Patents

Literature

185results about How to "Curb emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

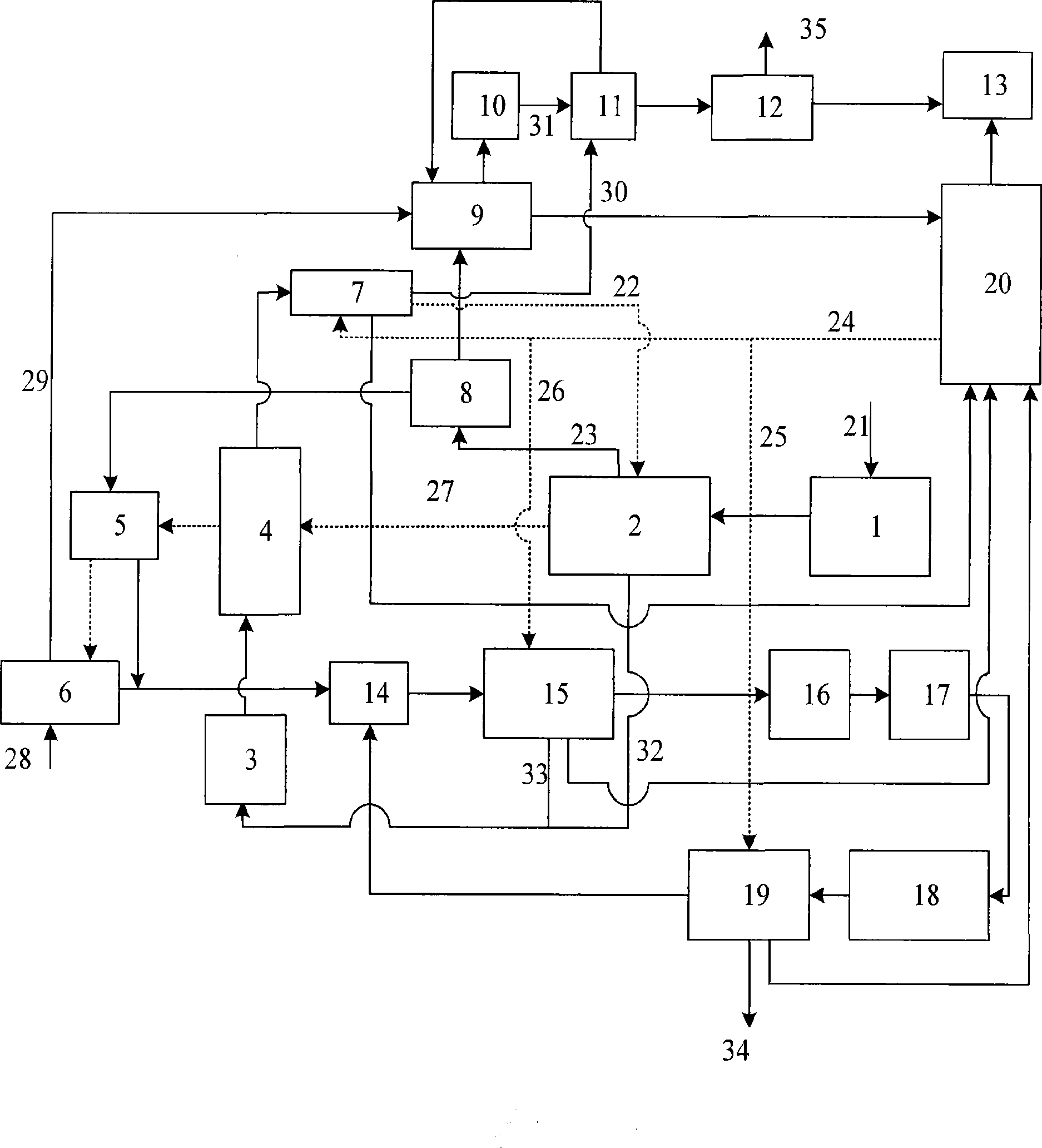

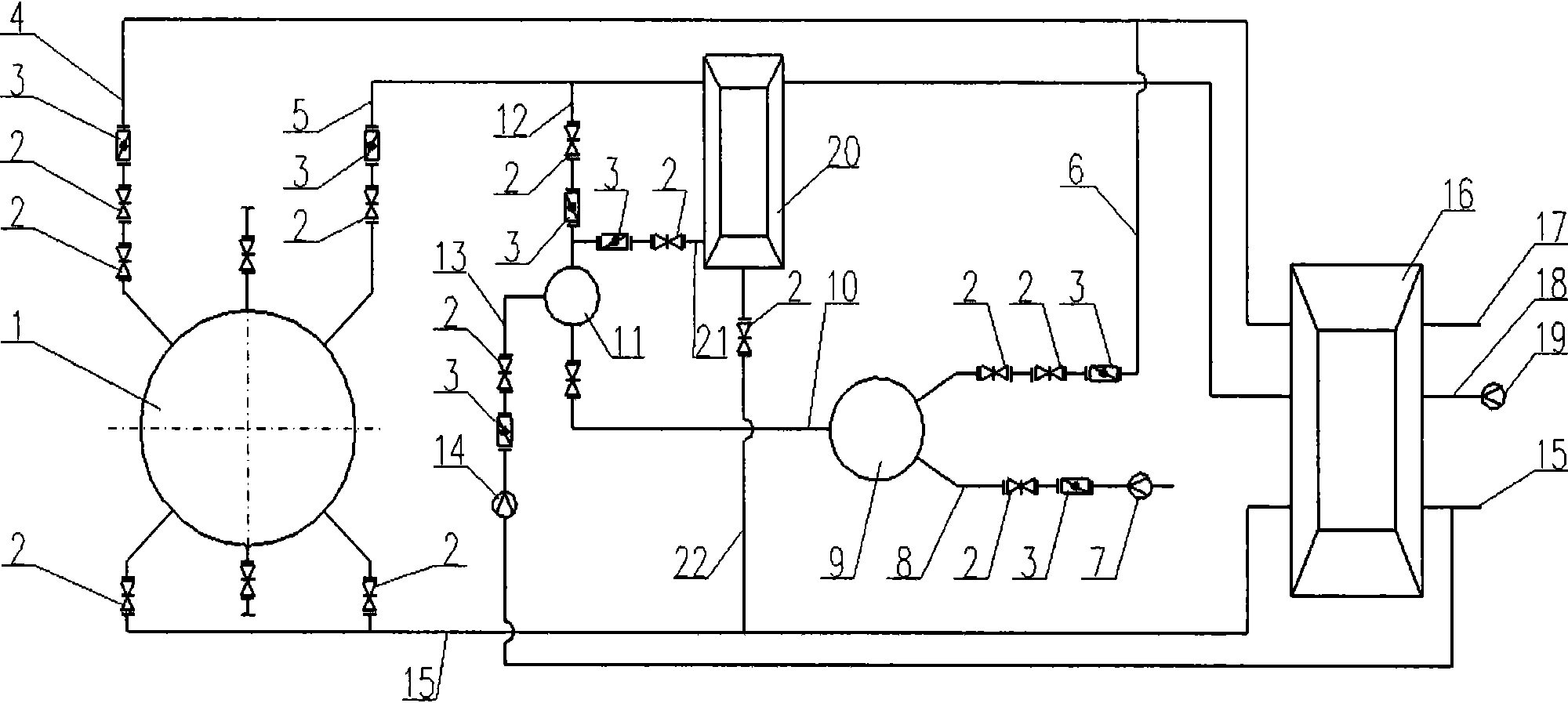

System for comprehensive utilization of three industrial wastes

InactiveCN101618292AAchieve energy saving and emission reductionReduce manufacturing costDispersed particle separationWater/sewage treatmentElectric powerToxic industrial waste

The invention provides a system for comprehensive utilization of three industrial wastes, mainly relating to the field of energy conservation and emission reduction, in particular to the comprehensive utilization of the three industrial wastes; to realize the objective of energy conservation and emission reduction required by the recycle economy, a system technology targeted at comprehensive utilization of the three industrial wastes of factories is adopted; in the invention, the reactor in the nuclear plant, the boiler in the coal-fired power plant and other types of supercritical boilers are utilized to provide a new cooling and turbine drive mode to solve the issue of industrial discharge of greenhouse gas and other polluting gases; in addition, collected emissions are utilized to produce nuclear fuel, compound chemical fertilizer or feedstuff and other chemical raw materials; moreover, to realize recycling of resources and sustainable utilization of energy, the original three wastes are innovatively applied to nuclear electric power generation. The system is characterized by comprising 10 major links and the beneficial effect thereof lies in utilizing new methods to realize energy conservation and emission reduction and production cost in the late stage of production can be reduced.

