Patents

Literature

51results about How to "Dimensional accuracy is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

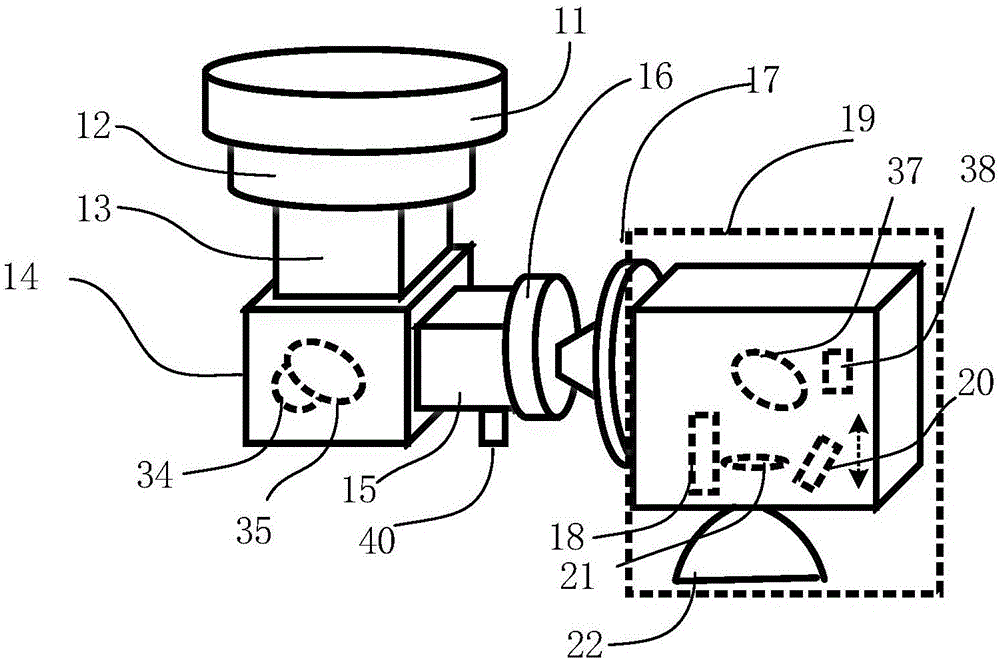

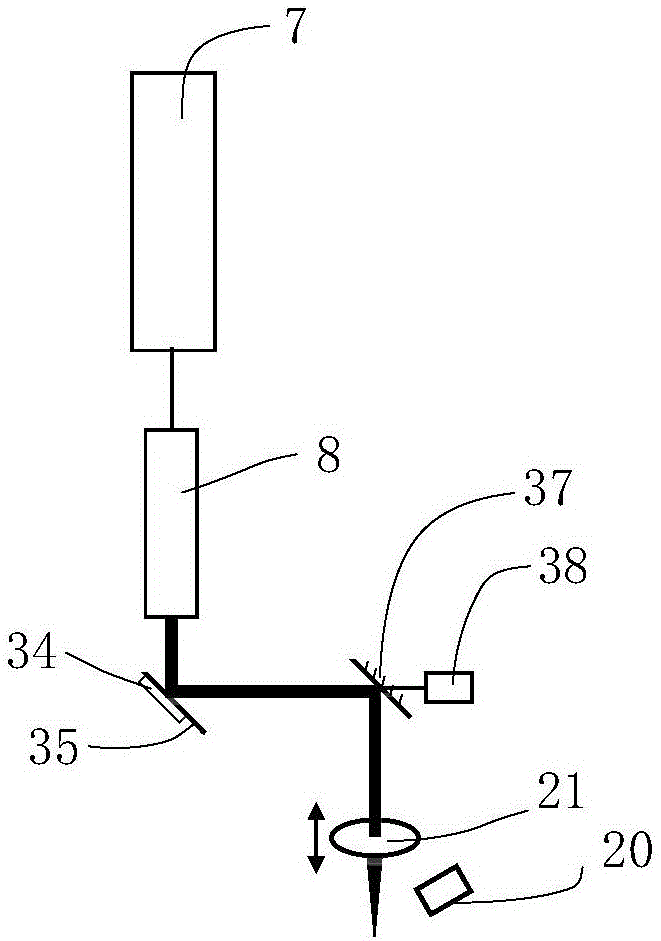

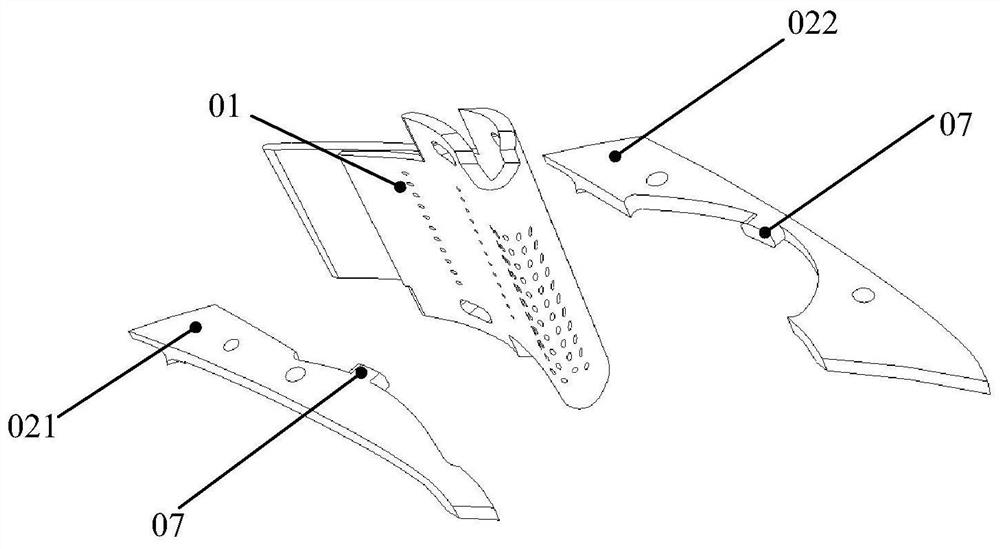

Multi-light source, multi-function and multi-axis laser processing head and apparatus

ActiveCN106563880AAchieve laser fine etchingRealize cutting processLaser beam welding apparatusNumerical controlEngineering

The present invention discloses a laser processing head and a multi-light source, multi-function and multi-axis processing apparatus comprising the same. The laser processing head includes a shell, an optical path system, a locating conical disk-shaped connecting mechanism, a laser range finder, a motor driving mechanism and a dust collection protection cover. The laser processing head has the advantages of a plurality of processing modes, flexibility in laser selection and easiness in replacement. The multi-light source, multi-function and multi-axis processing apparatus includes an apparatus control and operation system platform, a multi-axis linkage numerically-controlled machine tool and the laser processing head; the laser processing head is fixed on a high-precision multi-axis linkage machine tool through a blade handle type positioning cone device; and large-breadth and cross-scale laser fine processing only requires the switching of a laser light source, a laser optical path and the laser processing head, so that at least three kinds of large complex component fine surface processing application can be realized. The multi-light source, multi-function and multi-axis processing apparatus is especially for the aerospace field. The laser processing head and the multi-light source, multi-function and multi-axis processing apparatus comprising the same of the invention have the advantages of low manufacturing cost, wide application range, convenience in mass production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

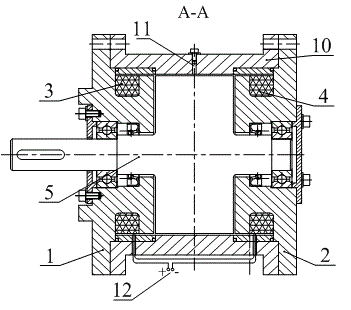

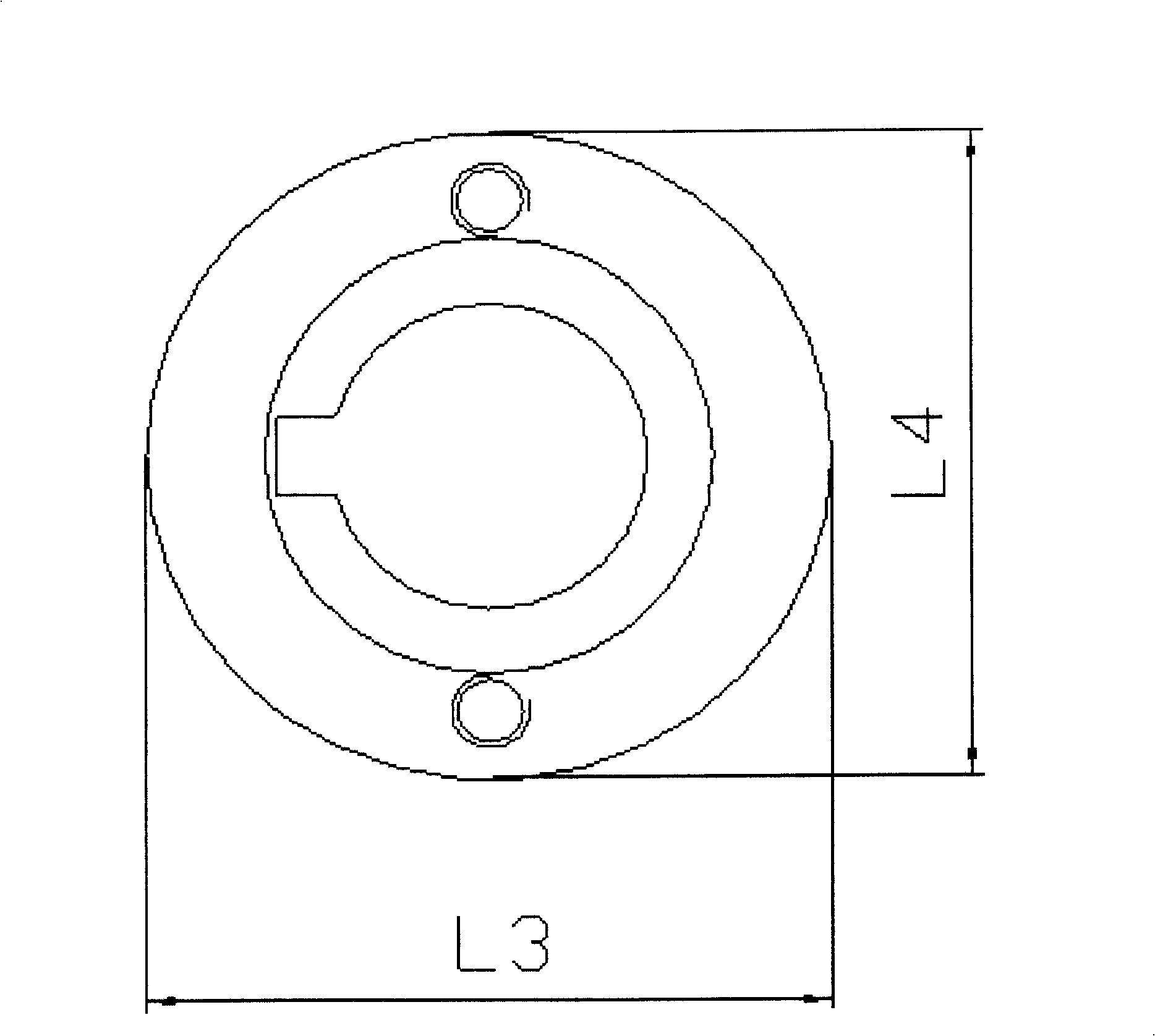

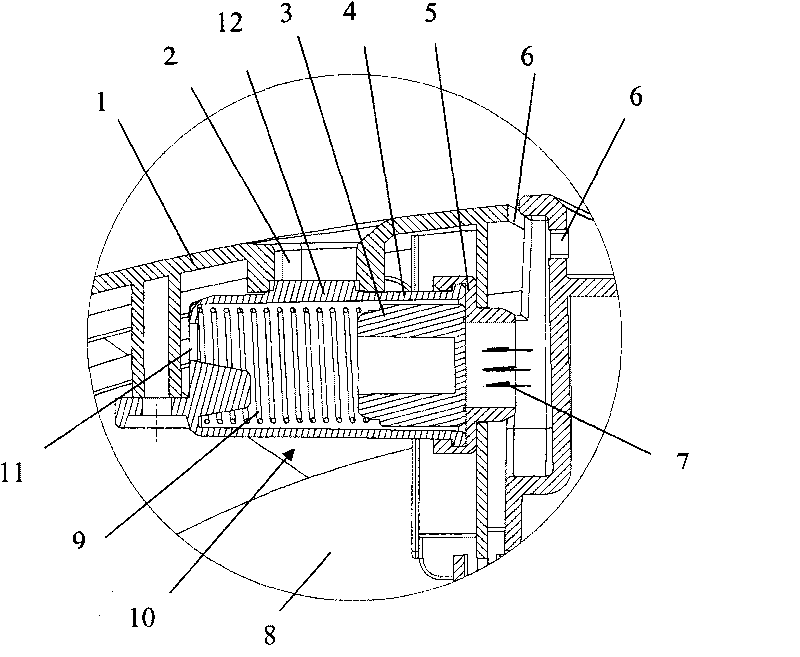

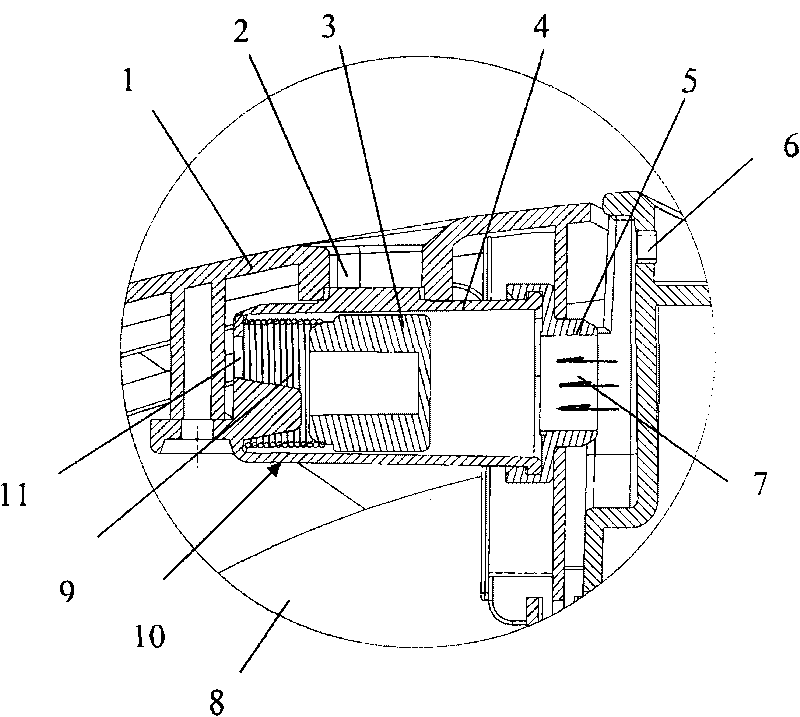

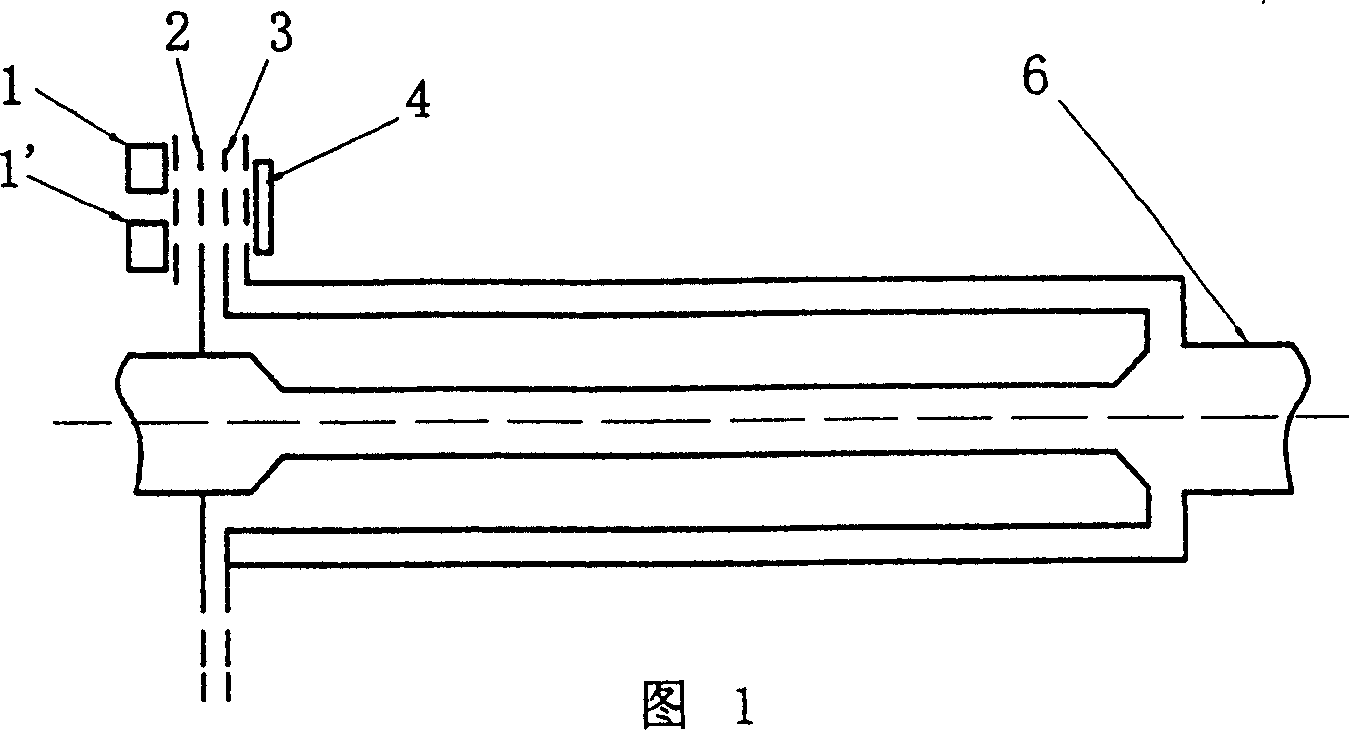

Rotary type magneto-rheological damper

InactiveCN102979847AIncrease working areaReduce thicknessNon-rotating vibration suppressionEngineeringMagneto rheological damper

The invention discloses a rotary type magneto-rheological damper which is characterized in that the damper mainly comprises an outer shell, a front end cap, a back end cap, a front magnet exciting coil, a back magnet exciting coil, a rotor, a bearing, a sealing washer, seal rings and magnetic isolation rings. The front and back end caps are located at the two sides of the rotor and are respectively connected with the outer shell, forming a stator. The bearing and the sealing washer are respectively arranged between the rotor and the front and back end caps. The front and back magnet exciting coils are wound inside the front and back end caps. The magnetic isolation rings are respectively installed between the front and back end caps and the outer shell, and O-shaped seal rings are respectively arranged between the magnetic isolation rings and the outer shell as well as the front and back end caps. A sealed liquid charging hole is formed at the upper part of the outer shell, and magneto-rheological fluid is filled in a hollow cavity between the stator and the rotor. The front and back magnet exciting coils are wound in the same direction, with the tail ends being connected with each other in series and the head ends being loaded with power sources. The two magnet exciting coils form two parallel magnetic pathways which generate two magnetic fields in opposite direction, and the magnetic flux is generated by a single piece of magnet exciting coils.

Owner:HEBEI UNIV OF TECH

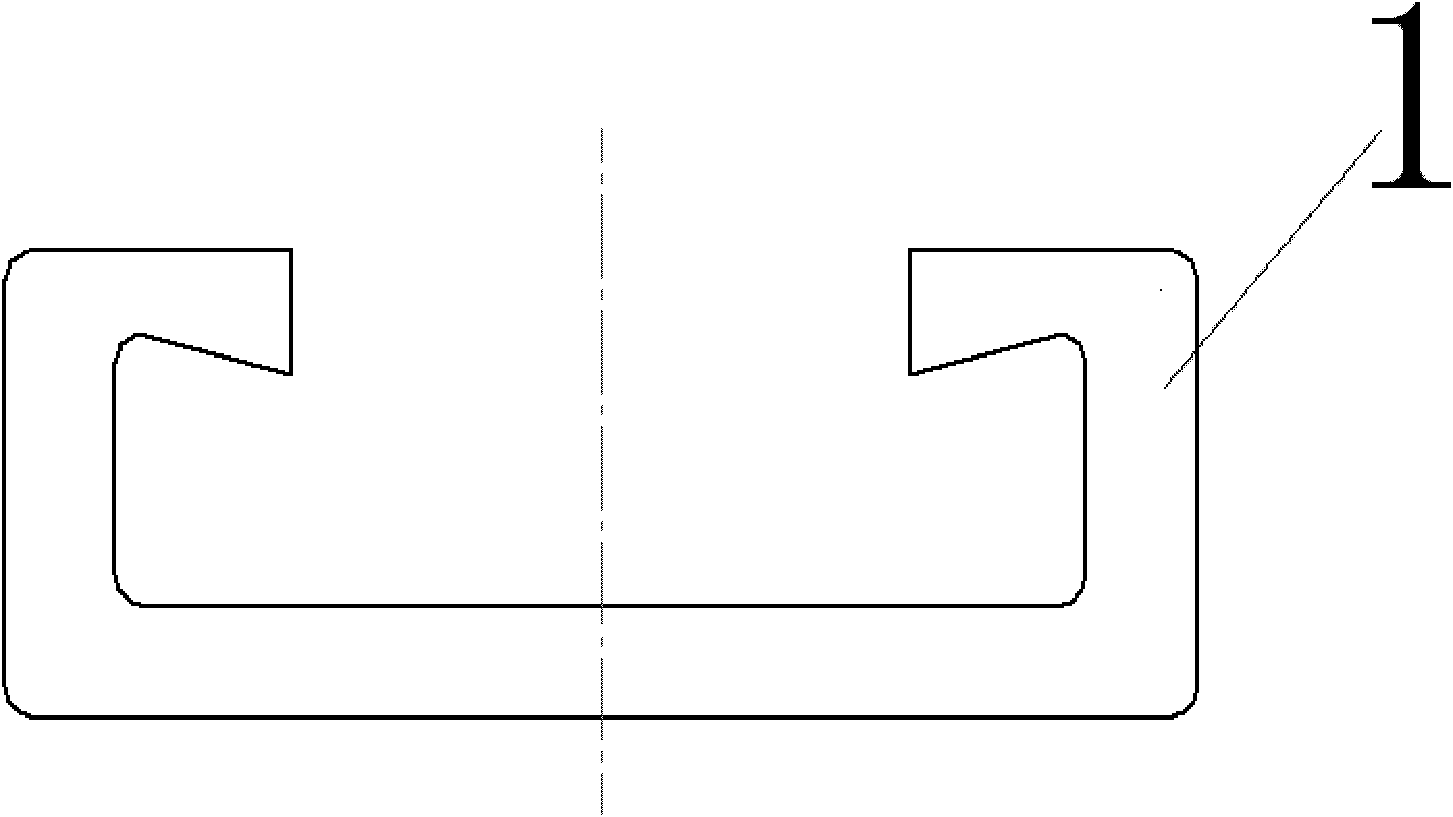

Forming process for special C-shaped channel steel

The invention provides a forming process for special C-shaped channel steel and belongs to the technical field of steel material rolling and forming. The special forming process for C-shaped channel steel comprises the following steps of: conveying and feeding band steel, leveling, micro-pressing, locally heating, forming a dovetail-shaped edge, cooling, gradually rolling and forming, straightening and discharging. The special forming process has the advantages that: when narrow band steel is used for manufacturing the special C-shaped channel steel, the C-shaped channel steel with a dovetail groove edge can be obtained by adopting the processes of locally heating and gradually and continuously rolling and forming, and synchronous motion of a band steel conveying mechanism and a discharging mechanism can be realized. By adoption of the process for manufacturing the special C-shaped channel steel, energy is saved, production efficiency is high, and the produced C-shaped channel steel has high shape and size precision and high bearing capacity.

