Method for repairing crack at jointing part of composite lightweight aggregate batten wall and a repairing layer thereof

A crack repairing and lightweight aggregate technology is applied in the field of crack repairing method and repairing layer at the stubble joint of composite lightweight aggregate slat wall, which can solve problems such as poor effect and cracks, and achieve improved appearance quality, good effect, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

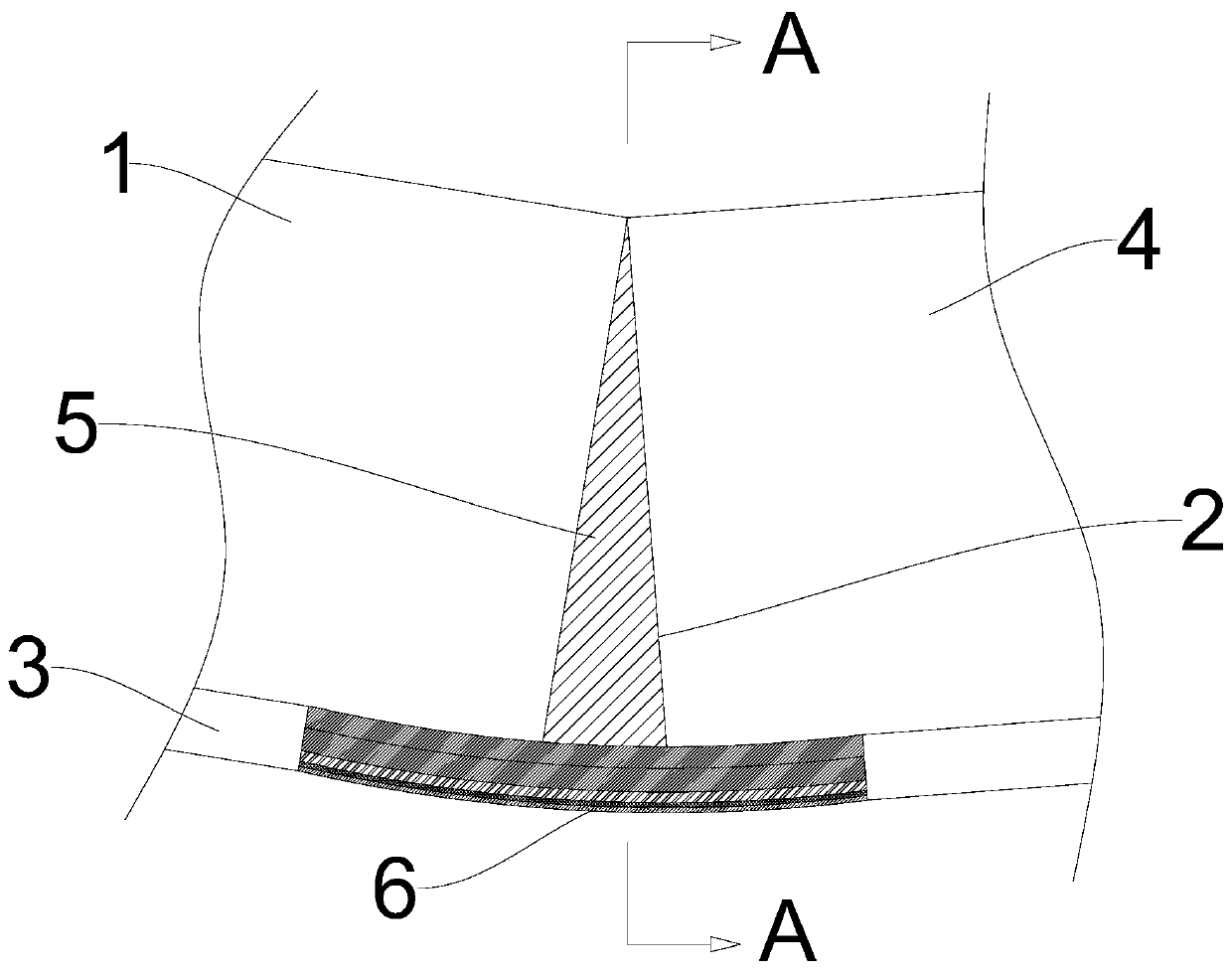

[0046] This embodiment provides a method for repairing cracks at the stubble joints of a composite lightweight aggregate slat wall, which includes the following steps:

