Patents

Literature

687results about How to "Precise control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

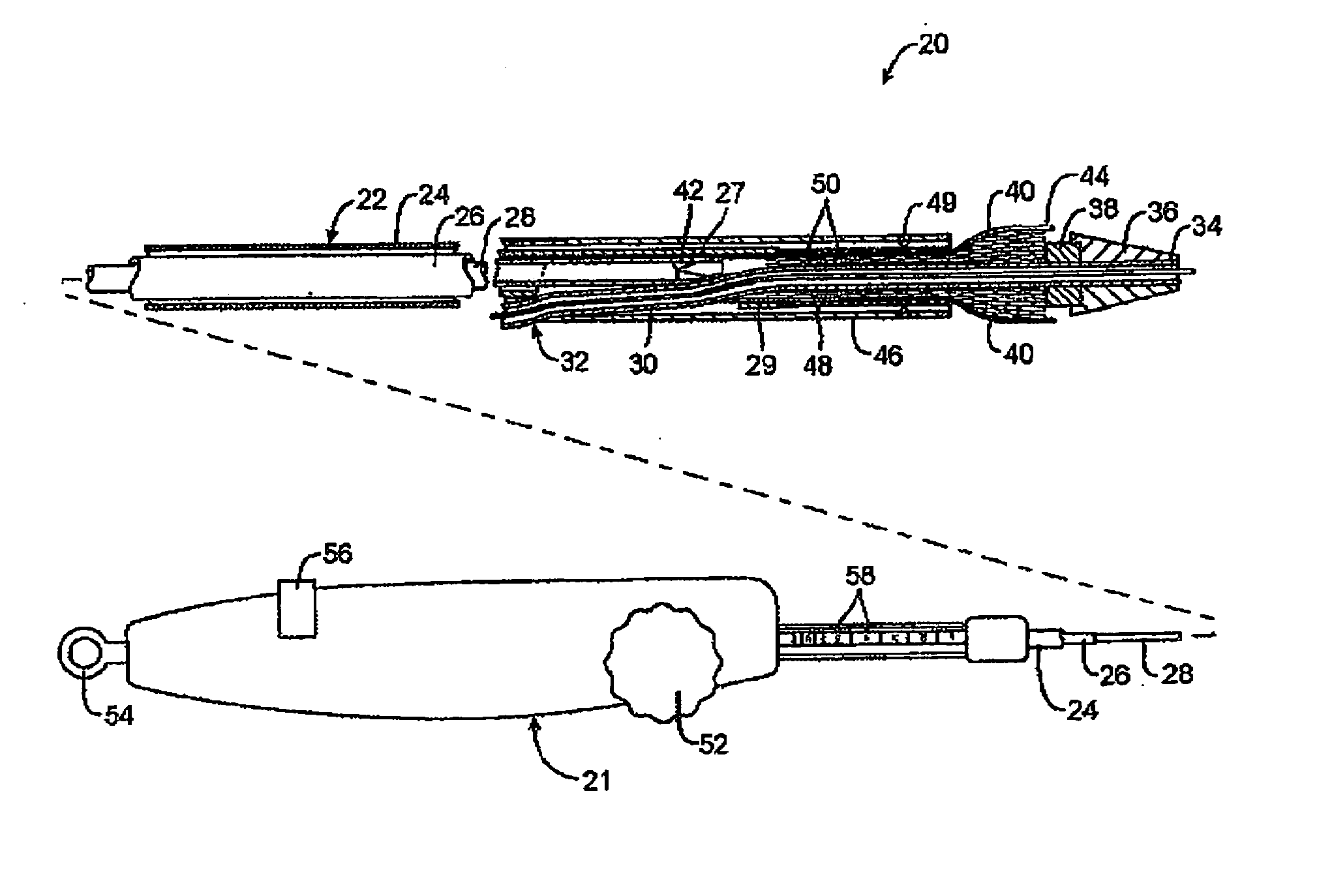

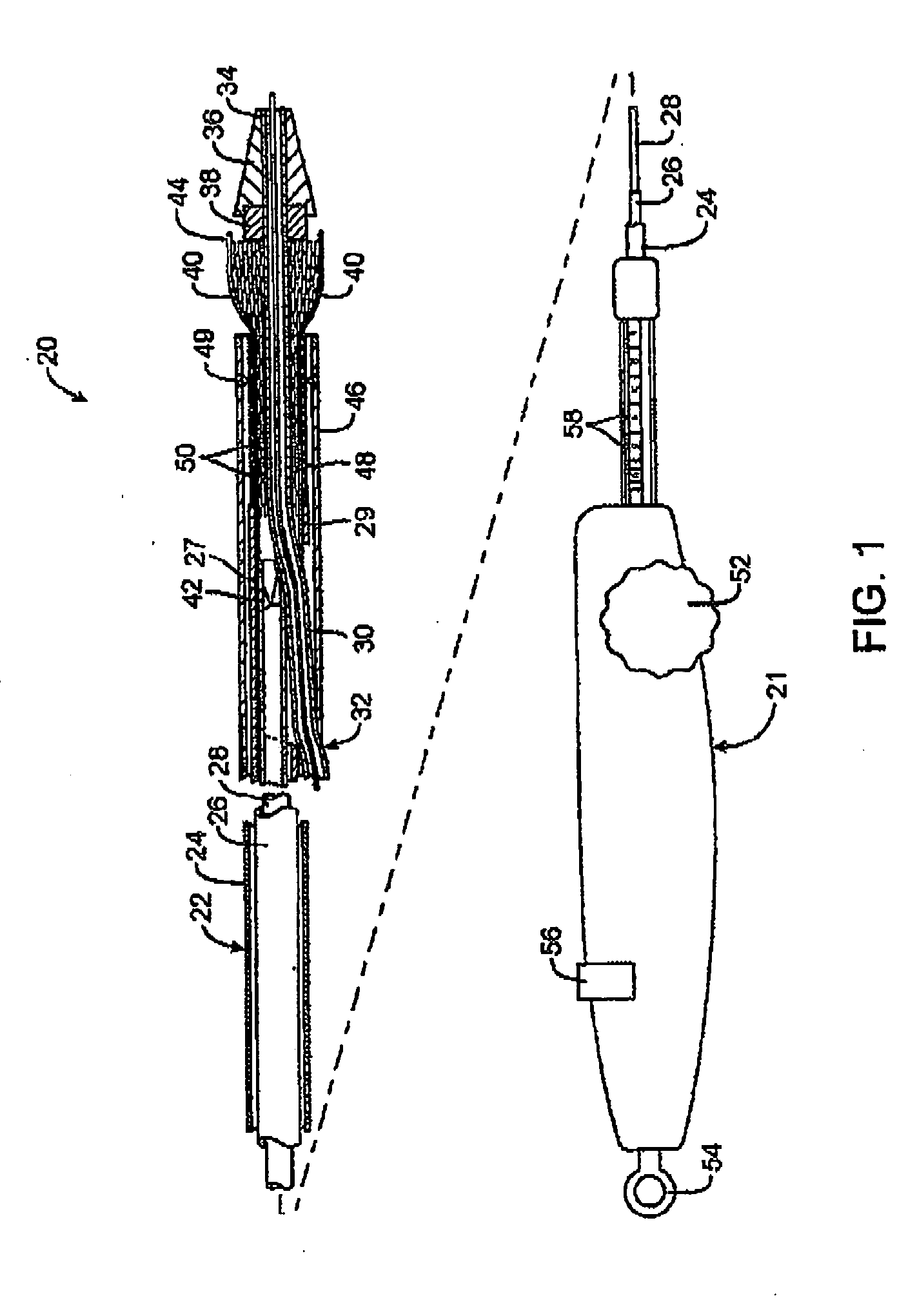

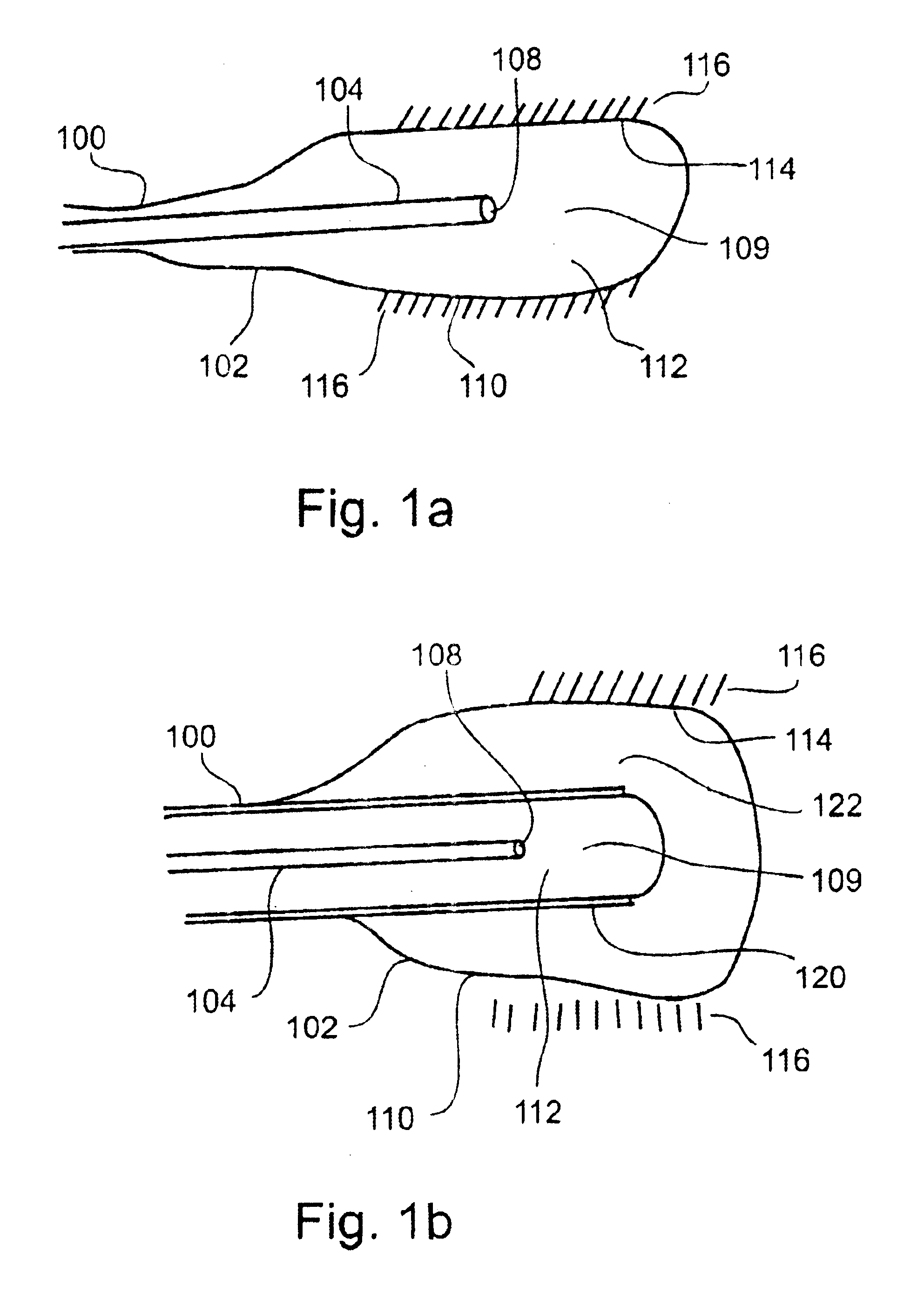

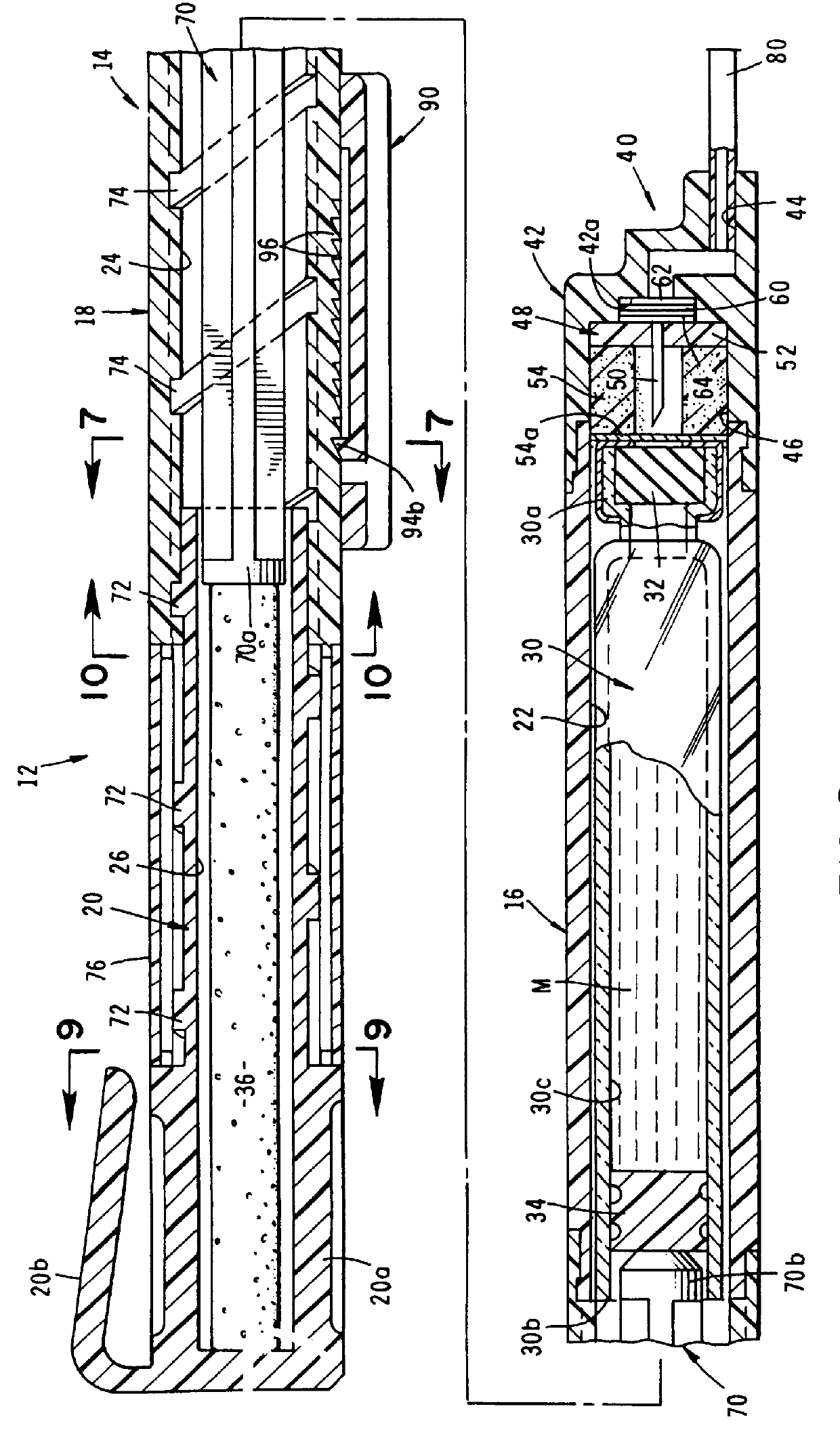

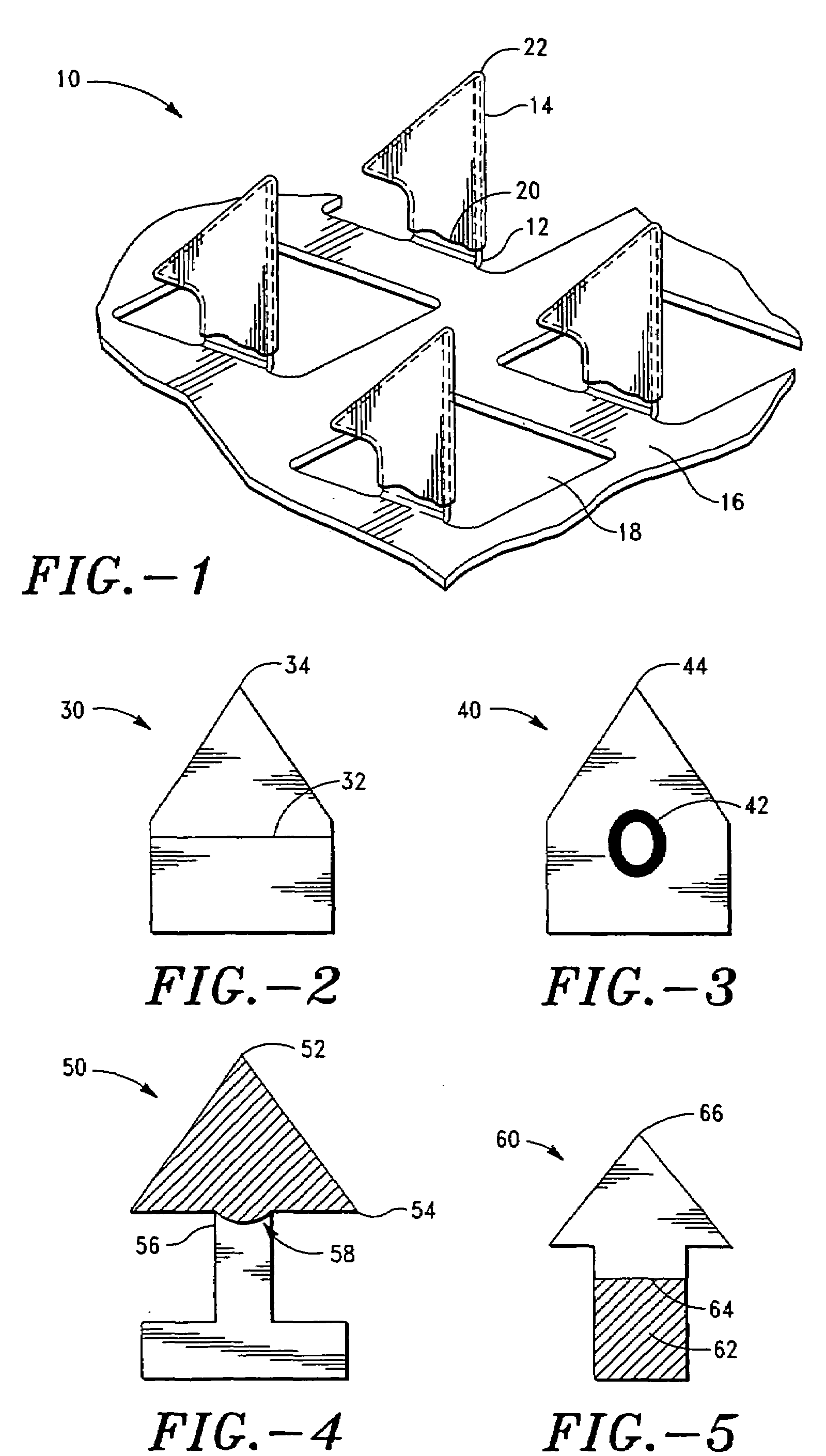

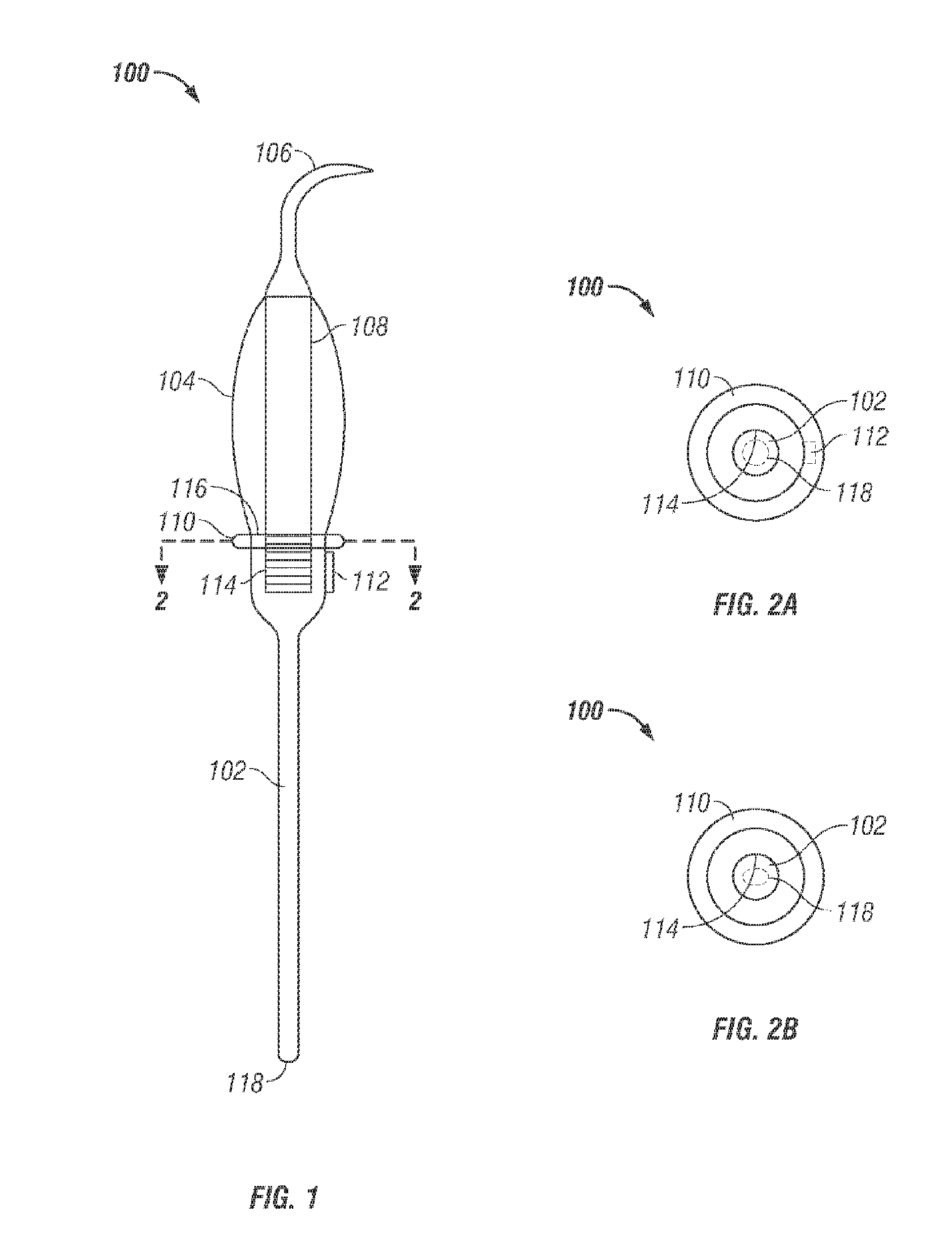

Devices and methods for controlling expandable prosthesis during develoyment

Prosthesis delivery devices and methods are provided that enable precise control of prosthesis position during deployment. The prosthesis delivery devices may carry multiple prostheses and include deployment mechanisms for delivery of a selectable number of prostheses. Control mechanisms are provided in the prosthesis delivery devices that control either or both of the axial and rotational positions of the prostheses during deployment. This enables the deployment of multiple prostheses at a target site with precision and predictability, eliminating excessive spacing or overlap between prostheses. In particular embodiments, the prostheses of the invention are deployed in stenotic lesions in coronary or peripheral arteries, or in other vascular locations.

Owner:XTENT INC

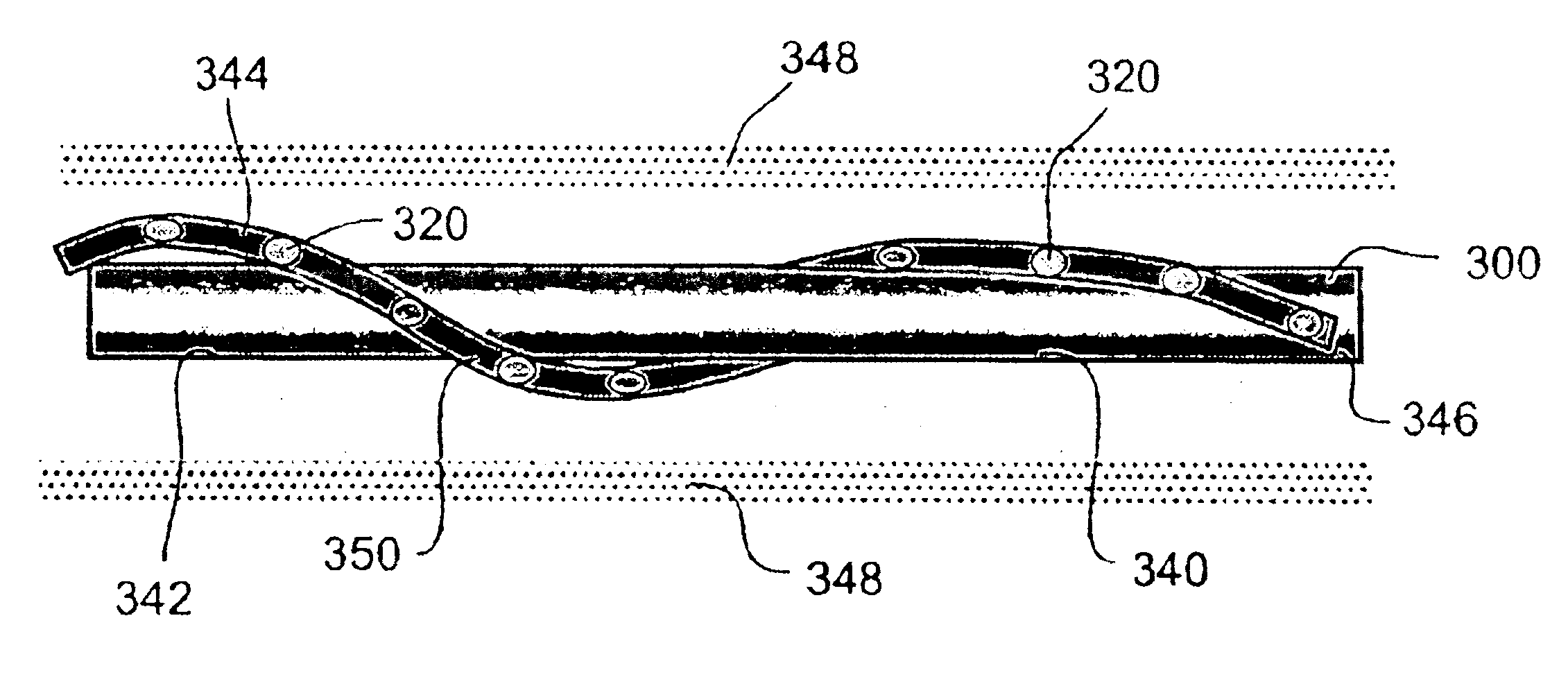

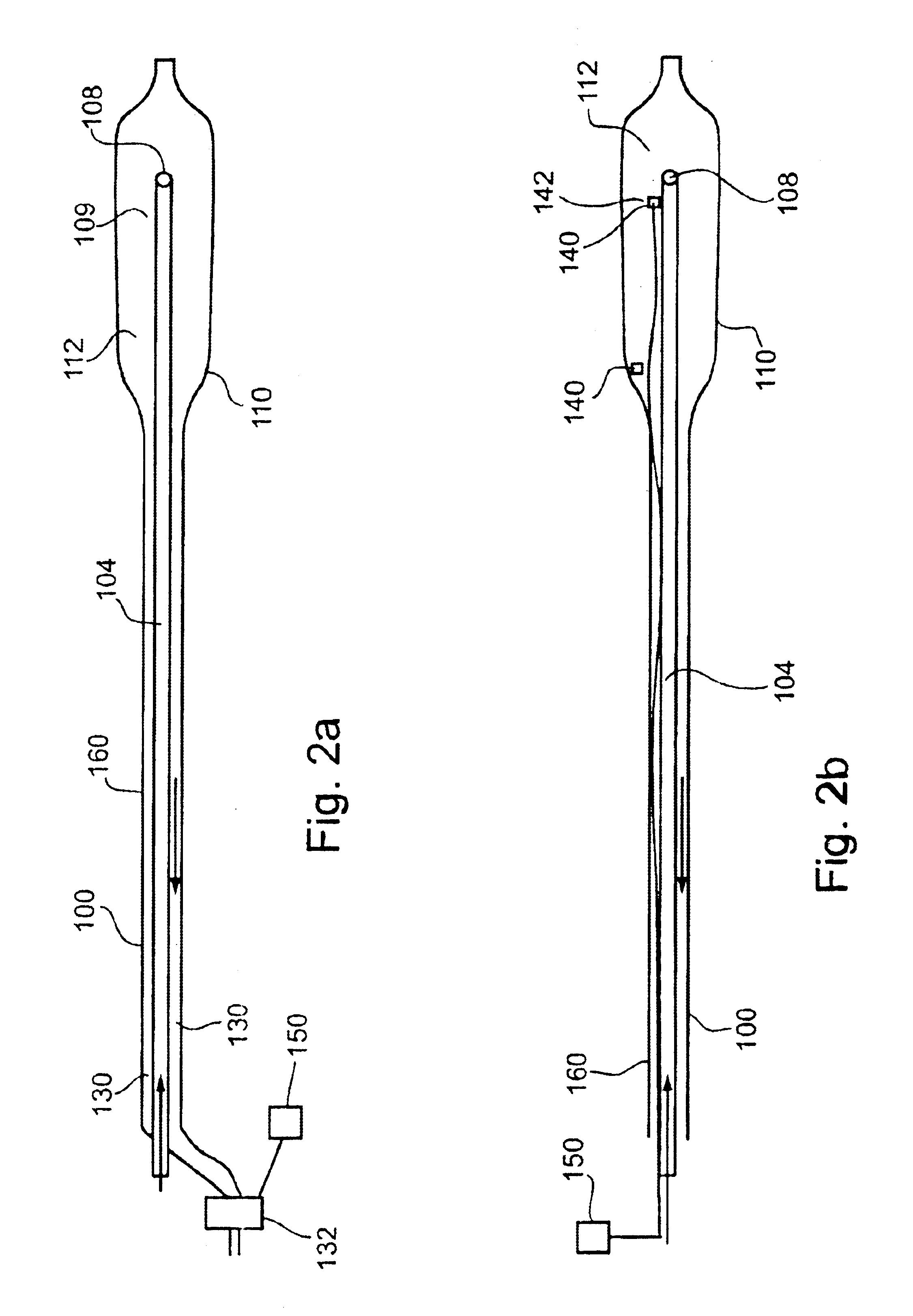

Cryoplasty apparatus and method

InactiveUS6875209B2Precise controlHighly evenly distributionCompression machinesCatheterPercent Diameter StenosisAngioplasty balloon catheter

The present invention relates to apparatus, systems, and methods utilizing cryogenic cooling in an angioplasty balloon catheter for treatment of arterial stenosis and prevention of restenosis. More particularly, the present invention relates to an angioplasty balloon catheter utilizing expansion of compressed gas to effect Joule-Thomson cooling of an angioplasty balloon, and optionally further incorporating external temperature sensors utilizable to identify a locus for treatment of arterial stenosis. The present invention further relates to angioplasty treatment systems incorporating such a catheter, and to cryogenic angioplasty methods for treating arterial stenosis and discouraging restenosis.

Owner:GALIL MEDICAL

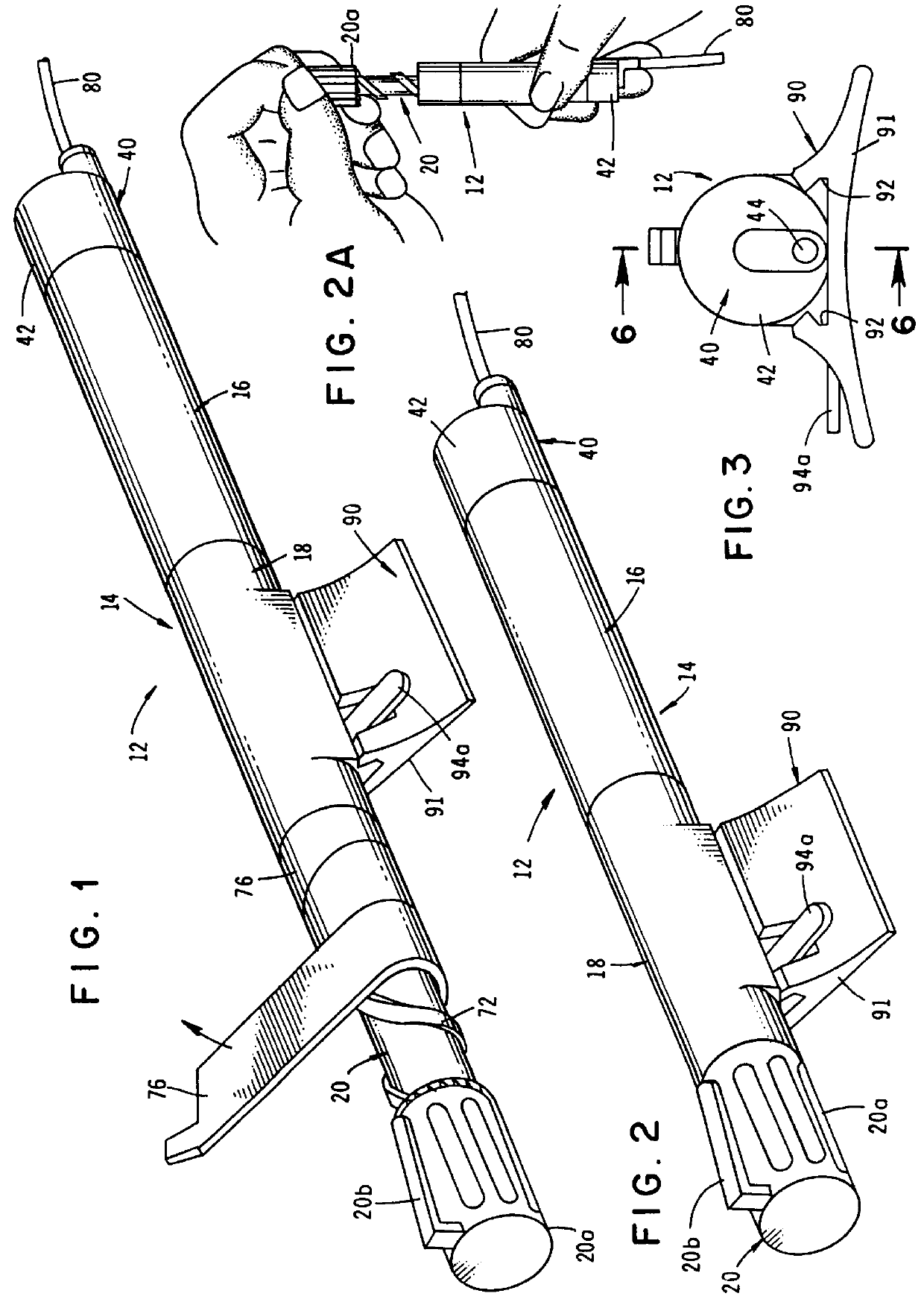

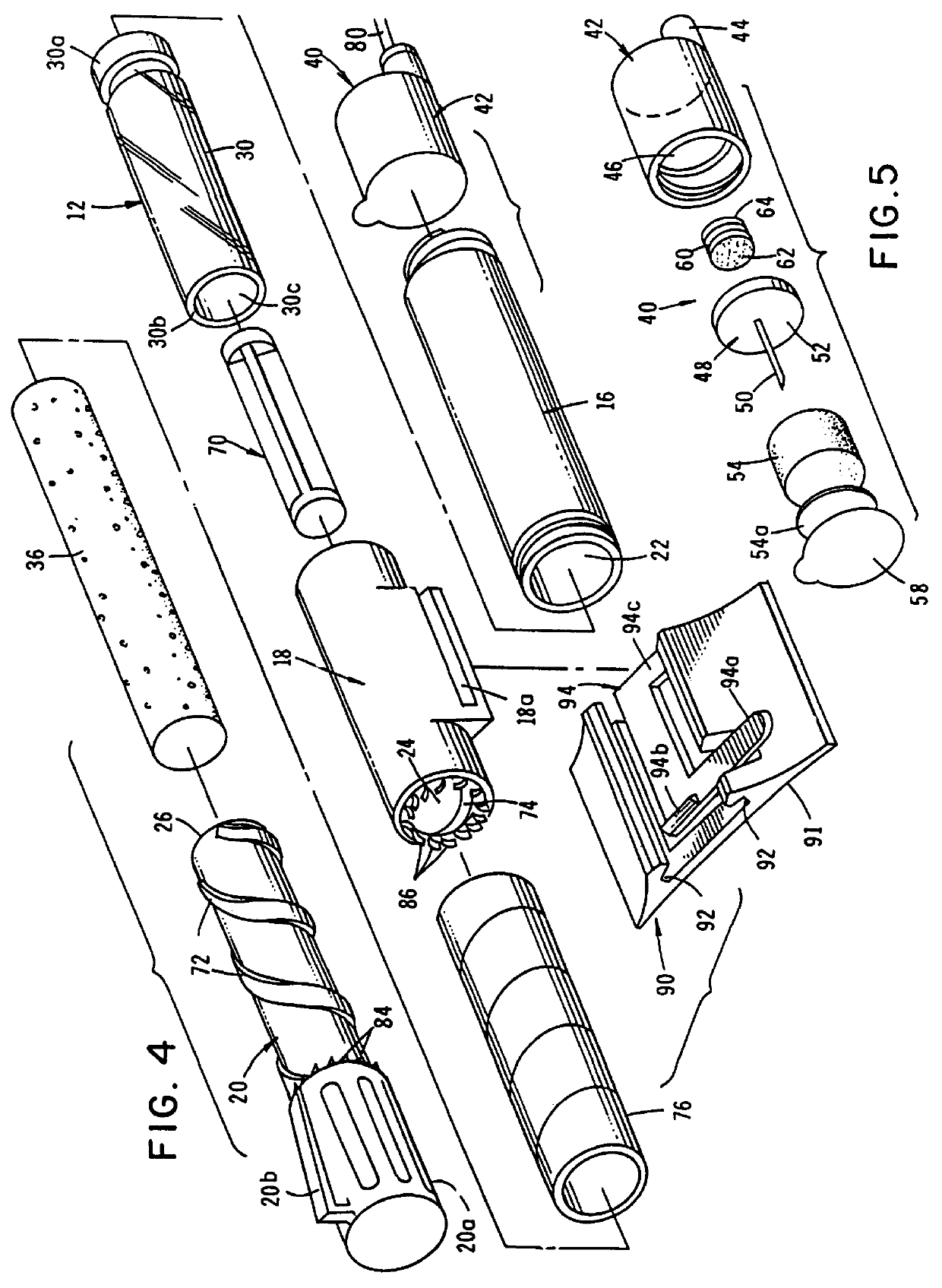

Medicament dispenser

InactiveUS6030363APrecise controlAccurate mannerAmpoule syringesMedical devicesMedication DispenserDrug

An injectable medicament dispenser for use in controllably dispensing fluid medicaments such as insulin, antibiotics, oncolytics and the like from a prefilled container at a uniform rate. The dispenser includes a unique stored energy source in the form of a compressively deformable, polymeric elastomeric member that provides the force necessary to controllably discharge the medicament from the prefilled container which is housed within the body of the device. After having been deformed, the polymeric, elastomeric member will return to its starting configuration in a highly predictable manner.