Owner:BAZHOU LAOBIAN METAL CURTAIN WALL MATERIALS

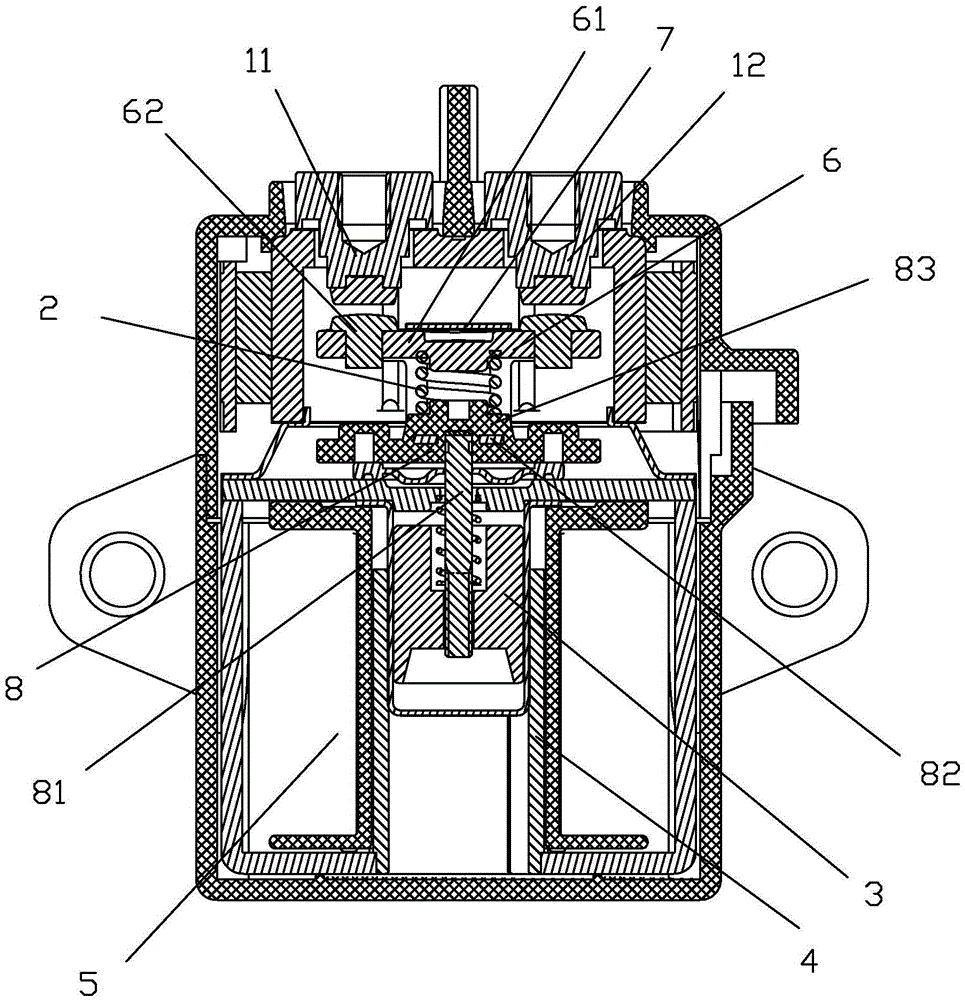

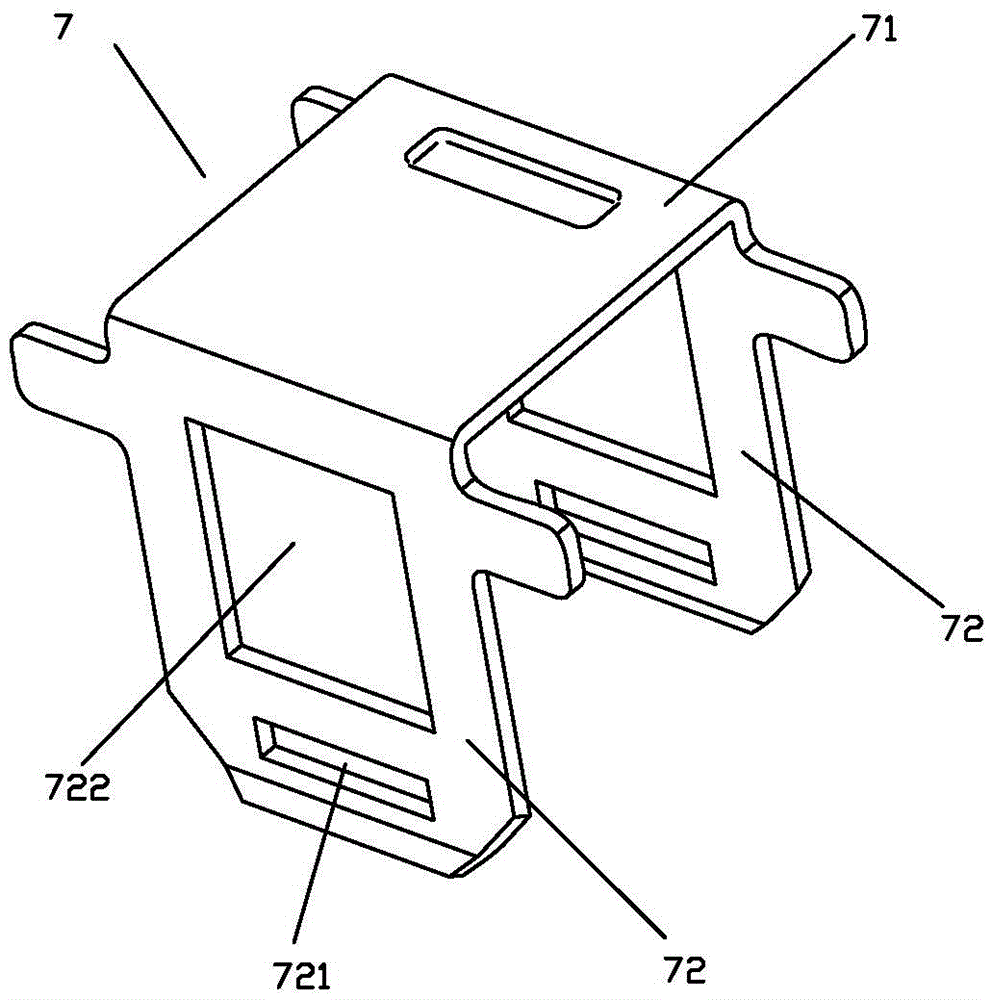

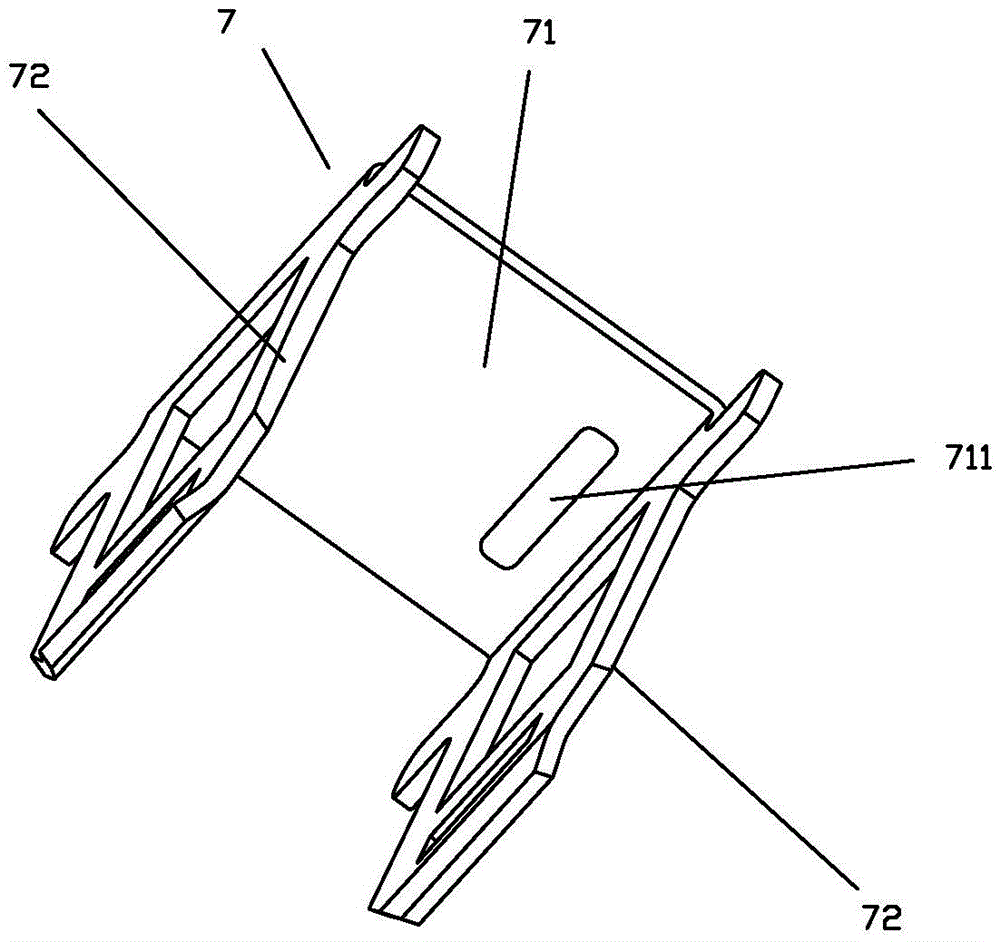

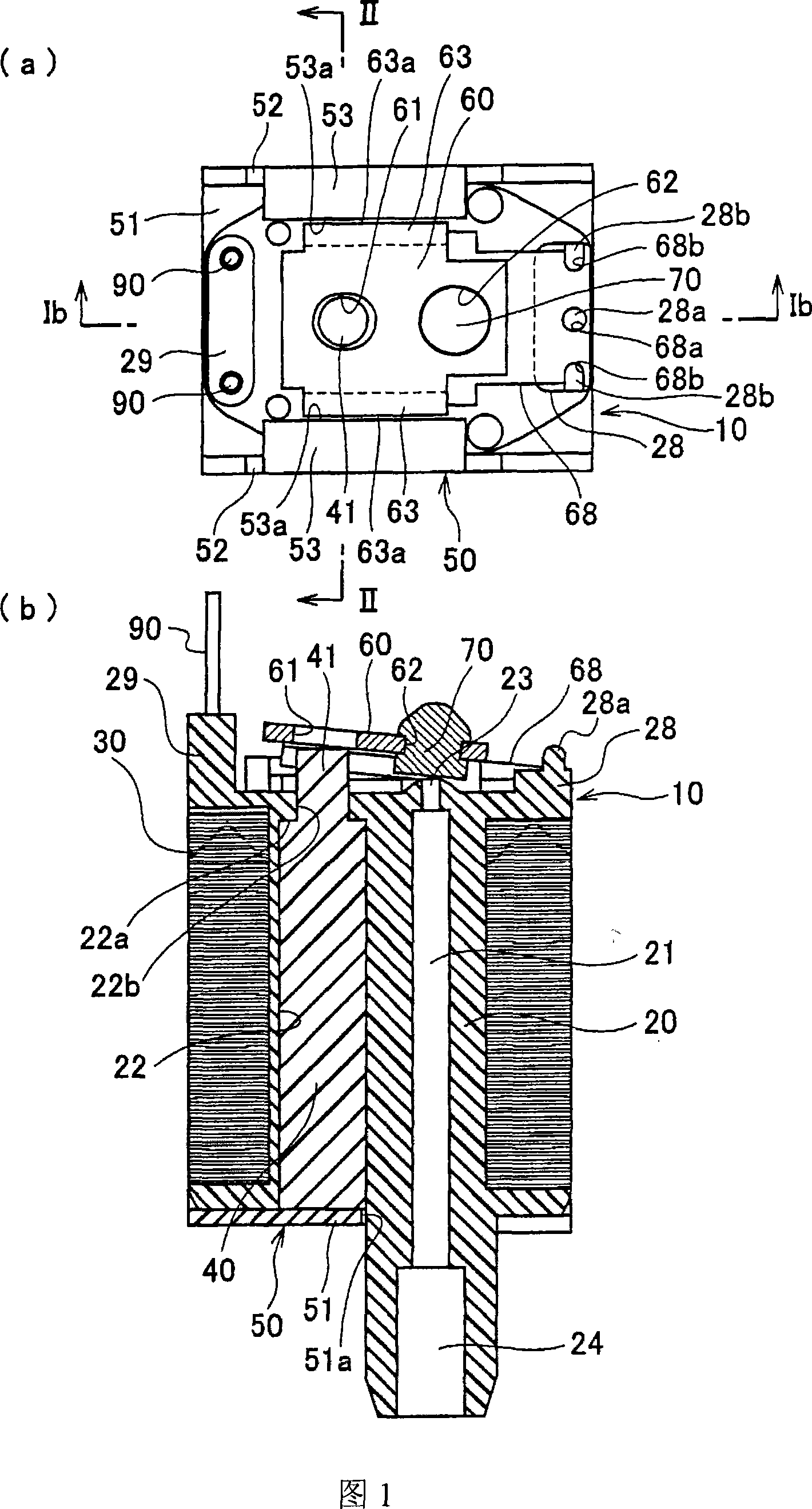

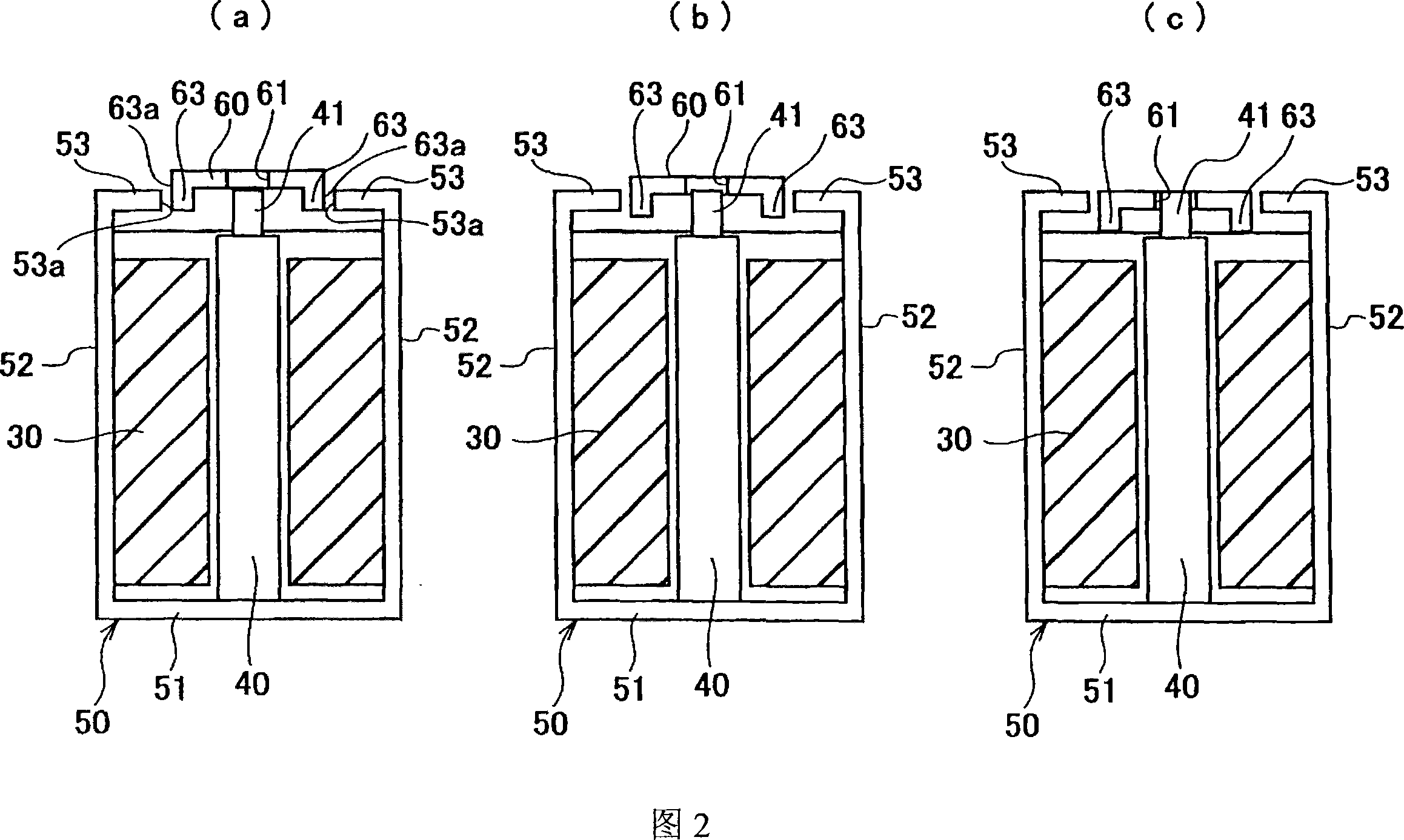

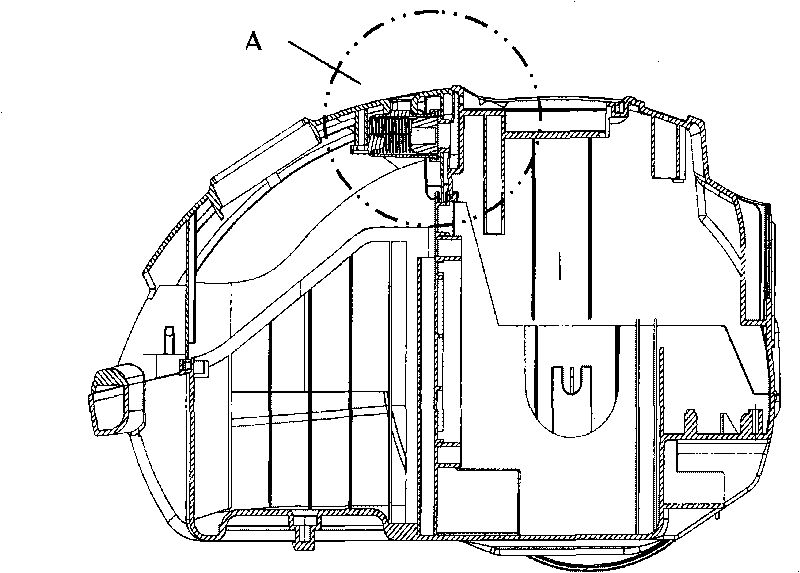

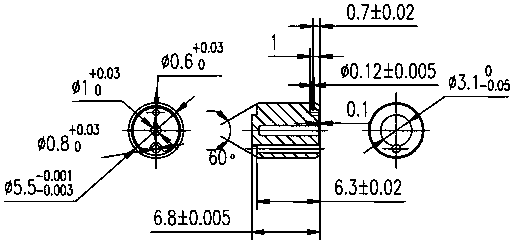

High-voltage DC relay and assembly method thereof

ActiveCN105551897ASimple structureDimensional accuracy is easy to guaranteeElectromagnetic relay detailsContact engagementsEngineeringHigh pressure

The invention discloses a high-voltage DC relay and an assembly method thereof. The high-voltage DC relay comprises two fixed contacts and a movable assembly, wherein the movable assembly comprises a movable spring part, a main spring and a push rod assembly, the push rod assembly comprises two independent parts of a push rod part and an U-shaped basket, the push rod part comprises a fixed piece and a push rod which are fixed together by insulation plastic, the two ends of the fixed piece are respectively fixed with the bottom of the side part of the U-shaped basket after the main spring, the movable spring part and the U-shaped basket are sequentially arranged at the top of the push rod part, so that the main spring is elastically tightened between the bottom surface of the movable spring part and the insulation plastic of the push rod part, and a movable spring piece props against the inner side of the top of the U-shaped basket. By dividing the push rod assembly into two independent parts, the high-voltage DC relay has the characteristics of simplicity in structure, convenience in forming and easiness in ensuring size accuracy; meanwhile, the two parts are easy to assemble, and automatic assembly of parts which are mutually matched is easily achieved; and moreover, the bonding resistant ability also can be enhanced.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

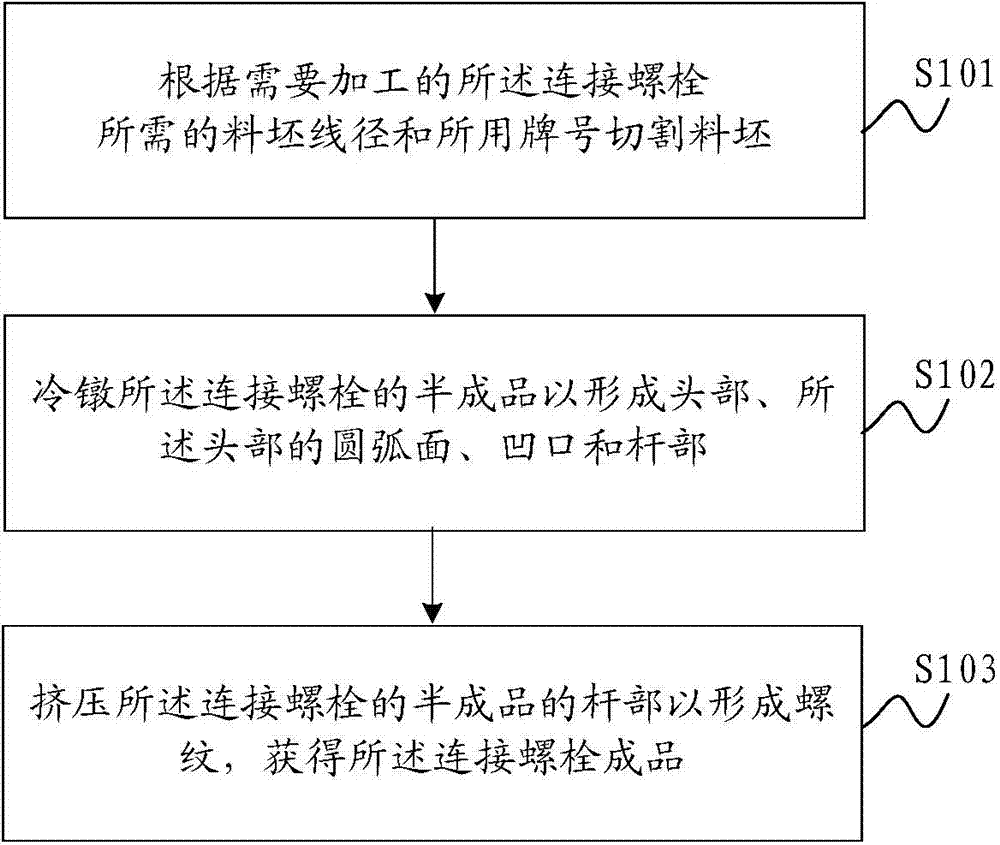

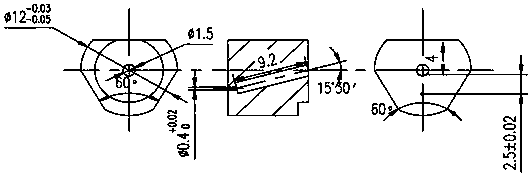

Cold heading manufacturing method for connection bolt of ignition switch and die

ActiveCN104117624ALow manufacturing costSlow wearBoltsForging/hammering/pressing machinesWork in processEngineering

The invention relates to the technical field of machining, and provides a cold heading manufacturing method for a connection bolt of an ignition switch. The method includes the steps that according to the wire diameter and the name needed during machining of the connection bolt, a material of a predetermined length is cut; cold heading is carried out on a semi-product of the connection bolt so that a head portion and a pole portion can be formed, and an arc face, a notch and a bottom end face of the head portion can be formed; the pole portion of the semi-product of the connection bolt is squeezed and threaded so that threads can be formed, and a finished product of the connection bolt is obtained. The invention further provides a connection bolt cold heading die based on the cold heading manufacturing method. Product quality problems are solved and production cost is reduced.

