Barrel wall type sheave mechanism for three dimensional vertical axes rotation transmission

A sheave mechanism and vertical shaft technology, applied in the field of graded shifting structure, can solve the problems of low mechanical efficiency, inconvenient maintenance, complex switch structure, etc., and achieve the effects of accurate spatial position, improved mechanical efficiency, and reduced overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

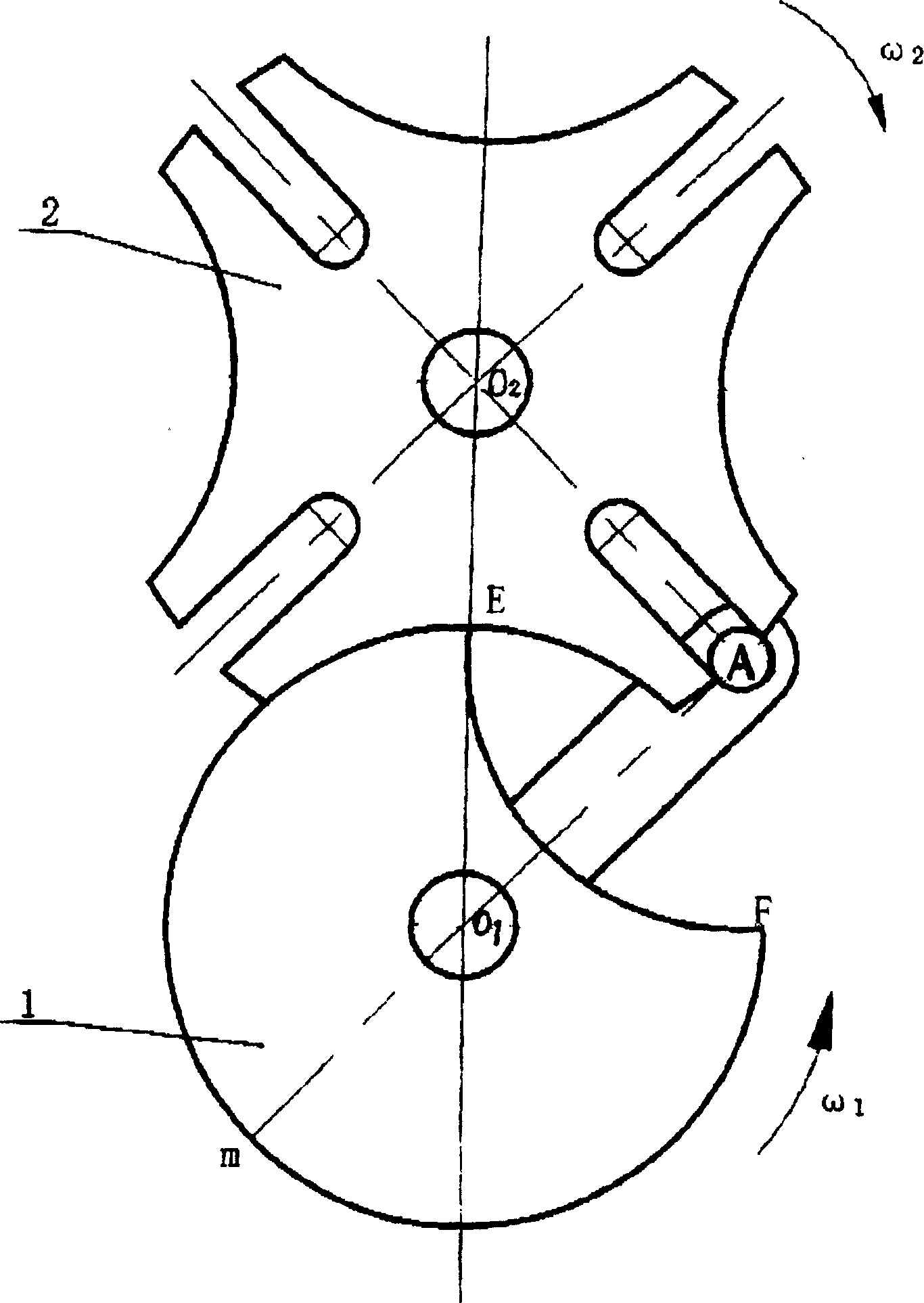

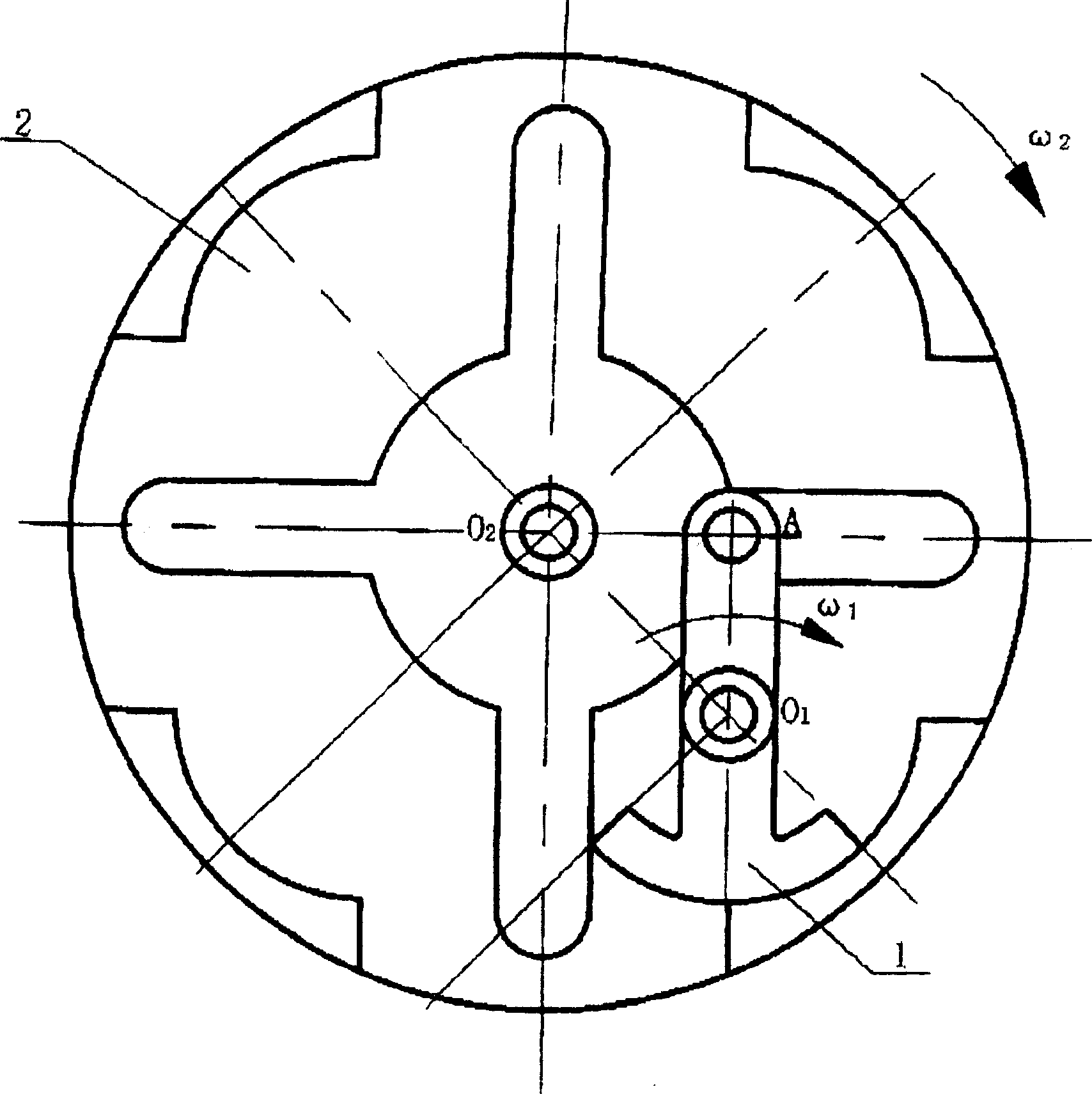

