Double channel magnetic current damp variation device with recombination of mixing mode and flowing mode

A magnetorheological damper, flow mode technology, applied in transportation and packaging, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problem that the magnetorheological fluid cannot pass through the channel smoothly, it is difficult to achieve the compensation effect, etc., to achieve recovery The effect of large force value, small compression force value and simplified design calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

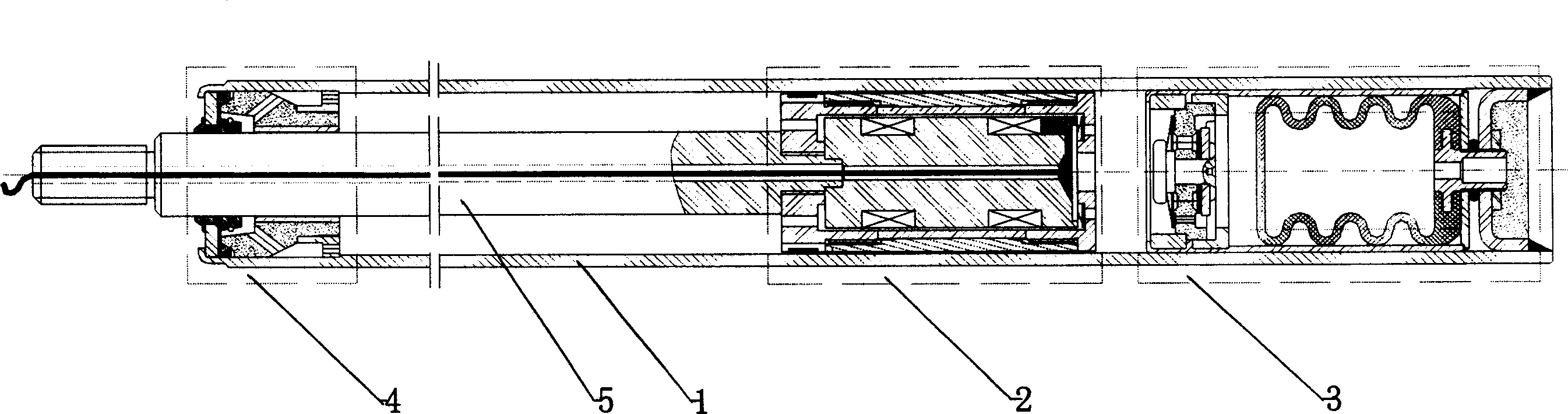

[0015] For the structure of the dual-channel magnetorheological damper with compound mixed mode and flow mode, see figure 1 :

[0016] It is mainly composed of a working cylinder 1, a piston-type magnetic field generator 2, a compensator 3 and a sealing device 4. The working cylinder 1 is filled with magnetorheological fluid and is divided into upper and lower chambers by the piston type magnetic field generator 2. The compensator 3 is located at the bottom of the working cylinder 1, and the end of the working cylinder is sealed by the sealing device 4, which is in line with the existing magnetic current The variable damping control device is similar.

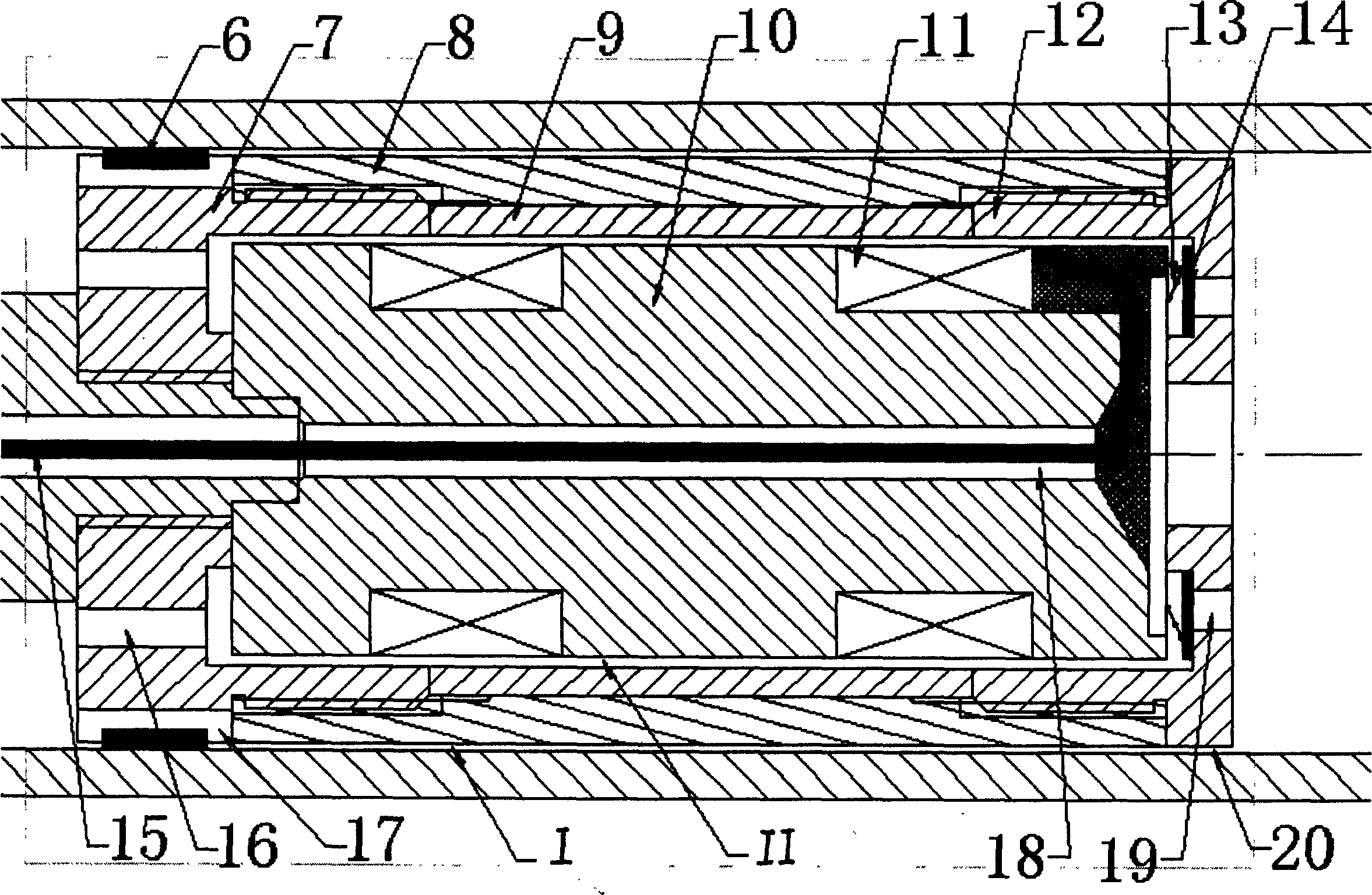

[0017] The piston type magnetic field generator of the damper consists of a piston rod 5, a guide ring 6, a guide 7, a magnetic field spacer 8, a magnetic sleeve 9, a piston 10, an excitation coil 11, a bottom cover 12, a spring 13 and a valve plate 14. composition.

[0018] The piston 10 is covered with a guide 7 at the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com