Owner:李元胜

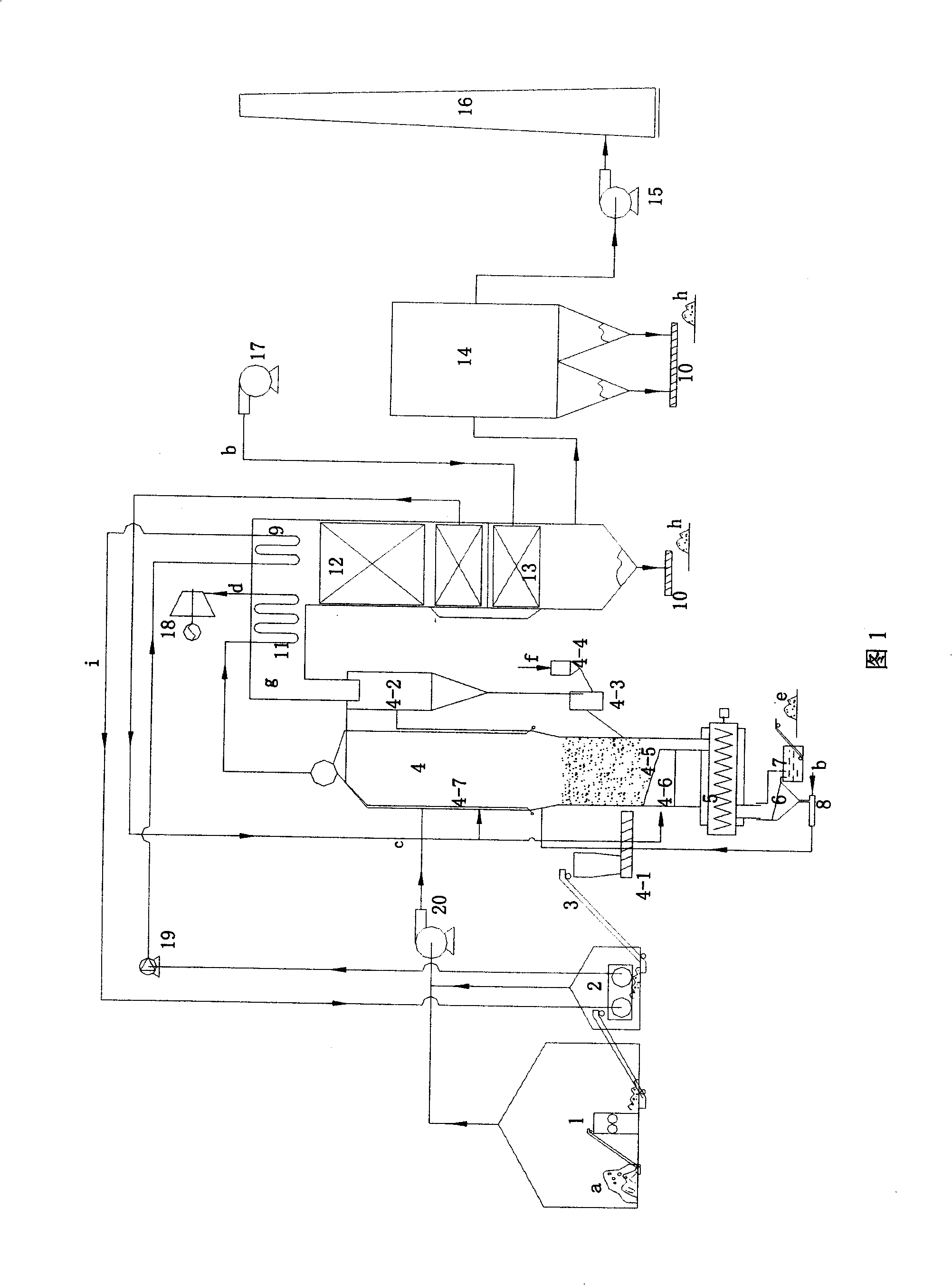

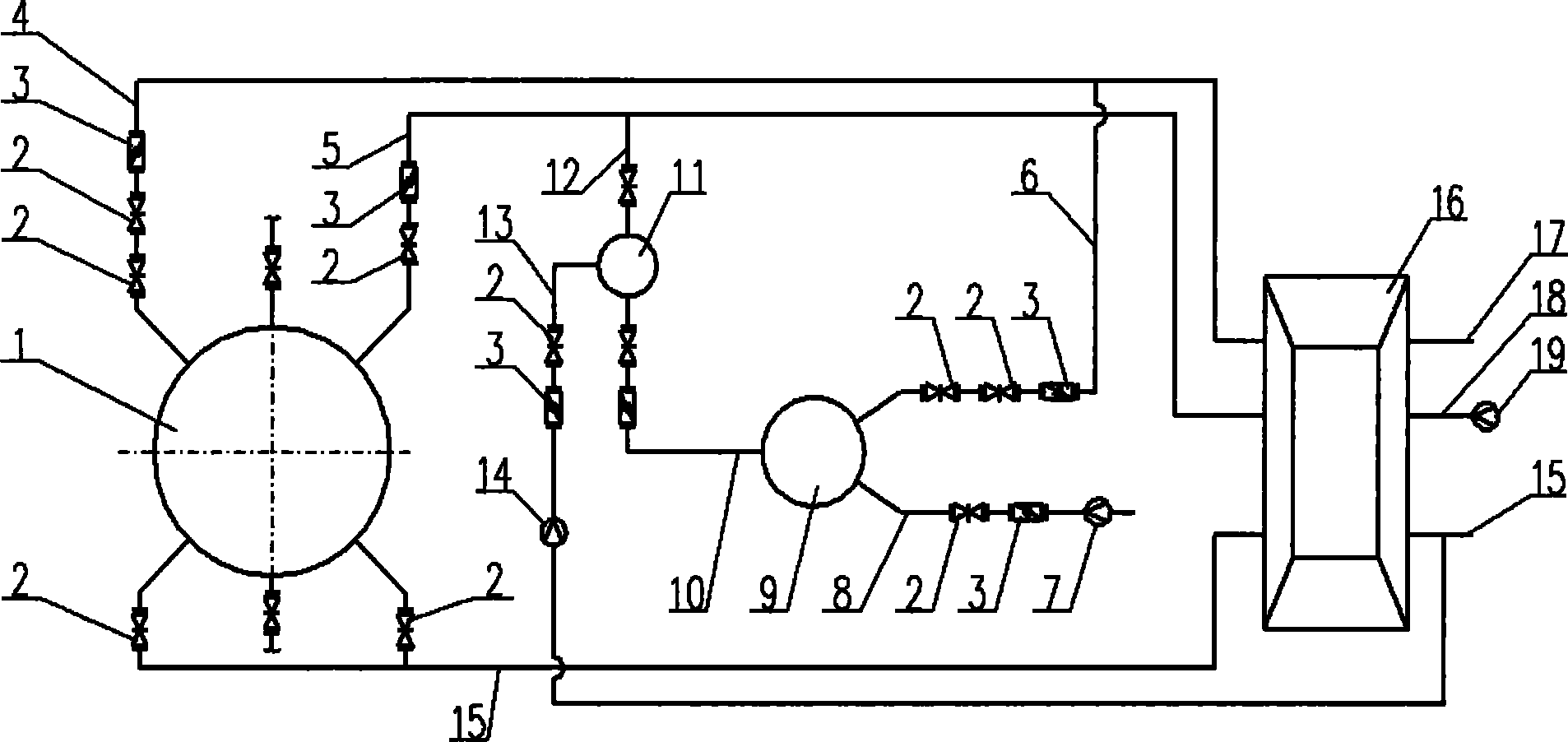

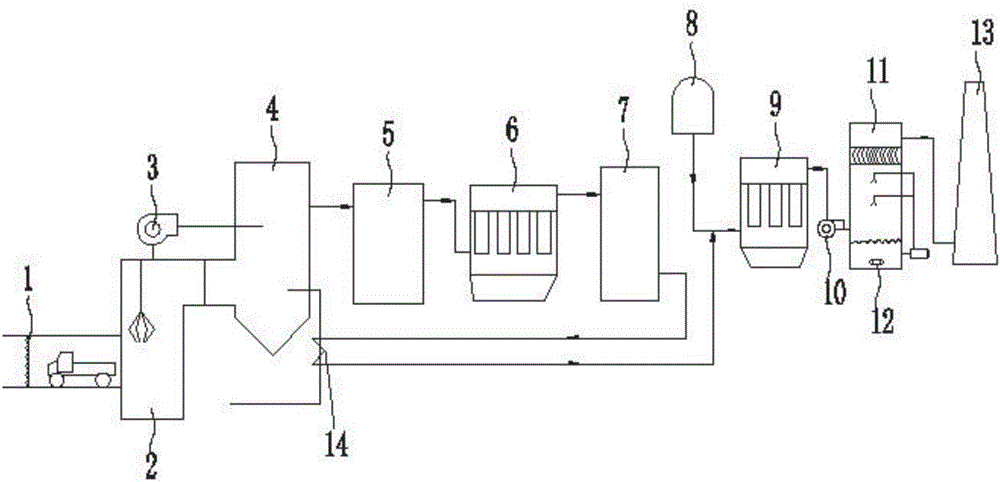

City life rubbish fluidized bed gasification combustion processing method

InactiveCN101294708ASafe and stable operationImprove securityAir supply regulationIndirect carbon-dioxide mitigationSlagHearth