Owner:PESCADERO BEACH HLDG

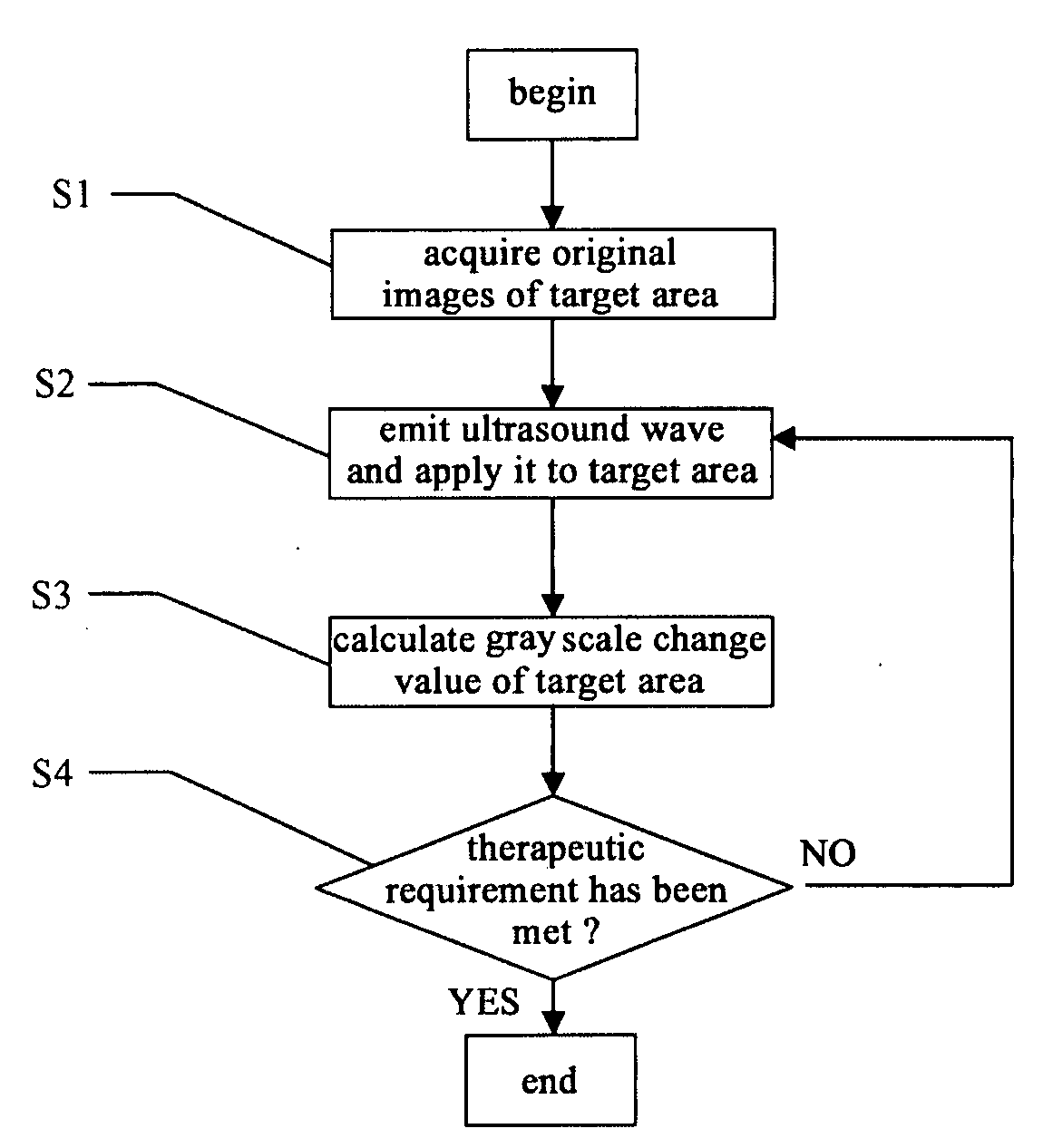

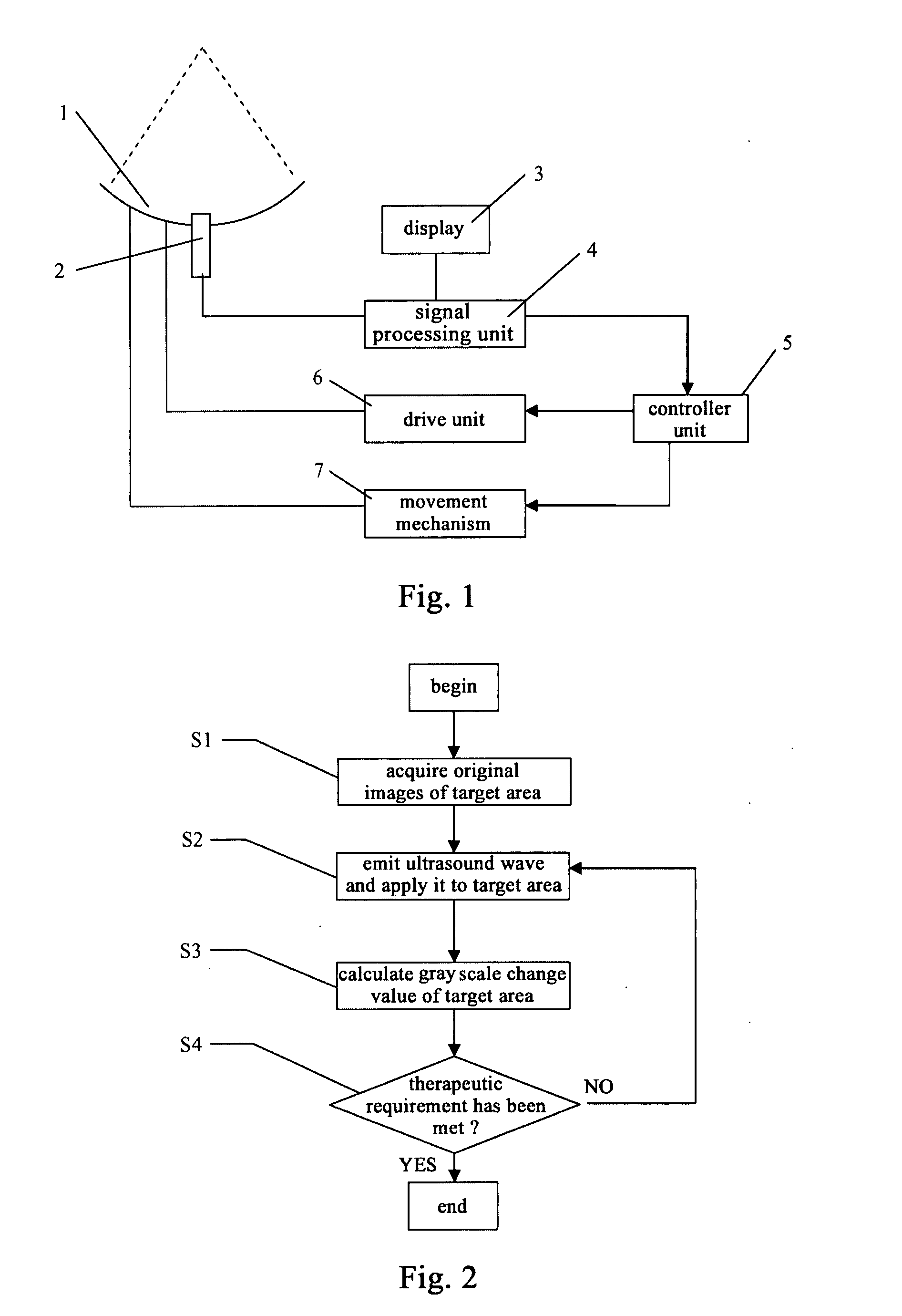

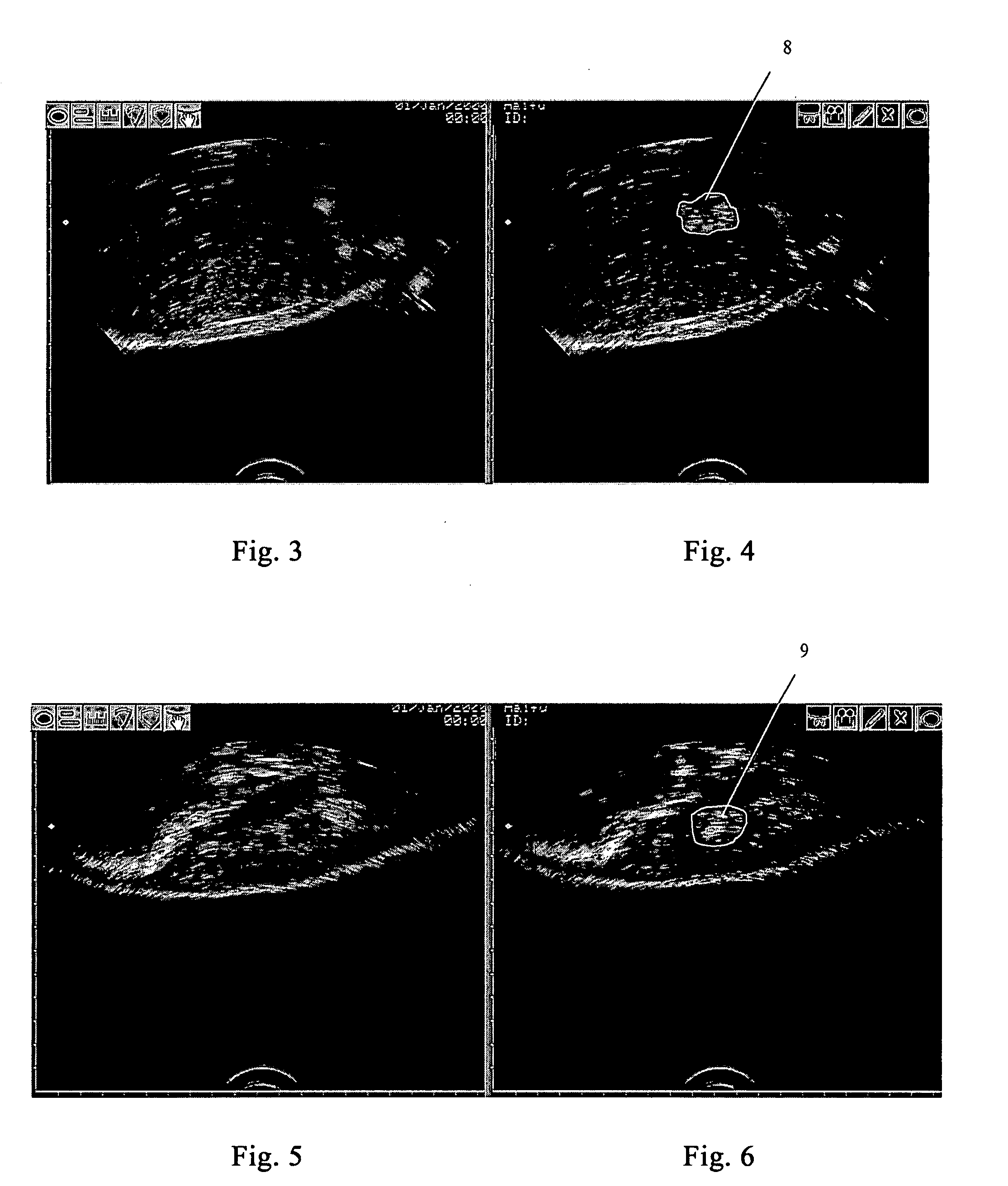

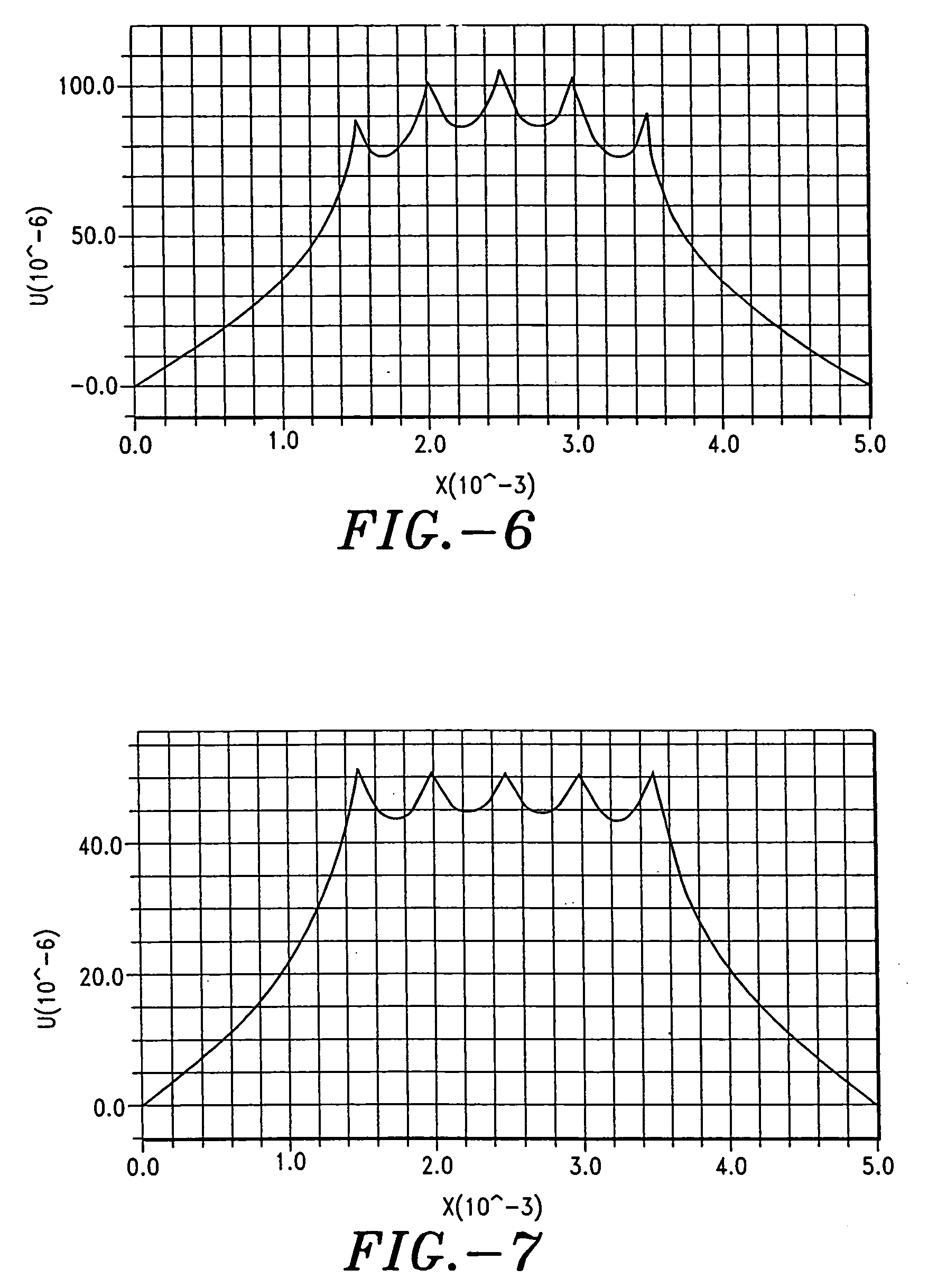

Method and Apparatus for High-Intensity Focused Ultrasound Therapy

InactiveUS20080188745A1Good therapeutic effectPrecise controlUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyHigh-intensity focused ultrasoundHigh intensity

The apparatus for high-intensity focused ultrasound therapy of the present invention usually comprises a ultrasound transducer, an image acquisition device, a driving unit for driving said ultrasound transducer and mechanical drive means for mechanically driving said ultrasound transducer and image acquisition device together. Additionally, this apparatus for high-intensity focused ultrasound therapy further comprises a signal processing unit connected to image acquisition device for receiving and saving the original images of the target area prior to treatment and for receiving and saving the images of the target area in a certain time during high-intensity focused ultrasound (HIFU) treatment and for evaluating the therapeutic effects according to the images of the target area before and after treatment, and a control unit respectively connected to signal processing unit, driving unit and mechanical driving means. When the signal processing unit judges that the therapeutic requirements have been met, the control unit controls the driving unit and mechanical driving means to stop the working of ultrasound transducer and when the signal processing unit judges that the therapeutic requirements have not been met, the control unit controls the driving unit and mechanical driving means to make the ultrasound transducer continue to work.

Owner:CHONGQING HAIFU MEDICAL TECH CO LTD

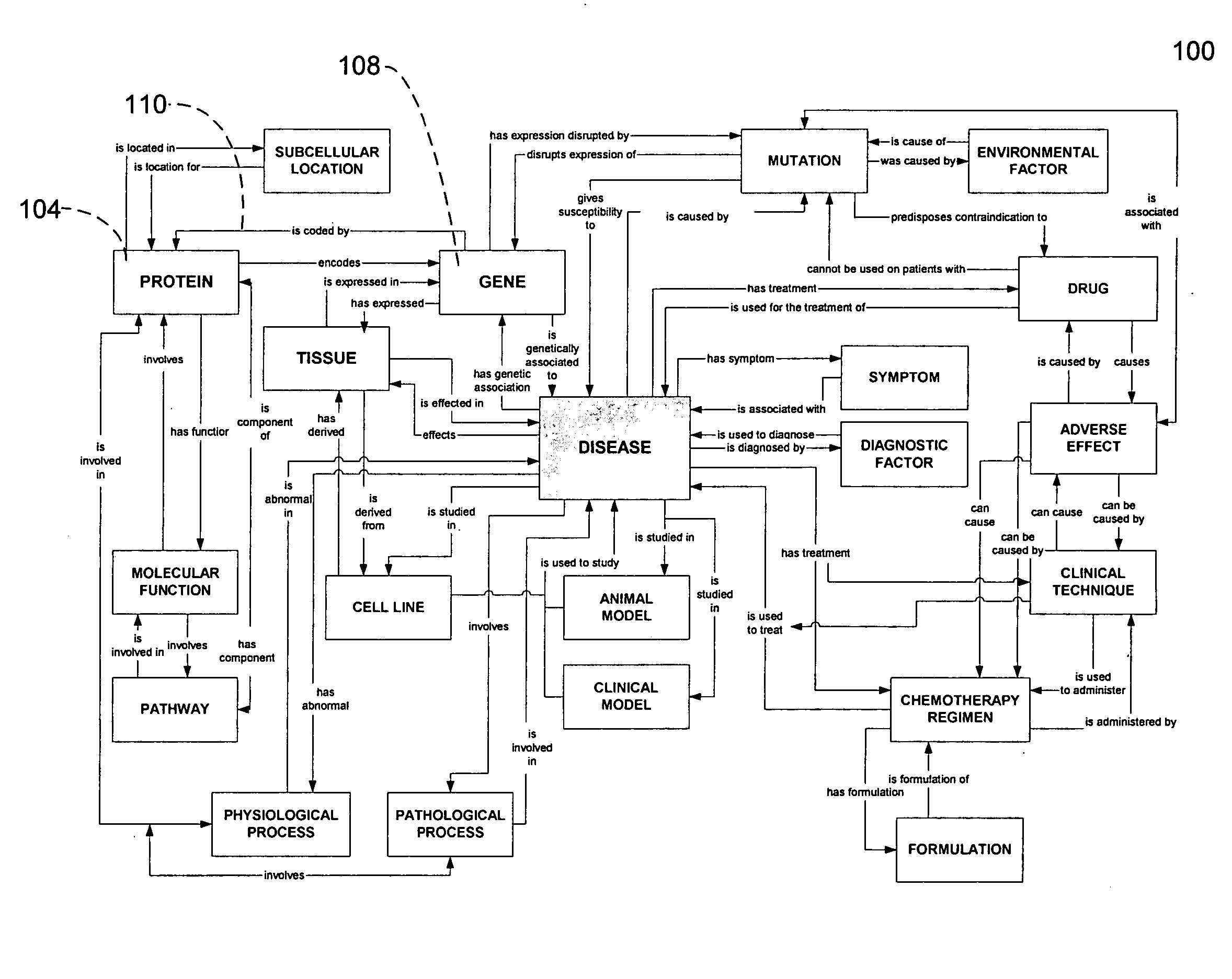

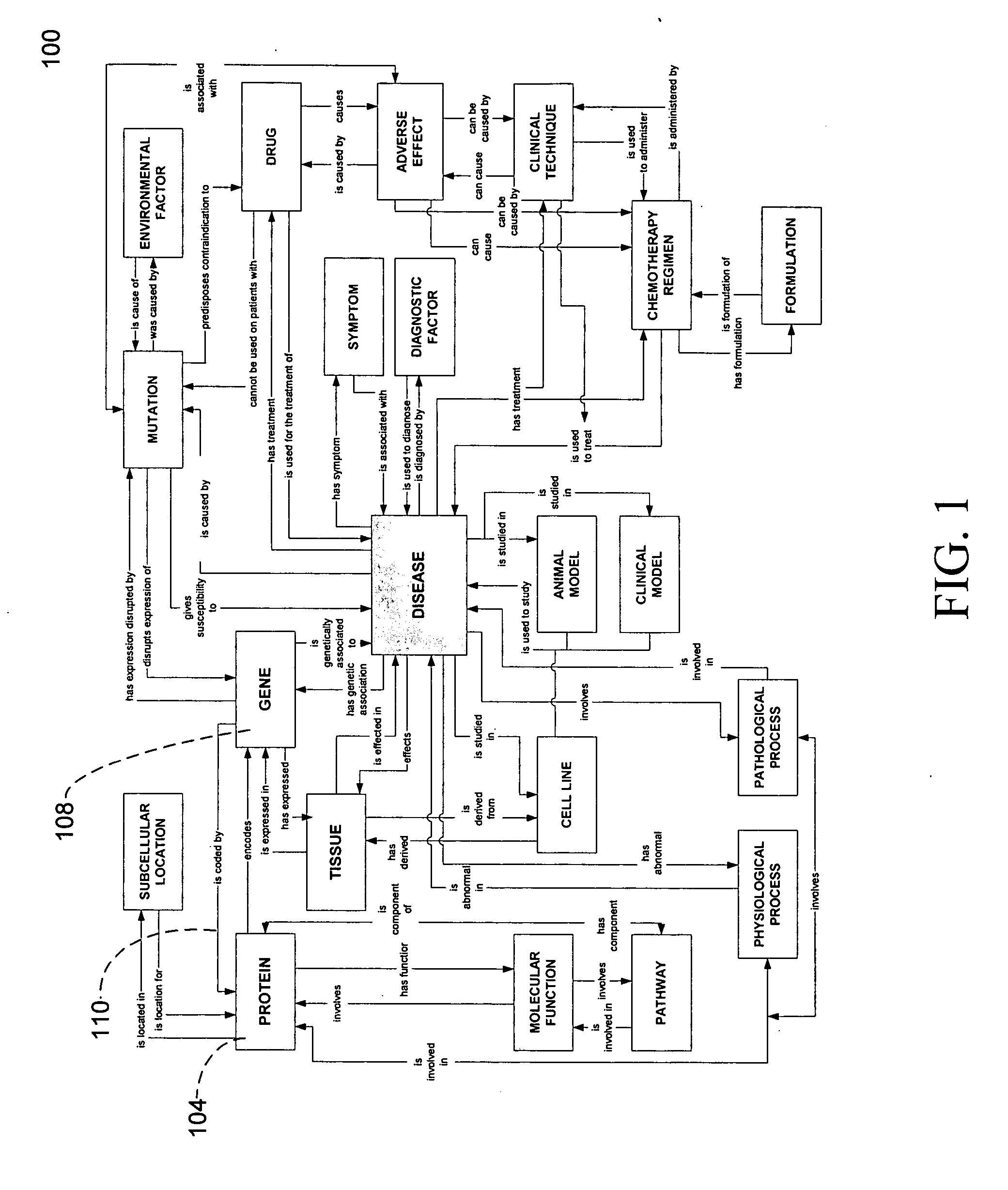

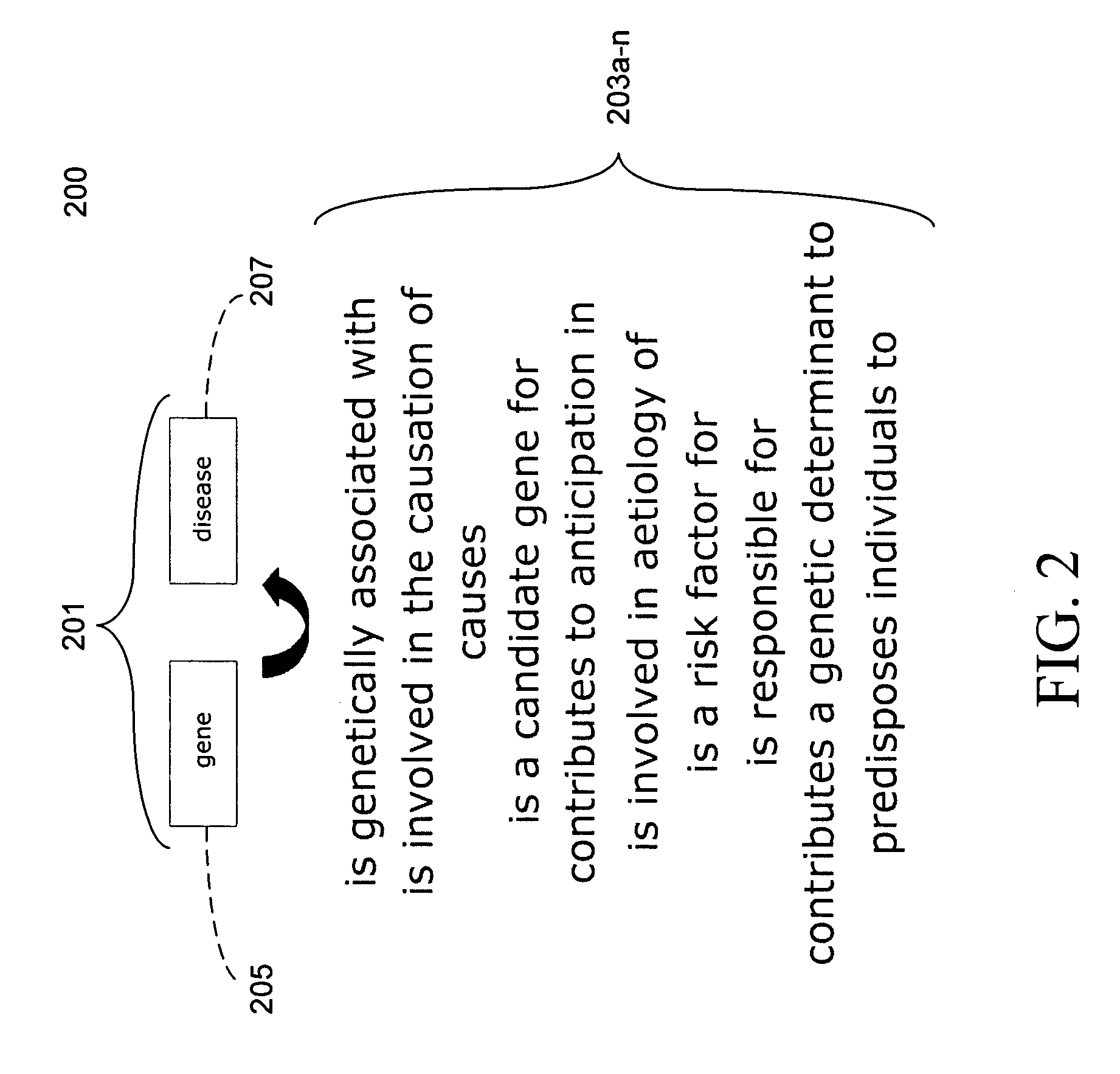

System and method for utilizing an upper ontology in the creation of one or more multi-relational ontologies

InactiveUS20060074832A1Precise controlEasy to controlKnowledge representationInference methodsInformation retrieval

The invention relates to the structure of an upper ontology and a system and method for utilizing an upper ontology in the creation of one or more multi-relational ontologies. The invention includes an upper ontology of predefined concept and relationship types, and a predefined set or relationships that may be used to connect particular pairs of concepts. The concept and relationship types may be dictated by the knowledge domains in which the resultant ontology is to reside. The invention may also include a hierarchy of concept types wherein the relationships that may exist between concept types is specified.

Owner:BIOWISDOM

Pot with intelligent temperature control device

The invention discloses a pot with an intelligent temperature control device, which comprises a pot body with a pot handle. The pot is characterized in that a temperature probe is arranged in the pot body and is separated from the pot body through a thermal-insulating layer; a temperature control circuit board which is in signal connection with the temperature probe is arranged in the pot handle; a signal transmitter is arranged on the temperature control circuit board. As the temperature probe is placed in the pot body, the temperature in the pot can be more accurately grasped, controlled and regulated, and a user can accurately grasp the temperature in the pot during cooking, so that the nutrition and the mouth feeling of food are better.

Owner:GUANGDONG MACRO GAS APPLIANCE

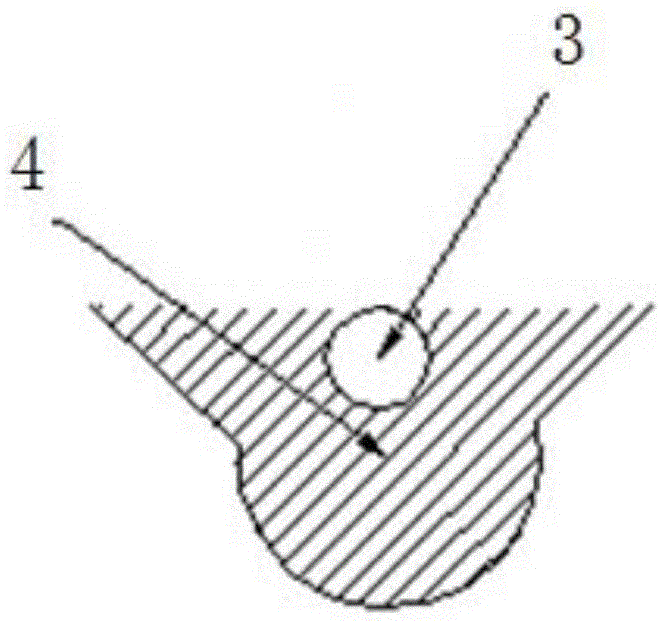

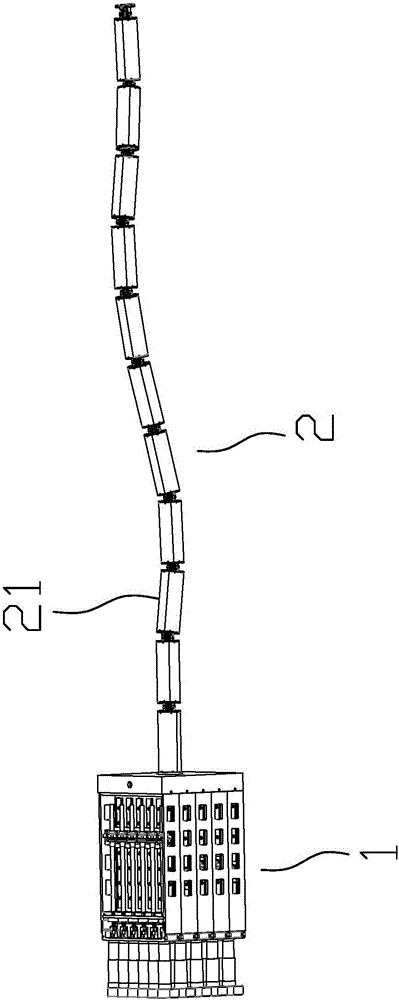

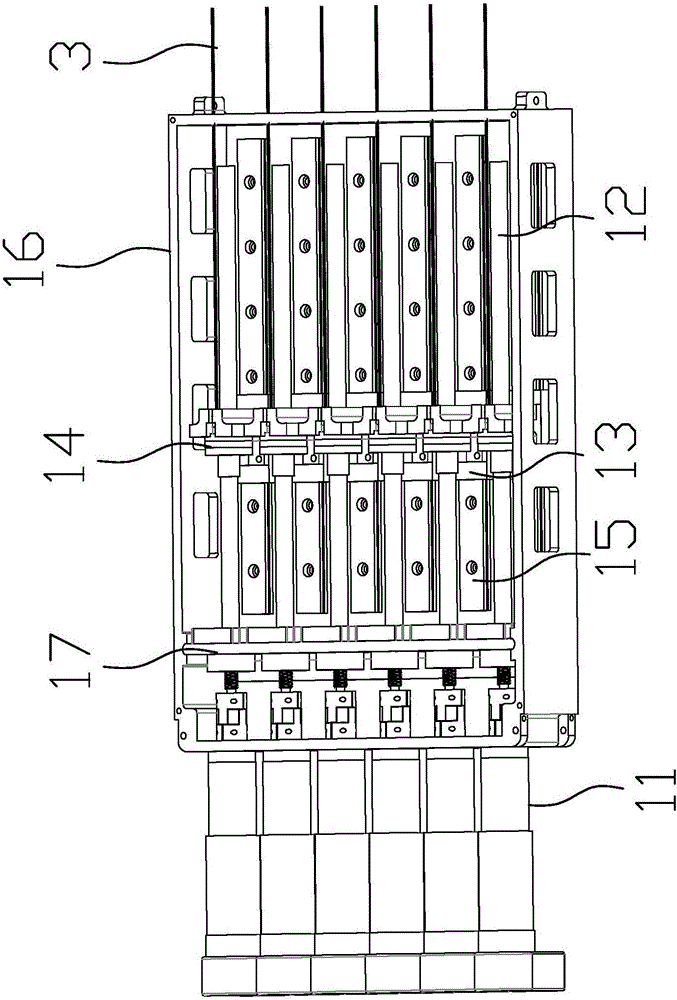

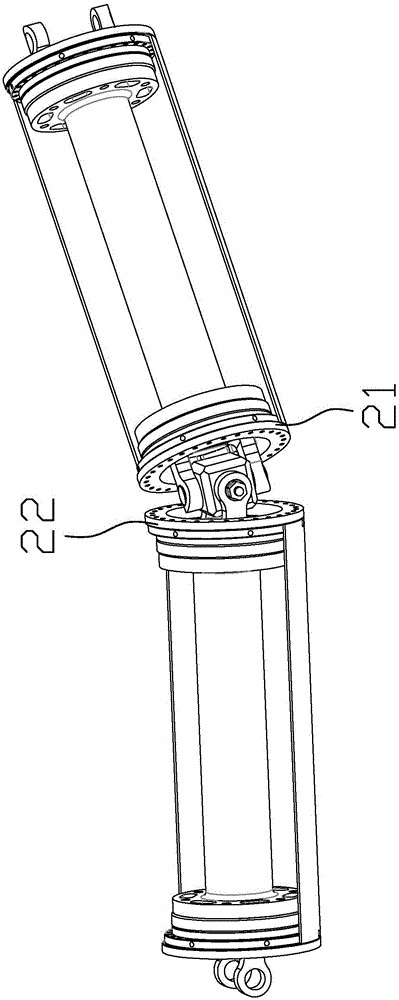

Super-redundant flexible mechanical arm based on rope driving

The invention discloses a super-redundant flexible mechanical arm based on rope driving. The super-redundant flexible mechanical arm comprises a driving module, a mechanical arm module and a plurality of driving ropes; the mechanical arm module comprises a plurality of joints in serial connection, the adjacent joints are connected through cross and perpendicular rotating shafts arranged between the adjacent joints, and at least three driving ropes are fixedly connected to any joint; the driving ropes can be driven by the driving module to move independently; and the driving ropes arranged on the same joint are arranged in a manner that the joint can be pulled by the driving ropes to rotate around the rotating shafts relative to the adjacent joints. According to the super-redundant flexible mechanical arm, all joints can be adjusted independently and controlled more accurately, the weight of the joints is greatly reduced, the bearing capacity of the mechanical arm is further improved, and the high-speed movement and the quick response of the mechanical arm are achieved. Meanwhile, the distributing work of electric lines is removed, the mechanical arm is only composed of mechanical structures and is not prone to being affected by severe environments, the service life is prolonged, and the mechanical arm is convenient to disassembly, maintain and assemble.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

