Patents

Literature

30results about How to "Design calculation is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

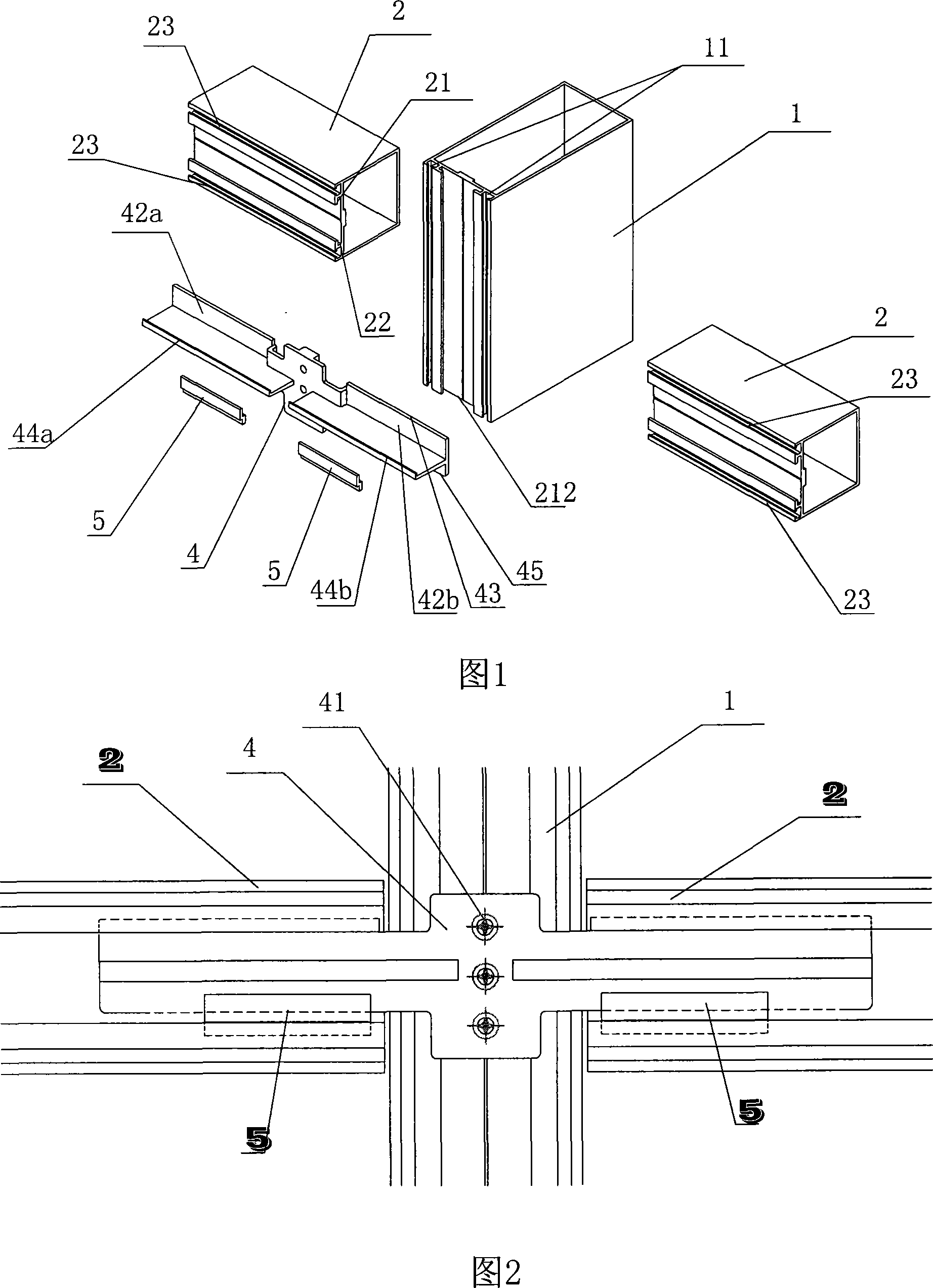

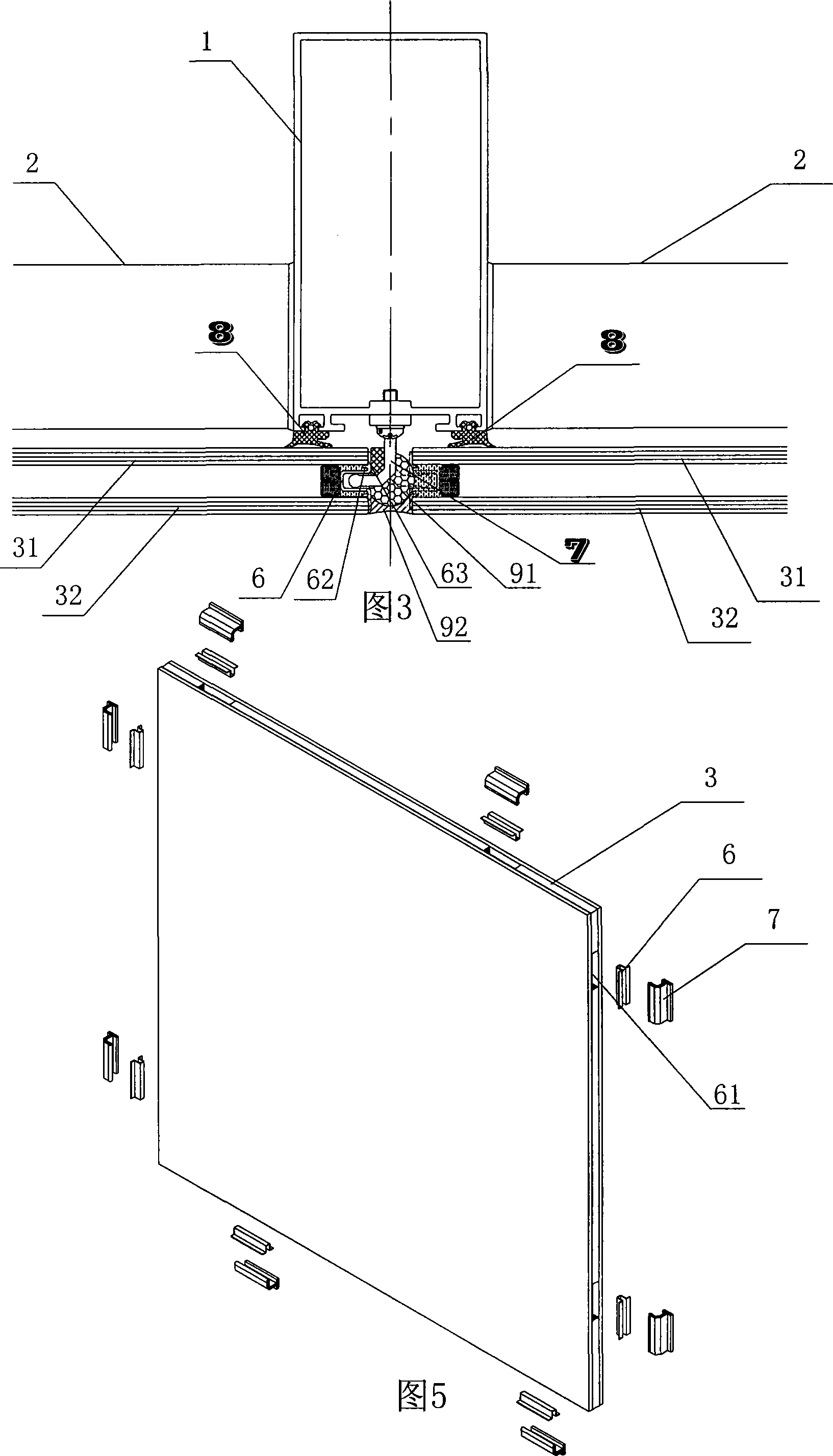

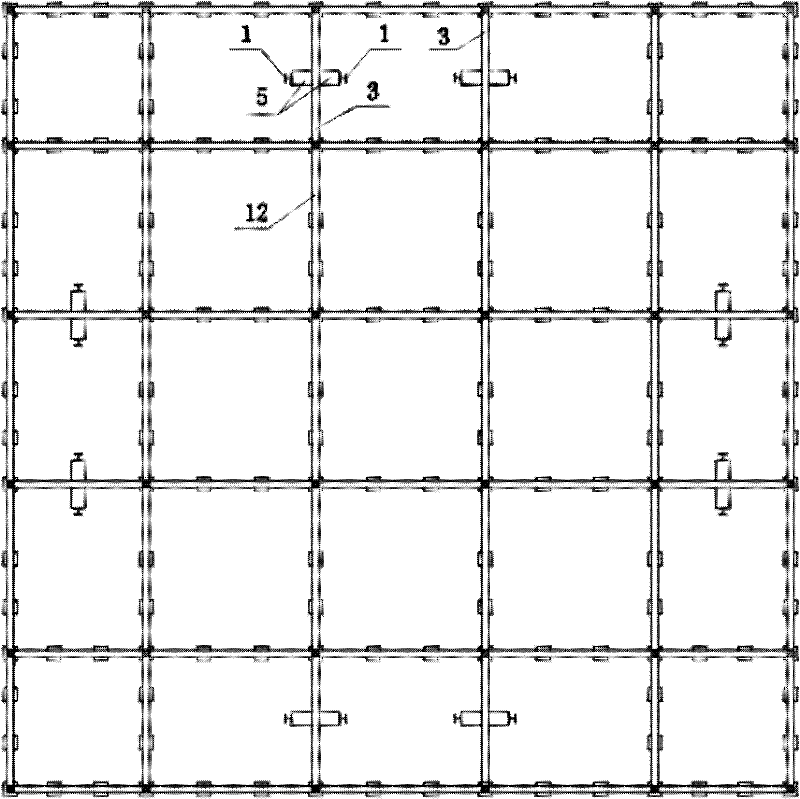

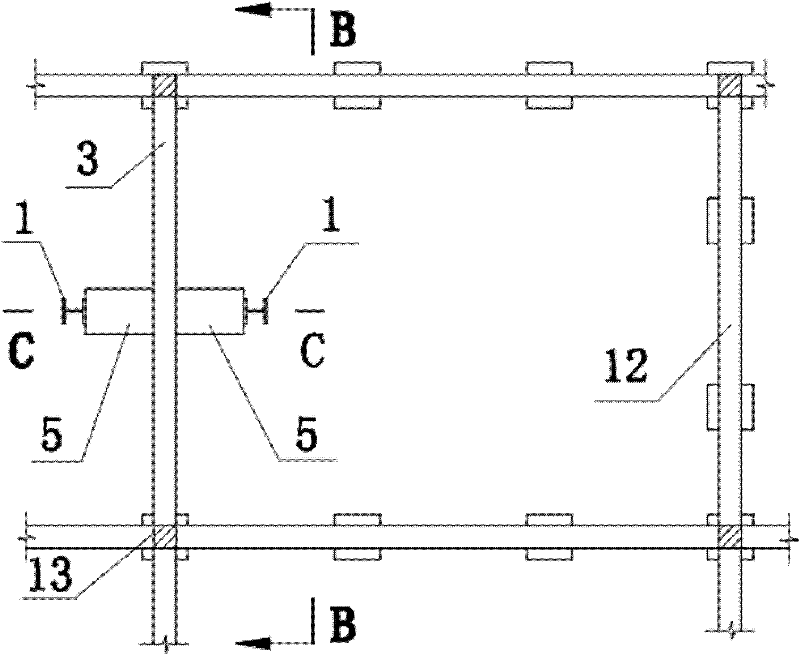

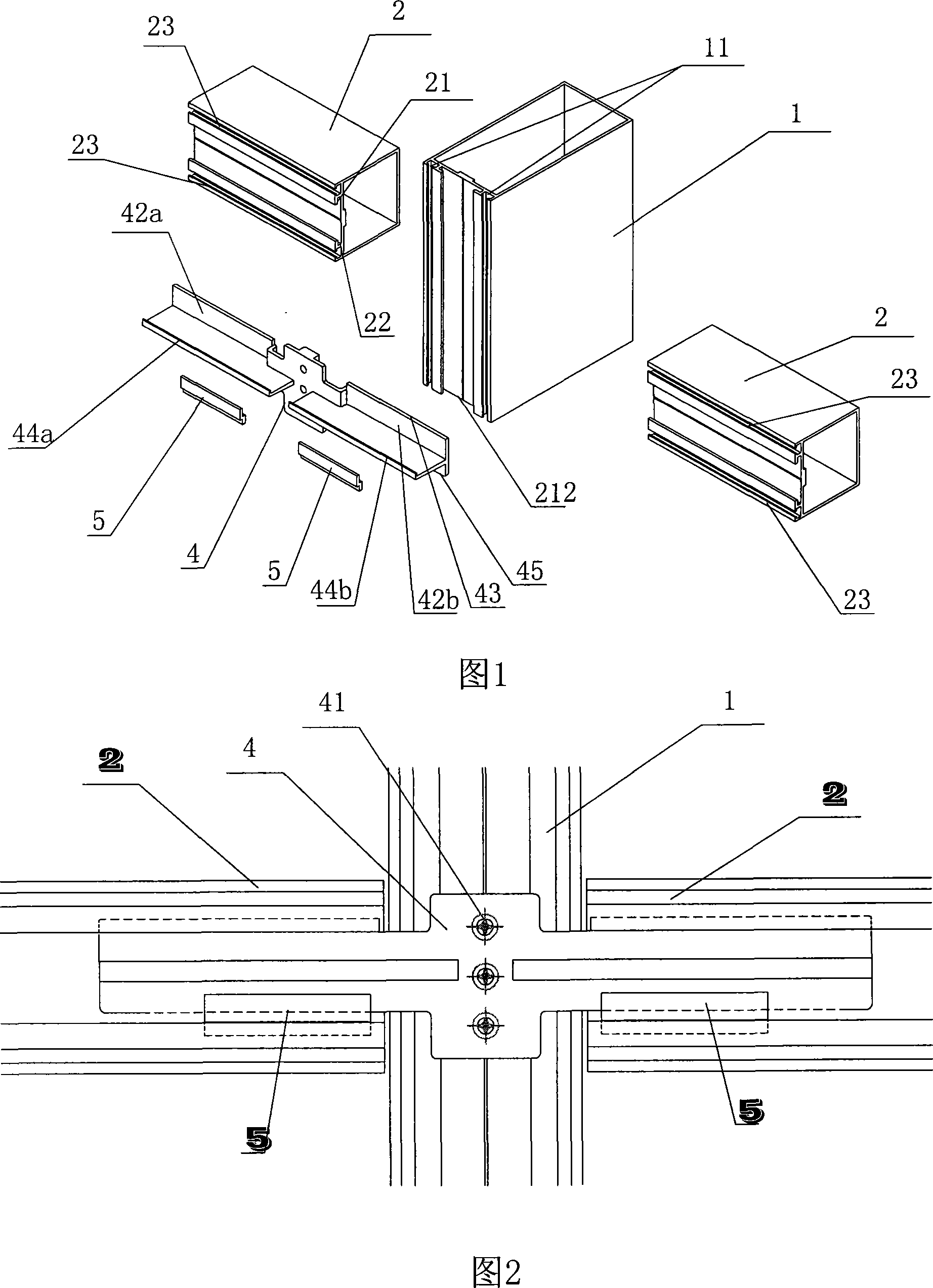

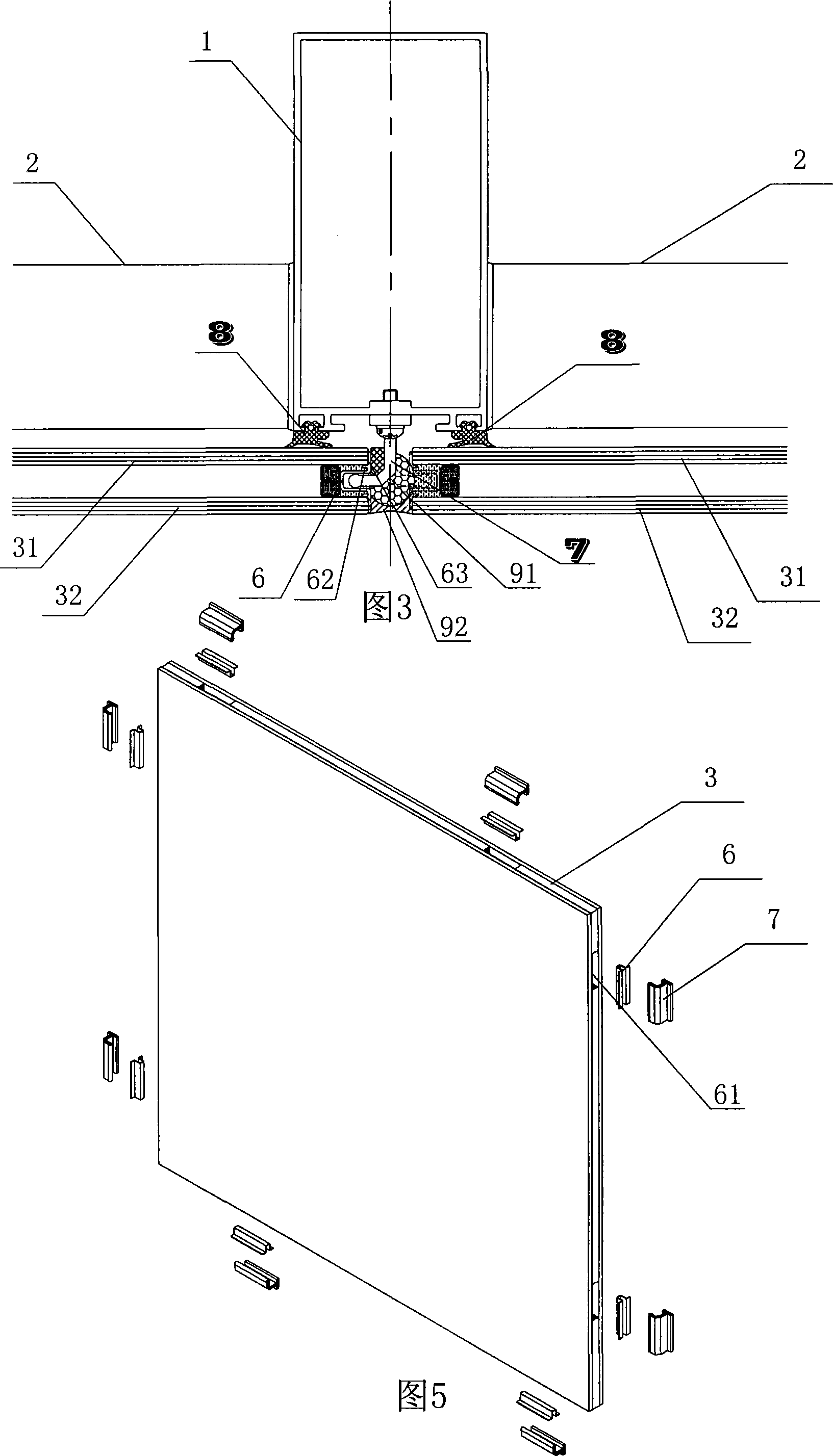

Hollow glass curtain wall

The invention provides a hollow glass curtain wall, which comprises an upright column, a bridging beam and a hollow glass slab, wherein the hollow glass slab comprises an inner layer glass slab and an outer glass slab, the hollow glass curtain wall is provided with a multifunctional connecting component, the multifunctional connecting component is mounted on the upright column, the multifunctional connecting component is provided with a wing slab which is connected with the bridging beam which is arranged on the two lateral of the upright column, the positive face of the bridging beam and the upper edge of the wing slab are articulated with a groove which is matched, the bridging beam is articulated on the wing slab, a supporting slab of the hollow glass slab is arranged on the wing slab of the multifunctional connecting component, and the supporting slab is supported by contiguous angles of the hollow glass slabs which are arranged in a row. The invention can simplify the load calculation of the bridging beam and save the material cost of the bridging beam, the connection between the bridging beam and the upright column can be simplified or omitted, the structure and the installation of the keel of the curtain wall can be simplified, the invention can also use the bridging beam which adopts closed section material, therefore, the load calculation of the bridging beam is further simplified and the material cost of the bridging beam is saved, furthermore, the invention has universal base of an exposed frame glass curtain wall system and a hidden frame glass curtain wall system.

Owner:ZHEJIANG CENT SOUTH CONSTR GROUP

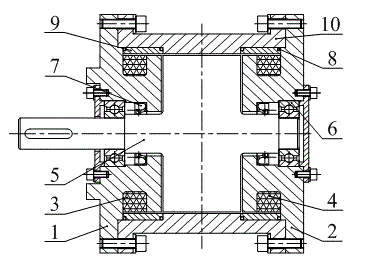

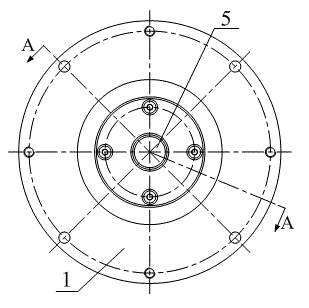

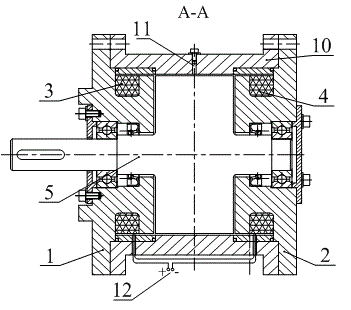

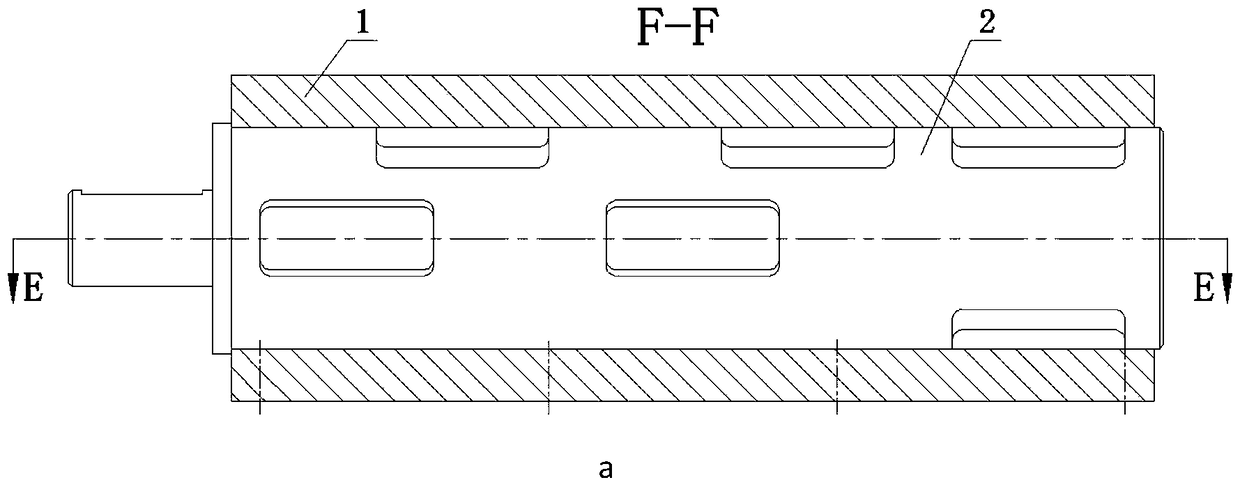

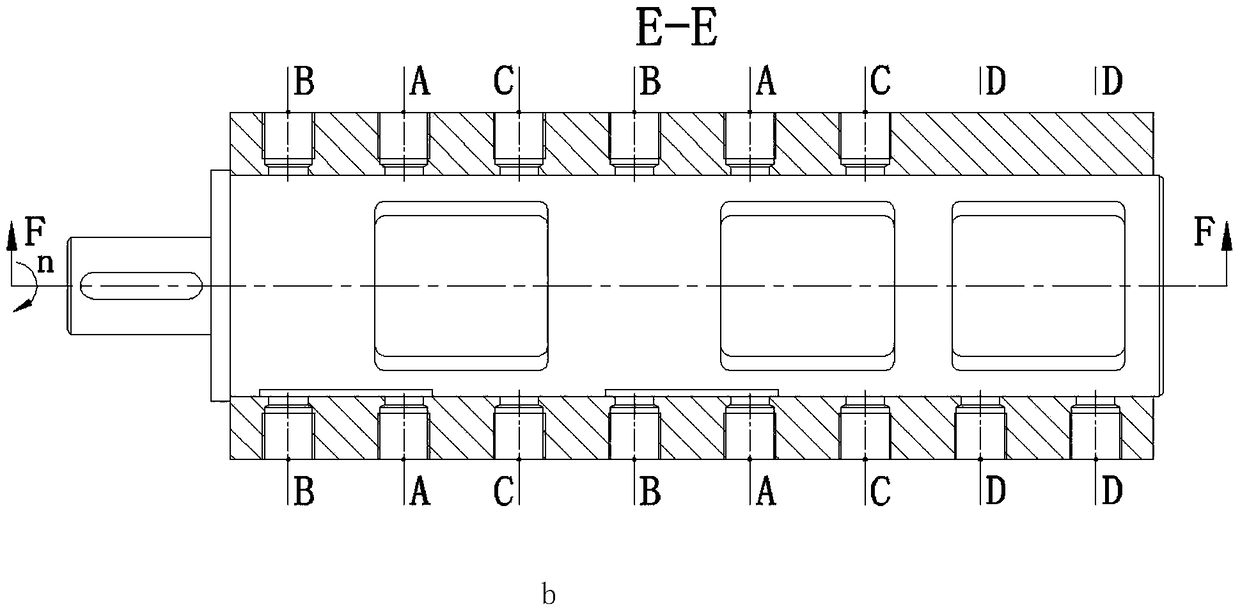

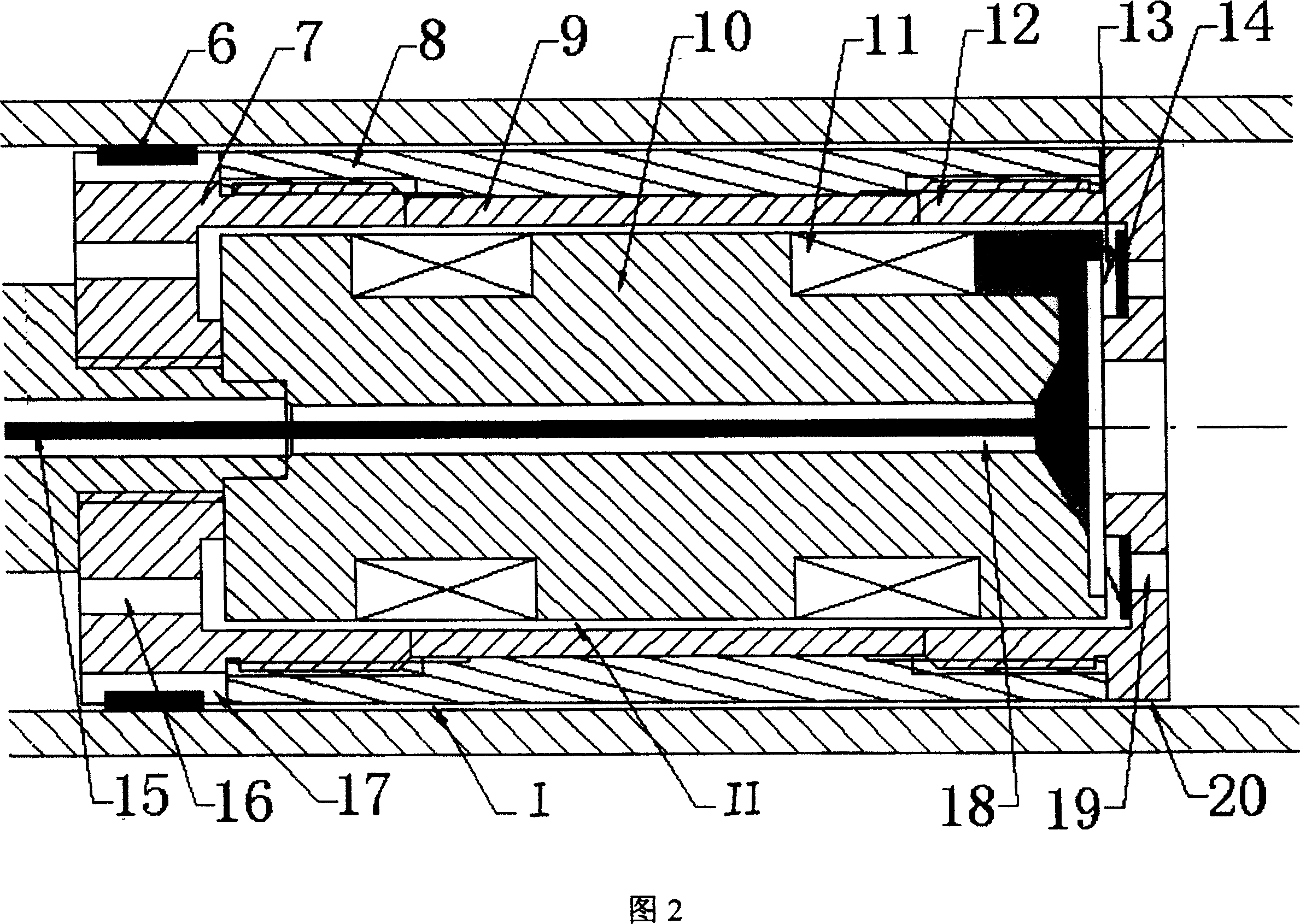

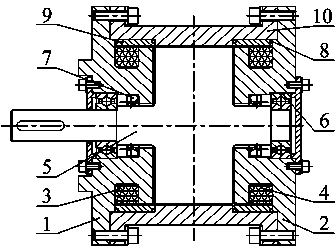

Rotary type magneto-rheological damper

InactiveCN102979847AIncrease working areaReduce thicknessNon-rotating vibration suppressionEngineeringMagneto rheological damper

The invention discloses a rotary type magneto-rheological damper which is characterized in that the damper mainly comprises an outer shell, a front end cap, a back end cap, a front magnet exciting coil, a back magnet exciting coil, a rotor, a bearing, a sealing washer, seal rings and magnetic isolation rings. The front and back end caps are located at the two sides of the rotor and are respectively connected with the outer shell, forming a stator. The bearing and the sealing washer are respectively arranged between the rotor and the front and back end caps. The front and back magnet exciting coils are wound inside the front and back end caps. The magnetic isolation rings are respectively installed between the front and back end caps and the outer shell, and O-shaped seal rings are respectively arranged between the magnetic isolation rings and the outer shell as well as the front and back end caps. A sealed liquid charging hole is formed at the upper part of the outer shell, and magneto-rheological fluid is filled in a hollow cavity between the stator and the rotor. The front and back magnet exciting coils are wound in the same direction, with the tail ends being connected with each other in series and the head ends being loaded with power sources. The two magnet exciting coils form two parallel magnetic pathways which generate two magnetic fields in opposite direction, and the magnetic flux is generated by a single piece of magnet exciting coils.

