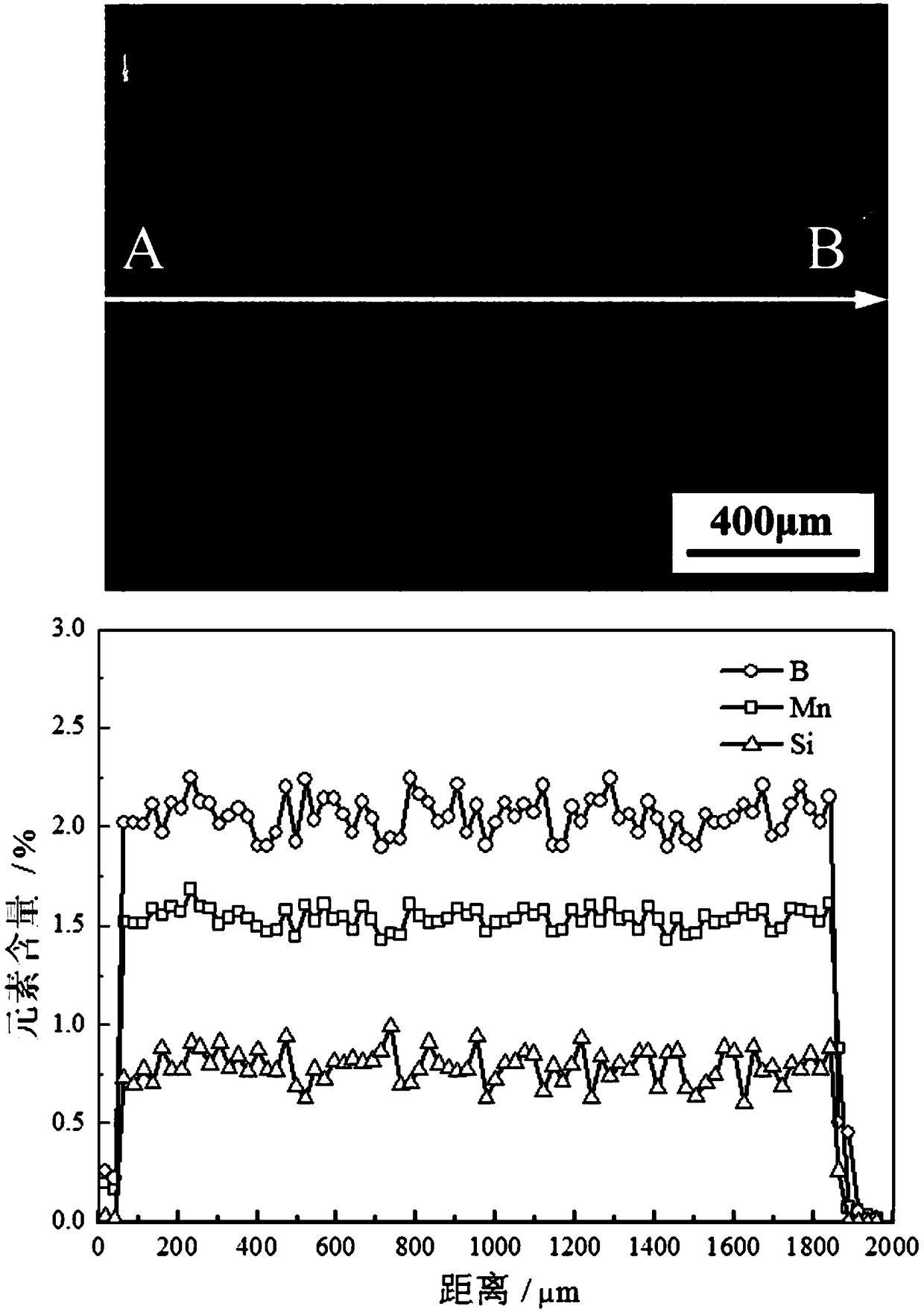

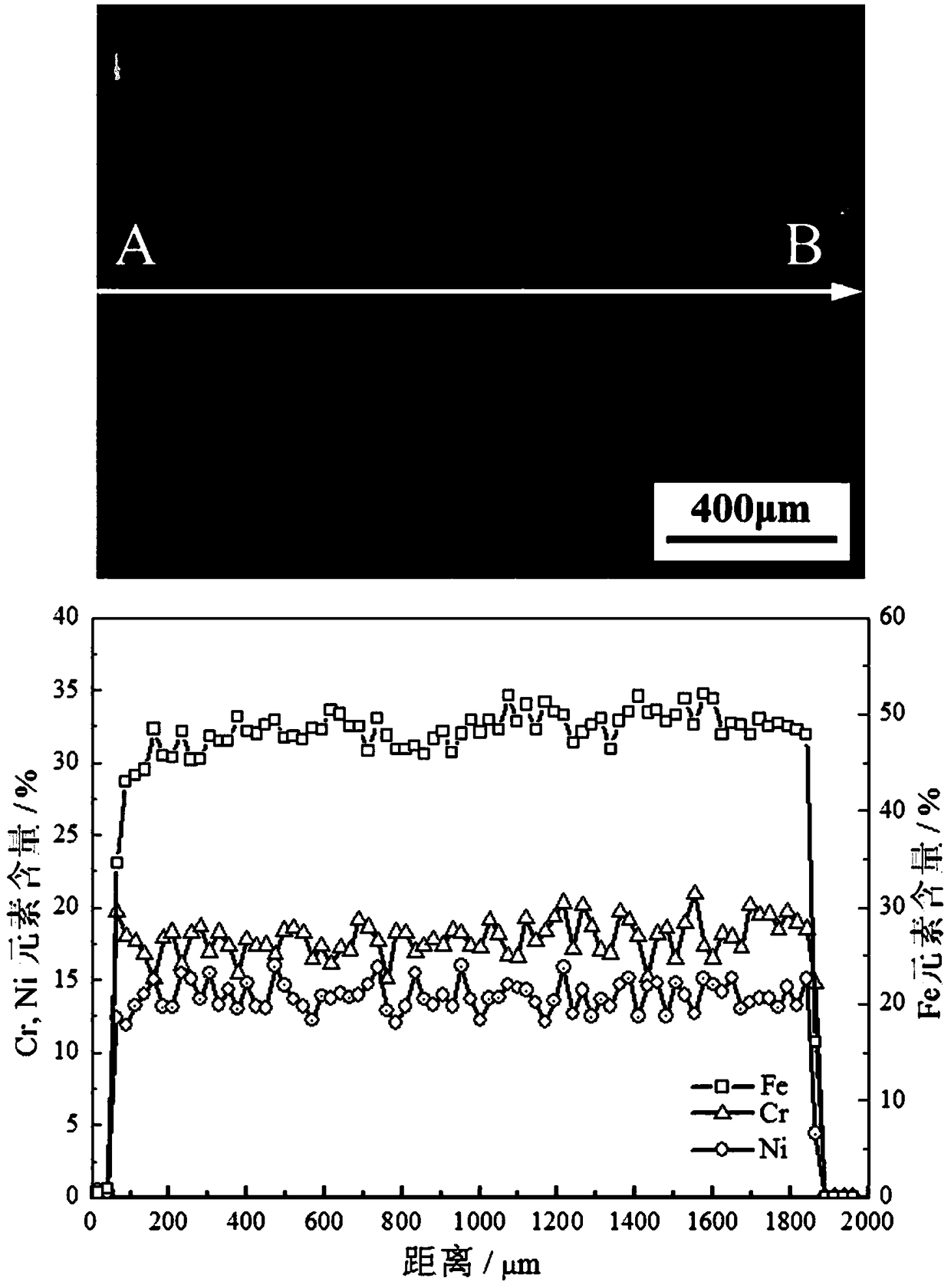

[0037] The molten steel enters the tundish, and then flows into the cavity surrounded by the two crystallization rolls and side sealing plates of the twin-roll continuous casting machine to form a molten pool, in which the two crystallization rolls rotate in opposite directions; the molten steel in the molten pool passes through two The roll gap between the crystallization rolls is solidified and exported to form a thin strip; the morphology of the thin strip and the distribution of each element are as follows: figure 2 and image 3 shown;

[0038] Air-cool the thin strip to 1100°C, and then use a hot rolling mill to perform single-pass hot rolling with a reduction rate of 38%, and the speed during hot ro...

Embodiment 2

[0043] Method is with embodiment 1, and difference is:

[0044] (1) Molten steel, its composition by mass percentage is: B 2.1%, C 0.004%, Cr 16.2%, Ni 17.4%, Mn 1.0%, Si 0.6%; Wherein Nieq=17.4+30×0.004+0.5×1.0= 18.02, Creq=16.2+1.5×0.6=17.1;

[0045] (2) The thin strip is air-cooled to 900°C, and then hot-rolled in a single pass with a hot rolling mill, with a reduction rate of 28%, and a speed of 1.0m / s during hot rolling; wherein the microstructure of the thin strip is as follows: Figure 6 shown;

[0046] (3) The hot-rolled sheet is water-cooled to 650°C and then coiled;