The invention is a fluid bed gasification and combustion processing method for urban garbage. The hearth of a fluid bed garbage furnace (4) is composed of two parts of a low temperature gasification area and a high temperature combustion area, additives (f) such as limestone, kaolin, etc. are added to the garbage furnace (4); acid gases such as chlorine, sulfur, nitrogen, etc. are removed in the furnace; and the generation of dioxin is controlled in the furnace. A water cooling spiral slag cooler (5) and a vibration sieve (6) can be utilized to efficiently reduce heat loss of slag and recycle bed materials. The whole system requires no addition of auxiliary fuel, and has the characteristics of safe reliability, no odor emission, low investment and operating cost, less secondary pollutant discharge, high power generation efficiency, etc.

Owner:SOUTHEAST UNIV +1

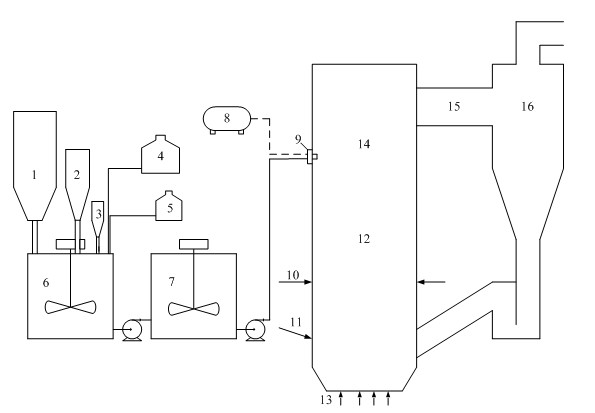

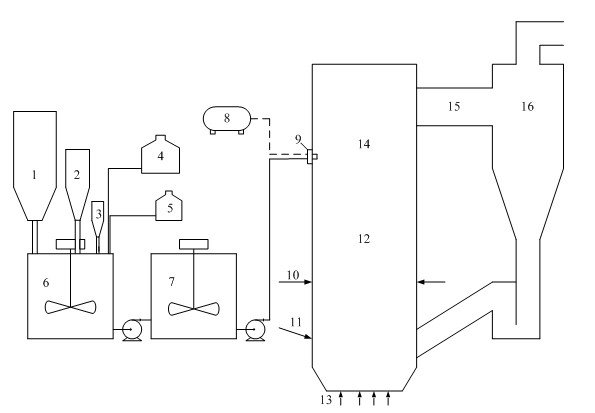

Slurry for desulfuration and denitration of recirculating fluidized bed boiler

ActiveCN102179161AImprove desulfurization effectRealize comprehensive utilizationLighting and heating apparatusDispersed particle separationFluidized bedProcess engineering

The invention discloses slurry for desulfuration and denitration of a recirculating fluidized bed boiler, which comprises desulfurizing agent slurry and a denitrfying agent solution. Composite desulfurizing and denitrfying agent slurry is prepared by adopting a calcium based absorbing agent, an additive, a co-additive and an amino reducing agent according to a certain proportion and programs and used for being atomized and sprayed into a region at the top of the recirculating fluidized bed boiler through a nozzle to react with SO2 and NOx in smoke to generate sulfate and N2. By applying the slurry disclosed by the invention, the problems of low desulfuration efficiency of calcined limestone doped in the recirculating fluidized bed boiler and low utilization rate of the desulfurizing agent are solved, desulfuration and denitration are realized simultaneously, the desulfuration efficiency reaches 85-95 percent and the denitration efficiency reaches 50-70 percent. The slurry has the advantages of low investment and operation costs and convenience for implementation.