Owner:HEBEI UNIV OF TECH

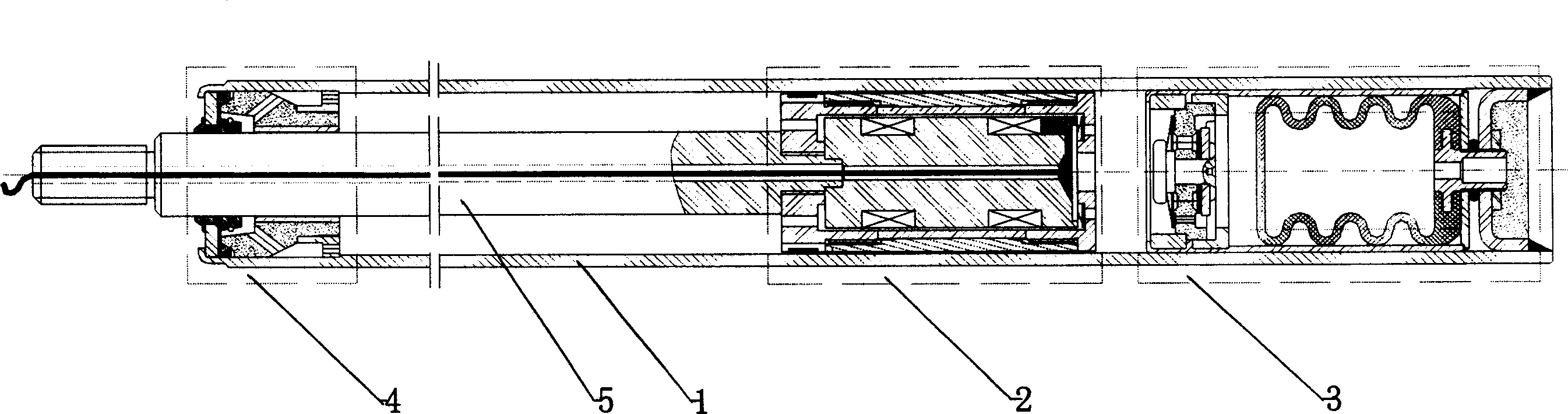

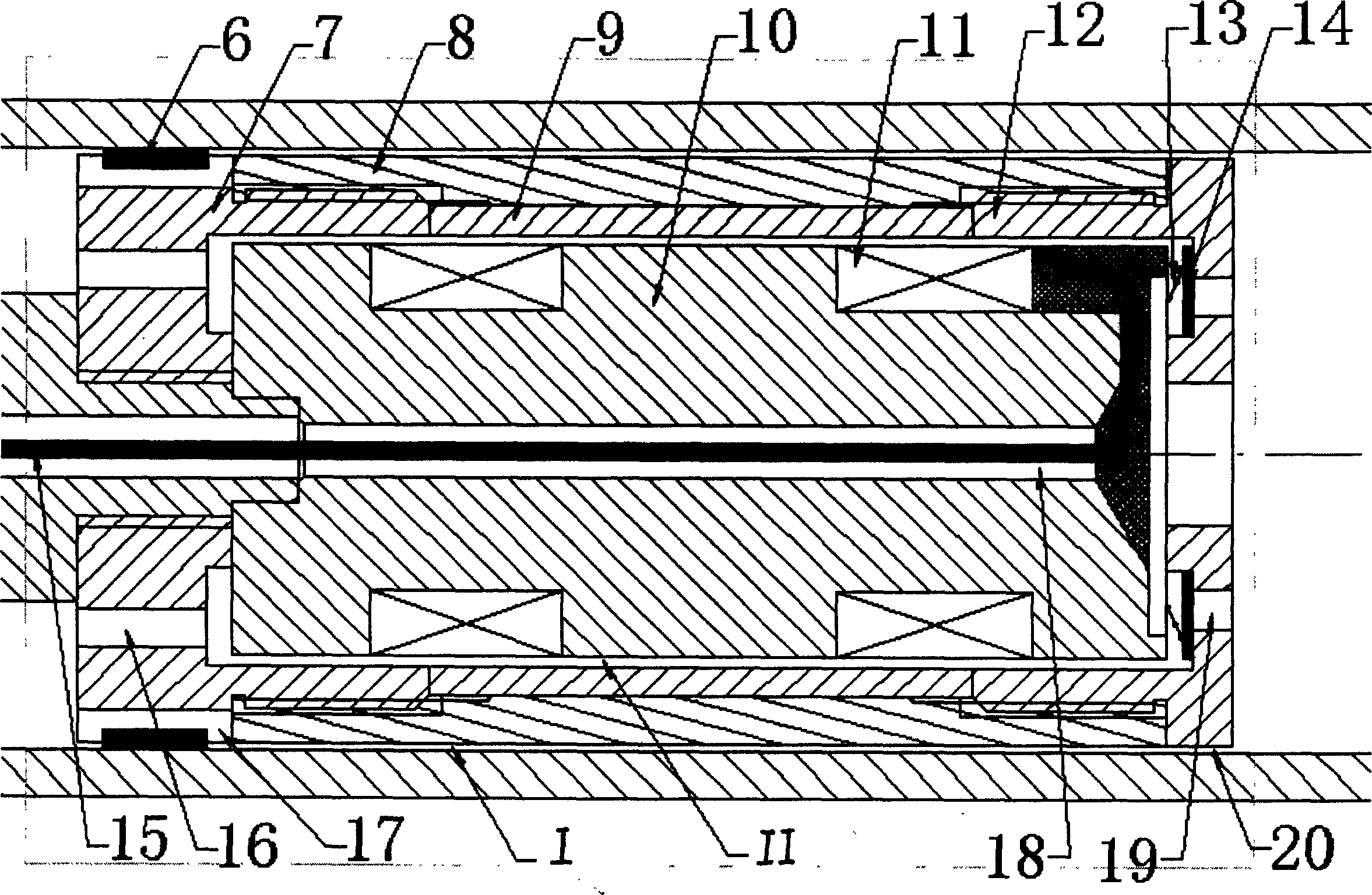

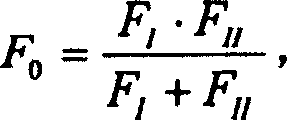

Double channel magnetic current damp variation device with recombination of mixing mode and flowing mode

InactiveCN1621707ANo compensation will occurNo problemNon-rotating vibration suppressionResilient suspensionsMagnetic currentSemi active

The composite mixed mode and flow mode double-channel magnetic rheologic damper includes work cylinder, piston type magnetic field generator, compensator and sealing unit. The piston type magnetic field generator has two flow channels, including the outer channel without magnetic field and operating in mixed mode and the inner channel inside magnetic field and operating in flow mode. The damper may operate in no outer exciting current state with relatively small damping and in large outer exciting current state with relatively great damping. This kind of double-channel structure makes the magnetic rheologic damper possess greatly lowered damping under the condition of no external magnetic field, has expanded dynamic regulation range and even suitable for the semi-active control of vehicle suspension.