Owner:EXCELLENT FASTENING SYST SHANGHAI

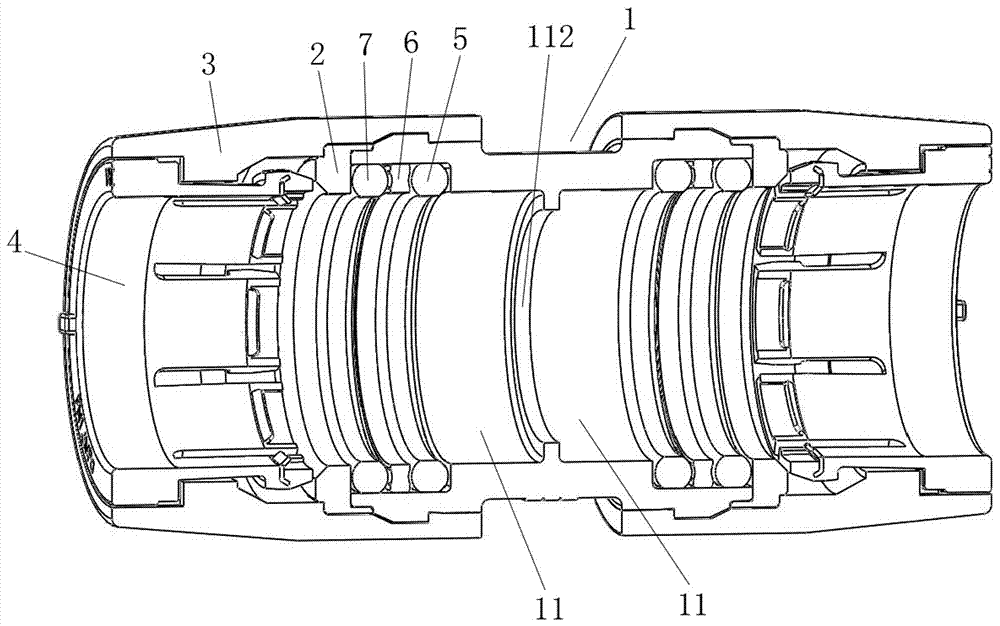

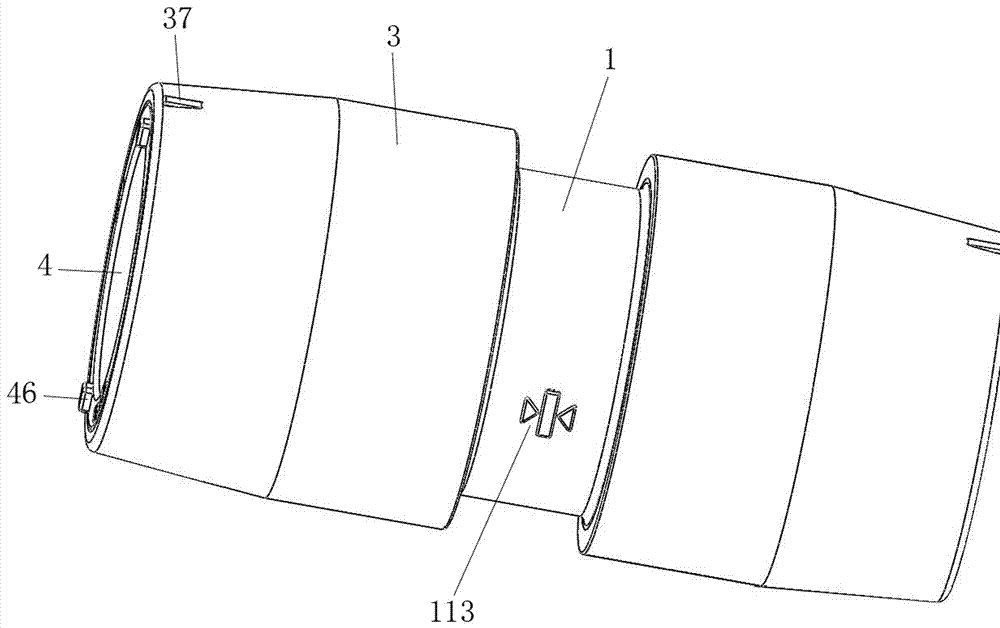

Rapid type pipeline connector

ActiveCN106979427ALarge thermal expansionSoft materialCouplingsPipe fittingElectrical and Electronics engineering

The invention discloses a rapid type pipeline connector. The rapid type pipeline connector comprises a pipeline connector, one or more rapid type connecting ports used for external connecting pipelines are formed in the pipeline connector, the inner wall of each rapid type connecting port is provided with a circle of connecting groove communicating to the end surface of the rapid type connecting port, and a sealing assembly is placed in each connecting groove. Each rapid type connecting port is sleeved with a rapid connecting assembly, and each rapid connecting assembly comprises a rapid connecting inner annular cover, an outer cylinder cover and a receding stopping sleeve, wherein the rapid connecting inner annular cover sleeves the corresponding connecting port and blocks the outside of the sealing assembly, the outer cylinder cover sleeves the corresponding rapid connecting inner annular cover and the corresponding connecting port, and the receding stopping sleeve is mounted in the corresponding outer cylinder cover and located at the outside of the corresponding rapid connecting annular cover. The external connecting pipelines can penetrate through the receding stopping sleeves and the rapid connecting inner annular covers to be inserted into the sealing assemblies in the connecting ports. According to the rapid type pipeline connector, rapid mounting and dismounting operation of the external connecting pipelines can be achieved, modularized connecting of multiple rapid connecting pipe fittings can be further achieved, and use is flexible and convenient.

Owner:深圳市安第斯制品有限公司

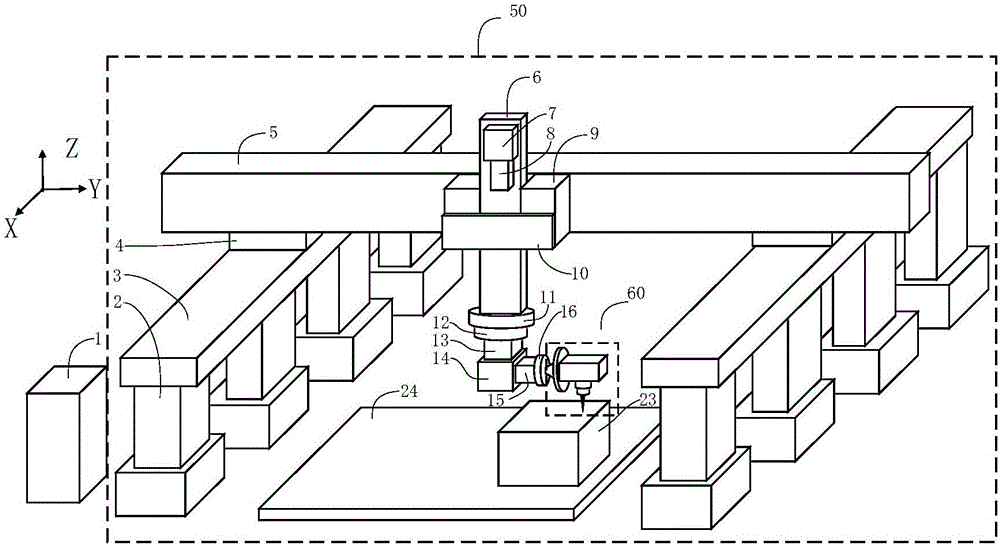

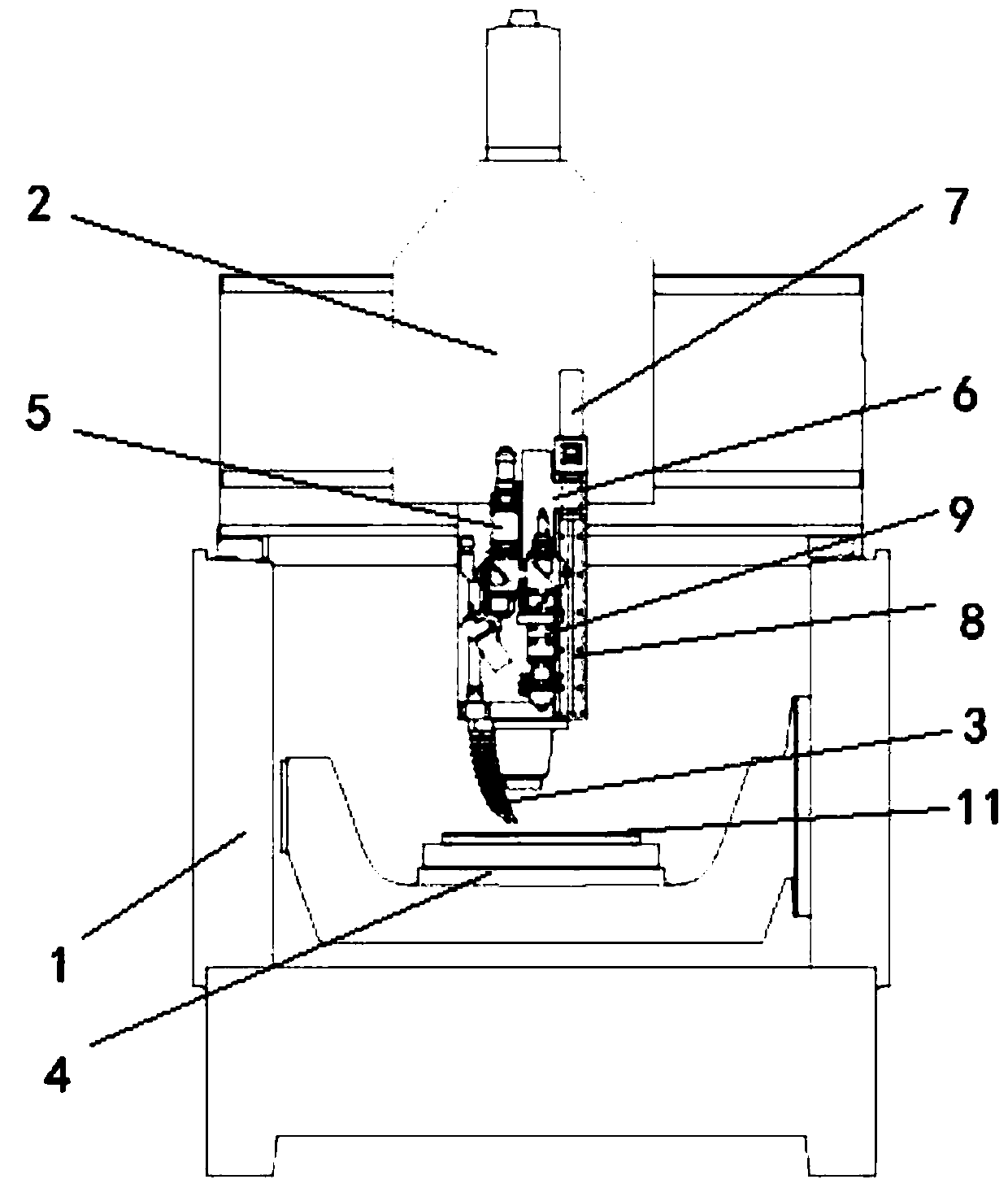

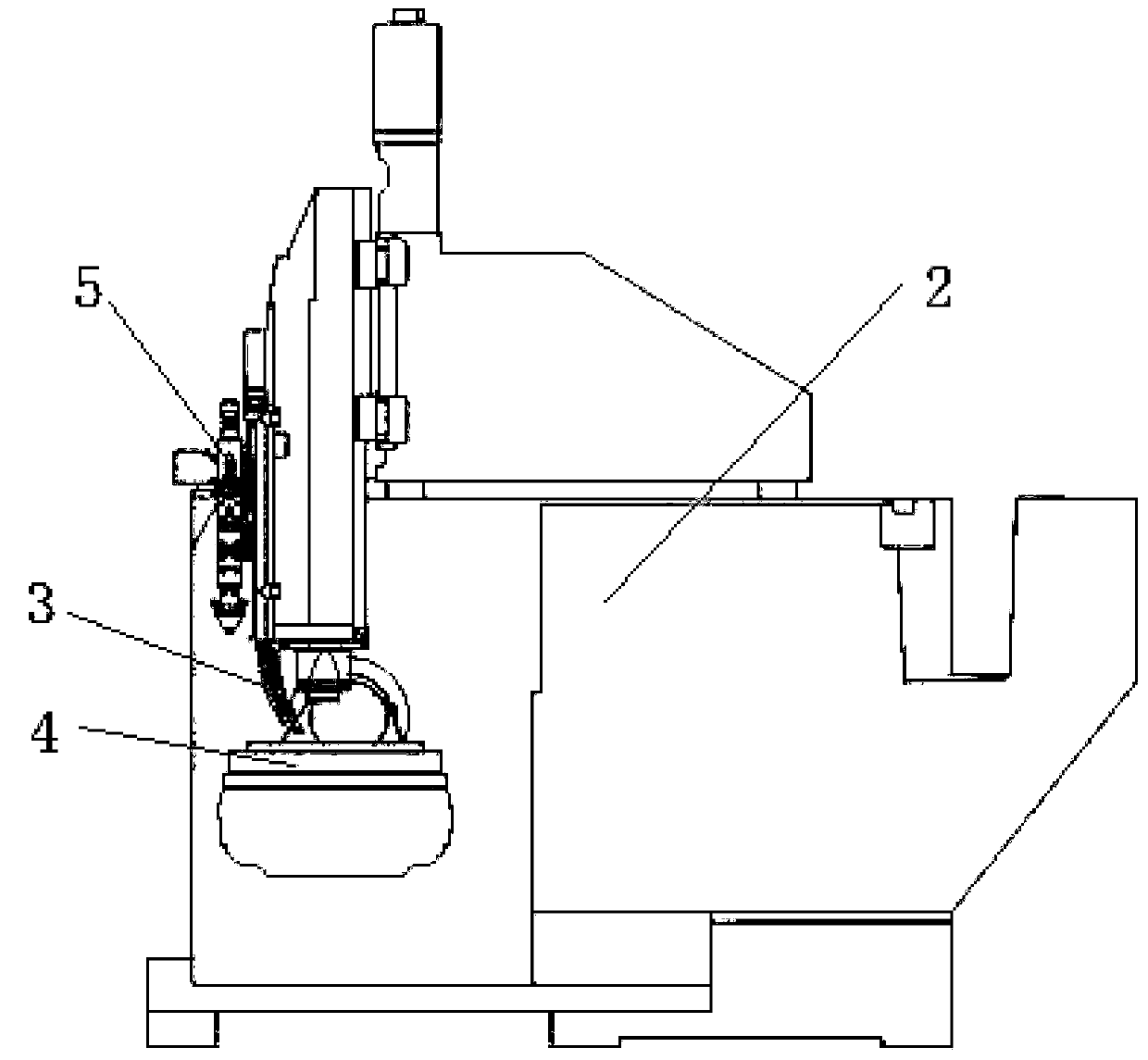

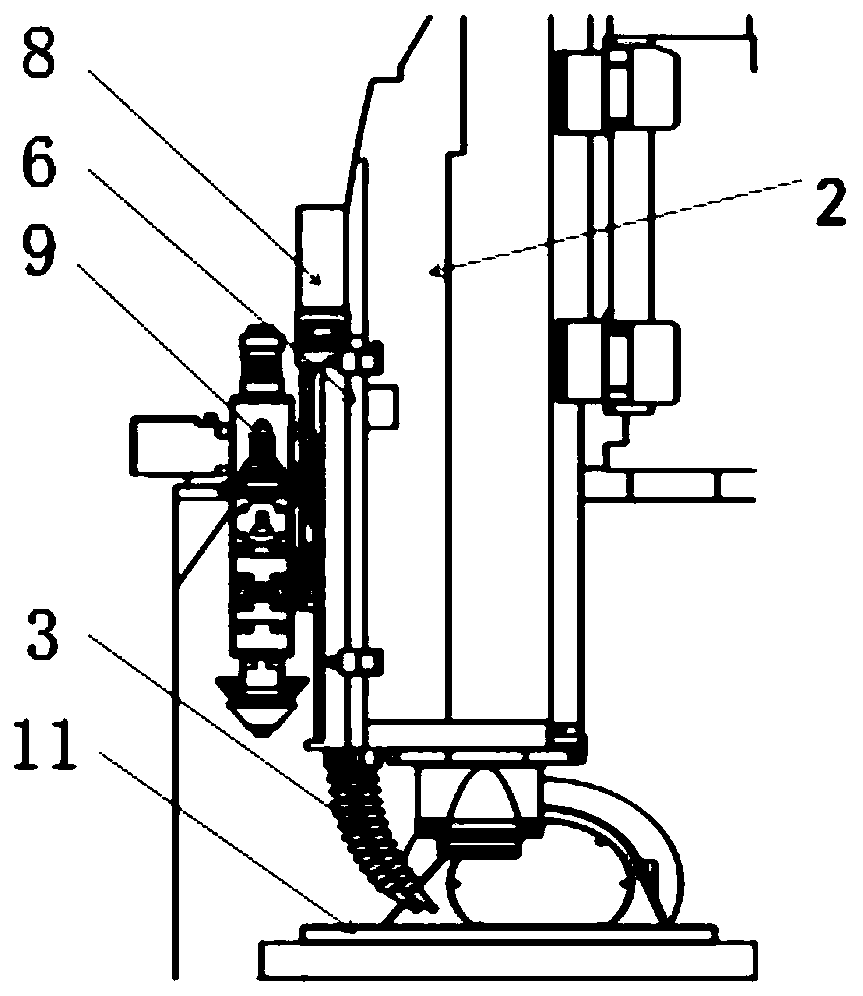

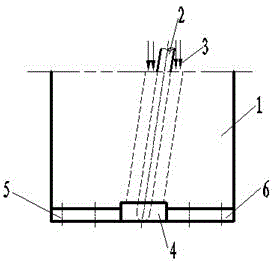

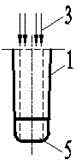

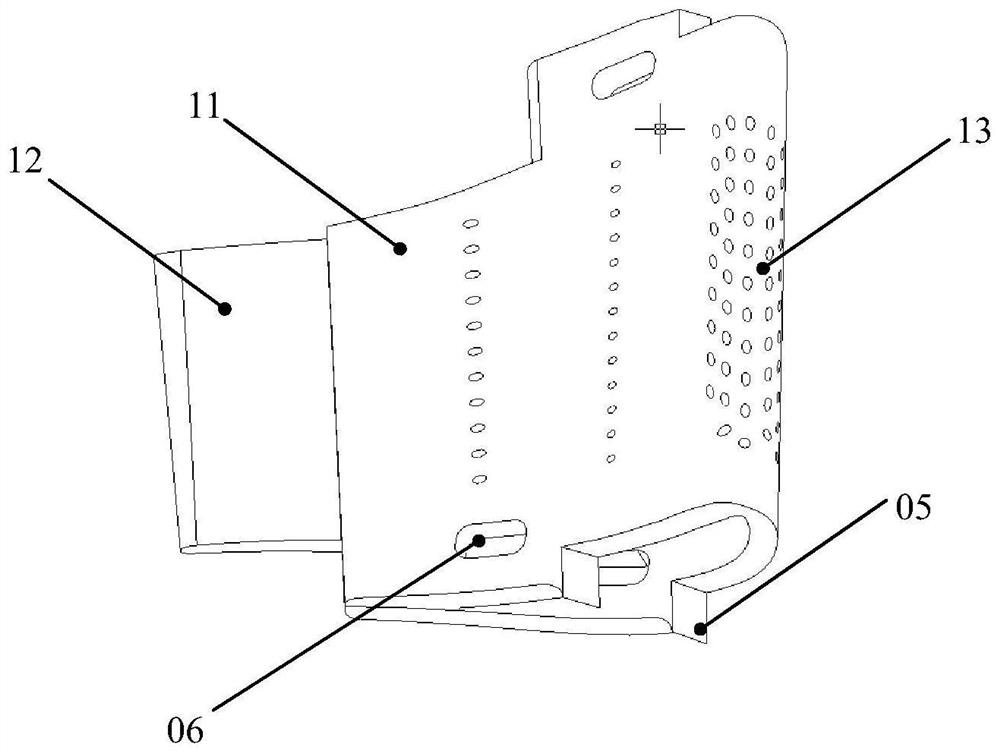

Additive and subtractive compound manufacturing equipment

PendingCN110026776AReduce temperature riseExtended service lifeAdditive manufacturing apparatusArc welding apparatusSubtractive colorSpray nozzle

The invention relates to additive and subtractive compound manufacturing equipment. In the equipment, additive and subtractive processes are finished independently, and a subtractive tool and an additive forming assembly are not switched by using a tool switching device on a machining center, so that the production efficiency is improved greatly. The equipment comprises the machining center, the additive forming assembly and a cooling nozzle. The additive forming assembly comprises a connecting plate, a motor, a rectilinear motion linear module and an energy depositing metal additive forming device. The rectilinear motion linear module is fixed to a spindle box of the machining center and is slidably connected to the connecting plate. The energy depositing metal additive forming device isfixedly mounted on the connecting plate. The motor provides power to the rectilinear motion linear module, so that the connecting plate drives the energy depositing metal additive forming device to move up and down. The cooling nozzle is fixed to the spindle box of the machining center, and an air outlet faces a working table-board of the machining center.