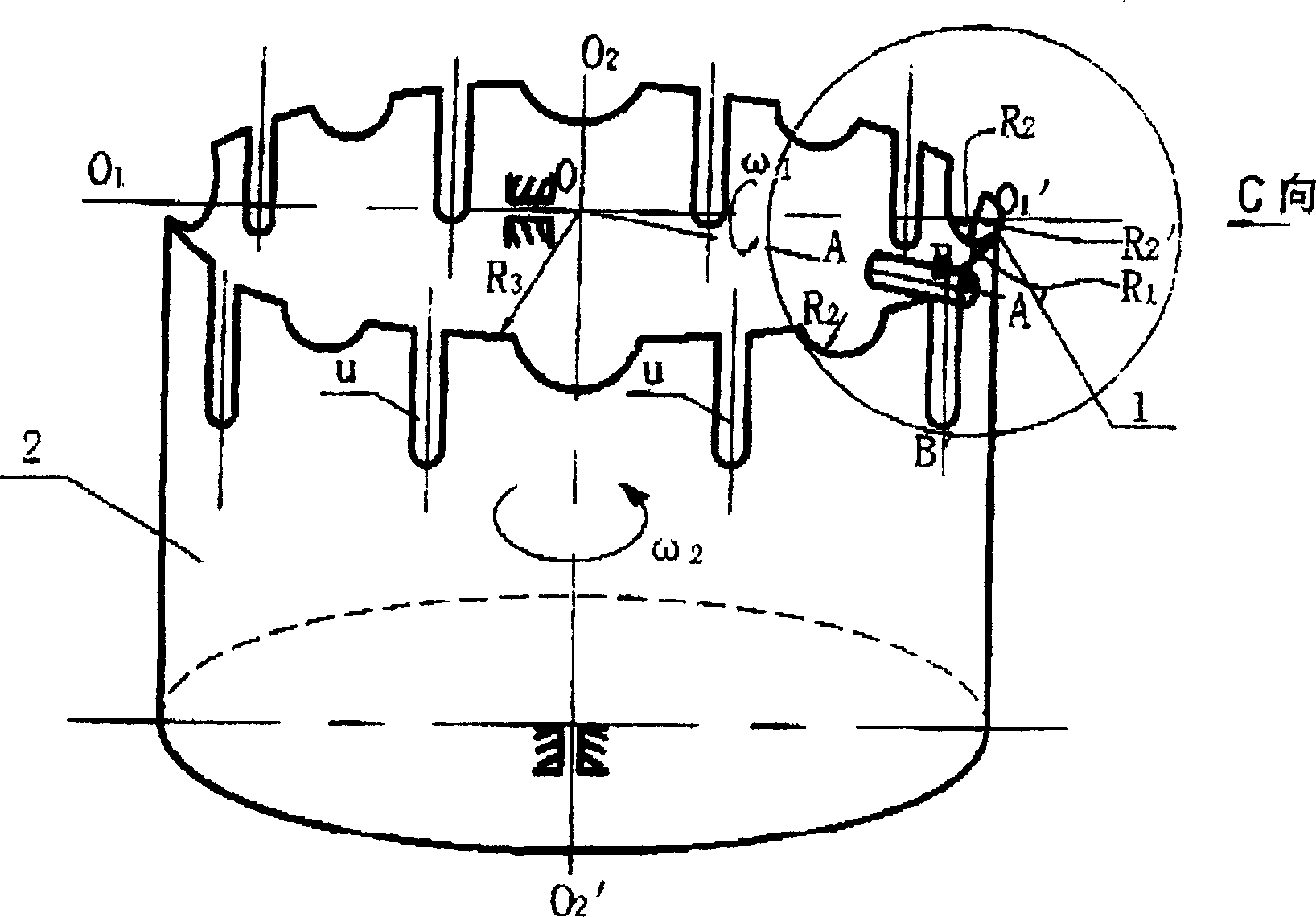

[0021] See Figure 6-9 , the specific structure of the bucket wall type sheave mechanism is illustrated by an embodiment: the slotting part 1 (ie the driving wheel) in the mechanism is composed of a driving shaft 1-1, a positioning half arc 1-2, a rotating rocker arm 1-3, and a shift fork shaft 1-4 and axle sleeve 1-5 constitute, and wherein driving shaft 1-1, positioning semi-arc 1-2 and rotating rocker arm 1-3 are affixed together, shift fork shaft 1-4 and rotating rocker arm 1-3 also Fixedly connected together, the axle sleeves 1-5 are movably sleeved on the shift fork shaft 1-4 to form a shift fork. The sheave 2 (being the driven wheel) is in the shape of a barrel, and the turning groove U of the sheave 2 and the positioning half-arc groove are respectively distributed on the circumferential port of the barrel wall at intervals.

[0022] Drive axis 1-1 is O 1 -O 1 ' is the rotation of the axis, and the positioning half-arc 1-2 is based on R 2 ' is the radius, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com