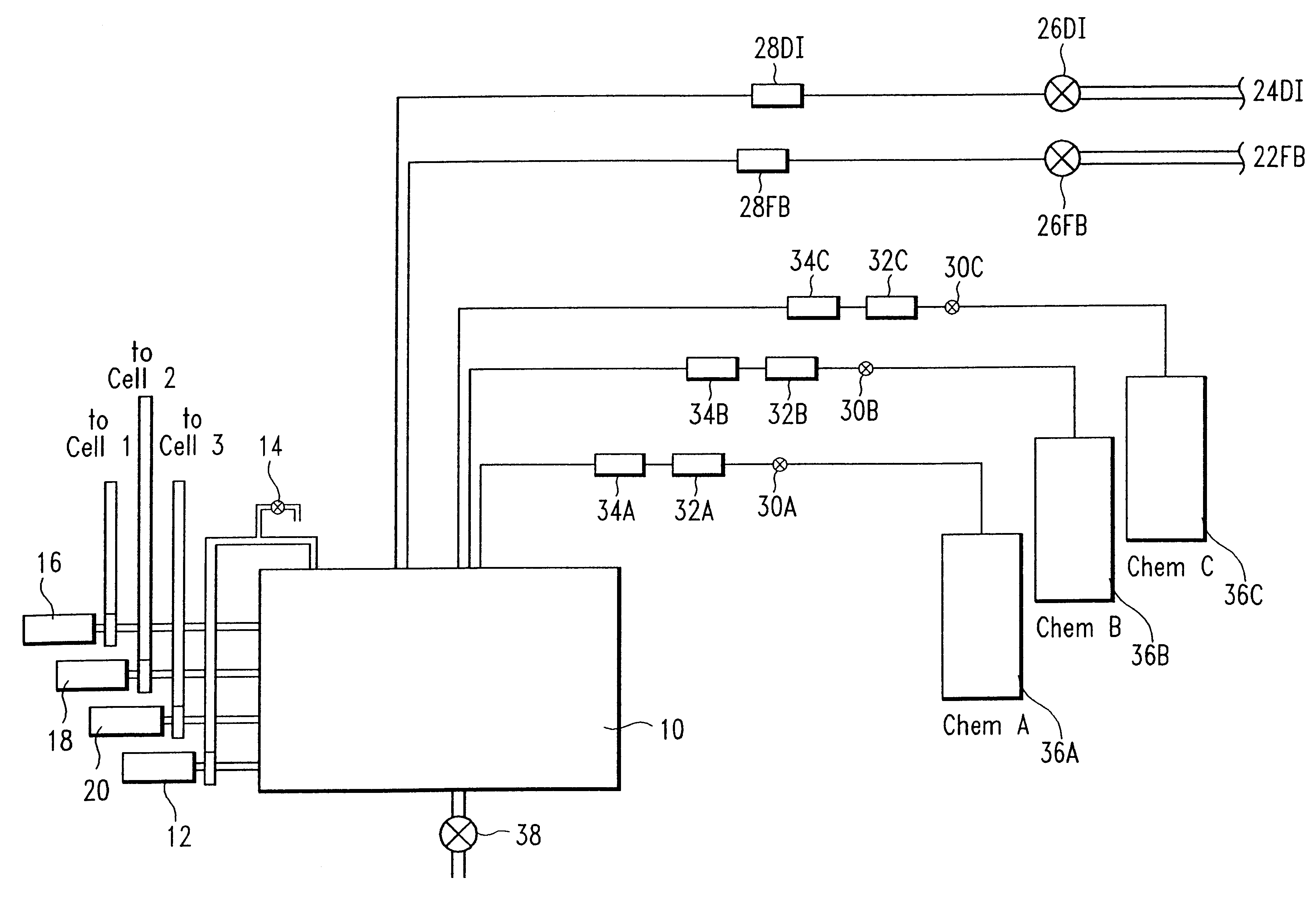

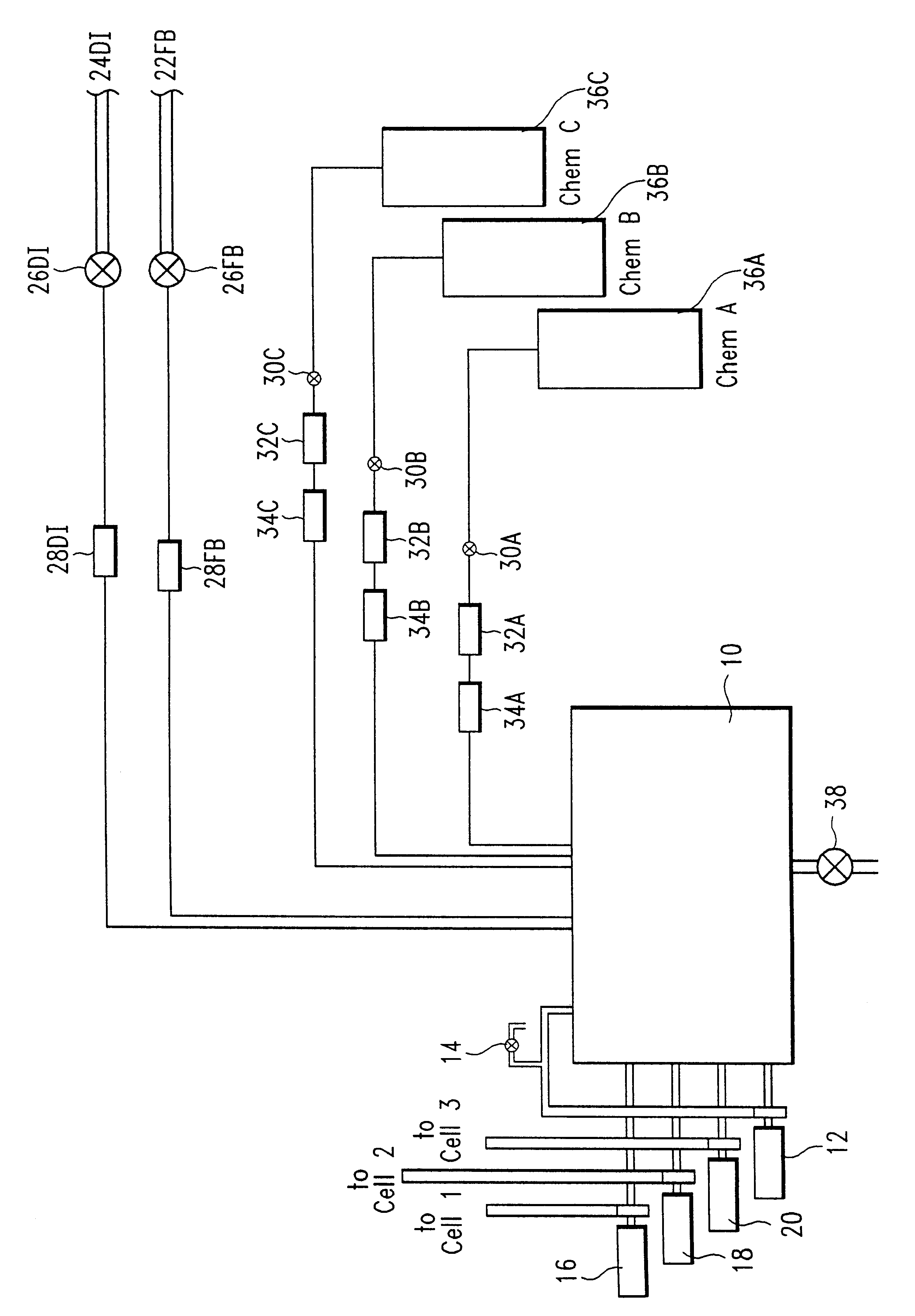

Method of controlling chemical bath composition in a manufacturing environment

InactiveUS6471845B1Little overheadPrecise controlCellsRatio controlProcess engineeringChemical composition

A method for controlling the composition of a chemical bath in which predictive dosing is used to account for changes in the composition of the bath in which the operating characteristics of the process are partitioned into a plurality of operating modes and the consumption or generation of materials related to the process are determined empirically and additions of material are made as appropriate.

Owner:IBM CORP

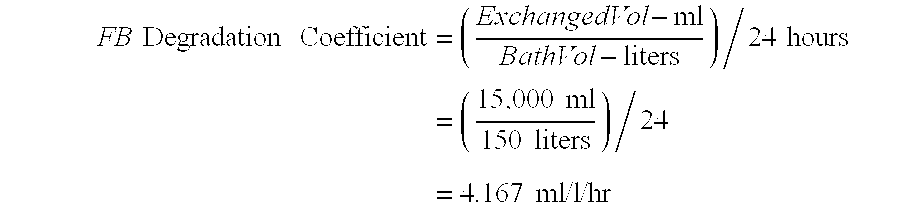

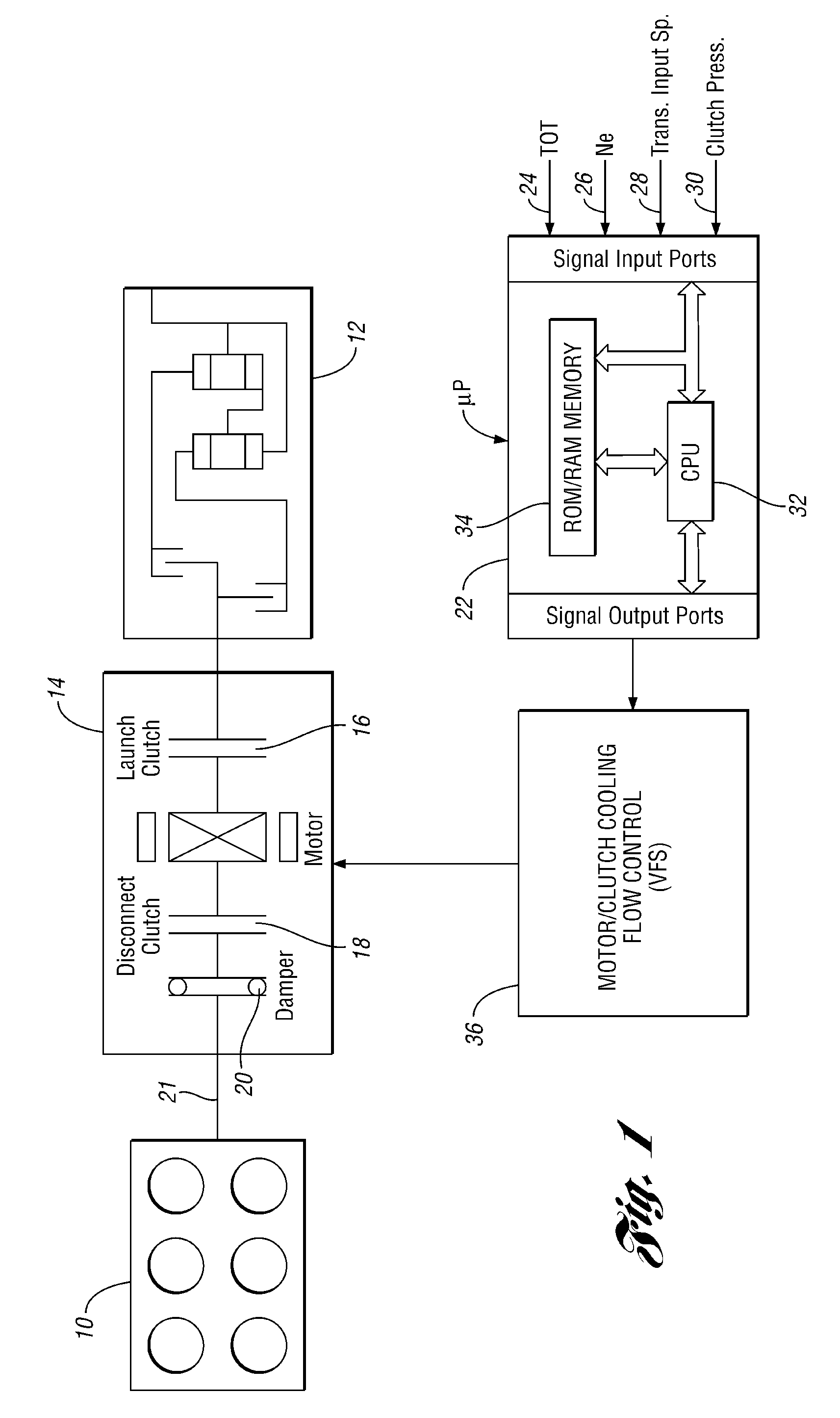

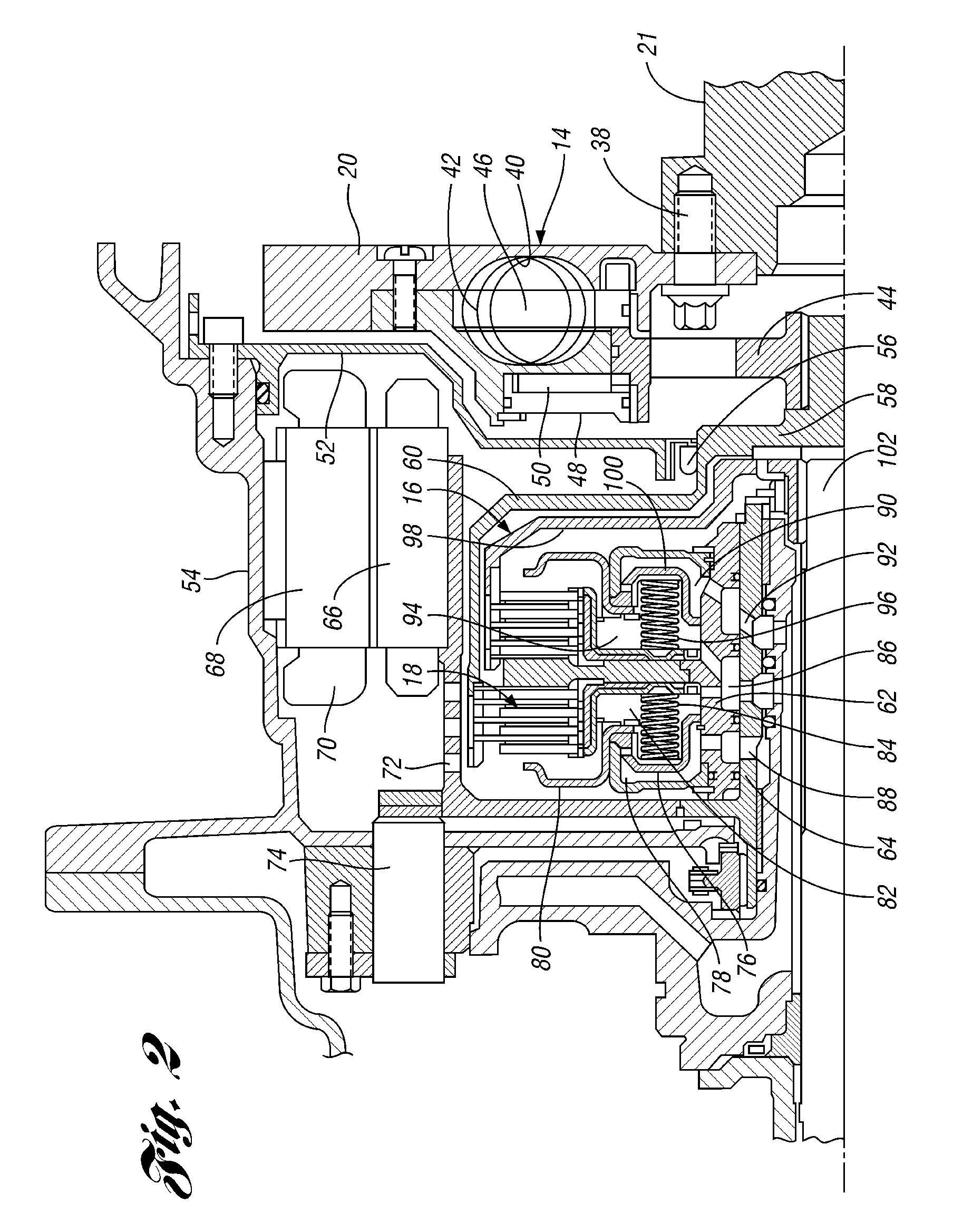

Control method for cooling a launch clutch and an electric motor in a hybrid electric vehicle powertrain

InactiveUS20070202989A1Transmission efficiency is maximizedPrecise controlElectric propulsion mountingFluid actuated clutchesClutchElectric vehicle

A method is disclosed for controlling a rate of flow of cooling oil to a friction launch clutch and electric motor in a hybrid electric vehicle powertrain. The rate of flow is determined by changes in clutch temperature and motor temperature. Cooling oil flow in excess of the flow required to maintain a desired temperature is avoided.

Owner:FORD GLOBAL TECH LLC

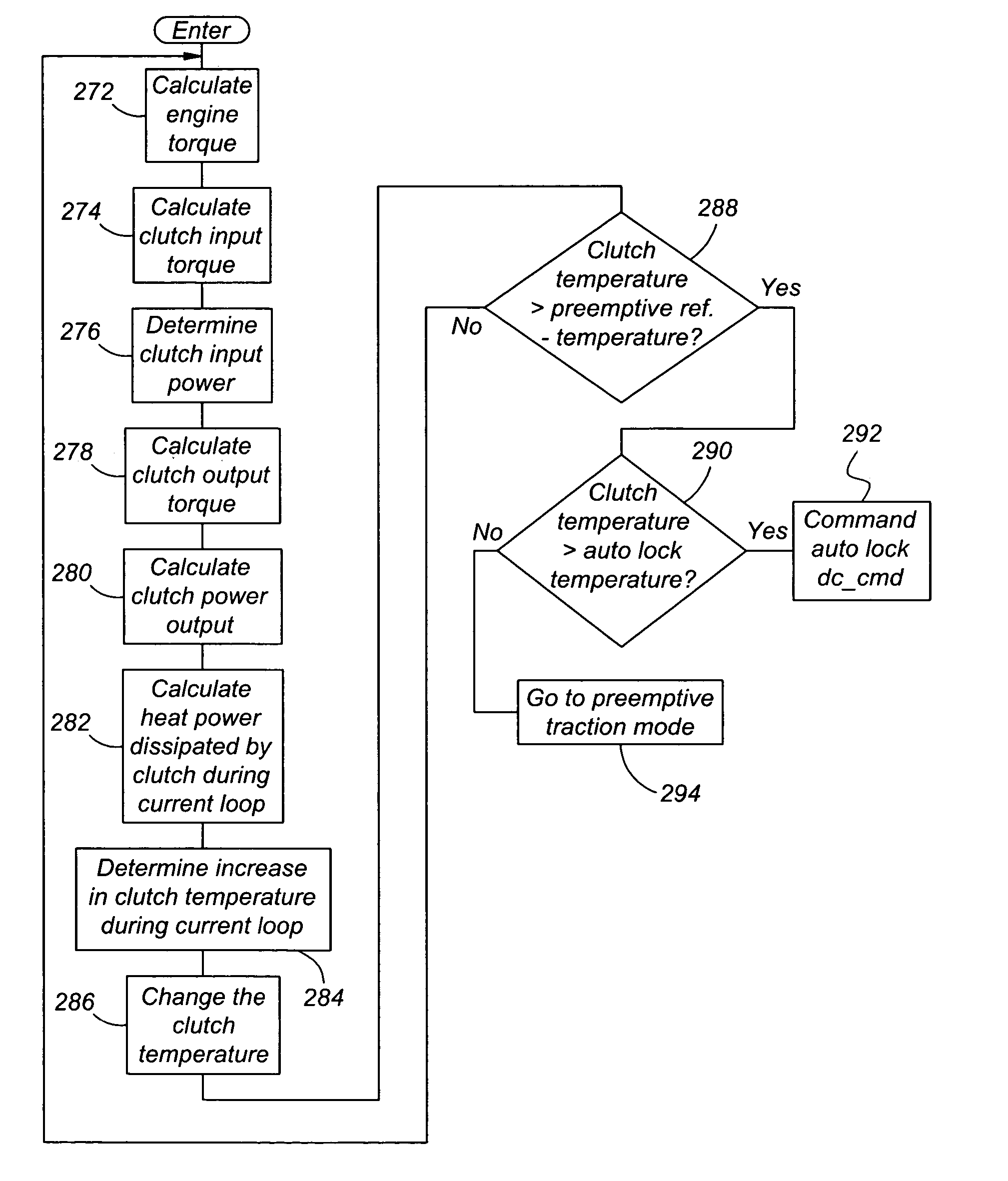

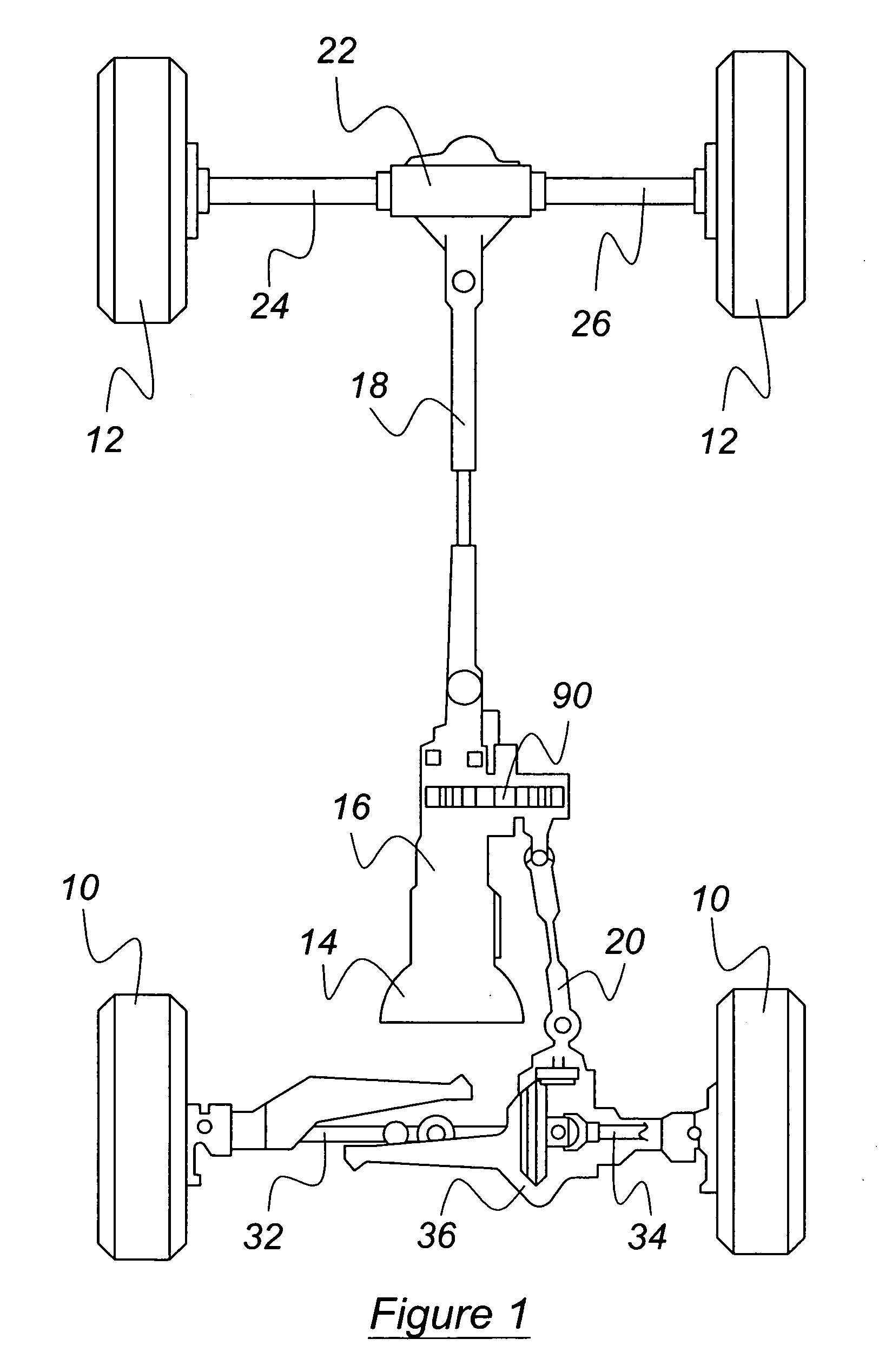

Method and system for controlling a transfer case clutch to protect against excessive heat

InactiveUS20050177294A1High clutch cooling capacityGreat clutch slipFluid couplingsDigital data processing detailsTransfer caseControl signal

In a motor vehicle driveline including a transfer case whose output is continually connected to a first output, a clutch, operating partially engaged, responds to a control signal to change the degree of clutch engagement, whereby a second output is connected driveably to the first output. A digital computer continually calculates a change in clutch temperature at frequent intervals and updates a running sum of clutch temperature changes. The control causes the clutch to more fully engage if the current calculated clutch temperature exceeds a predetermined reference clutch temperature.

Owner:FORD GLOBAL TECH LLC

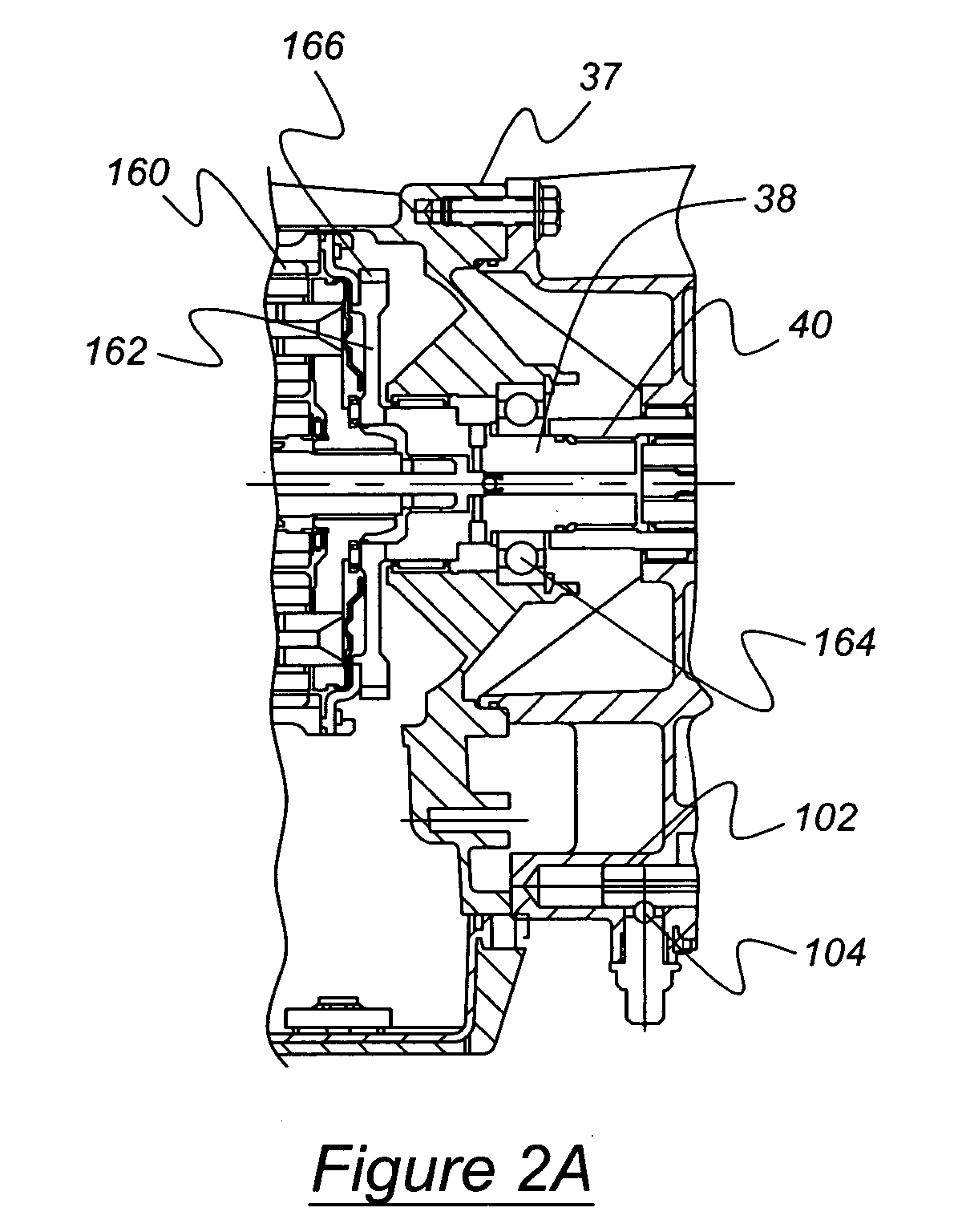

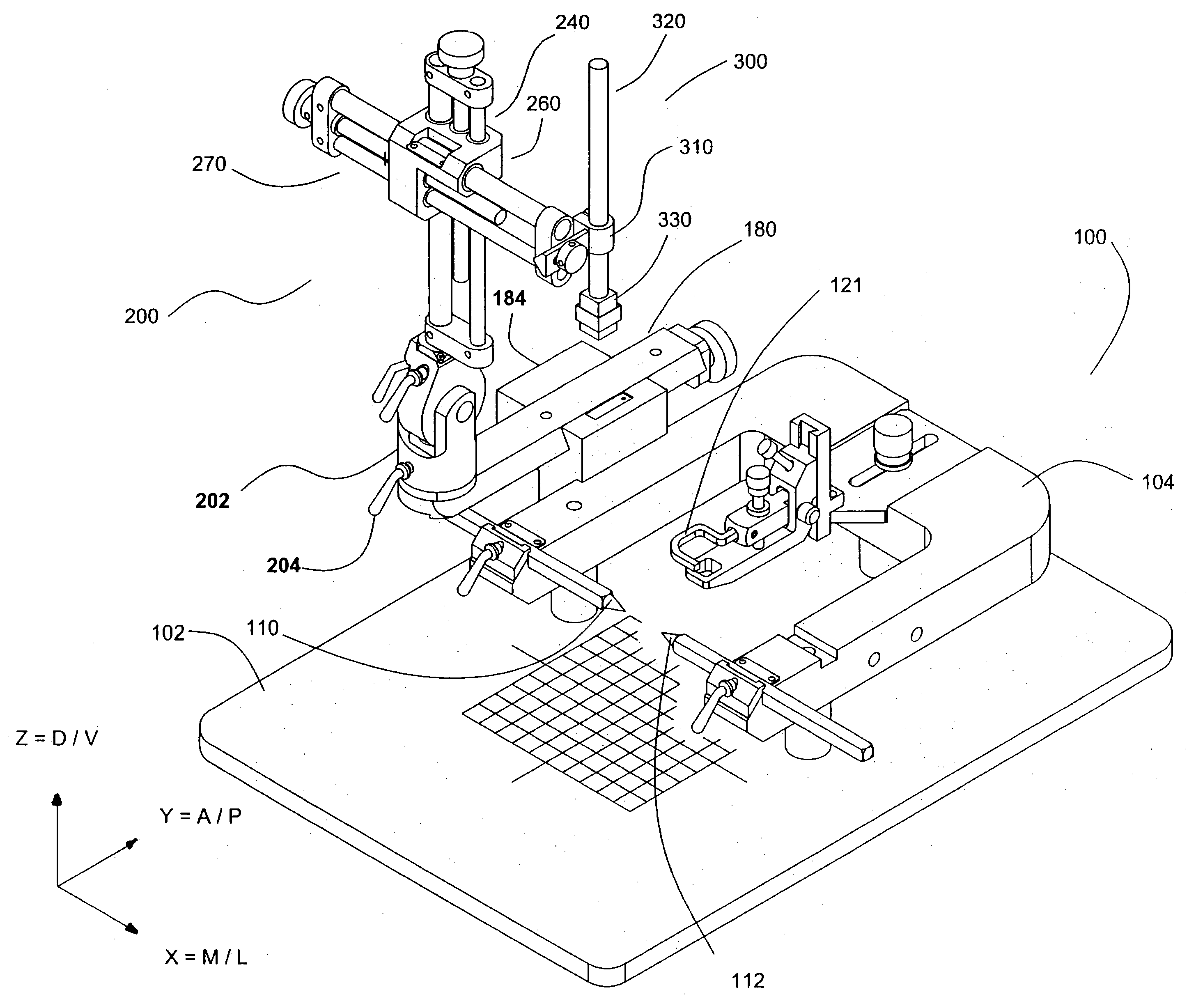

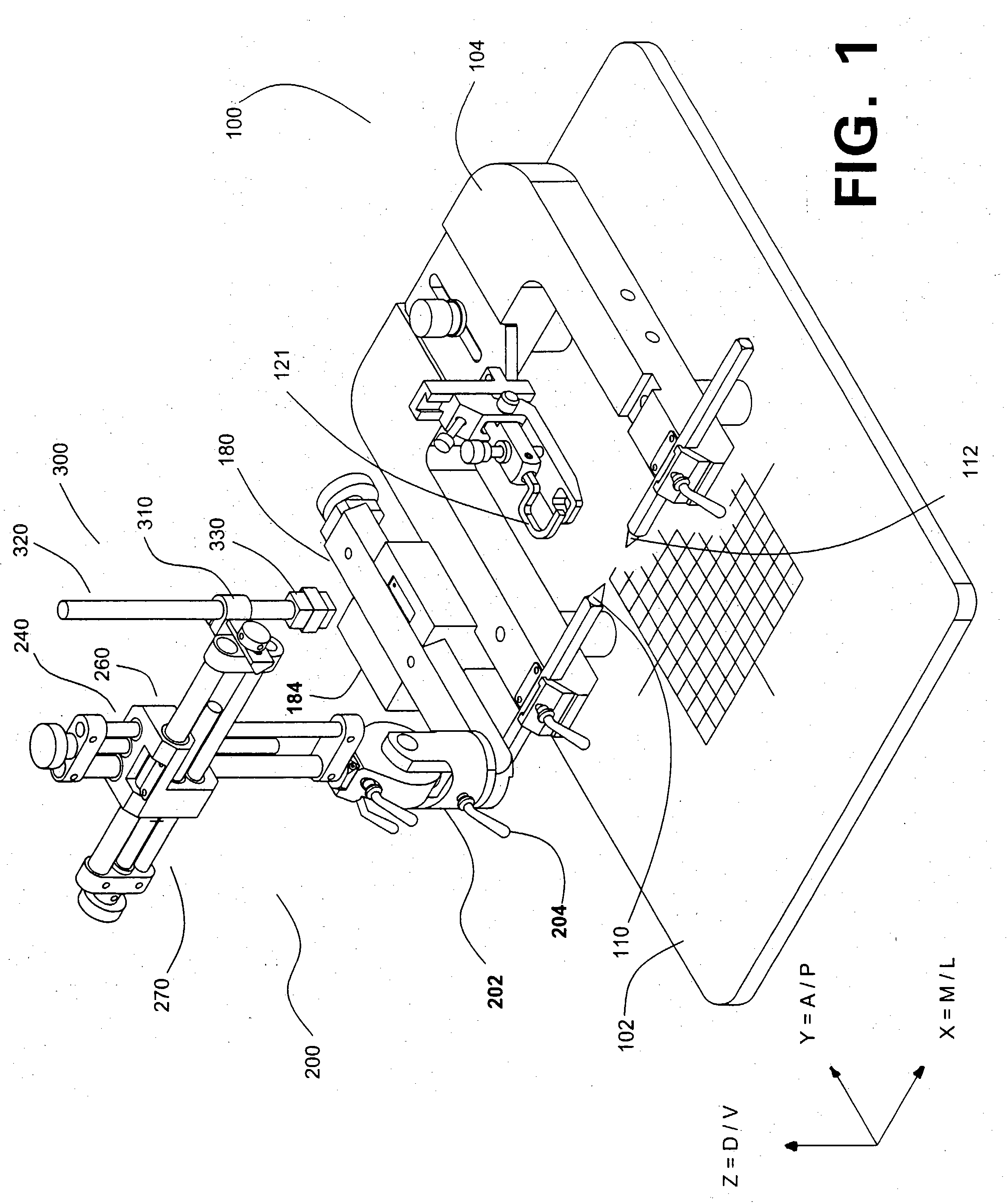

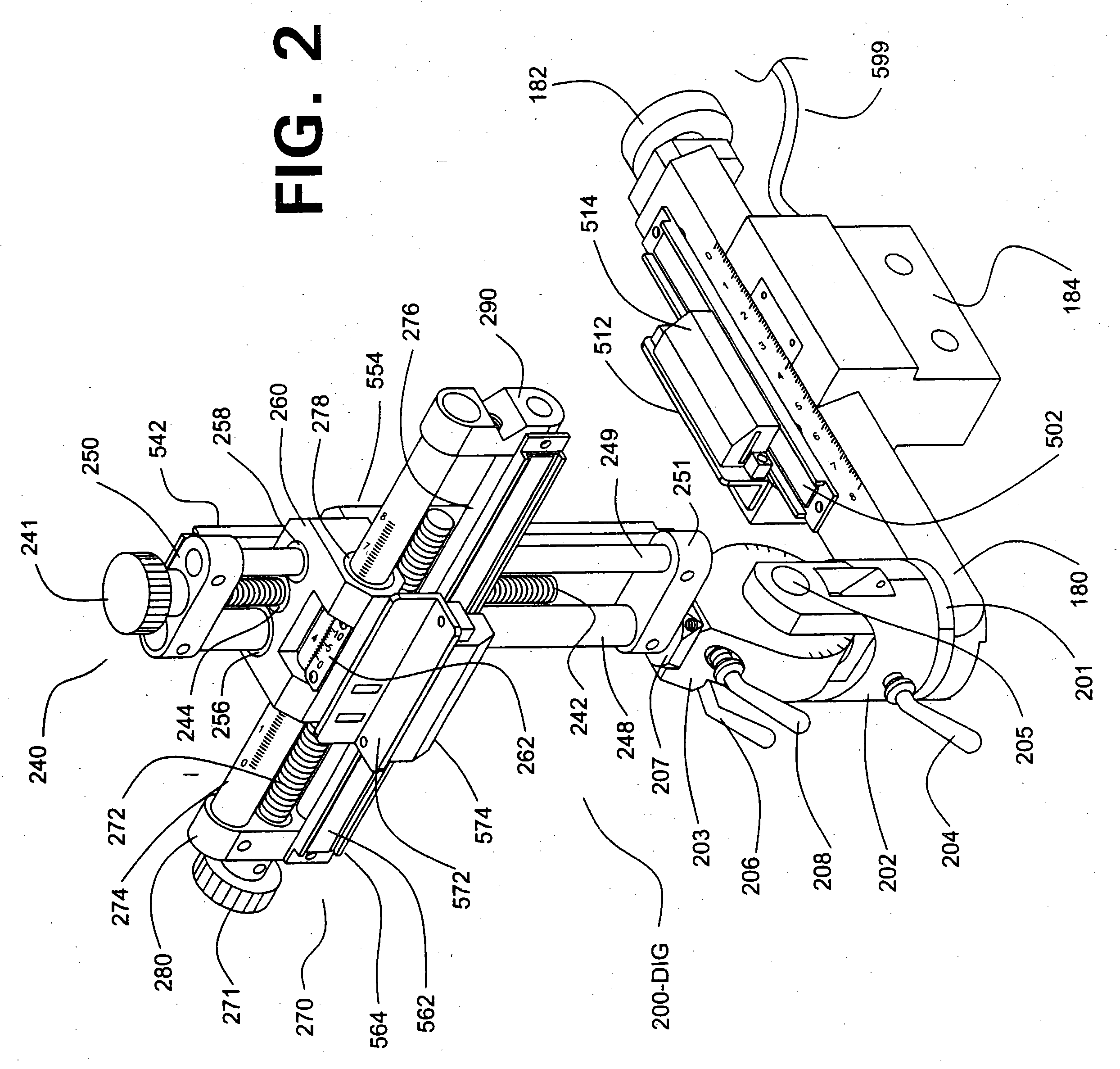

Digital stereotaxic manipulator with controlled angular displacement and fine-drive mechanism

InactiveUS20070055289A1Precise controlEasy to controlDiagnosticsAnimal fetteringVertical motionOrthogonal coordinates

A digital stereotaxic manipulator for animal research is provided with two enhancements. In one enhancement, rotary encoders are provided, to allow tilting of the manipulator, about vertical and / or horizontal axes, to be measured within a fraction of a degree. With assistance from software that applies sine and cosine values, orthogonal coordinates that are emitted by linear reader heads can be corrected to provide accurate orthogonal coordinates, even when an instrument has been rotated and / or tilted substantially. In a second enhancement, a “fine-drive” mechanism provides precise control over dorsal / ventral motion of an instrument. A radial gear is mounted on the main threaded shaft in the vertical arm assembly. A helical gear on a horizontal shaft is used to drive rotation of the radial gear and vertical shaft. If a 1:20 gearing ratio is provided by the helical and radial gears, this provides an operator with 20-times more precise control over vertical motion of an instrument. A detente is also provided, to enable the helical gear to pop out of position without damage, if an operator rotates the main vertical shaft before disengaging the fine-drive mechanism. A digital display device with touch-screen controls is also disclosed.