Owner:BEIJING WANWEI ADDITIVE MFG TECH CO LTD

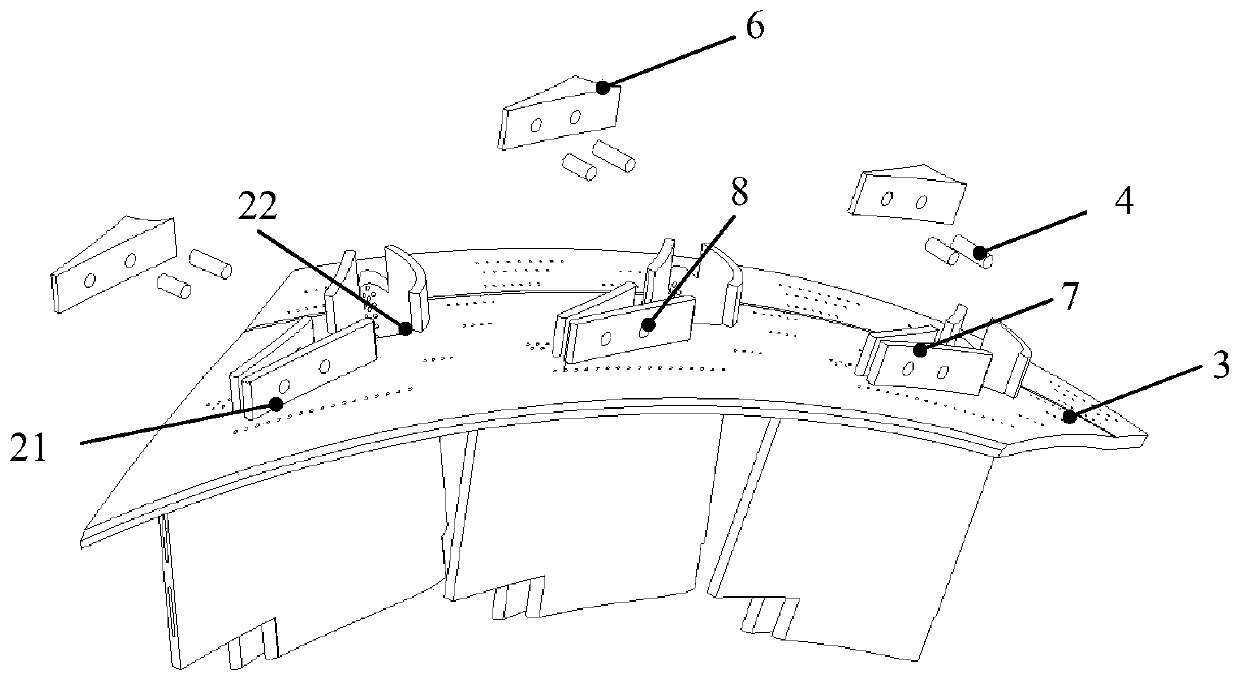

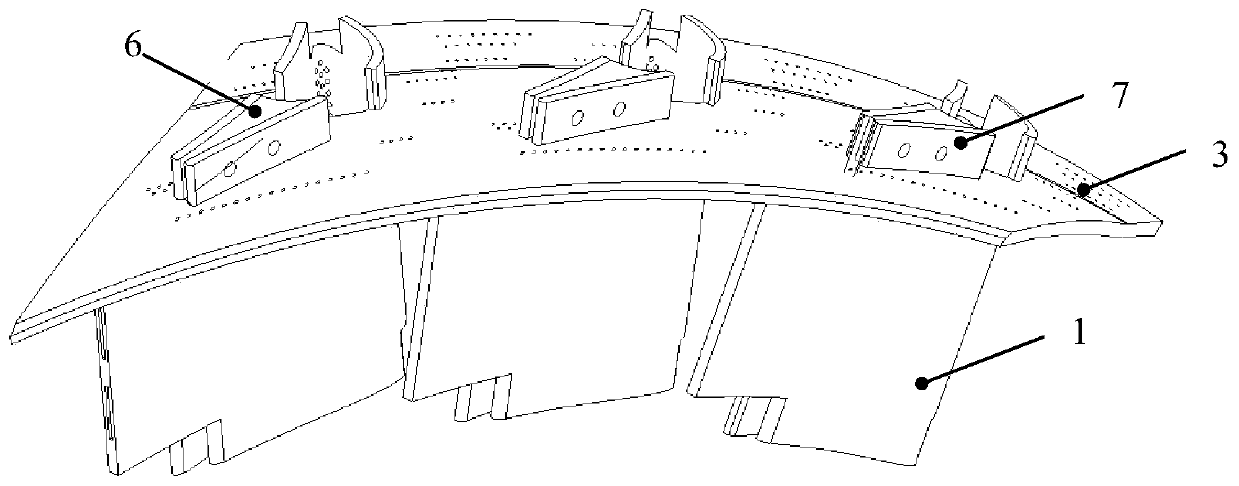

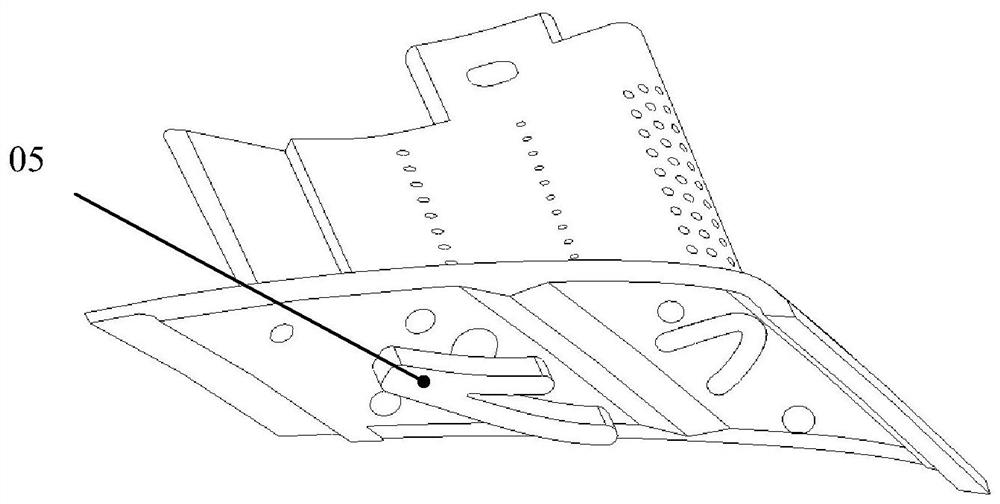

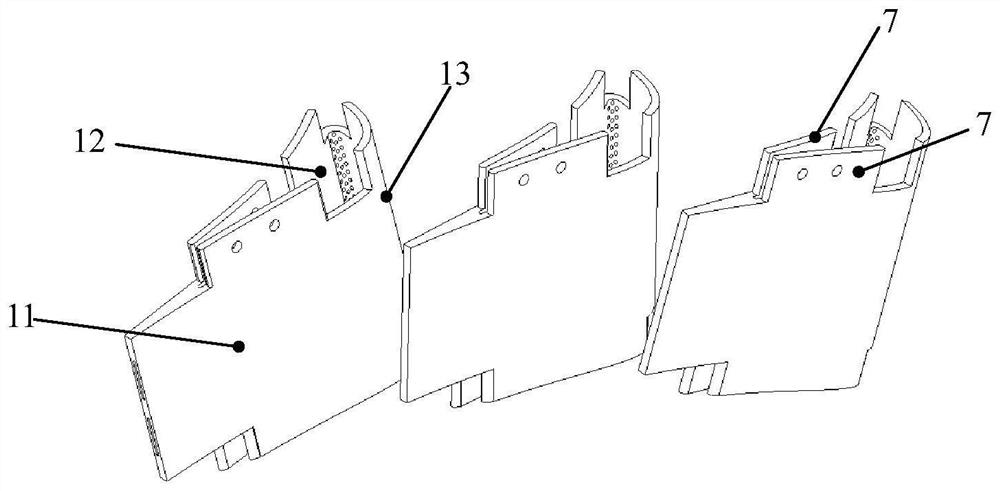

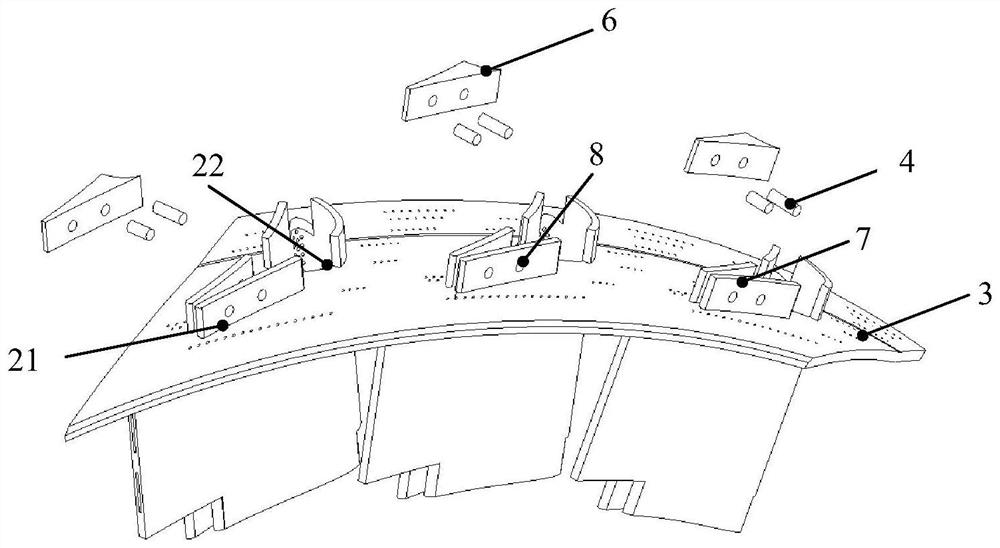

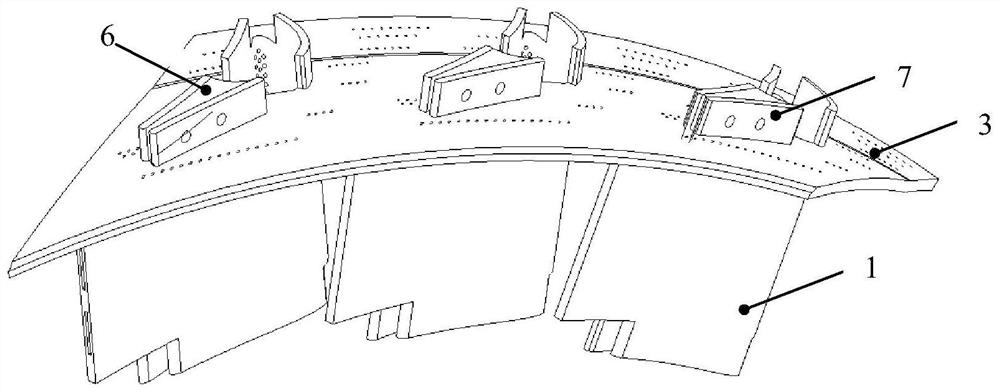

Aero-engine ceramic matrix composite fixation guider blade structure and molding method thereof

ActiveCN110966049AAvoid the defects of insufficient strengthGood workmanshipStatorsMachines/enginesEngineeringTurbine

The invention belongs to the technical field of preparation of an aero-engine fixation guider, relates to an aero-engine ceramic matrix composite fixation guider blade structure and a molding method thereof, and is to overcome the structural defects that an existing CMC guider blade prefabricated body is unreasonable in design and poor in blade root strength. A turbine guider blade manufactured in an integrated assembly mode comprises multiple stages of guide blades, parts are integrally assembled in a riveting mode, and an assembly structure adopts a SiC ceramic matrix to achieve welding; aneffective space between an upper edge plate and an outer casing is fully utilized, the blade body and the upper edge plate are installed and positioned through limiting rivets and a limiting table, the SiC ceramic matrix is deposited on the whole product through the CVI technology, and integrated preparation is completed; by means of the structure, the complex SiC / SiC multi-connected high-pressure guide blade has good manufacturability, the edge plate and the blade are easier to manufacture and more reliable to install, and the dimensional precision of a final product is easier to guarantee;and the structure can be fully applied to medium-sized and large-sized engines and five-generation engines.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