Owner:CHONGQING UNIV

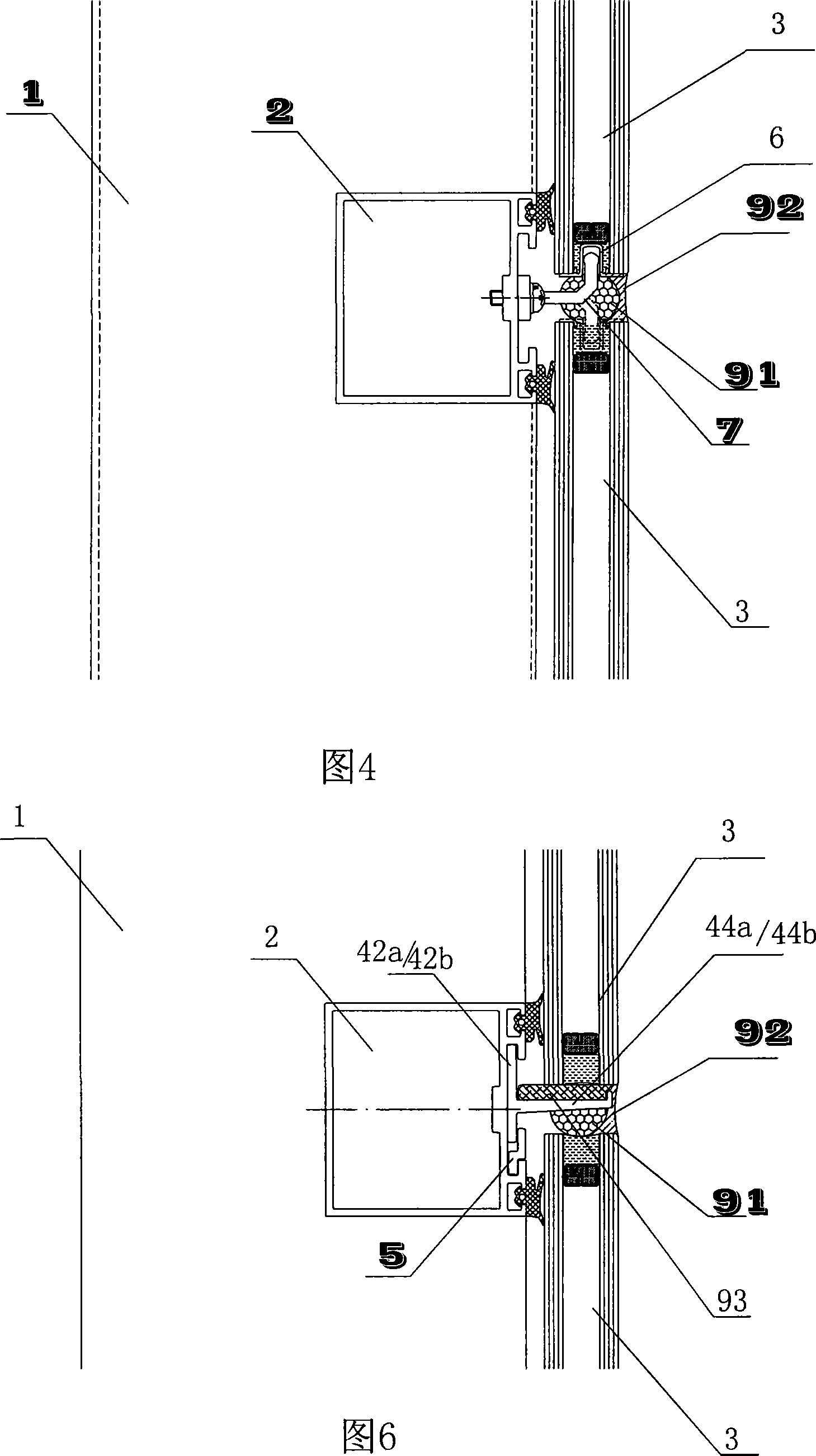

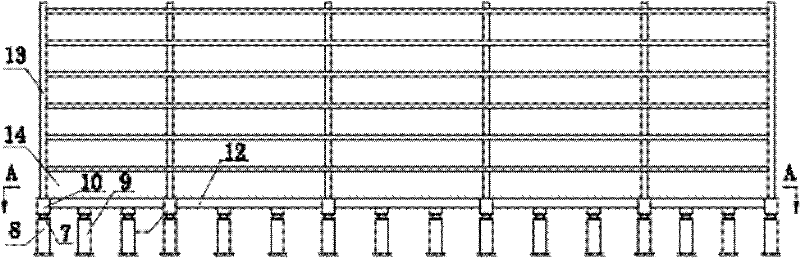

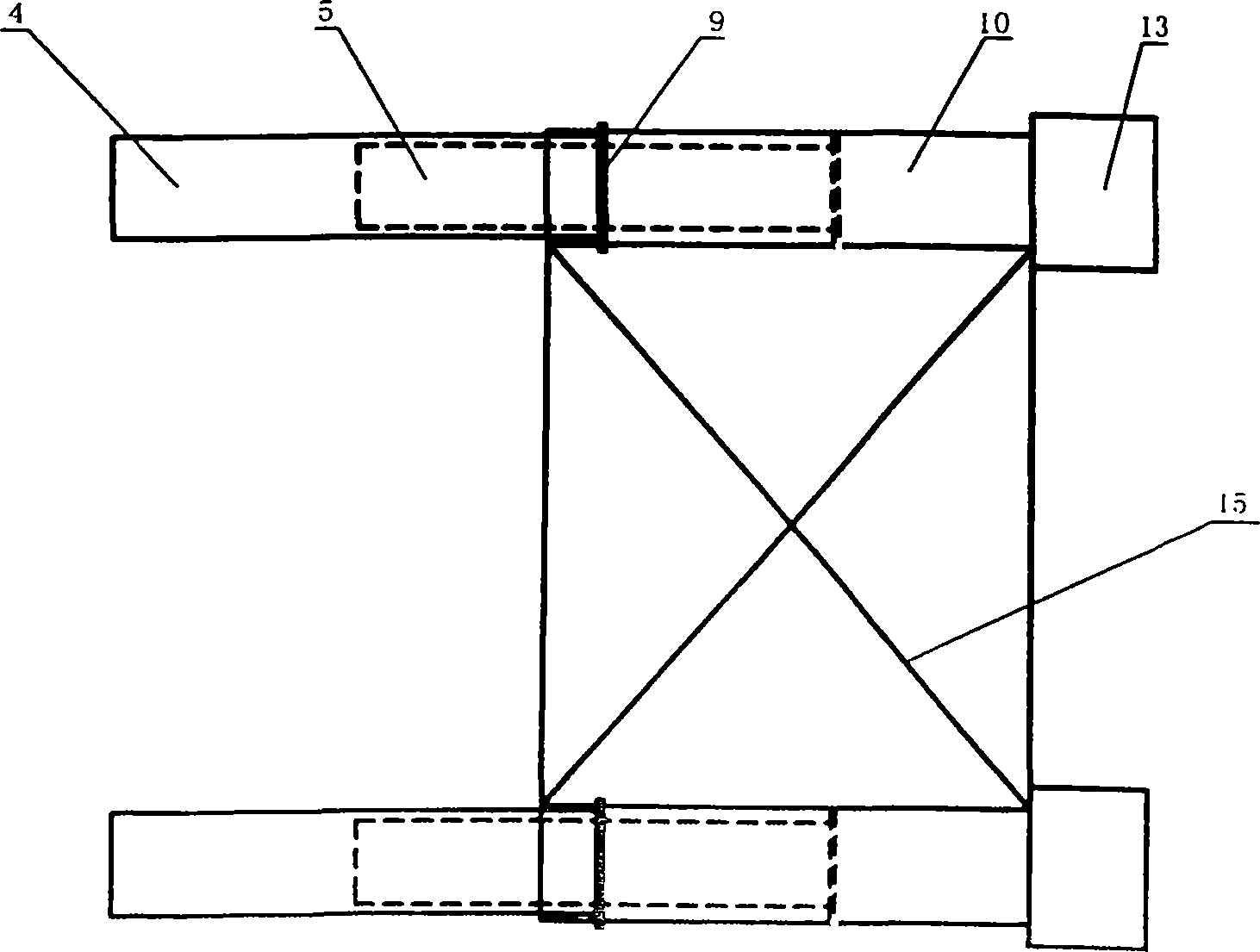

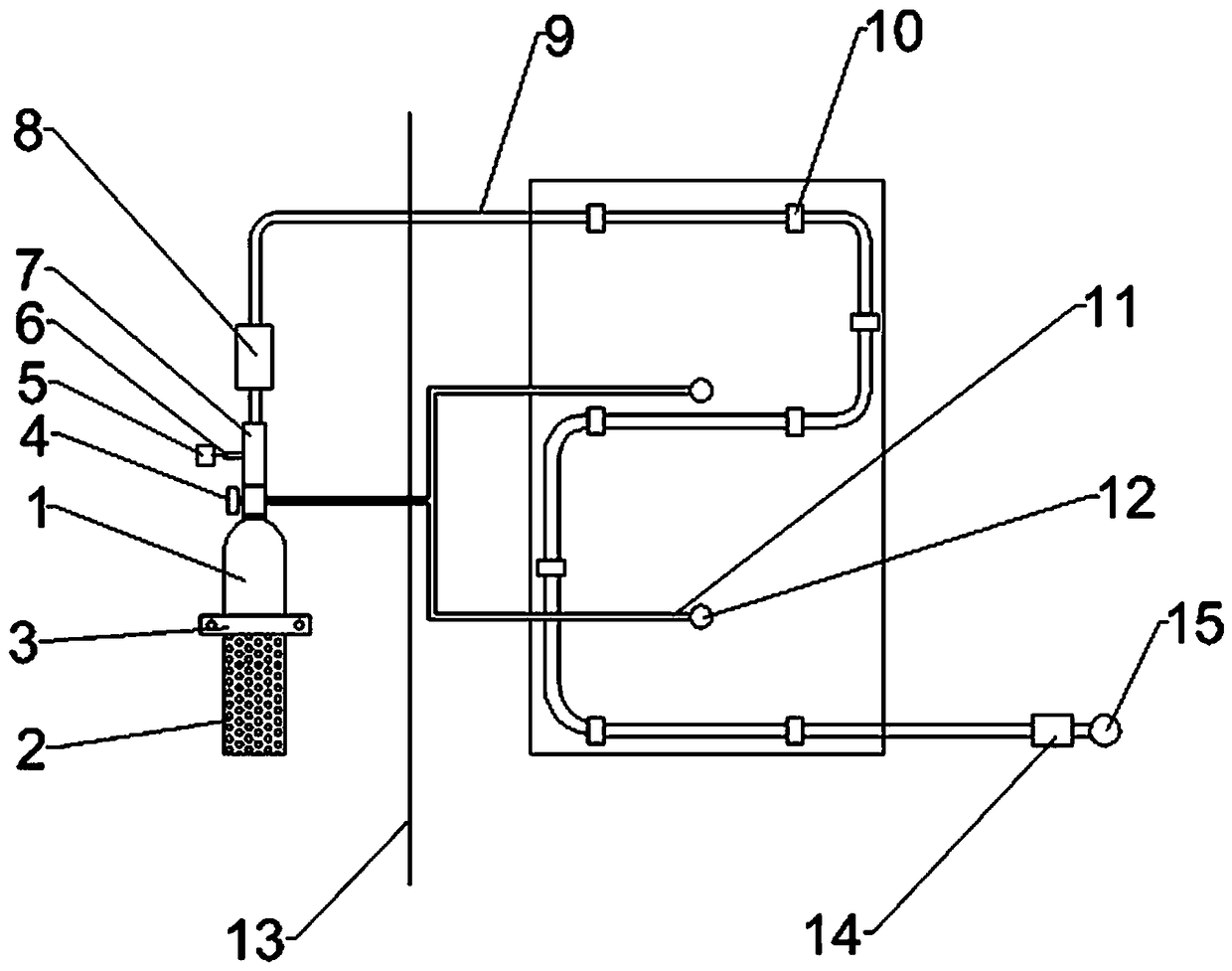

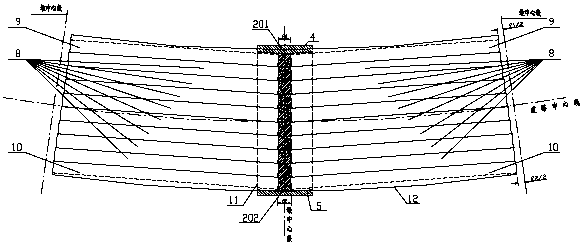

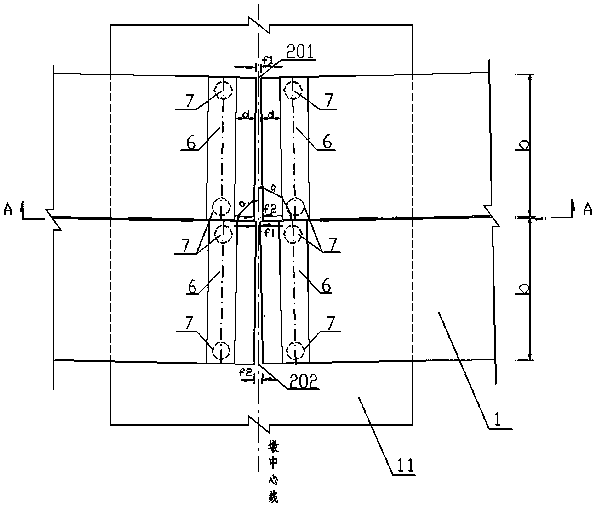

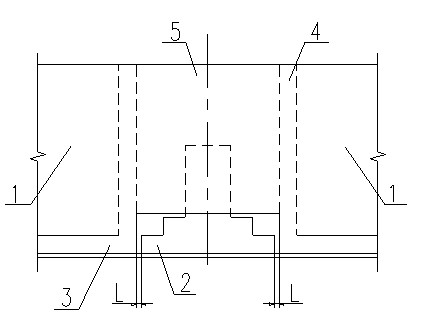

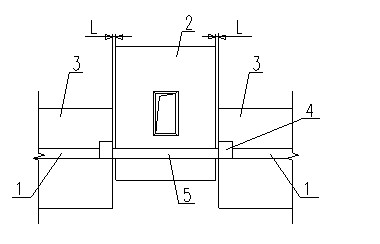

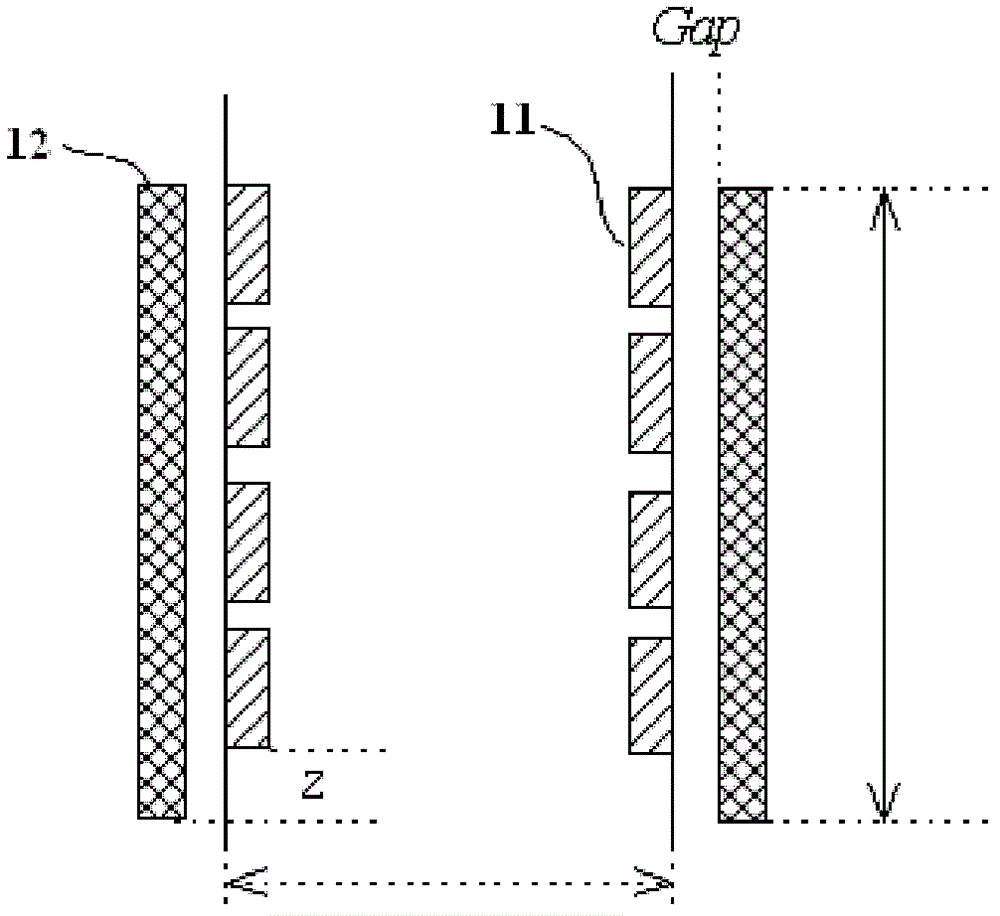

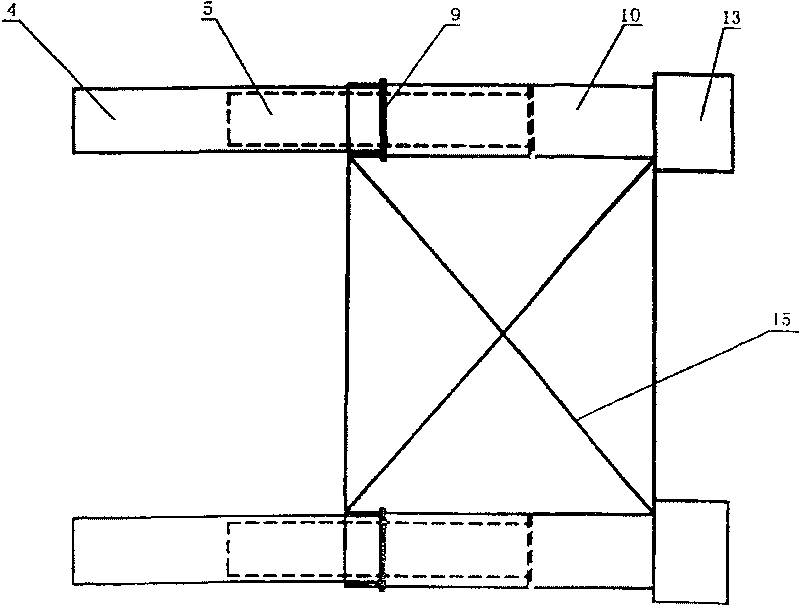

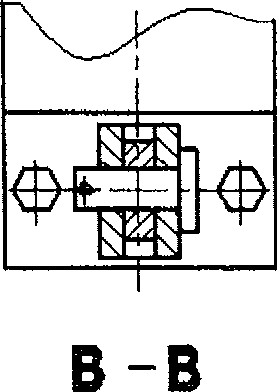

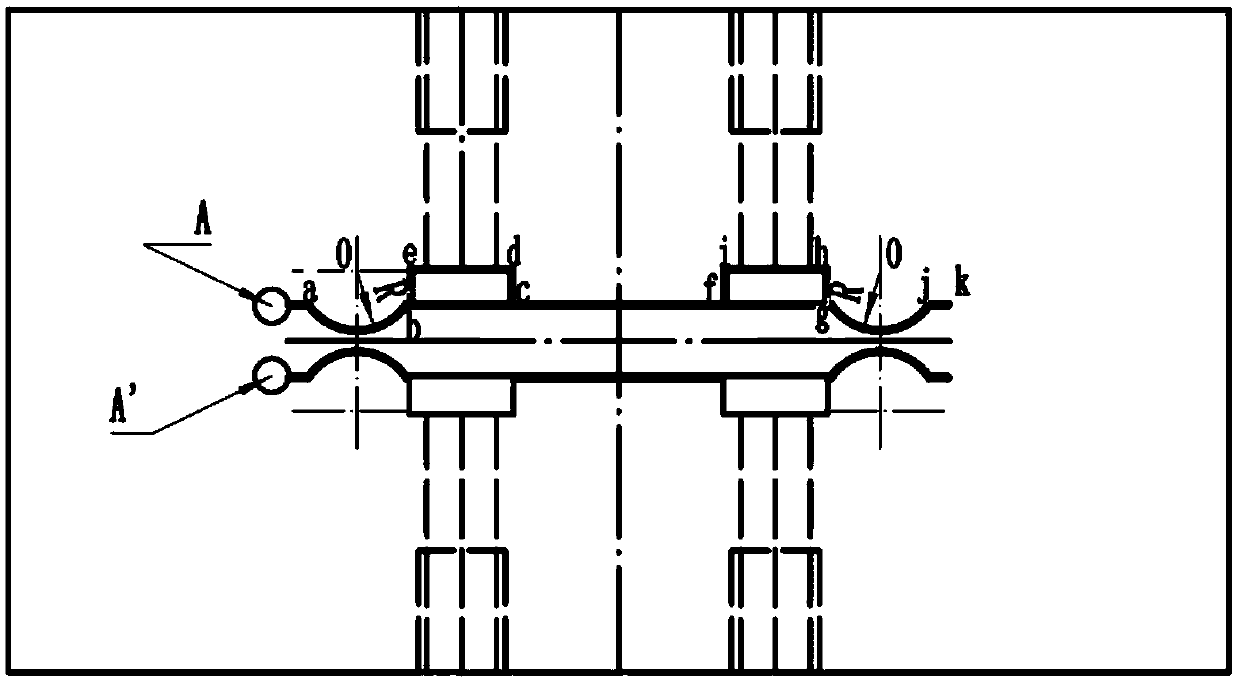

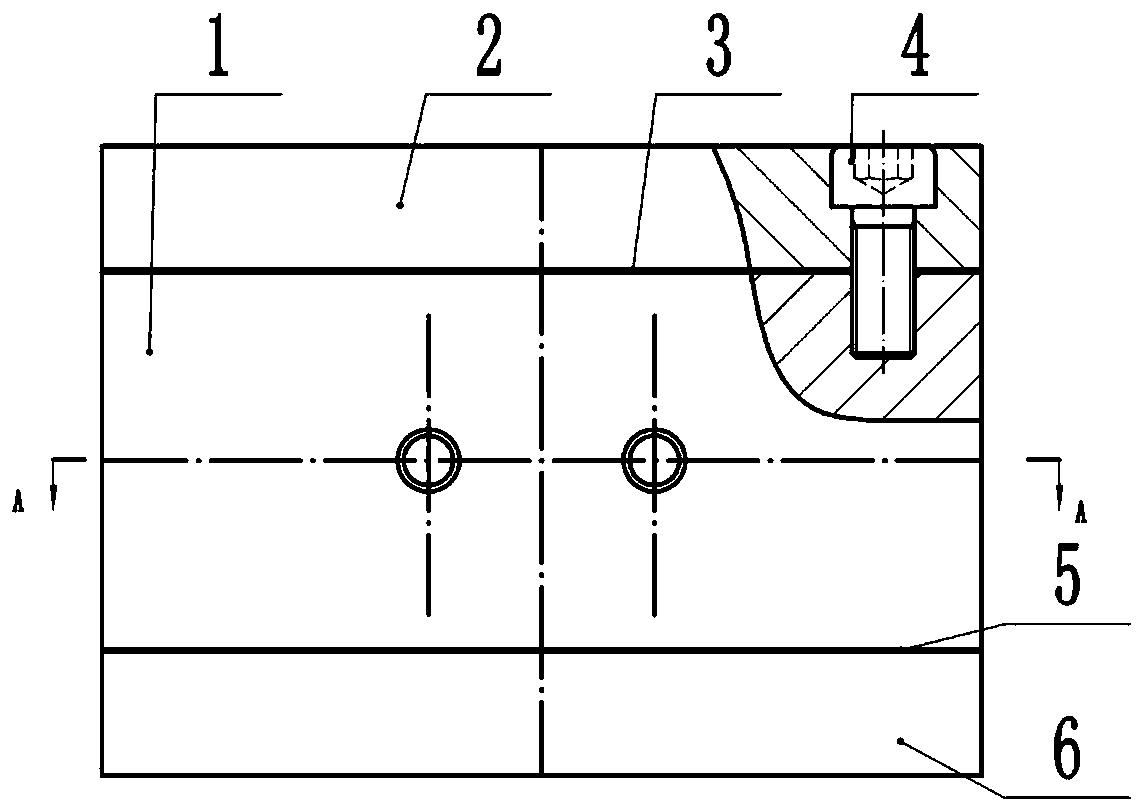

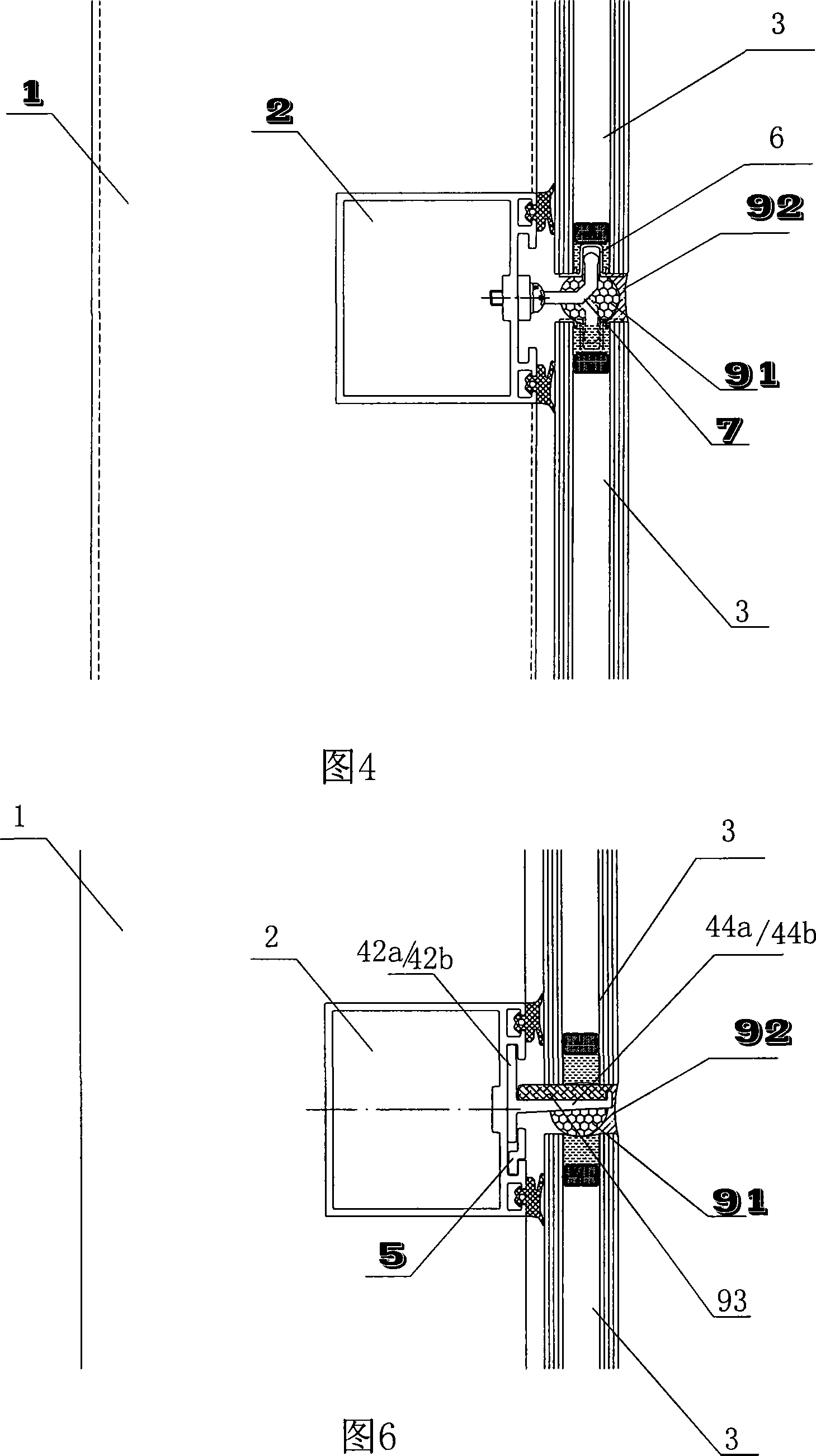

A seismic isolation method for high-rise buildings

InactiveCN102296642ADesign calculation is simpleReduce computing workProtective foundationShock proofingHorizontal diameterEngineering

The invention discloses a seismic isolation method for a high-rise building. The method is mainly composed of the following steps: at least one cross beam (12) intersecting with the periphery of the high-rise building is selected in the middle of each surface as the seismic isolation structural beam at the periphery of the upper structure. (3) A special seismic isolation beam (4) parallel to the seismic isolation structure beam (3) is arranged directly under each seismic isolation structure beam (3), and a tie rod (1) is respectively fixed on both sides of the middle of each seismic isolation structure beam (3). ), the two tie rods (1) extend vertically downward to the lower part of the special beam (4) for seismic isolation respectively, and are respectively connected with one end of the horizontal bar (2); corresponding to the directly below each column (13) of the superstructure A first column pier (8) is provided, and a second column is provided directly below the beam (12) corresponding to the lower part of the shear wall (14) of the superstructure, except for the special beam (4) for seismic isolation A pier (9), each of the first column piers (8) and each of the second column piers (9) is provided with a vibration isolation support (7).

Owner:GUANGZHOU UNIVERSITY

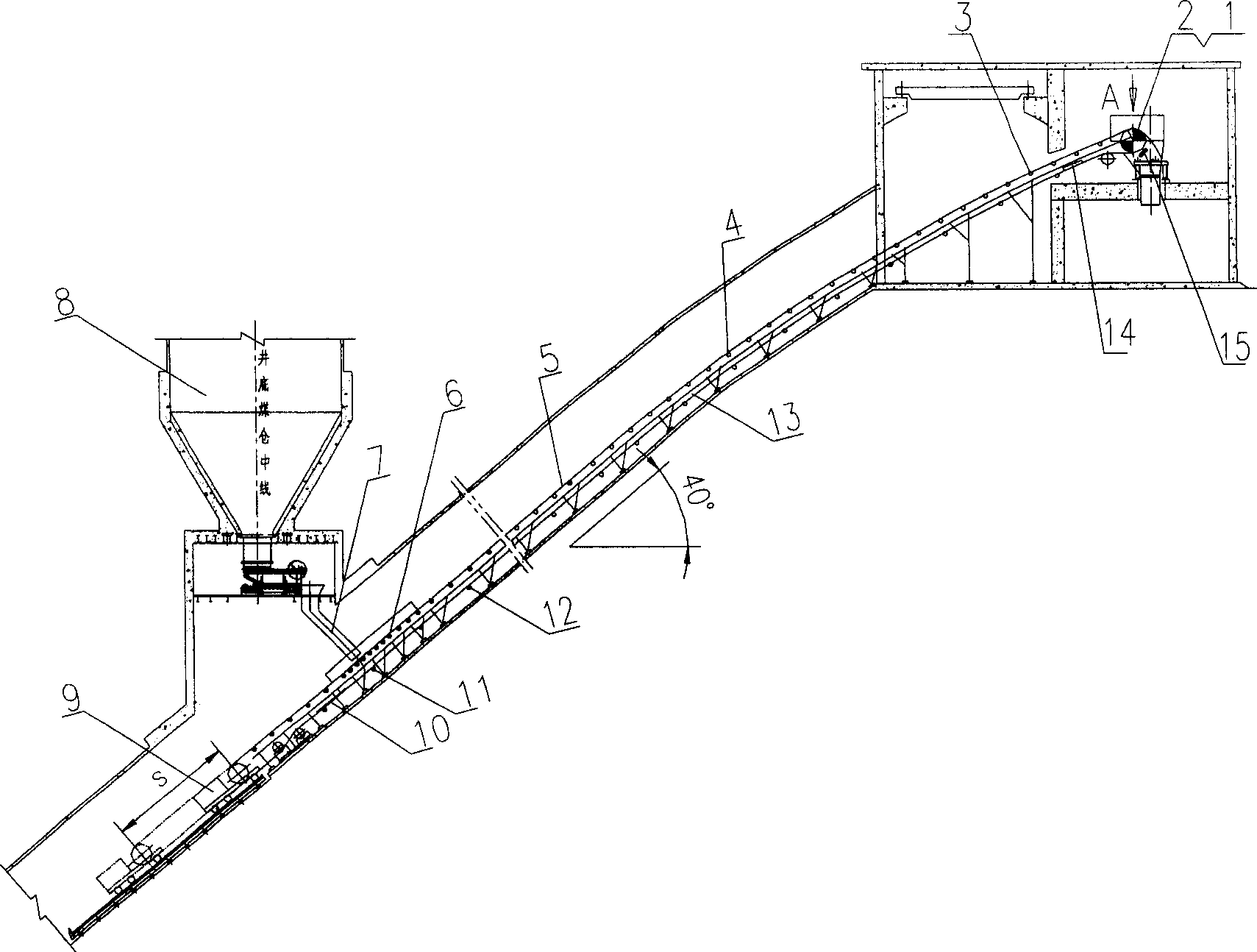

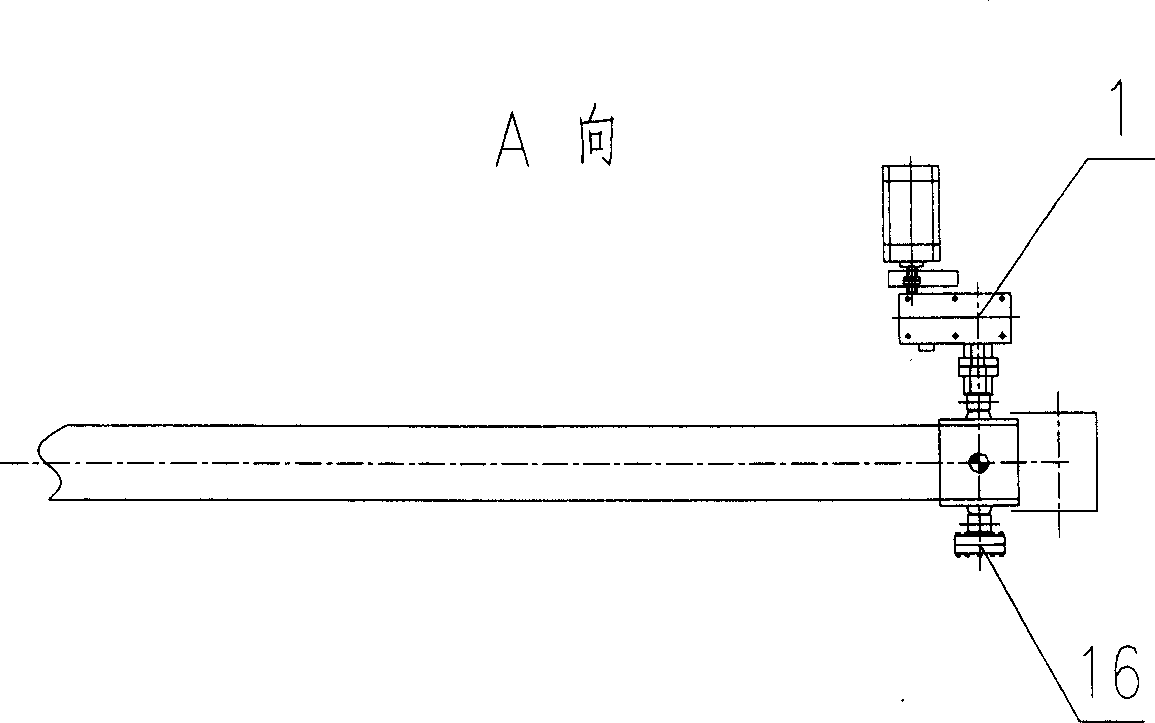

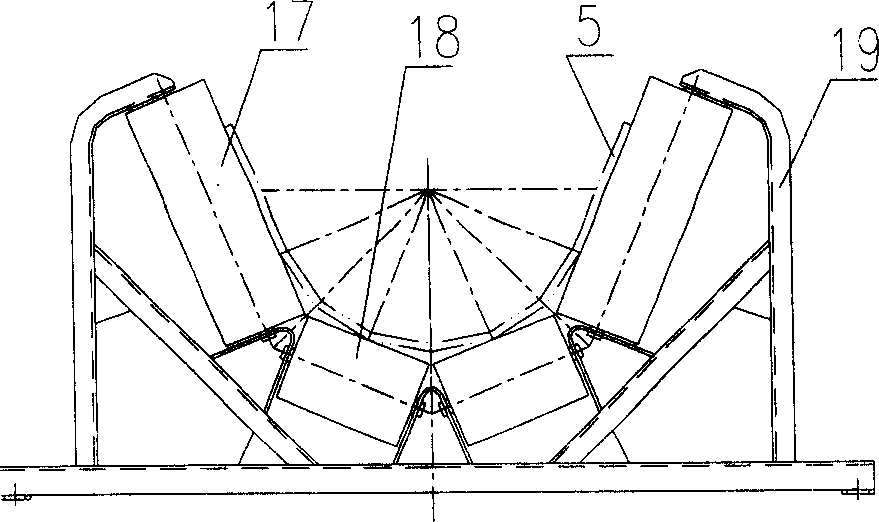

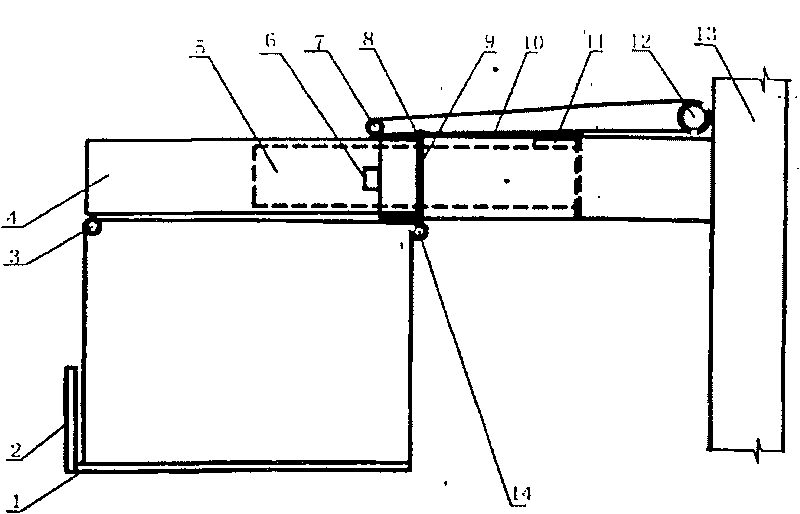

Semicircular belt conveyor with deep groove and big dig

A belt conveyer with deep semi-circular channel and big inclination up to 40 deg is composed of a machine frame, a drum group, a group of supporting rollers including central supporting rollers and side supporting rollers for rolling the conveying belt to become a deep semi-circular channel, a conveying patterned rubber belt, a carriage-type tension unit for the pull drum, and cleaning unit with brush and vibration cleaner.

Owner:SHENYANG MINING MACHINERY GROUP

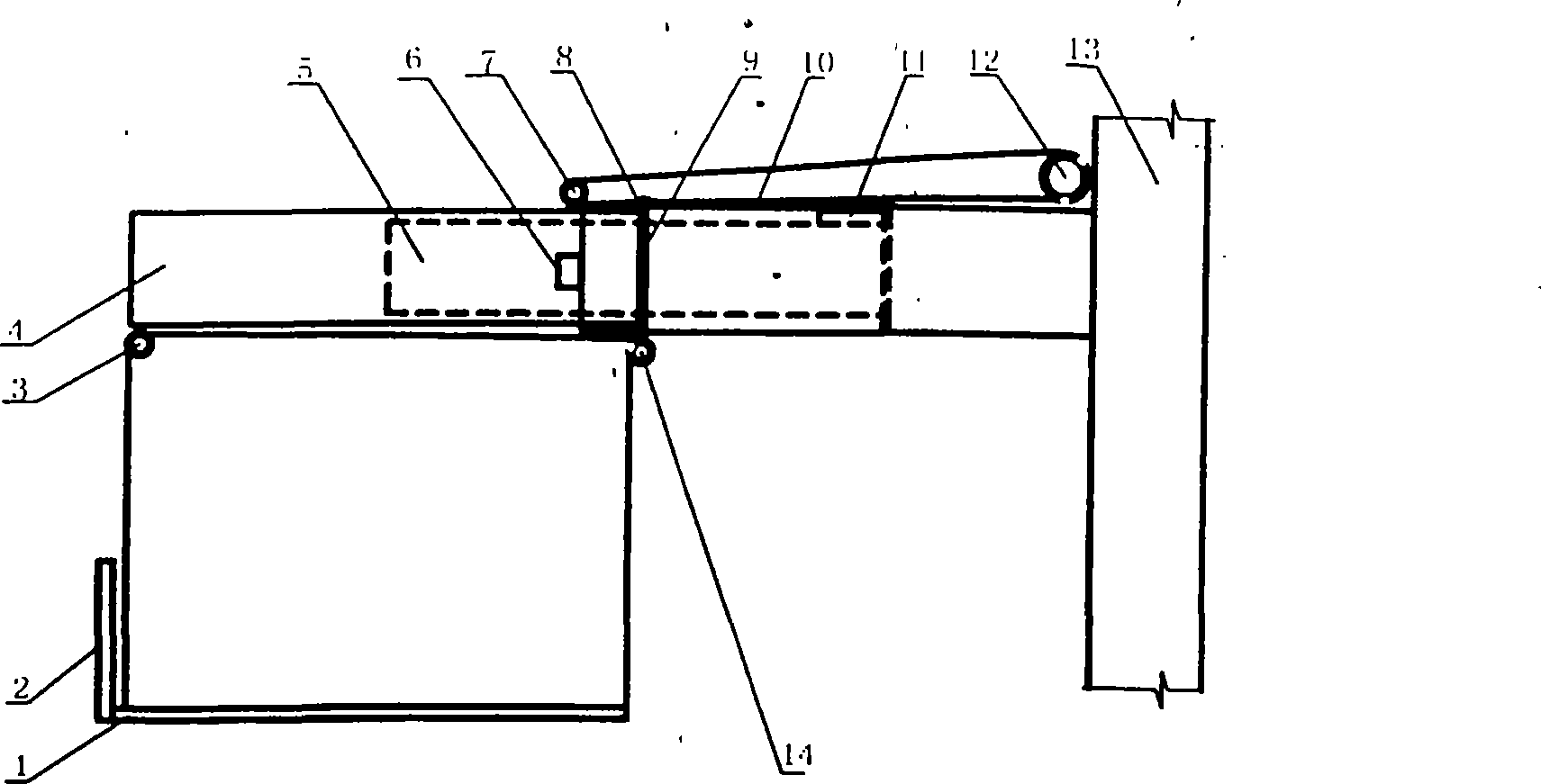

Fully automatic stereo-parking garage

The invention discloses a full automatic stereo garage, including the main frame with multi-layer and multiple-row integral garage and the hoisting system with gondola, and including the adjustable system of each integral garage and the controlled system, both the adjustable system and the hoisting system is controlled by several fast-pulley and wire cable, and the main frame adopt steel element. The invention is compact conformation, cost price low, no need special man management, delay time is few, and other garage operation will not affect when one integral garage appear fault.