Owner:SCOUTEN CHARLES W +2

One Global Precise Time And One Maximum Transmission Time

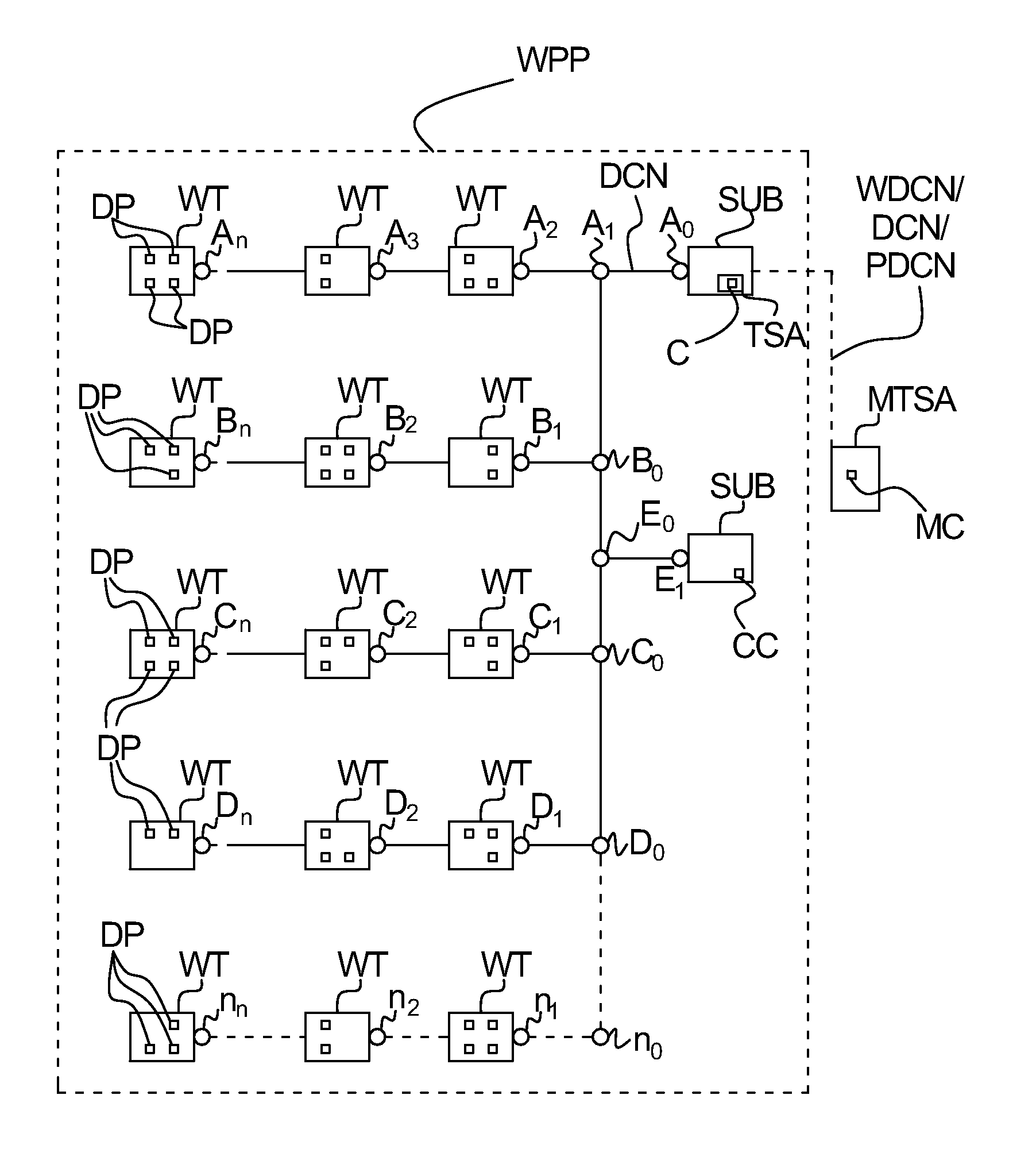

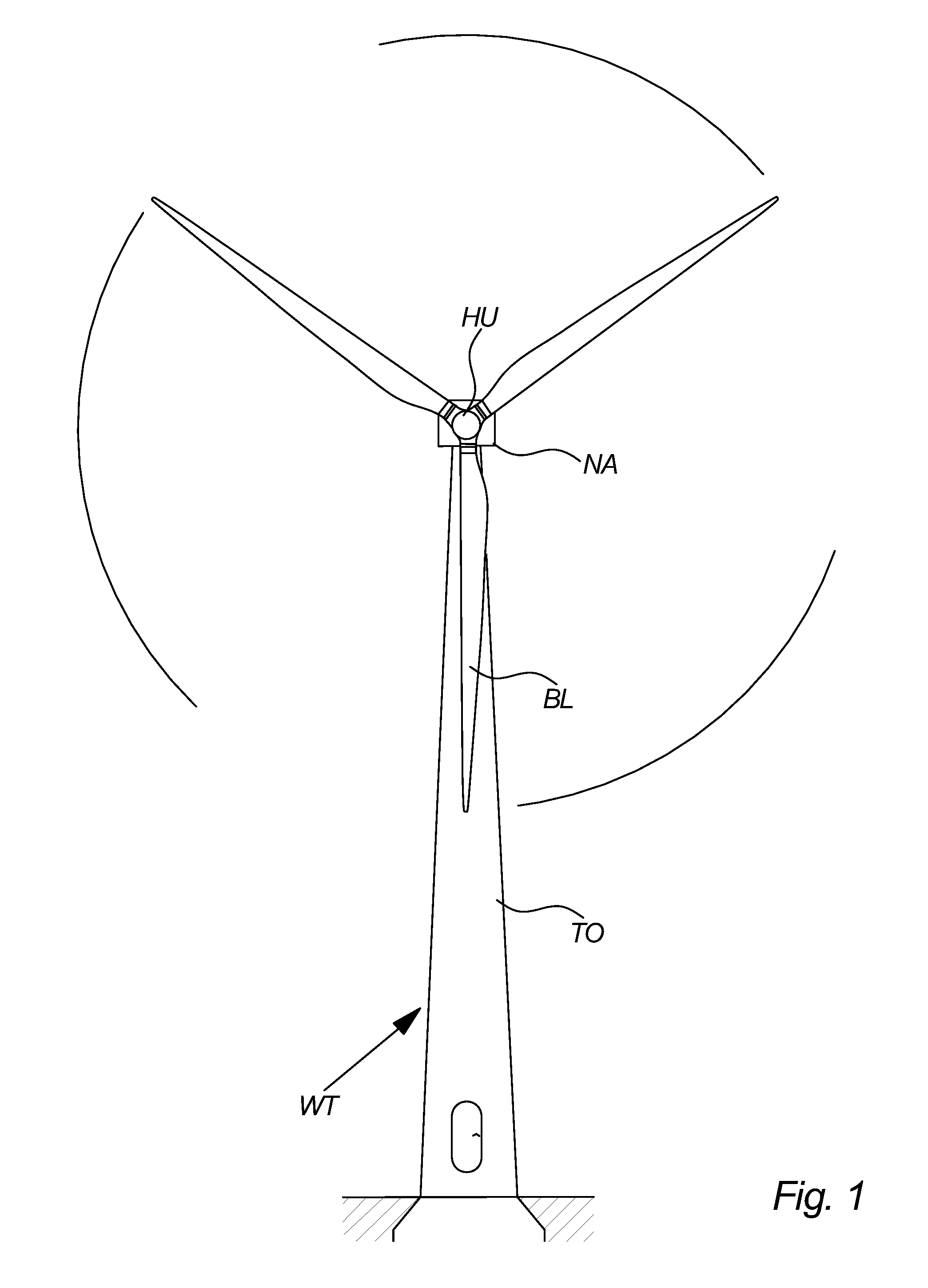

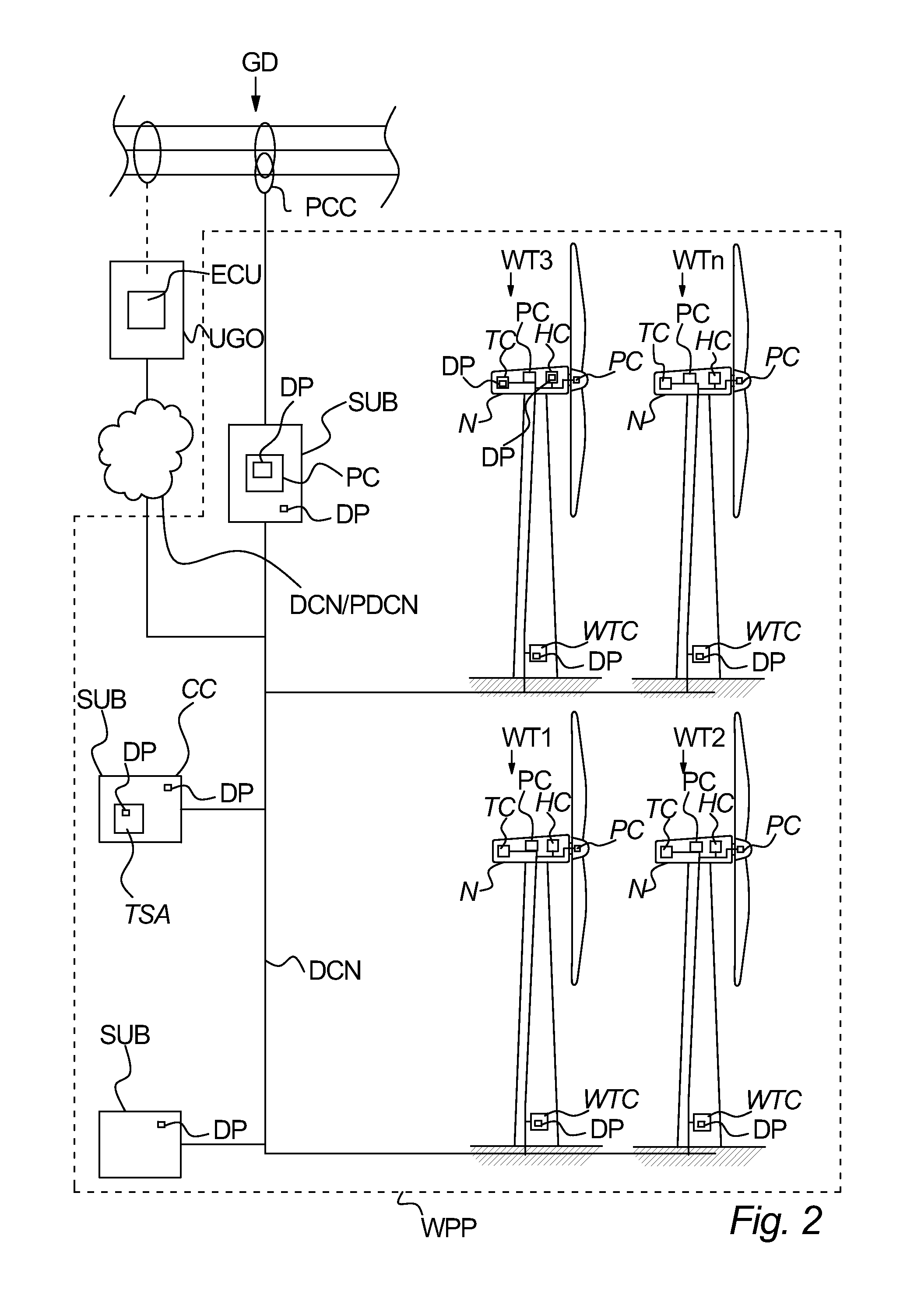

ActiveUS20100305767A1Precise controlPrecise and reliable calculationLevel controlWind motor controlSystem elementPeak value

Method of controlling a wind power system including a plurality of system elements, the wind power system including a plurality of data processors distributed in the system elements, the method including the steps of: synchronizing at least a part of the data processors to at least one reference signal distributed to the data processors from a time synchronization arrangement, associating the data processors with local clock generation circuitries, wherein the local clock generation circuitries associated with data processors of a first subset of the data processors have a peak-to-peak tracking jitter higher than or equal to a predetermined threshold value and wherein a second subset of the data processors have a peak-to-peak tracking jitter less than the predetermined threshold value, controlling at least one of the system elements at least partly by means of a data processor from the first or second subset of data processors.

Owner:VESTAS WIND SYST AS

Microprojections with capillary control features and method

InactiveUS20070224252A1Precise controlMicroneedlesMedical devicesBiomedical engineeringStratum corneum

The present invention provides methods and devices for reducing the coating variability of a transdermal microprojection delivery device. The device includes one or more stratum corneum-piercing microprojections, wherein each microprojection has a capillary control feature that restricts migration of a coating formulation.

Owner:ALZA CORP

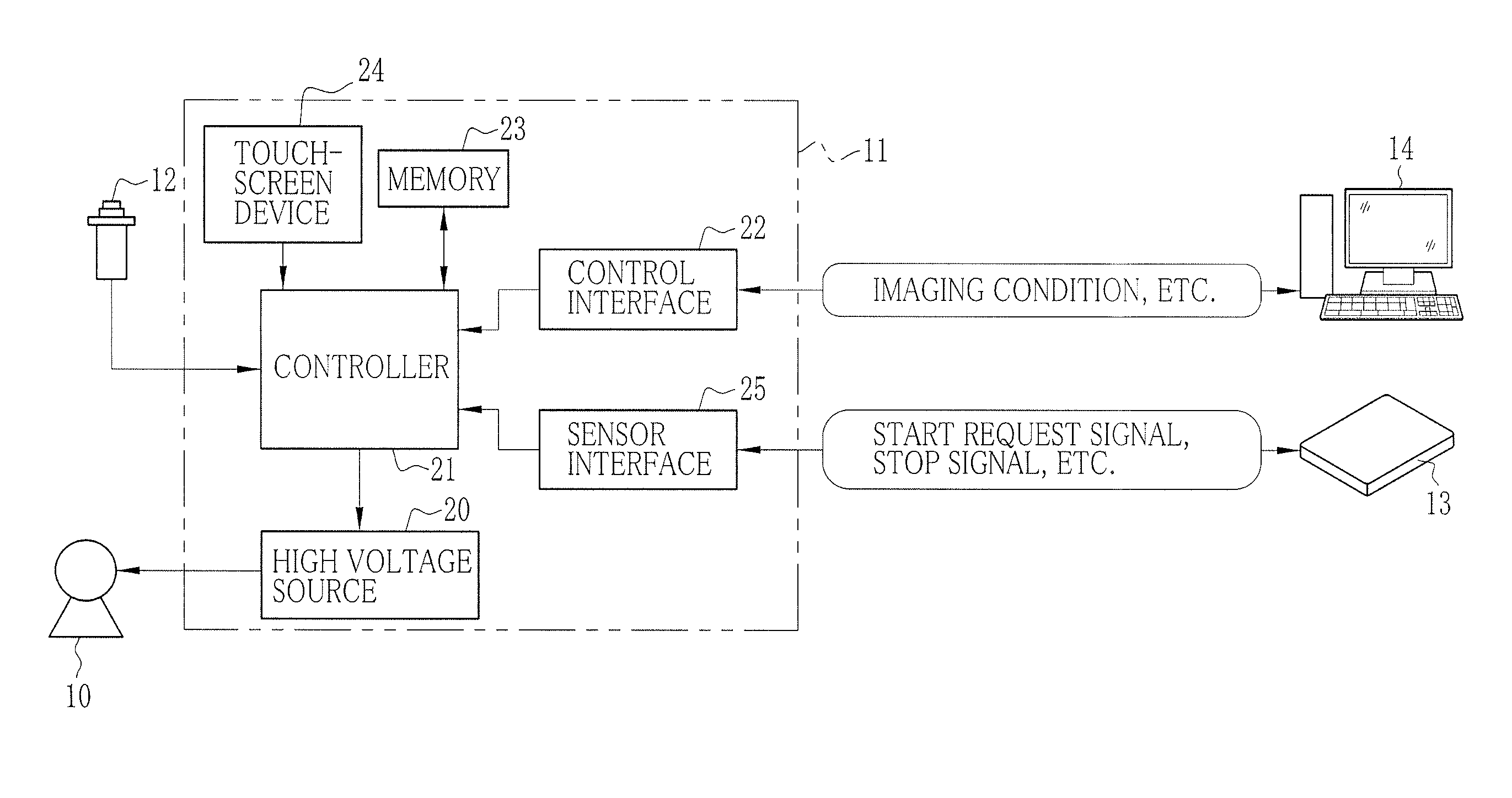

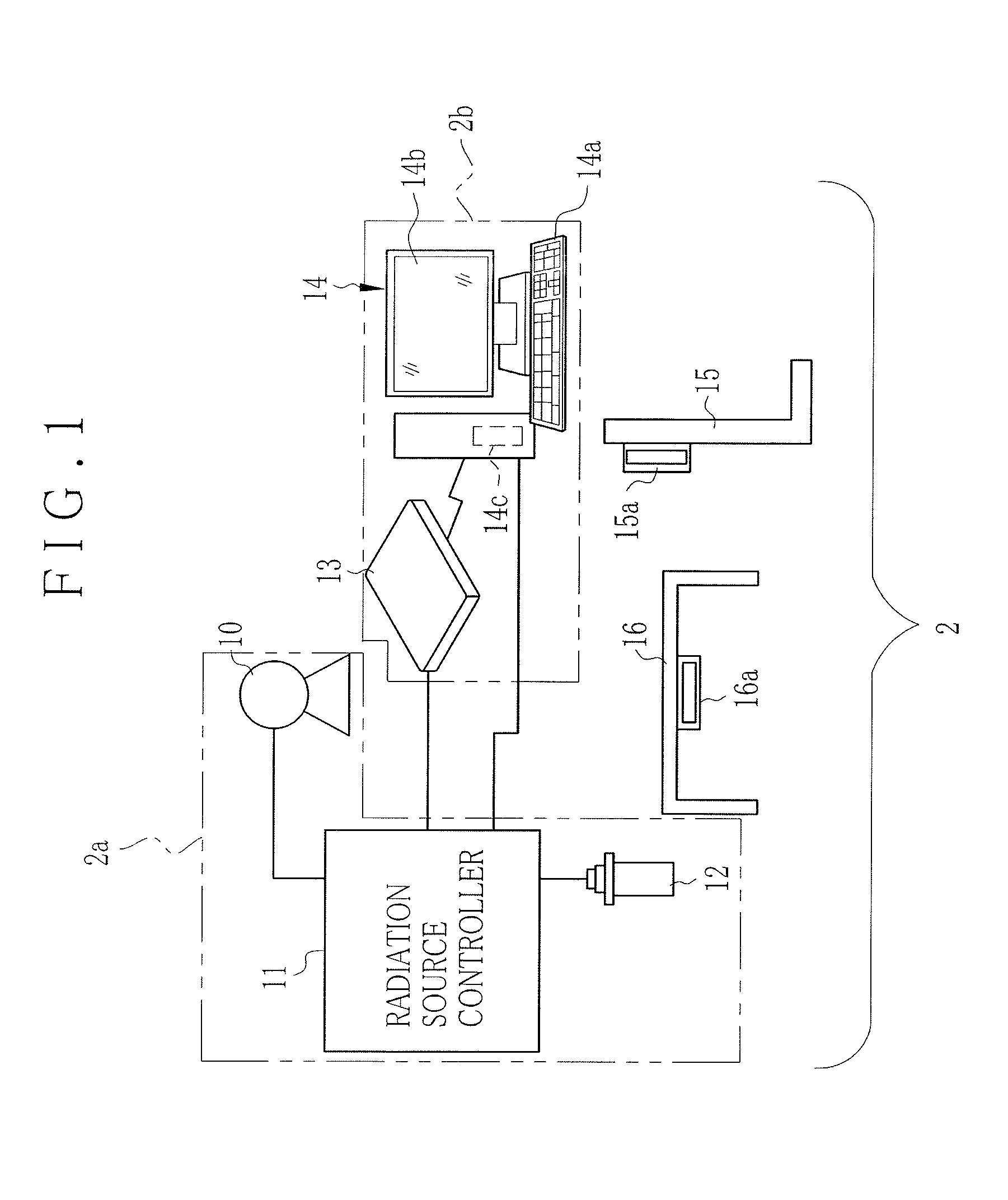

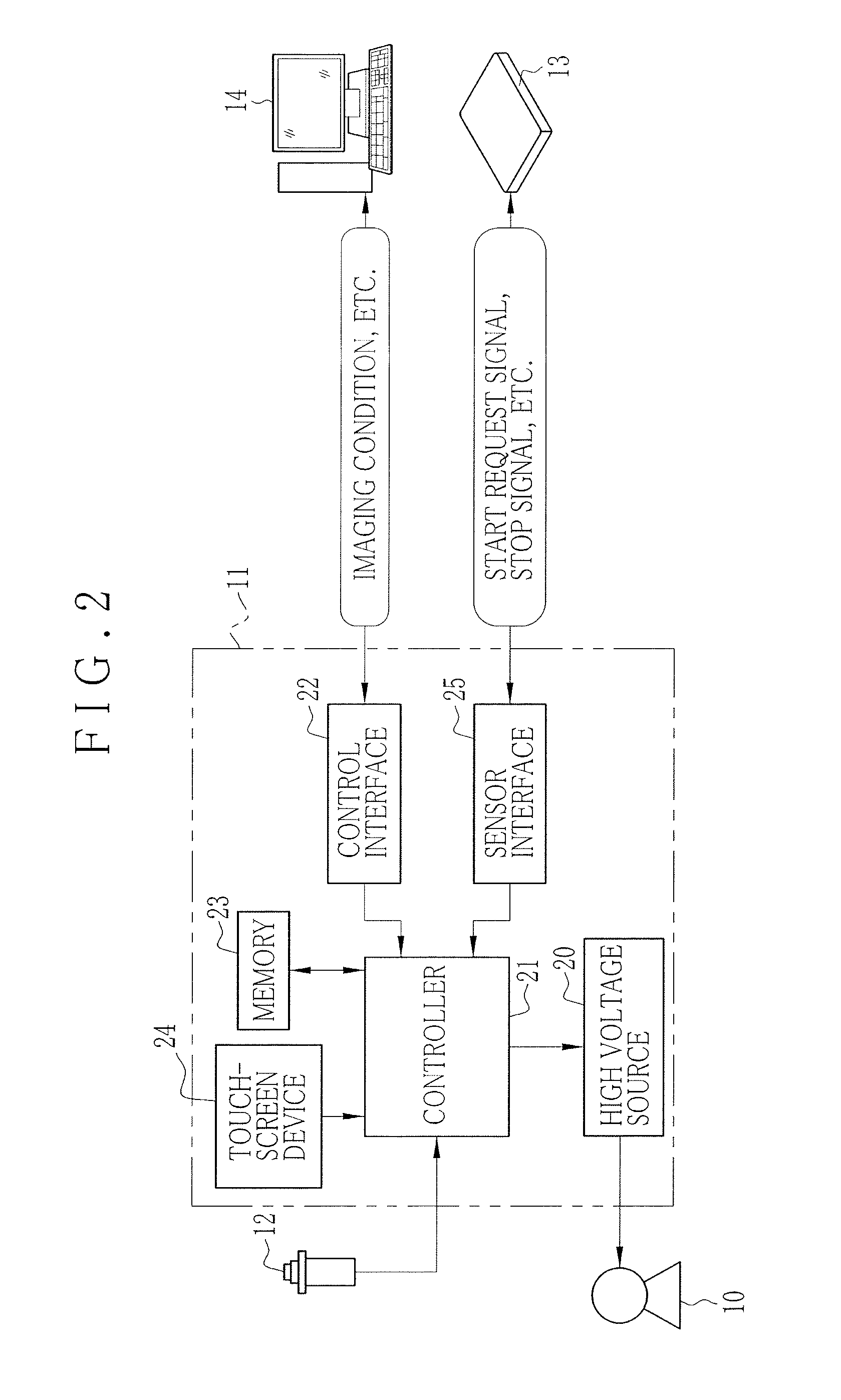

Radiographic imaging apparatus, method and system

ActiveUS20150078528A1Precise controlTelevision system detailsRadiation diagnostic device controlX ray irradiationStart time

In an X-ray imaging apparatus, a detection panel has monitor pixels for monitoring X-rays. A signal processor samples a dose signal of a dose per unit time of X-rays according to an output of the monitor pixels. A start detector checks whether irradiation of X-rays is started according to a result of comparison between the dose signal and a start threshold. An AEC device acquires cumulative dose from a start time of the start of irradiation of X-rays until acquisition time after a predetermined time according to the dose signal. According to the cumulative dose, a predicted time point of a reach of the cumulative dose to a target dose is estimated. A stop signal is transmitted to a radiation source controller at the predicted time point, to stop the irradiation of X-rays.

Owner:FUJIFILM CORP

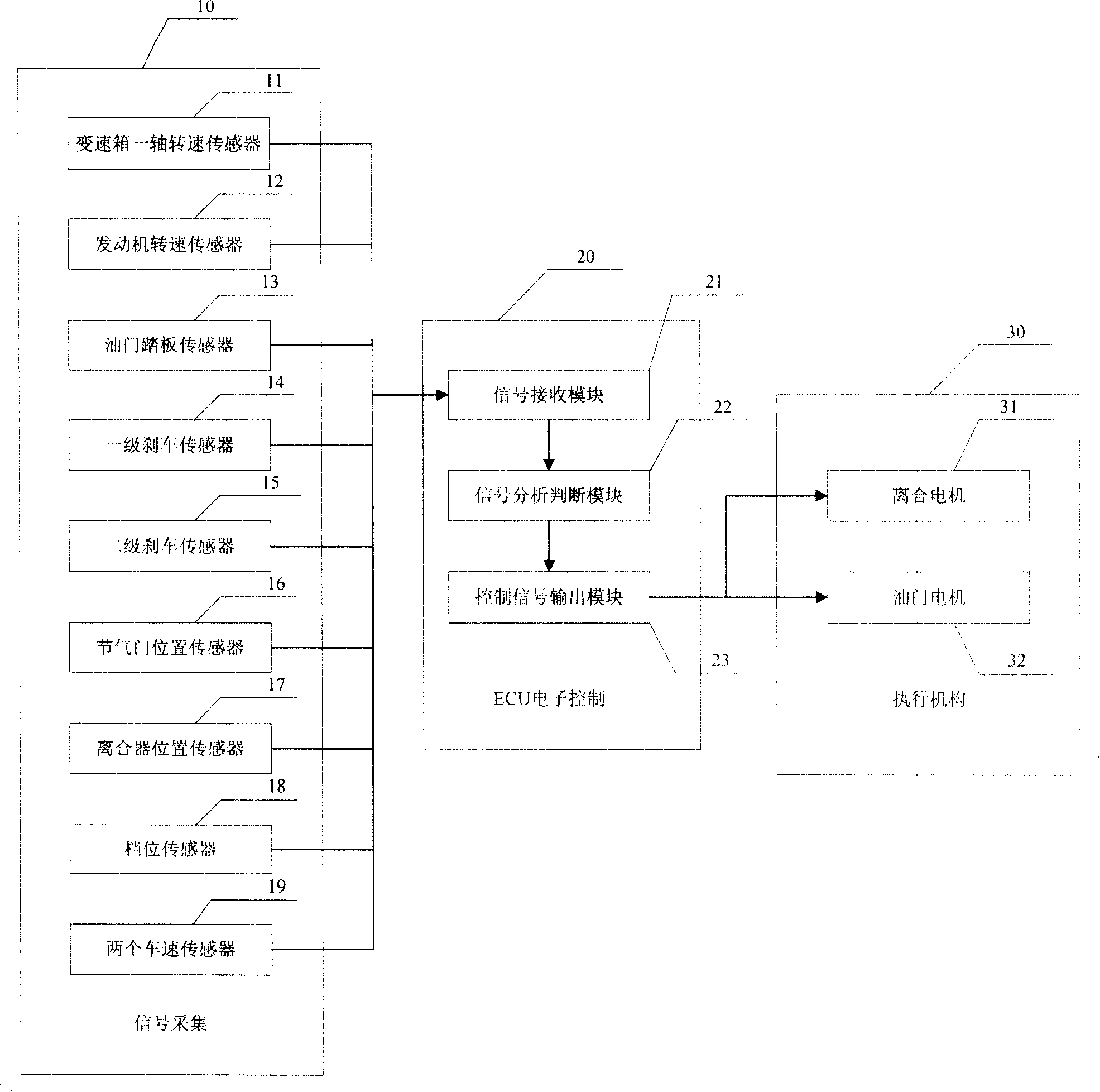

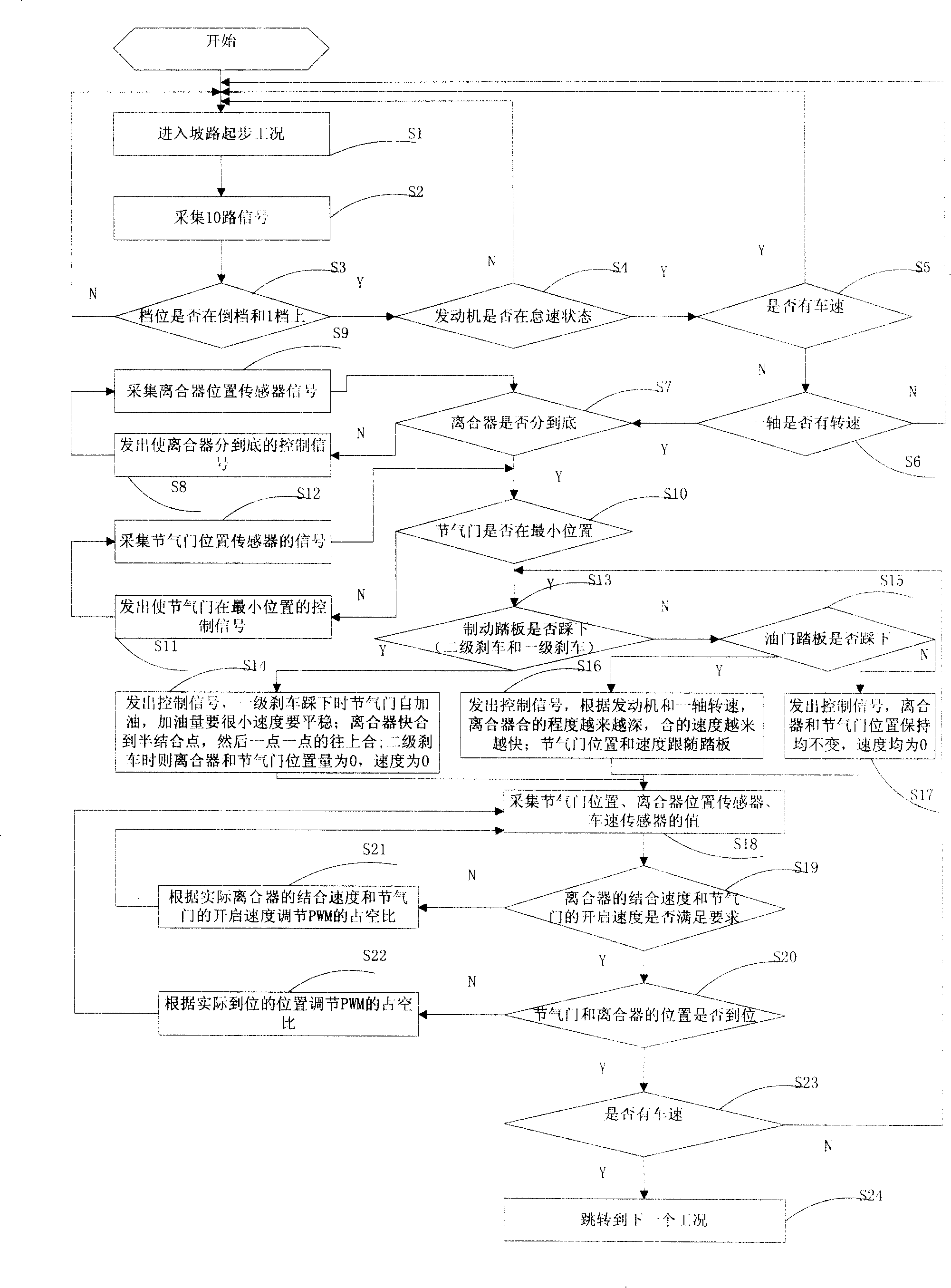

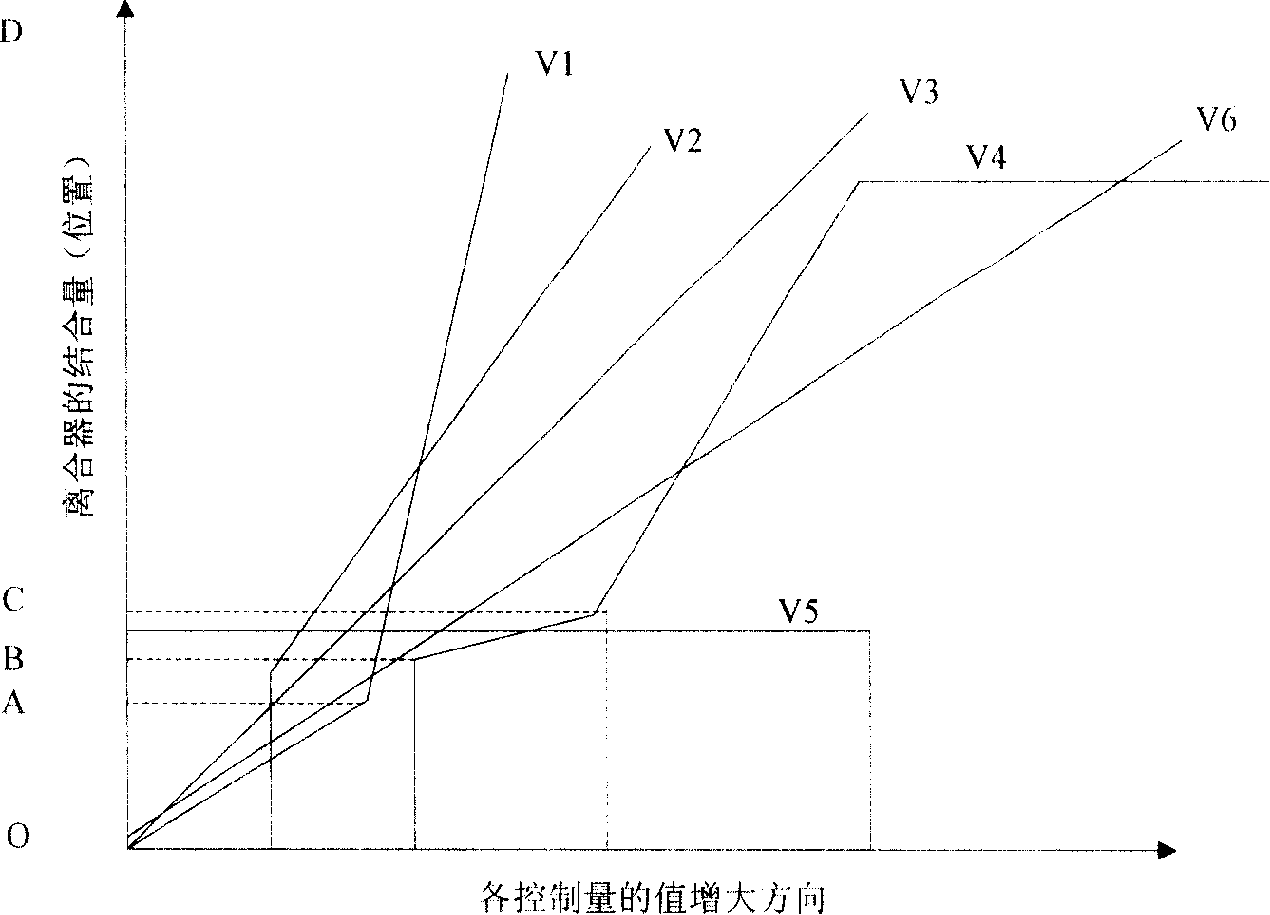

Control device and method for AMT vehicle sloping route starting

The invention discloses a control device and method for starting of an AMT vehicle on a ramp, which comprises a signal collecting unit, an electronic control unit and an actuating mechanism. The electronic control unit comprises a signal receiving module, a signal analysis and judgment module and a control signal output module, and the actuating mechanism comprises a clutch motor and a throttle motor. The signal collecting unit at least comprises a brake sensor of first level and a brake sensor of second level, the signal analysis and judgment module determines the engaging extent of a clutch and the opening extent of an air control shutter according to the signals collected by the brake sensors of first and second level and received by the signal receiving module, and the control signal output module respectively controls the actions of the clutch motor and the throttle motor according to the engaging extent of the clutch and the opening extent of the air control shutter. The control method for starting of the AMT vehicle on the ramp provided by the invention enables the engaging extent of the clutch and the opening extent of the air control shutter not to be zero when a brake pedal is released, thereby overcoming the starting spark extinction and back sliding of the vehicle caused by factors like friction force, engine torque, etc. during staring of the vehicle on the ramp.