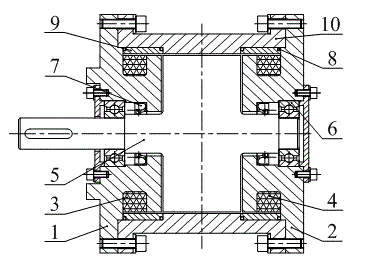

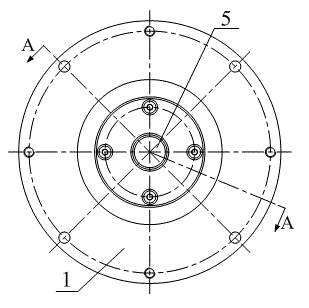

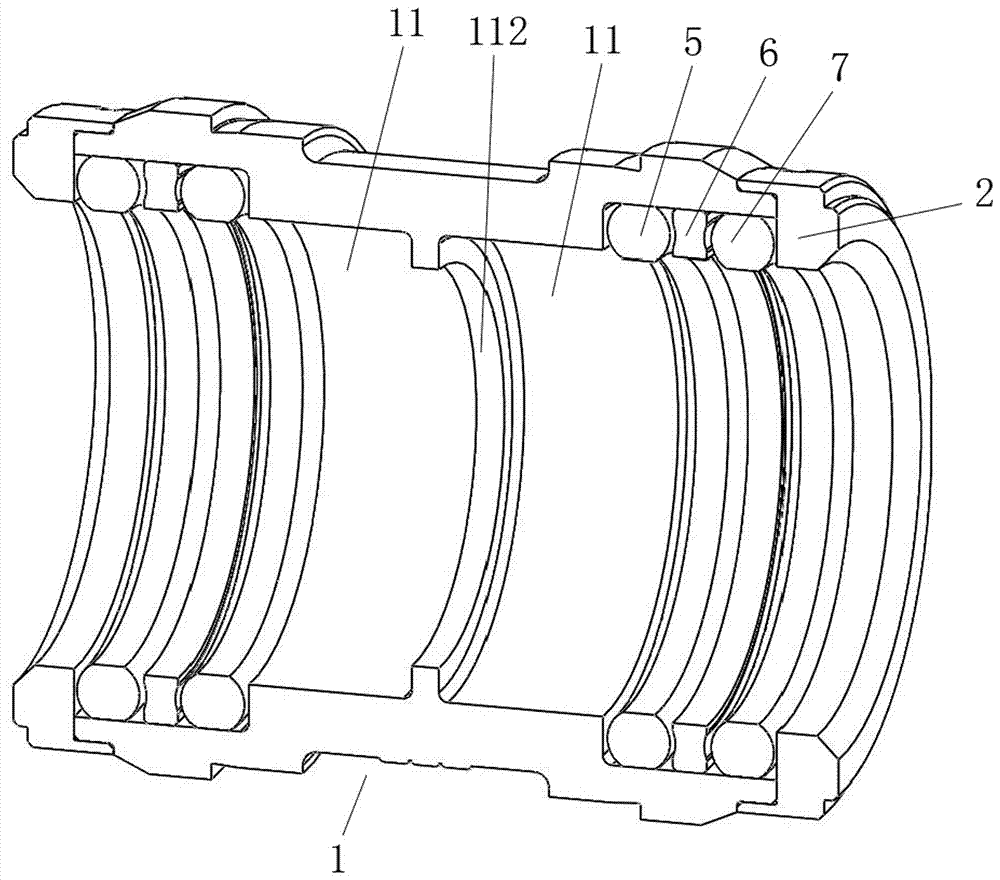

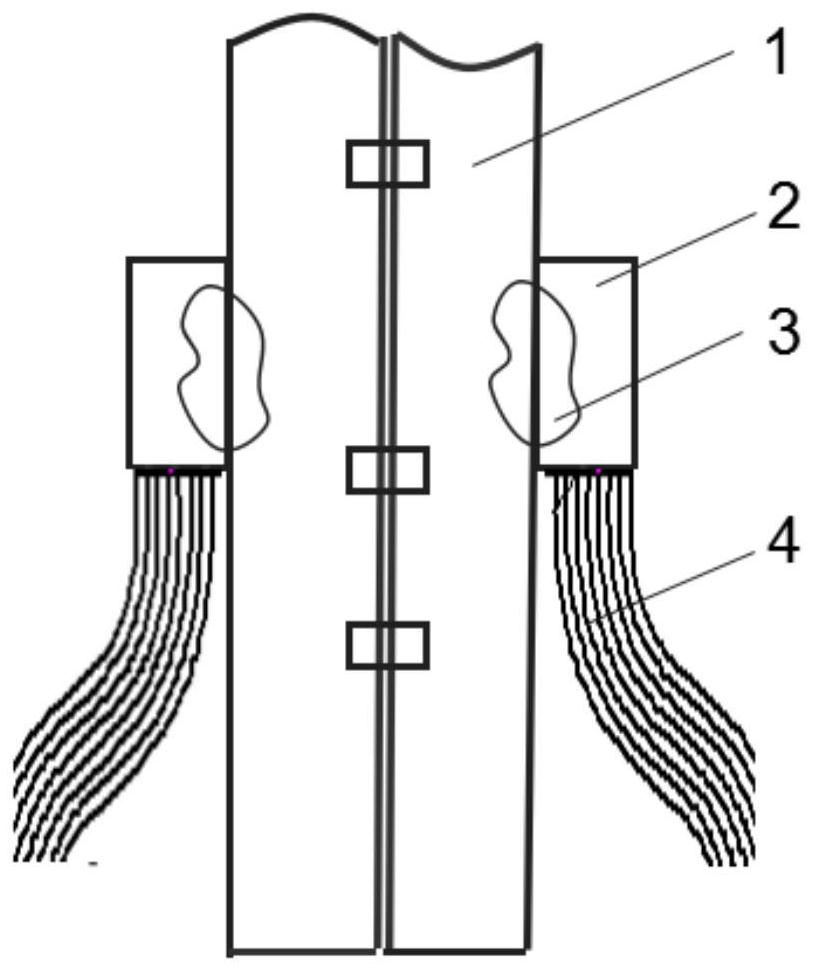

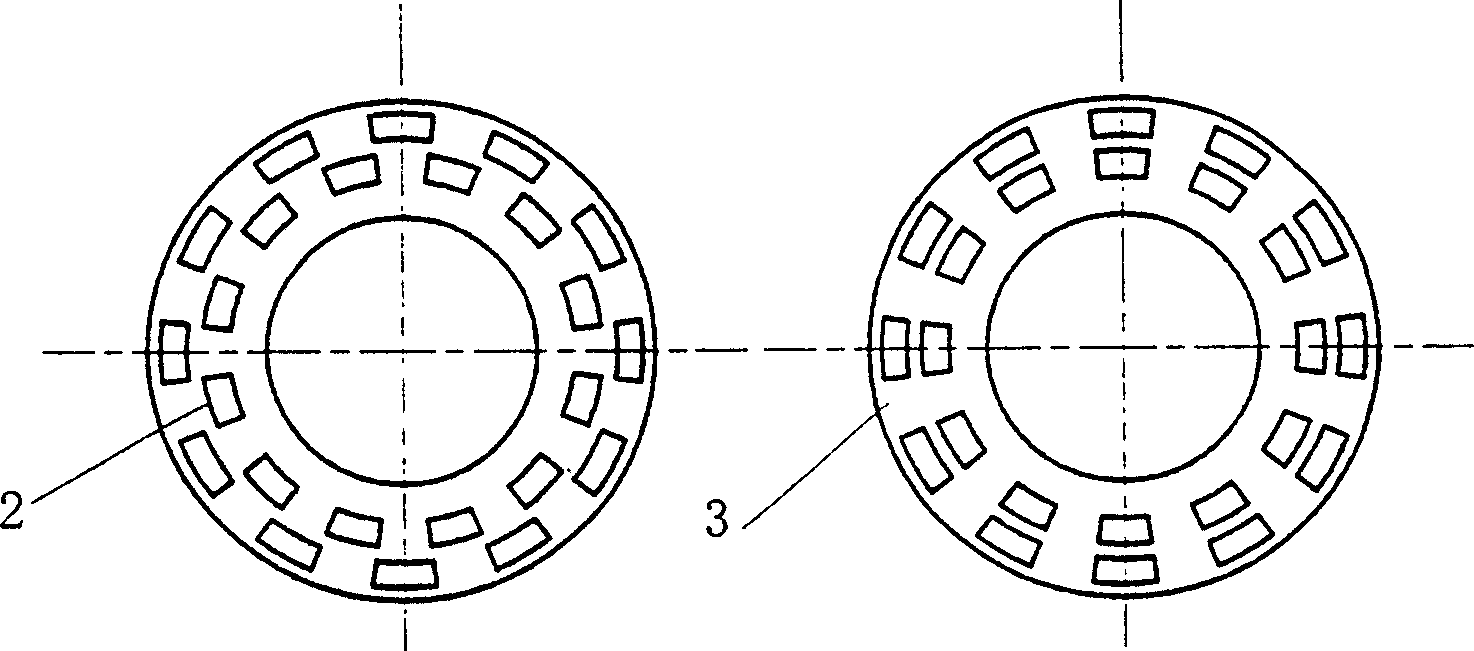

Drive wheel end face drive finish turning clamp for bevel gear

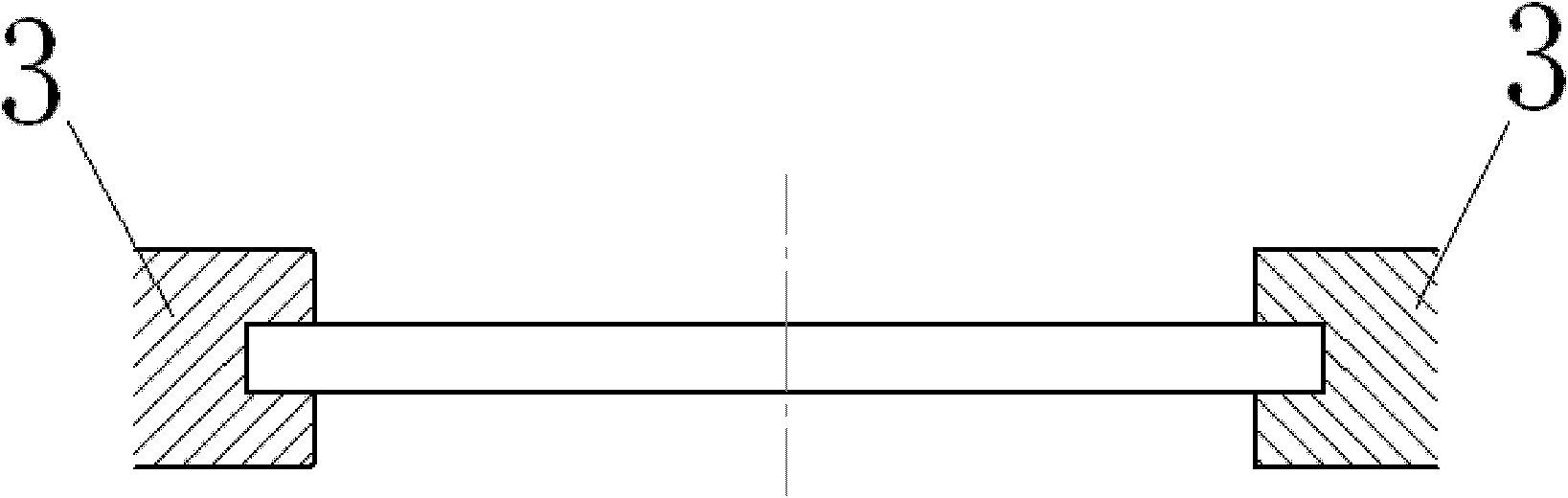

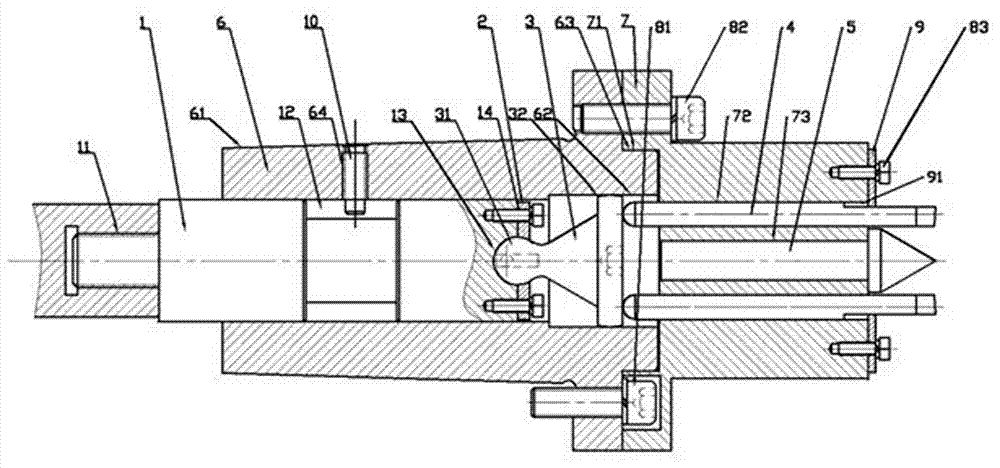

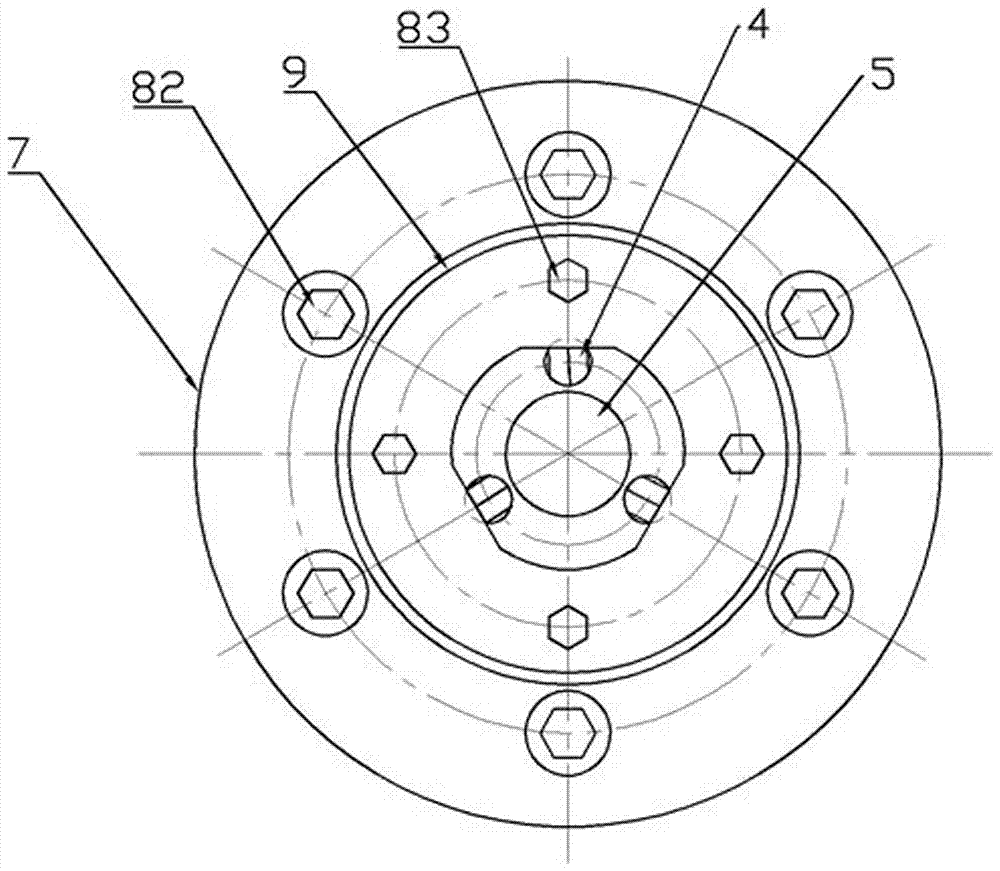

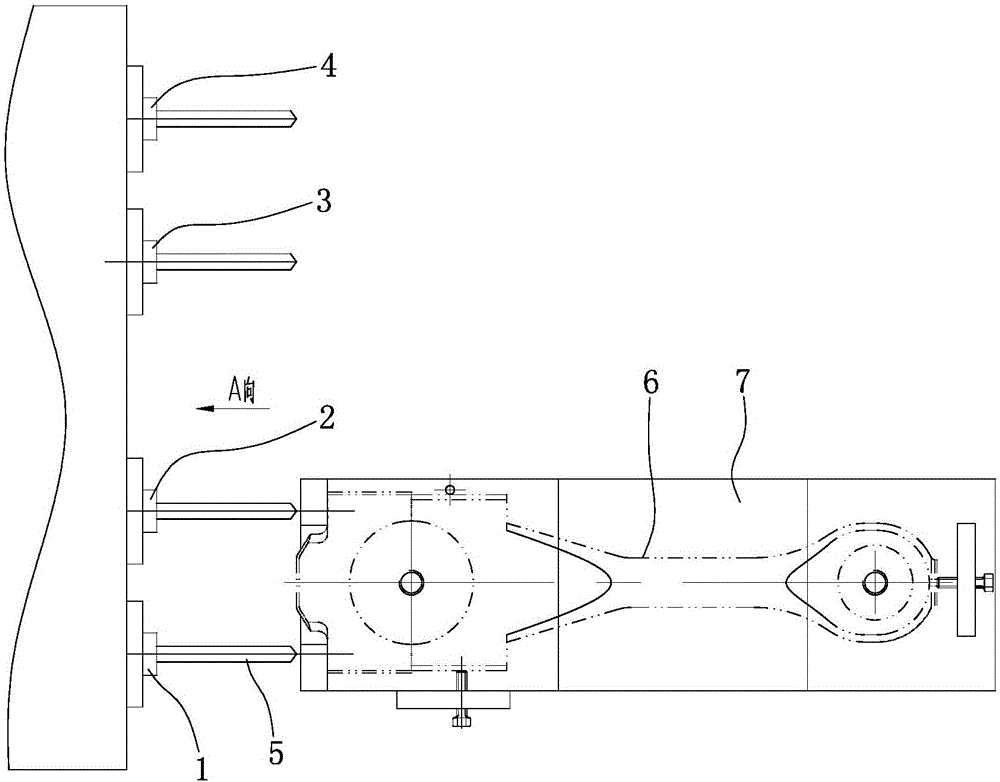

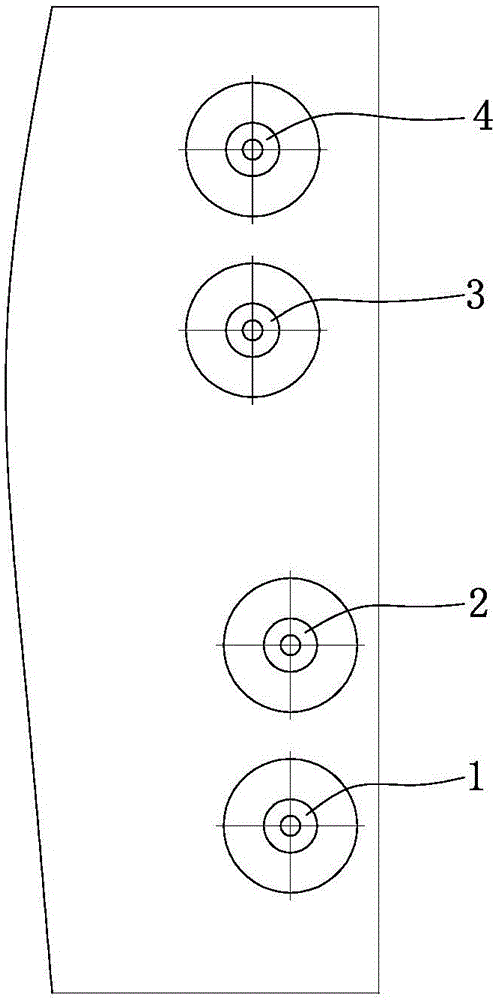

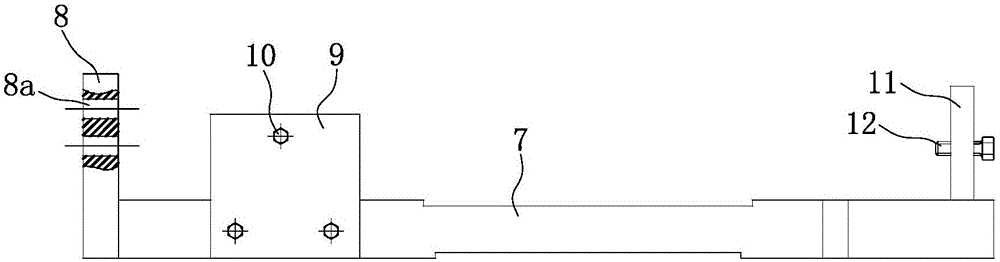

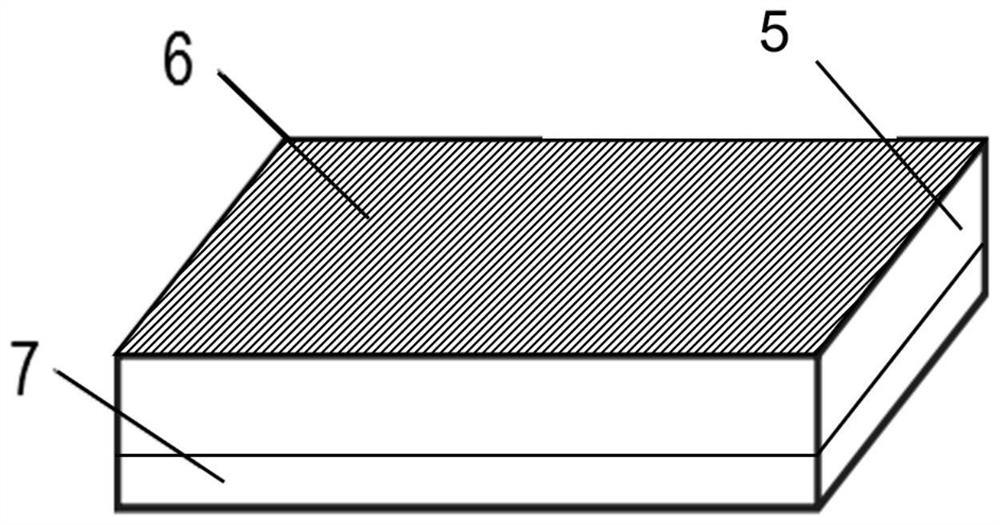

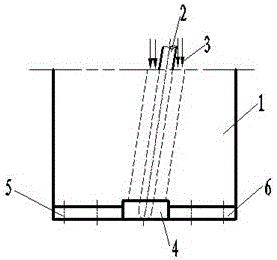

ActiveCN107234474ADimensional accuracy is easy to guaranteeEasy clampingTailstocks/centresPositioning apparatusDrive wheelReciprocating motion

The invention discloses a drive wheel end face drive finish turning clamp for a bevel gear. The drive wheel end face drive finish turning clamp for the bevel gear comprises a connection rod (1), a cover plate (2), a push plate (3), a drive pin (4), a centre (5), a clamp body (6) and a front cover (7). The clamp body (6) is connected with the front cover (7). The drive pin (4) is matched with a drive pin hole (72) of the front cover (7), and the centre (5) is matched with an inner cavity (73) of the front cover (7). The connection rod (1) is connected with the push plate (3) through the cover plate (2) to form a component which does reciprocating motion in an inner cavity (62) of the clamp body (6) to push the drive pin (4) and the centre (5) to position a workpiece. The drive wheel end face drive finish turning clamp for the bevel gear is simple and reliable, clamping is convenient, finish turning of a whole gear shaft can be finished at one-time clamping, the size precision of the shaft is guaranteed easily, and the efficiency is high.

Owner:GUILIN FUDA GEAR

Contour method for machining elliptic cam

InactiveCN1759988AGood quality and stabilityEasy to processBelt grinding machinesEllipseReciprocating motion

A technology for machining the elliptical cam on hobbing-relieving-grinding machine-tool by copying method includes such steps as making a copying elliptical cam, installing it onto the mainshaft of said machine-tool, regulating the machine-tool for synchronous rotation between mainshaft and copying elliptical cam, clamping the blank of the elliptical cam to be machined onto said machine-tool, and turning on the machine-tool to machine said blank until it become a finished product.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

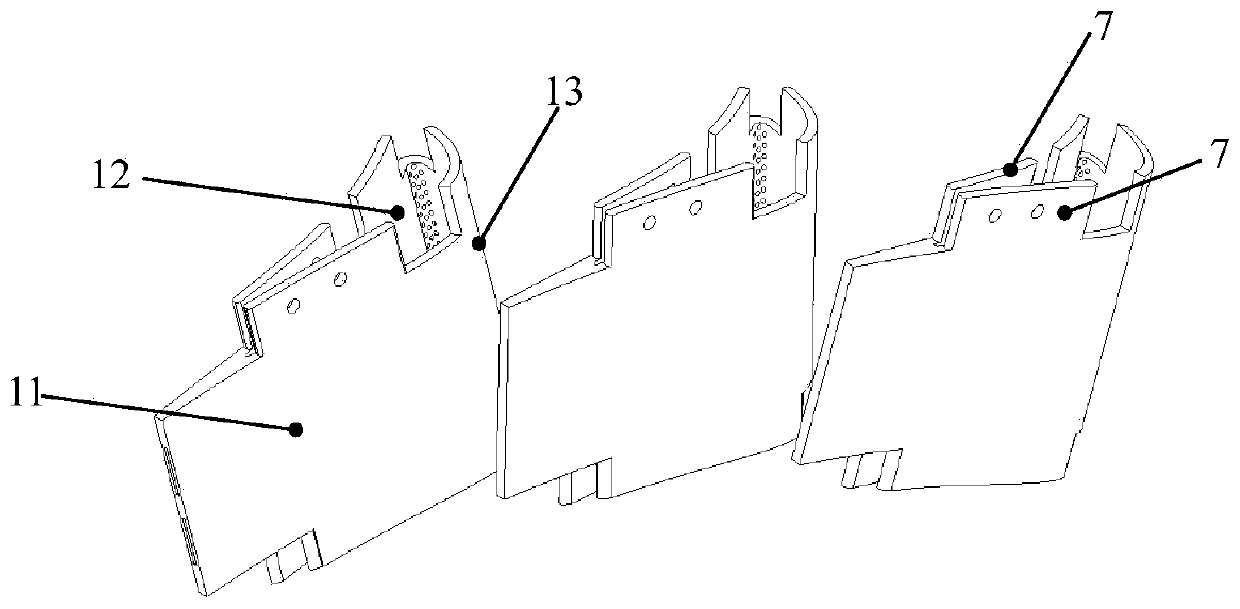

Assembled ultra-narrow gap MAG/MIG welding insulating spray nozzle

InactiveCN104923891AExtend working lifeSimple appearanceShielding gas supply/evacuation devicesWorking temperatureWorking environment

The invention relates to an assembled ultra-narrow gap MAG / MIG welding insulating spray nozzle which comprises a left insulating strip arranged on the left side of a current contact nozzle at the end of an ultra-narrow gap MAG / MIG welding gun body through a sunk screw, front-rear insulating plates and a right insulating strip, wherein the front-rear insulating plates and the right insulating strip are arranged in the middle and on the right portion of the end of the welding gun body respectively. According to the assembled ultra-narrow gap MAG / MIG welding insulating spray nozzle, the spray nozzle is improved to be of a 4-piece-assembled type from a traditional integral type, cracking, breakage and invalidation caused by large local work temperature difference are greatly lowered, and the service life of the spay nozzle is greatly prolonged; the region, with the highest risen temperature, of the spray nozzle under a long-term working environment is located at the front-rear insulating plates at the current contact nozzle, the allowable free expansion amount of the front-rear insulating plates is given in the design, manufacturing and mounting processes, in work, when the front-rear insulating plates are heated through strong thermal radiation of electric arc and convection current, the insulating spray nozzle extends freely totally without rigid constraint in the thermal expansion state, otherwise the spray nozzle can be shortened freely, so that the service life of the insulating spray nozzle is greatly prolonged.

Owner:武汉纳瑞格智能设备有限公司

Method of preparing channel steel by local heating and stepwise roll pressing

InactiveCN107398488AIncrease productivitySimple processMetal rolling arrangementsEngineeringStrip steel

The invention relates to a channel steel forming method, which belongs to the technical field of rolling, processing and forming of iron and steel materials. The forming process of channel steel is as follows: strip steel feeding → leveling → micro pressure → local heating → dovetail edge forming → cooling → step-by-step cold bending forming → straightening → blanking. The channel steel is prepared by local heating and multi-channel step-by-step roll forming. The dimensional accuracy of the prepared professional channel steel is easy to ensure, and the appearance is free of burrs. The production efficiency of channel steel produced by the method of the invention is high, the process is simple, and the obtained special channel steel has strong bearing capacity, long service life and low production cost.

Owner:TIANJIN LEYING TECH CO LTD

Shaping method of fine diameter cast iron profile material

InactiveCN1718320AImprove filling abilityAdjustable lengthWelding/cutting media/materialsSoldering mediaHigh rateCast iron

A method for preparing fine-diameter cast iron section includes such steps as putting a casting mould in a vacuum system, vacuumizing, filling molten iron in the cavity of mould via sprue cup under the action of vacuum, and solidifying in vacuum state. Its advantages are high rate of finished products and precision, and high quality.