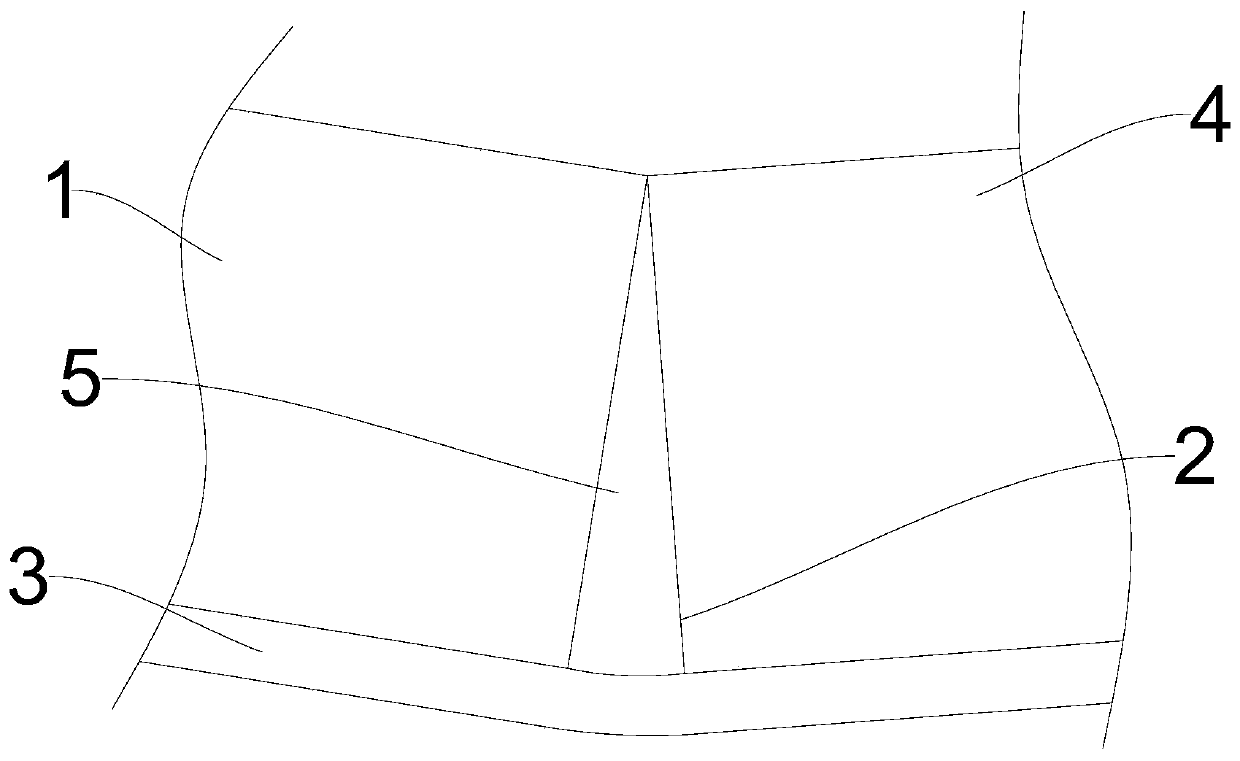

[0047] S1. Base treatment: use a wide shovel to scrape off the decorative surface 3 on both sides of the crack with a distance of 80mm from the crack, expose part of the first composite light aggregate strip 1 and part of the second composite light aggregate strip 4, and expose The residual substances on part of the first composite light aggregate slat 1 and part of the second composite light aggregate slat 4 are cleaned up to obtain the first bare panel and the second bare panel.

