Boron-containing stainless steel thick plate with excellent plasticity and toughness and preparation method thereof

A stainless steel, plastic toughness technology, applied in the field of metallurgical materials, can solve the problems of the plasticity and toughness of the mechanical properties of the finished plate at room temperature, the increase of the size and distribution of the solidified structure, and the difficulty of satisfying the mechanical properties of the finished plate. Effect of mechanization and automation, improvement of uniform deformation ability, excellent plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

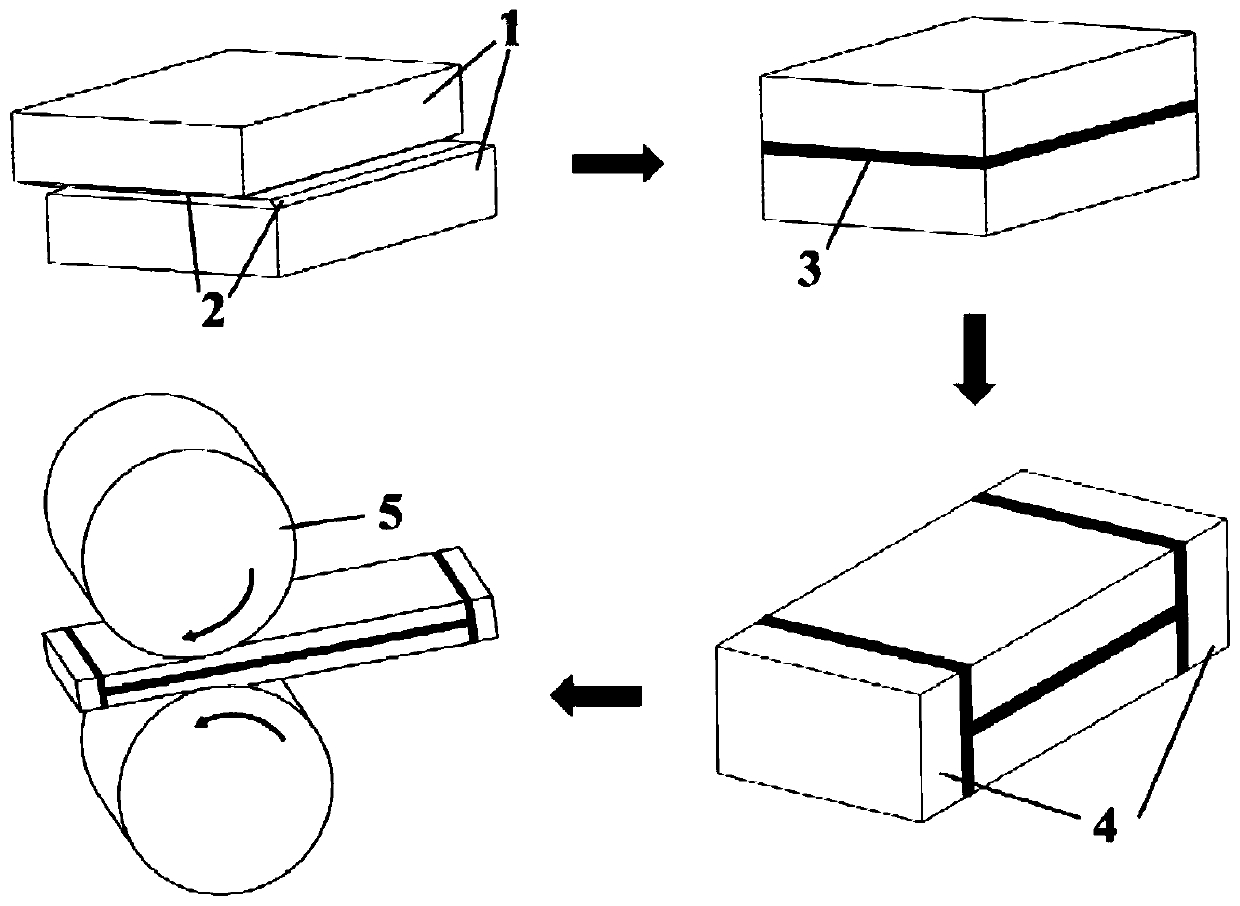

Method used

Image

Examples

Embodiment 1

[0050] The molten steel is smelted, and then the molten steel is made into a boron-containing stainless steel slab through die casting or continuous casting; the thickness of the boron-containing stainless steel slab is 160mm, and the composition contains Cr 18.5%, Ni 14.6%, Mn 0.7%, B 1.25% by mass percentage , Si0.31%, C 0.011%, the rest is Fe and unavoidable impurity elements;

[0051] Put the boron-containing stainless steel slab into the heating furnace and heat up to the soaking temperature T with the furnace, and keep it warm for 120 minutes, and then perform multi-pass rough rolling. 1 Meet 10mm≤△h 1 ≤H 1 mm, to obtain a rough rolled billet with a thickness of 65mm;

[0052] T=(1155-1450×1.25%)=1137°C;

[0053] H in the first rough rolling pass 1 =0.065×1137-1500×1.25%-20=74-39=35mm;

[0054] The compression ratio of rough rolling is 160 / 65=2.46;

[0055] After the rough rolling billet is milled to a surface roughness Ra≤0.8μm, a V-shaped bevel for welding is mad...

Embodiment 2

[0065] Method is with embodiment 1, and difference is:

[0066] (1) The thickness of the cast slab of boron-containing stainless steel is 220 mm, and the composition contains Cr 18.2%, Ni 13.4%, Mn 1.15%, B 0.65%, Si 0.23%, and C 0.013% by mass percentage;

[0067] (2) Put the boron-containing stainless steel cast slab into the heating furnace and heat it up to the soaking temperature T with the furnace, and keep it warm for 120 minutes, then carry out multi-pass rough rolling, the rough rolling final rolling temperature is 925 ° C, and obtain a rough rolled slab with a thickness of 60 mm;

[0068] T=(1155-1450×0.65%)=1146°C;

[0069] H during the first rough rolling 1 =0.065×1146-1500×0.65%-20=74.5-9.8-20=44.7mm;

[0070] The compression ratio of rough rolling is 3.67;

[0071] (3) Vacuum welding of 3 composite blanks to form a composite blank; V-shaped groove depth 4mm, angle 40°; composite blank width 360mm, thickness 180mm, aspect ratio 2;

[0072] (4) The length of or...

Embodiment 3

[0079] Method is with embodiment 1, and difference is:

[0080] (1) The thickness of the boron-containing stainless steel slab is 110mm, and the composition contains Cr 19.4%, Ni 14.76%, Mn 0.61%, B 1.47%, Si 0.19%, and C 0.009% by mass percentage;

[0081] (2) Put the boron-containing stainless steel cast slab into the heating furnace and heat up to the soaking temperature T with the furnace, and keep it warm for 95 minutes, then perform multi-pass rough rolling, the rough rolling final rolling temperature is 935 ° C, and obtain a rough rolled slab with a thickness of 50 mm;

[0082] T=(1155-1450×1.47%)=1134°C;

[0083] H during the first rough rolling 1 =0.065×1134-1500×1.47%-20=73.7-22.1-20=31.6mm;

[0084] The compression ratio of rough rolling is 2.2;

[0085] (3) Two composite blanks are stacked and vacuum-welded to form a composite blank; the depth of the V-shaped groove is 4.5mm, and the angle is 45°; the width of the composite blank is 400mm, the thickness is 100mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com