Owner:张正泉

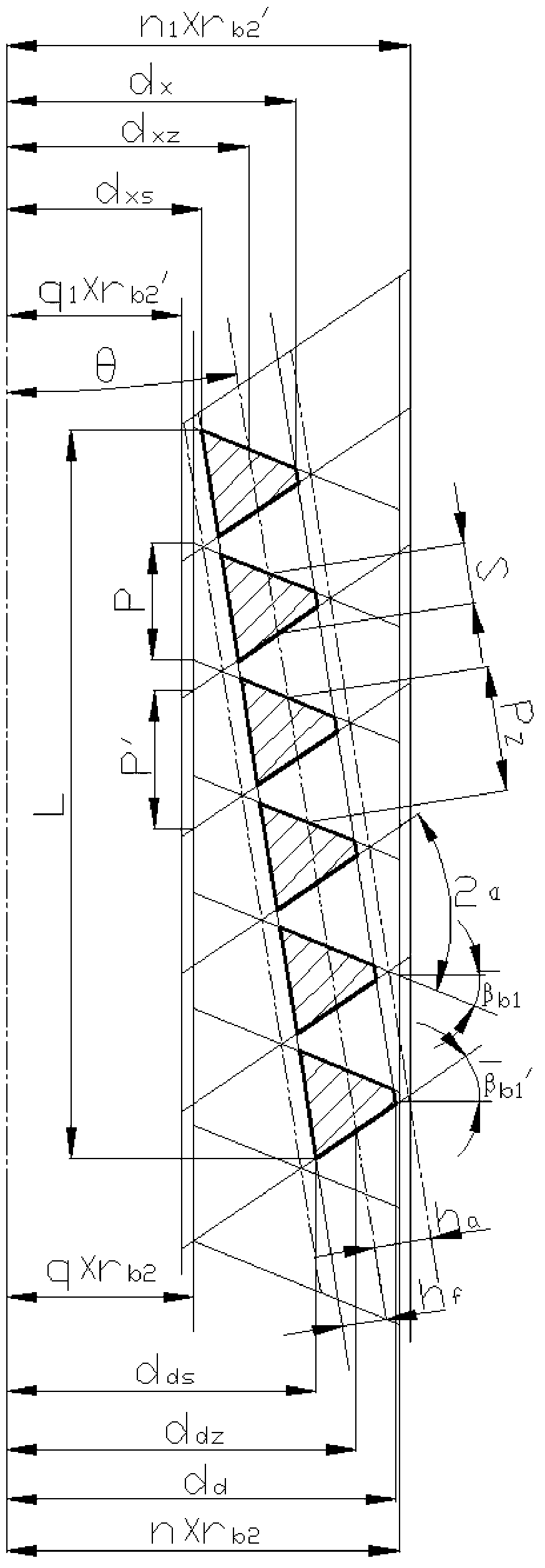

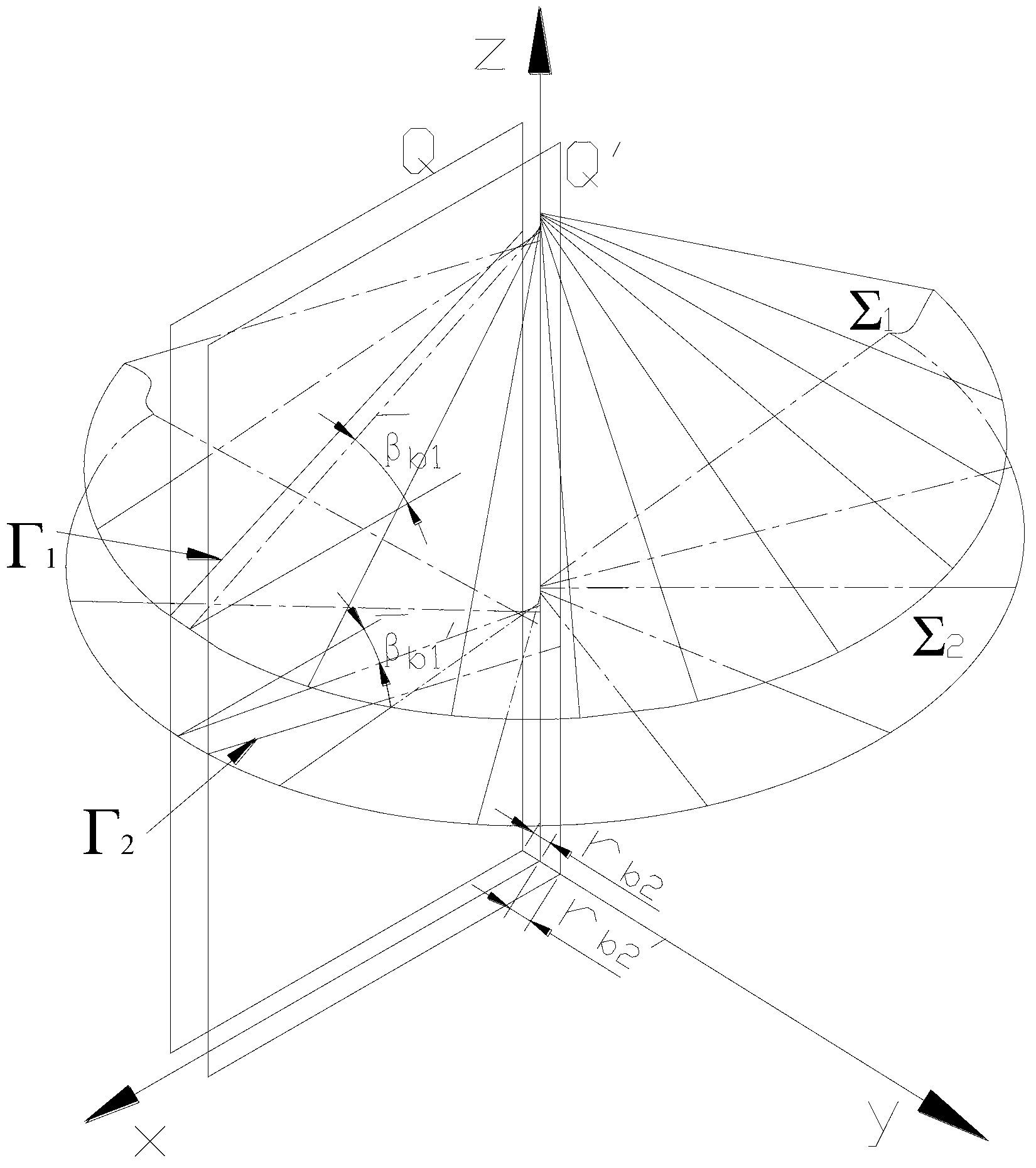

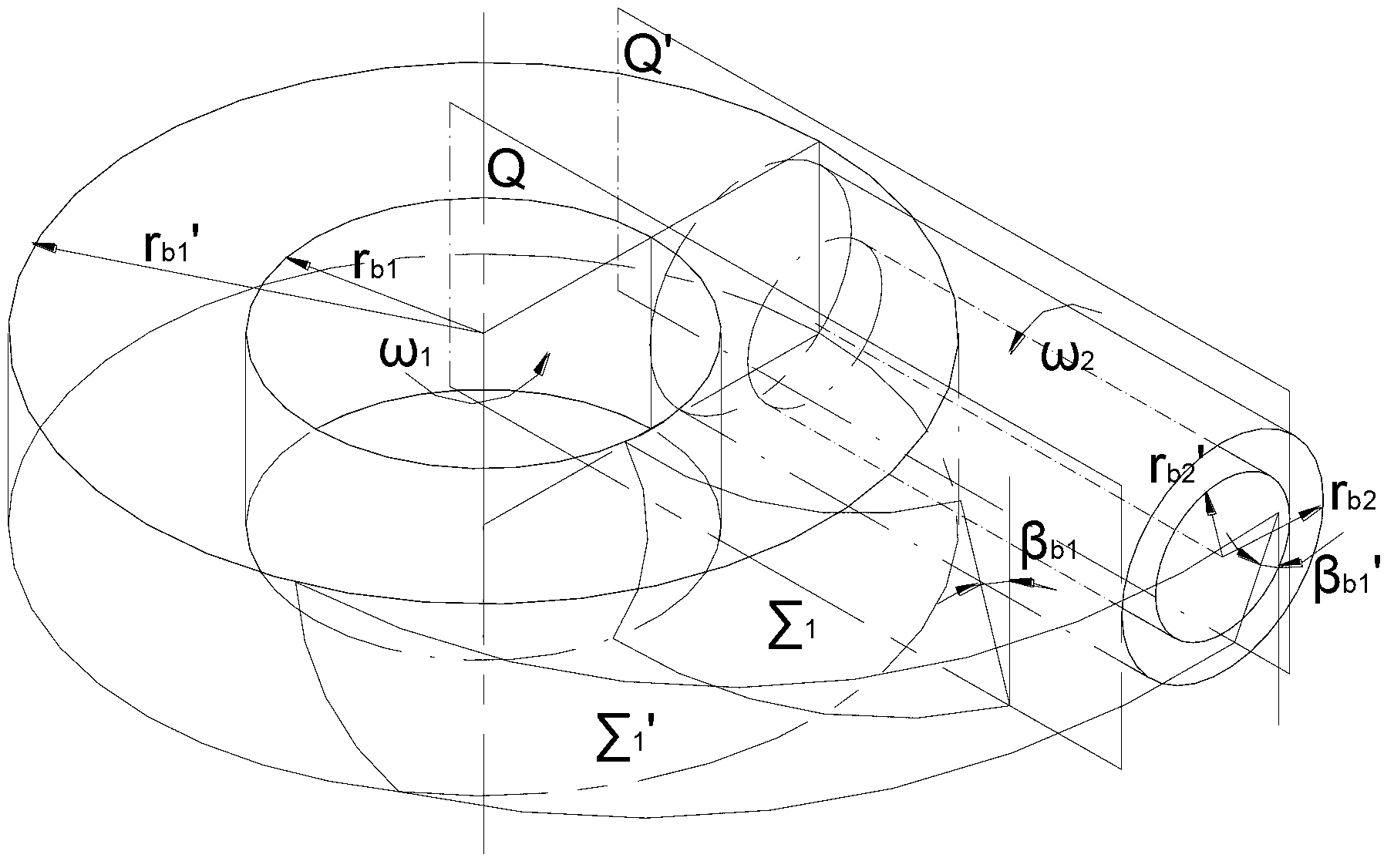

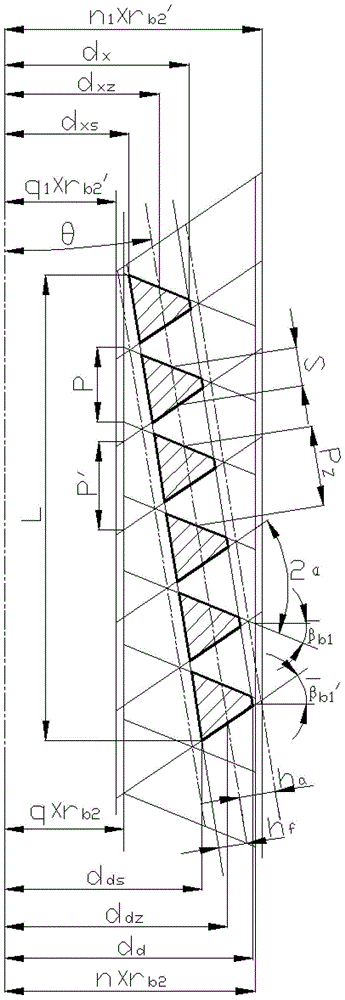

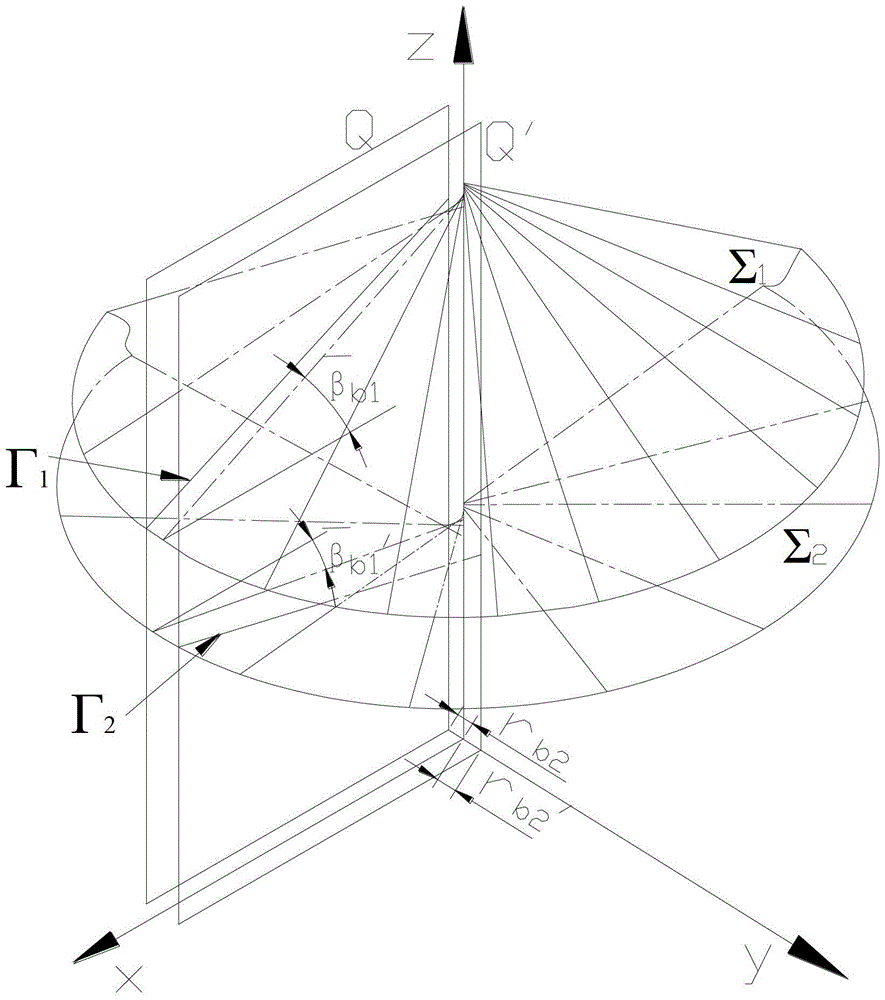

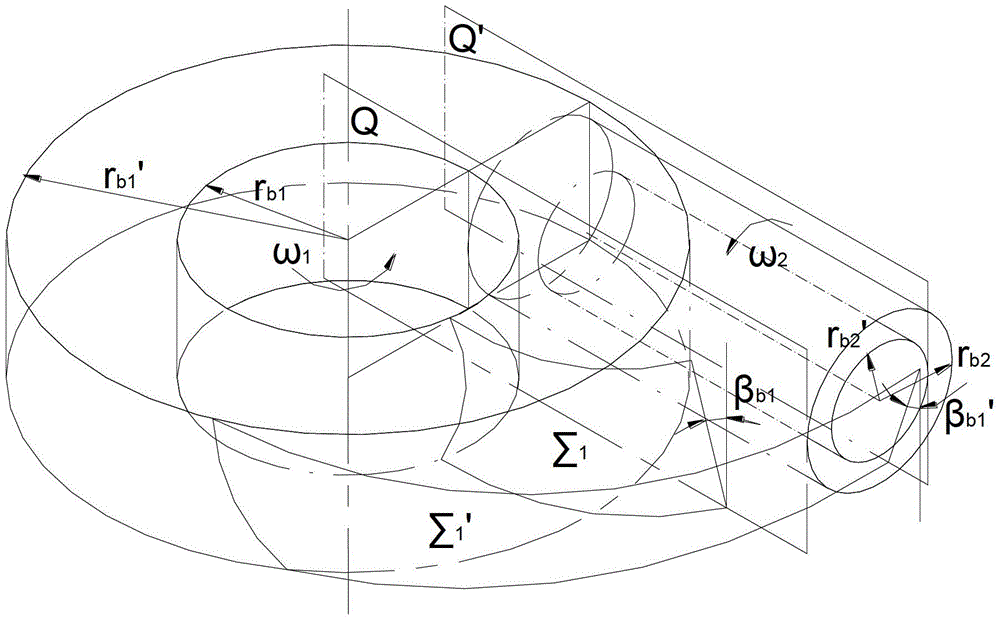

Design method for quasi dual-lead conical worms and worm gears

InactiveCN102797829ASmooth transmissionImprove transmission efficiencyPortable liftingGearing elementsOffset distanceDesign methods

The invention discloses a design method for quasi dual-lead conical worms and worm gears. The method comprises the steps as follows: 1. designing natural tooth profile angle alpha for a quasi dual-lead conical worm; 2. designing an approximate tooth profile angle betab1 in an outer engaging surface section Q-Q and an approximate tooth profile angle betab1' in an inner engaging surface section Q'-Q'; 3. designing a taper angle theta for the quasi dual-lead conical worm; 4. designing the lead of the quasi dual-lead conical worm; 5. designing the installation center distance from the quasi dual-lead conical worm to the worm gear; 6. designing the inner and outer engaging parameters of the quasi dual-lead conical worm; 7. testing and verifying the transmission ratio and the lead of the quasi dual-lead conical worm; 8. designing the tooth depth of the quasi dual-lead conical worm; 9. designing the threaded part of the quasi dual-lead conical worm; 10. designing the radial parameter of the quasi dual-lead conical worm; 11. designing the tooth thickness of the quasi dual-lead conical worm; 12. designing the installation offset distance of the quasi dual-lead conical worm; 13. designing the installation height of the quasi dual-lead conical worm; 14. designing the geometrical parameters of the worm gear; 15. analyzing errors; and 16. carrying out accurate design.

Owner:JILIN UNIV

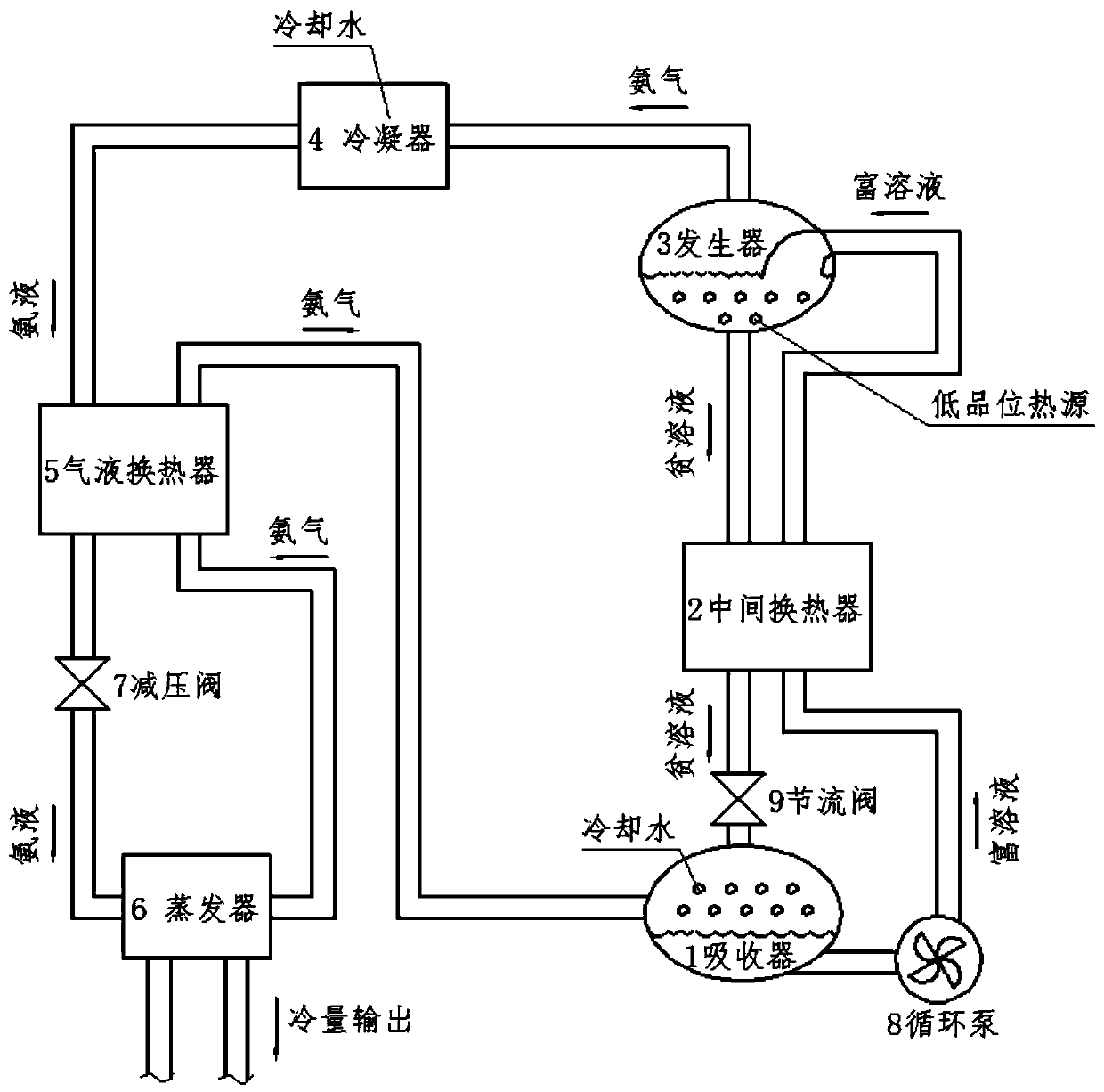

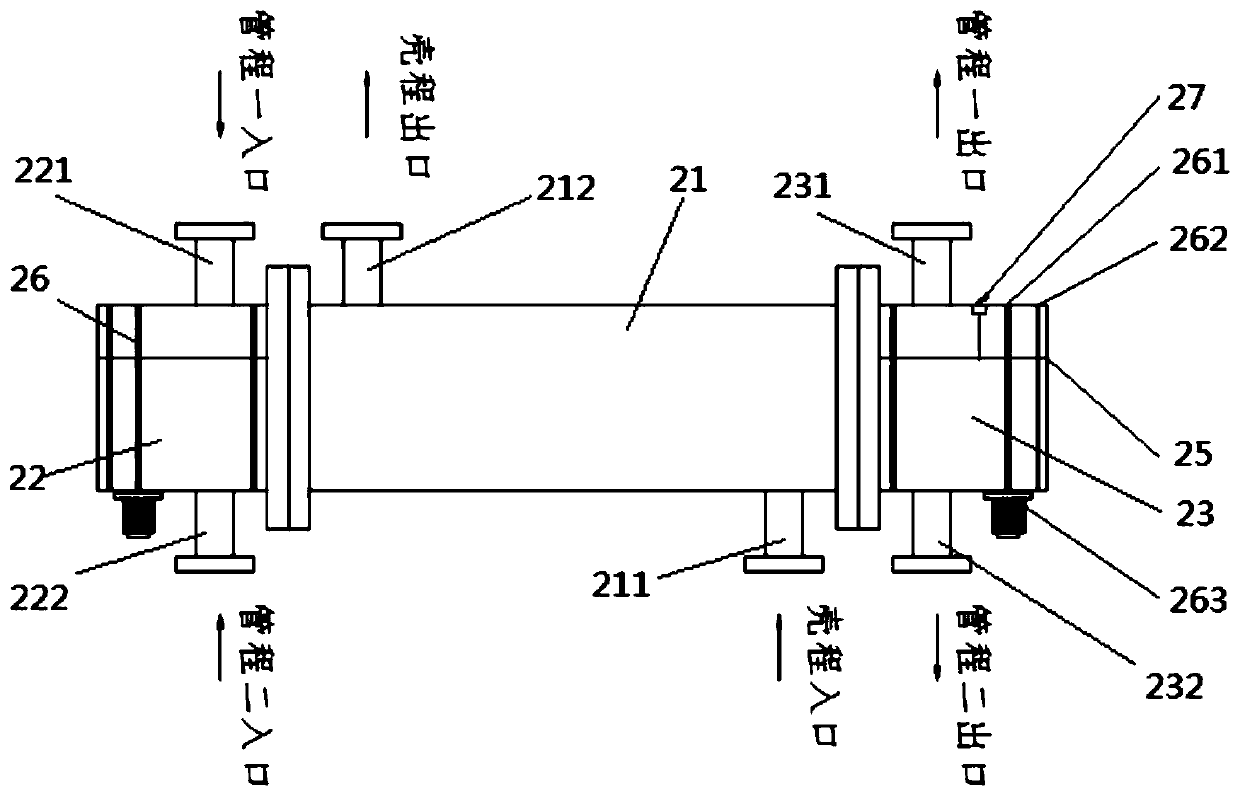

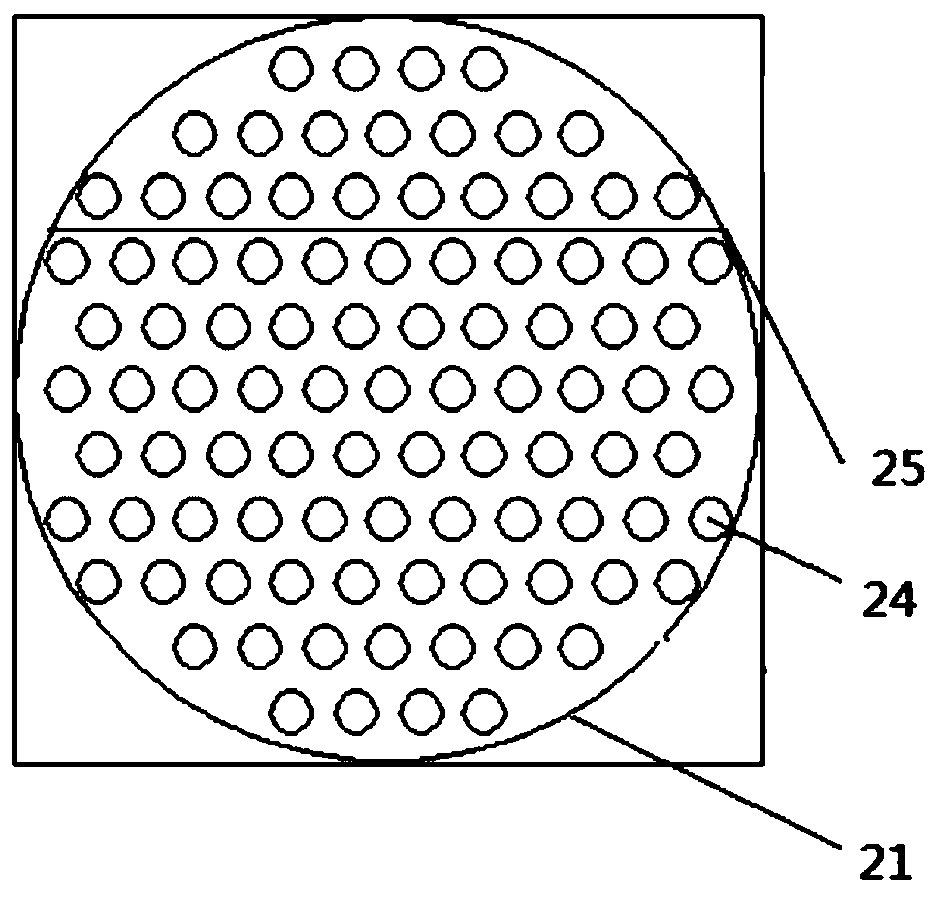

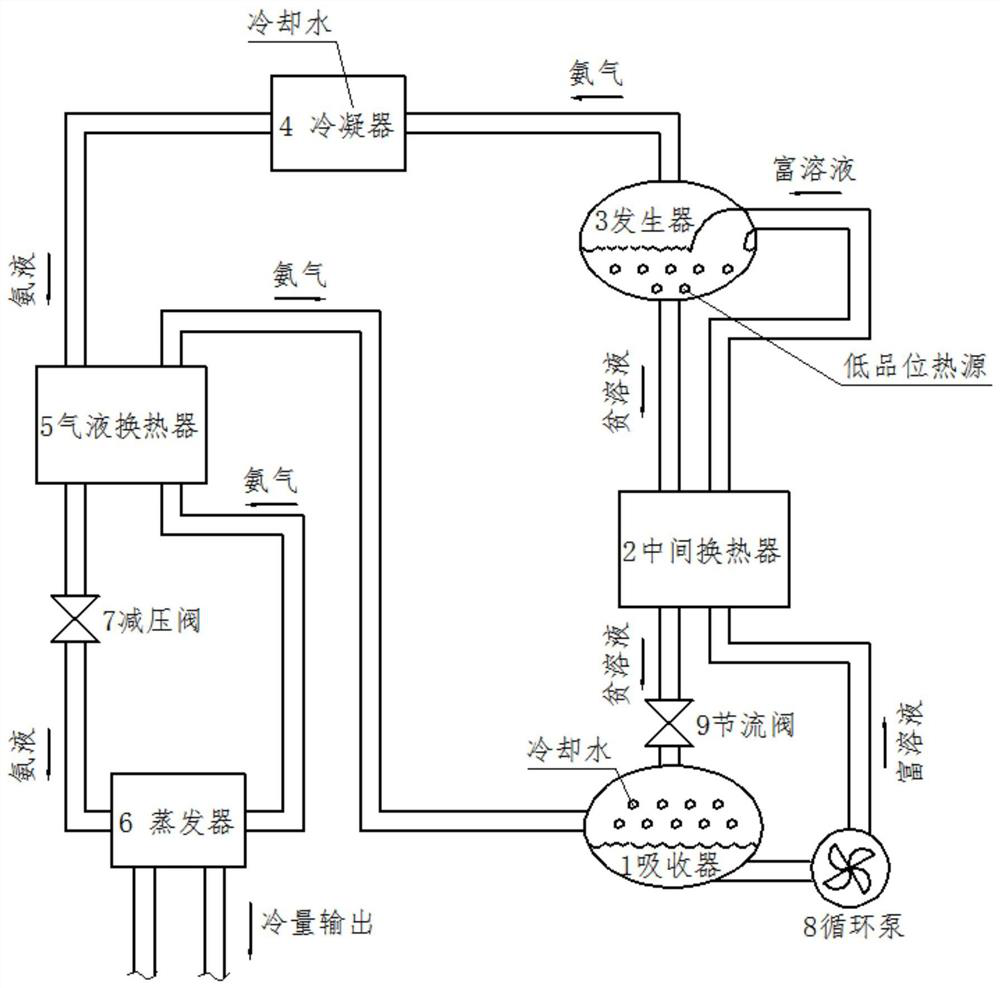

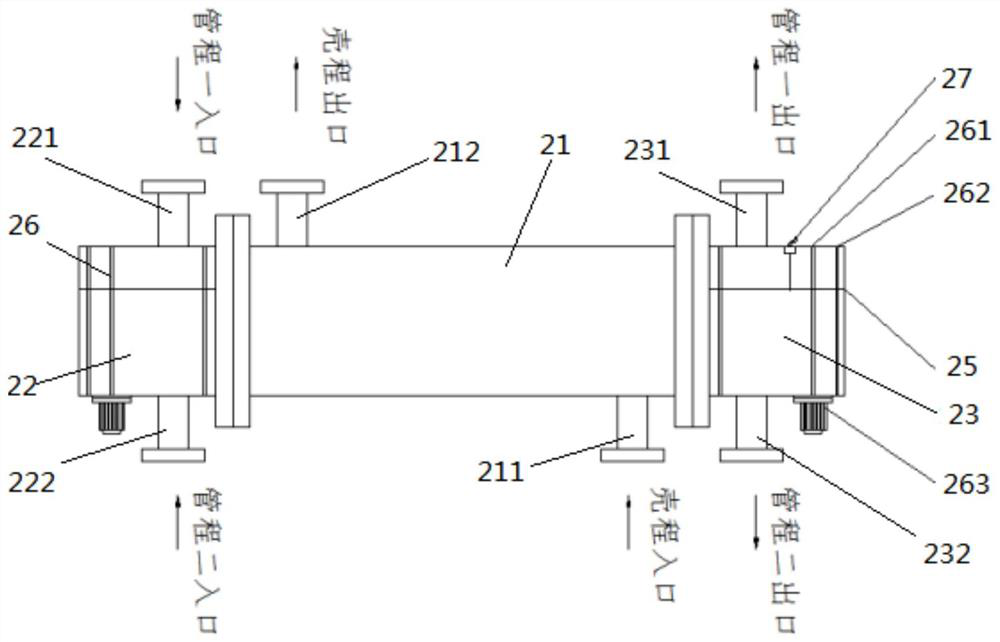

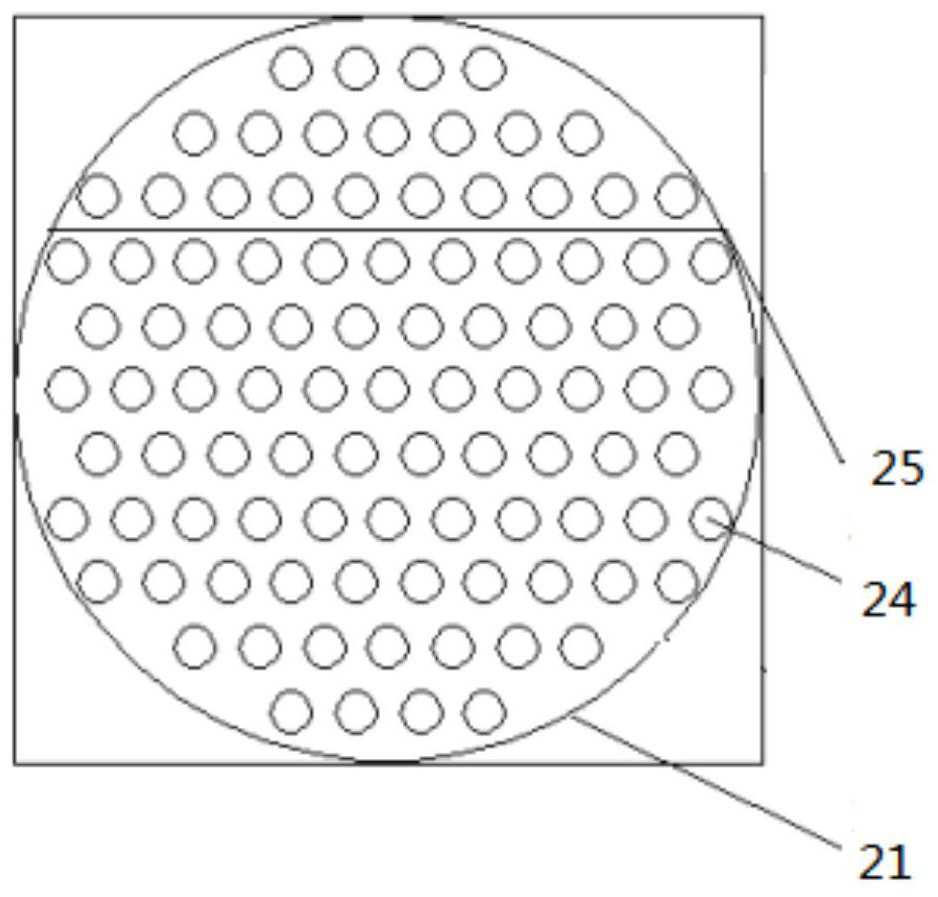

Three-phase heat exchanger and absorption type refrigeration system comprising same

ActiveCN110567297AReduce demandImprove heat utilizationClimate change adaptationEnergy efficient heating/coolingEngineeringThree-phase

The invention relates to a three-phase heat exchanger and an absorption refrigeration system comprising the same, and belongs to the technical field of refrigeration systems. The three-phase heat exchanger comprises a shell pass barrel body and two tube pass barrel bodies, wherein the two tube pass barrel bodies communicate with each other through heat exchange tubes; a shell pass inlet and a shell pass outlet are formed in the shell pass barrel body; two tube pass inlets are formed in one tube pass barrel body and two tube pass outlets are formed in the other tube pass barrel body; and a tubepass partition plate is arranged between the tube pass inlets of one tube pass barrel body, the other tube pass partition plate is arranged between the tube pass outlets of the other tube pass barrelbody, and each heat exchange tube is divided into two tube pass channels which are independent from each other through the tube pass partition plates. Compared with an existing absorption type refrigeration system utilizing two common heat exchangers, the three-phase heat exchanger and the absorption type refrigeration system comprising the same are more compact in structure, and the occupied area and space are saved; and a column tube type heat exchanger is adopted and the manufacturing is simple. The distribution ratio between the two tube passes is realized through the different positionsof the tube pass partition plates, the design and calculation are simple, and thus the heat exchange efficiency is higher. Through the design of the inlets and outlets, the heat exchange process is fully countercurrent, and thus the heat exchange efficiency is higher.

Owner:ANHUI WATERPOWER ENERGY SAVING TECH

Automobile-mounted automatic powder extinguishing device

The invention relates to an automobile-mounted automatic powder extinguishing device, and belongs to the technical field of fire-fighting extinguishing devices. The invention relates to an automatic extinguishing system integrating fire detection with extinguishing. Rapid, accurate and effective detection for a fire source can be realized by pressure-charged fire detection pipe and container bottle group by virtue of the own pressure storage, the automatic extinguishing system has the advantages of being simple to design and calculate, simple and convenient to construct and install, rapid andeffective in extinguishing, purely mechanical in automatic control and start-up, and is an automatic extinguishing system which is low-carbon, environment-friendly, simple, low in cost, highly reliable and independent. According to the automobile-mounted automatic powder extinguishing device disclosed by the invention, container bottles are arranged outside an engine cabin, so that influence on the sealing performance of the container bottles when the temperature of the engine cabin part liable to cause fire, on an automobile, is high during the running of the automobile, is reduced; and moreover, the fire detection pipe is arranged in the form of S-shape, free from dead angles in fire prevention, capable of stretching into the engine cabin with a complex structure and really realizing nodead angles in safety protection, applicable to various occasions, and capable of realizing no blank in protection.

