Protecting device for steel ingot pouring and using method of protecting device

A protection device and technology for steel ingots, which are applied in the field of metallurgy to achieve the effects of improving the quality of steel ingots, reducing the temperature drop of molten steel and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

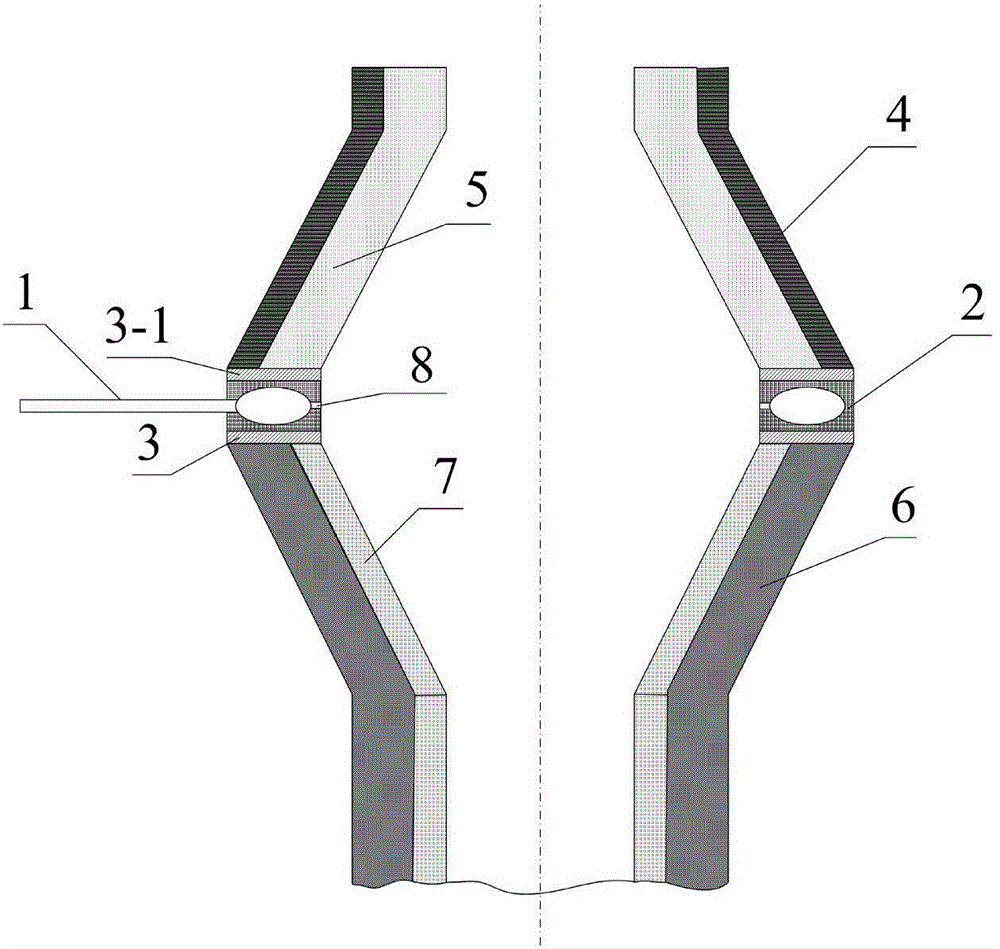

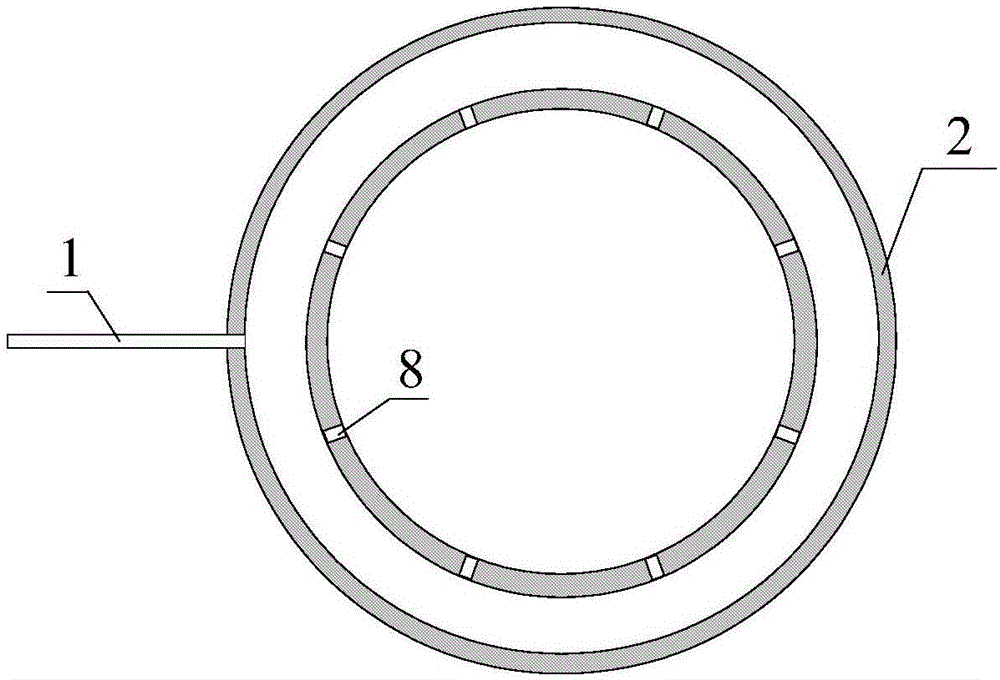

[0018] A protective device for pouring steel ingots, such as figure 1 , figure 2 As shown, it includes an air blowing ring 2, a protective box 4, a protective box lining 5, a sealing ring one 3, and a sealing ring two 3-1. The air blowing ring 2 is fixed on the middle injection pipe 6, and the protection box 4 and the inner liner 5 of the protection box are fixed on the air blowing ring 2, between the air blowing ring 2 and the middle injection pipe 6, and between the protection box 4 and the air blowing ring 2 Sealing ring one 3 and sealing ring two 3-1 are respectively used for sealing.

[0019] The protection case 4 is made of iron material, which can be used repeatedly, and the protection case lining 5 is made of light heat-insulating refractory material. The lower part of the protection box 4 is a conical cylindrical structure, and the upper part is a straight cylindrical structure with a length of 70-100 mm, the purpose of which is to form a vertically upward argon fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com