Owner:BYD CO LTD

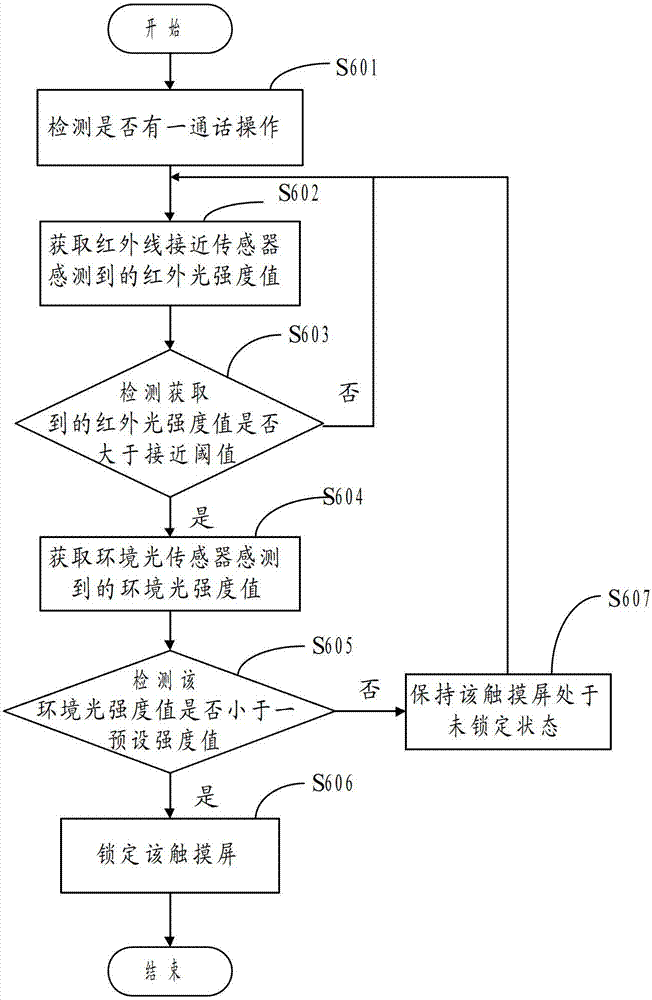

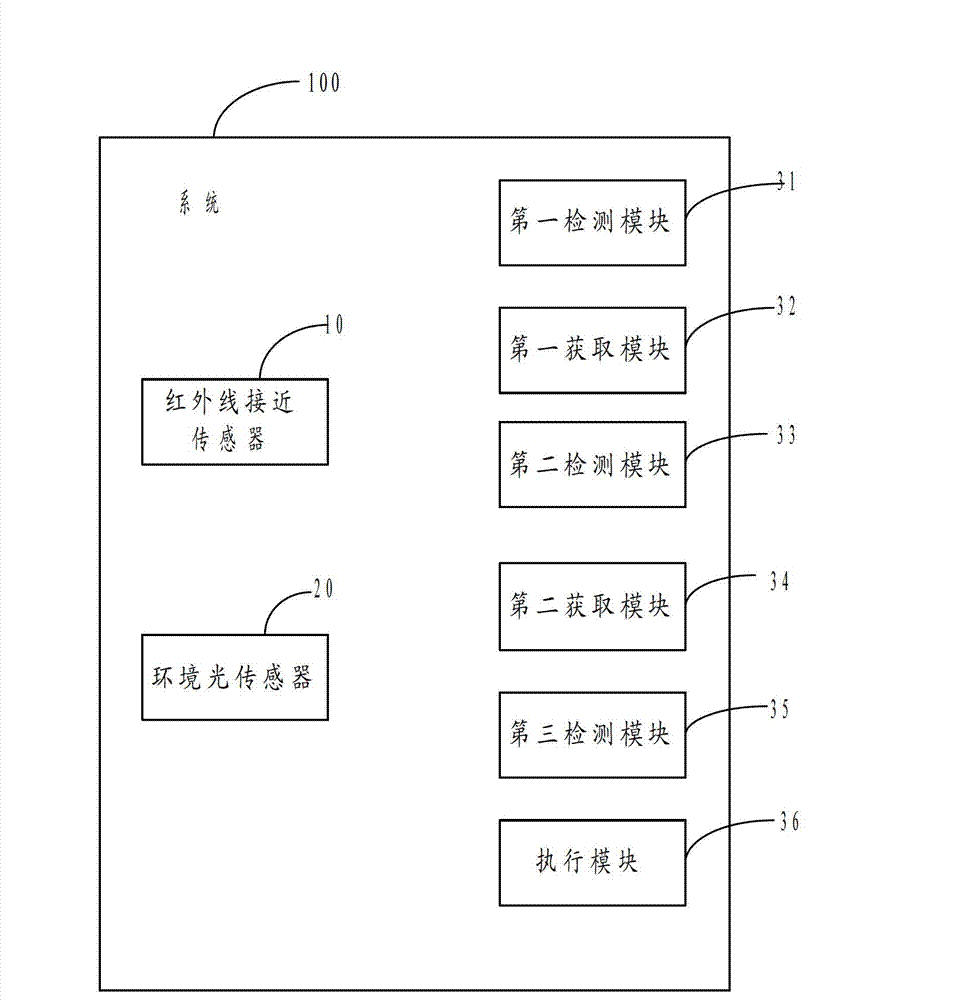

Method and system for controlling working state of touch screen of mobile terminal

The invention provides a method and a system for controlling a working state of a touch screen of a mobile terminal. The mobile terminal comprises an infrared proximity sensor and an ambient light sensor. The infrared proximity sensor is used for sensing infrared light intensity values, and the ambient light sensor is used for sensing ambient light intensity values. The method includes steps of detecting whether communication operation is carried out or not; acquiring an infrared light intensity value sensed by the infrared proximity sensor if the communication operation is carried out; detecting to judge whether the infrared light intensity value is larger than a proximity threshold value or not; acquiring an ambient light intensity value sensed by the ambient light intensity sensor if the infrared light intensity value is larger than the proximity threshold value; detecting to judge whether the ambient light intensity value is smaller than a preset intensity value or not; and locking the touch screen if the ambient light intensity value is smaller than the preset intensity value. The method and the system have the advantage that the threshold value of the infrared proximity sensor is set, so that influence of ambient light on the accuracy of a detection function of the infrared proximity sensor can be prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

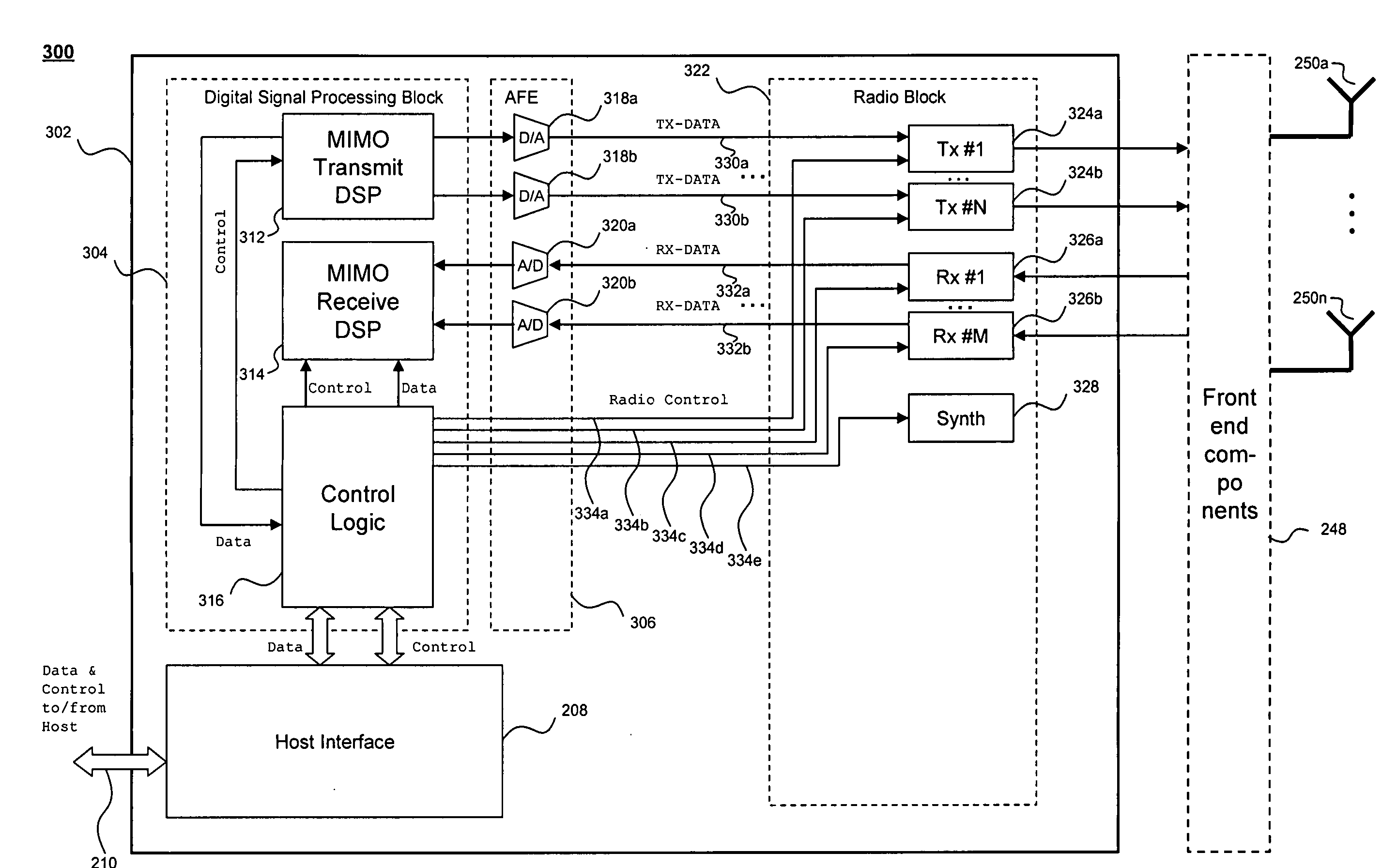

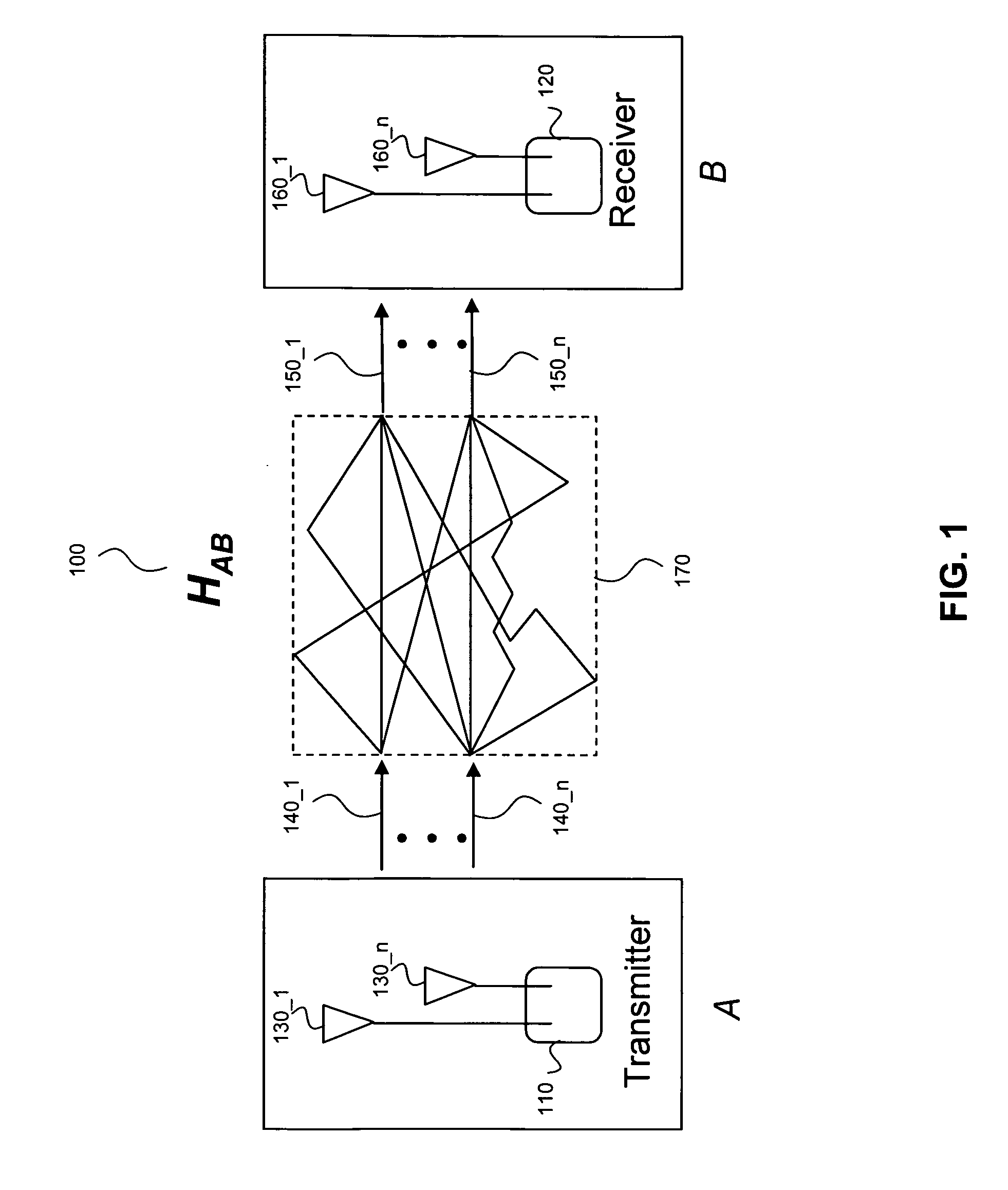

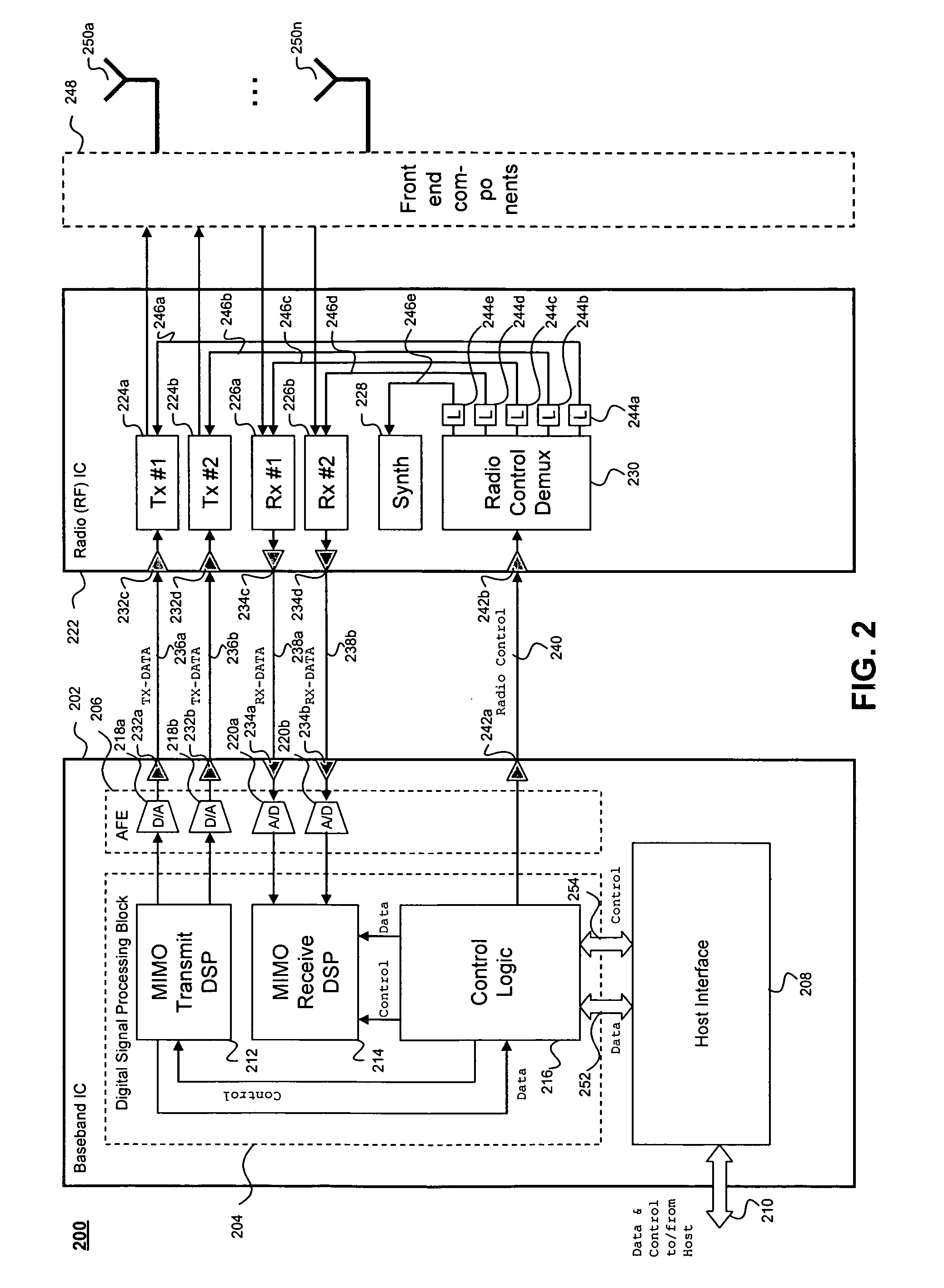

Single-chip wireless tranceiver

ActiveUS20080310487A1Precise controlPrecise low-latency controlSolid-state devicesDiversity/multi-antenna systemsDigital signal processingTransceiver

Embodiments of a wireless transceiver are provided. Embodiments can be used in multiple-input-multiple-output (MIMO) wireless transceivers. In an embodiment, radio control signal bundles are provided as direct parallel interconnects between digital signal processing modules and the radio module of the wireless transceiver to enable a precise low-latency control of radio functions. In another embodiment, a separate physical line is provided to control each radio setting of the radio module, thereby enabling simultaneous real-time control of any number of radio settings. In a further embodiment, the various digital and analog components of the wireless transceiver are integrated within a single chip of the same process technology.

Owner:AVAGO TECH INT SALES PTE LTD

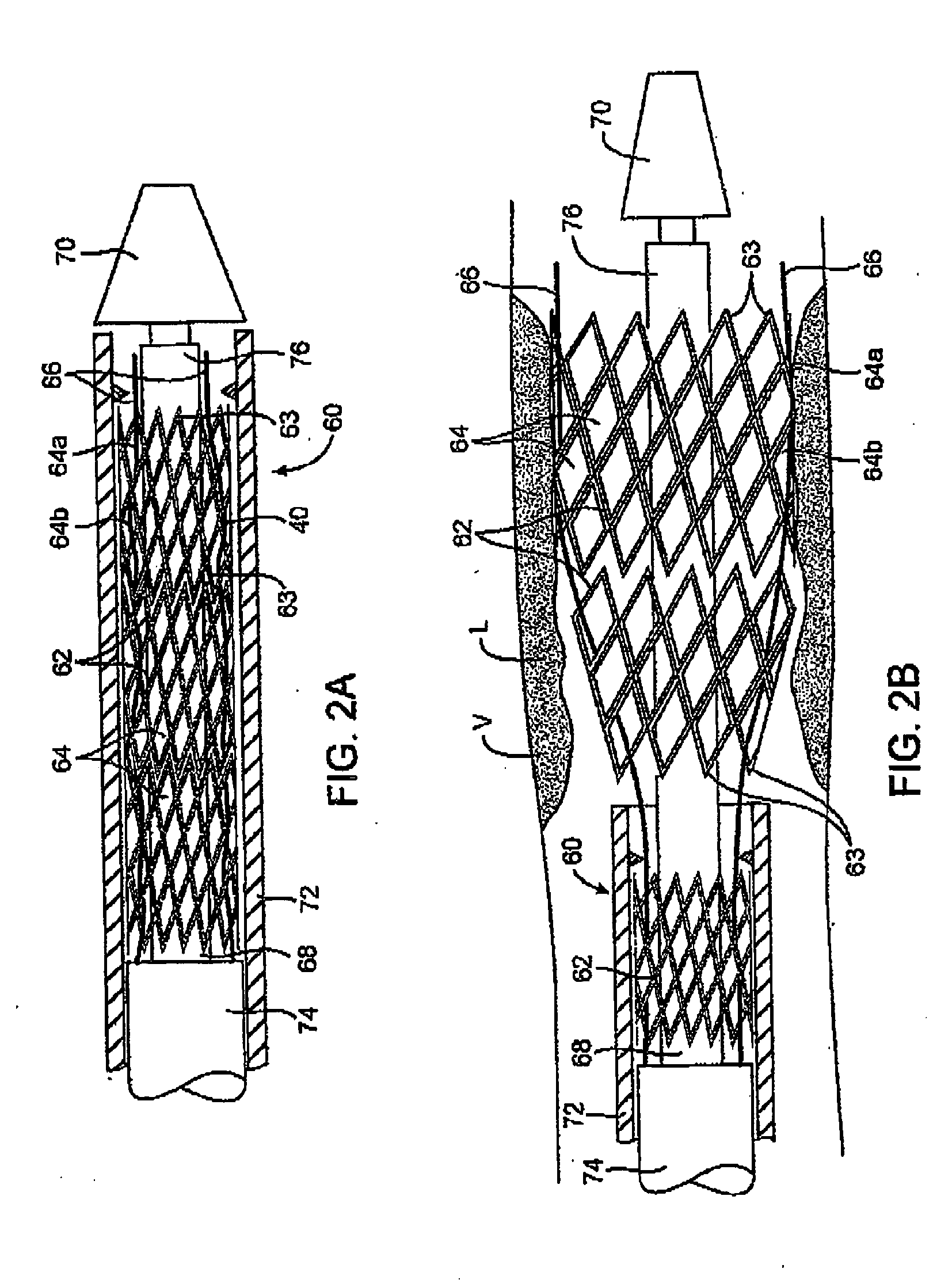

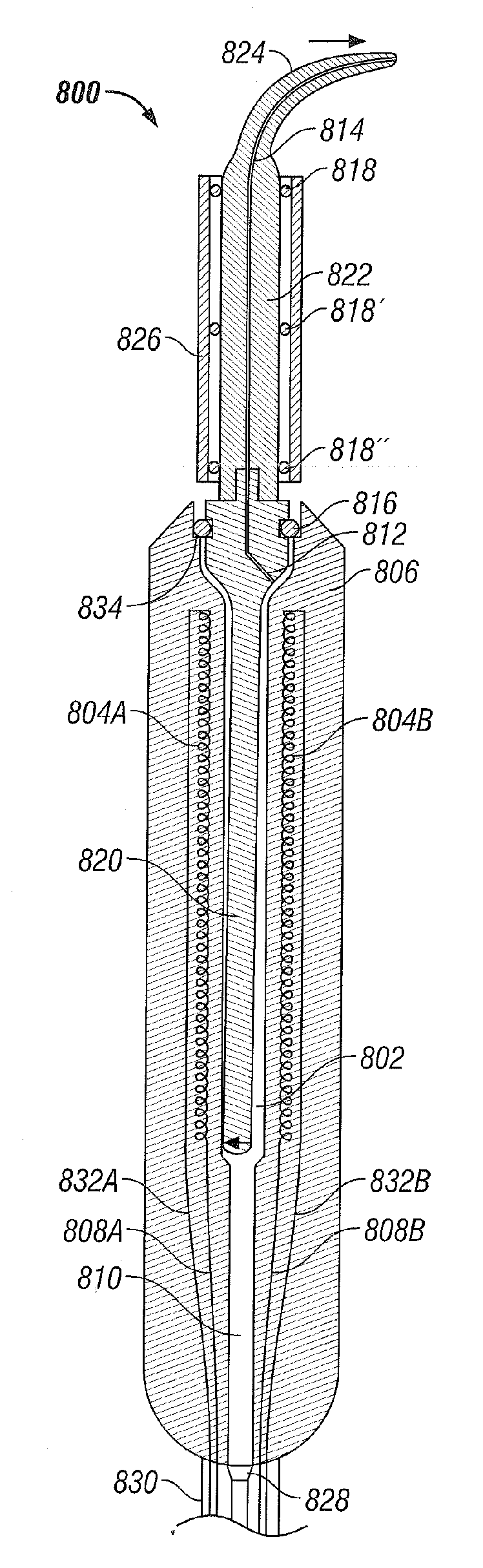

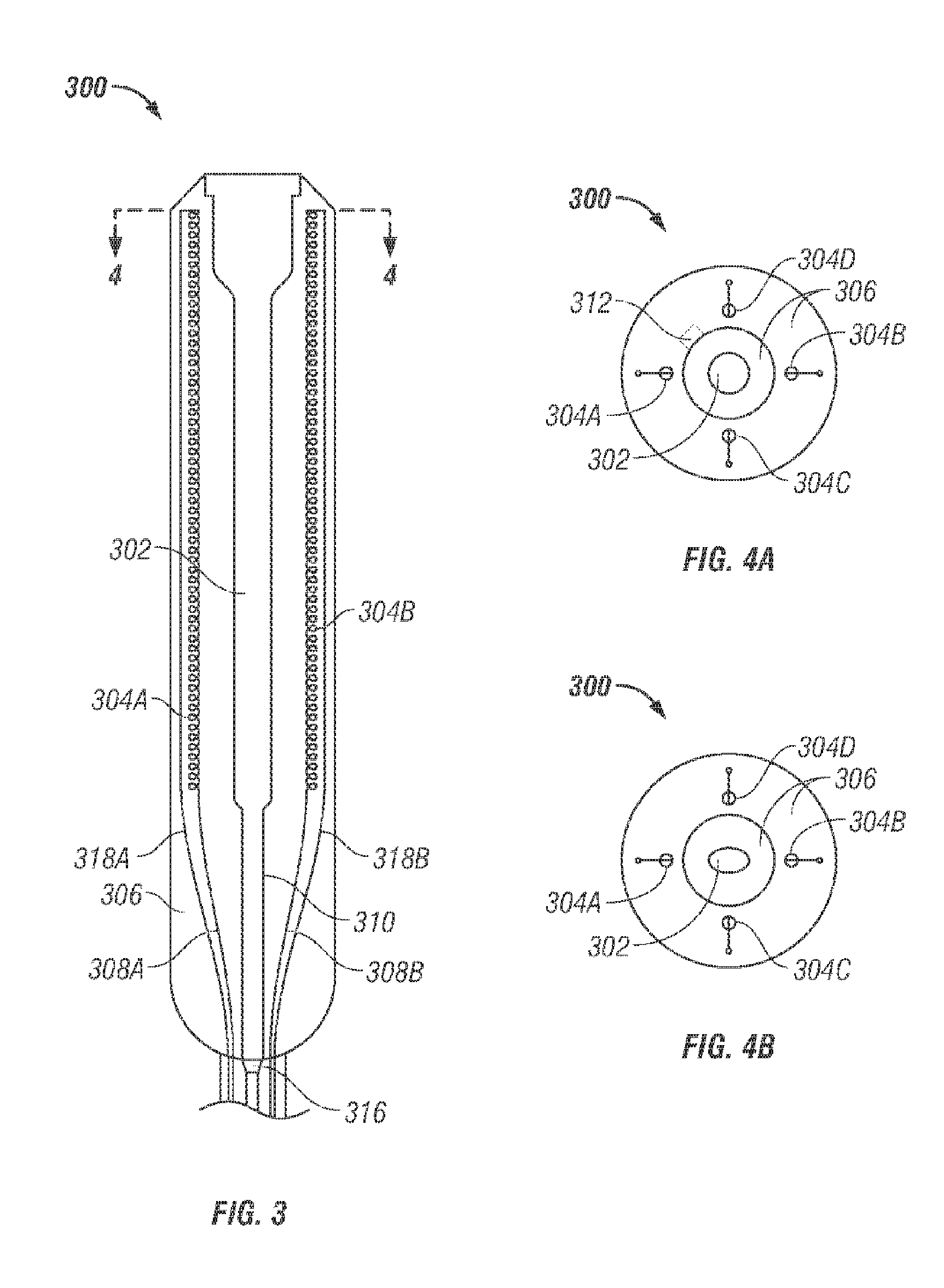

Movable Pin Ultrasonic Transducer

InactiveUS20080015551A1High precision frequency controlPrecise controlTooth pluggers/hammersSurgeryElectromagnetic fieldEngineering

An ultrasonic tool is disclosed with a handpiece (300, 500, 806) containing coils (304A-304D; 504A-504D; 804A-804B) that produce an electromagnetic field that vibrates a magnetic rod (102, 702A, 702B, 820) of a moveable pin transducer (MPT) 100 disposed within the handpiece. Ultrasonic vibrations are produced when the coils are selectively powered by an ultrasonic signal generator, which can include a stepper motor control apparatus (1300, 1400). A tip 106 can be removably attached to an MPT 100. A channel (708A, 708B) in the magnetic rod (700A, 700B) can allow fluidic communication with a handpiece fluid supply channel (310, 510). A method of vibrating a tool can include controllably energizing at least one electromagnetic coil contained within a handpiece to vibrate a magnetic rod and an attached tip. The method can include varying the energy to at least one of the electromagnetic coils with a stepper motor control apparatus.