Owner:丁玉琴

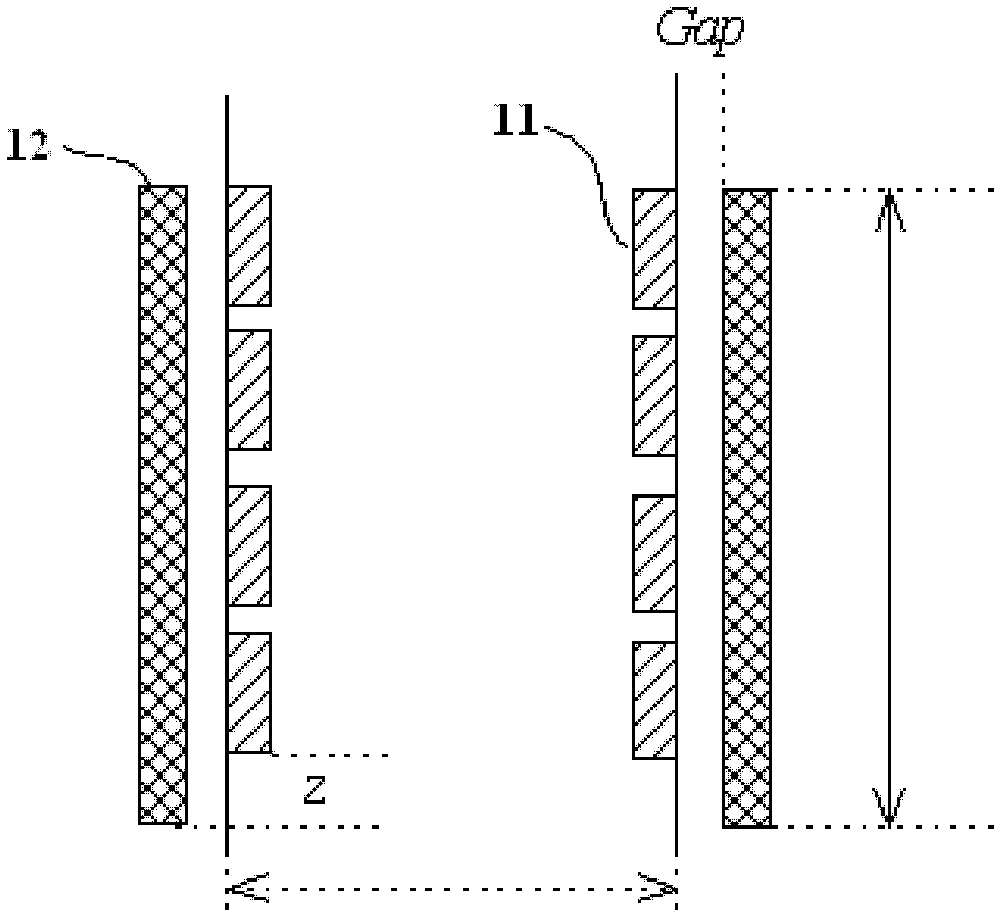

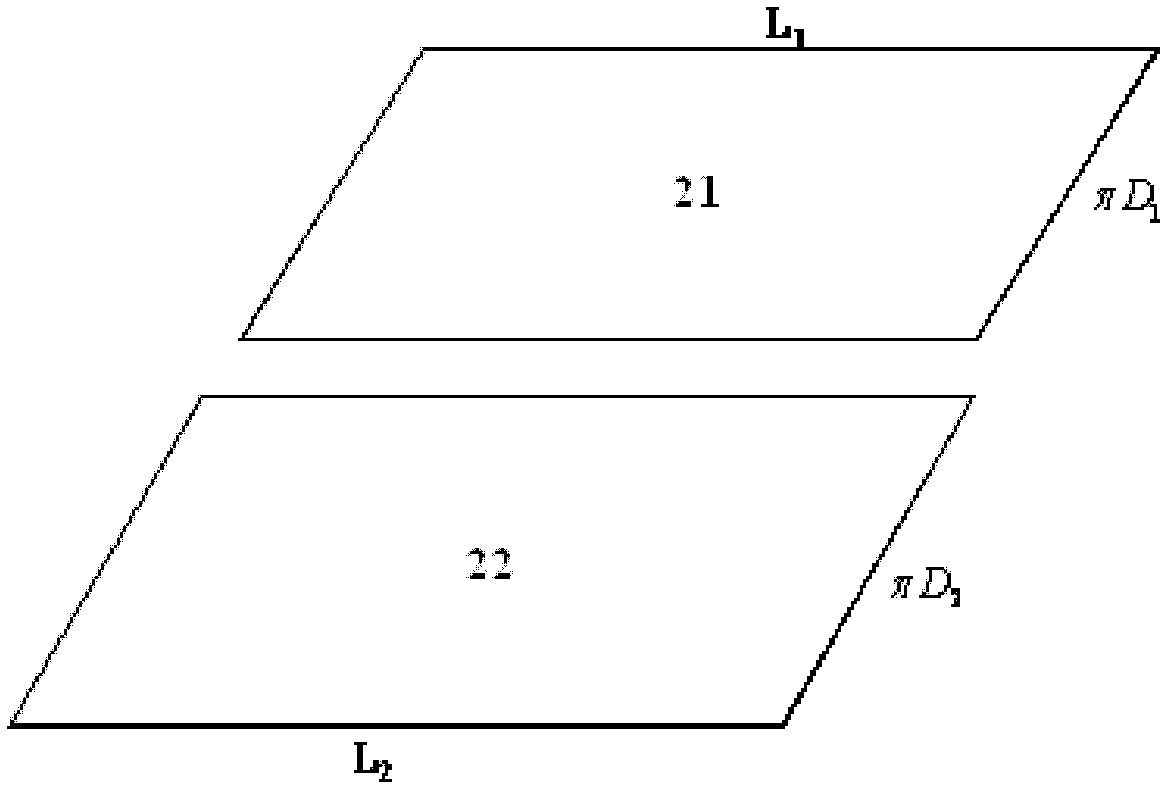

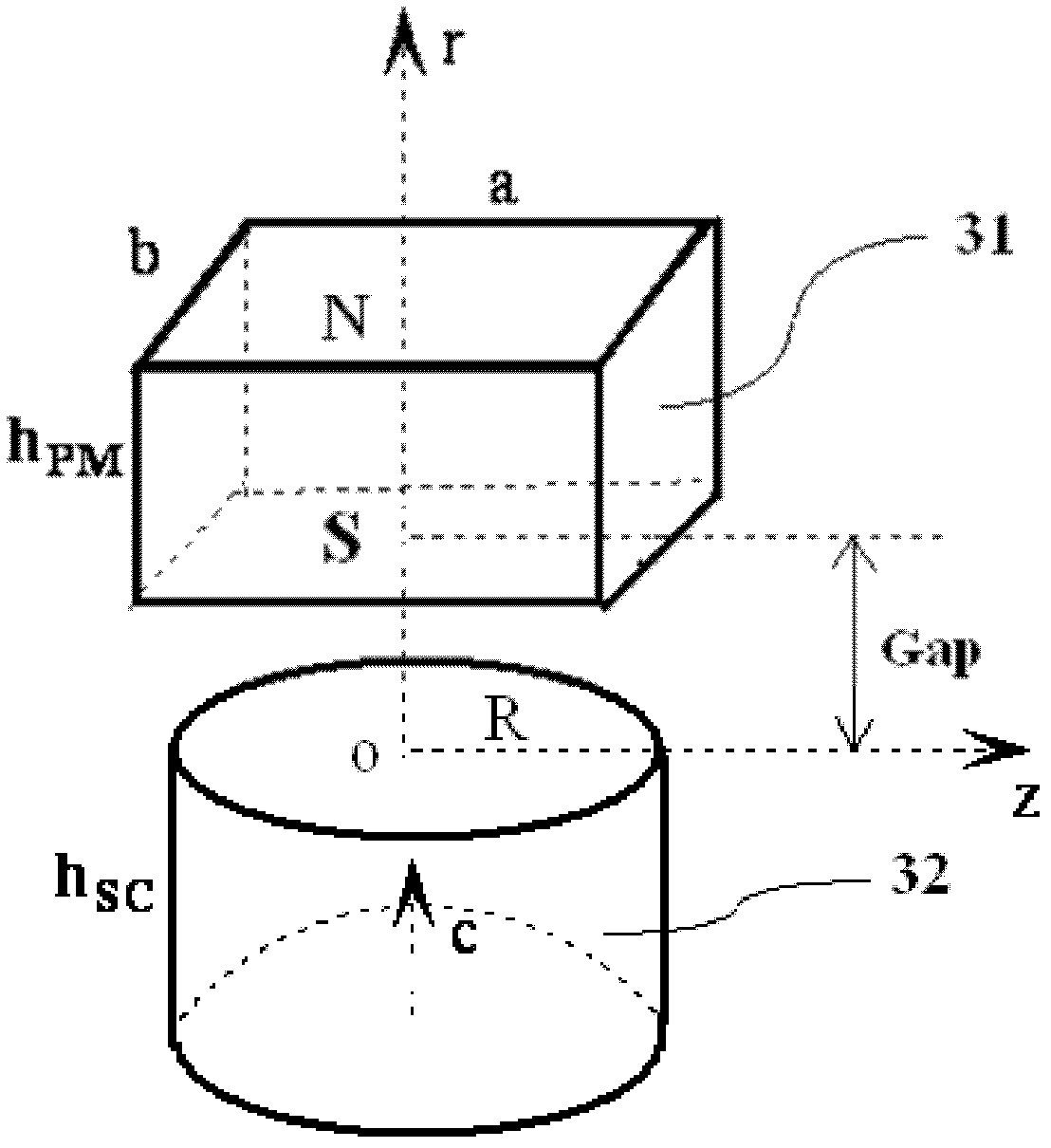

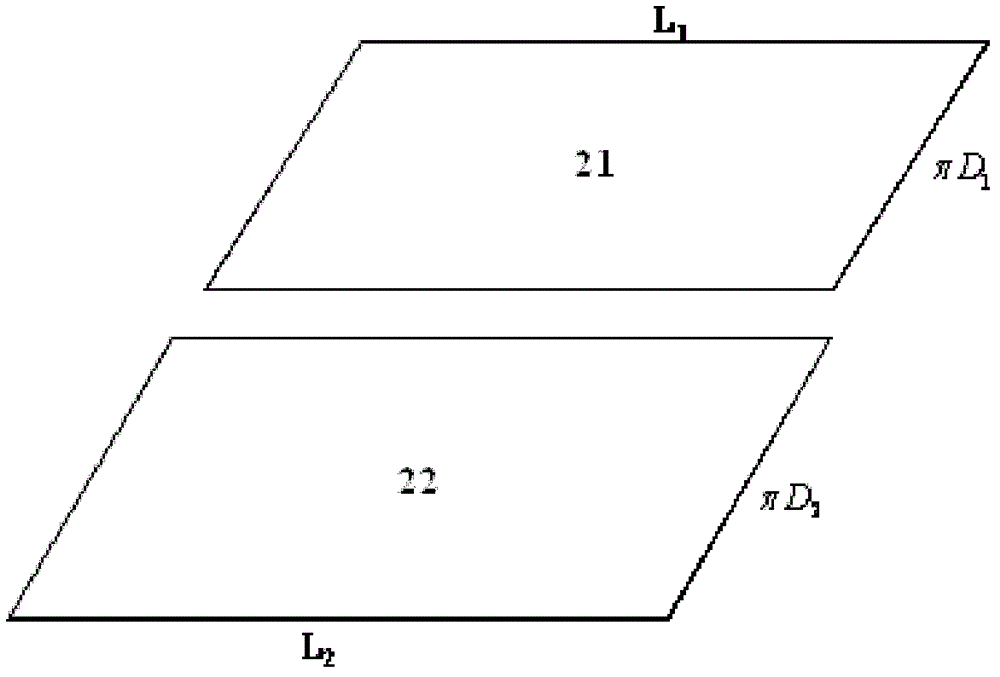

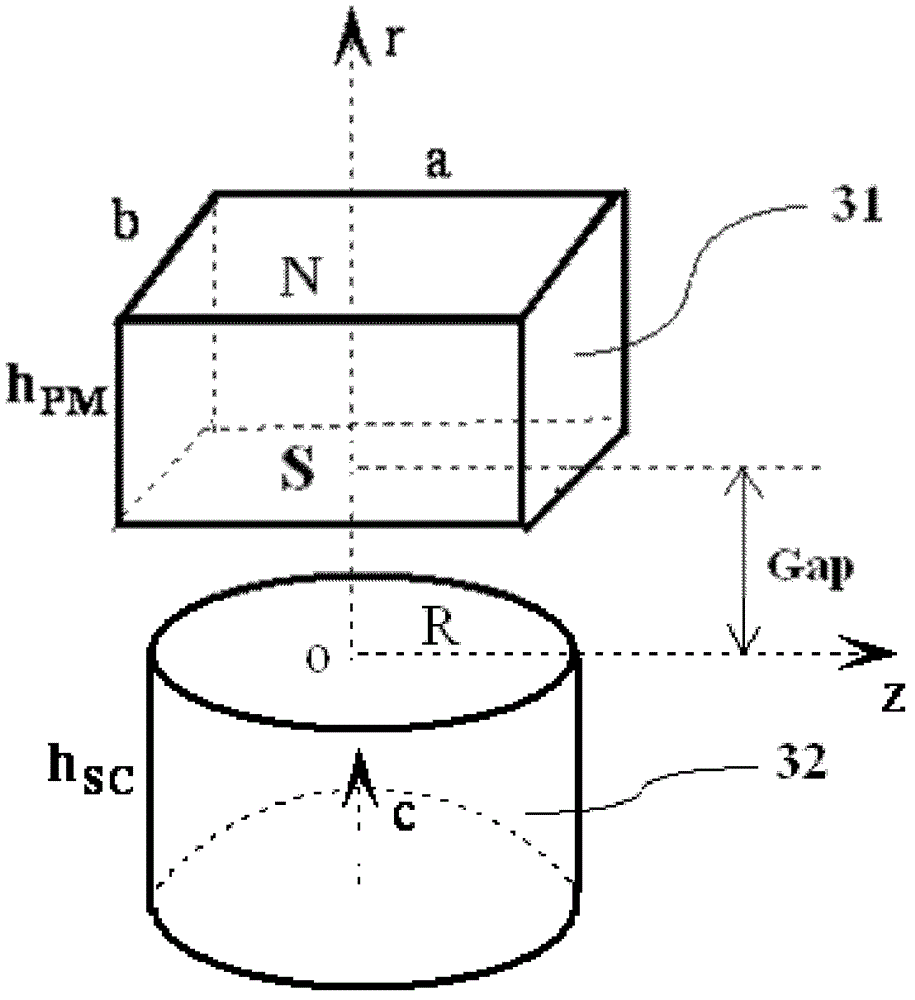

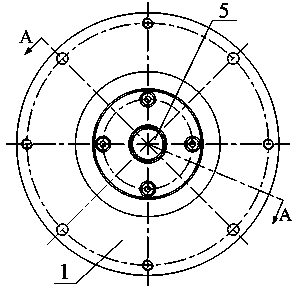

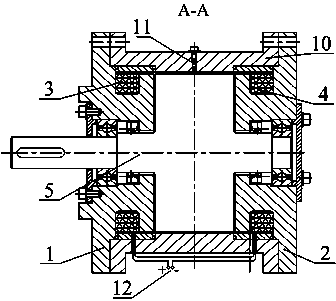

Simplified calculation method of radial high-temperature superconducting magnetic-suspension bearing

ActiveCN103185072ADesign calculation is simpleEasy to operateBearingsPermanent magnet rotorElectrical conductor

The invention relates to a simplified calculation method of a radial high-temperature superconducting magnetic-suspension bearing. The method comprises the steps that: A, permanent magnet rotor and a high-temperature superconductor stator of the radial high-temperature superconducting magnetic-suspension bearing are considered as two concentric cylinders, wherein a gap between the two cylinders is a suspension air gap of the bearing; B, the permanent magnet rotor cylinder is expanded into a rotor rectangle, and the high-temperature superconductor stator is expanded into a stator rectangle; C, with a reference of the sizes of the rectangles, permanent magnets and high-temperature superconductors are subjected to optimized arrangement, such that permanent magnet number and single-block size are obtained, and high-temperature superconductor number and single-block size are obtained; D, a suspension system composed of single permanent magnet and single high-temperature superconductor is subjected to calculation simulation, such that suspension force and internal force are obtained; and E, suspension force and internal force between single permanent magnet and single high-temperature superconductor are respectively multiplied by the block numbers, such that the axial suspension force of the entire bearing rotor is obtained.

Owner:GRIMAT ENG INST CO LTD

Curved bridge fitting laying structure based on orthogonal prefabricated beam plate and laying method thereof

PendingCN108265632AGuarantee the construction qualityDesign calculation is simpleBridge erection/assemblyEngineeringCantilever

Provided is a curved bridge fitting laying structure based on orthogonal prefabricated beam plates and a laying method thereof. The fitting laying structure includes an upper portion beam plate system, a beam plate protection structure and a lower portion support structure. The upper portion beam plate system comprises a plurality of spans of the beam plates arranged in the curve chord tangent direction of the curve, and each of the beam plates is the same in size, and each of the beam plates comprises the orthogonal prefabricated beam plates arranged side by side. Plate seams of every span formed by each of the orthogonal prefabricated beam plate are trapezoidal staggered, and the plate seams are filled with wedge-shaped wood strips. The laying method includes the determination of a benchmark span, the laying of pier capping beams, cushion rock and support seats, the laying of middle beams and cantilever side beams, and the laying of the filling of the plate seams and shielding structures of the plate beams. The curved bridge fitting laying structure based on the orthogonal prefabricated beam plates and the laying method thereof are applicable to a curved bridge with assembly typeconstruction on an upper portion of the curved bridge, and prefabricated beam plates of each span of the curved bridge are the same in size, the plate seams between each span are regularly staggered,the laying method is reasonable and ingenious, and the calculation of the design of the beam plates is simplified, the construction quality of the prefabricated beams is ensured, and the assembly construction can shorten the construction period of the curved beam bridge.

Owner:LUOYANG INST OF SCI & TECH

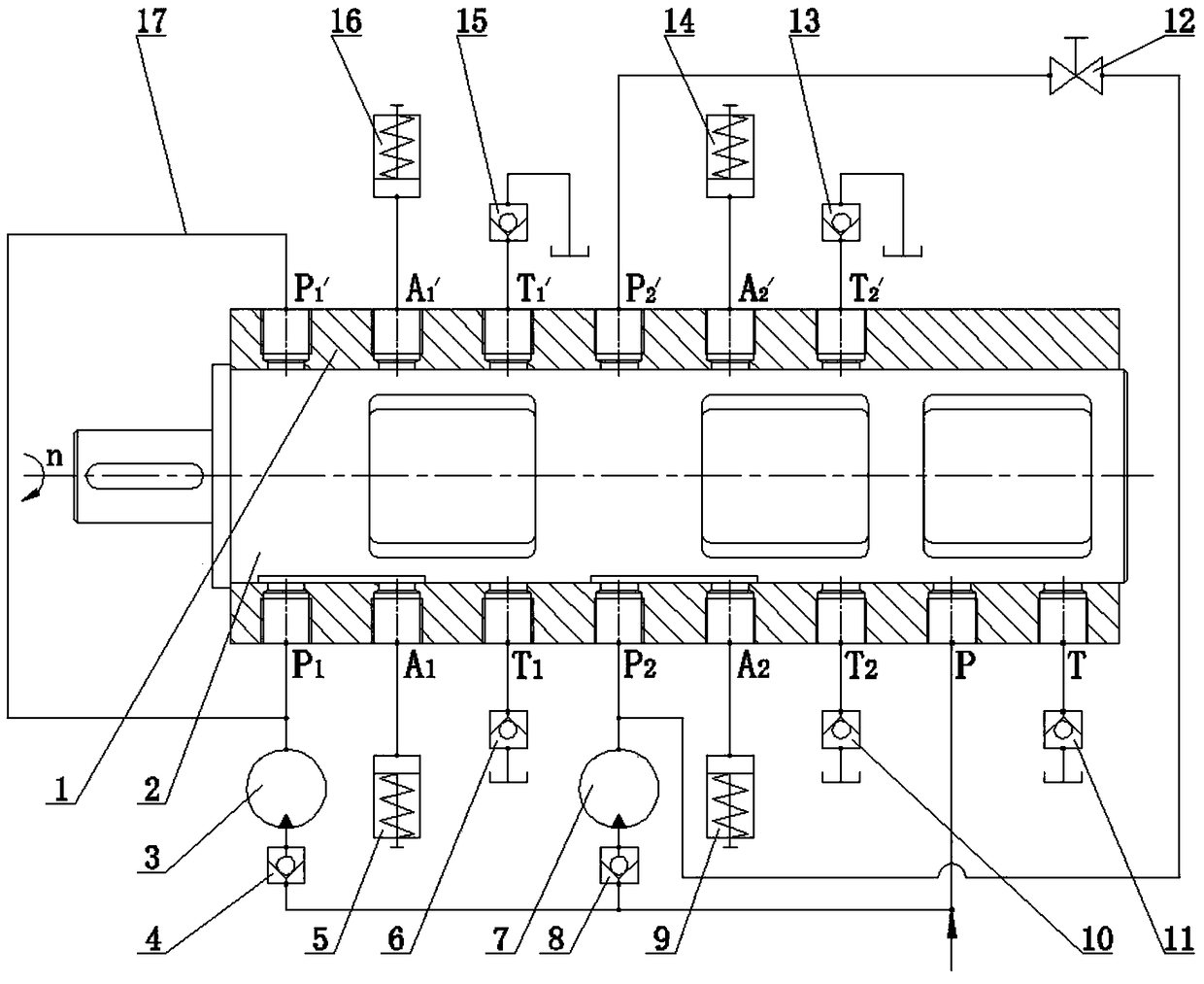

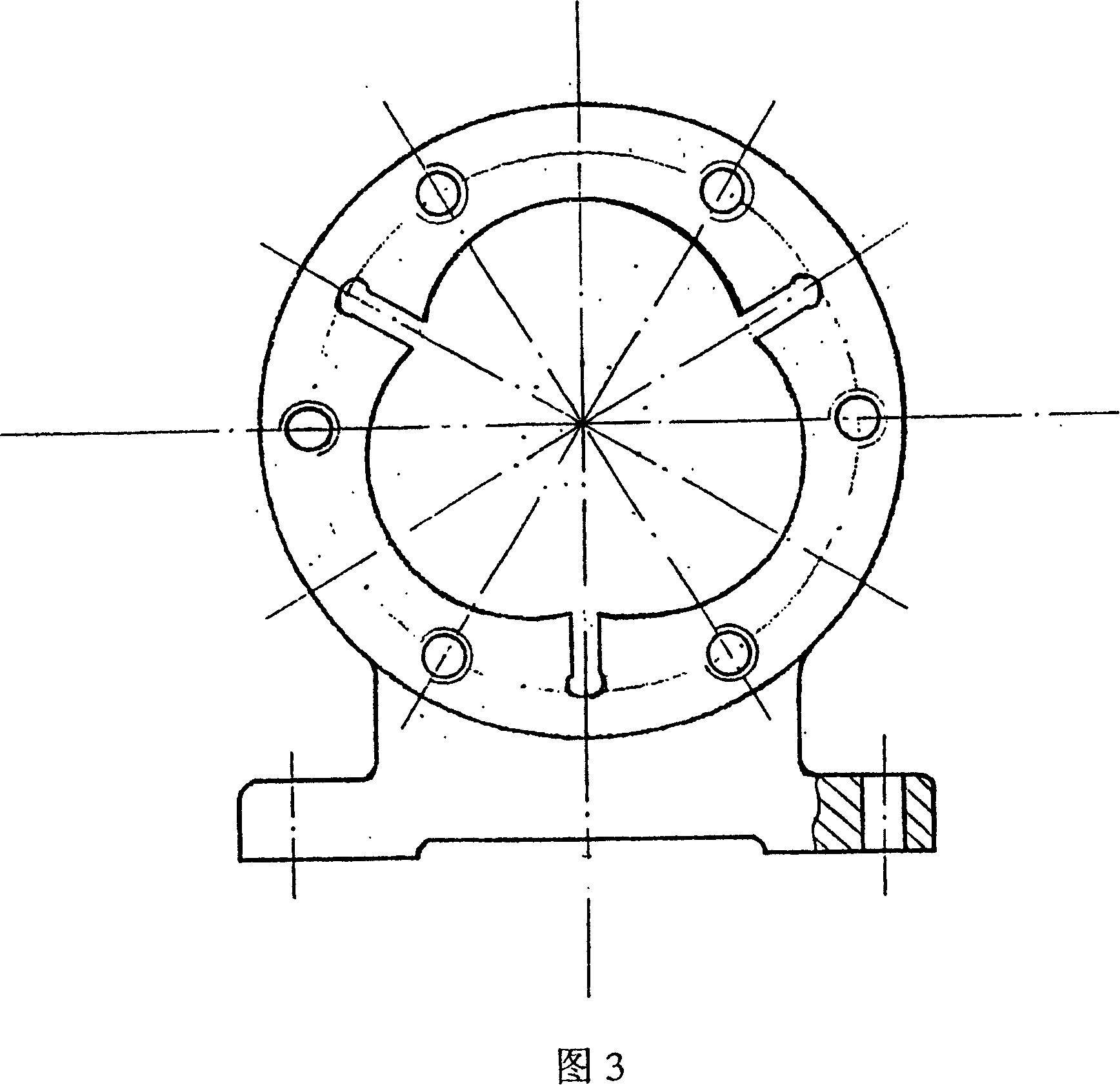

A reversing rotary valve for controlling hydraulic double-return and double-feeding of cold-rolled pipe mill

InactiveCN104806597BReduce in quantitySimple transmission structureServomotor componentsServomotorsPipe fittingRotary valve

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Treatment method and cast structure for contact position of retaining wall with workshop column foundation

InactiveCN102561386ASimple forceReduce dosageArtificial islandsUnderwater structuresContact positionRetaining wall

The invention discloses a treatment method and a cast structure for a contact position of a retaining wall with a workshop column foundation. When the retaining wall is cast inside a workshop and the retaining wall contacts with the workshop column foundation, a retaining wall foundation of the cast retaining wall is removed within the range of the workshop column foundation, and retaining wall foundations cast on two outer sides of the workshop column foundation are 80-120mm away from the workshop column foundation. Retaining wall columns are cast at the edges of the retaining wall foundations close to the two sides of the workshop column foundation, a retaining plate is disposed on the workshop column foundation, two sides of the retaining plate are firmly inset into the retaining wall columns on two sides, and accordingly the retaining wall and the workshop column foundation can be designed and constructed as two individuals of different structural forms. The treatment method and the cast structure have the advantages that stress reasonability and construction simplicity of the retaining wall and a workshop column can be guaranteed, raw materials can also be saved, and the cast structure is simple, easy in design calculation, low in manufacturing cost and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

