Sliding block rotor pump

A rotor pump and slider type technology, which is used in rotary piston pumps, pumps, and rotary piston machines, etc., can solve the problems of short service life of rotor pumps, unstable working conditions, and low working efficiency of slider pumps. Small fluid pulsation, long service life and low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

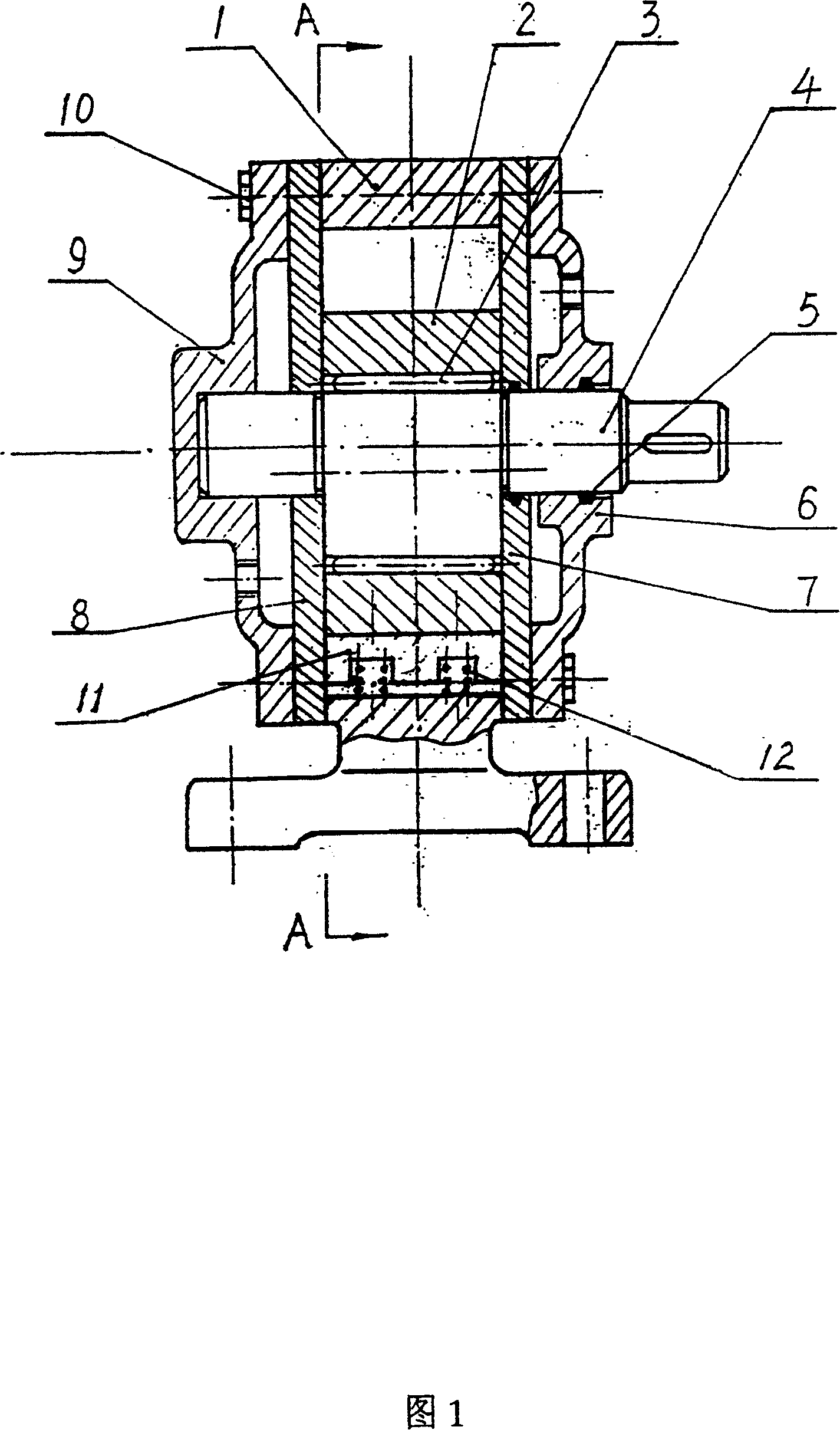

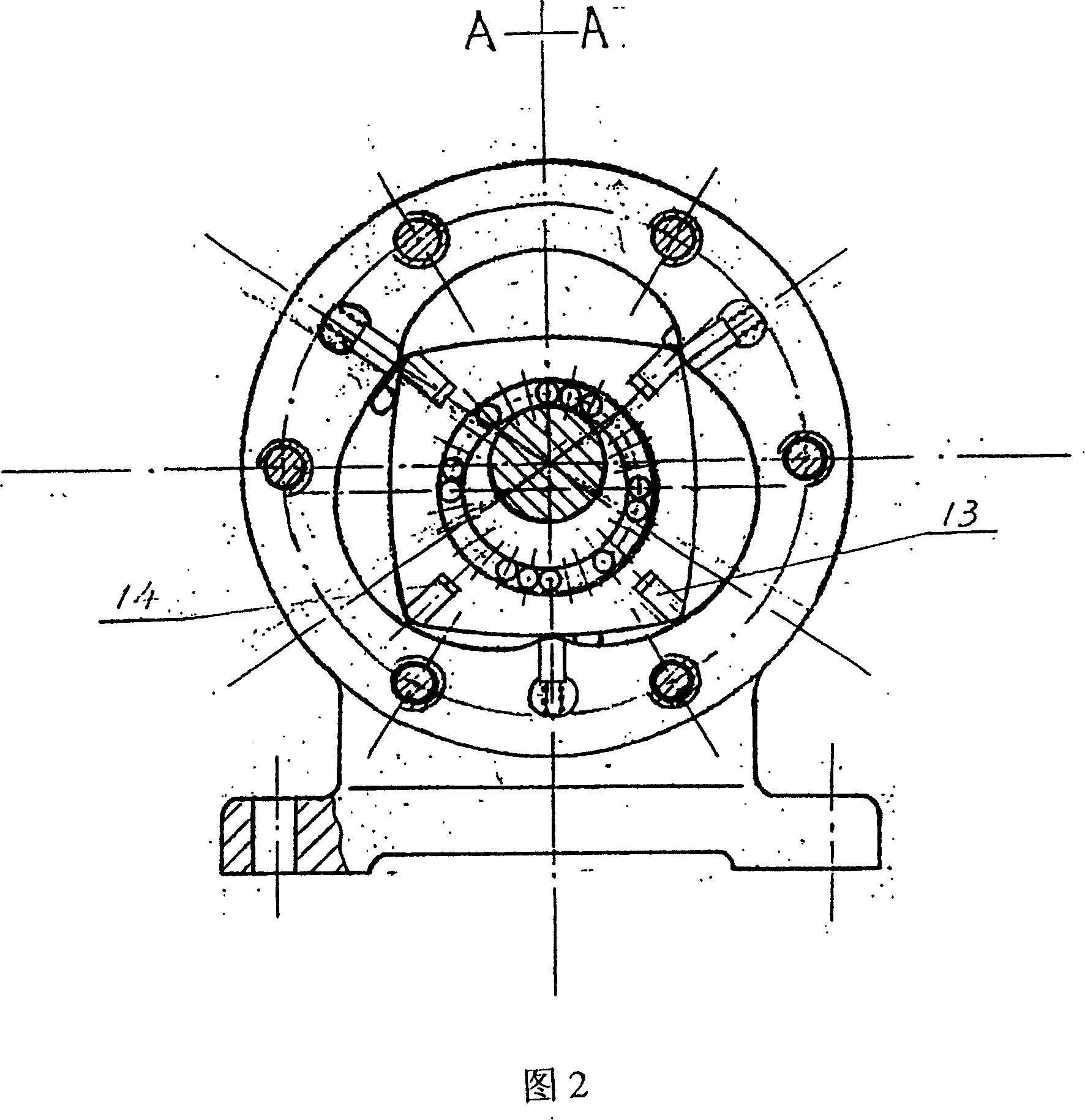

[0029] Embodiment 1 is a slider type rotor pump composed of a quadrilateral rotor 2 and a three-arc stator 1 composed of three-segment curves with an inner cavity that is equally divided. The pump consists of a three-arc stator 1, a quadrilateral rotor 2, and rolling elements 3 , eccentric shaft 4, front distribution plate 7, rear distribution plate 8, front inlet flow cover 6, rear end cover 9, a quadrilateral rotor 2 is installed in the inner cavity of the three-arc stator 1, and a quadrilateral rotor 2 is installed in the inner hole of the quadrilateral rotor 2 Install a number of rolling elements 3 and eccentric shaft 4, put the central circular holes of the front distribution plate 7 and the rear distribution plate 8 into the two ends of the eccentric shaft 4 respectively, and place them on the two ends of the three-arc stator 1. The central round holes of the front inlet flow cover 6 and the rear end cover 9 are inserted into the two ends of the eccentric shaft 4 respecti...