Owner:XIAN UNIV OF TECH

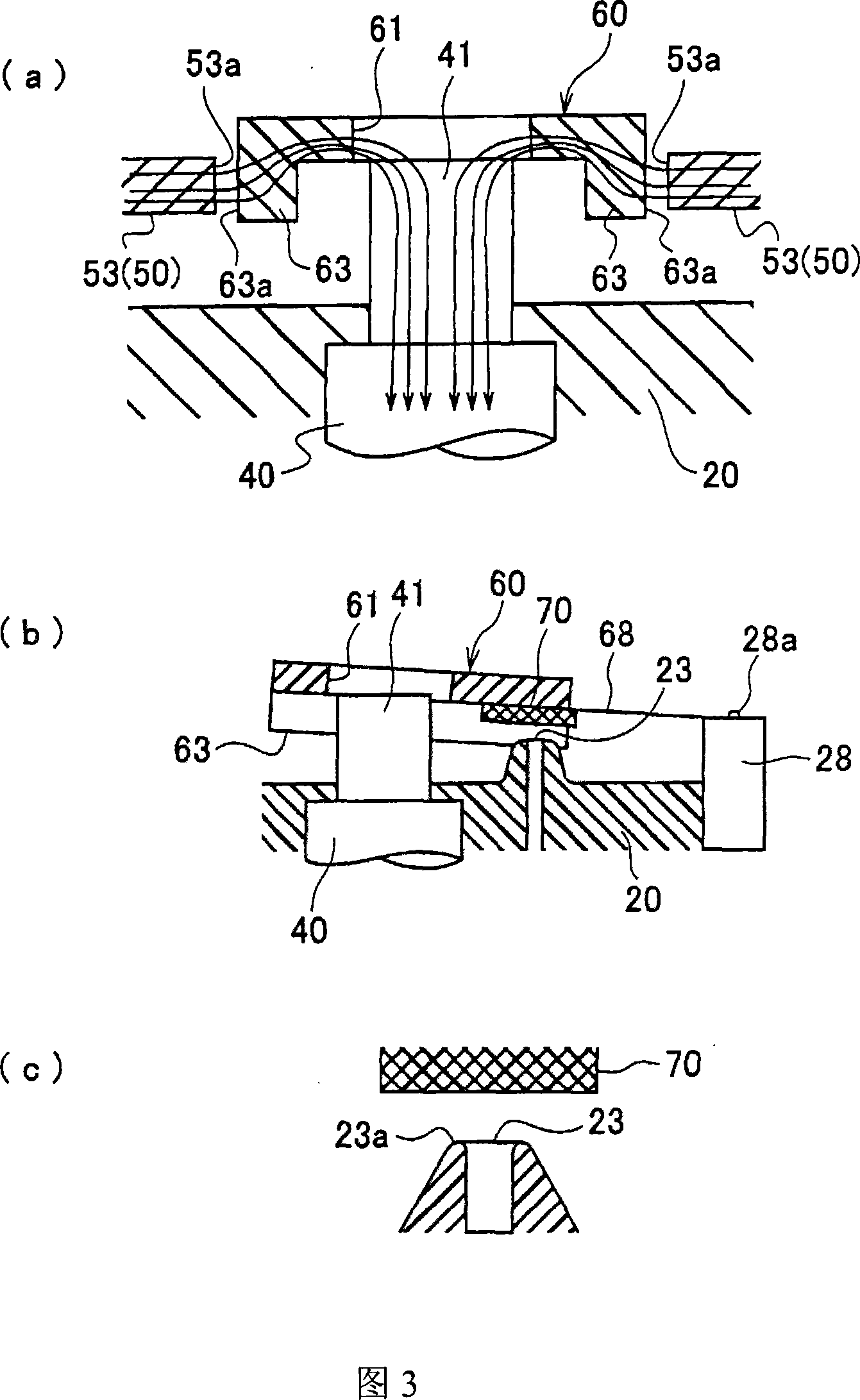

Electric-powered air release valve and blood pressure gauge

ActiveCN101055040AAvoid the phenomenon of being attracted to the fixed iron core sharplyControl discharge flowOperating means/releasing devices for valvesEvaluation of blood vesselsMagnetic tension forceBobbin

The present invention provides an electric exhaust valve of simple and compact structure easily assembled to reduce production cost and exhibiting stable characteristics regardless of the posture difference. The electric exhaust valve has a nozzle 23 provided at the end of an air passage 21 in a bobbin 20; a fixed iron core 40 disposed in the bobbin side by side with the nozzle; an exciting coil 30 magnetizing the fixed iron core by carrying a current; a movable iron piece 60 displaced toward the nozzle from its initial position according to the magnetic attracting force when the fixed iron core is magnetized; a plate spring 68 energizing the movable iron piece into the initial position; a rubber valve 70 provided at the movable iron piece to adjust the opening of the nozzle; and a yoke 50 with its tip parts facing both side parts of the movable iron piece through magnetic gaps. The movable iron piece is formed with a circular hole 61 into which one end cylindrical part 41 of the fixed iron core can intrude when the movable iron piece is displaced toward the nozzle, and a magnetic gap is secured between the inner periphery of the circular hole and the outer periphery of the one end cylindrical part.

Owner:NIPPON SEIMITSU SOKKI KK

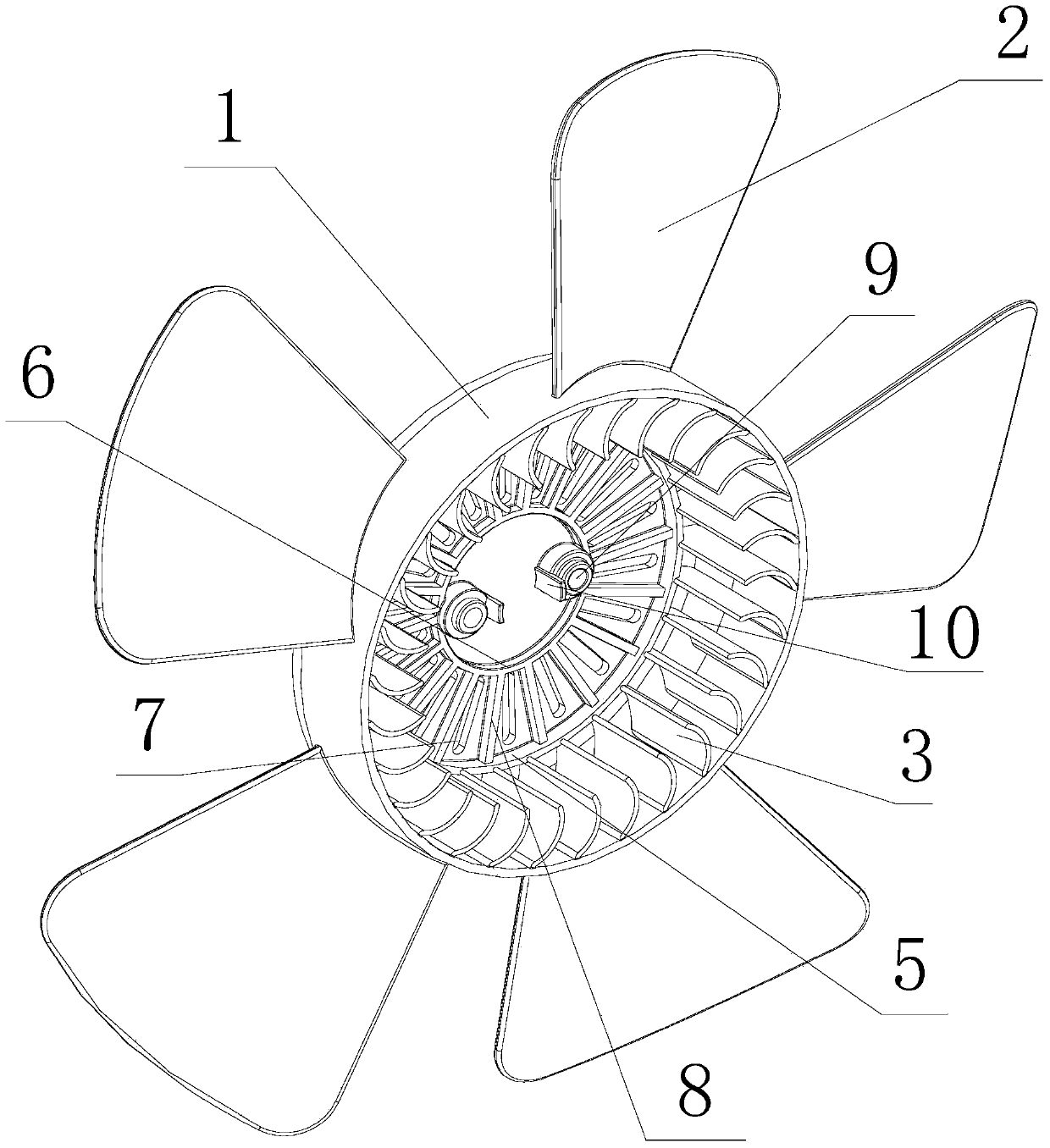

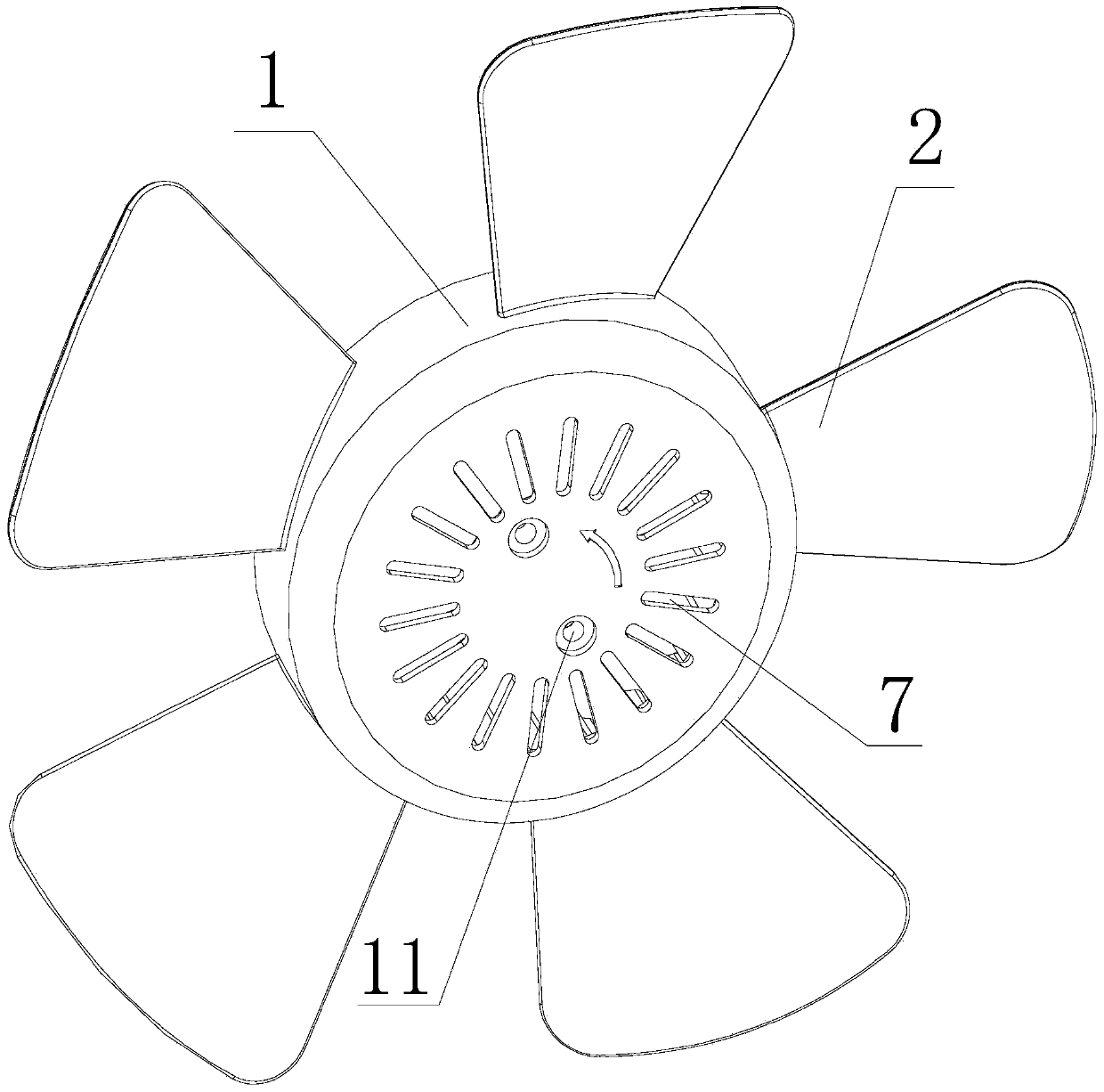

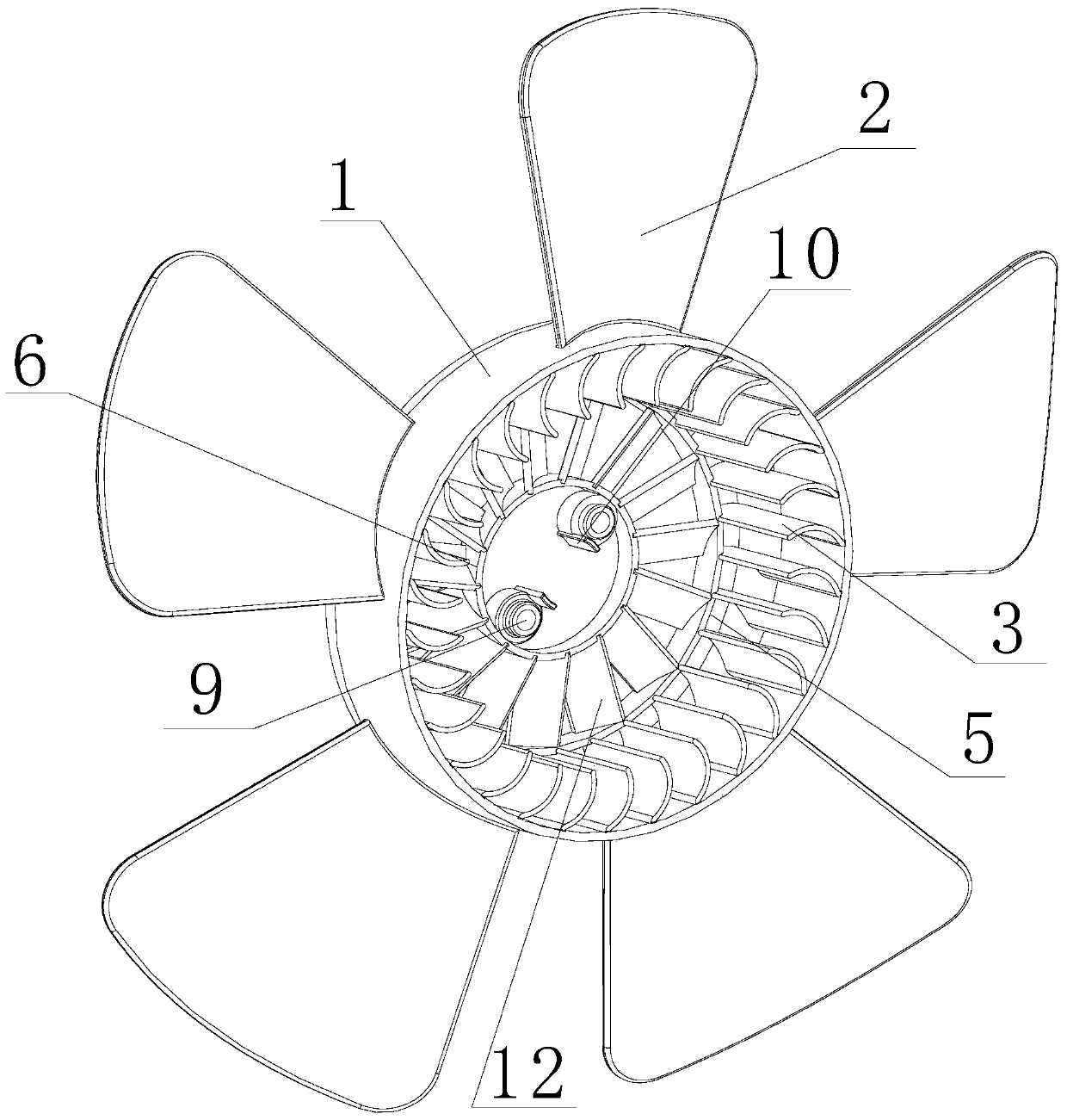

Multifunctional fan blade hub

The invention provides a multifunctional fan blade hub. The multifunctional fan blade hub comprises a hub body and axial flow blades arranged on the outer circumferential surface of the hub body. The inner wall of the circumference of the hub body is provided with multiple centrifuge blades which are arranged evenly at intervals. The long edge of the axial side of each centrifuge blade is arranged on the inner wall of the circumference of the hub body. According to the multifunctional fan blade hub, the mode that an original hub is directly connected with a motor shaft through a single shaft is changed into the mode that the hub is directly connected with an armature through bosses, so that the connection stability is guaranteed, jumping between the hub and the armature is reduced, and the balancing performance is improved; when the multifunctional fan blade hub is applied to a matching fan, the ambient environment can be cooled, and a motor in the hub body can be effectively cooled through heat dissipation holes or cooling fins, so that the reliability of the fan is improved, and the service life of the fan is prolonged; the multifunctional fan blade hub is not provided with inserts and is integrally formed, so that the size precision of the blades is guaranteed more easily.

Owner:SHANGHAI MALU RI YONG JEA GATE ELECTRIC +2

Tool for bending electrostatic ring lead of transformer

InactiveCN101651027AFlat shapeNice appearanceInductances/transformers/magnets manufactureUnwanted magnetic/electric effect reduction/preventionTransformerEngineering

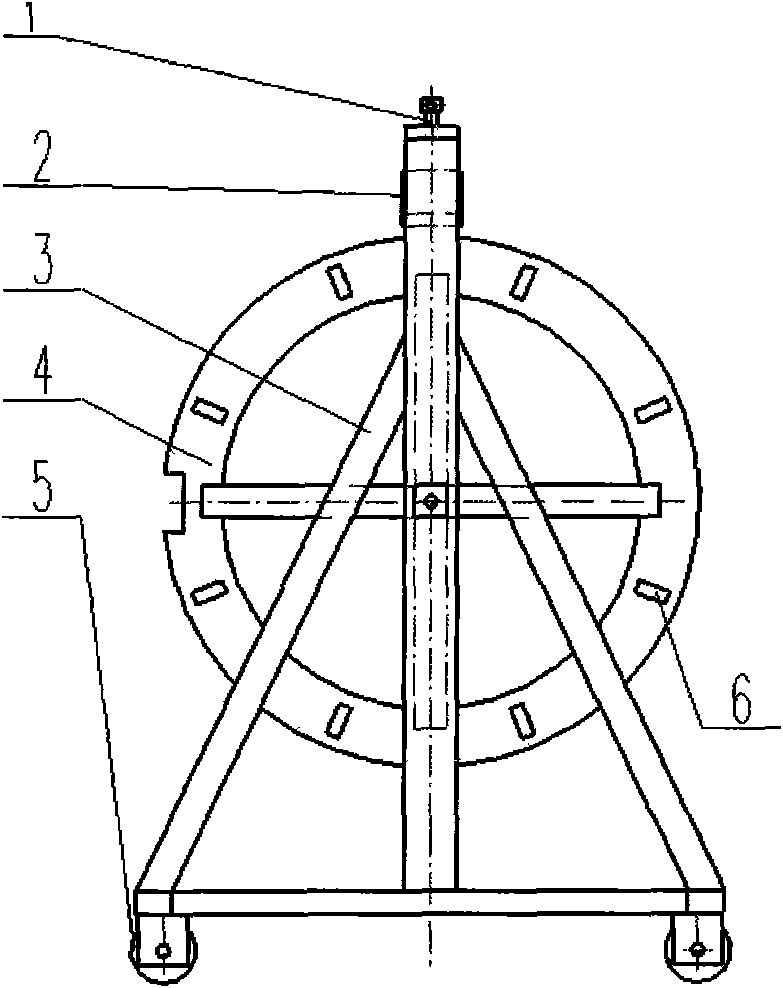

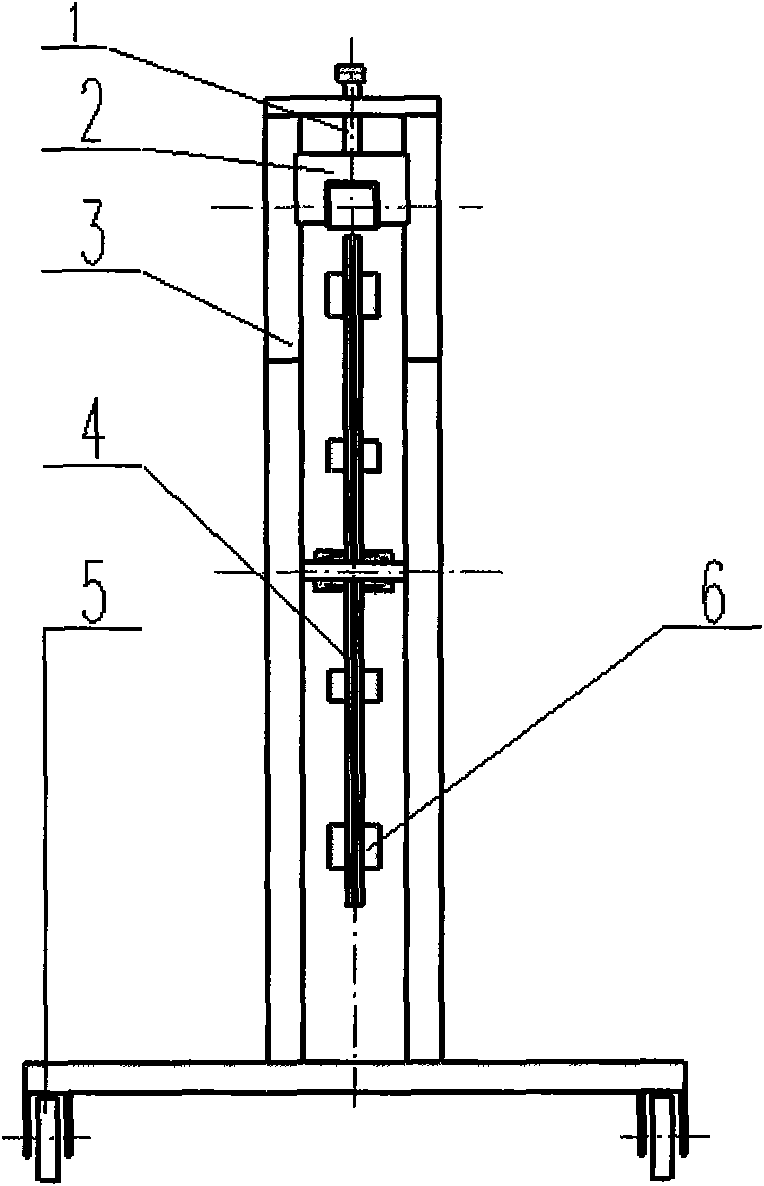

The invention provides a tool for bending an electrostatic ring lead of a transformer, belonging to technical field of transformer manufacture and comprising a contact roller, a support, a rotation disc, and a hold-down mechanism used for regulating the radial clearance between the contact roller and the rotation disc, wherein the rotation disc and the hold-down mechanism are respectively arrangedon the support, the contact roller is connected to the hold-down mechanism; the outside circumferential surface of the rotation disc is provided with a circumferential slot; the width of the circumferential slot adapts to the thickness of the electrostatic ring lead of the transformer; the contact roller is arranged outside the outside circumferential surface of the rotation disc; and the axial line of the contact roller is parallel to the axial line of the rotation disc. The invention changes manual manufacture into tool manufacture, thereby creating a brand-new method for producing an electrostatic ring, improving work efficiency reducing the technical content of operation, and being is easy to learn and operate; the appearance of a bent forming copper bus is smooth and attractive, andthe dimension precision is easy to guarantee; the appearance of the bent forming copper bus has no scratches or sharp angles, and the electric property is higher. The tool has small volume and can beflexibly moved.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