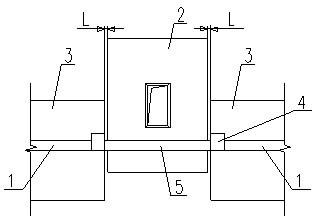

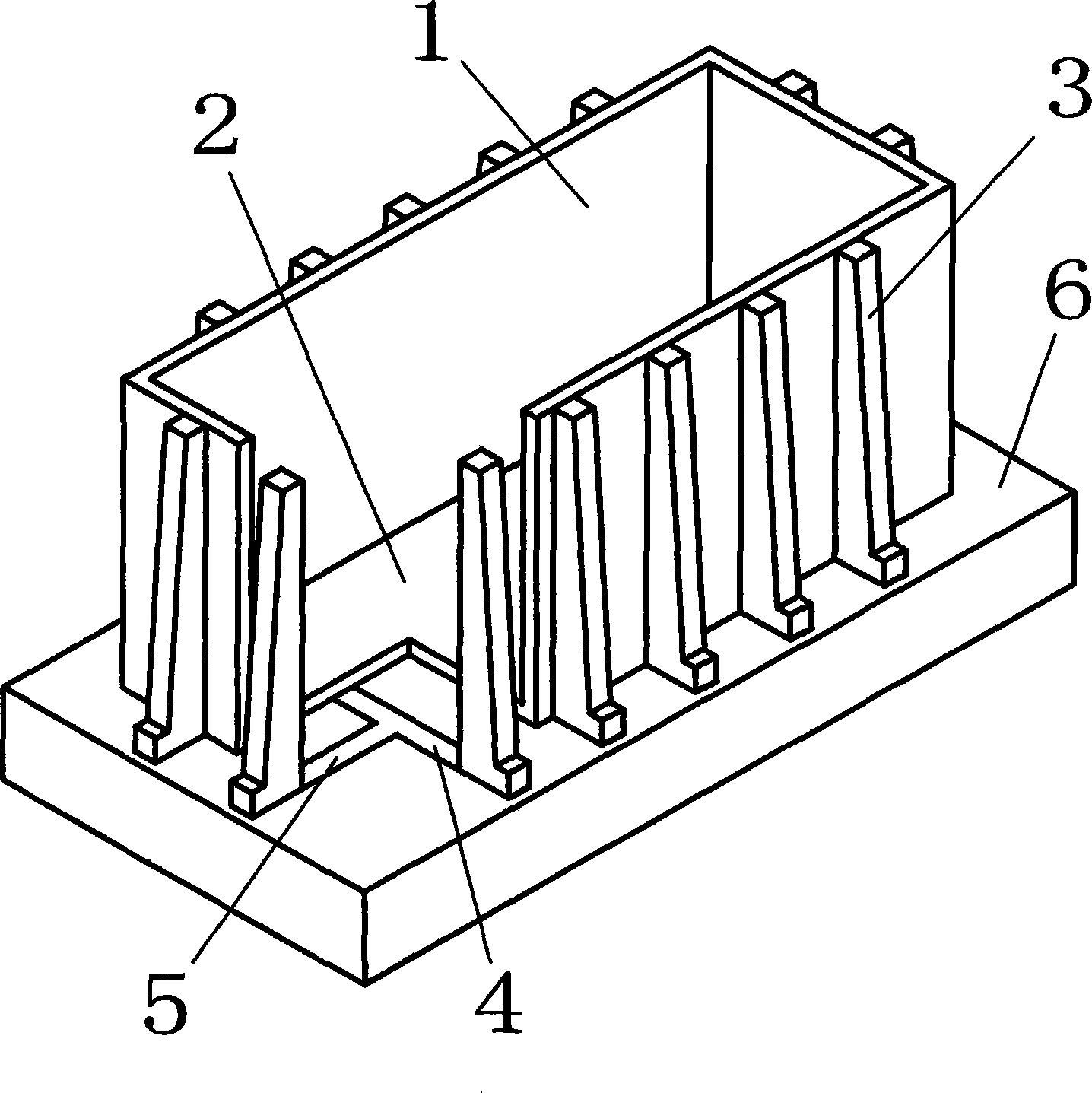

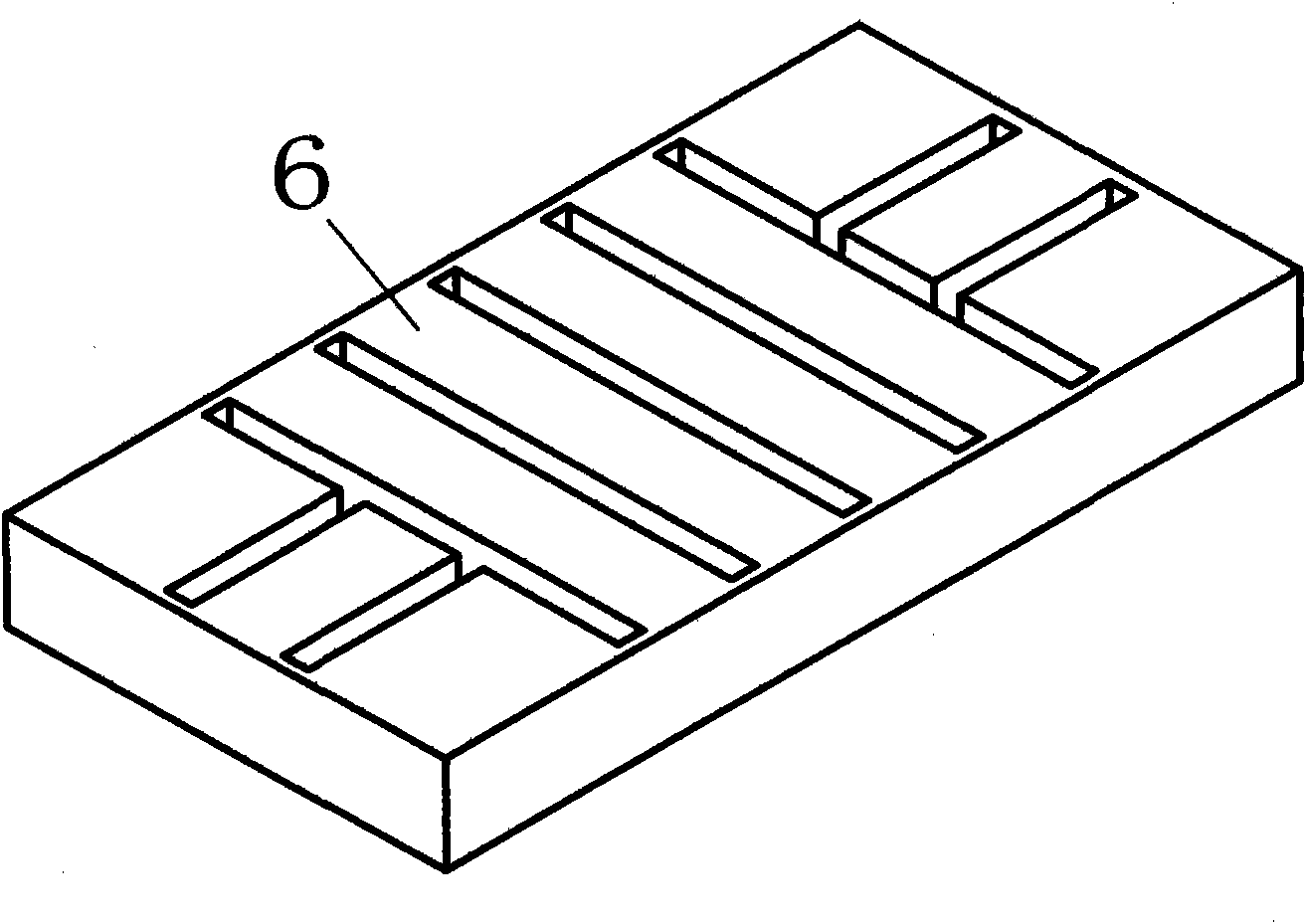

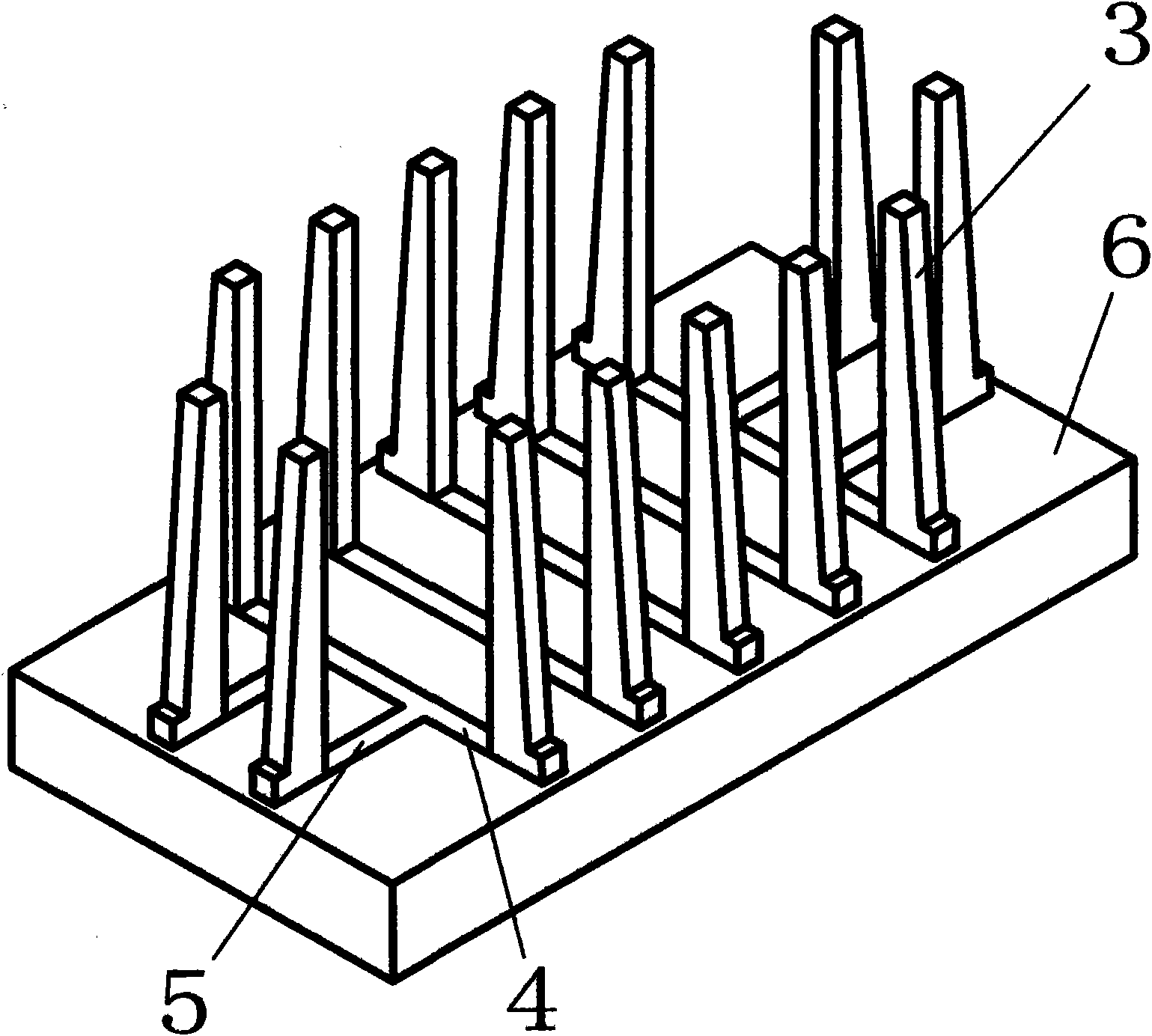

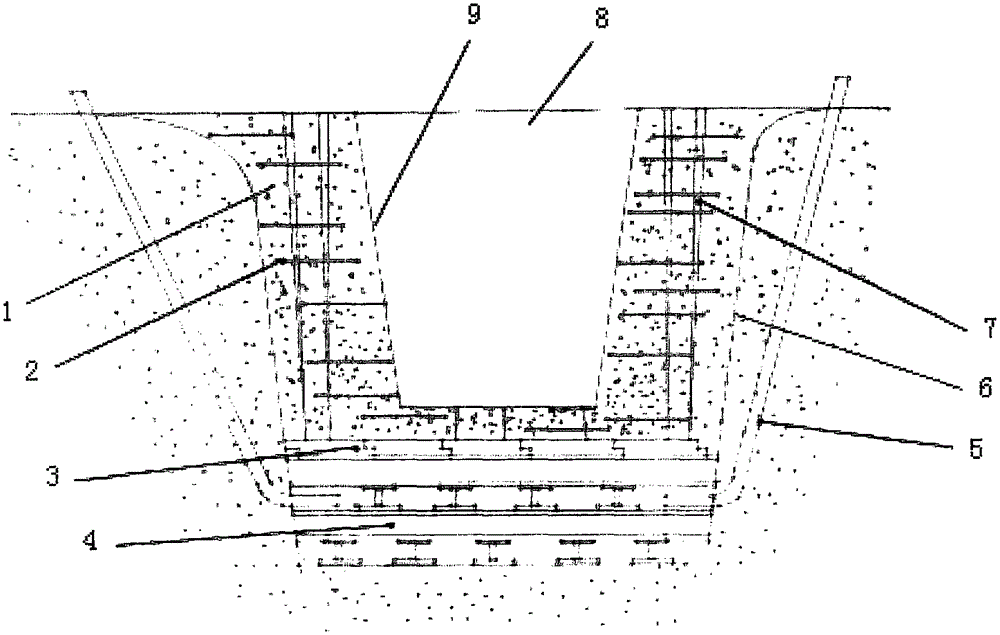

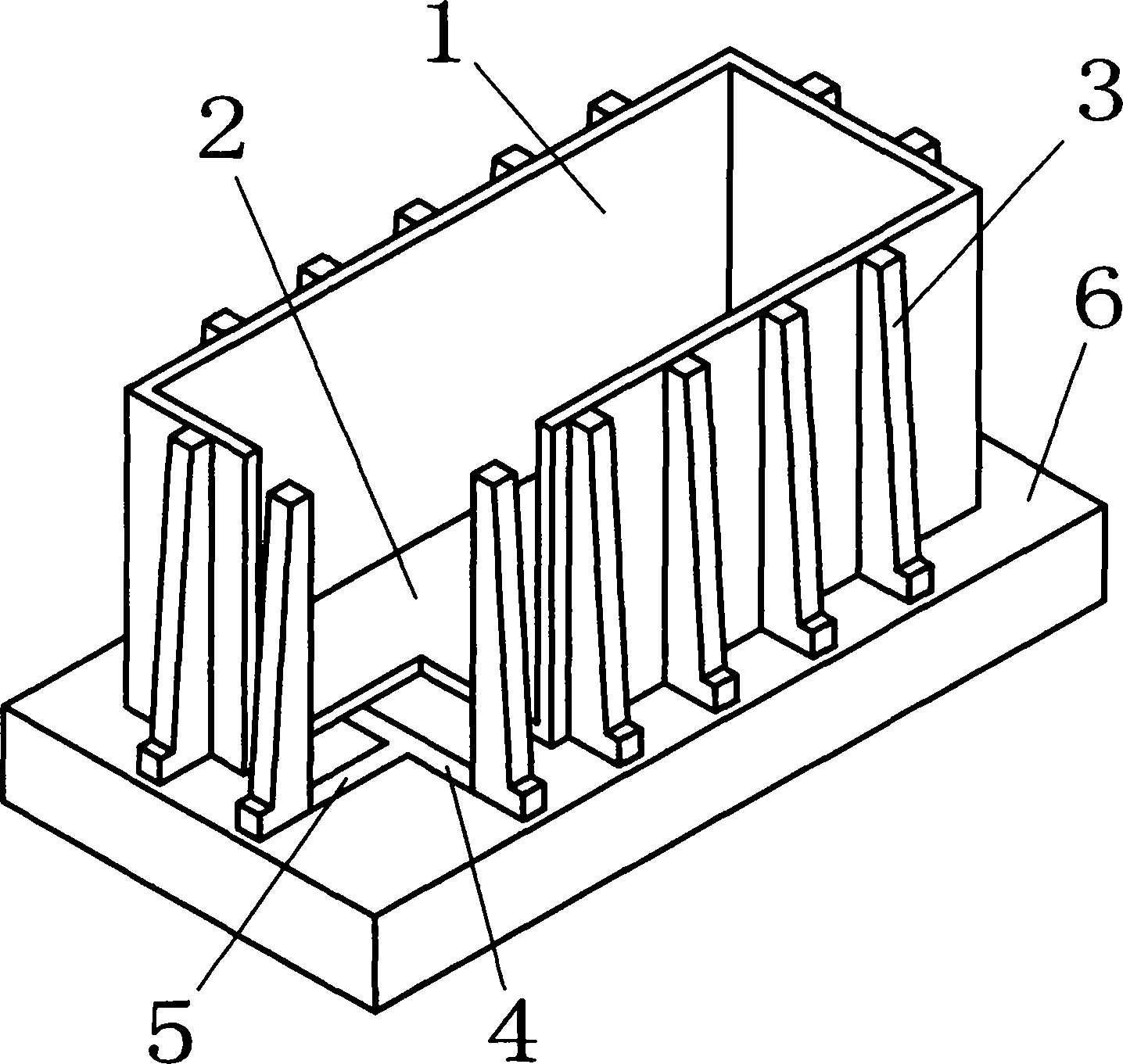

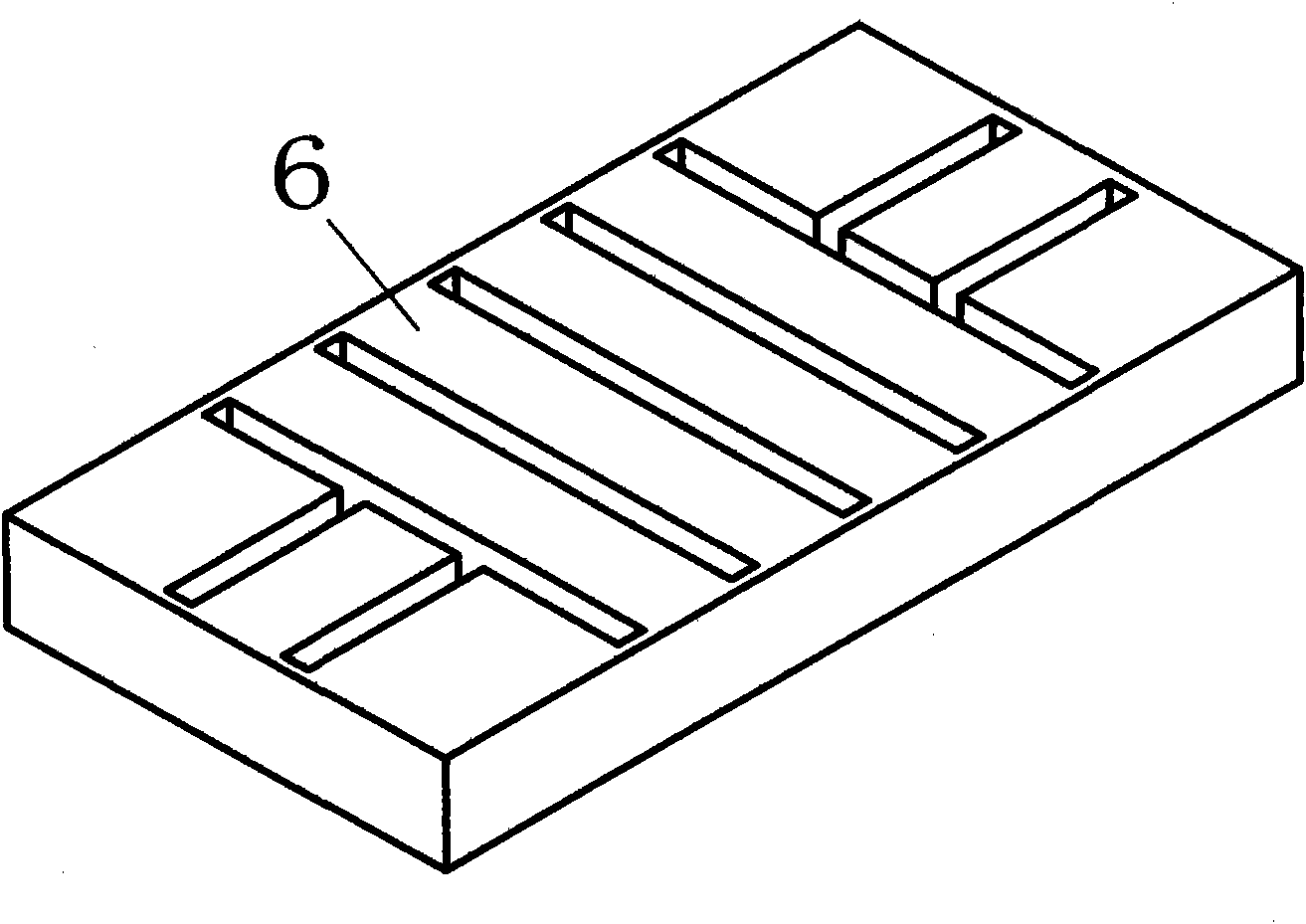

Method for constructing deep pit, and pit structure

InactiveCN102094427BLess materialHigh resistance to lateral earth pressureExcavationsButtressEngineering

The invention discloses a method for constructing a deep pit, and a pit structure. The method comprises the following steps of: arranging a bottom beam at the bottom of the pit, and casting wall-supporting columns which are integrally connected with the bottom beam at the two ends of the bottom beam; and casting a bottom plate and wall plates on the upper part of the bottom beam and the inner sides of the wall-supporting columns. The structure comprises a cushion layer (6) which is provided with the bottom beam, wherein the bottom beam is symmetrically provided with the wall-supporting columns (3); and the bottom plate (2) is arranged above the bottom beam, and the wall plates (1) are arranged on the inner sides of the wall-supporting columns (3). The bottom plate and the wall plates are not required to be thick compared with those in the prior art, so materials can be saved; the wall-supporting columns and the two ends of the bottom beam are integrally cast at one time, so the base of the wall-supporting columns is not required to be large and can have sufficient extrusion resistance; and the invention has the characteristics that: the pit structure is easy to design and calculate, and convenient to construct, and has a short construction period and high lateral soil pressure resistance.

Owner:GUIYANG AL-MG DESIGN & RES INST

Simplified calculation method of radial high-temperature superconducting magnetic-suspension bearing

ActiveCN103185072BDesign calculation is simpleEasy to operateBearingsPermanent magnet rotorElectrical conductor

The invention relates to a simplified calculation method of a radial high-temperature superconducting magnetic-suspension bearing. The method comprises the steps that: A, permanent magnet rotor and a high-temperature superconductor stator of the radial high-temperature superconducting magnetic-suspension bearing are considered as two concentric cylinders, wherein a gap between the two cylinders is a suspension air gap of the bearing; B, the permanent magnet rotor cylinder is expanded into a rotor rectangle, and the high-temperature superconductor stator is expanded into a stator rectangle; C, with a reference of the sizes of the rectangles, permanent magnets and high-temperature superconductors are subjected to optimized arrangement, such that permanent magnet number and single-block size are obtained, and high-temperature superconductor number and single-block size are obtained; D, a suspension system composed of single permanent magnet and single high-temperature superconductor is subjected to calculation simulation, such that suspension force and internal force are obtained; and E, suspension force and internal force between single permanent magnet and single high-temperature superconductor are respectively multiplied by the block numbers, such that the axial suspension force of the entire bearing rotor is obtained.

Owner:GRIMAT ENG INST CO LTD

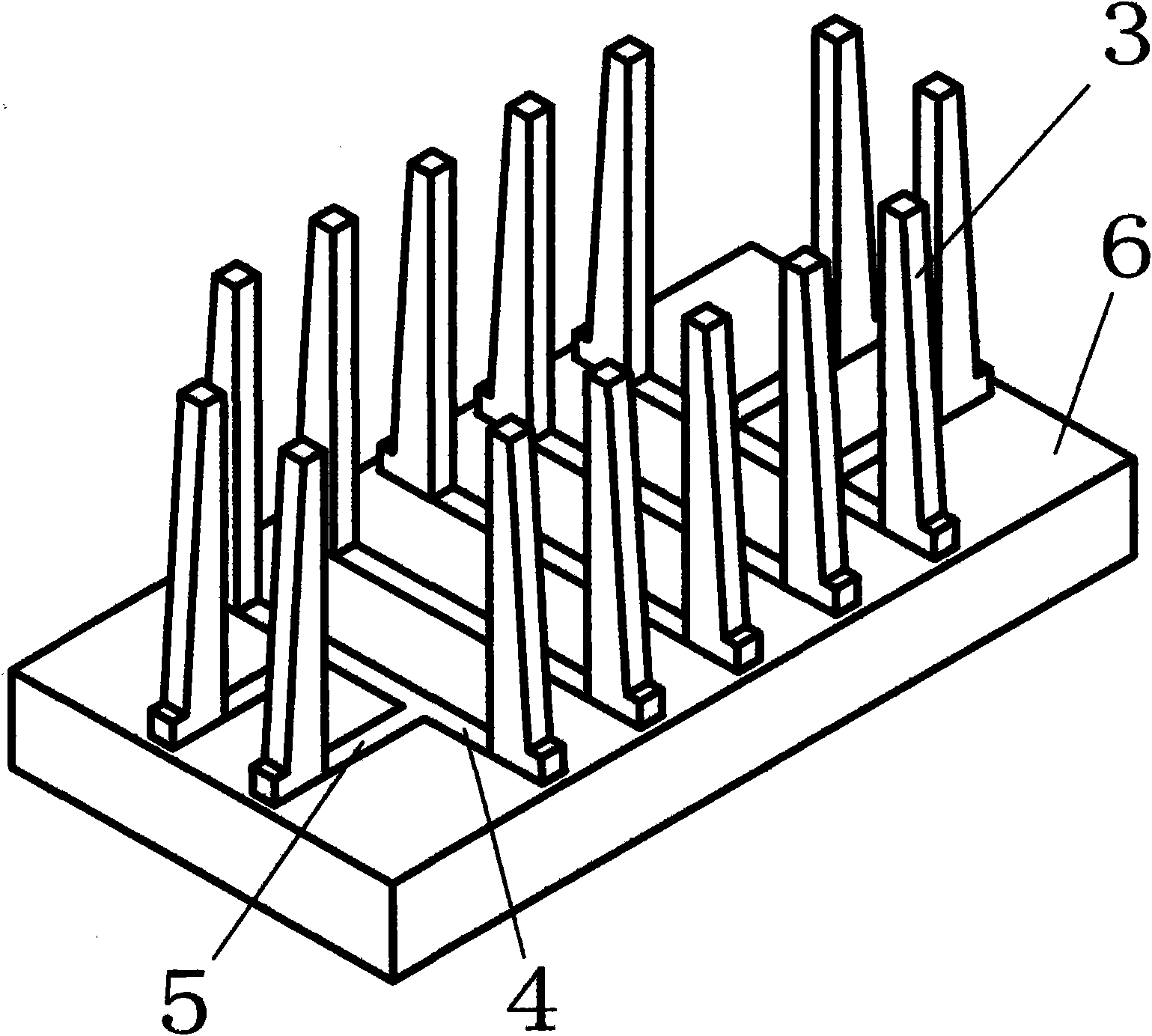

Workshop pit and construction method thereof

InactiveCN106759491AGood heat preservation and dehumidification effectUncrowded venueArtificial islandsProtective foundationInstabilityStructural engineering

The invention relates to a workshop pit and a construction method thereof. The workshop pit comprises a supporting layer composed of multiple layers of supporting rods, exhaust pipes arranged on the periphery of the supporting layer, an exhaust supporting plate arranged on the top of the supporting layer, exhaust passages connecting the exhaust supporting plate with the ground and a cast-cured layer. The outer wall of the cast-cured layer is provided with a facing sand layer. The construction method of the workshop pit comprises the steps of laying the supporting layer in the pit, arranging the exhaust pipes, laying the exhaust supporting plate, pouring castables and additionally the facing sand layer. Through the arrangement of the steel part supporting layer, the problem of gravel pouring instability can be effectively avoided. Meanwhile, the exhaust pipes are arranged on the periphery of the supporting layer, and the exhaust supporting plate and an air draft humidity exhaust fan are arranged on a supporting frame, and the exhaust effect of a whole hard sand bed can be effectively improved. According to the workshop pit, the layered poured cast-cured layer is laid on the exhaust supporting plate, and reinforcing rib plates are evenly distributed, so that the castables are kept clean and are free of contamination, and the pressure resistance of the cast-cured layer is also enhanced.

Owner:CHANGSHA XIANGRUI HEAVY IND

Double channel magnetic current damp variation device with recombination of mixing mode and flowing mode

InactiveCN100334368CTimely compensationSmall damping force valueNon-rotating vibration suppressionResilient suspensionsMagnetic currentSemi active

The composite mixed mode and flow mode double-channel magnetic rheologic damper includes work cylinder, piston type magnetic field generator, compensator and sealing unit. The piston type magnetic field generator has two flow channels, including the outer channel without magnetic field and operating in mixed mode and the inner channel inside magnetic field and operating in flow mode. The damper may operate in no outer exciting current state with relatively small damping and in large outer exciting current state with relatively great damping. This kind of double-channel structure makes the magnetic rheologic damper possess greatly lowered damping under the condition of no external magnetic field, has expanded dynamic regulation range and even suitable for the semi-active control of vehicle suspension.