Owner:SHANDONG UNIV

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

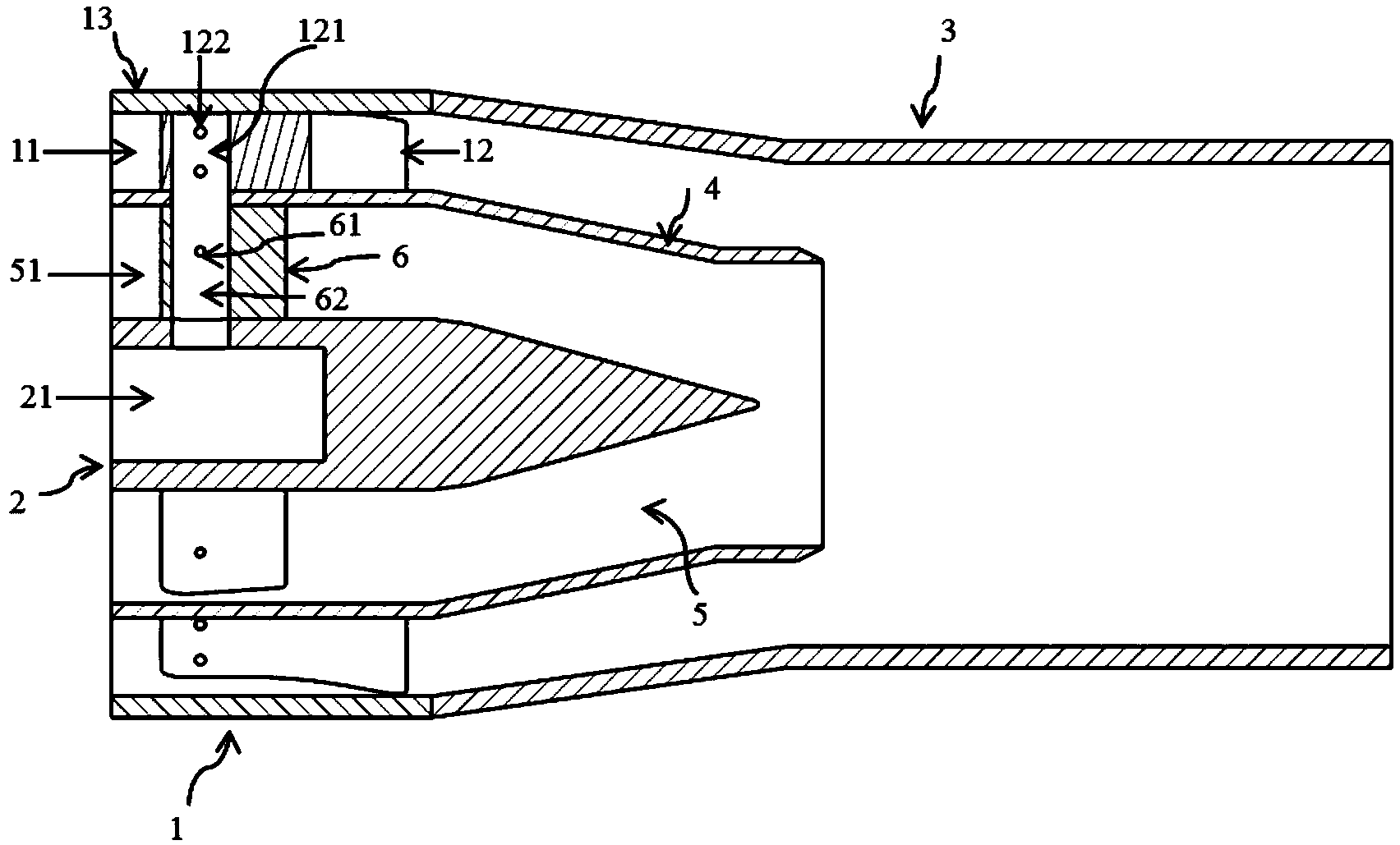

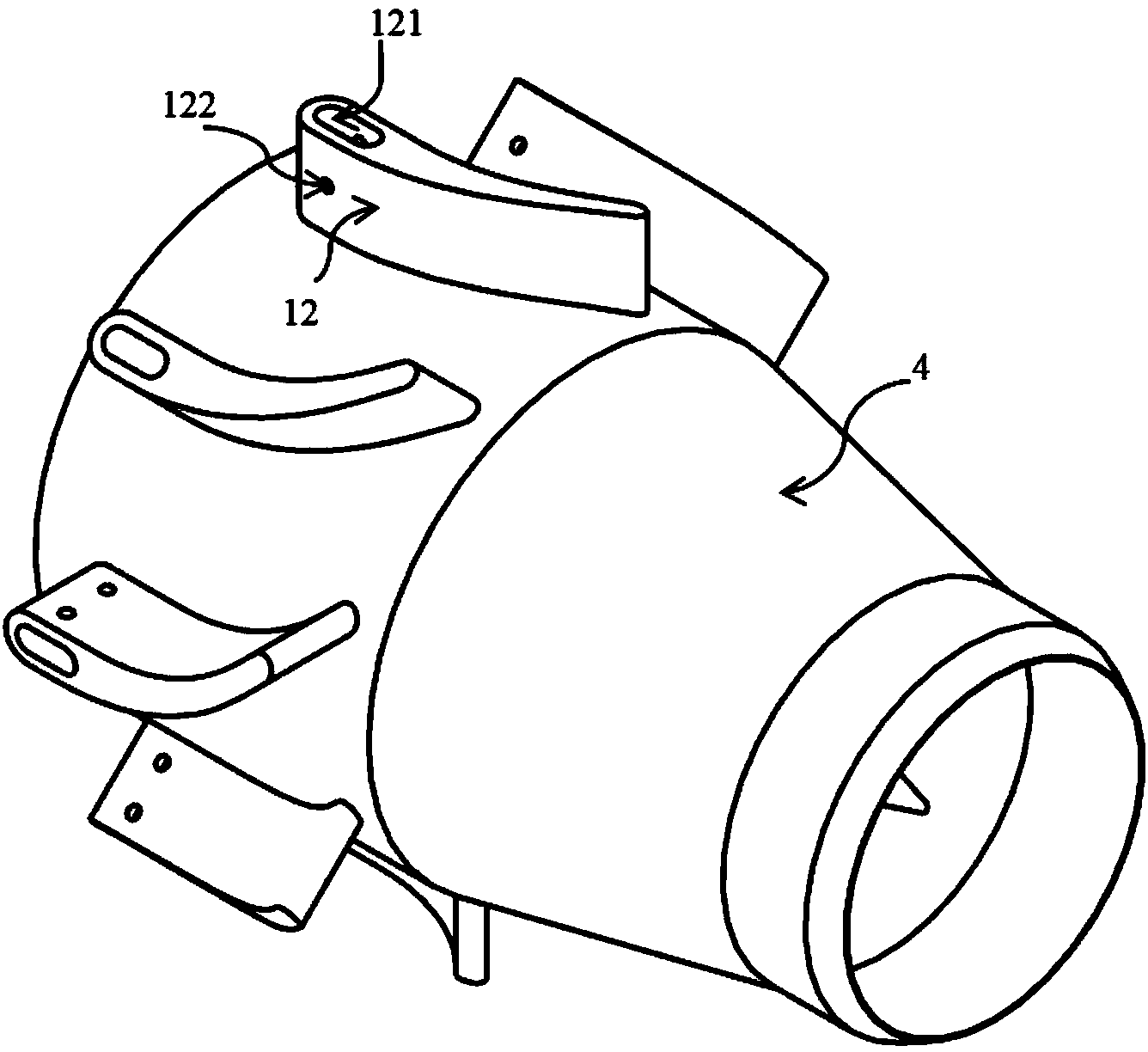

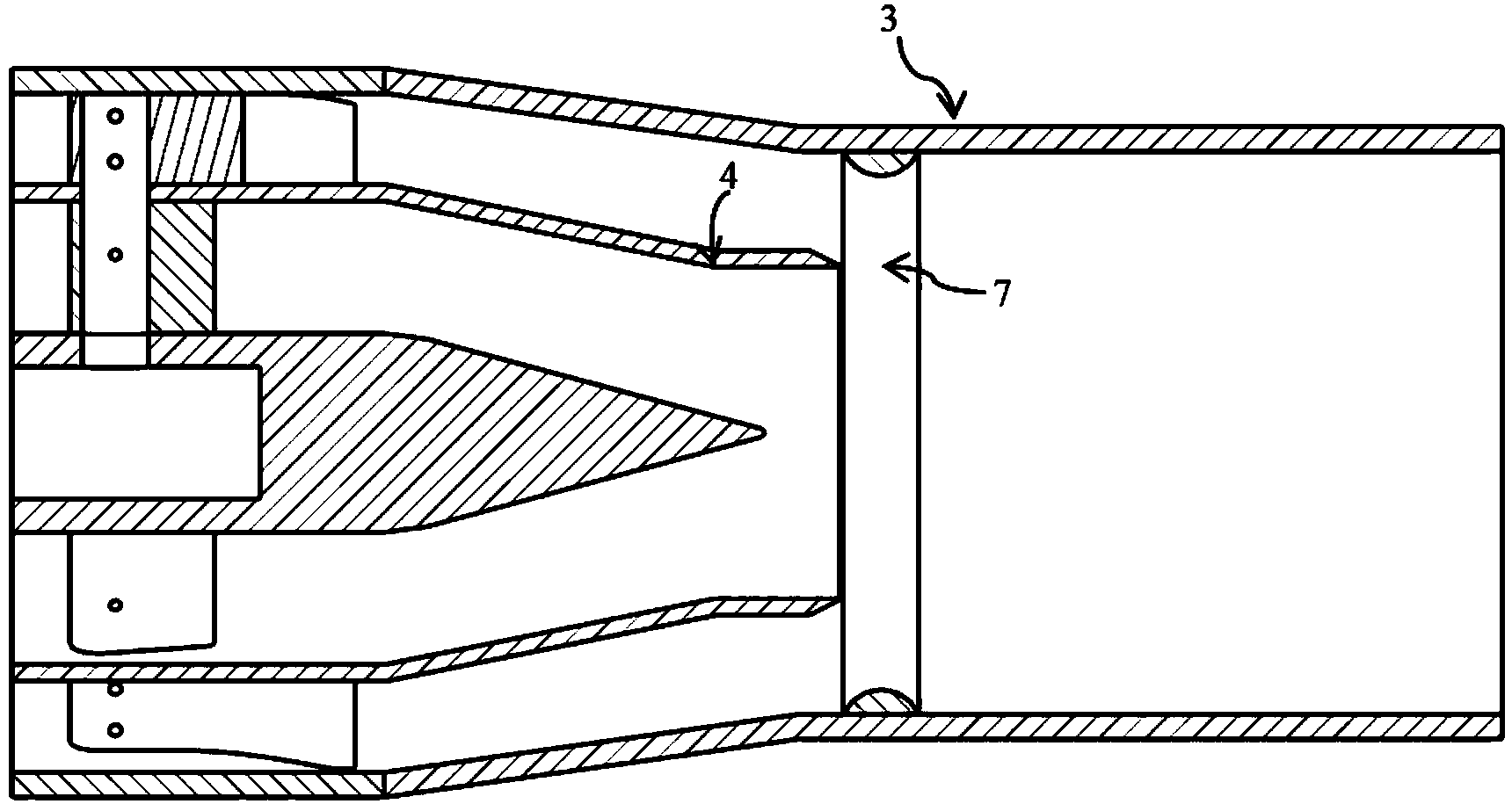

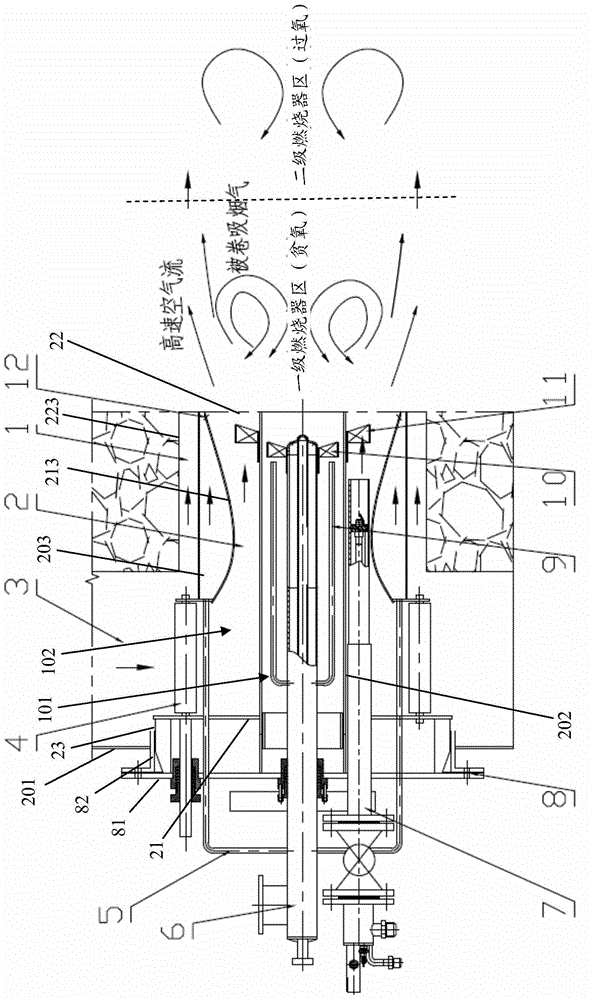

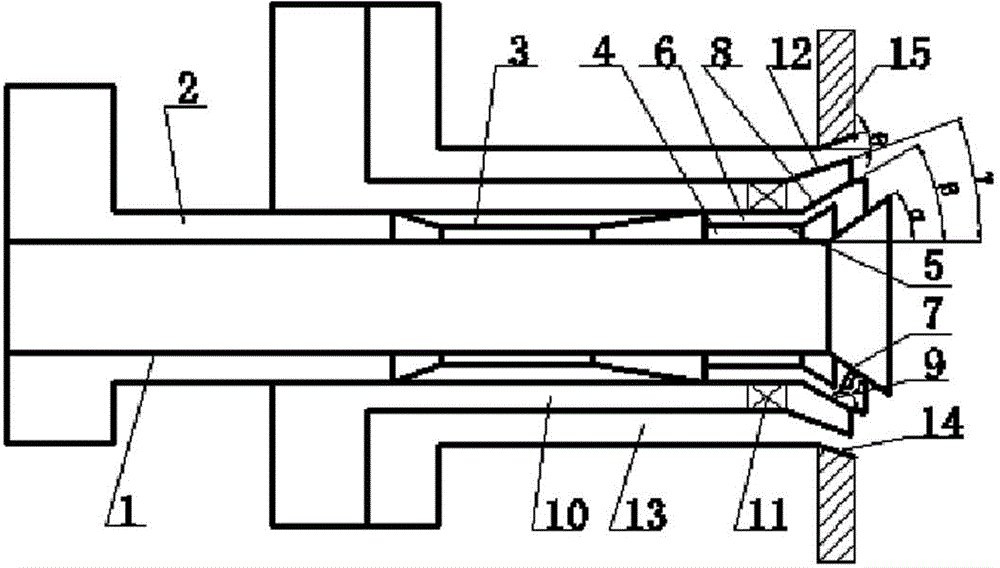

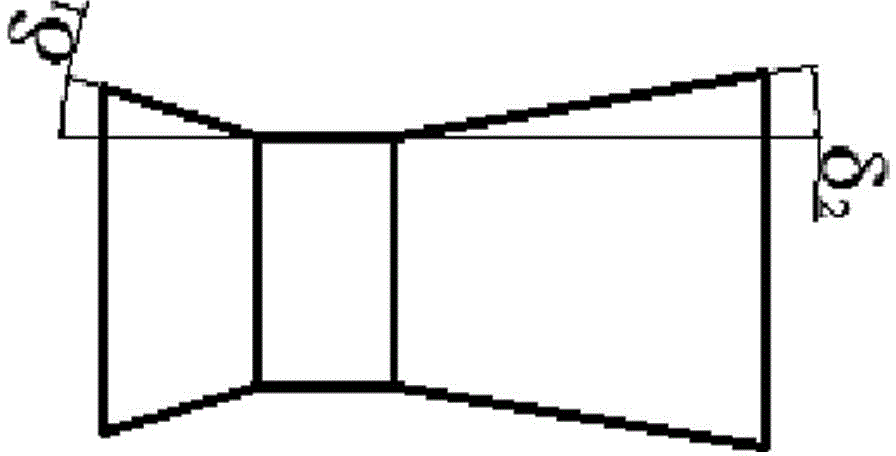

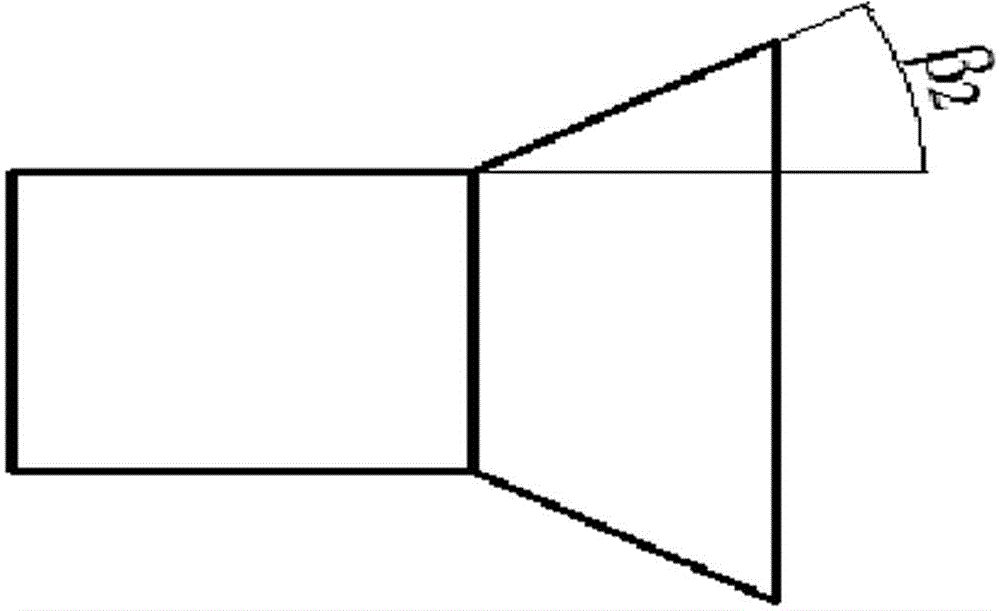

Premixing nozzle of gas turbine combustion chamber

ActiveCN104110699AReduce the low speed zoneEliminate low speed areasContinuous combustion chamberGas turbinesCombustion chamber

The invention discloses a premixing nozzle of a gas turbine combustion chamber and relates to a nozzle structure with axial rotational flow. According to the technical scheme, a gradually-shrinking type annular pipe is arranged between a gradually-shrinking type center body and an axial cyclone, an annular channel is formed between the gradually-shrinking type annular pipe and the gradually-shrinking type center body, an inner-layer air inlet is formed in the front end of the annular channel, and a guide vane is arranged in the annular channel. The guide vane is provided with an inner-layer fuel outlet and an inner-layer fuel channel, and the inner-layer fuel channel is communicated with a center gas fuel inlet and an outer-layer fuel channel. According to premixing nozzle, due to the feature that backfire is prone to occurring in a low-speed area, a layer of irrotational-flow or weak rotational-flow circulation channel is added on the outer side of the gradually-shrinking type center body and on the inner side of the axial cyclone. The low-speed area, caused by the rotating centrifugal force of the