Rotary type magneto-rheological damper

A magneto-rheological damper, a rotary technology, applied in non-rotational vibration suppression, vibration suppression adjustment, etc., can solve problems such as enlargement, large axial size, failure to use the rotor end face, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

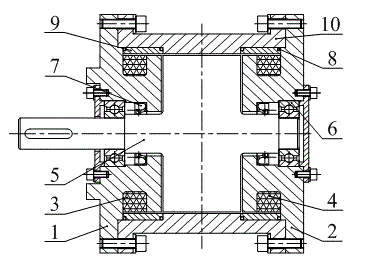

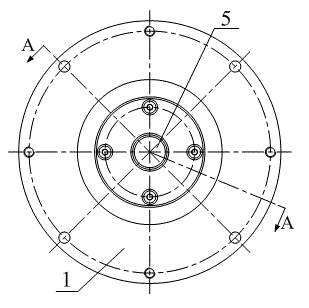

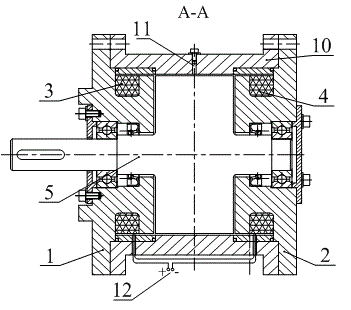

[0015] The rotary magneto-rheological damper designed by the present invention (referred to as the damper, see Figure 1-4 ), characterized in that the damper mainly includes a housing 10, a front end cover 1, a rear end cover 2, a front excitation coil 3, a rear excitation coil 4, a rotor 5, a bearing 6, a sealing ring 7, a sealing ring 8, and a magnetic isolation ring 9 and housing 10 .

[0016] The front end cover 1 and the rear end cover 2 of the damper of the present invention are located on both sides of the rotor 5, and the front end cover 1 and the rear end cover 2 are respectively connected with the shell 10 by screws to form a stator. Between the rotor 5 and the front end cover 1 and between the rotor 5 and the rear end cover 2, bearings 6 and sealing rings 7 are respectively placed; the front excitation coil 3 is wound in the front end cover 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com