Owner:CHONGQING UNIV

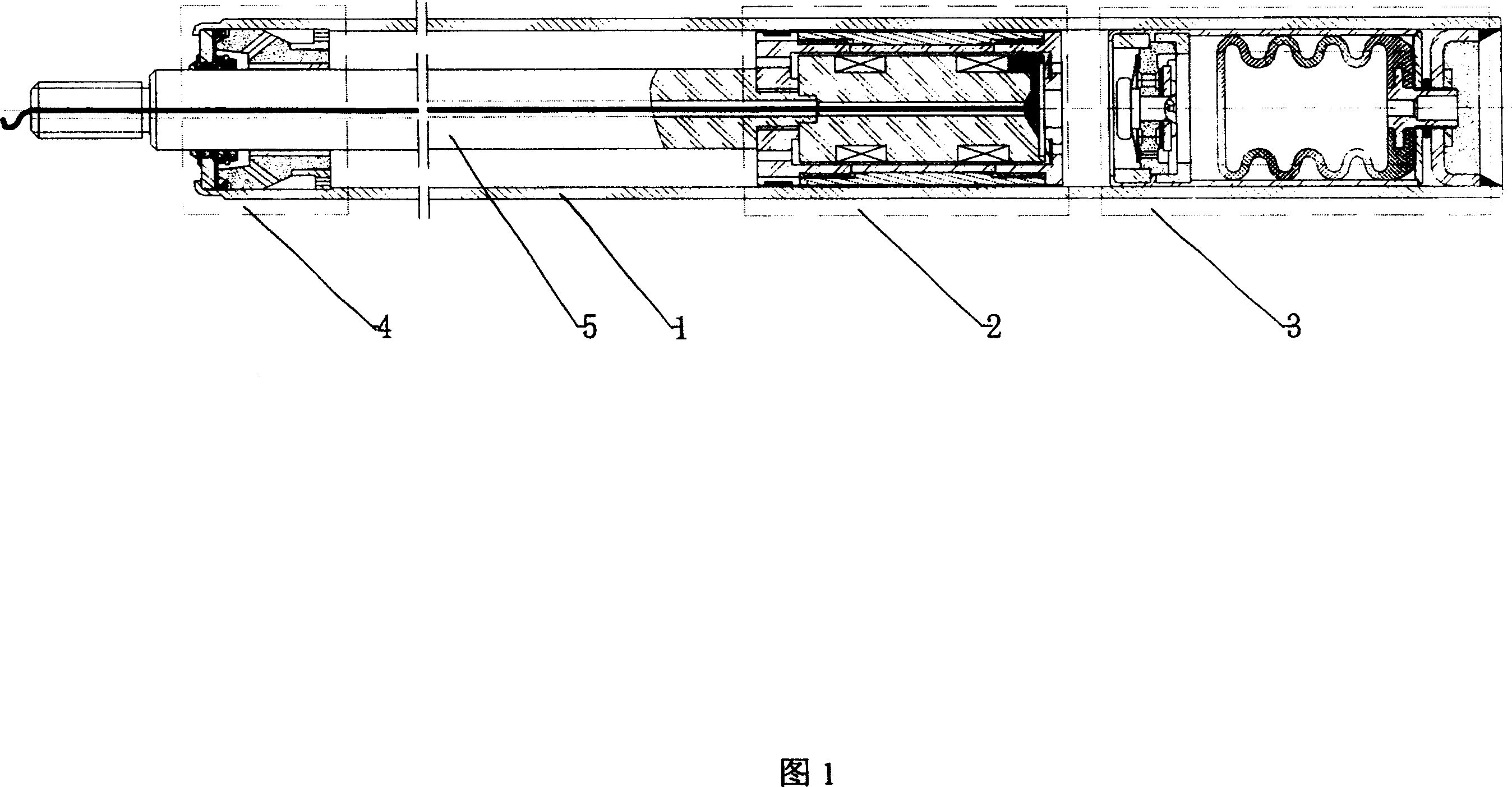

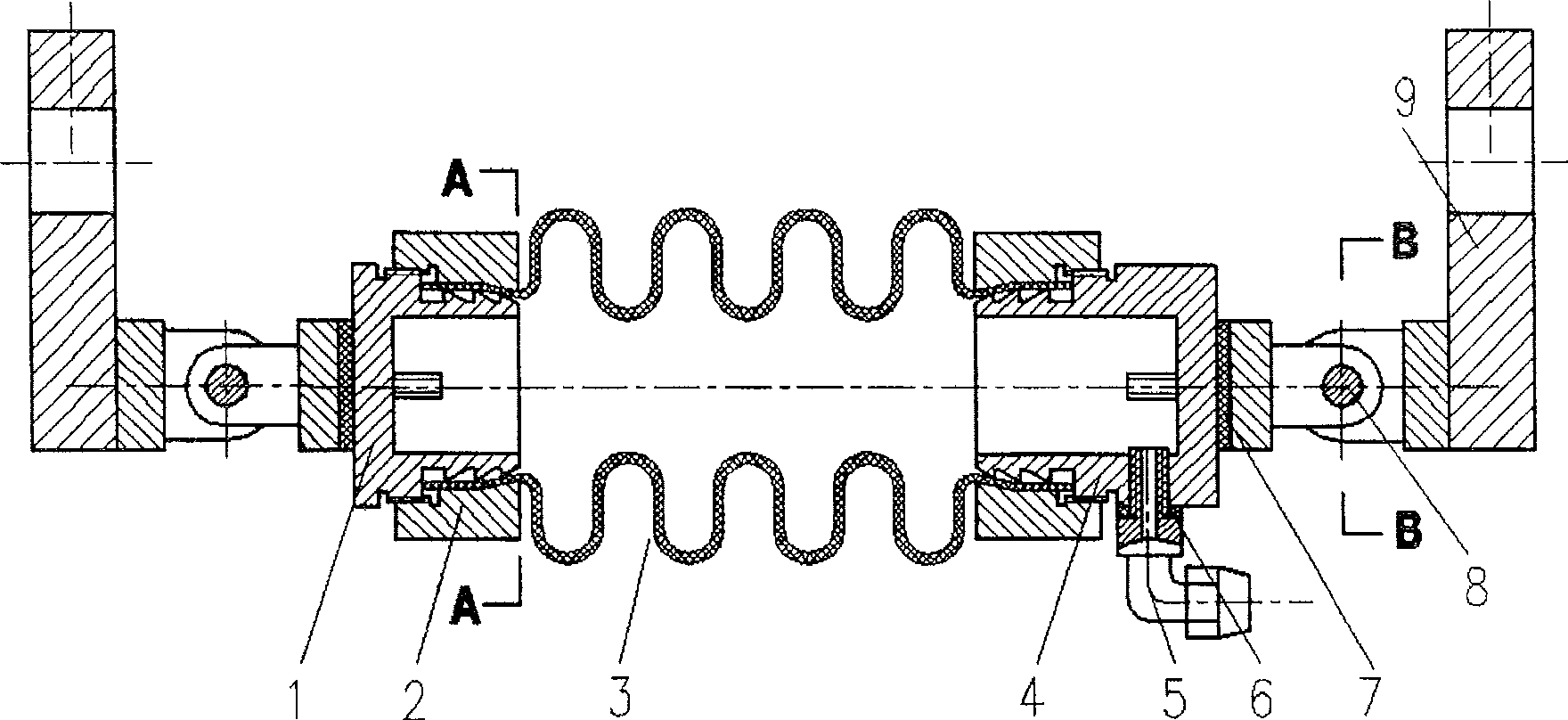

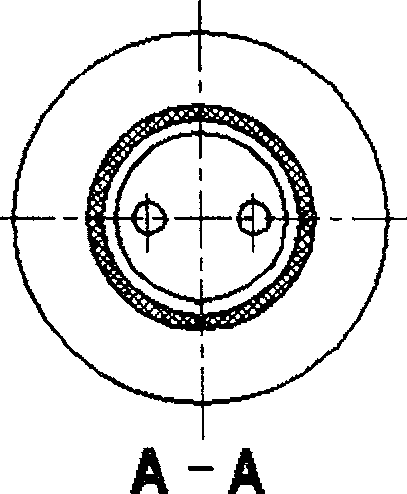

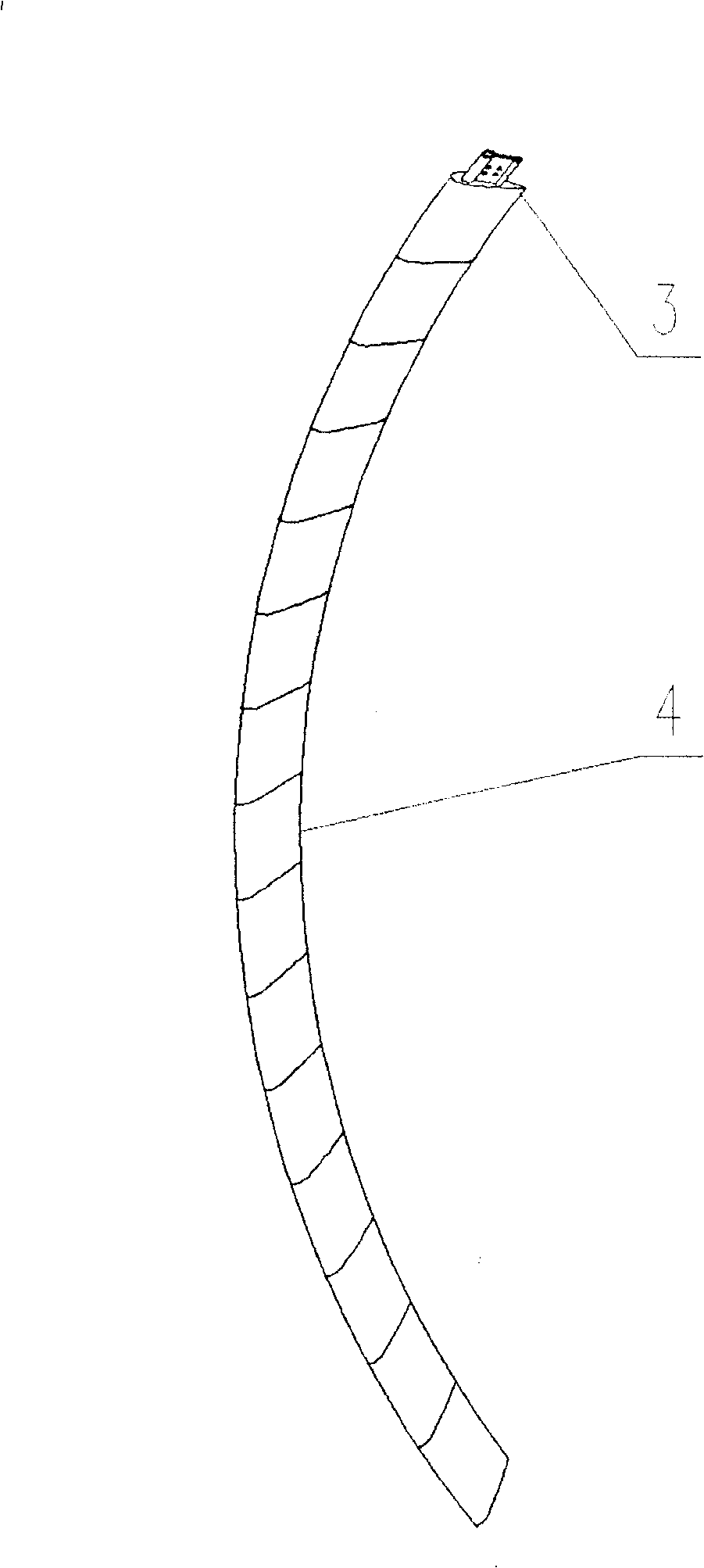

Bending joint driven by linear expansion artificial muscle

InactiveCN100519100CDesign calculation is simpleEasy to calculateJointsSingle degree of freedomEngineering

The present invention relates to a linear expansion artificial muscle and its driven bending joint, which can be used as a mechanical actuator, or as a finger, knee and elbow joint of a robot, as a mechanical device, especially as an actuator of a robot, The utility model belongs to the application technical field of robots and mechatronics. The present invention uses the elastic wave shell in the artificial muscle to inflate and expand as the muscle power. The structure design is unique. Bending and certain twists are generated, the volume change of the elastic wave shell is easy to calculate and measure, the structure of the elastic wave shell is easy to design, and the control method of joint bending is simpler; combined with elastic elements such as plate springs, torsion springs, and tension springs, the straight line Joint bending driven by artificial muscles can be single-degree-of-freedom or multi-degree-of-freedom.

Owner:JIANGNAN UNIV

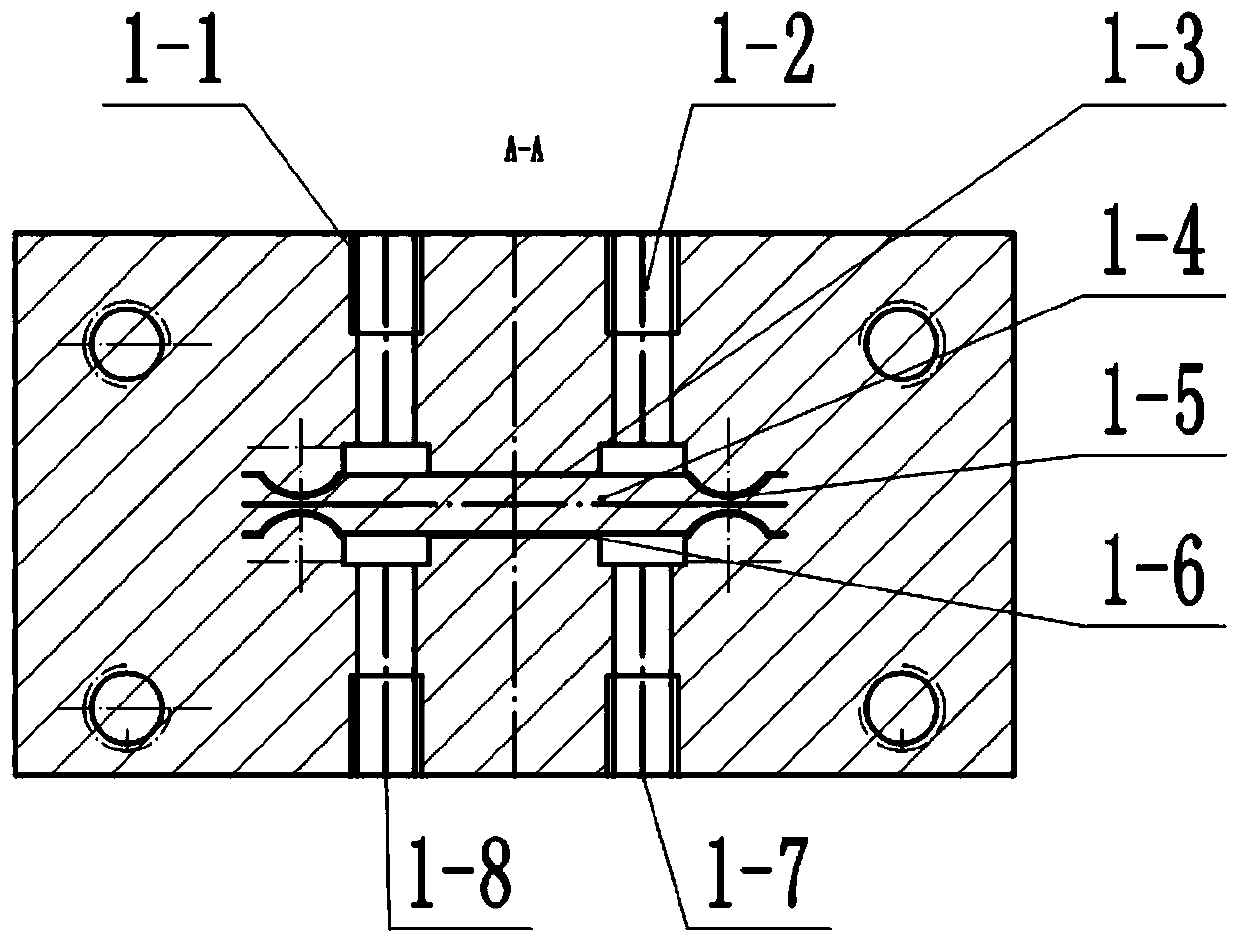

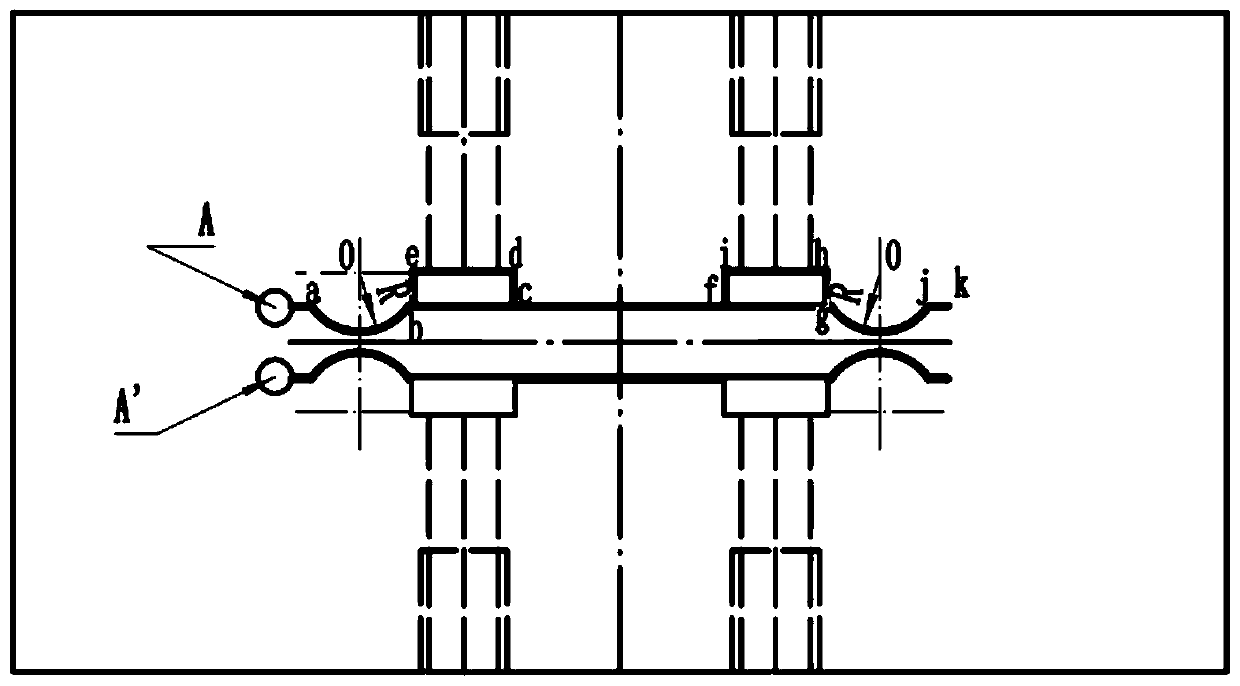

Integral flexural hinge thick-film throttler machining method

The invention discloses an integral flexural hinge thick-film throttler machining method. By means of the method, the problems that thin film in the prior art is quite prone to machining deformation,initial throttling clearances in the two sides are hard to be guaranteed to be consistent, and the throttling clearances are difficult to calculate after stress deformation are solved. The method hasthe beneficial effects that clearances in the two sides of thick film are guaranteed to be consistent, and thick film translational regulation is achieved. The scheme of the method is as follows: theintegral flexural hinge thick-film throttler machining method comprises the steps that a first through hole is drilled in a valve body, and a cutting wire is arranged in the first through hole in a penetrating mode; a flexural hinge profile, an oil inlet cavity profile, a throttling clearance profile and an oil outlet cavity profile on one side and a flexural hinge profile on the other side are cut in sequence; after cutting is completed, the cutting wire exits the first through hole; a second through hole is drilled in the valve body, and the structure of the other half of the valve body is machined; and oil inlet holes and oil outlet holes are machined in the oil inlet cavity profile and the oil outlet cavity profile which are already machined correspondingly.

Owner:SHANDONG UNIV

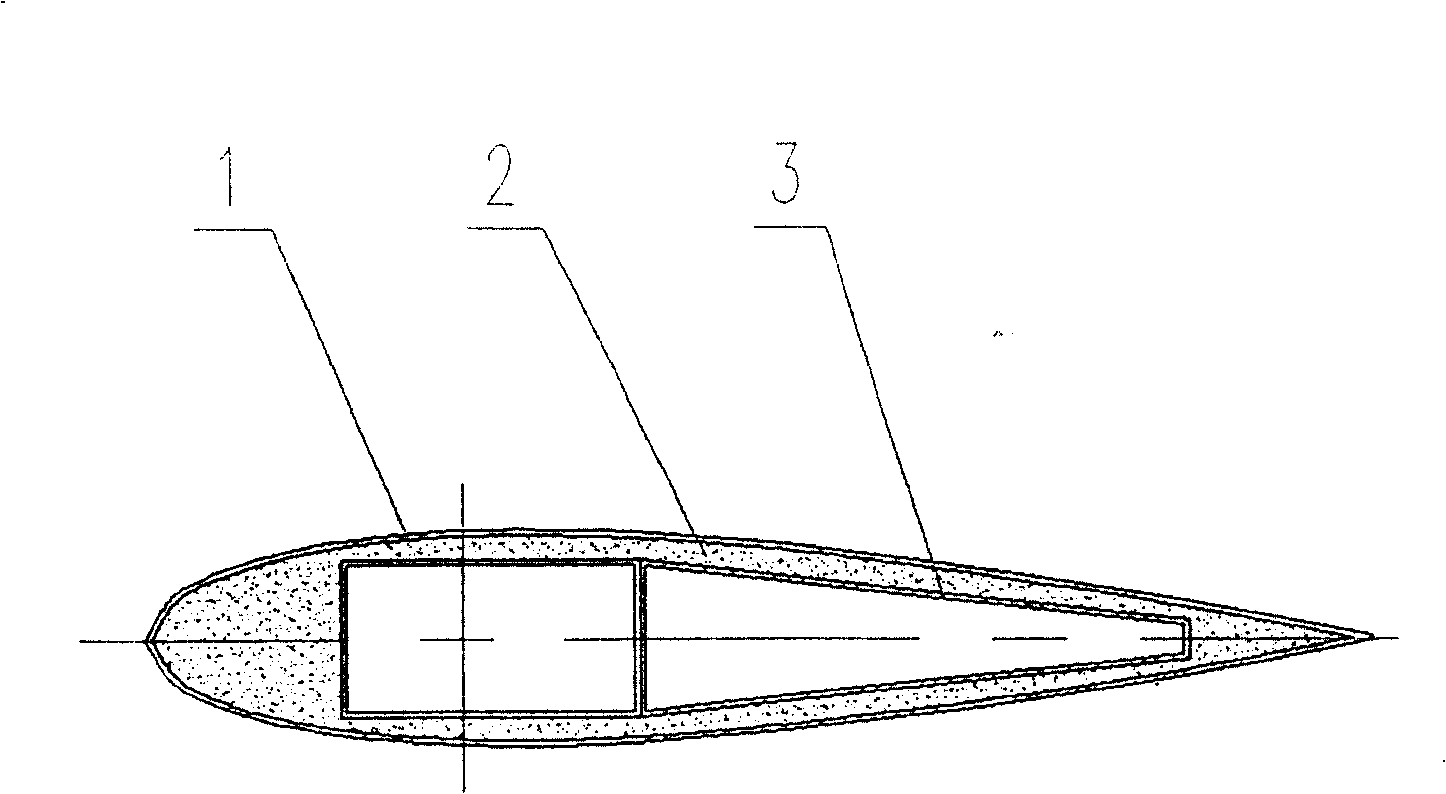

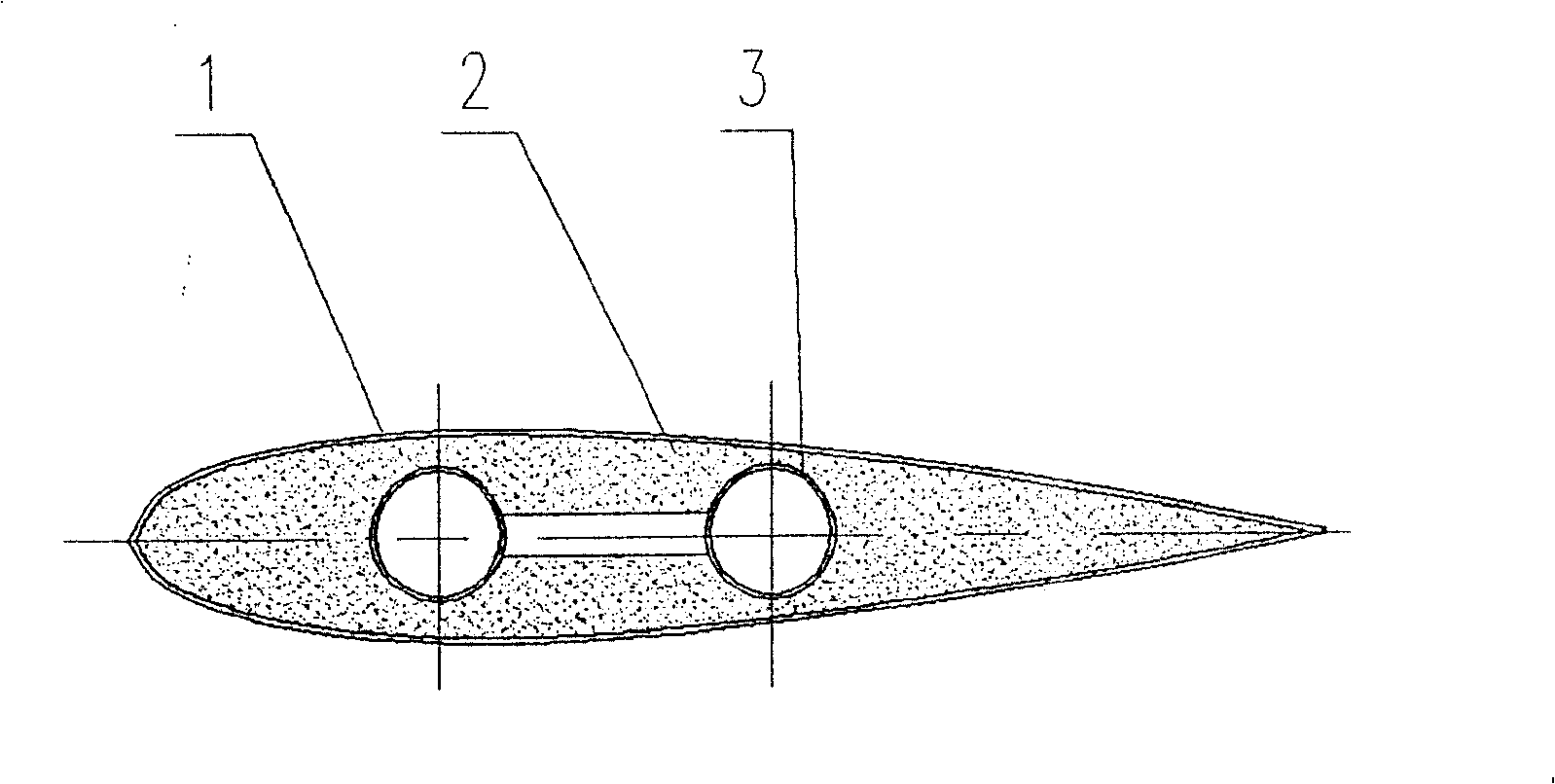

Vane for vertical shaft wind-driven generator and its making process

InactiveCN100441860CReasonable structureReduce weightFinal product manufactureMachines/enginesWind drivenVertical axis wind turbine

The present invention relates to wind generating technology, and is one vane for vertical shaft wind-driven generator and is making process. The vane is one three-layer structure including an outer layer of thin wall coating in the required vane shape, a middle layer of light material stuffing and an inner layer as the main beam with ends stretched beyond the vane and in box-shaped or dumbbell-shaped cross section. The making process of the vane includes making vane sections in the equal length and the required three-layer structure on the main beam, and connecting the sections firmly to complete the vane. The vane of the present invention has low manufacture, transportation and installation cost and is easy to make in large size.

Owner:海油双帆(北京)科技有限责任公司

Design Method of Quasi-Double Lead Cone Worm Gear

InactiveCN102797829BSmooth transmissionImprove transmission efficiencyPortable liftingGearing elementsNatural toothOffset distance

The invention discloses a design method for quasi dual-lead conical worms and worm gears. The method comprises the steps as follows: 1. designing natural tooth profile angle alpha for a quasi dual-lead conical worm; 2. designing an approximate tooth profile angle betab1 in an outer engaging surface section Q-Q and an approximate tooth profile angle betab1' in an inner engaging surface section Q'-Q'; 3. designing a taper angle theta for the quasi dual-lead conical worm; 4. designing the lead of the quasi dual-lead conical worm; 5. designing the installation center distance from the quasi dual-lead conical worm to the worm gear; 6. designing the inner and outer engaging parameters of the quasi dual-lead conical worm; 7. testing and verifying the transmission ratio and the lead of the quasi dual-lead conical worm; 8. designing the tooth depth of the quasi dual-lead conical worm; 9. designing the threaded part of the quasi dual-lead conical worm; 10. designing the radial parameter of the quasi dual-lead conical worm; 11. designing the tooth thickness of the quasi dual-lead conical worm; 12. designing the installation offset distance of the quasi dual-lead conical worm; 13. designing the installation height of the quasi dual-lead conical worm; 14. designing the geometrical parameters of the worm gear; 15. analyzing errors; and 16. carrying out accurate design.

Owner:JILIN UNIV

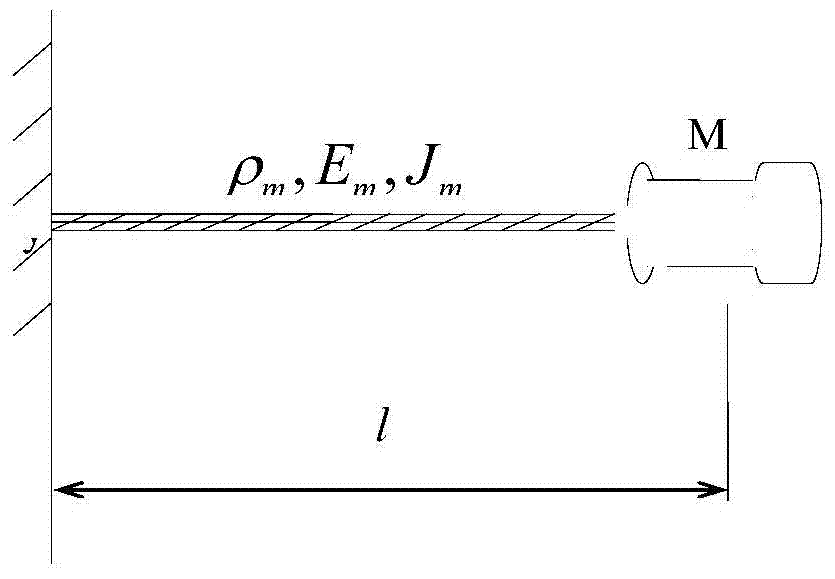

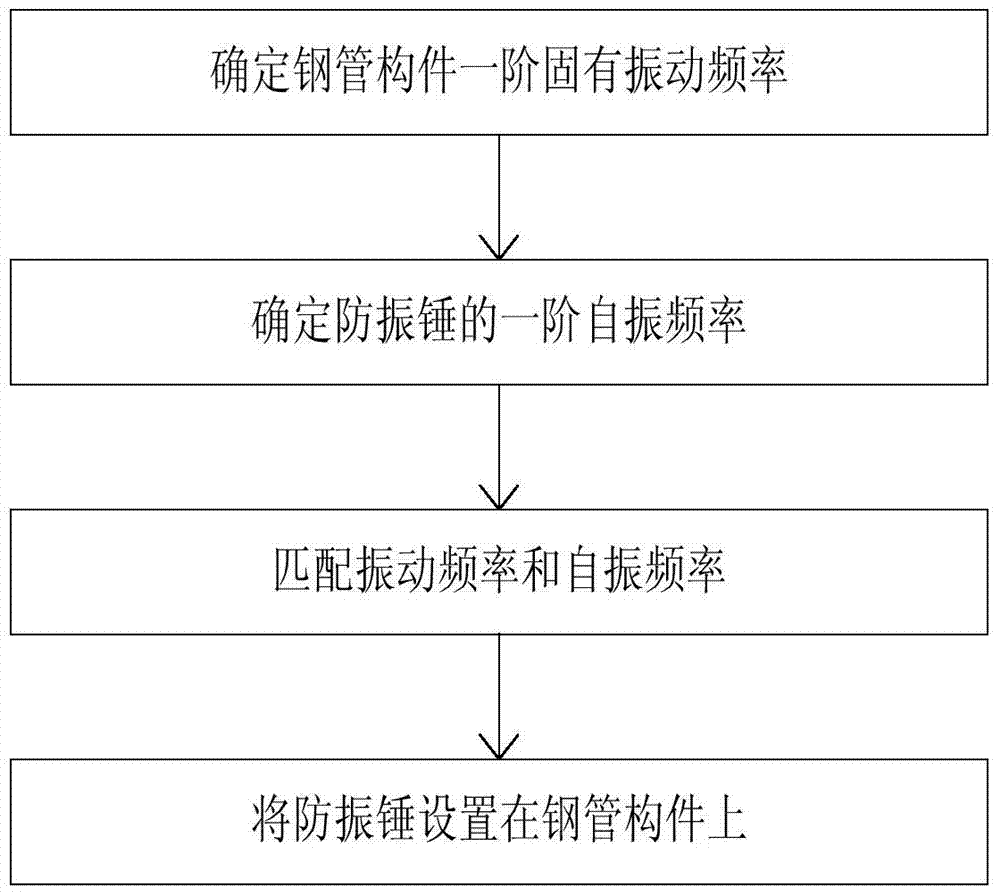

A vibration-proof hammer control method for vortex-induced wind vibration of steel pipe components of electric power towers

ActiveCN104265052BGood control effectDesign calculation is simpleTowersShock proofingVibration controlEngineering

The invention relates to a vibration preventing hammer control method for vortex-induced wind vibration of an electric power tower frame steel tube member. A vibration preventing hammer comprises a hammer head and a steel stranded wire. The vibration preventing hammer control method comprises the following steps of determining the first-order natural vibration frequency of the steel tube member; determining the first-order natural vibration frequency of the vibration preventing hammer; matching the vibration frequency with the natural vibration frequency; arranging the vibration preventing hammer on the steel tube member. The vortex-induced wind vibration control effect of the steel tube member is remarkable by means of the vibration preventing hammer control method. The vibration preventing hammer is simple in selection calculation and is simply and conveniently installed and implemented on an existing tower frame structure, and the safety and economical efficiency of the structure can be improved.