cyclone, of the center portion is effectively eliminated, and therefore the backfire problem of premixing combustion can be prevented, the service life of the premixing nozzle can be prolonged, and the use and maintaining cost of the gas turbine combustion chamber can be reduced.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Method for preparing biomass carbon based on waste crop straw

InactiveCN101993701ASolve the problem of the large amount of land required for stackingReduce pollutionBiofuelsSpecial form destructive distillationBiomass carbonRoom temperature

The invention relates to a method for preparing biomass carbon based on waste crop straw. The method comprises the following steps of: (1) cutting the crop straw into straw particles, washing and drying; (2) loading the processed straw particles in a quartz tube of a carbonizing furnace and introducing an inert gas; (3) heating to 350 to 550 DE C from room temperature in an environment with inert gas flow rate of 100mL / min at the heating rate of 25 DEG C / min, maintaining for 1 to 3 minutes, stopping heating, and cooling to the room temperature to obtain solid; and (4) washing and drying the solid obtained in the step (3) to obtain the biomass carbon. The device of the invention is simple in operation, the raw material has low cost and is readily available, and the method is suitable for large-scale industrial production; and the biomass carbon prepared by the method has a high specific area, can be used as a soil modifying agent to improve the fertility of the soil and can also be used as a soil repairing agent to repair the polluted soil, and has good application prospect.

