Electric-powered air release valve and blood pressure gauge

一种排气阀、电动的技术,应用在血压计领域,能够解决影响测量精度、可动部分重、排气特性变化等问题,达到高精度血压测量、改善控制特性、组装作业容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, various embodiments of the present invention will be described in detail with reference to the drawings.

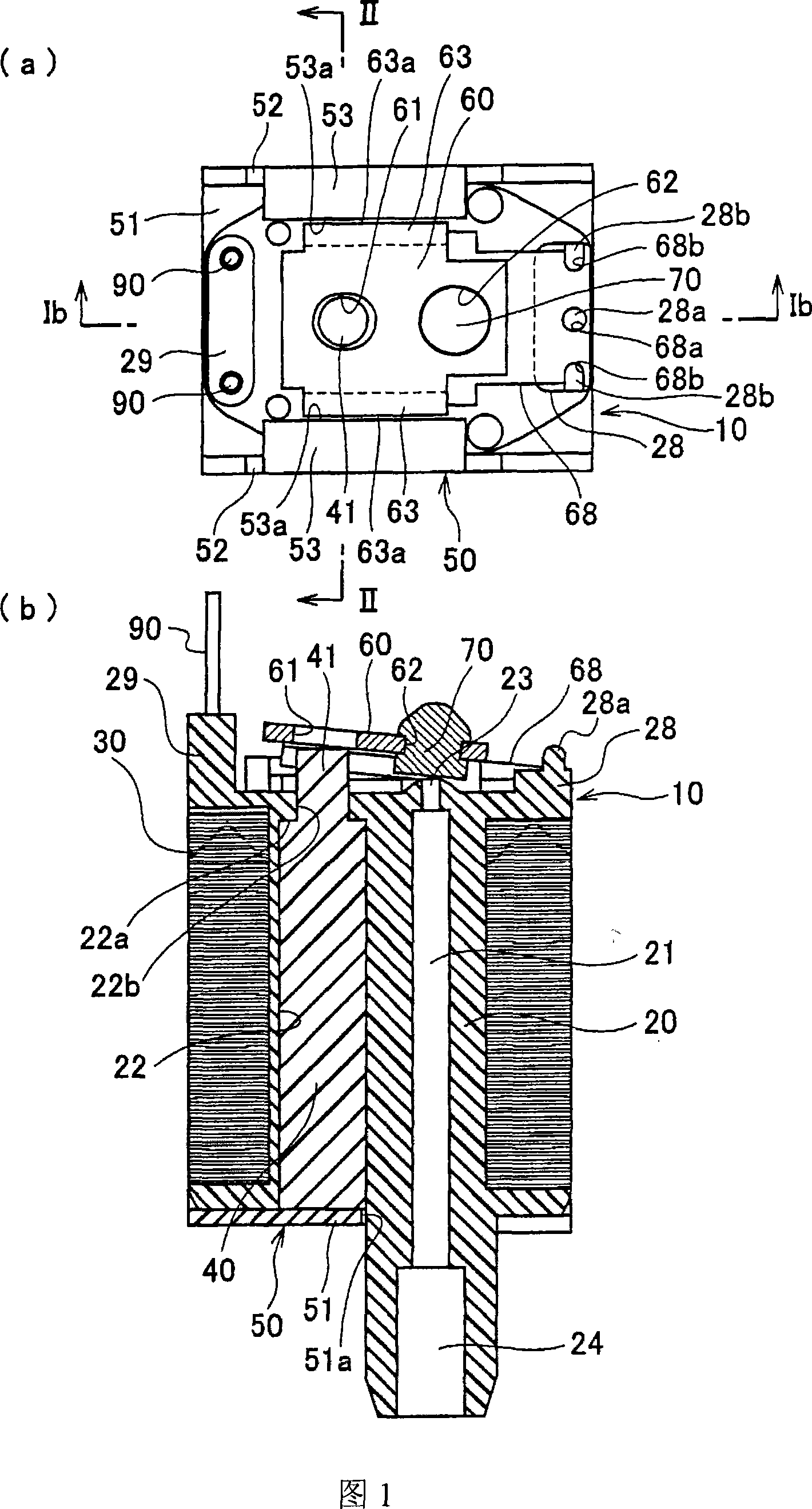

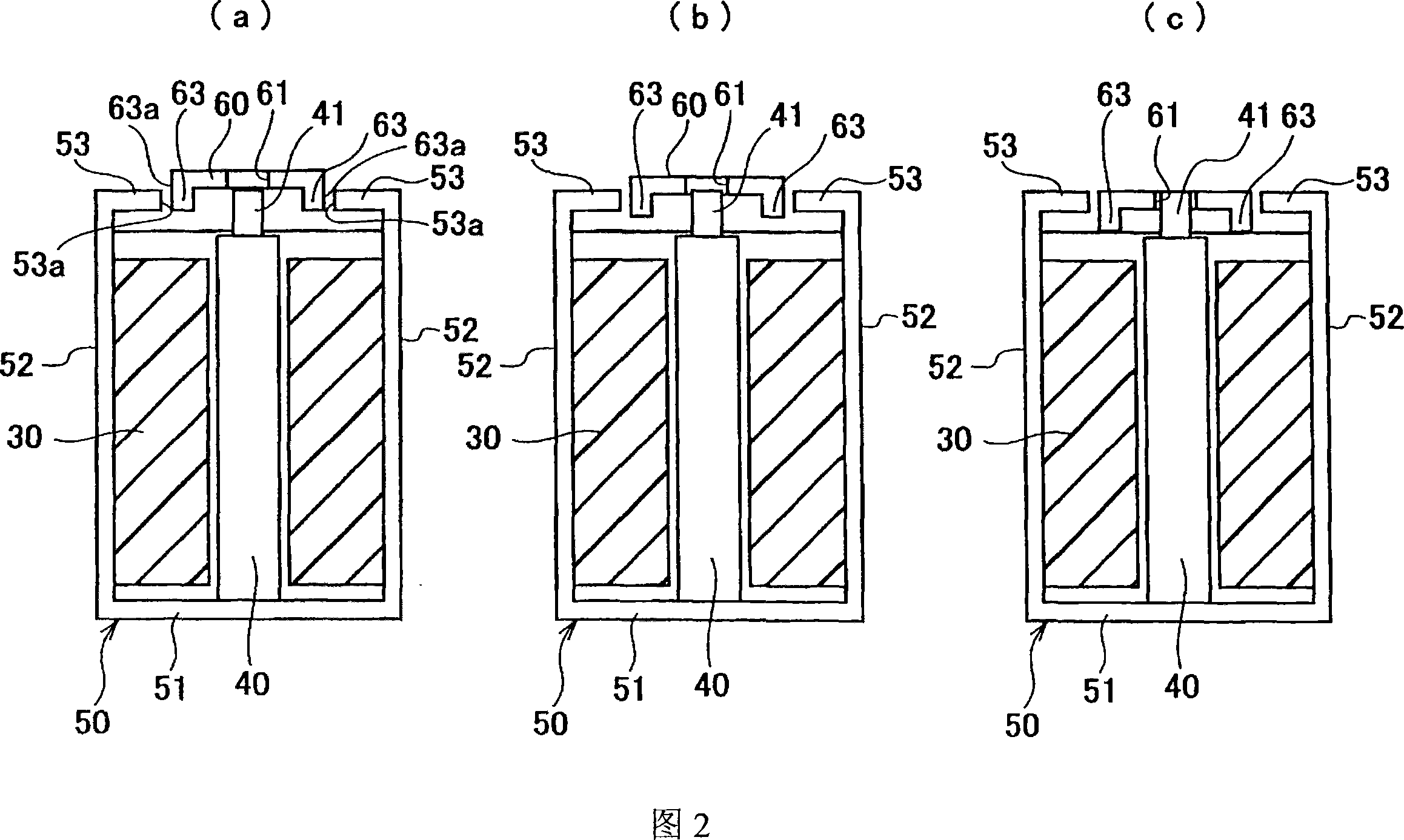

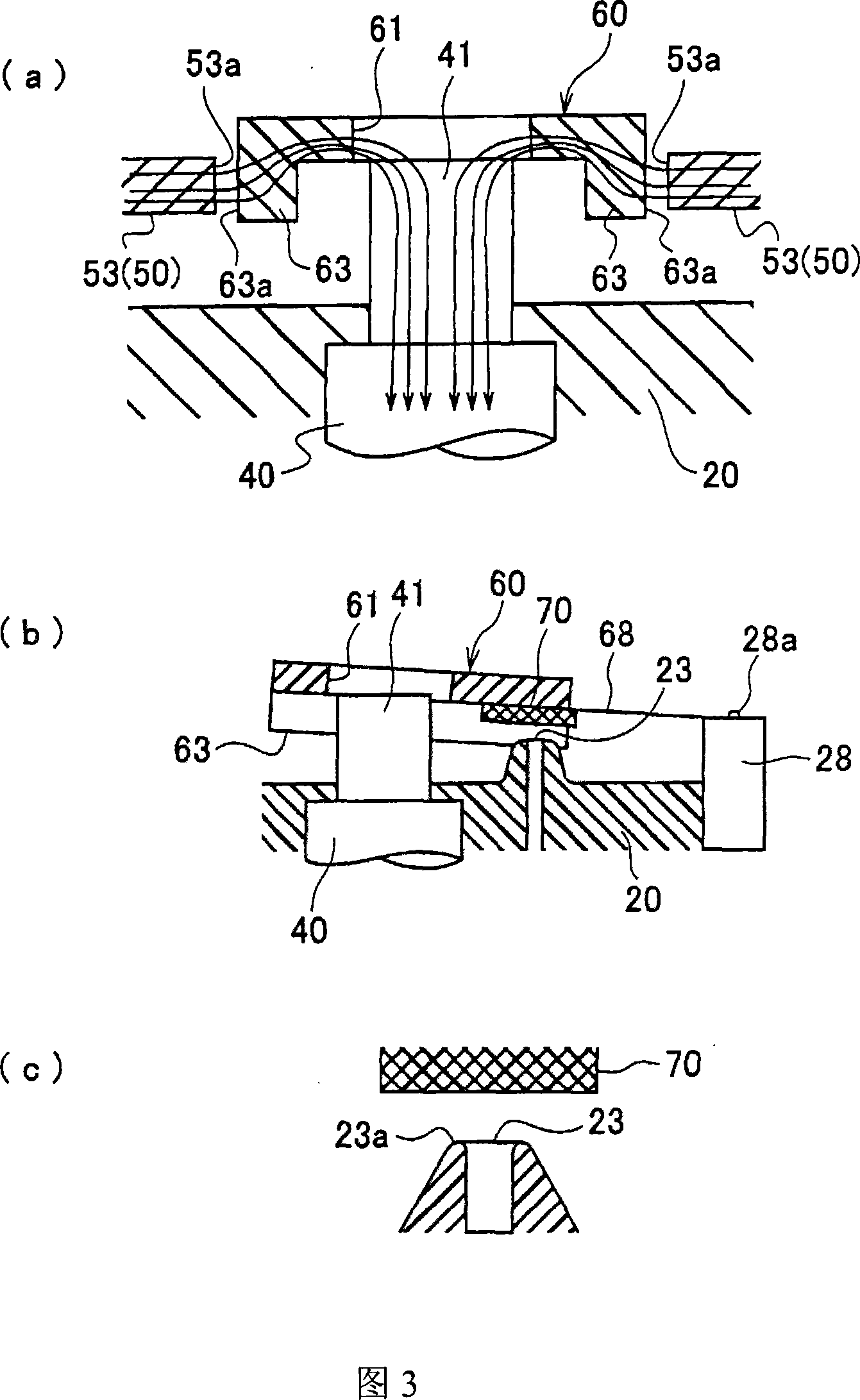

[0060] Fig. 1 is the structural representation of the electric exhaust valve 10 that the present invention relates to, (a) is a plan view; (b) is along (a) middle Ib—the sectional view that the direction shown by Ib arrow cuts off. Fig. 2 is a simplified sectional view taken along the direction indicated by II——II arrow in Fig. 1(a), (a) is a schematic diagram of the state before applying the driving force or the initial state of applying the driving force; (b) is applying a medium driving force A schematic diagram of the state; (c) is a schematic diagram of the state when the maximum driving force is applied. In addition, Fig. 3, Fig. 4 and Fig. 5 are simplified enlarged schematic diagrams of the states shown in Fig. 2 (a), (b) and (c) respectively, wherein (a) is the main part and the magnetic flux in Fig. 2 after enlargement A schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com