Owner:STATE GRID CORP OF CHINA +1

A processing method of an integral flexible hinge thick film restrictor

The invention discloses an integral flexural hinge thick-film throttler machining method. By means of the method, the problems that thin film in the prior art is quite prone to machining deformation,initial throttling clearances in the two sides are hard to be guaranteed to be consistent, and the throttling clearances are difficult to calculate after stress deformation are solved. The method hasthe beneficial effects that clearances in the two sides of thick film are guaranteed to be consistent, and thick film translational regulation is achieved. The scheme of the method is as follows: theintegral flexural hinge thick-film throttler machining method comprises the steps that a first through hole is drilled in a valve body, and a cutting wire is arranged in the first through hole in a penetrating mode; a flexural hinge profile, an oil inlet cavity profile, a throttling clearance profile and an oil outlet cavity profile on one side and a flexural hinge profile on the other side are cut in sequence; after cutting is completed, the cutting wire exits the first through hole; a second through hole is drilled in the valve body, and the structure of the other half of the valve body is machined; and oil inlet holes and oil outlet holes are machined in the oil inlet cavity profile and the oil outlet cavity profile which are already machined correspondingly.

Owner:SHANDONG UNIV

A three-phase heat exchanger and its absorption refrigeration system

ActiveCN110567297BReduce demandImprove heat utilizationEnergy efficient heating/coolingClimate change adaptationEngineeringRefrigeration

The invention relates to a three-phase heat exchanger and an absorption refrigeration system thereof, belonging to the technical field of refrigeration systems, comprising a shell-side cylinder and two tube-side cylinders, the two tube-side cylinders are connected through heat exchange tubes, and the shell There are shell-side inlets and outlets on the shell-side cylinder, two tube-side inlets and two tube-side outlets on the two tube-side cylinders, and tube-side partitions between the tube-side inlets and outlets of each tube-side cylinder , separate the heat exchange tubes into two independent tube-side passages. The three-phase heat exchanger and its absorption refrigeration system of the present invention are more compact in structure than the existing absorption refrigeration system using two ordinary heat exchangers, saving floor space and space, and adopting tube-and-tube heat exchange device, easy to manufacture. The distribution ratio between the two tubes is achieved through the different positions of the tube-side partitions, and the design and calculation are simple and the heat exchange efficiency is higher. Through the design of the inlet and outlet, the heat exchange process is fully countercurrent, and the heat exchange efficiency is higher.

Owner:ANHUI WATERPOWER ENERGY SAVING TECH

Method for constructing deep pit, and pit structure

The invention discloses a method for constructing a deep pit, and a pit structure. The method comprises the following steps of: arranging a bottom beam at the bottom of the pit, and casting wall-supporting columns which are integrally connected with the bottom beam at the two ends of the bottom beam; and casting a bottom plate and wall plates on the upper part of the bottom beam and the inner sides of the wall-supporting columns. The structure comprises a cushion layer (6) which is provided with the bottom beam, wherein the bottom beam is symmetrically provided with the wall-supporting columns (3); and the bottom plate (2) is arranged above the bottom beam, and the wall plates (1) are arranged on the inner sides of the wall-supporting columns (3). The bottom plate and the wall plates are not required to be thick compared with those in the prior art, so materials can be saved; the wall-supporting columns and the two ends of the bottom beam are integrally cast at one time, so the base of the wall-supporting columns is not required to be large and can have sufficient extrusion resistance; and the invention has the characteristics that: the pit structure is easy to design and calculate, and convenient to construct, and has a short construction period and high lateral soil pressure resistance.

Owner:GUIYANG AL-MG DESIGN & RES INST

Rotary type magneto-rheological damper

InactiveCN102979847BIncrease working areaReduce thicknessNon-rotating vibration suppressionEngineeringMagneto rheological

The invention discloses a rotary type magneto-rheological damper which is characterized in that the damper mainly comprises an outer shell, a front end cap, a back end cap, a front magnet exciting coil, a back magnet exciting coil, a rotor, a bearing, a sealing washer, seal rings and magnetic isolation rings. The front and back end caps are located at the two sides of the rotor and are respectively connected with the outer shell, forming a stator. The bearing and the sealing washer are respectively arranged between the rotor and the front and back end caps. The front and back magnet exciting coils are wound inside the front and back end caps. The magnetic isolation rings are respectively installed between the front and back end caps and the outer shell, and O-shaped seal rings are respectively arranged between the magnetic isolation rings and the outer shell as well as the front and back end caps. A sealed liquid charging hole is formed at the upper part of the outer shell, and magneto-rheological fluid is filled in a hollow cavity between the stator and the rotor. The front and back magnet exciting coils are wound in the same direction, with the tail ends being connected with each other in series and the head ends being loaded with power sources. The two magnet exciting coils form two parallel magnetic pathways which generate two magnetic fields in opposite direction, and the magnetic flux is generated by a single piece of magnet exciting coils.

Owner:HEBEI UNIV OF TECH

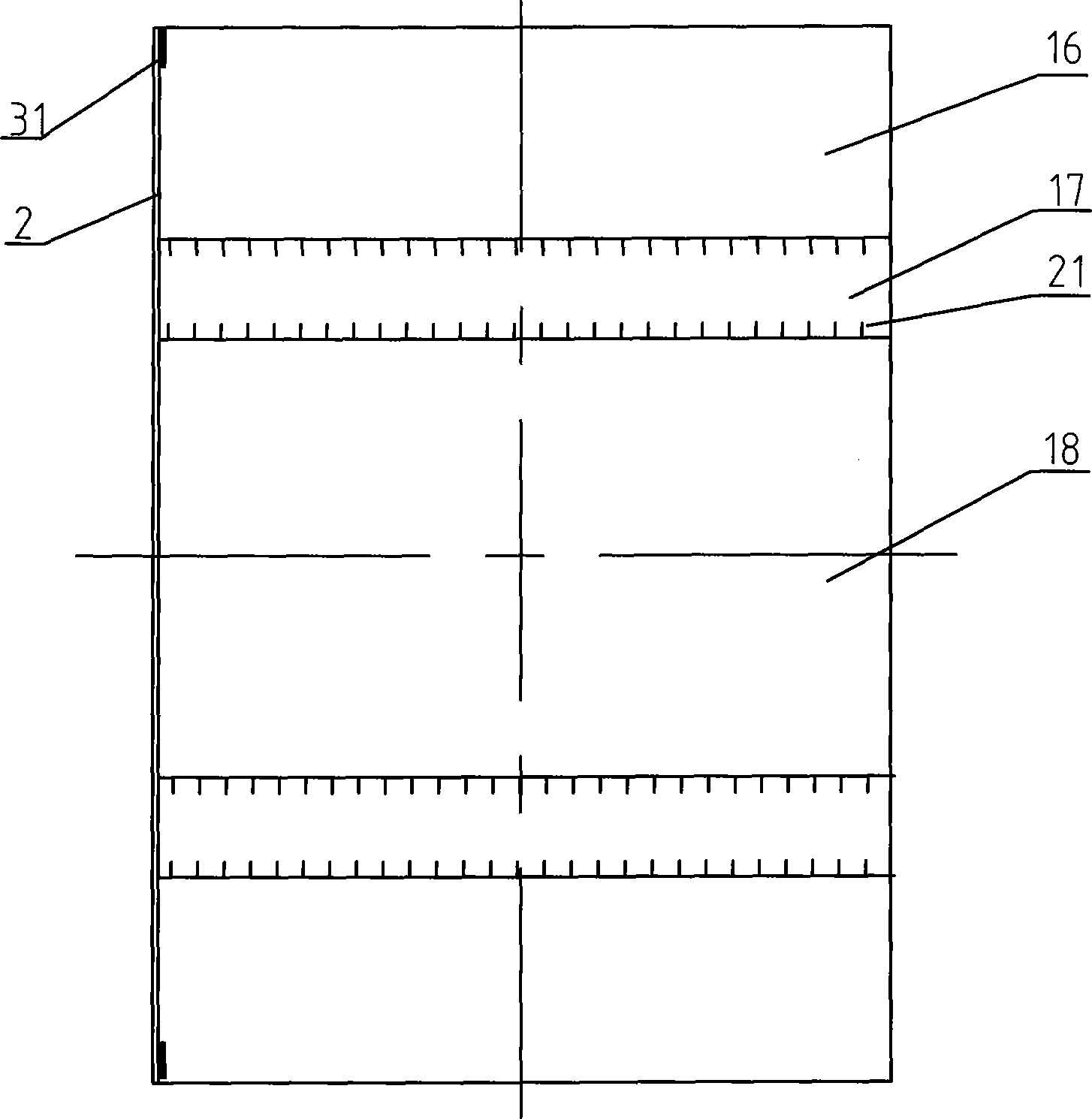

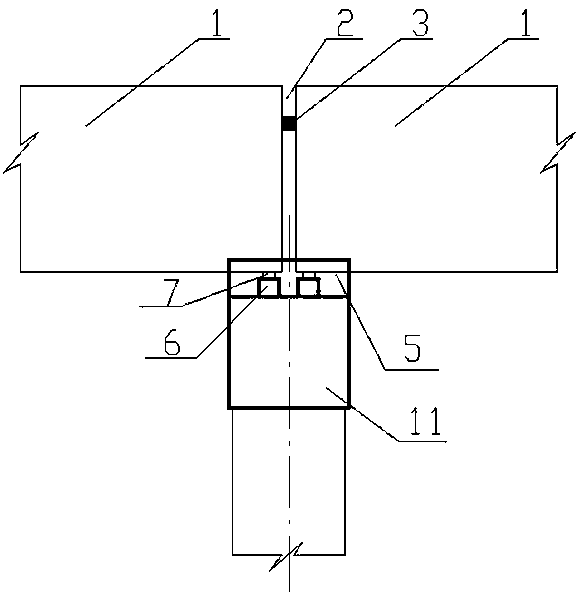

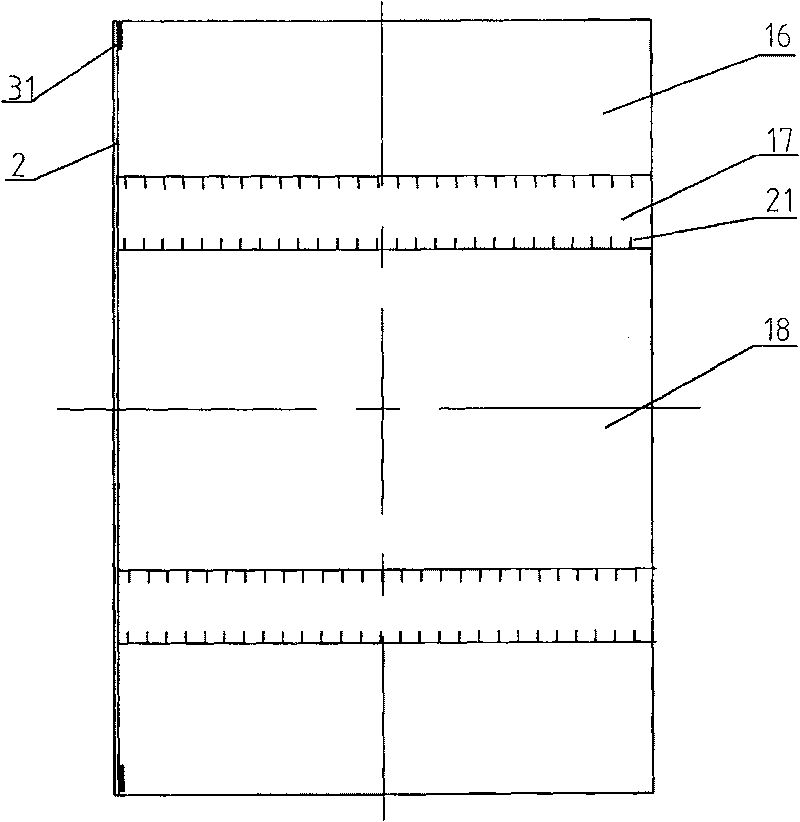

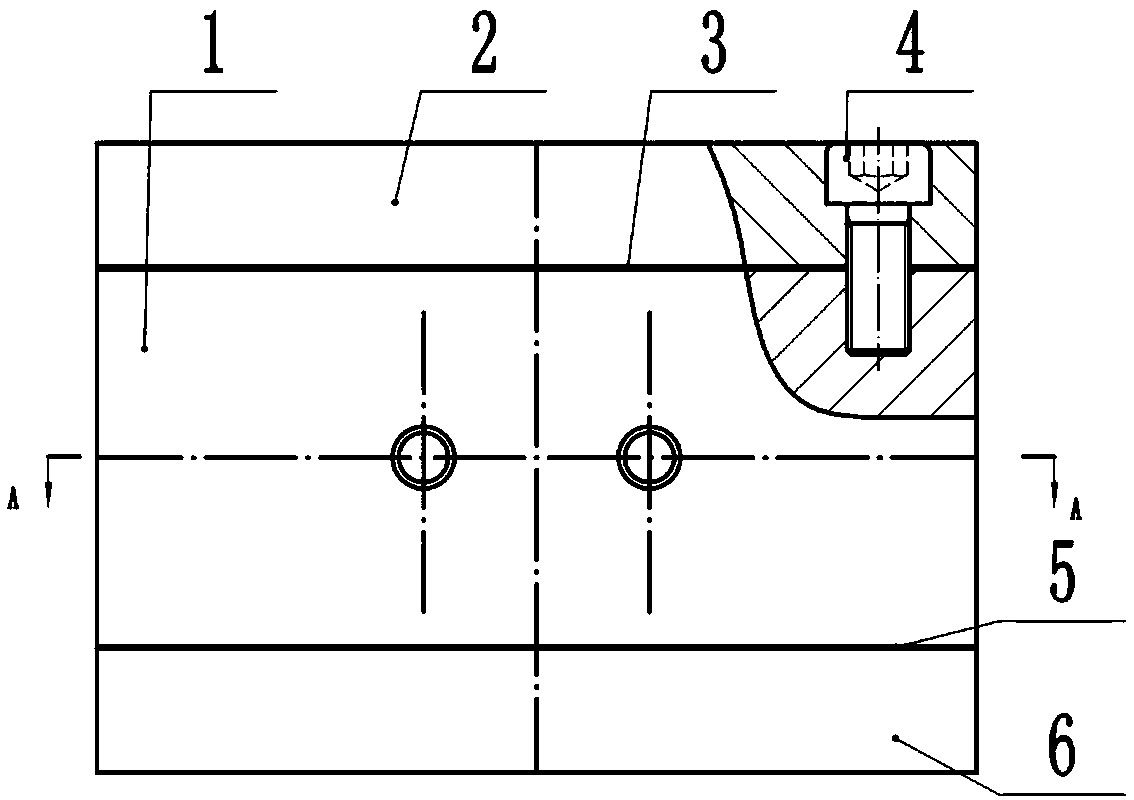

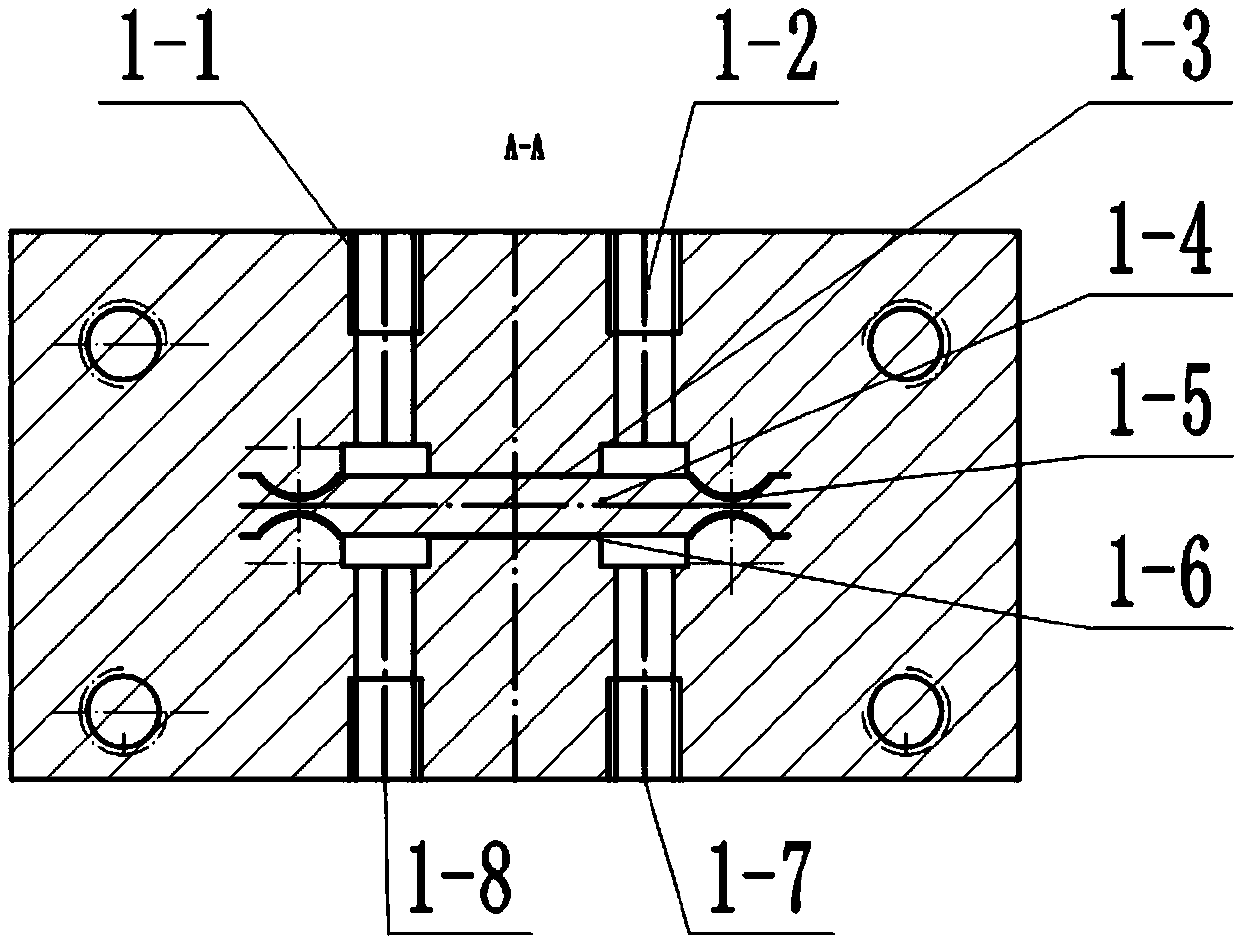

Hollow glass curtain wall

ActiveCN101215863BDesign calculation is simpleSimple structureWallsMechanical engineeringGlass sheet

The invention provides a hollow glass curtain wall, which comprises an upright column, a bridging beam and a hollow glass slab, wherein the hollow glass slab comprises an inner layer glass slab and an outer glass slab, the hollow glass curtain wall is provided with a multifunctional connecting component, the multifunctional connecting component is mounted on the upright column, the multifunctional connecting component is provided with a wing slab which is connected with the bridging beam which is arranged on the two lateral of the upright column, the positive face of the bridging beam and theupper edge of the wing slab are articulated with a groove which is matched, the bridging beam is articulated on the wing slab, a supporting slab of the hollow glass slab is arranged on the wing slab of the multifunctional connecting component, and the supporting slab is supported by contiguous angles of the hollow glass slabs which are arranged in a row. The invention can simplify the load calculation of the bridging beam and save the material cost of the bridging beam, the connection between the bridging beam and the upright column can be simplified or omitted, the structure and the installation of the keel of the curtain wall can be simplified, the invention can also use the bridging beam which adopts closed section material, therefore, the load calculation of the bridging beam is further simplified and the material cost of the bridging beam is saved, furthermore, the invention has universal base of an exposed frame glass curtain wall system and a hidden frame glass curtain wall system.

Owner:ZHEJIANG CENT SOUTH CONSTR GROUP

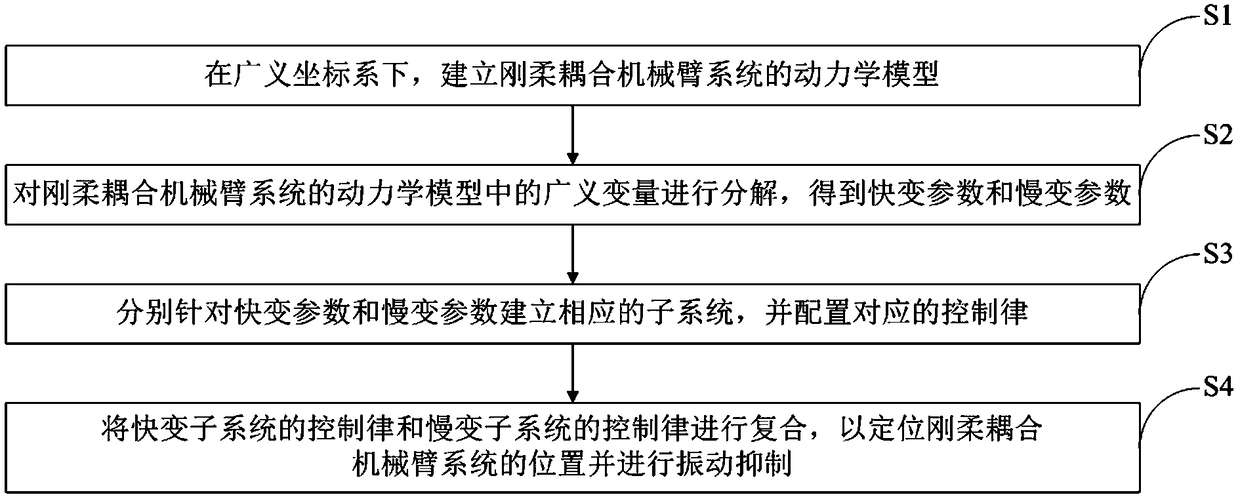

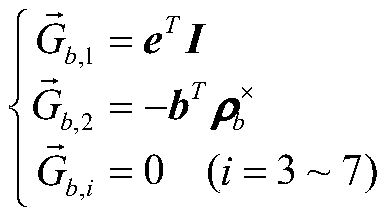

A Vibration Suppression Algorithm for Space Flexible Manipulator

ActiveCN106094528BReduce vibrationSuppression of flexural vibrationAdaptive controlVibration controlCoupling

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

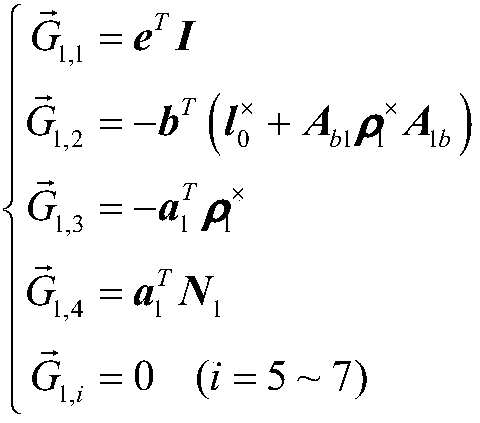

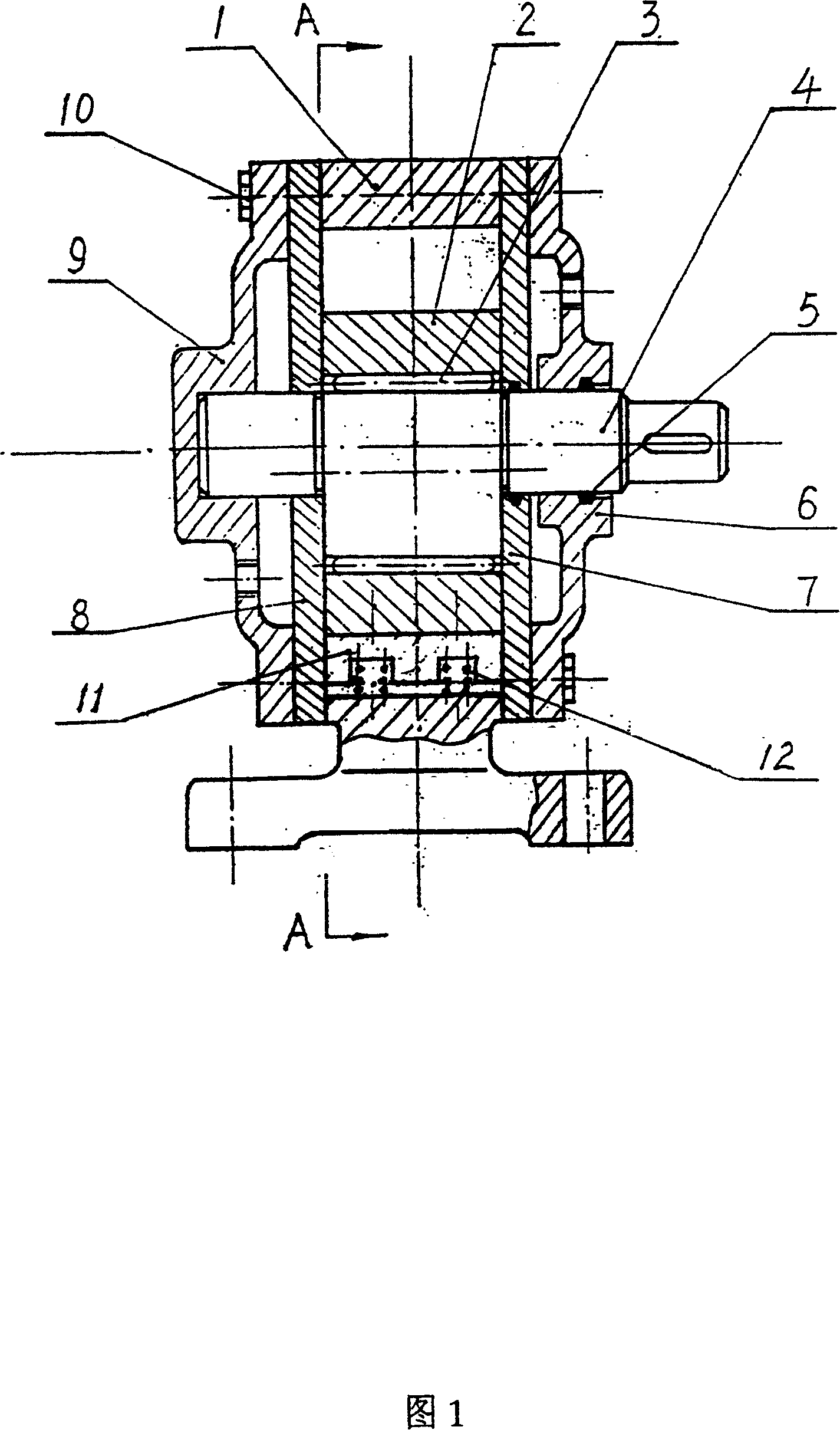

Sliding block rotor pump

InactiveCN100363620CImprove mechanical efficiencyImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesRefrigeration compressorEngineering

The invention relates to a slider rotor pump that a through groove is set at the top of every apex angle section along the axis direction. Rotator slider that has the same width as the rotor is located in the through groove, and the slider could freely extend along the radial direction. A through groove is set at the top of every apex angle section of stator along the axis direction and locating a stator slider that has the same width as the stator in the through groove that can make the slider freely extend along the radial direction. The invention has the advantage of high mechanism efficiency of rotor pump, high volumetric efficiency, low liquid impulse, low working noise and large pressure ratio, and moving contact that has no clearance and long useful life. It can be broadly used in oil pump, water pump, gas compressor, refrigeration compressor, vacuum pump, etc.

Owner:CHONGQING JINYANG REFREGRATION EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com