Owner:DONGHUA UNIV +1

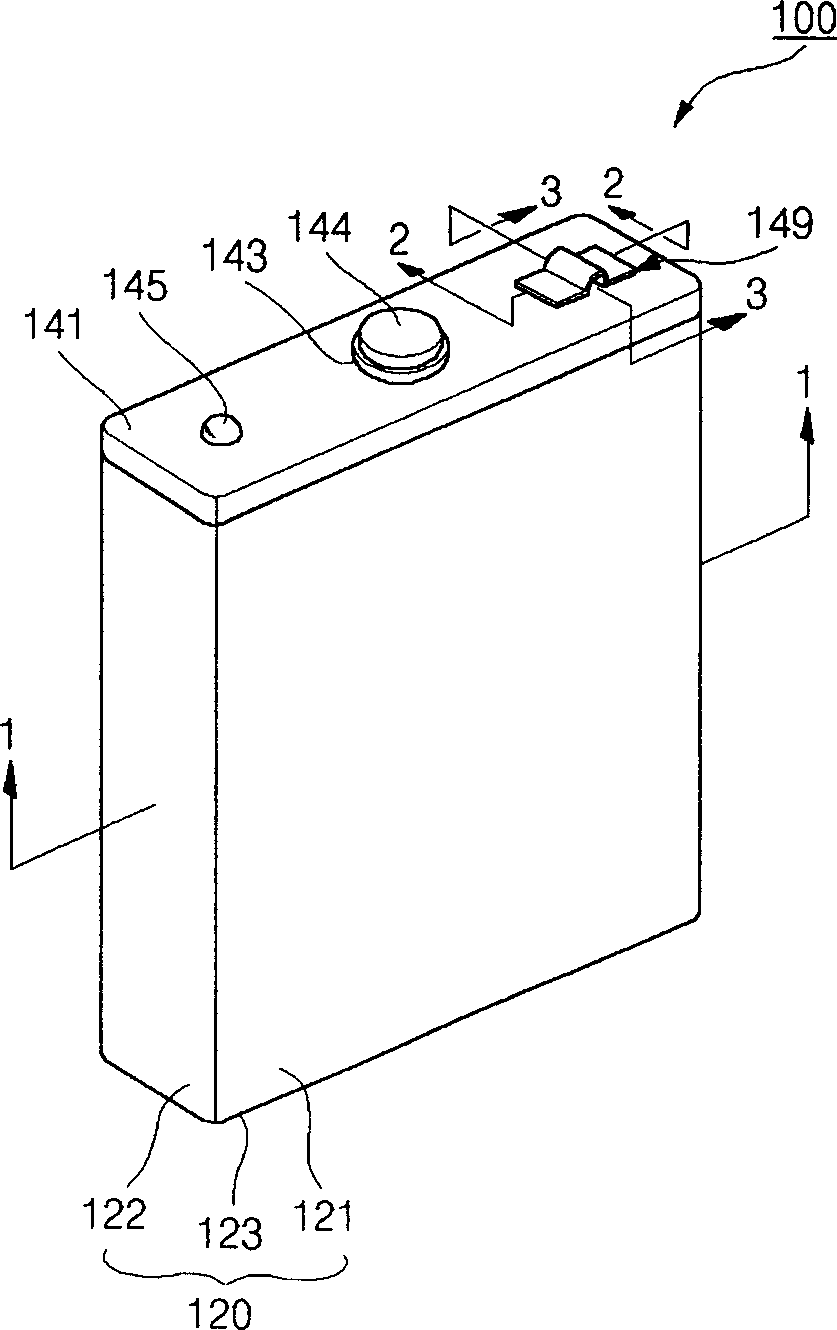

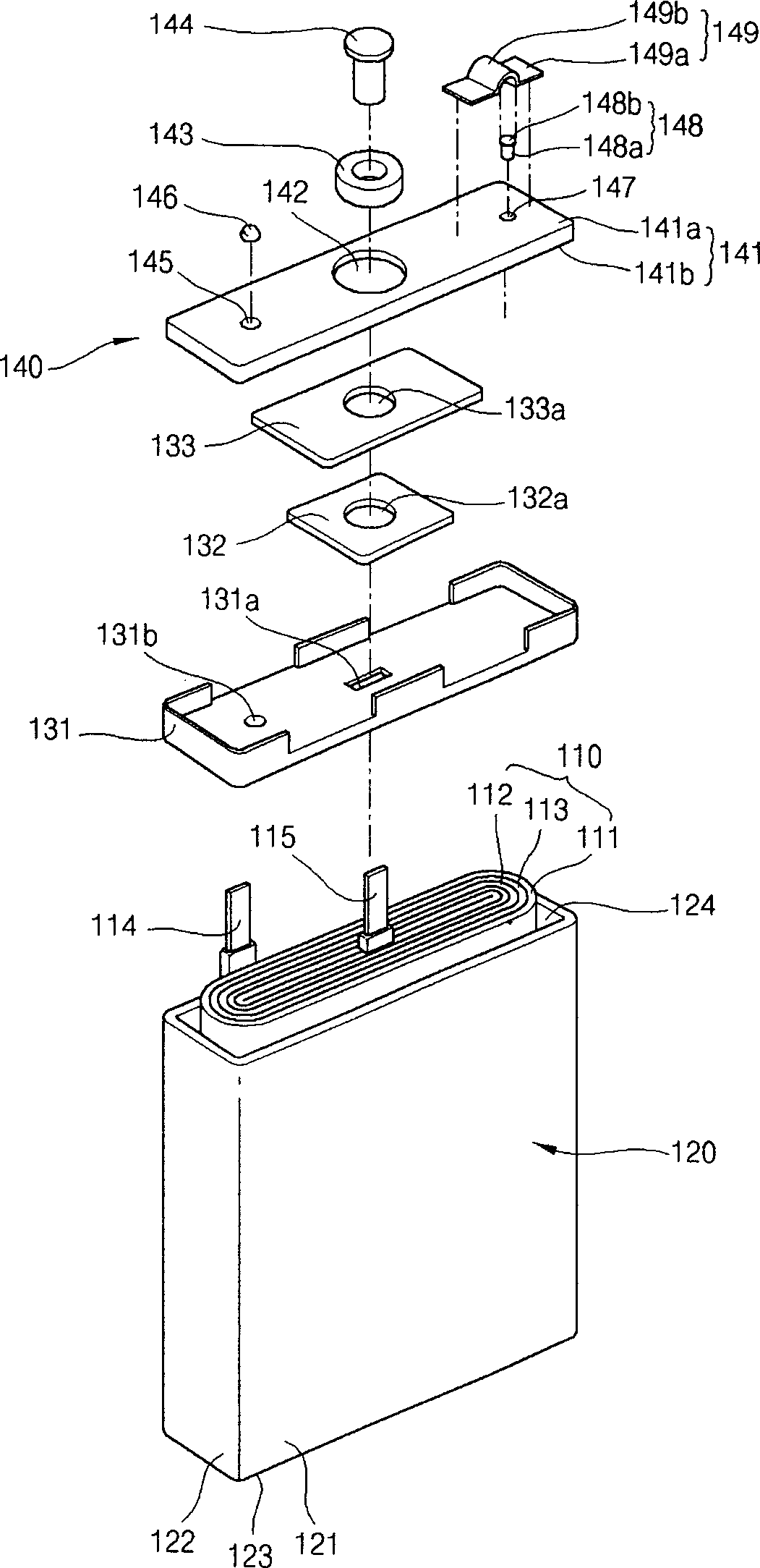

Lithium ion secondary battery having shape memory safety vent

InactiveCN1747198AImprove securityAccurate operationFinal product manufactureCell lids/coversLithiumEngineering

A lithium ion secondary battery has a shape memory safety vent adapted to discharge internal compressed gas by temporarily being opened when the temperature reaches a predetermined level to avoid a swelling phenomenon of the battery and improve safety. The lithium ion secondary battery includes an electrode assembly having first and second electrode plates wound a number of times with a separator interposed between them; a can having an opening formed on a side thereof to contain the electrode assembly; and a cap plate adapted to cover the can and provided with a vent hole on a side thereof, to which a safety vent adapted to deform at a predetermined temperature and discharge gas from inside the can to the exterior is coupled.