Embodiment 2

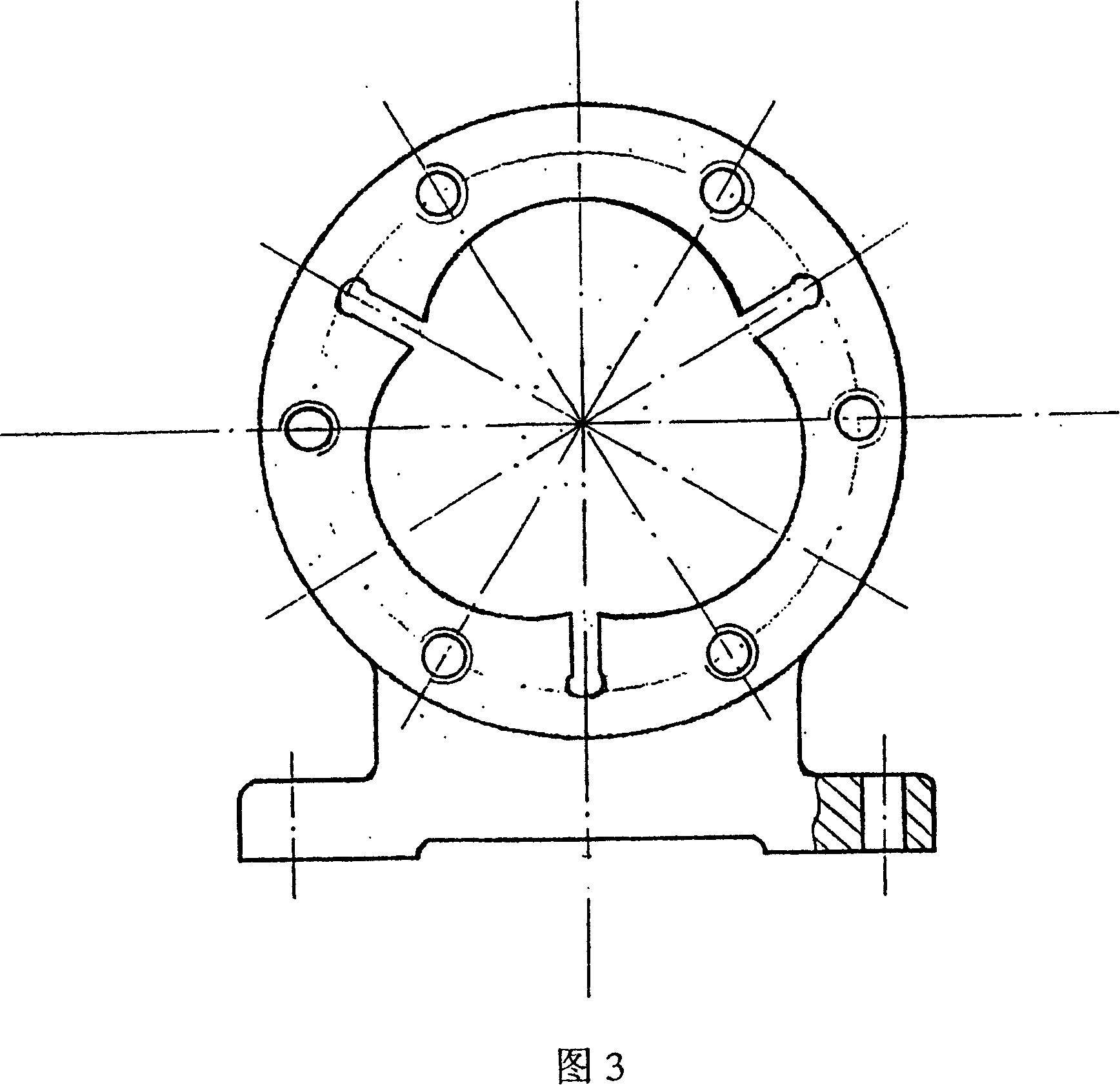

[0035] Embodiment 2 is a slider-type rotor pump composed of a triangular rotor 15 and an 8-shaped stator 16 formed by two curves in the inner cavity. Above the three apex sections of the triangular rotor 15, a through slot is opened along the axial direction. , and have a certain depth in the radial direction. A rotor slider 13 with the same width as the rotor in the axial direction is placed in each of the three through grooves. A shrapnel 14 is installed between the bottom of each slider and the bottom of the through groove, so that The slider can be freely expanded and contracted in the radial direction: above the two apex sections of the stator, a through slot is opened along the axial direction, and has a certain depth in the radial direction, and a slot along the axial direction and Stator sliders 11 with the same width as the stator, springs 12 are respectively installed between the bottom of each slider and the bottom of the through groove, so that the slider can freely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com