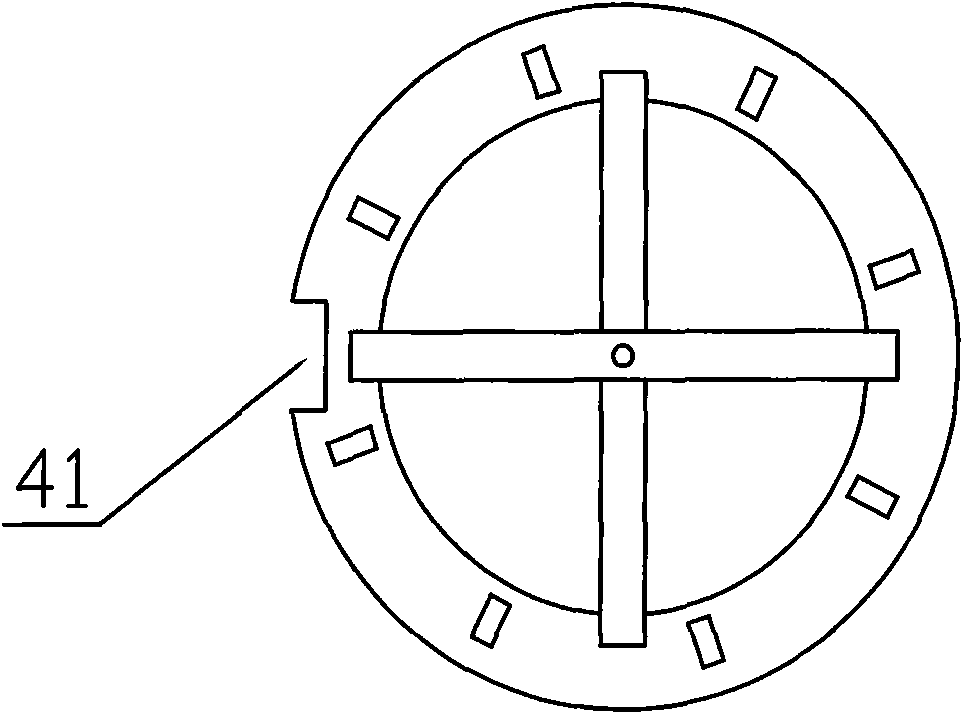

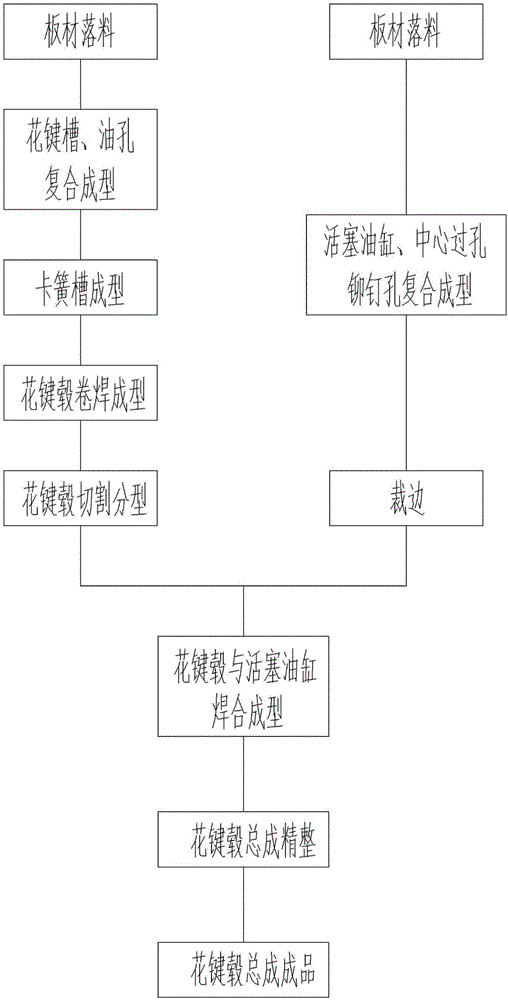

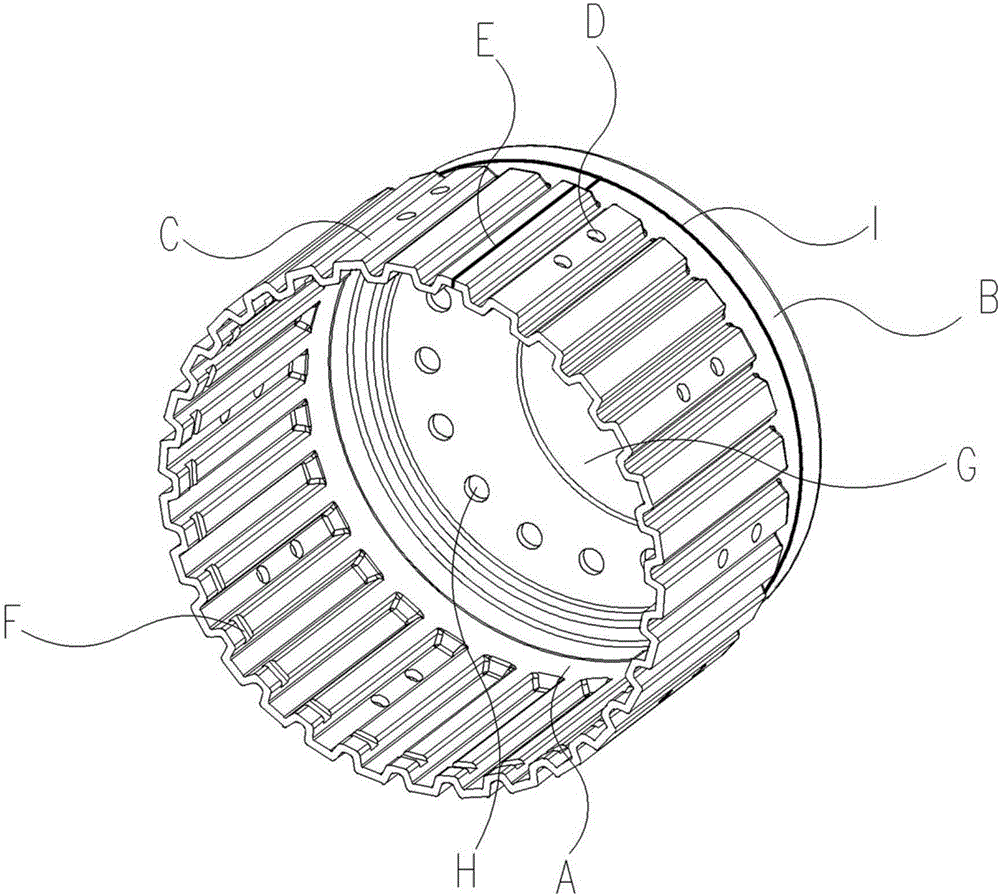

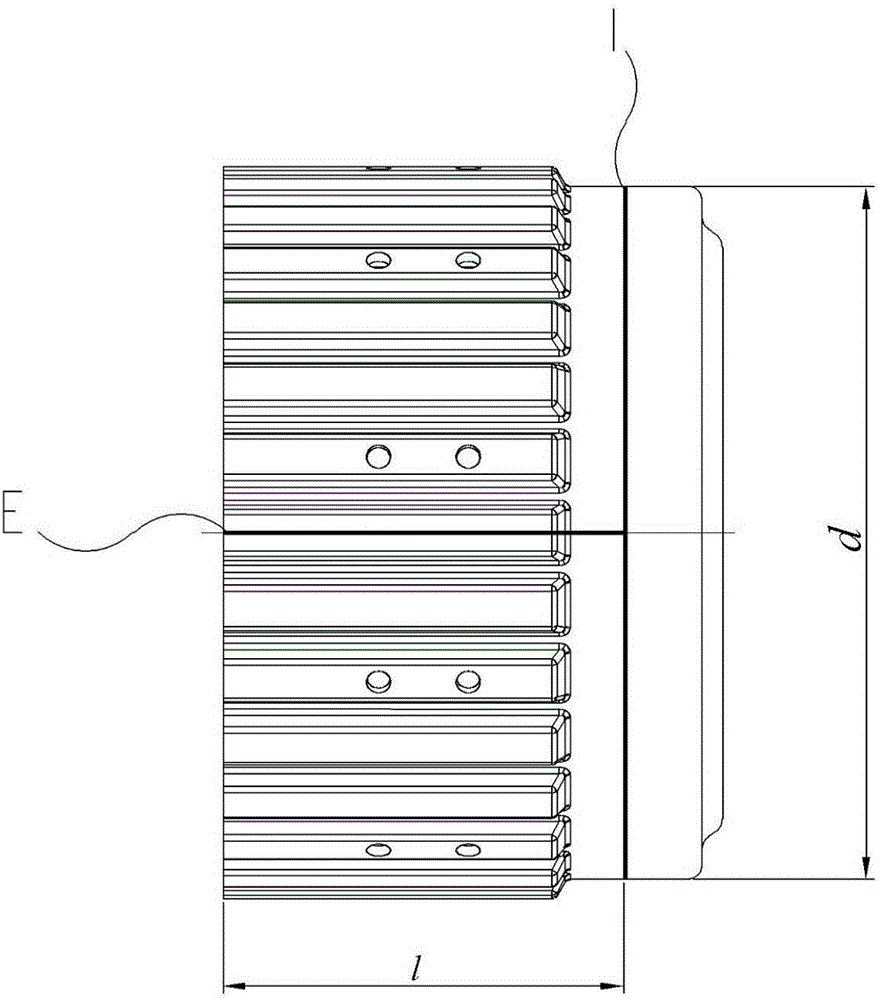

Manufacturing method for stamping and welding forming of sheet of clutch spline hub assembly

ActiveCN106736305AGuaranteed dimensional accuracySimple structureFriction clutchesEngineeringMachining

The invention relates to a manufacturing method for stamping and welding forming of a sheet of a clutch spline hub assembly. The manufacturing method is characterized in that the clutch spline hub assembly is structurally regarded as two parts of a spline hub and a piston oil cylinder body, firstly, the spline hub and the piston oil cylinder body are manufactured separately; then the spline hub and the piston oil cylinder body are welded into a semi-finished product of the spline hub assembly; and finally a finished product is obtained through finishing. The manufacturing processes of the spline hub comprise board blanking, spline groove stamping, oil hole stamping, clamp spring groove forming, spline hub winded welding and spline hub cutting and parting in sequence. The manufacturing processes of the piston oil cylinder body comprise board blanking, piston oil cylinder body stamping forming, central via hole stamping, rivet hole stamping and edge cutting in sequence. The manufacturing method has the characteristics that the spline hubs are manufactured through group processing in two-by-two mode by utilizing boards, then cutting is conducted to form two independent spline hub blanks, next one spline hub blank and the piston oil cylinder body are welded and formed, and finishing is conducted to obtain the spline hub assembly product. The manufacturing method has the advantages of high machining efficiency, material saving, easily-controlled size precision and low cost.

Owner:HEFEI UNIV OF TECH

Machining method for deep hole of marine engine connecting rod

ActiveCN106346046AMachining accuracy is easy to guaranteeEasy to operatePositioning apparatusMetal-working holdersPosition toleranceProcessing cost

The invention discloses a machining method for deep hole of marine engine connecting rod. The method comprises the following steps: Firstly, a tool is installed for positioning the connecting rod on the work table of the machine tool, and a total of four main axes is arranged on the machine tool, each of which is provided with a gun drill. Secondly, the connecting rod to be processed is fixed to the tooling. Thirdly, the table is fast moved to the first station, so that the first spindle and the second spindle on the gun drill slowly into the tooling of the guide sleeve hole, while processing two lower bolts of connecting rod through the hole. Fourthly, the table is fast moved to the second station, so that the third spindle and the fourth spindle on the gun drill slowly into the tooling guide sleeve hole, while processing two head bolts of connecting rod through the hole. Fifthly, when processing is completed, the table is moved back to the reference point. The invention can complete all the processing, and the clamping operation is simple, and the processing efficiency is high, and the invention also can reduce the processing cost twice, and the dimensional accuracy, the shape and position tolerance are easy to be guaranteed.

Owner:CHONGQING YUEJIN MACHINERY

Channel steel forming method

The invention provides a channel steel forming process and belongs to the technical field of steel and iron material rolling and forming. The channel steel forming process comprises the steps of strip steel conveying and feeding, leveling, micro-pressing, local heating, dovetail edge forming, cooling, step-by-step rolling, straightening and discharging. The channel steel forming process has the advantages that channel steel with dovetail groove edges can be obtained and synchronous movement of a strip steel conveying and discharging mechanism can be achieved by adopting the processes of local heating and step-by-step continuous roll forming when ribbon steel is utilized to manufacture channel steel. By the adoption of the channel steel forming process for channel steel manufacture, energy sources are saved, the production efficiency is high, and the produced channel steel is high in shape and size accuracy and good in bearing capacity.

Owner:丁春燕

Contour method for machining elliptic cam

InactiveCN100448613CGood quality and stabilityEasy to processBelt grinding machinesEllipseReciprocating motion

A technology for machining the elliptical cam on hobbing-relieving-grinding machine-tool by copying method includes such steps as making a copying elliptical cam, installing it onto the mainshaft of said machine-tool, regulating the machine-tool for synchronous rotation between mainshaft and copying elliptical cam, clamping the blank of the elliptical cam to be machined onto said machine-tool, and turning on the machine-tool to machine said blank until it become a finished product.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

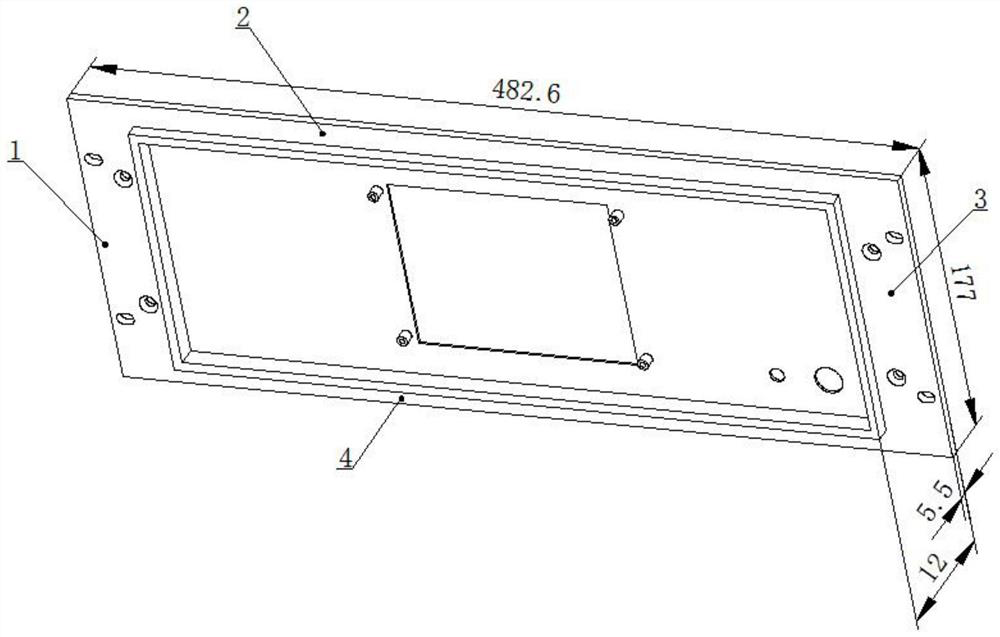

Case panel machining method

ActiveCN112975013ASolve the deformationDimensional accuracy is easy to guaranteeNumerical controlElectric machine

A case panel machining method mainly comprises the technological steps of wire-electrode cutting electric machining blanking and numerical control milling. A universal multi-process and multi-work-type machining technology is changed, a wire-electrode cutting electric machining mode is adopted for blanking, and a plane, a cavity and a rectangular annular flange are milled in a numerical control mode in the length direction for machining, so that the deformation problem in the machining process can be effectively solved, the dimensional precision is easy to guarantee, the quality is stable and consistent, the surface quality is good, the planeness is smaller than 0.1 mm, a heat treatment destressing procedure is not needed, the production process is compact, concentrated and short, the machining cost is low, the production period is short, and safety and reliability are achieved.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

Aeroengine ceramic matrix composite fixed guide vane structure and its molding

ActiveCN111102017BAvoid the defects of insufficient strengthGood workmanshipEfficient propulsion technologiesStatorsEngineeringTurbojet engine

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

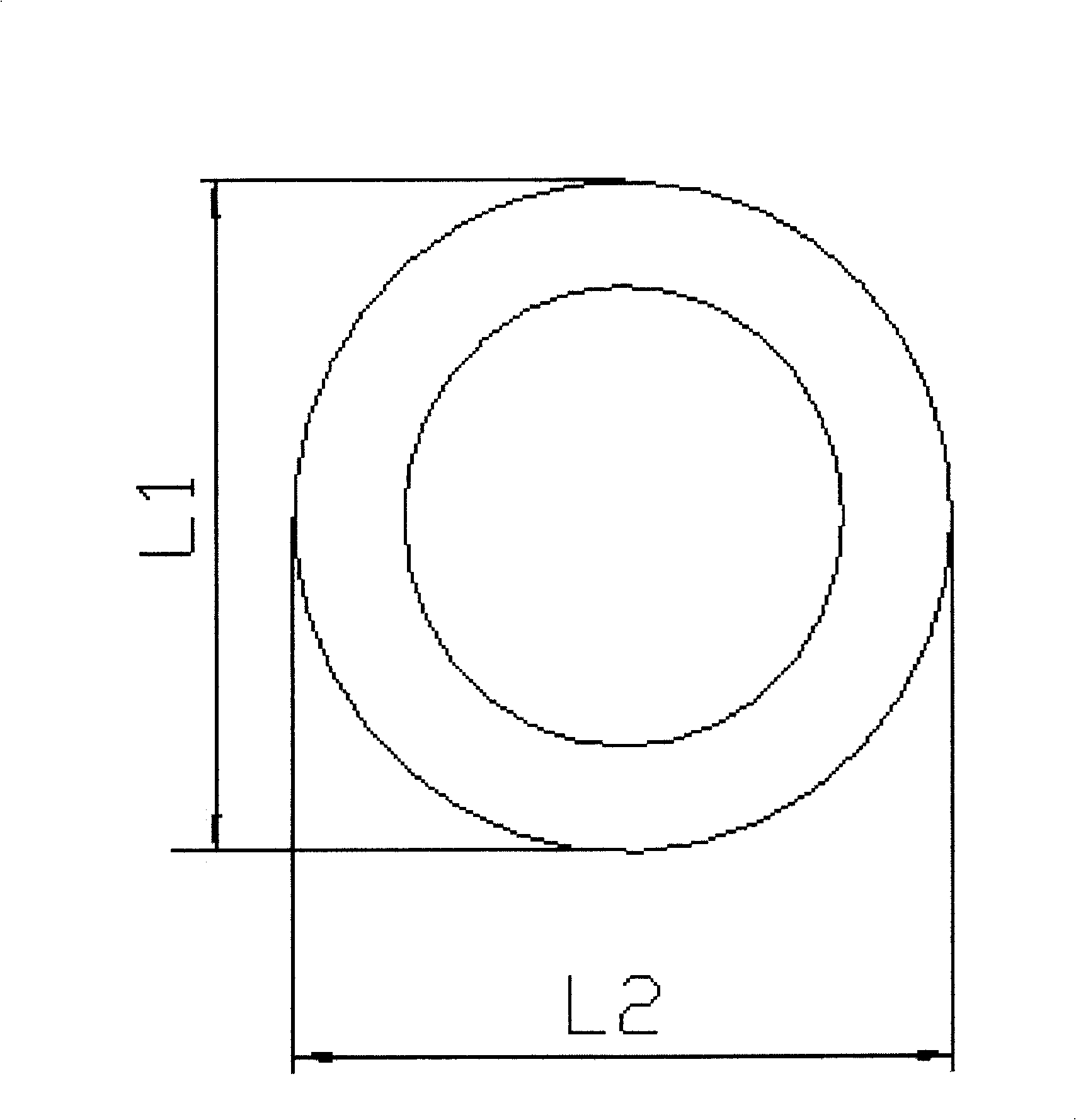

Annular airbag display for dust collector

InactiveCN101732007ADimensional accuracy is easy to guaranteeSimple processing technologySuction filtersEngineeringDisplay device

The invention provides an annular airbag display for a dust collector. The display comprises a shell, a movable indicating body arranged in the shell and a cover connected to the shell, wherein the shell is a round shell of which one end is open while the other end is closed; the center of the closed end is provided with a round convex column projecting inwards; the upper part of the shell is provided with a boss inserted into a display window; the lower part of the shell close to the closed end is provided with an air outlet; the four sides of the indicating body are depressed inwards to form a concave part of which the middle is provided with projecting positioning column; an annular airbag arranged on the round convex column of the shell is also provided; the other end of the annular airbag is inserted into the positioning column of the indicating body; and the middle of the cover is provided with an air inlet, which closes the shell by a disk part and is connected to the shell. The annular airbag is used as a resetting element of the indicating body, and gas with set pressure is filled in the airbag in advance, so the annular airbag display is opened under specific pressure. The size accuracy of the airbag is easy to be ensured and the processing technique is simple, so the indicating body acts correctly and the acting failure rate of the indicating body is lowered.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Structure and Forming of Aeroengine Ceramic Matrix Composite Fixed Guide Vane

ActiveCN110966049BAvoid the defects of insufficient strengthGood workmanshipStatorsMachines/enginesAviationTurbine

The invention belongs to the technical field of preparation of fixed guides of aero-engines, and relates to a blade structure of a fixed guide made of a ceramic matrix composite material of an aero-engine and its forming. To overcome the structural defects of unreasonable design of the existing CMC guide vane prefabrication and poor blade root strength, the turbine guide vane including multi-stage guide vanes is prepared by integrated assembly method, and the parts are integrated and assembled by riveting, and the assembly structure is realized by SiC ceramic matrix "Welding"; and make full use of the effective space between the upper edge plate and the outer casing, install and position the blade body and the upper edge plate through limit rivets and limit platforms, and use CVI technology to deposit SiC ceramic substrates on the entire product , to complete the integrated preparation. This structure makes the complex SiC / SiC multi-connected high-pressure guide vane have good manufacturability, the preparation of the edge plate and the vane is simpler, the installation is more reliable, and the dimensional accuracy of the final product is easier to guarantee. This structure can be fully applied to medium and large engines and fifth-generation aircraft.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

A Welding Method for Reducing Electrolyzer Voltage Drop

ActiveCN110064807BImprove wettabilityEasy deformation guaranteeWelding/cutting media/materialsSoldering mediaBusbarVoltage drop

The invention discloses a welding method for reducing the voltage drop of an electrolytic cell. Firstly, the surface to be welded at the junction of a column busbar and a short-circuit busbar is polished and cleaned, and the two are closely attached together. Prepare the corresponding amount of solder and flux in advance according to the number of electrolytic cells to be welded. Next, select an aluminum plate with a suitable size, apply a layer of flux on the surface of the aluminum plate, then heat the aluminum plate and apply a layer of solder. Apply a layer of flux on the surface of the workpiece to be welded, and after confirming that it is correct, attach the aluminum plate to the surface to be welded and fix it. Finally, the workpiece is uniformly heated for a short period of time and then cooled to room temperature to complete the weld. After the unit has cooled completely to room temperature, it is cleaned and sanded to remove debris and bring the appearance to specification. The construction method of the invention is simple, the cost is low, and the voltage drop of the electrolytic cell can be obviously and effectively reduced without damaging the electrolytic cell.