Owner:FEINE JAMES MR

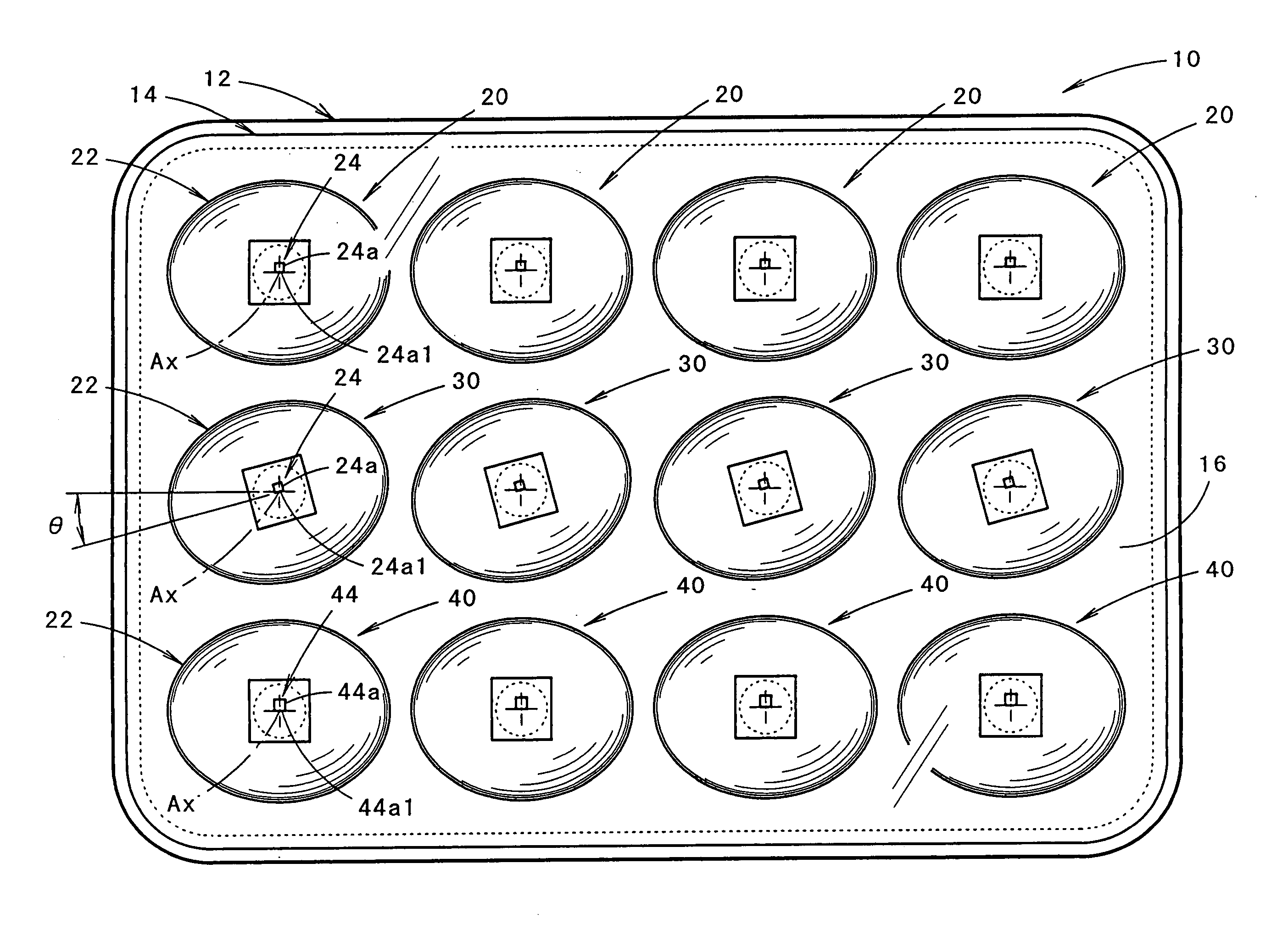

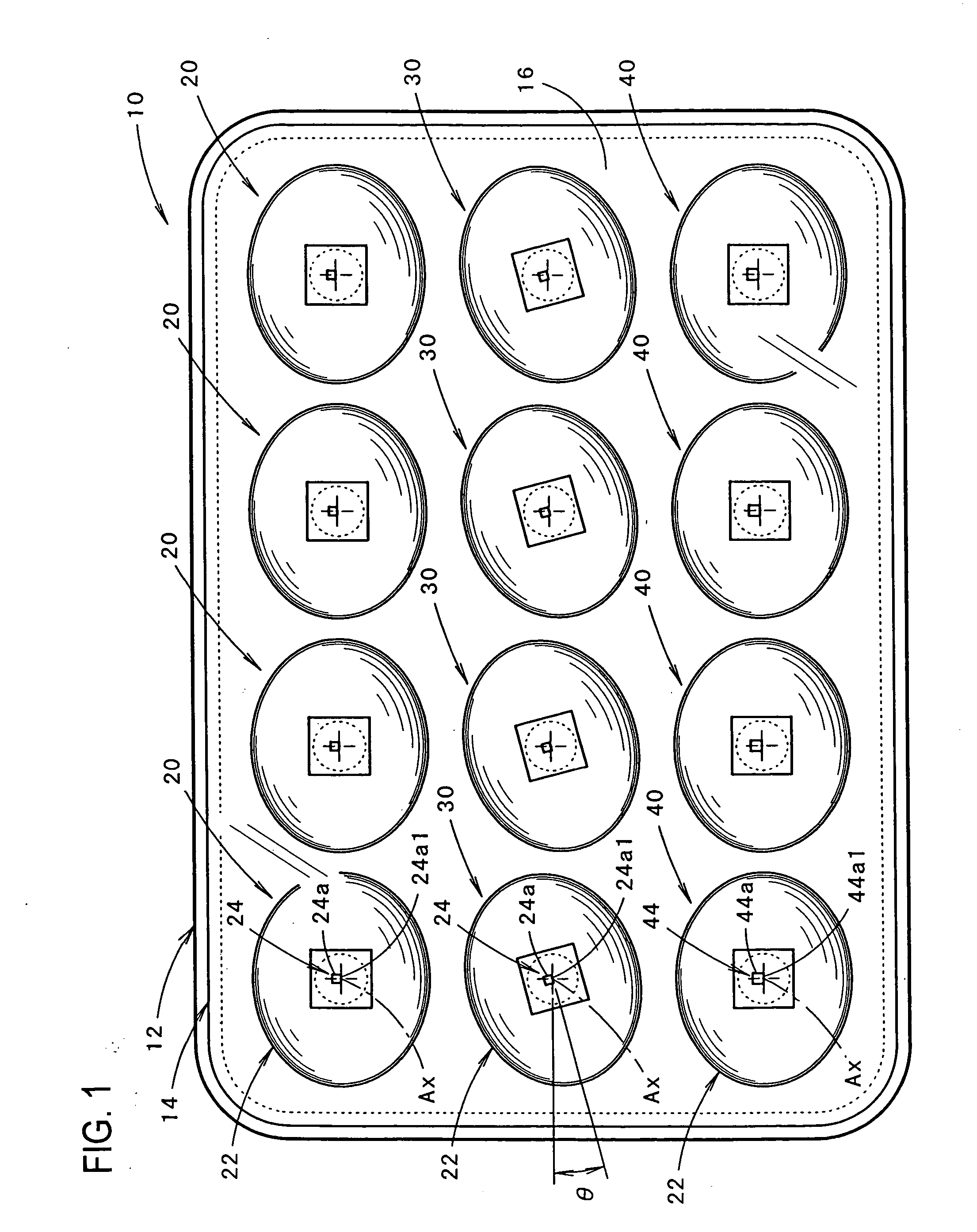

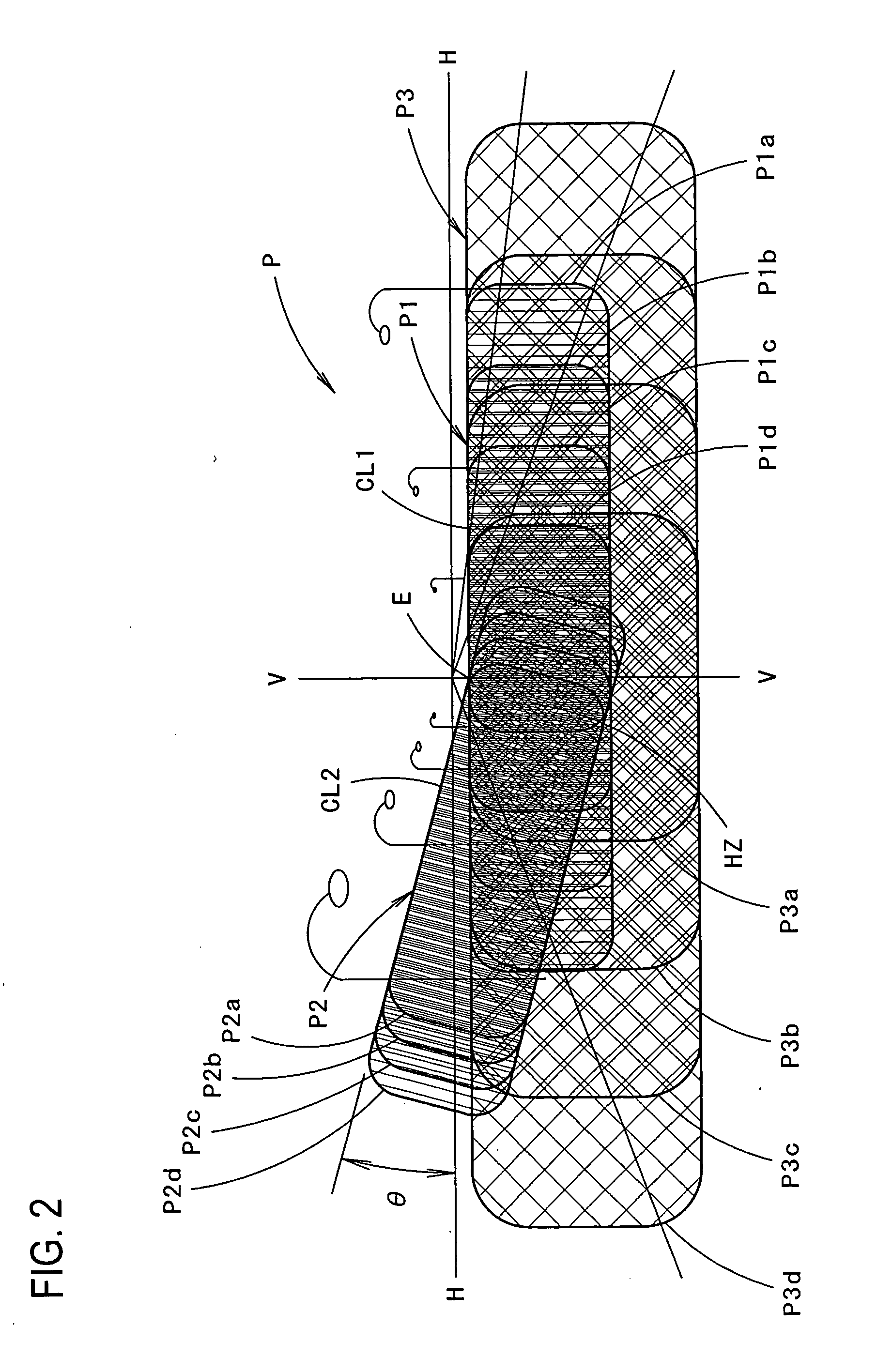

Lamp unit for forming a cut-off line and vehicular headlamp using the same

ActiveUS20050068786A1Simple configurationPrecise controlLighting support devicesPoint-like light sourceHeadlampEngineering

A lamp unit for a vehicular headlamp includes a projection lens disposed on an optical axis extending in a vehicle longitudinal direction and a semiconductor light-emitting element having a light-emitting chip with a lower end edge formed linearly. The semiconductor light-emitting element is disposed in the rear of the projection lens facing forward so as to position the lower end edge 24a1 on the optical axis. The projection lens projects light from a point on the optical axis of the lower end edge within a vertical cross section as parallel light, and projects light from a point on the optical axis of the lower end edge within a horizontal cross section as diffused light.

Owner:KOITO MFG CO LTD

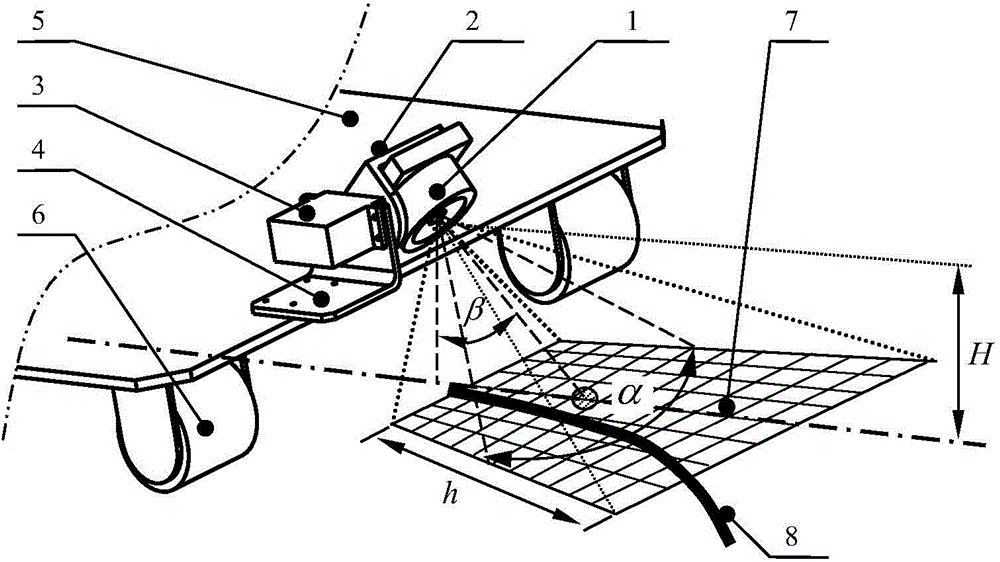

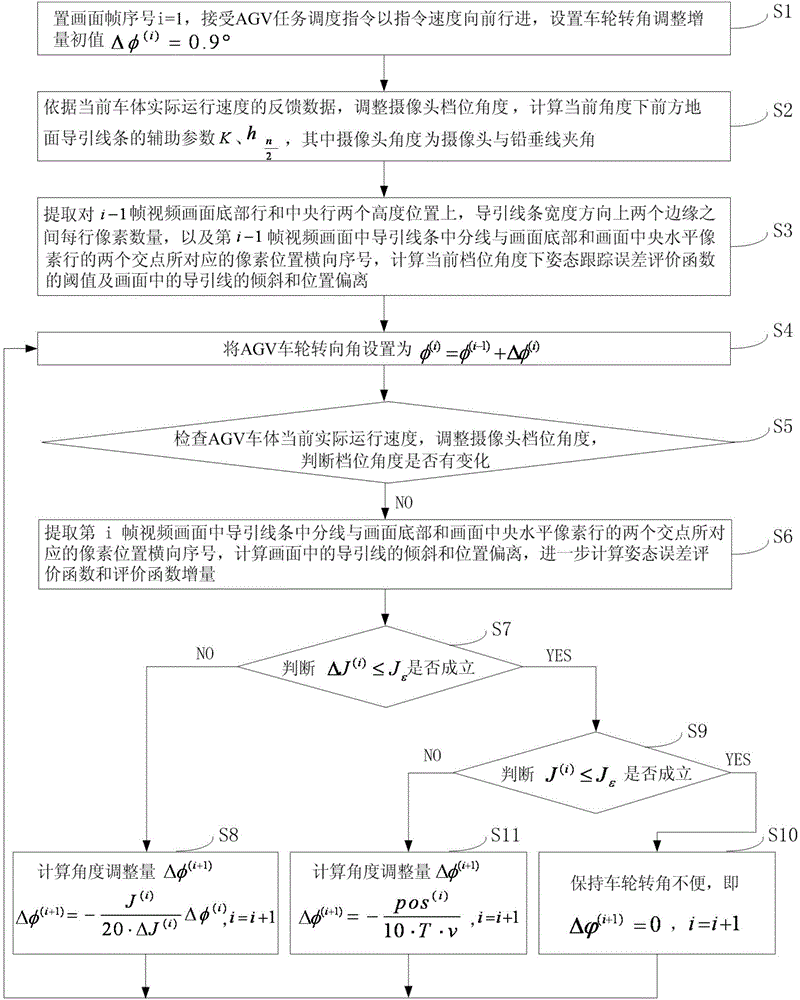

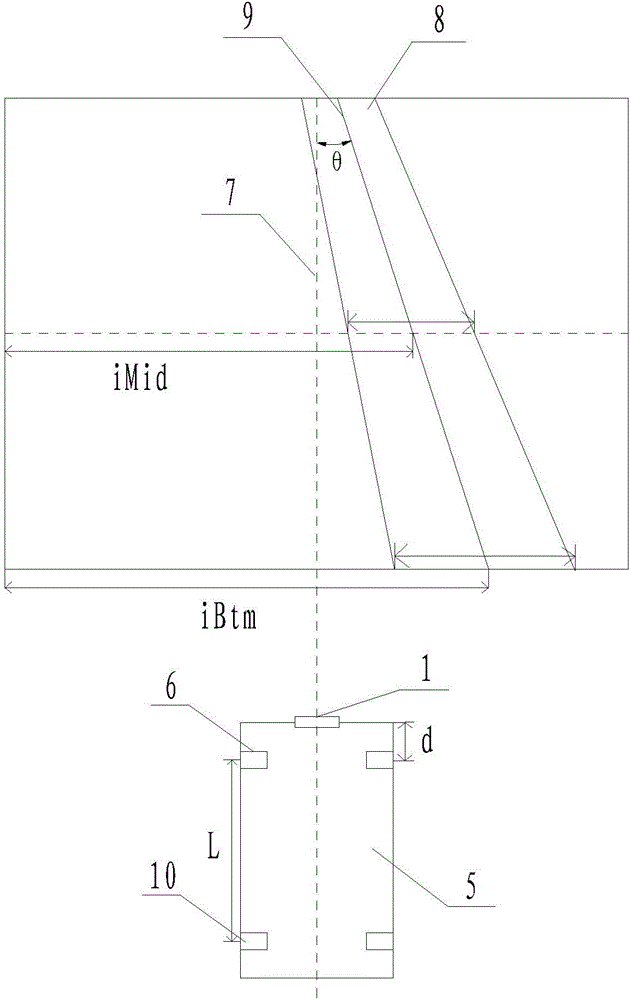

Self-adaptive AGV (Automatic Guided Vehicle) visual navigation sight adjusting device and trace tracking method

InactiveCN104699104AUnobscuredPrecise controlPosition/course control in two dimensionsSelf adaptiveEngineering

The invention provides a self-adaptive AGV (Automatic Guided Vehicle) visual navigation sight adjusting device and a trace tracking method. The device comprises a camera, a rotary support, a steering engine and a support frame, wherein the support frame is fastened on an AGV body, the steering engine is fixed on the support frame and is fixedly connected with the rotary support, the camera is fixed on the rotary support and is located on a middle axis in front of the AGV body and the camera can be driven to adjust a sight gear angle by the steering engine. According to the device provided by the invention, the sight angle of the camera can be automatically adjusted according to the speed of the AGV body, the camera view is opened, and the navigation and location is precise to control, therefore the working efficiency can be improved.

Owner:WUHAN TEXTILE UNIV

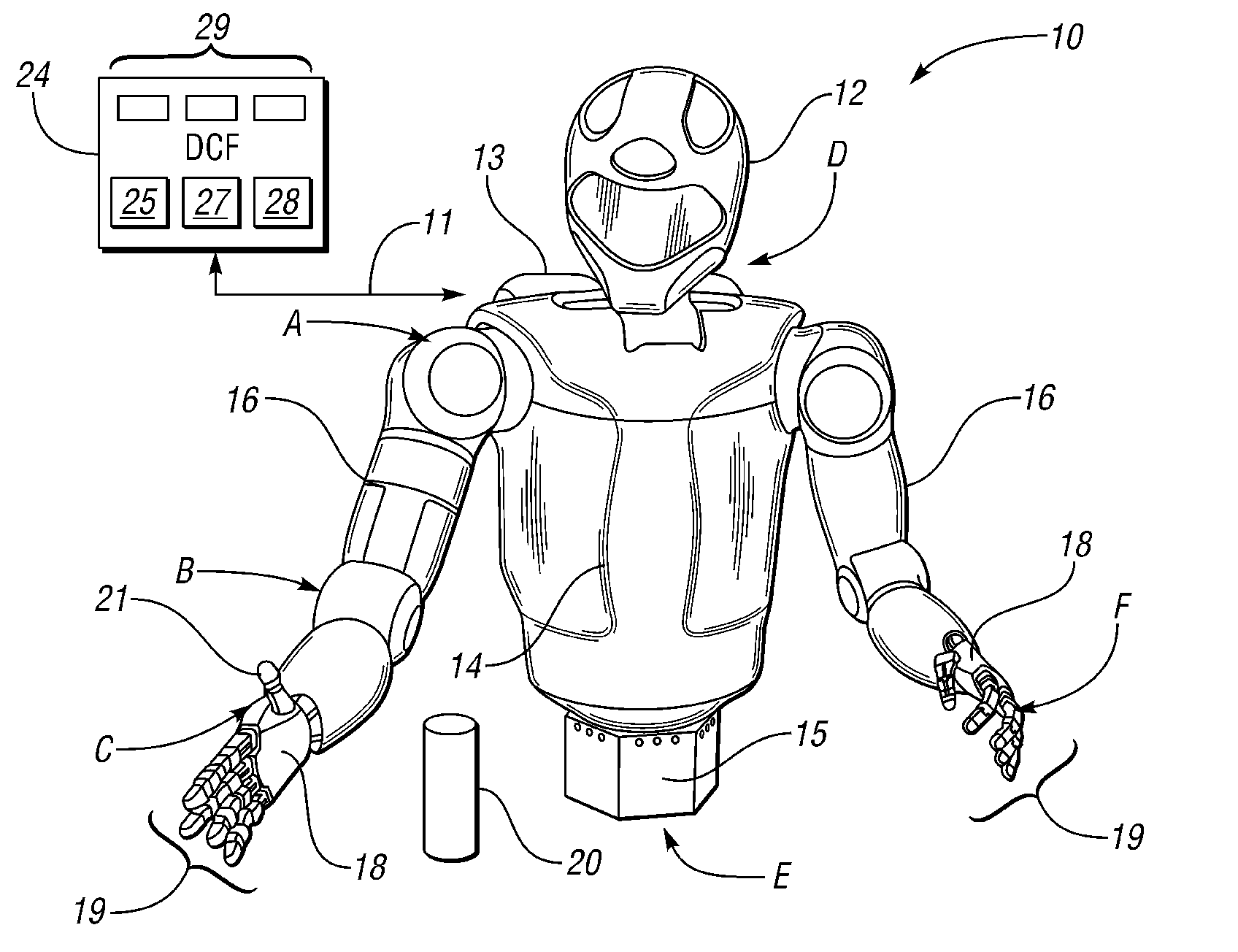

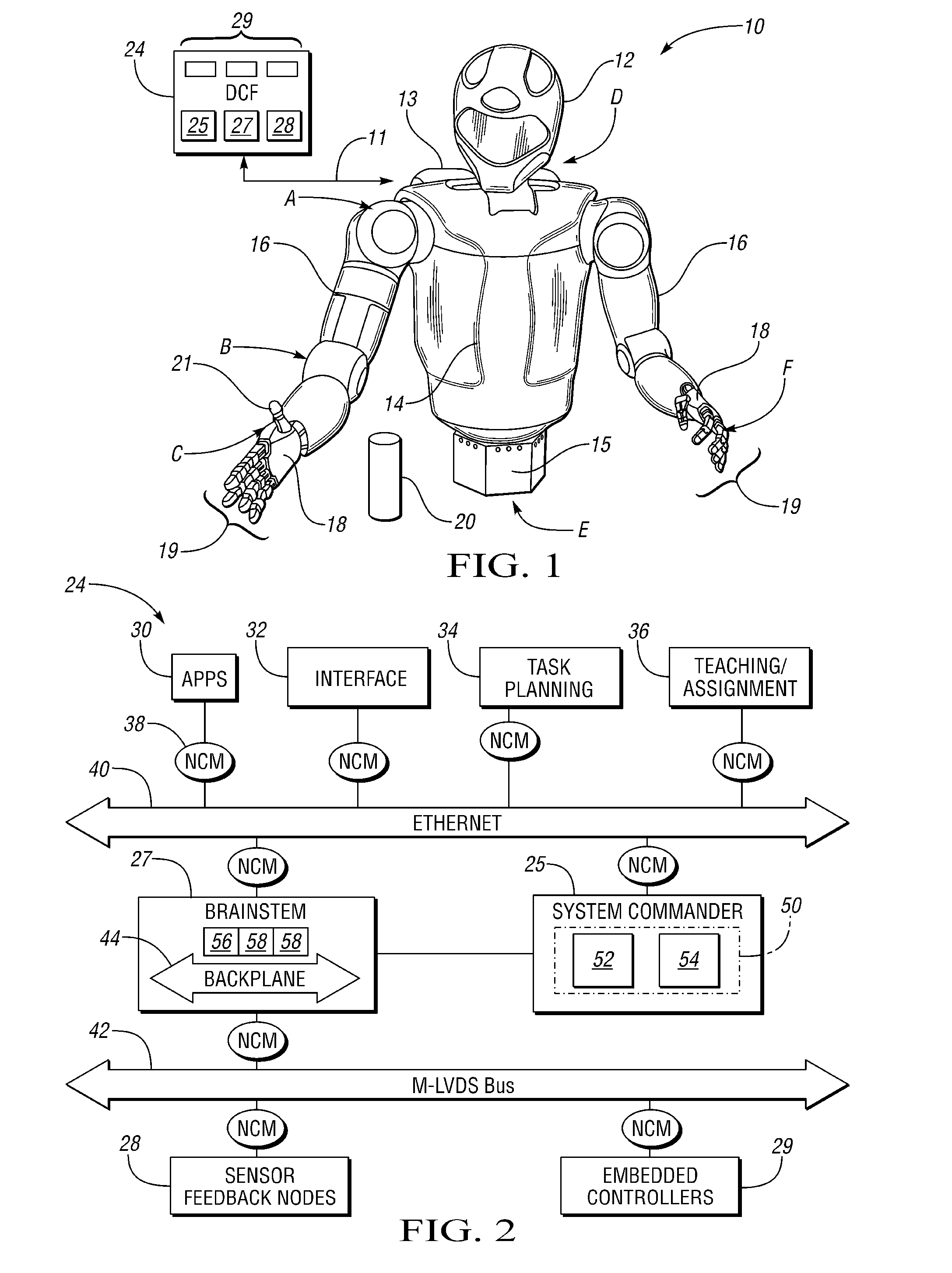

Framework and method for controlling a robotic system using a distributed computer network

ActiveUS20110071672A1Precise controlEasy to scaleProgramme controlProgramme-controlled manipulatorRobotic systemsIntegrated systems

A robotic system for performing an autonomous task includes a humanoid robot having a plurality of compliant robotic joints, actuators, and other integrated system devices that are controllable in response to control data from various control points, and having sensors for measuring feedback data at the control points. The system includes a multi-level distributed control framework (DCF) for controlling the integrated system components over multiple high-speed communication networks. The DCF has a plurality of first controllers each embedded in a respective one of the integrated system components, e.g., the robotic joints, a second controller coordinating the components via the first controllers, and a third controller for transmitting a signal commanding performance of the autonomous task to the second controller. The DCF virtually centralizes all of the control data and the feedback data in a single location to facilitate control of the robot across the multiple communication networks.

Owner:NASA +1

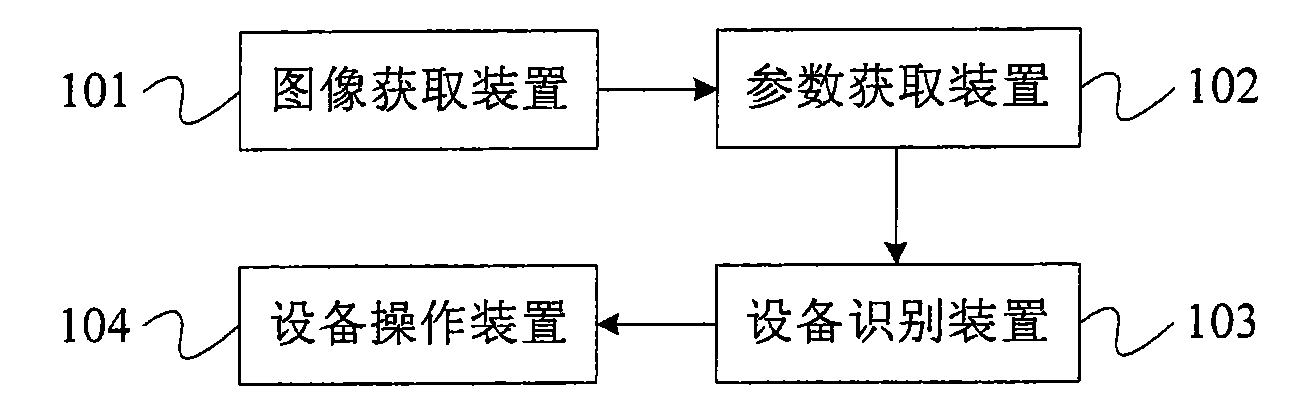

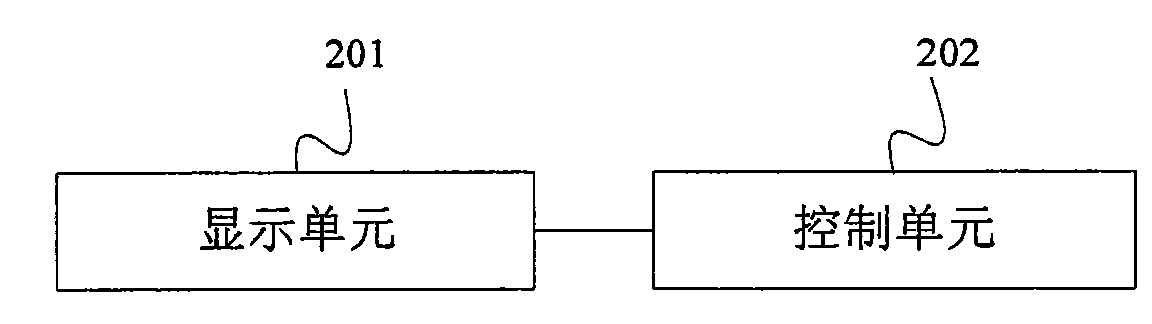

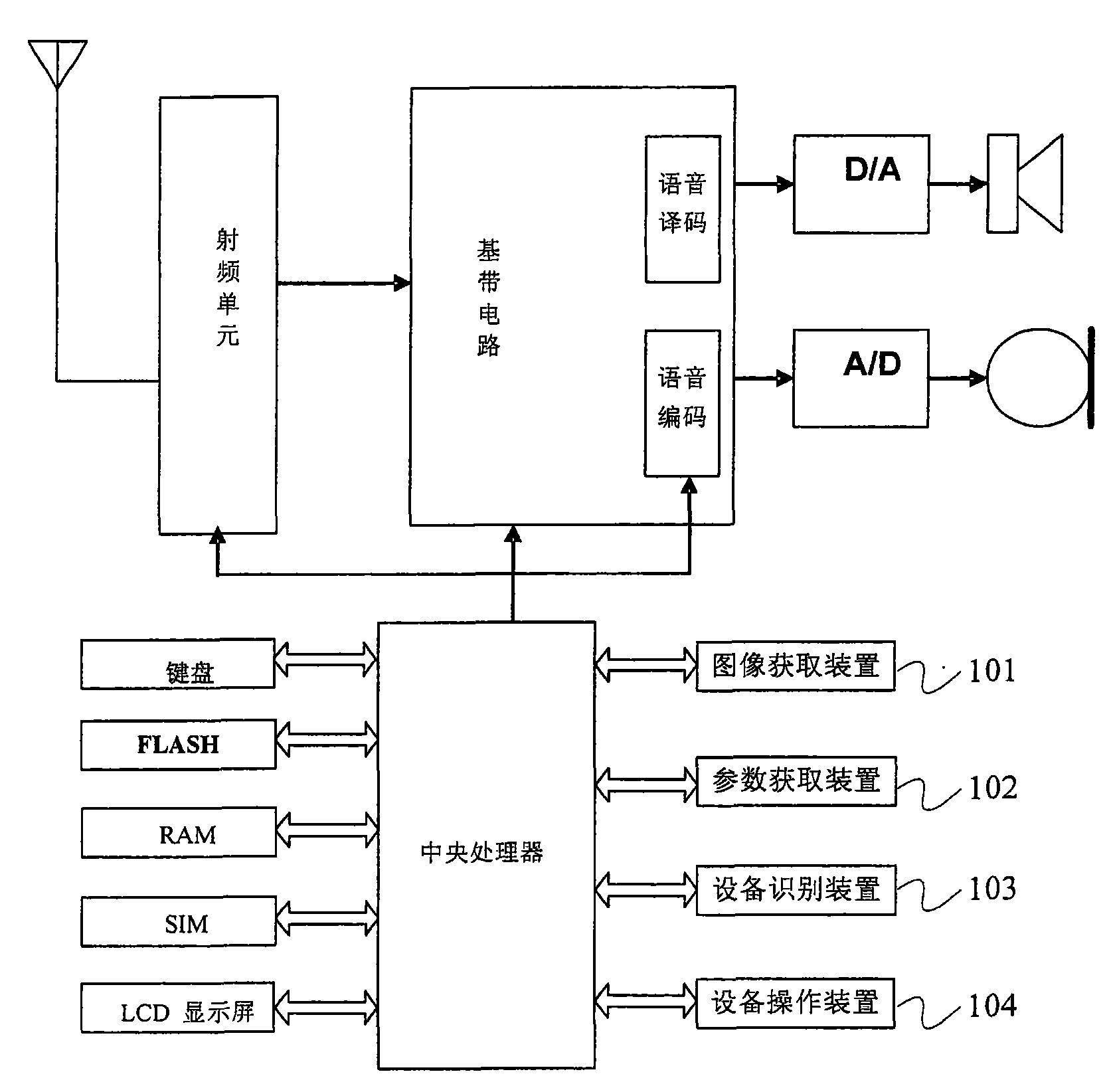

Equipment remote-control method, remote controller and mobile communication terminals thereof

InactiveCN101621583AQuick identificationPrecise controlNon-electrical signal transmission systemsCharacter and pattern recognitionControl parametersIdentification device

The embodiment of the invention provides an equipment remote-control method, a remote controller and mobile communication terminals thereof. The remote controller comprises an image acquisition device, a parameter acquisition device, an equipment identification device and an equipment operation device, wherein the image acquisition device is used for capturing and storing a reference image of reference equipment; the parameter acquisition device is used for capturing operation control parameters corresponding to the reference equipment; the equipment identification device is used for the image acquisition of equipment to be operated and identifying the equipment to be operated by comparing the captured image of the equipment to be operated with the stored reference image of the reference equipment; and the equipment operation device is used for controlling the equipment to be operated according to operation control parameters corresponding to the reference equipment when the equipment identification device identifies that the equipment to be operated is the reference equipment. The invention realizes that a mobile phone rapidly identifies a plurality of equipment, downloads accurate parameters by a network and accurately controls the equipment so that one mobile phone can substitute a plurality of remote equipment controllers to control a plurality of equipment.

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

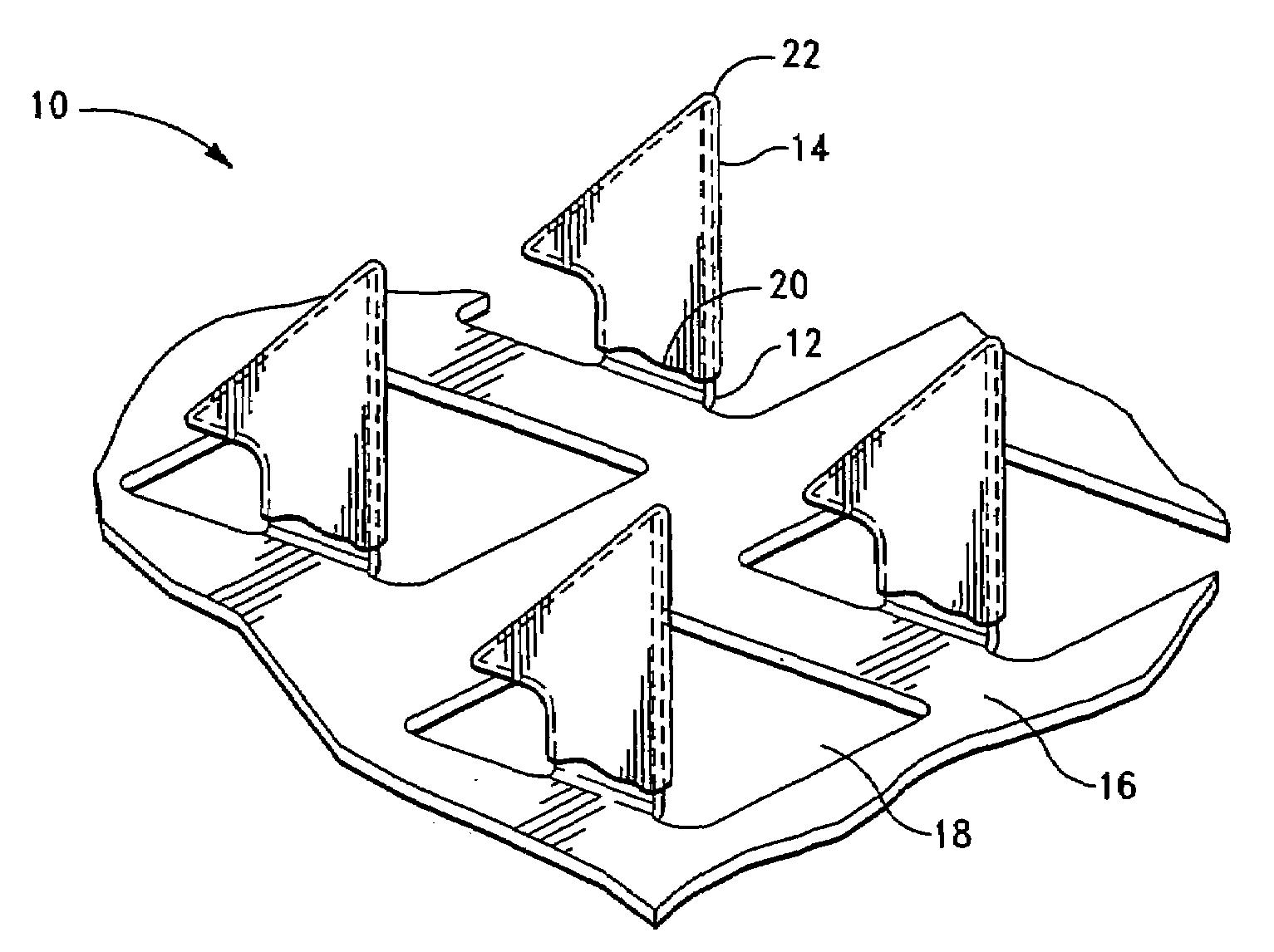

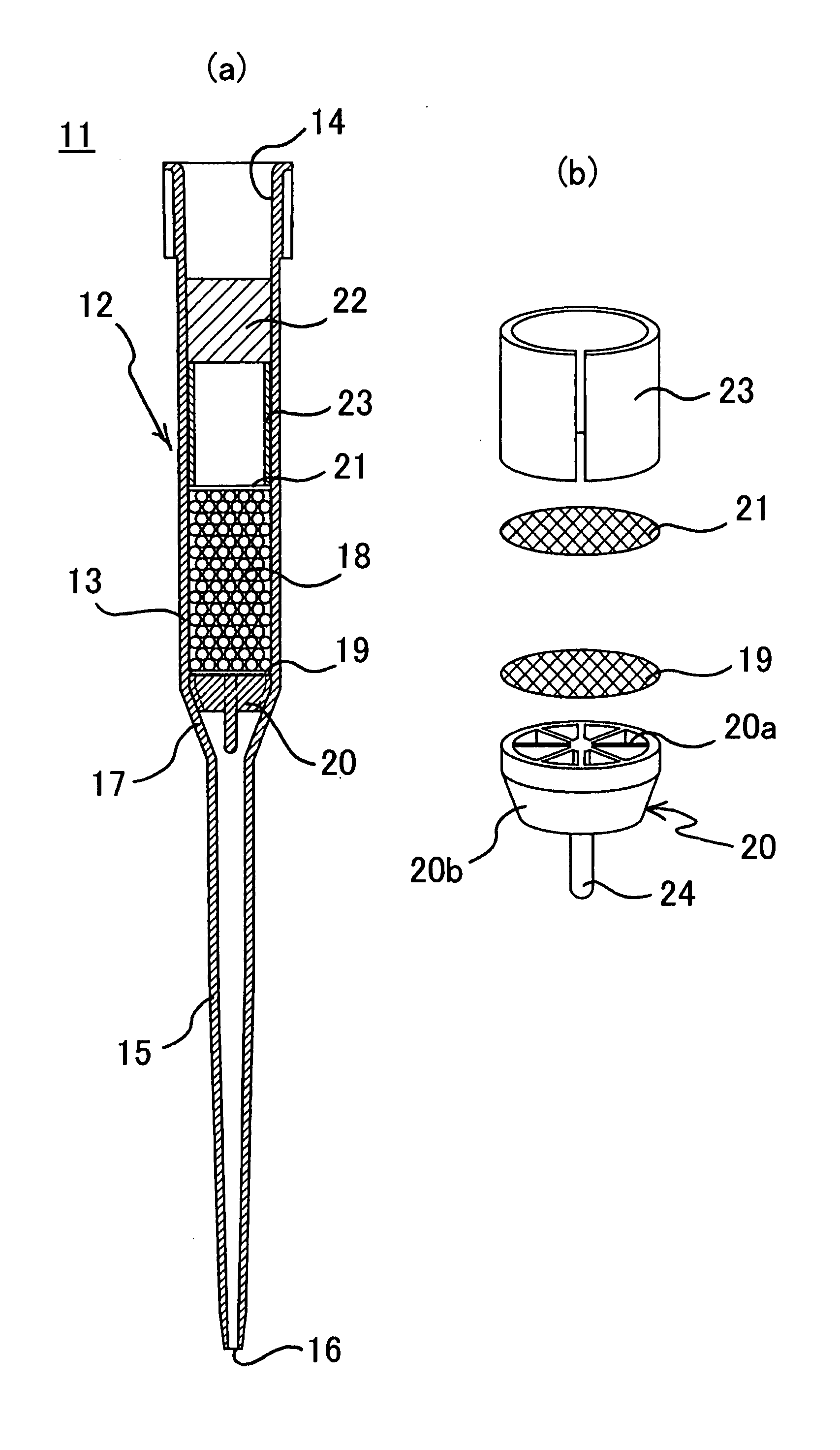

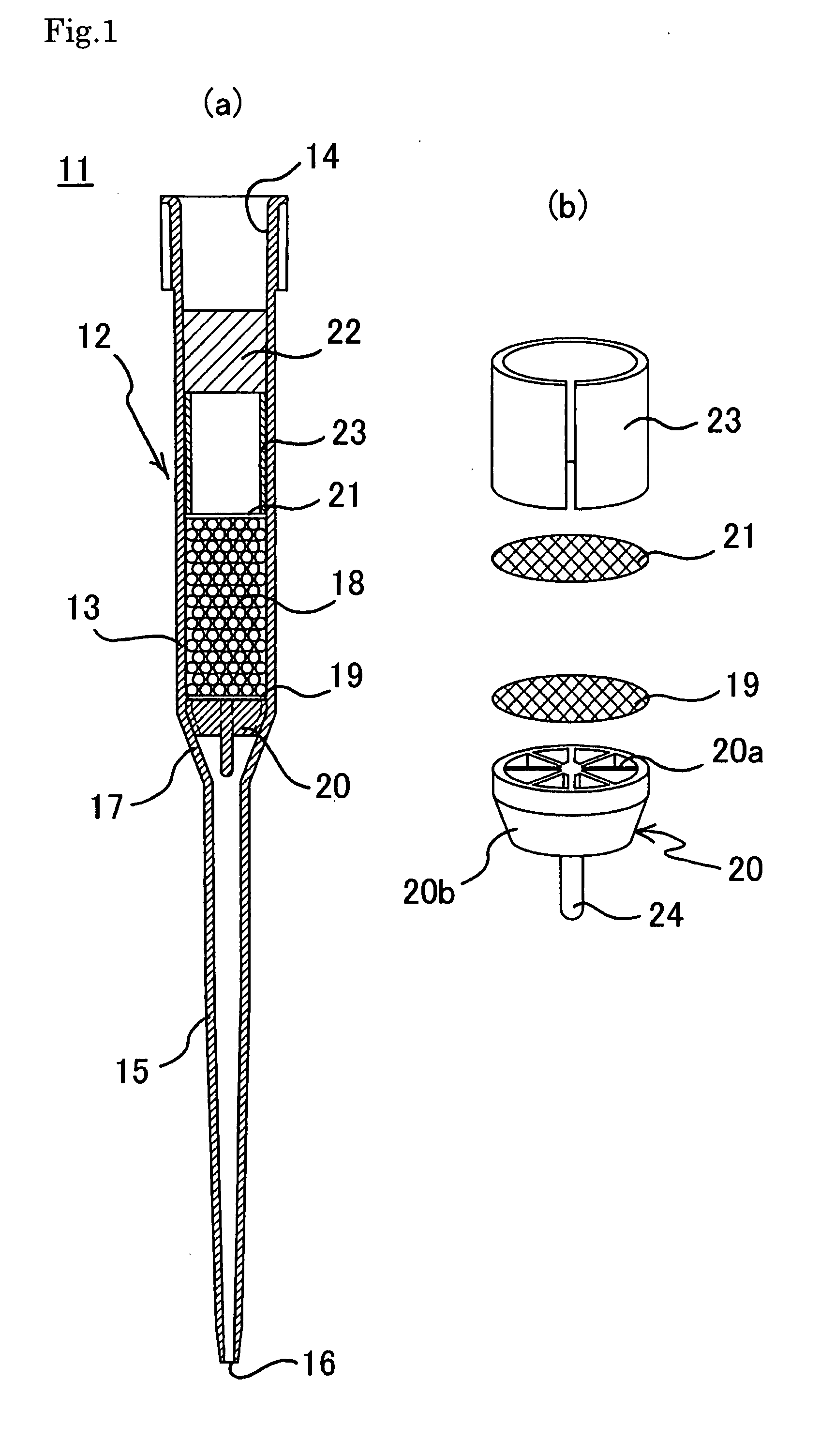

Carrier enclosing tip, carrier treating apparatus and method of carrier treatment