Owner:SAMSUNG SDI CO LTD

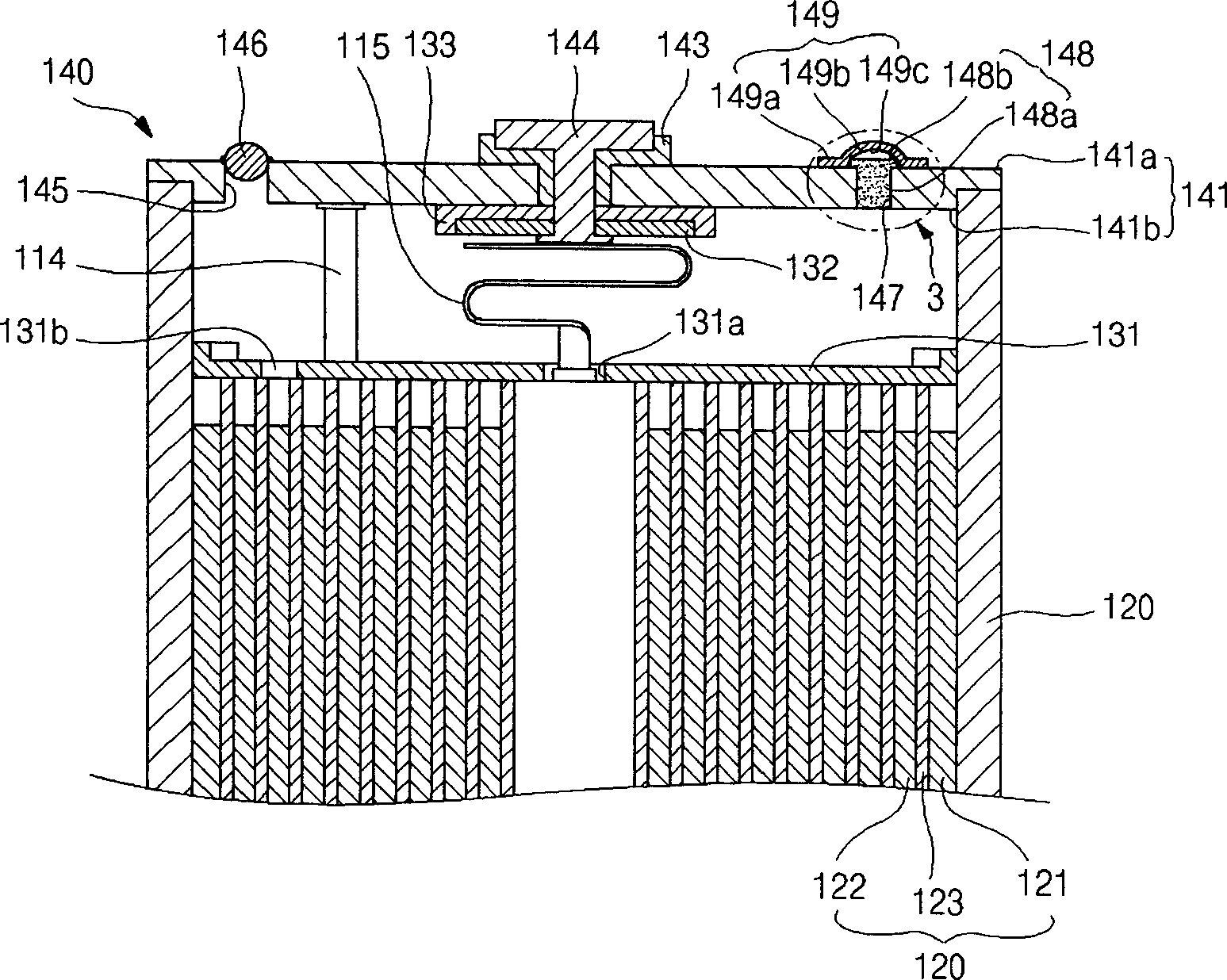

Improved heat integration coal-fired power plant decarbonization system and method

InactiveCN103272467ARealize the integration of power generation and decarbonizationReduce power generation efficiencyDispersed particle separationSteam useReboilerHigh energy

The invention discloses an improved heat integration coal-fired power plant decarbonization system and method, belonging to the technical field of energy conservation and emission reduction. The system mainly consists of two parts, namely a power plant steam turbine power generation unit and a CO2 capturing unit, wherein the two units are communicated through a cooler at the top of an analytic tower, a reboiler and a multi-stage compression cooled heat exchanger. According to the system, the low-pressure cylinder safety performance of the CO2 capture power plant is guaranteed; and meanwhile, due to the integration of the power plant steam turbine power generation unit and the CO2 capturing unit, the steam turbine power generation unit extracts steam and recovers the pressure energy through a small steam turbine, and the heat released by the CO2 capturing unit heats condensate water in the power plant through the cooler at the top of the analytic tower and the multi-stage compression cooled heat exchanger, so that the CO2 capture energy consumption is greatly reduced. According to the integration system, the safety operation of the CO2 capture power plant is guaranteed, the gradient energy utilization is realized, the CO2 emission can be effectively suppressed, the energy consumption of carbon emission reduction is reduced, and high energy utilization efficiency and technical and economic performance are obtained.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

