Workshop pit and construction method thereof

A technology for workshops and pits, applied in construction, water conservancy projects, artificial islands, etc., can solve the problems of cumbersome design and calculation, long construction period, prone to water accumulation, etc., to improve the exhaust effect, short construction period, and reliable safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

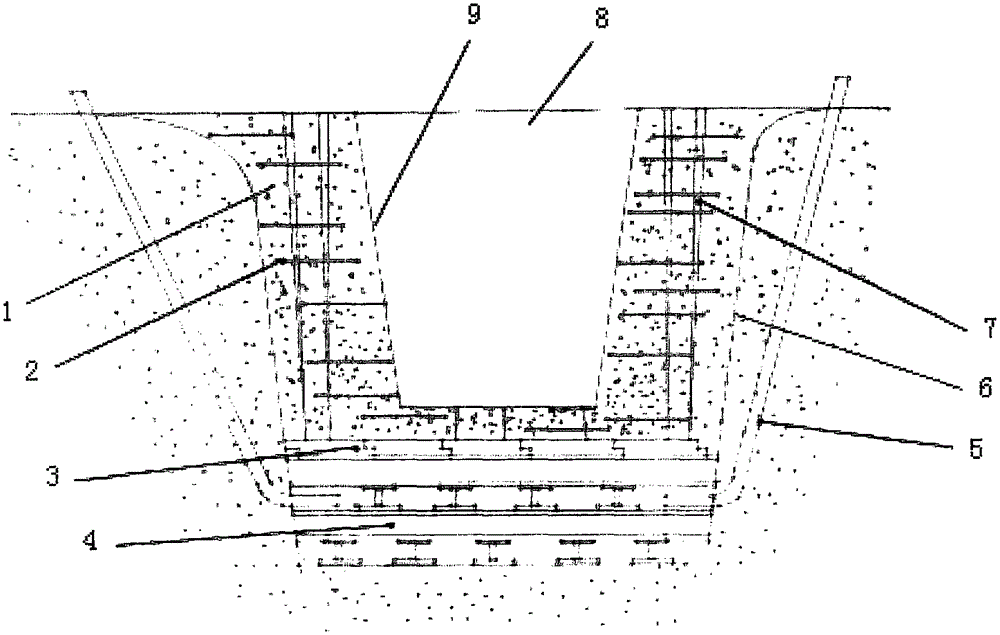

[0020] Such as figure 1 As shown, the pit includes a support layer formed by multi-layer staggered support rods 4 arranged at the bottom of the excavated deep pit 6, and an exhaust pipe 5 that is arranged around the support layer and extends upward from the top of the deep pit. The exhaust supporting plate 3 on the top of the supporting layer, one end is connected to the exhaust supporting plate 3, and the other end reaches the exhaust passage 7 on the ground, and poured on the inner wall of the deep pit 6 and the pit working chamber 8 and the exhaust supporting plate 3 Between pouring cured layer 1. Wherein the cast solidified layer 1 is located on the outer wall of the working chamber 8 of the pit, and a surface sand layer 9 is arranged on it. As shown in the figure, the cast solidified layer 1 is provided with a reinforcing rib plate 2 . The ground outlet end of the exhaust pipe is provided with an exhaust fan (figure omitted). The ground outlet end of the exhaust passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com