ActiveUS20100119416A1Precise controlGood conditionAnalysis using chemical indicatorsSamplingEngineeringTreatment use

A carrier enclosing chip; a carrier treating apparatus; and a method of carrier treatment. It is intended to carry out separation / purification with increased efficiency and rapidity as compared with those of treatment using conventional liquid chromatograph or filter. There is provided a carrier enclosing chip comprising a nozzle for gas suction and discharge, or opening for fitting fittable to a member fitted to a nozzle; a container of chip form having a port through which fluid inflow and outflow can be effected by the gas suction and discharge; and a carrier enclosed in the container of chip form, the carrier capable of adsorption of any biosubstance contained in the fluid or capable of reaction with or binding to the biosubstance.

Owner:UNIVERSAL BIO RESEARCH CO LTD

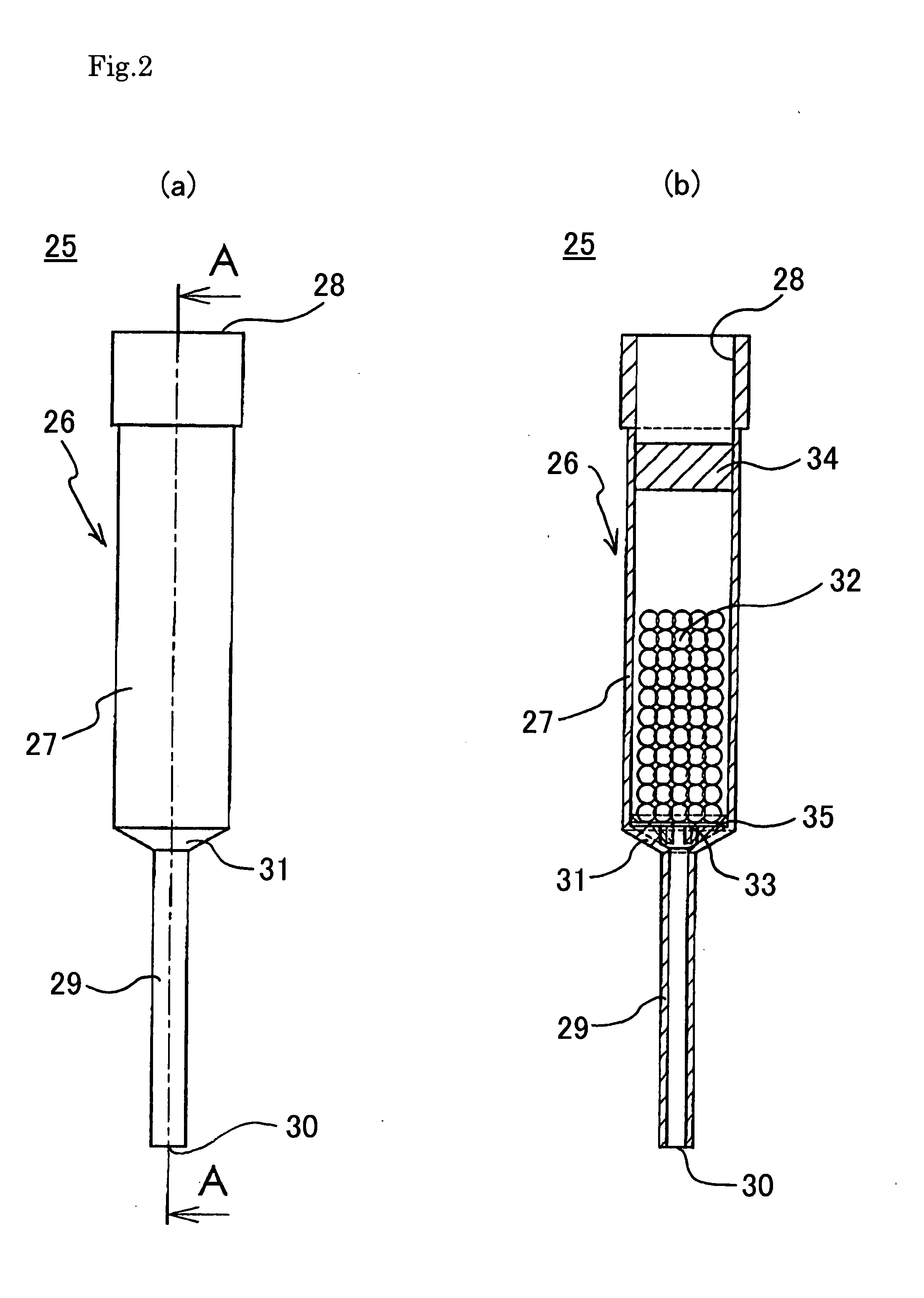

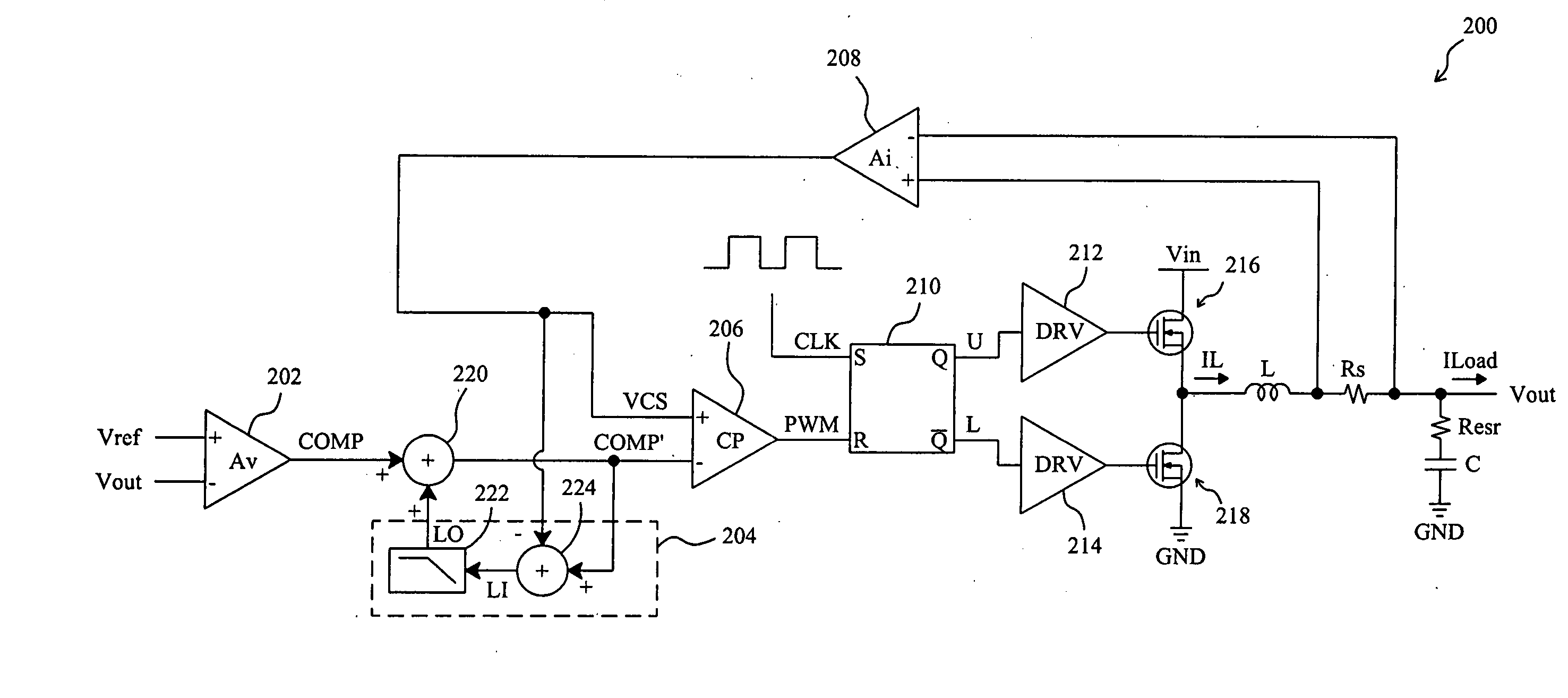

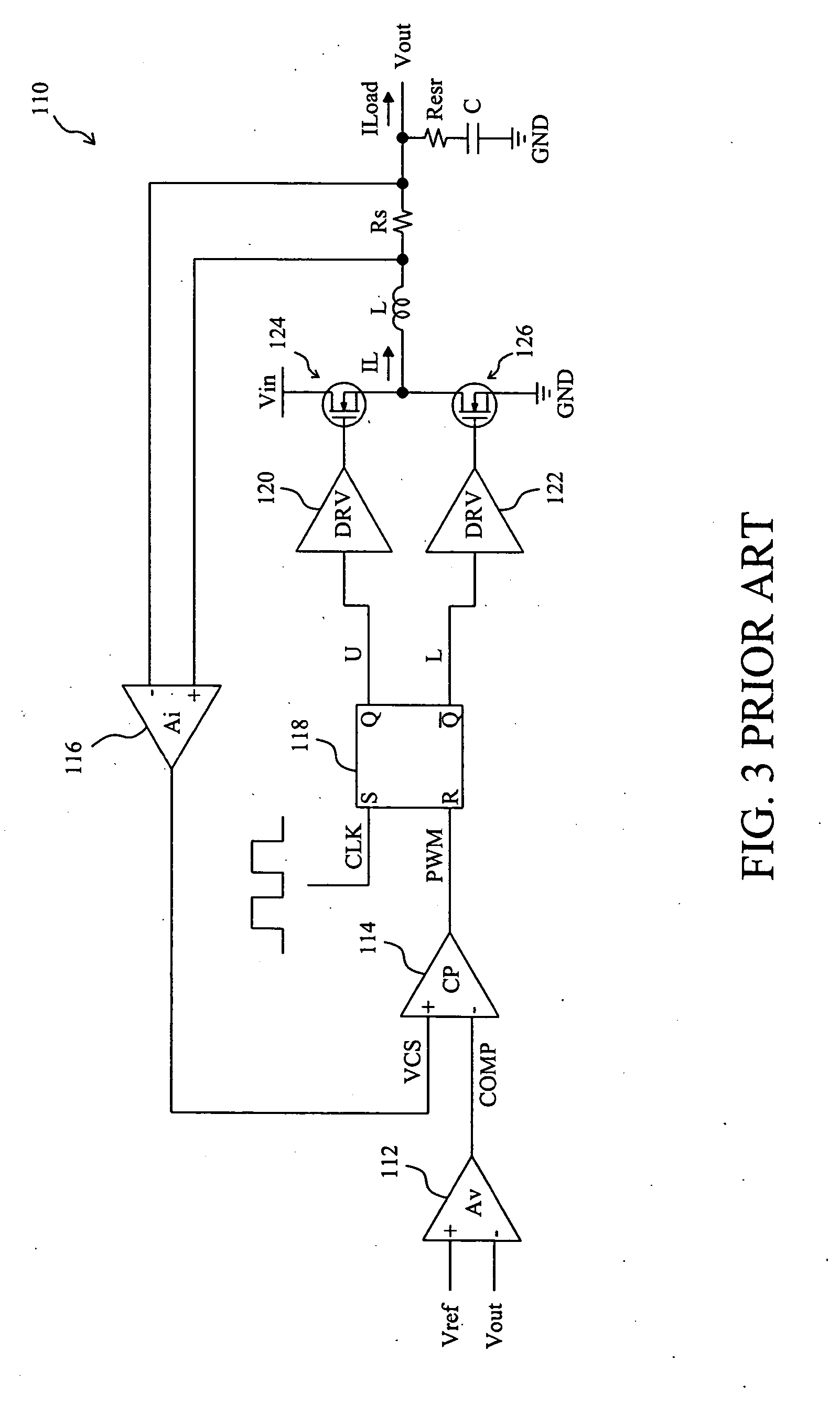

Low-gain current-mode voltage regulator

ActiveUS20080024100A1Control precisionPrecise controlDc-dc conversionElectric variable regulationLow gainInductor

In a low-gain current-mode voltage regulator having a PWM comparator in response to the varying output voltage and inductor current of the voltage regulator to produce a PWM signal to regulate the output voltage, an offset signal is derived from a subtraction between the inputs of the PWM comparator, and the offset signal is injected into the PWM comparator to cancel the output offset of the voltage regulator.

Owner:RICHTEK TECH +1

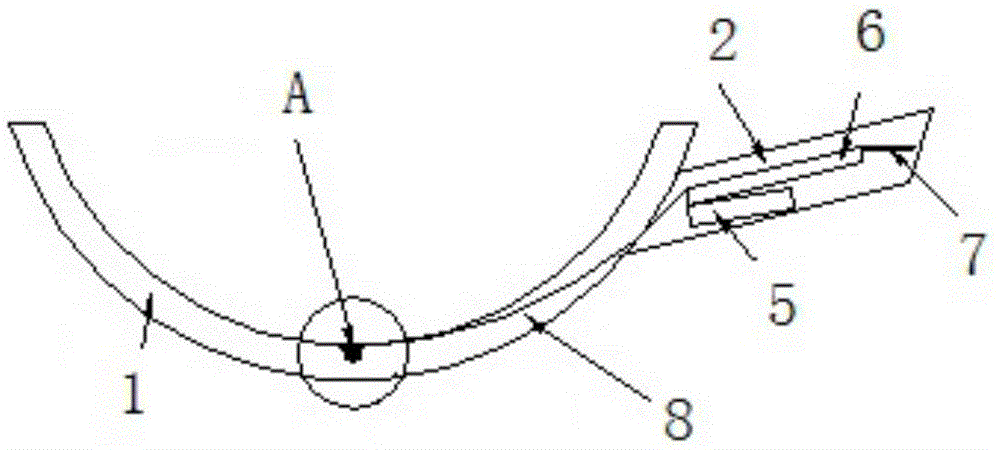

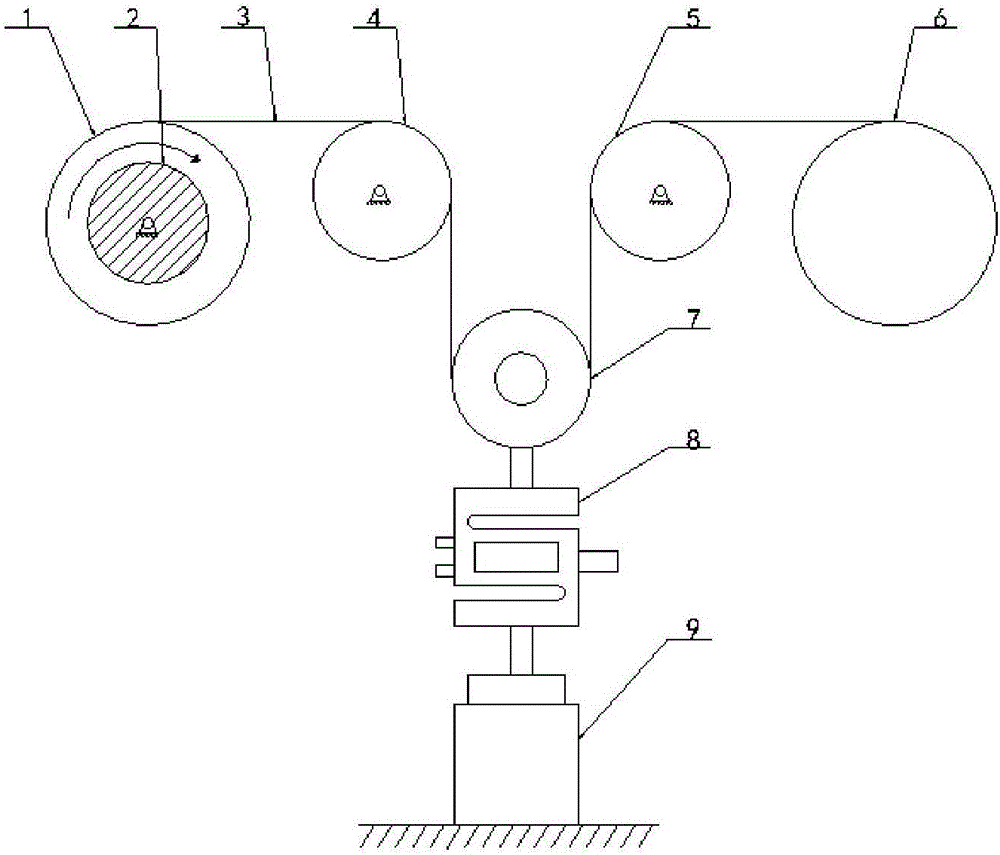

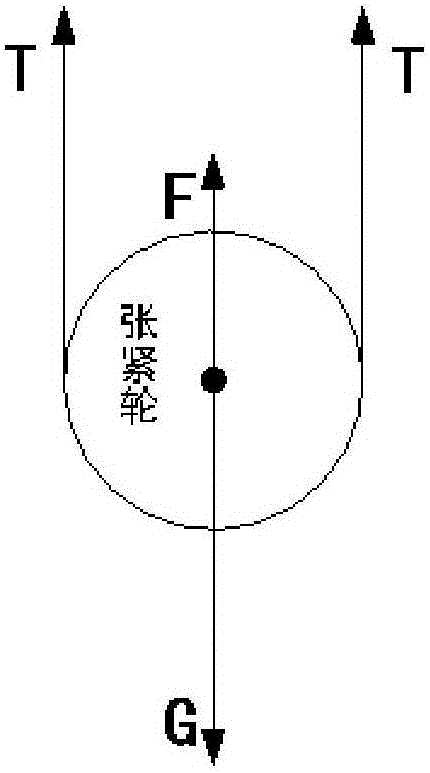

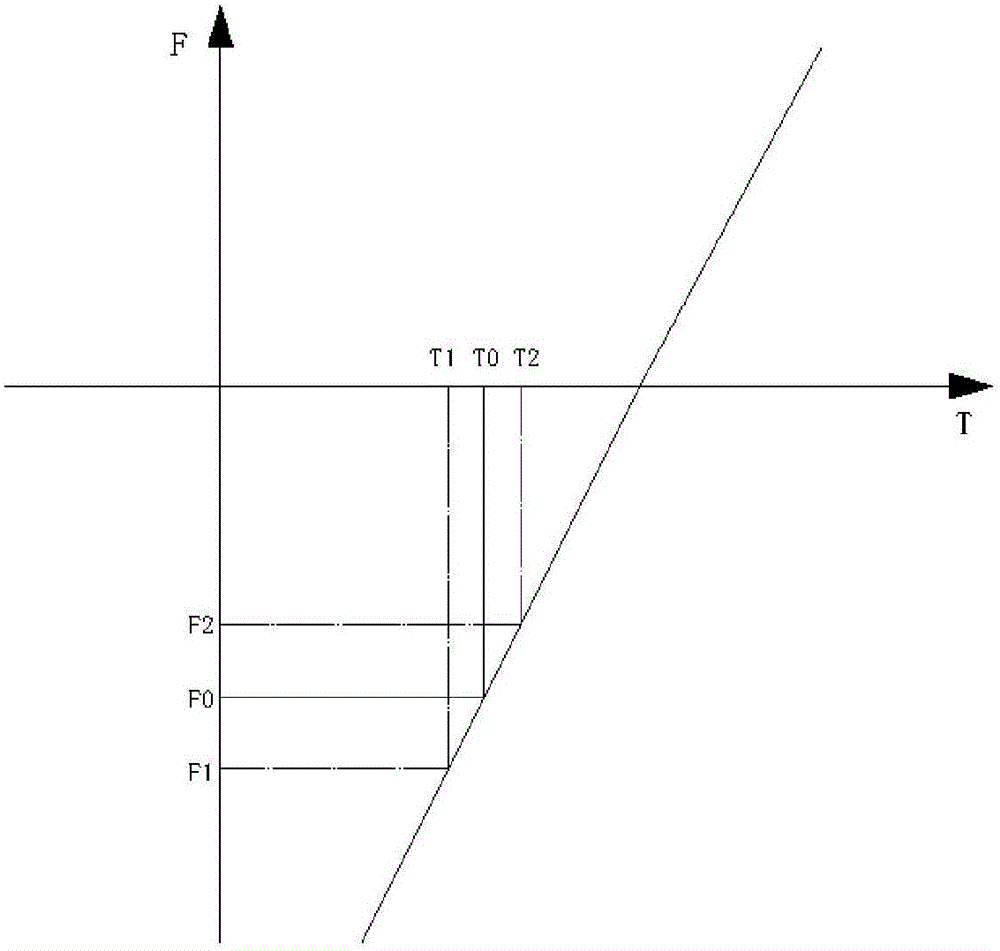

Multi-stage control device and method for dynamic tension of optical fiber winding machine

InactiveCN105800384APrecise controlPowerfulMeasurement devicesFilament handlingWinding machineFibre optic gyroscope

The invention firstly provides a multi-stage control device for the dynamic tension of an optical fiber winding machine. The device comprises a paying-off wheel and a taking-up ring and further comprises a guide wheel A and a guide wheel B. The paying-off wheel, the guide wheel A and the guide wheel B are fixedly arranged in sequence from left to right. The taking-up ring is movably arranged at the tail end of the right side. A tensioning wheel capable of vertically moving is arranged between the guide wheel A and the guide wheel B. The lower portion of the tensioning wheel is sequentially and fixedly connected with a tension and pressure sensor and a micromechanism. The tensioning wheel and the tension and pressure sensor can vertically move at the same time through the micromechannism. The paying-off wheel is connected with a paying-off wheel motor. The micromechanism, the tension and pressure sensor and the paying-off wheel motor are connected with an upper computer. The invention further provides a multi-stage control device for the dynamic tension of the optical fiber winding machine. The multi-stage control technology is adopted, the control precision of the tension of an optical fiber and the quality of an optical fiber loop are improved, it is effectively guaranteed that the optical fiber loop is evenly wound, and the requirement of a high-precision optical fiber gyroscope is met.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

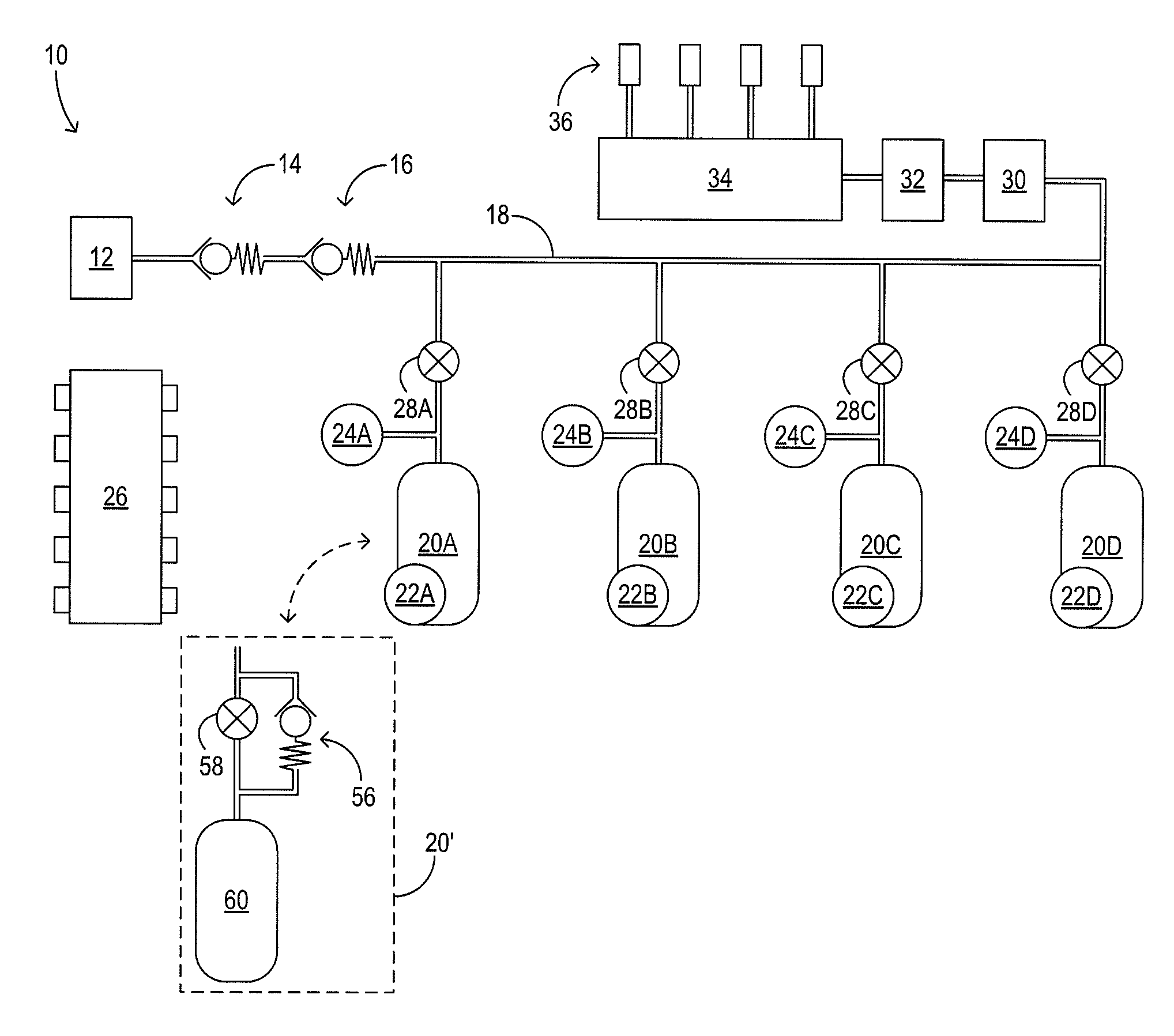

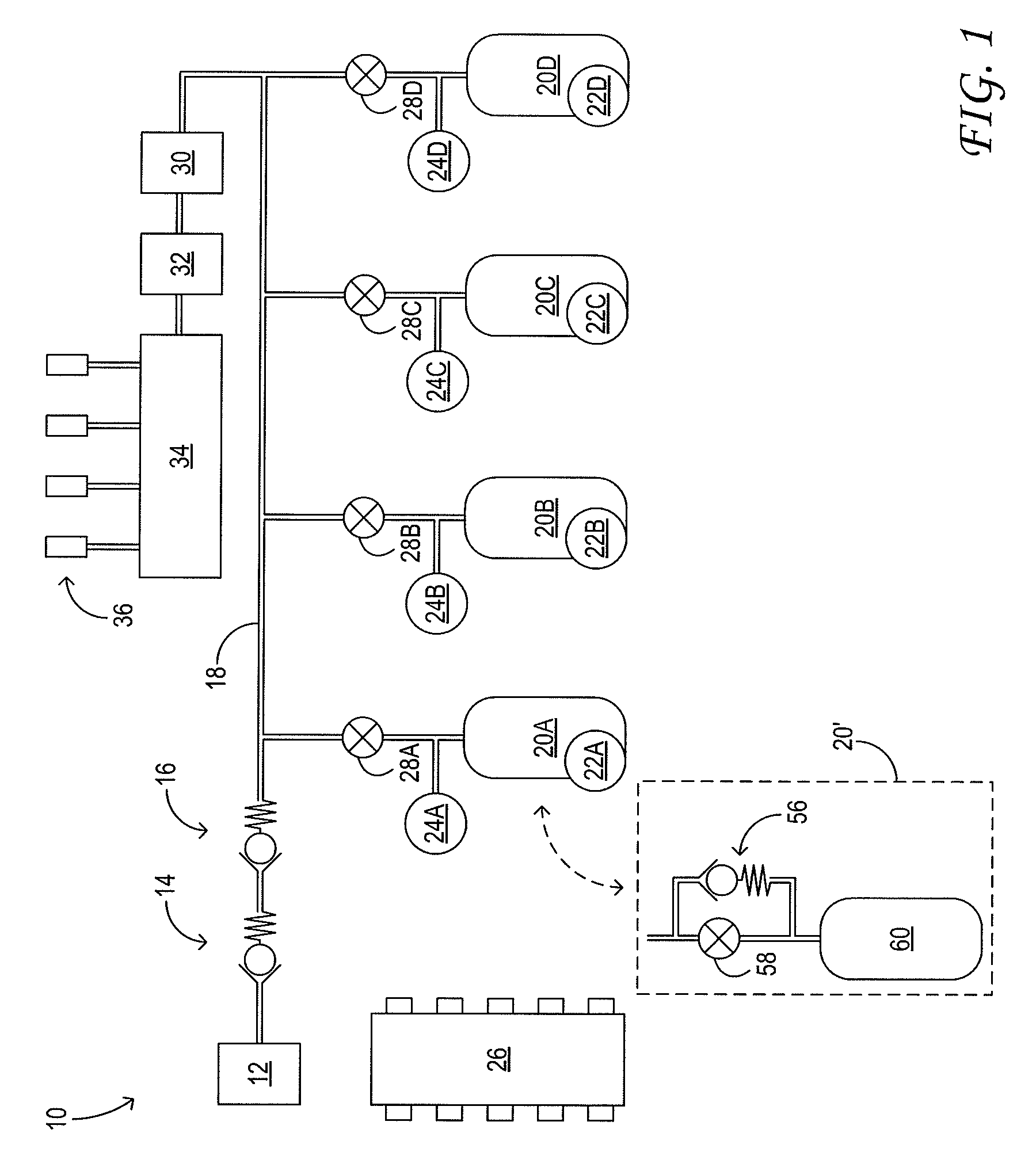

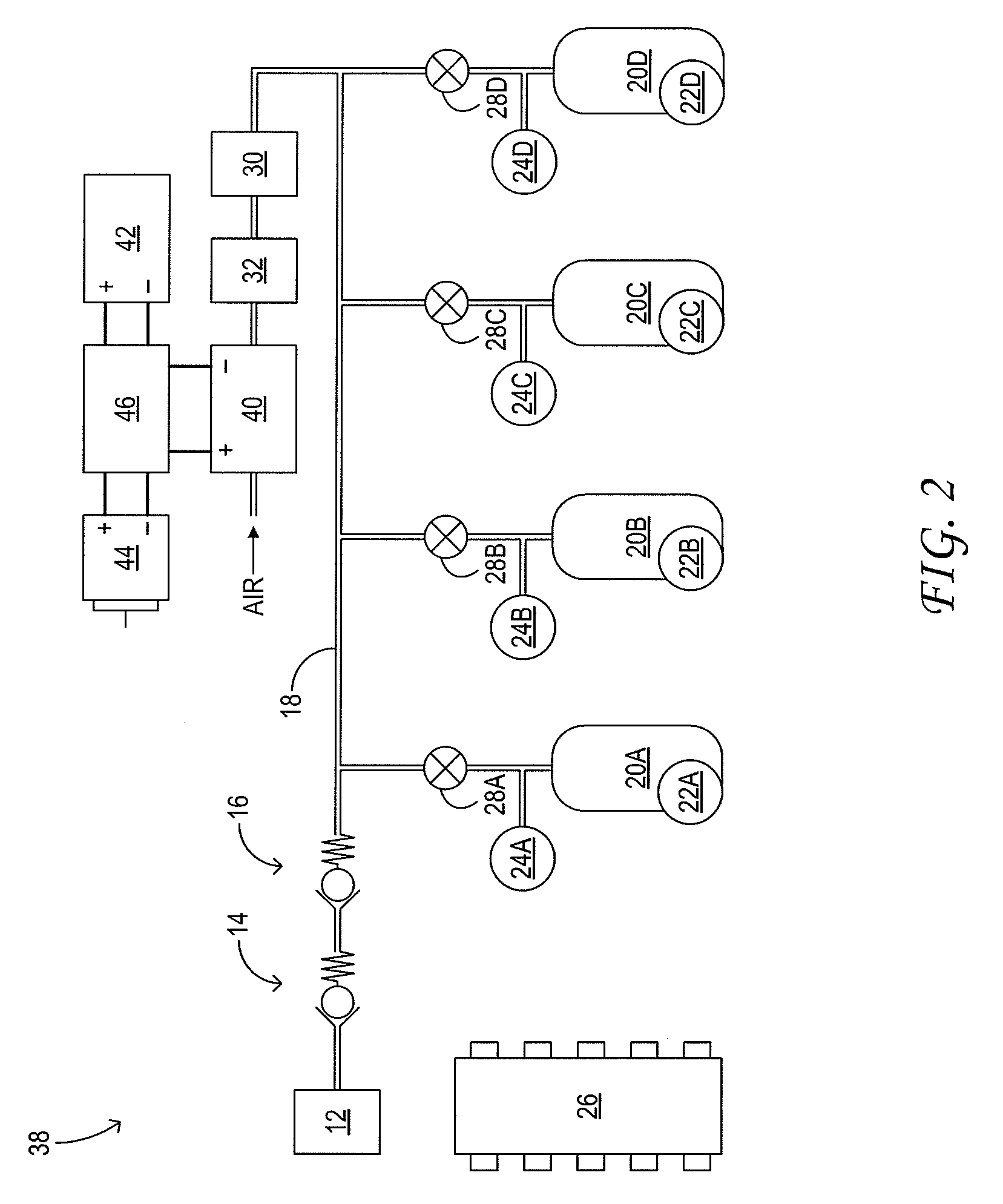

Fuel Distribution in Multi-Fuel Tank Compressed Gas Fuel Systems

InactiveUS20100307454A1Precise controlHigh octane ratingElectrical controlInternal combustion piston enginesAutomotive engineeringFuel tank

A method for distributing fuel in a fuel system of a motor vehicle. The method may be applied in a fuel system having a first fuel tank, where fuel is confined at a first pressure, and a second fuel tank, where fuel is confined at a second pressure greater than the first pressure. The method comprises releasing fuel already resident in the second fuel tank to the first fuel tank, and admitting fuel to the first and second fuel tanks simultaneously.