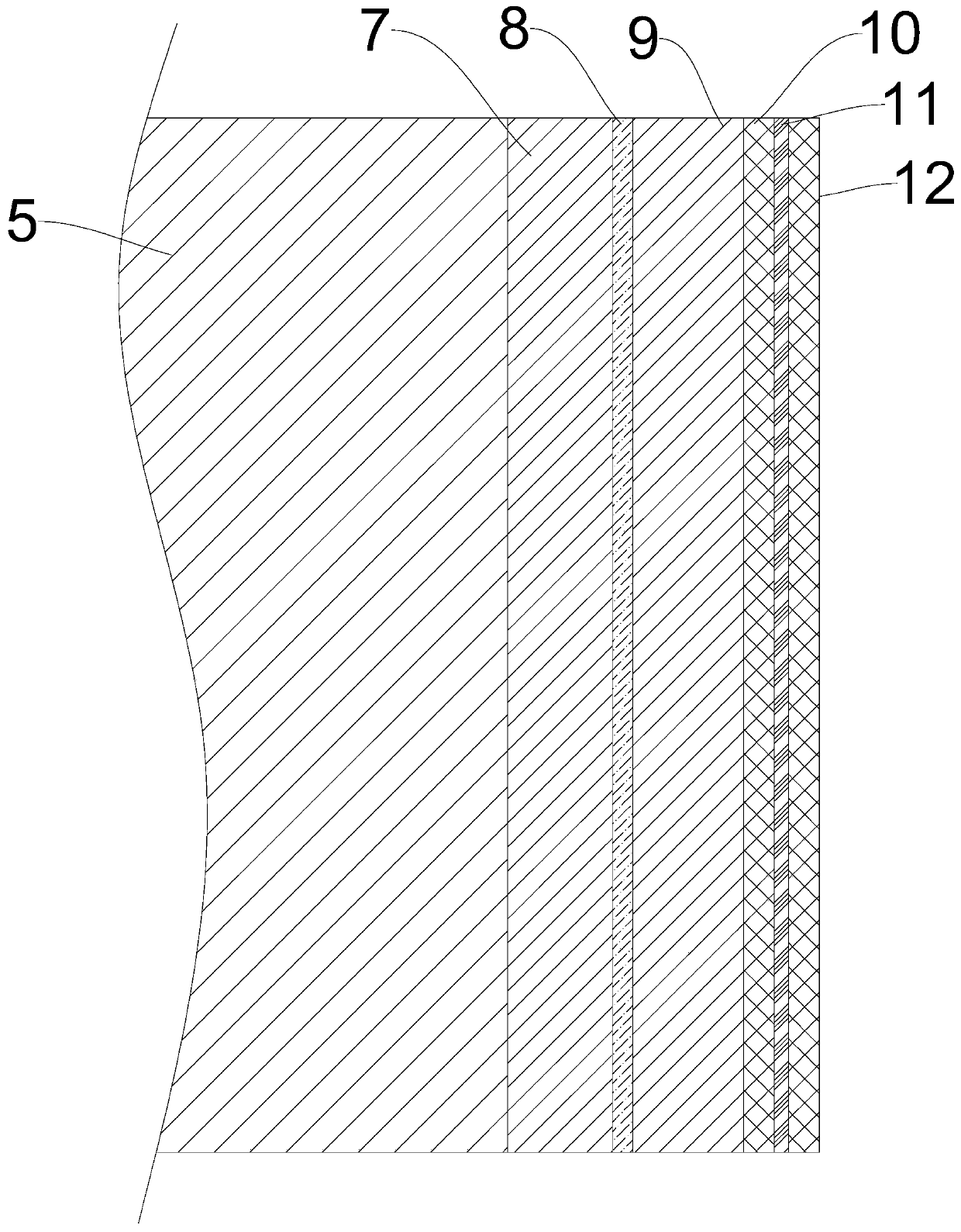

[0048] S2, brushing interface agent: take interface agent, evenly brush on the surface of the first exposed panel and the second exposed panel in step S1, to obtain an interface agent layer with a thickness of 1.5mm, the interface agent has very strong permeability, can The surfaces of the first exposed panel and the second exposed...

Embodiment 2

[0057] This embodiment provides a method for repairing cracks at the stubble joints of a composite lightweight aggregate slat wall, which includes the following steps:

[0058] S1. Base treatment: use a wide shovel to scrape off the decorative surface 3 on both sides of the crack with a distance of 50mm from the crack, expose part of the first composite light aggregate strip 1 and part of the second composite light aggregate strip 4, and expose The residual substances on part of the first composite light aggregate slat 1 and part of the second composite light aggregate slat 4 are cleaned up to obtain the first bare panel and the second bare panel.

[0059] S2, brushing interface agent: take interface agent, evenly brush on the surface of the first exposed panel and the second exposed panel in step S1, to obtain an interface agent layer with a thickness of 1.8mm, the interface agent has very strong permeability, can The surfaces of the first exposed panel and the second exposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com