Owner:WUHAN UNIV

An assembled ultra-narrow gap mag/mig welding insulating nozzle

InactiveCN104923891BExtend working lifeSimple appearanceShielding gas supply/evacuation devicesWorking temperatureWorking environment

The invention relates to an assembled ultra-narrow gap MAG / MIG welding insulating nozzle, which comprises a left insulating strip installed on the left side of the conductive tip of the ultra-narrow gap MAG / MIG welding gun body end through a countersunk head screw, respectively installed on the welding gun body Center and right front and rear insulation panels and right insulation strips at the ends. The nozzle of the present invention is improved from a traditional integral type to a 4-piece assembly type, and the cracking failure caused by a large local working temperature difference is greatly reduced, and the working life of the nozzle is greatly improved; the area with the highest temperature rise in the long-term working environment of the nozzle is located at the conductive tip The front and rear insulating plates of the part are designed, manufactured and installed with the allowable free expansion and contraction. When the strong thermal radiation and convection of the arc heat the front and rear insulation during work, the thermal expansion state can be freely elongated without rigid constraints. , On the contrary, it can be freely shortened, which is an important reason for the substantial increase in its working life.

Owner:武汉纳瑞格智能设备有限公司

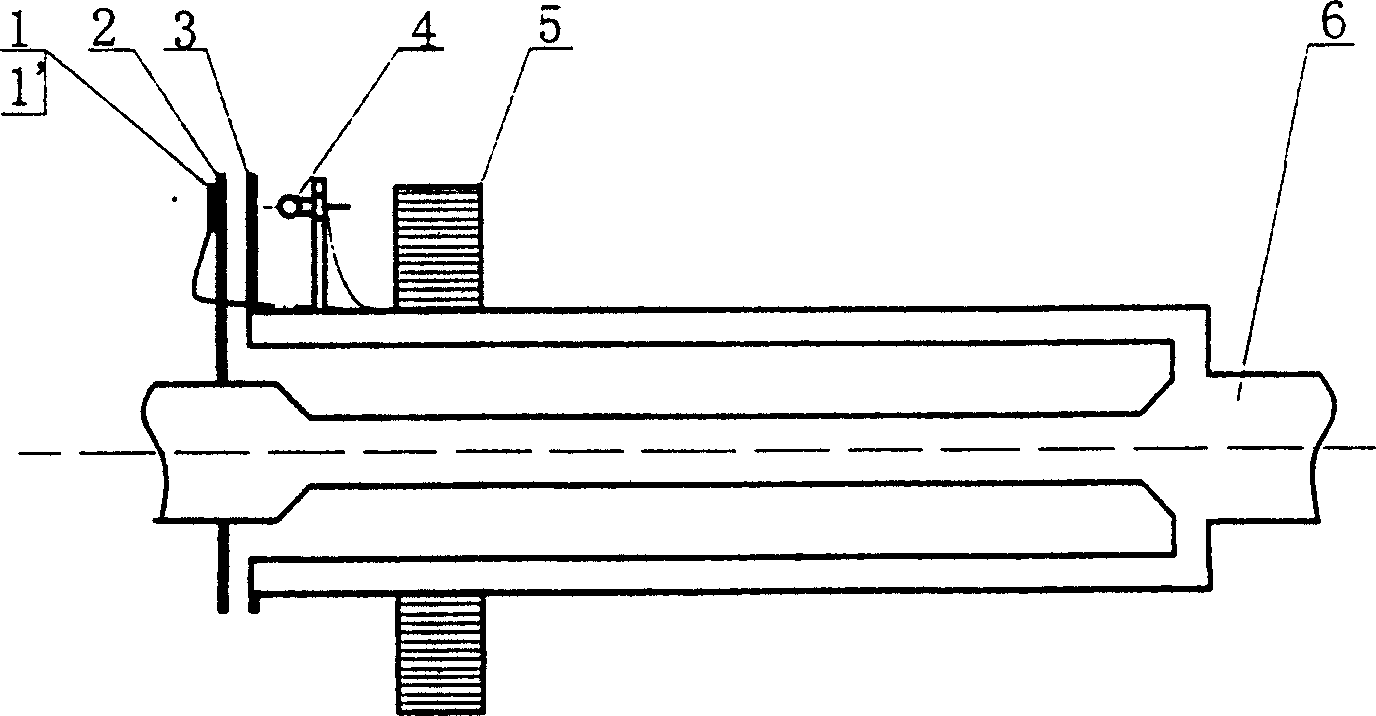

Photoelectric torque sensor for vehicle

InactiveCN1156678CSimple structureDimensional accuracy is easy to guaranteeWork measurementTorque measurementElectric power steeringTransducer

A torque transducer in photoelectric type for vehicle belonging to special electronic equipment of transport vehicle is a photoelectric torque transducer in non-contacting type, which mainly composes of two photoelectric cells, a light-transparent arm with light-transparent hole and a light barrier arm with light-uiding hole, luminous diode, torsion bar and pencil of conducting line. The light transparent arm and light barrier arm are fixed at two ends of torsion bar separately, the photoelectric cell and luminous diode will be placed at outer side of light-transparent arm and light barrier arm separately and the conducting wires of photoelectric cell and luminous diode will be connected with outside through winding box. The invented transducer has simple structure, high accuracy measurement and no limitative of measuring range and it is especially good for measurement of steering torque in power-assisted steering system.

Owner:TSINGHUA UNIV

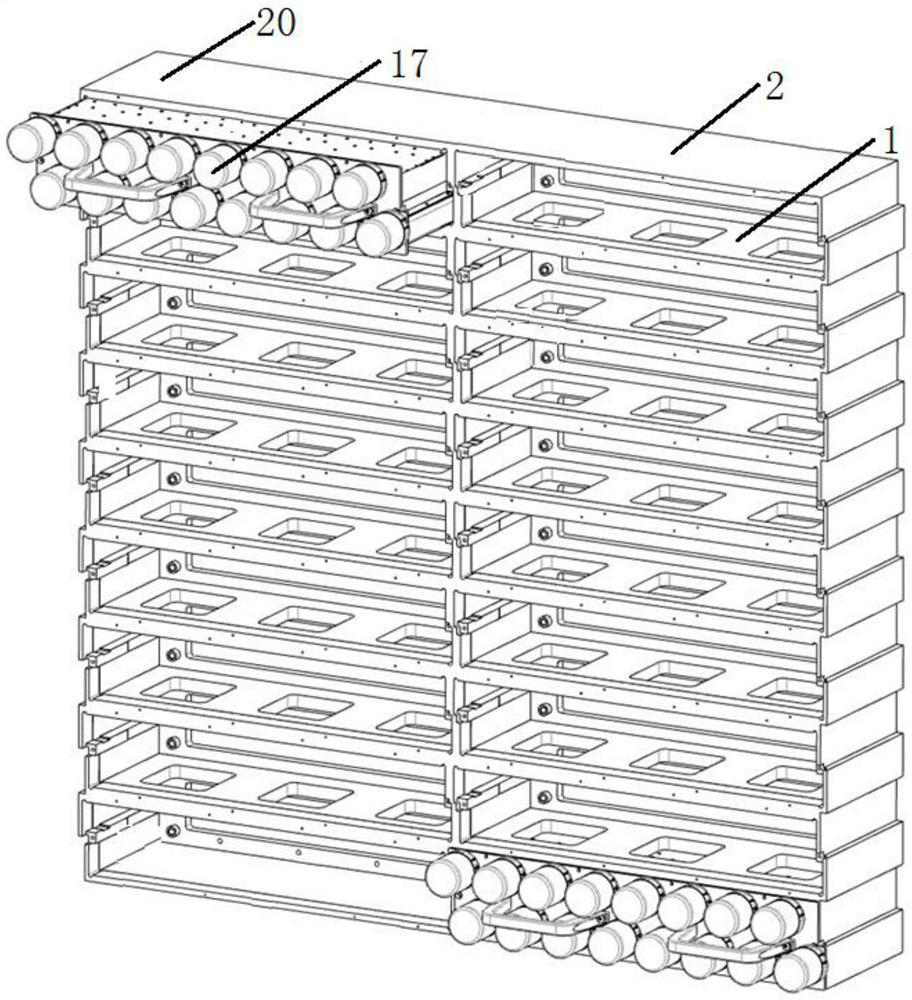

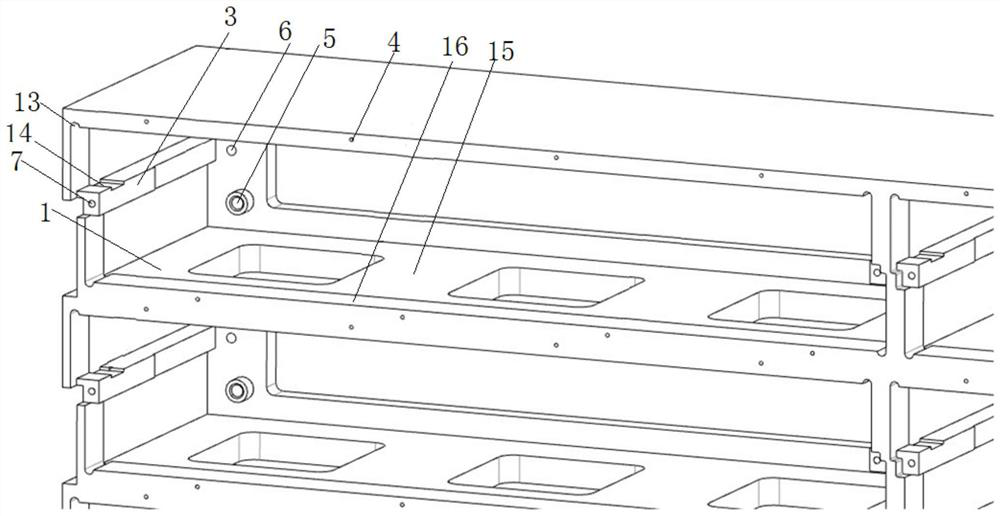

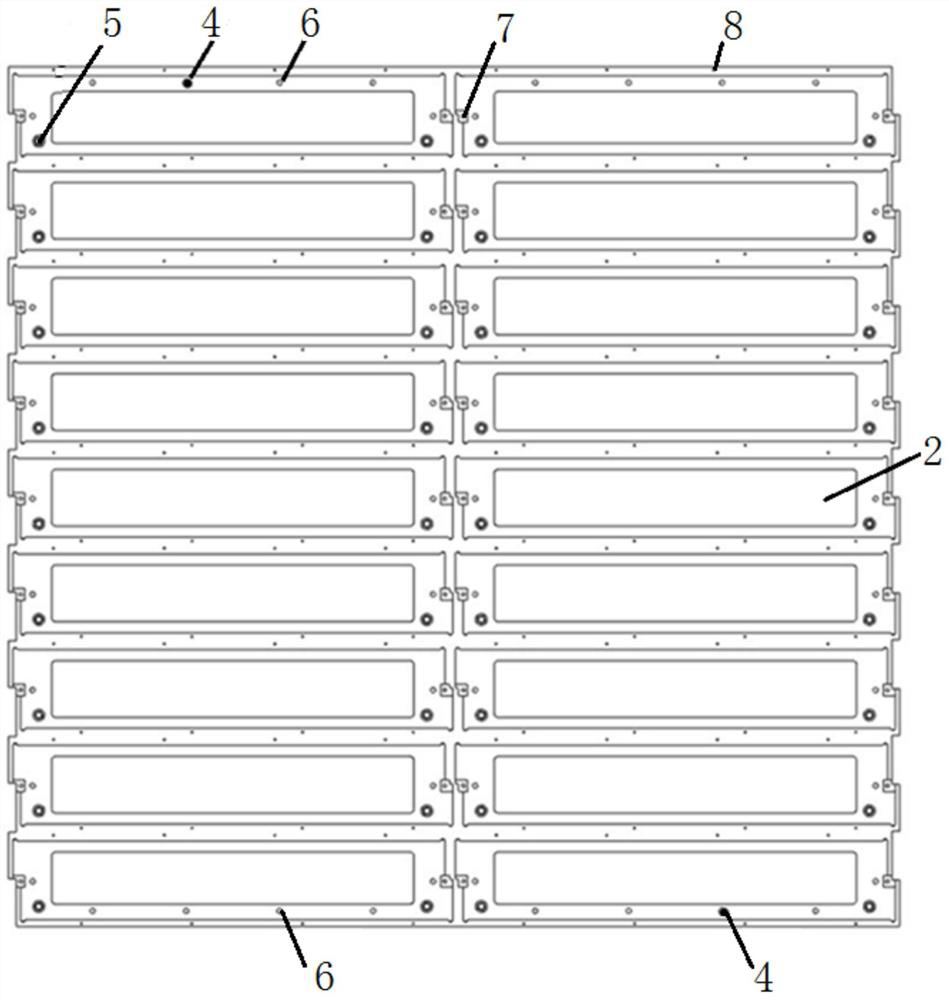

A kind of honeycomb support and module assembly for installing module assembly

The invention discloses a honeycomb support and a module assembly for installing a module assembly, comprising a plurality of support units arranged in an N×M array, N≥1, M≥1, each support unit is provided with a first Opening, the rear end is provided with a second opening, the upper and lower sides of the first opening are respectively provided with the first installation interface for connecting the module assembly, and the two sides of the bottom of the second opening are respectively provided with the first installation interface for connecting the lower end surface of the module assembly. A positioning interface, the inner walls on both sides of the support unit are respectively provided with guide rails for positioning the module components, the guide rails are perpendicular to the first opening surface, and the area around the inner wall of the support unit is 1 / 5 from the front end to the rear end. The processing surface and the rest are non-processing surfaces. The invention integrates the installation and support structure of the module components into a honeycomb support. Both the support units of the module components and the honeycomb support have two-dimensional array expandability, which improves the installation accuracy.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

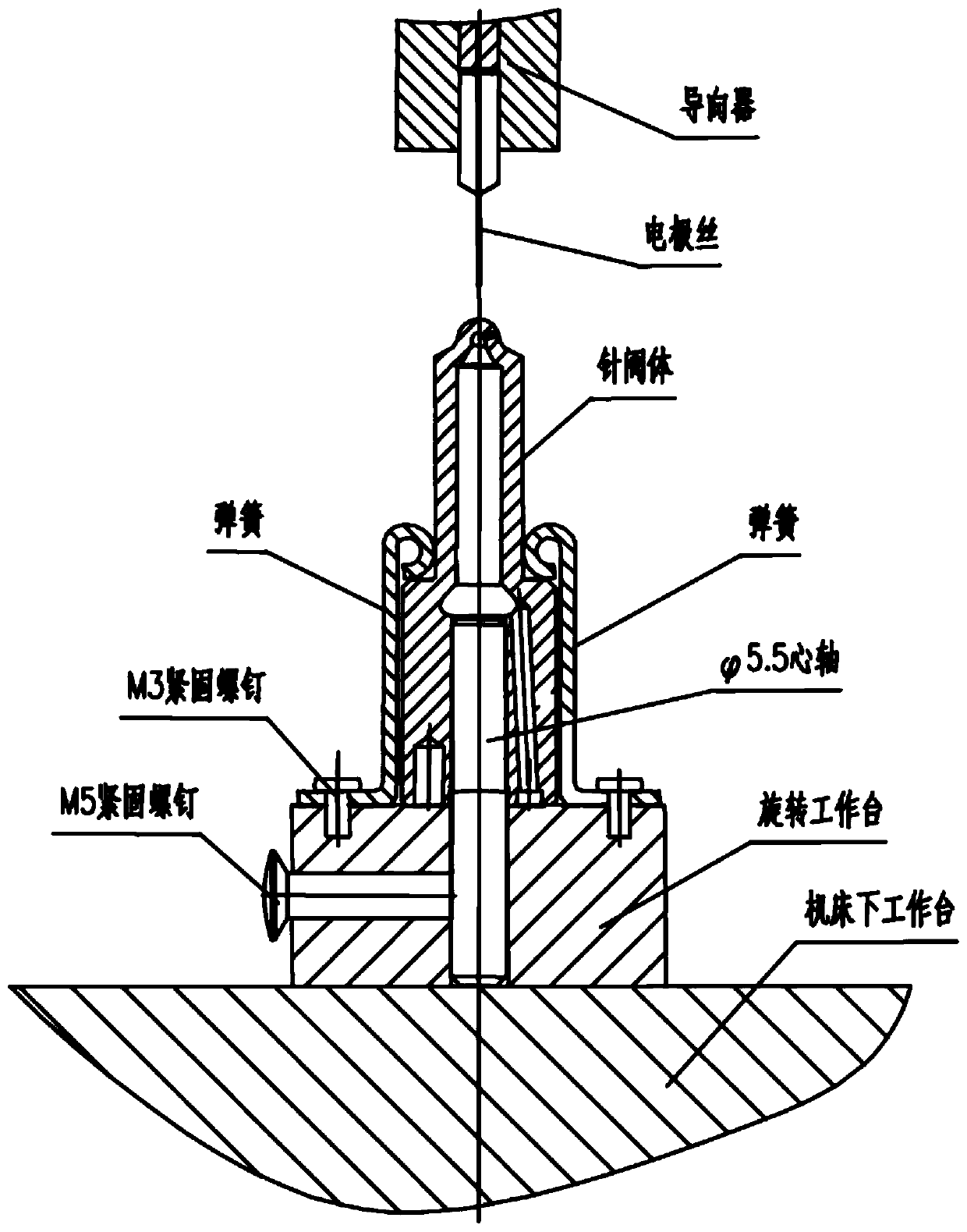

Multifunctional micro metering hole electric spark machining clamp

PendingCN111112765ASolve the problem of deviationQuick swapElectrical-based auxillary apparatusSpool valveElectrical discharge machining

The invention discloses a multifunctional micro metering hole electric spark machining clamp. The multifunctional micro metering hole electric spark machining clamp comprises a base, a clamping blockI and a clamping block II, wherein the center of the base is provided with a variable diameter hole, and the diameter of an upper hole is smaller than the diameter of a lower hole in the variable diameter hole; a positioning shaft I is arranged at the bottom of the clamping block I, the diameter of the positioning shaft I is matched with the diameter of the upper hole, an eccentric sliding valve mounting groove is formed in the upper part of the clamping block I, and a to-be-machined sliding valve is arranged in the sliding valve mounting groove; a positioning shaft II is arranged at the bottom of the clamping block II, the diameter of the positioning shaft II is matched with the diameter of the upper hole, an eccentric valve block mounting groove is formed in the upper part of the clamping block I, and a to-be-machined valve block is arranged in the valve block mounting groove; when the clamp is used for machining the sliding valve, the clamping block I is arranged on the base, and the sliding valve is arranged into the clamping block I; and when the valve block is machined, the clamping block II is arranged on the base, and the valve block is arranged in the clamping block II. The multifunctional micro metering hole electric spark machining clamp has the advantages that the clamp assembly is simple in structure, clamping of an operator is fast, the manufacturability is high,the machining freedom degree of a part is reasonably limited, and the size precision of the pat is guaranteed easily.

Owner:STATE RUN NO 616 FACTORY

Groove steel forming method

The invention provides a groove steel forming process and belongs to the technical field of steel and iron material rolling forming. The groove steel forming process comprises the steps of band steelconveying feeding, leveling, micro-pressing, local heating, dovetail edge forming, cooling, step-by-step rolling forming, straightening and discharging. The groove steel forming process has the advantages that when narrow band steel is utilized to manufacture groove steel, groove steel with a dovetail groove edge can be obtained through the process of local heating and step-by-step continuous rolling forming, and synchronous motion of band steel conveying and a discharging mechanism can be achieved. By adopting the groove steel forming process to manufacture the groove steel, energy sources are saved, the production efficiency is high, and the produced groove steel is high in shape and size precision and high in bearing capacity.

Owner:吴红霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com