Owner:FORD GLOBAL TECH LLC

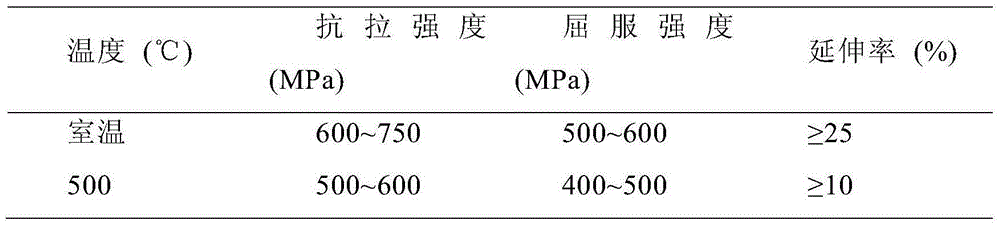

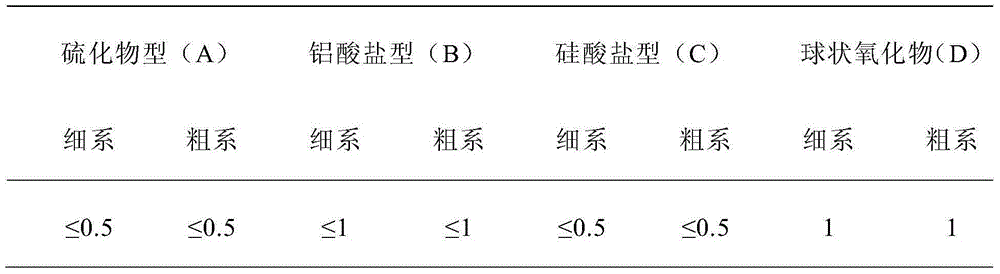

Austenitic stainless steel jacketing pipe for lead-bismuth fast reactor and preparation method of austenitic stainless steel jacketing pipe

ActiveCN105112811APrecise controlLow content of impurity elements and inclusionsQuenchingAustenitic stainless steel

The invention discloses an austenitic stainless steel jacketing pipe for a lead-bismuth fast reactor and a preparation method of the austenitic stainless steel jacketing pipe. The austenitic stainless steel jacketing pipe comprises, by weight, 0.06%-0.1% of C, 0.5%-1.0% of Si, 14%-16% of Ni, 14%-16% of Cr, 0.3%-0.6% of Ti, 1.5%-2.0% of Mn, 1.2%-1.8% of Mo, smaller than or equal to 0.03% of P, smaller than or equal to 0.05% of Co, smaller than or equal to 0.05% of Al, smaller than or equal to 0.01% of B, smaller than or equal to 0.02% of N, and the balance Fe. The method for preparing the jacketing pipe through the materials includes the steps of smelting, forging, hot working, solution treatment, cold rolling and intermediate annealing, final heat treatment, final cold working, straightening, cleaning, finished product inspection, identification, packaging and the like. In the final heat treatment step, quenching is conducted in a high-pressure nitrogen cooling mode, and in the cleaning process, an acidic degreasing agent is prohibited.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

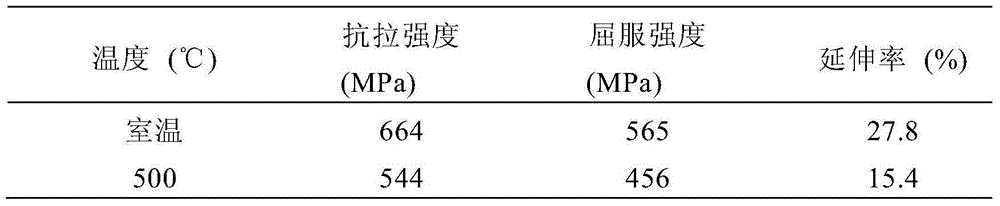

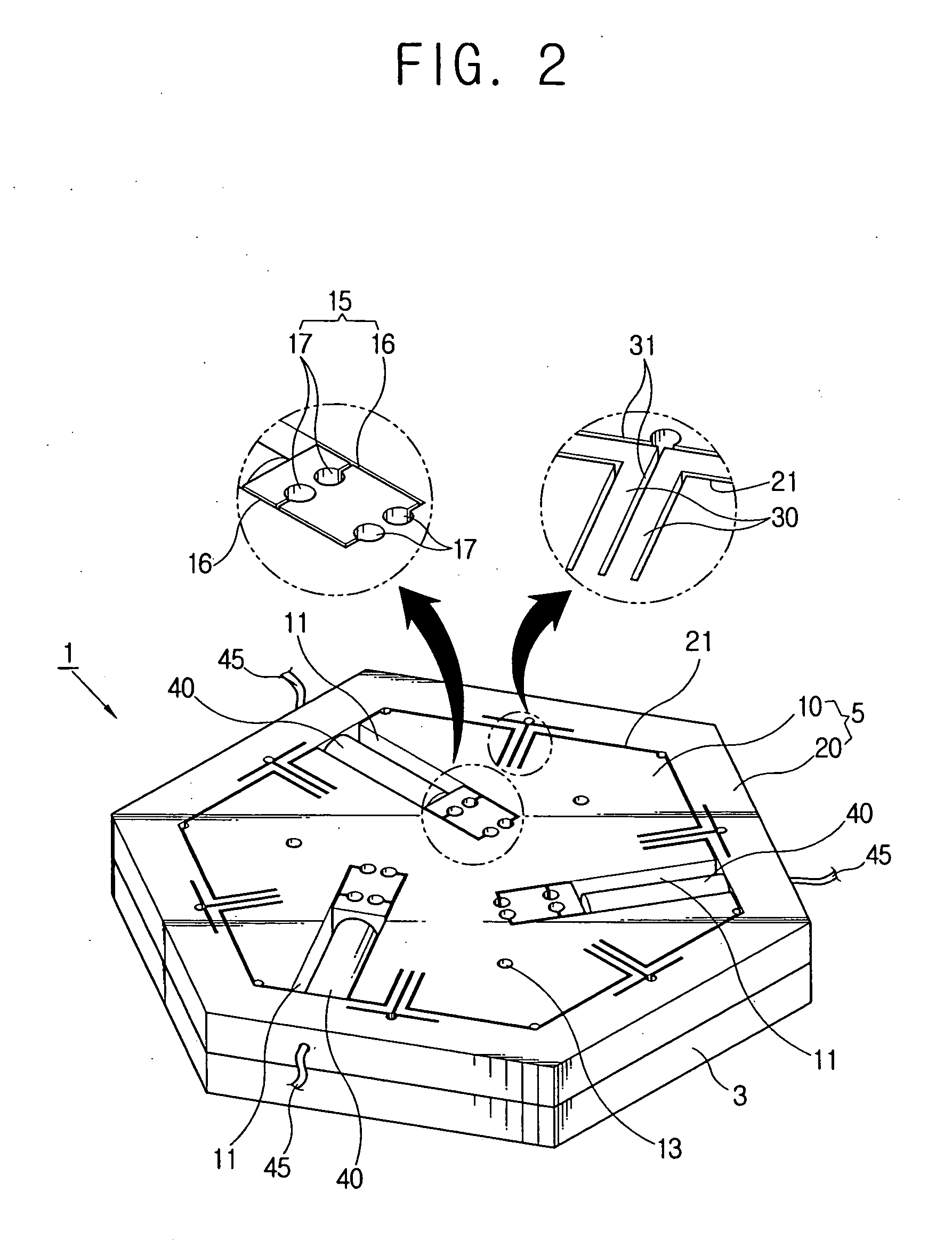

Stage apparatus

ActiveUS20050198844A1Precise controlWorkpiece holdersPrecision positioning equipmentPosition errorSecondary stage

A stage apparatus may include a first stage, a second stage movable with respect to the first stage, at least one flexure hinge to connect the first stage with the second stage, a plurality of actuators provided between the first stage and the second stage to push the first stage and the second stage and to be symmetric with respect to a center of the first stage and the second stage, and a controller to control the plurality of actuators to move one of the first stage and the second stage with respect to the other one of the first stage and the second stage. Thus, a position error of the stage can be reduced, which enables an ultra precision position control. Further, a piezoelectric driver using piezoelectric elements may be used as the actuator to decrease the position error more than a conventional driver such as a motor. The position error may be decreased to ±10 nm.

Owner:SAMSUNG ELECTRONICS CO LTD

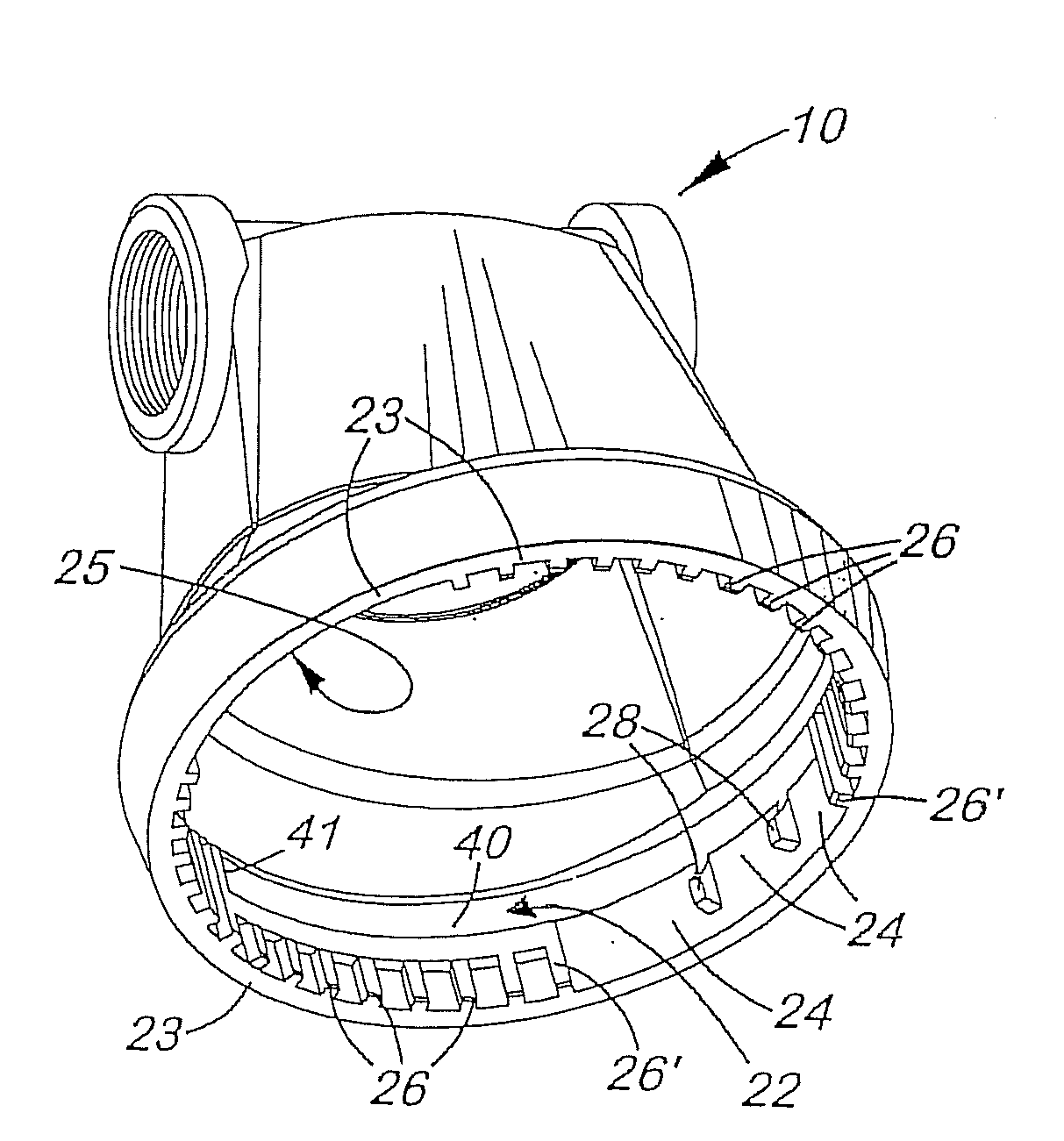

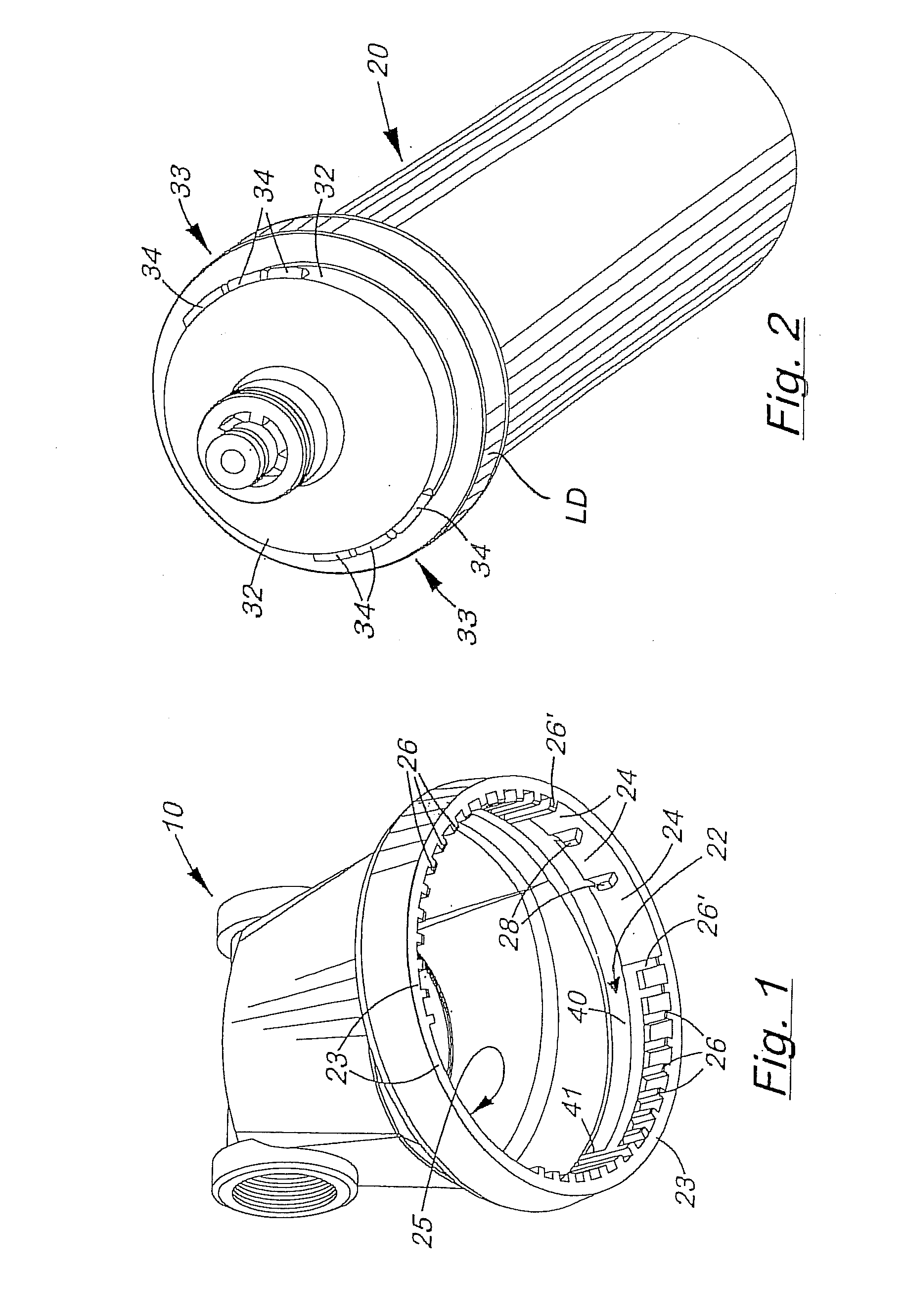

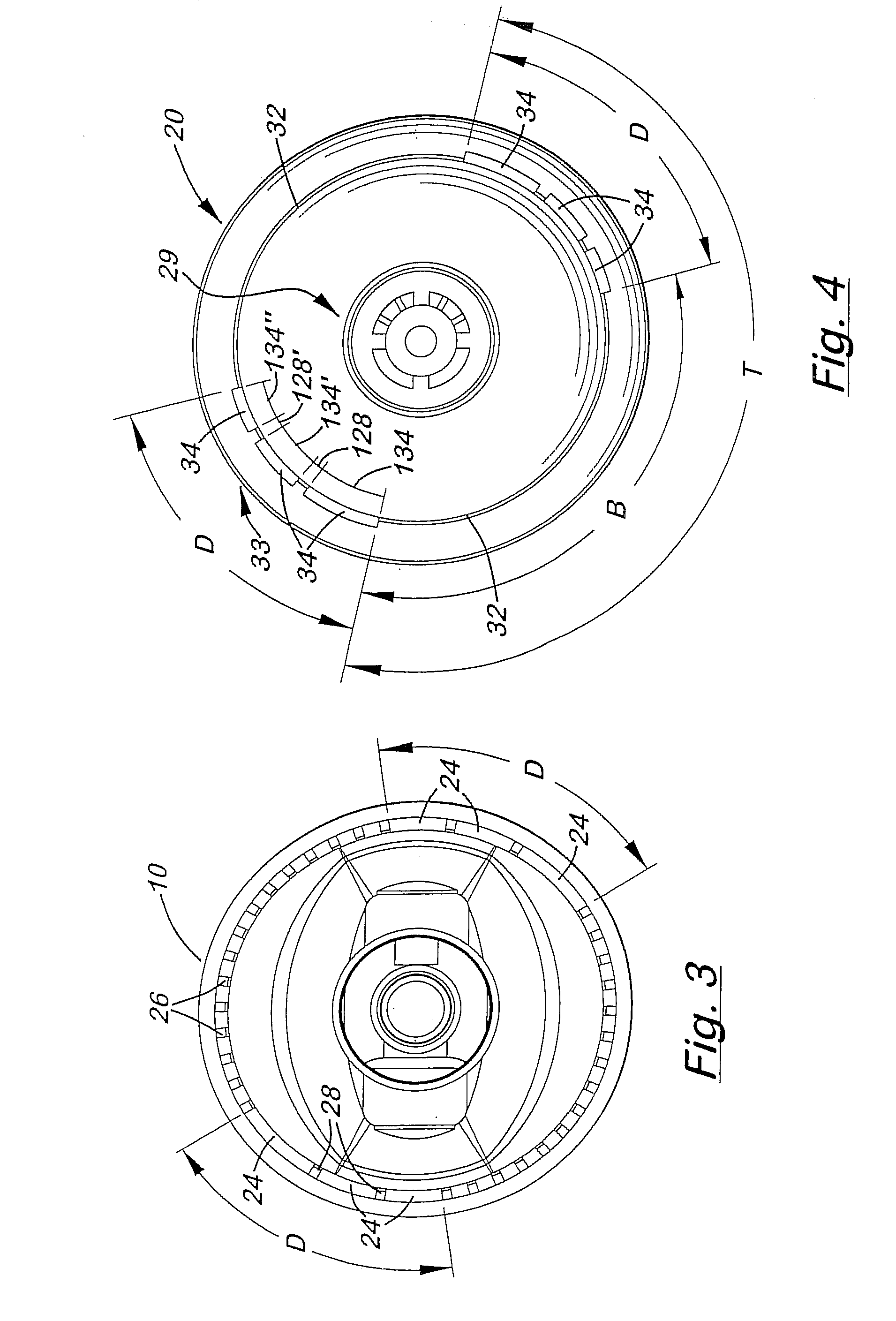

Keyed system for connection of filter to filter holder

InactiveUS20110203985A1Placement is limitedPrecise controlMembrane filtersWater/sewage treatment apparatusMatched filterEngineering

A filter and its holder each have a keyed surface, one being a protruding “key” and one being a recessed “lock,” wherein cooperation of these keyed surfaces is required in order for the filter to be installed in the holder. Modification / adaptation of the keyed surfaces, by changing the location, number and length of the key protrusions and cooperating recesses during manufacture, allows various sets of mating filters and holders to be produced so that only mating / matching filters and holders may be connected together. The keyed protrusions are preferably located on an upper shoulder or on protruding flange(s) of the upper end of the filter. The cooperating recess structure inside the filter holder comprises axial recesses that allow axial insertion of the key protrusions, and hence the filter, into the holder and also a circumferential recesses portion that receives multiple key protrusions to retain the filter in the holder. This way, multiple key protrusions slide into and are retained in a single circumferential recess / slot, rather than each key protrusion being received in its own separate circumferential recess / slot.

Owner:OMNIPURE FILTER CO INC

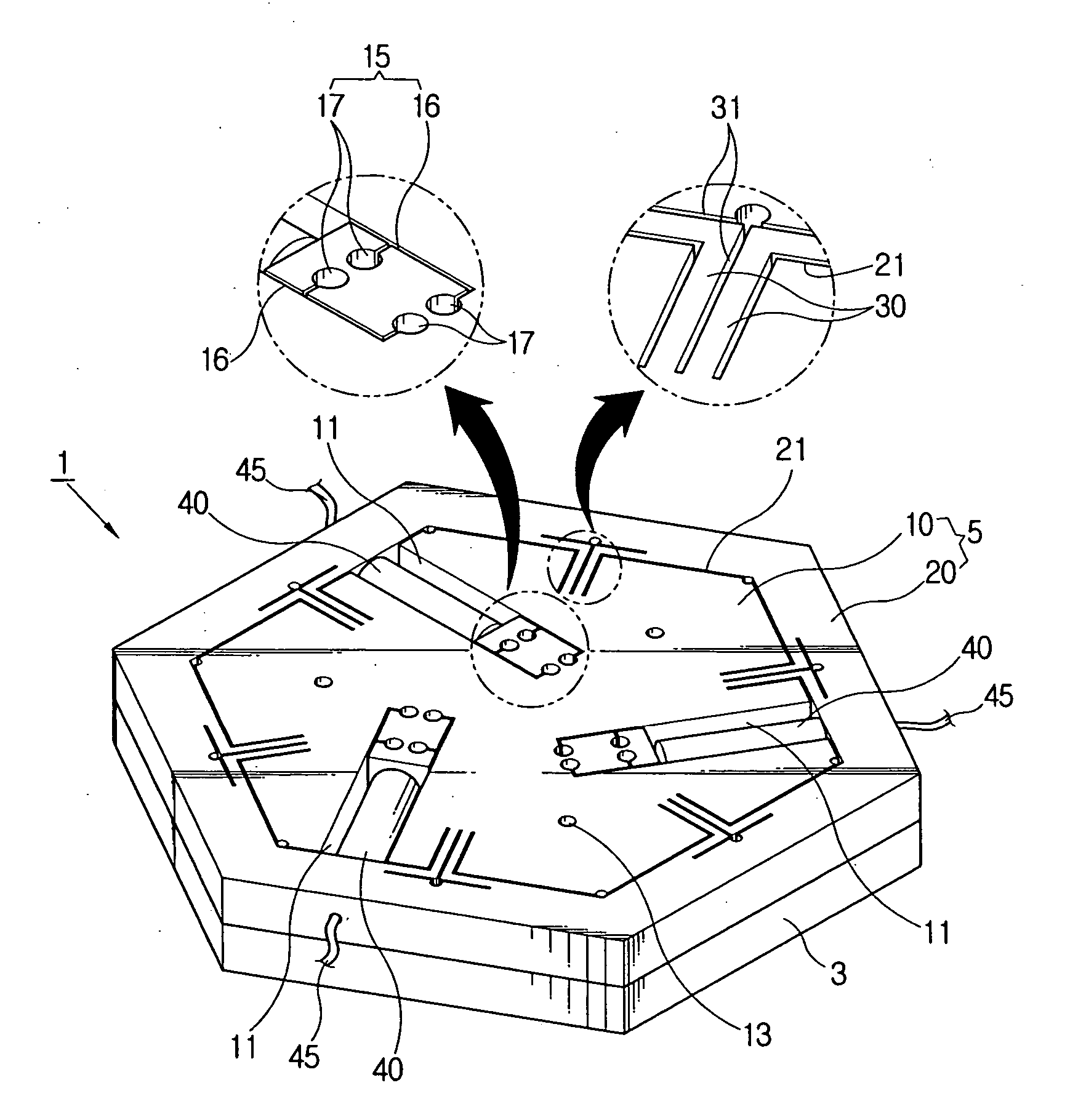

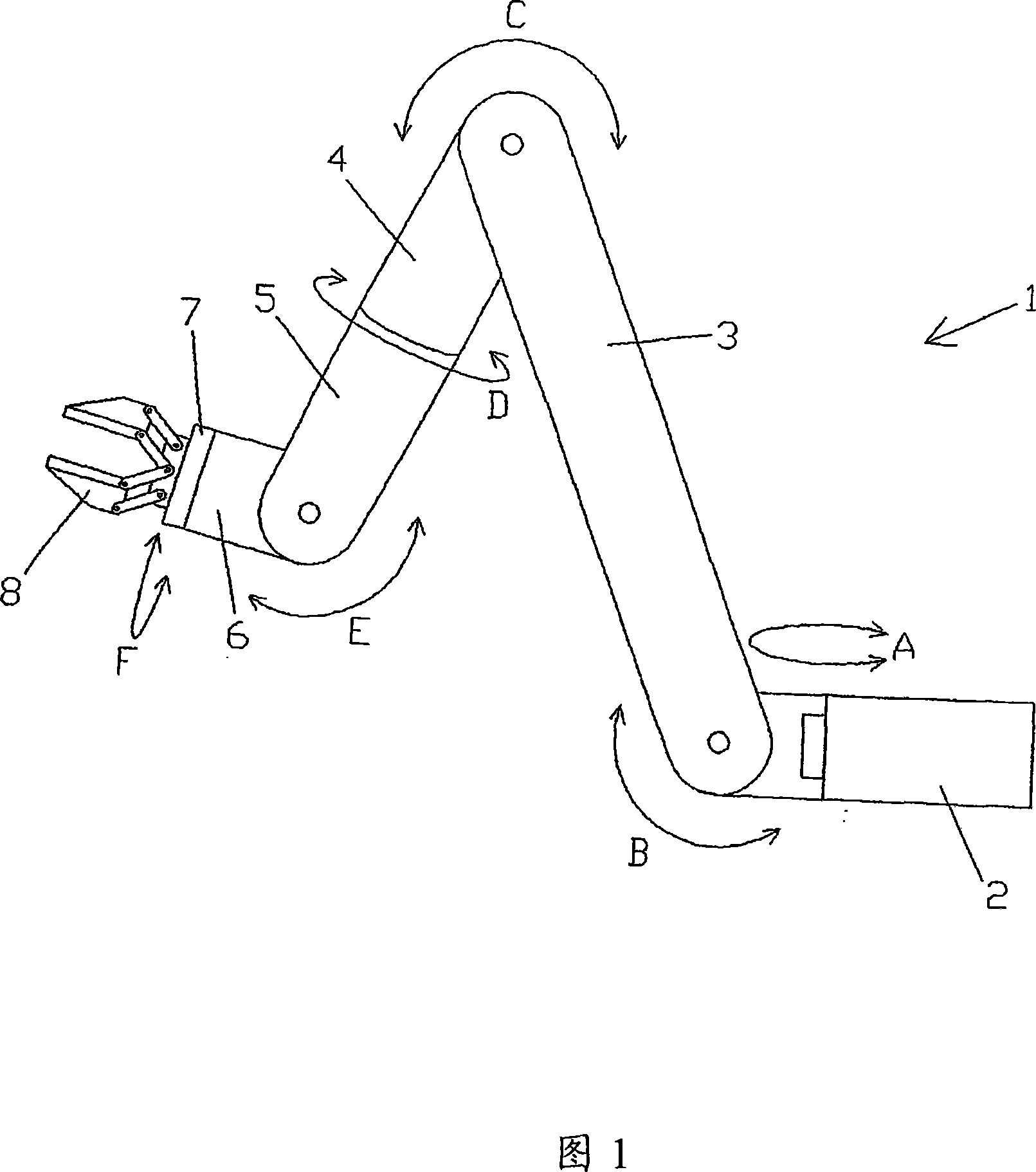

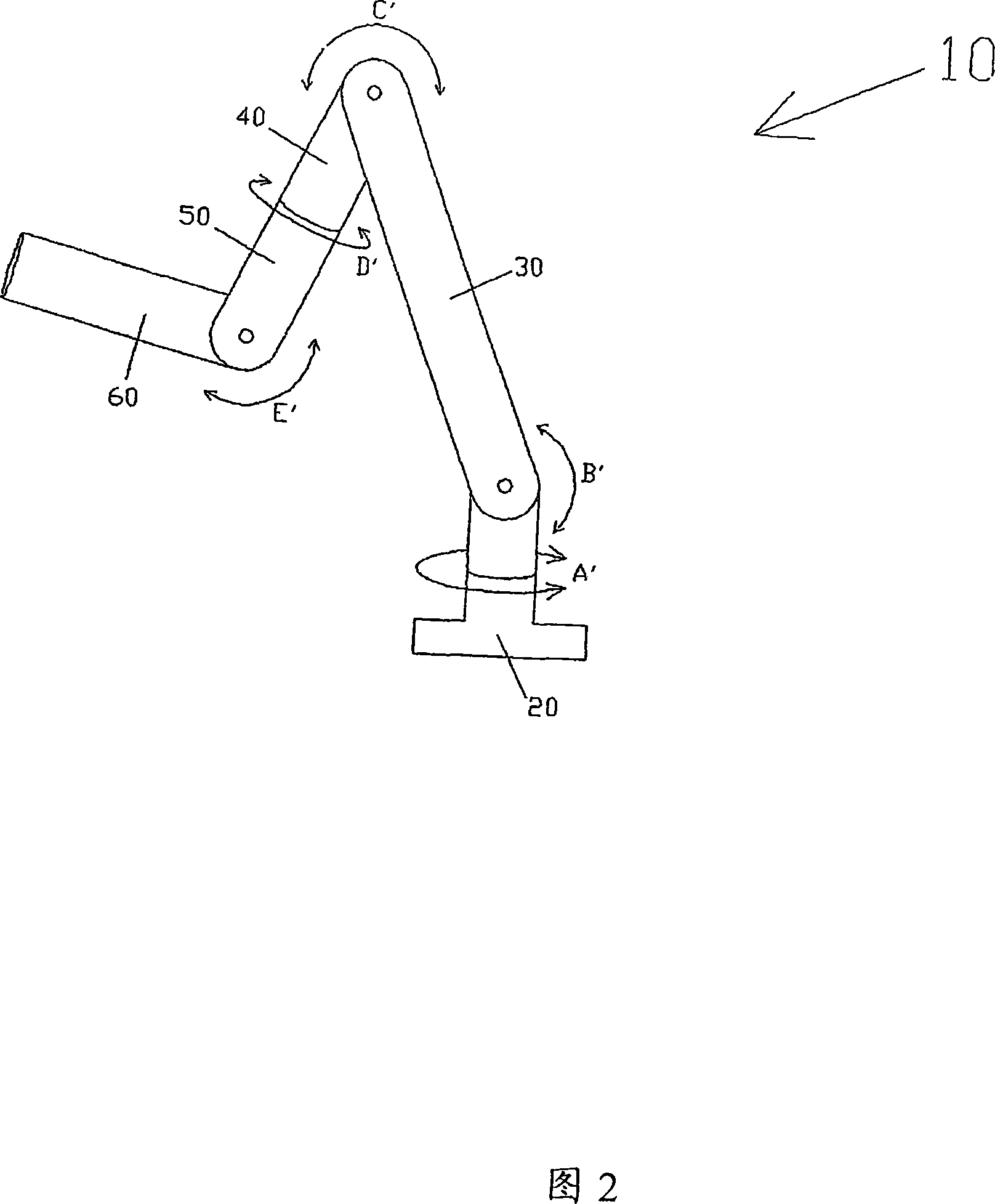

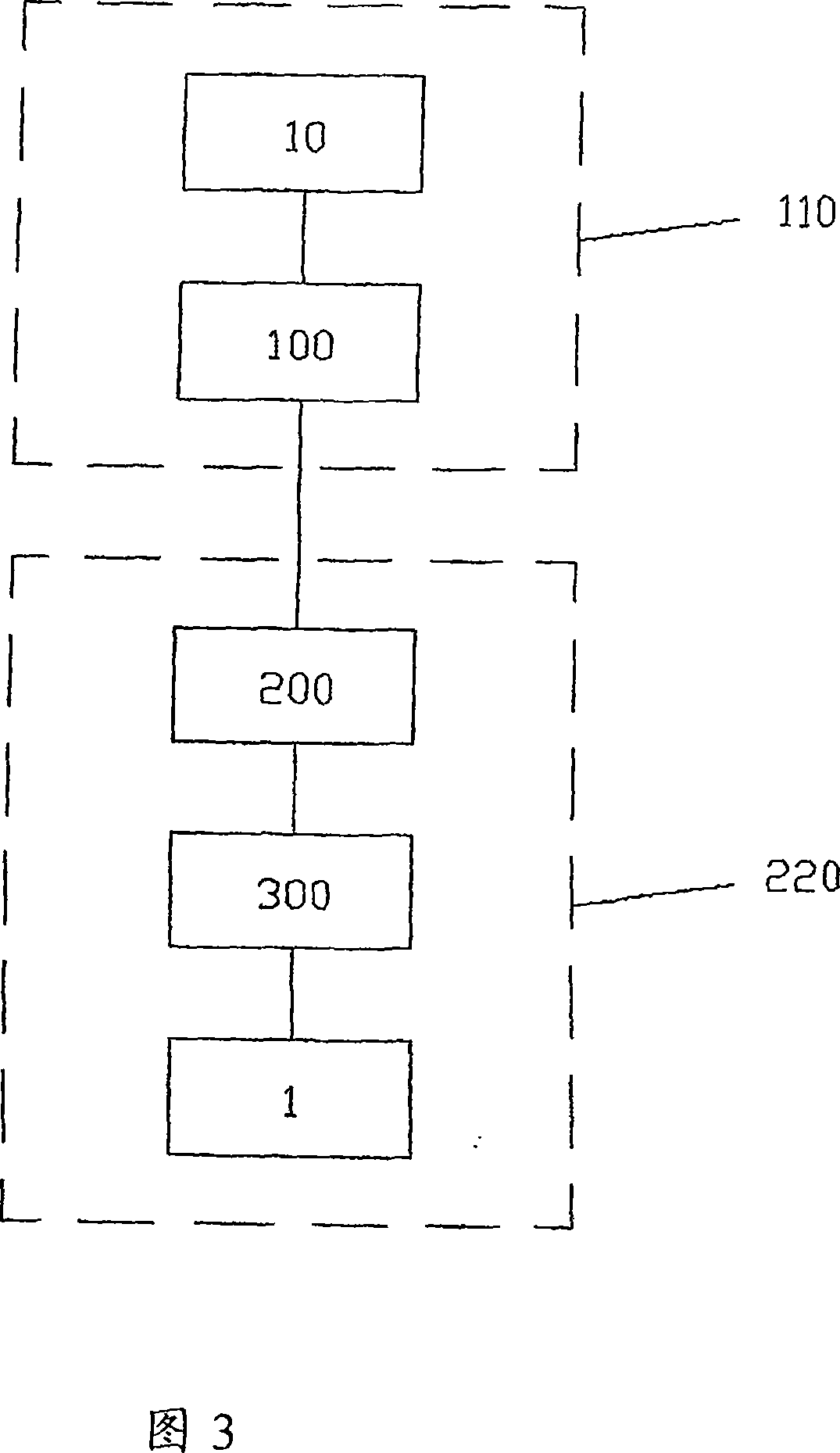

Control system for an articulated manipulator arm

InactiveCN101102869AEliminate Stability IssuesPrecise controlProgramme-controlled manipulatorManipulatorMaster controller

A control system for an articulated manipulator arm (1), the manipulator arm having at least three degrees of freedom, said control system comprising a master controller (10) moveable to replicate the at least three degrees of freedom of the manipulator arm (1); means for determining the rate of movement of the master controller in each direction replicating a degree of freedom of the manipulator arm; and control means (200) for controlling actuation of the manipulator arm whereby the rate of movement of the manipulator arm in each of said at least three degrees of freedom is proportional to the rate of movement of the master controller (10) in each direction replicating a degree of freedom of the manipulator arm.

Owner:佩里·斯林斯里系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com