[0047] (4) The annealing temperature is 1000°C, the annealing holding time is 30min, and the reduction rate during smoothing is 1.0%;

[0048] (5) The thickness of high-strength and toughness high-boron stainless steel sheet is 1.3mm, the tensile strength is 760MPa, the elongation at room temperature is 15.2%, and the impact toughness at room temperature is 246KJ / m 2 The borides with a particle size...

Embodiment 3

[0050] Method is with embodiment 1, and difference is:

[0051] (1) Molten steel, its composition by mass percentage is: B 2.3%, C 0.007%, Cr 17.5%, Ni 16.0%, Mn1.3%, Si 1.0%; Wherein Nieq=16.0+30×0.007+0.5×1.3= 16.86, Creq=17.5+1.5×1.0=18;

[0052] (2) The thin strip is air-cooled to 1050°C, and then hot-rolled in a single pass with a reduction rate of 20%, and the speed during hot rolling is 0.5m / s;

[0053] (3) The hot-rolled sheet is water-cooled to 650°C and then coiled;

[0054] (4) The annealing temperature is 1100°C, the annealing holding time is 15min, and the reduction rate during smoothing is 1.0%;

[0055] (5) The thickness of high-strength and toughness high-boron stainless steel sheet is 2.4mm, the tensile strength is 800MPa, the elongation at room temperature is 14.5%, and the impact toughness at room temperature is 232KJ / m 2 ; The borides with a particle size smaller than 1.0 μm accounted for 63.2% of the total area, and the borides with a particle size larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com