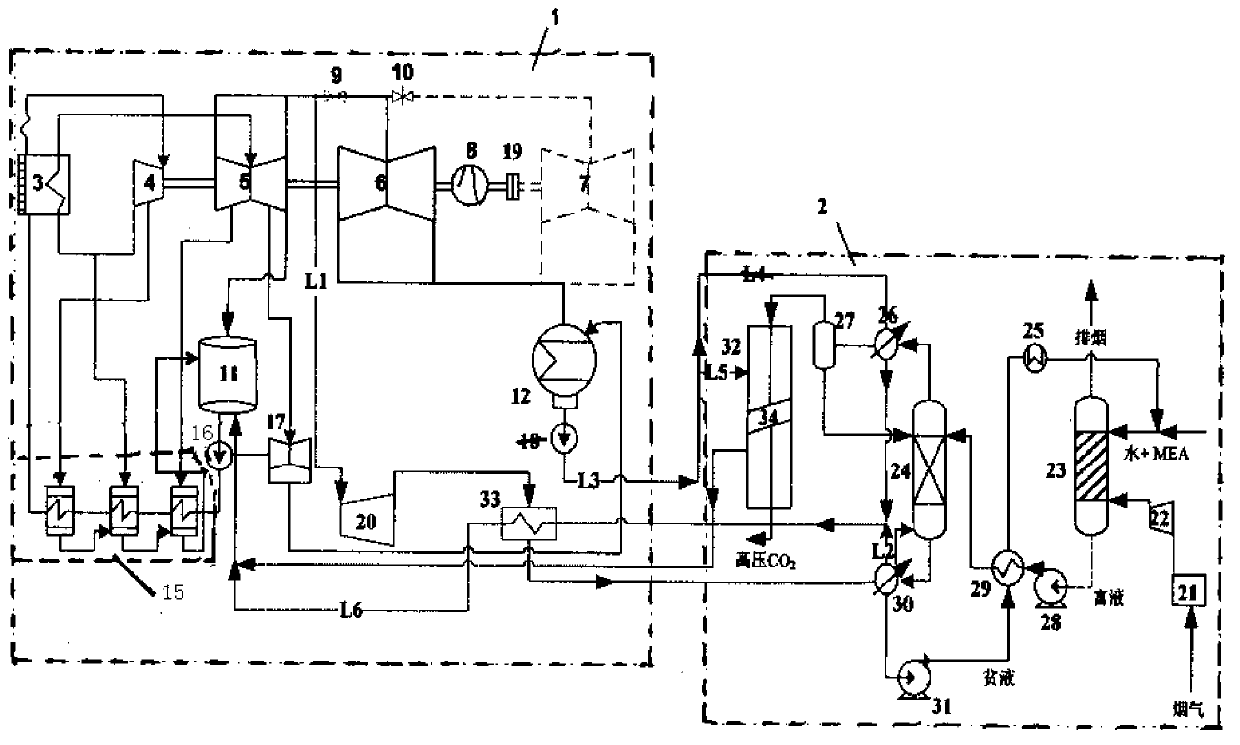

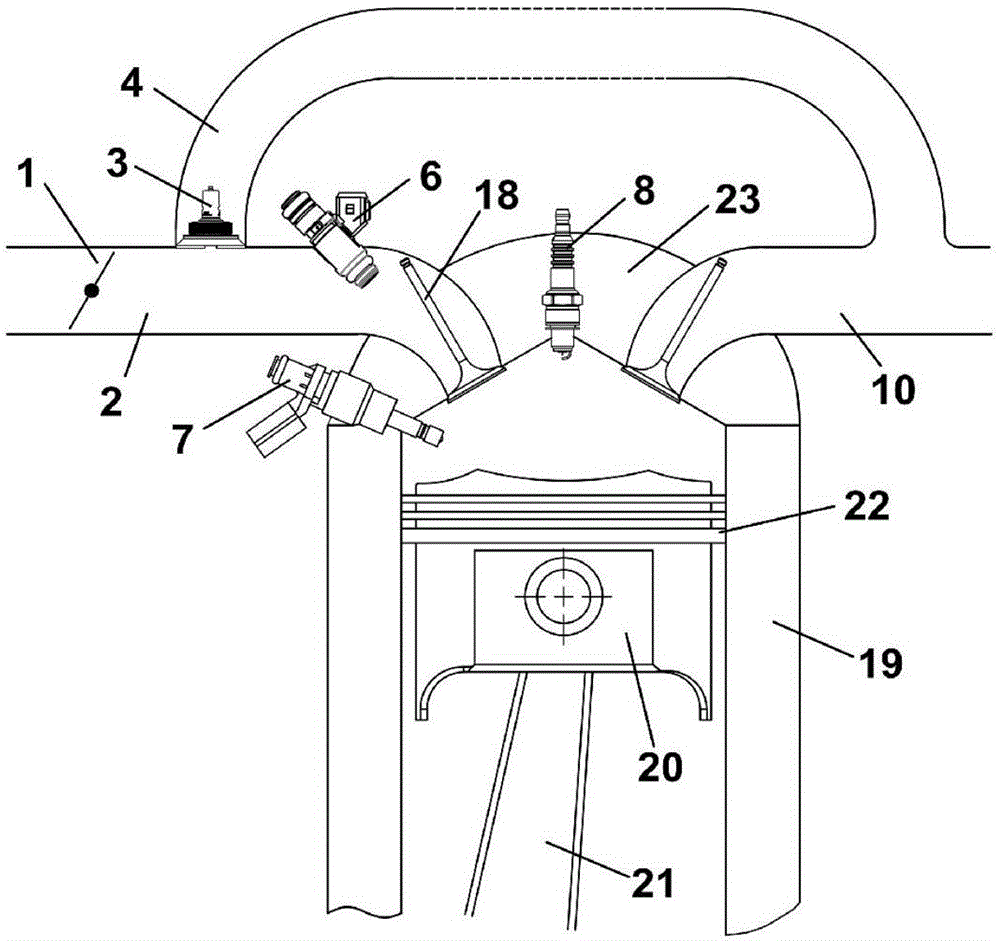

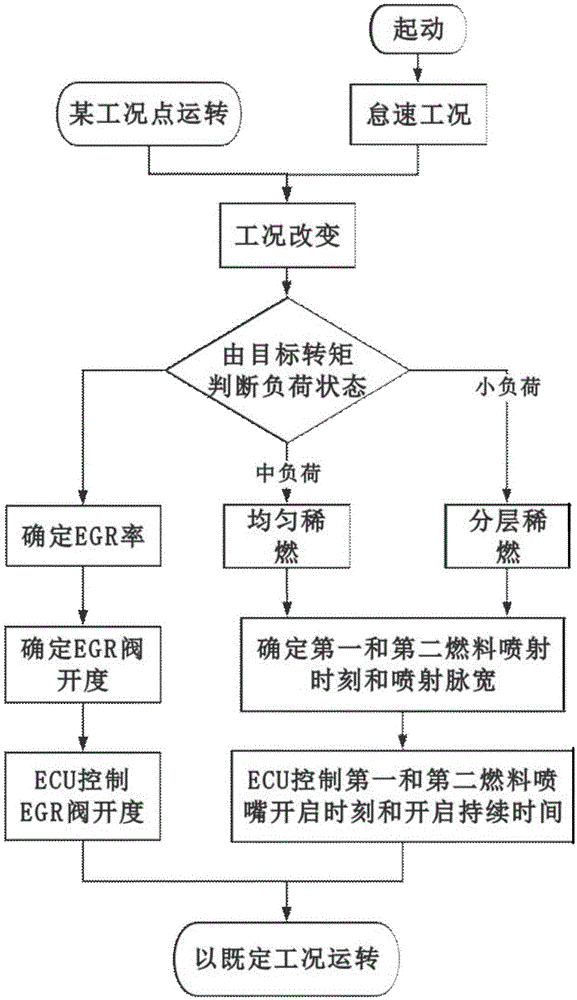

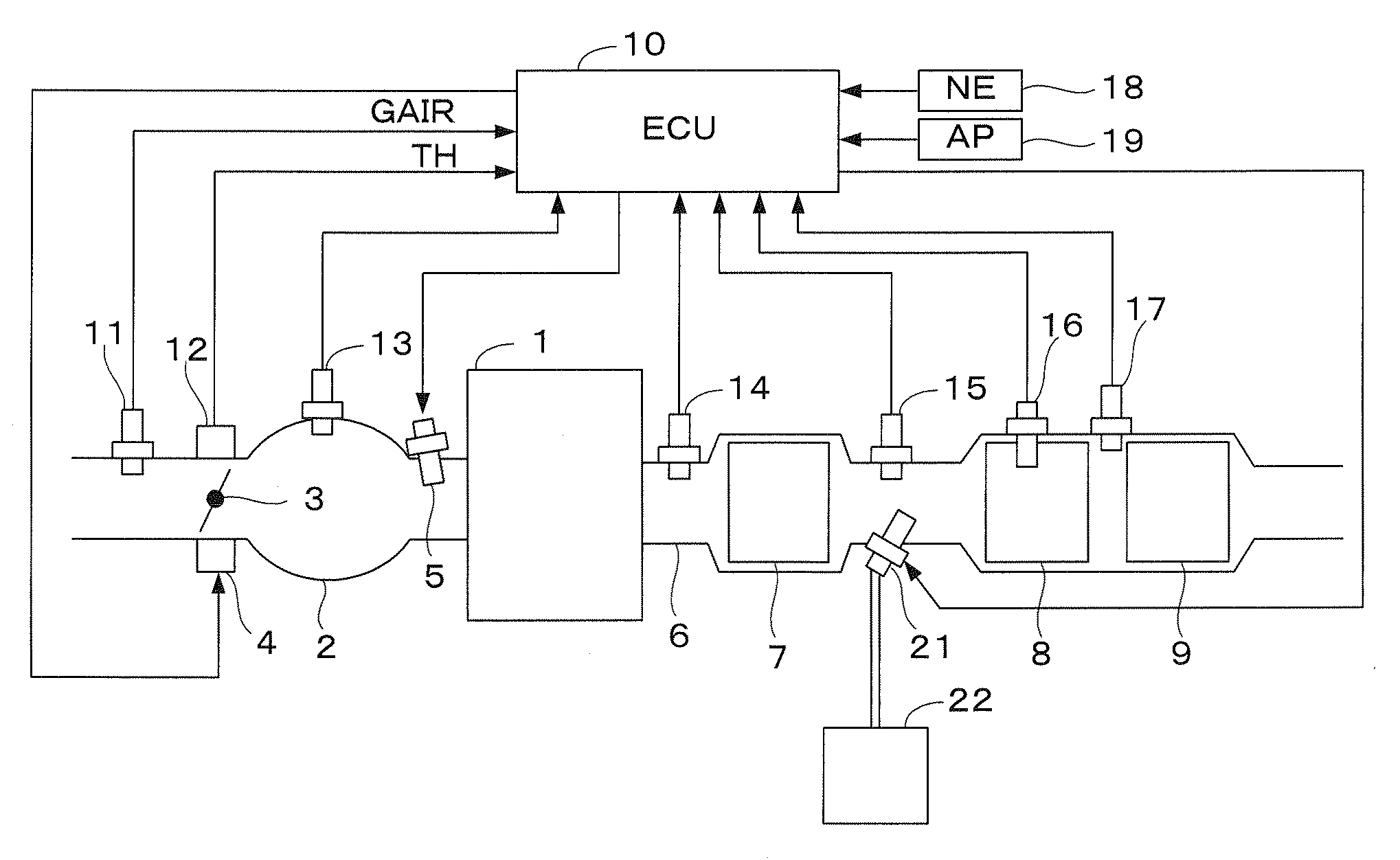

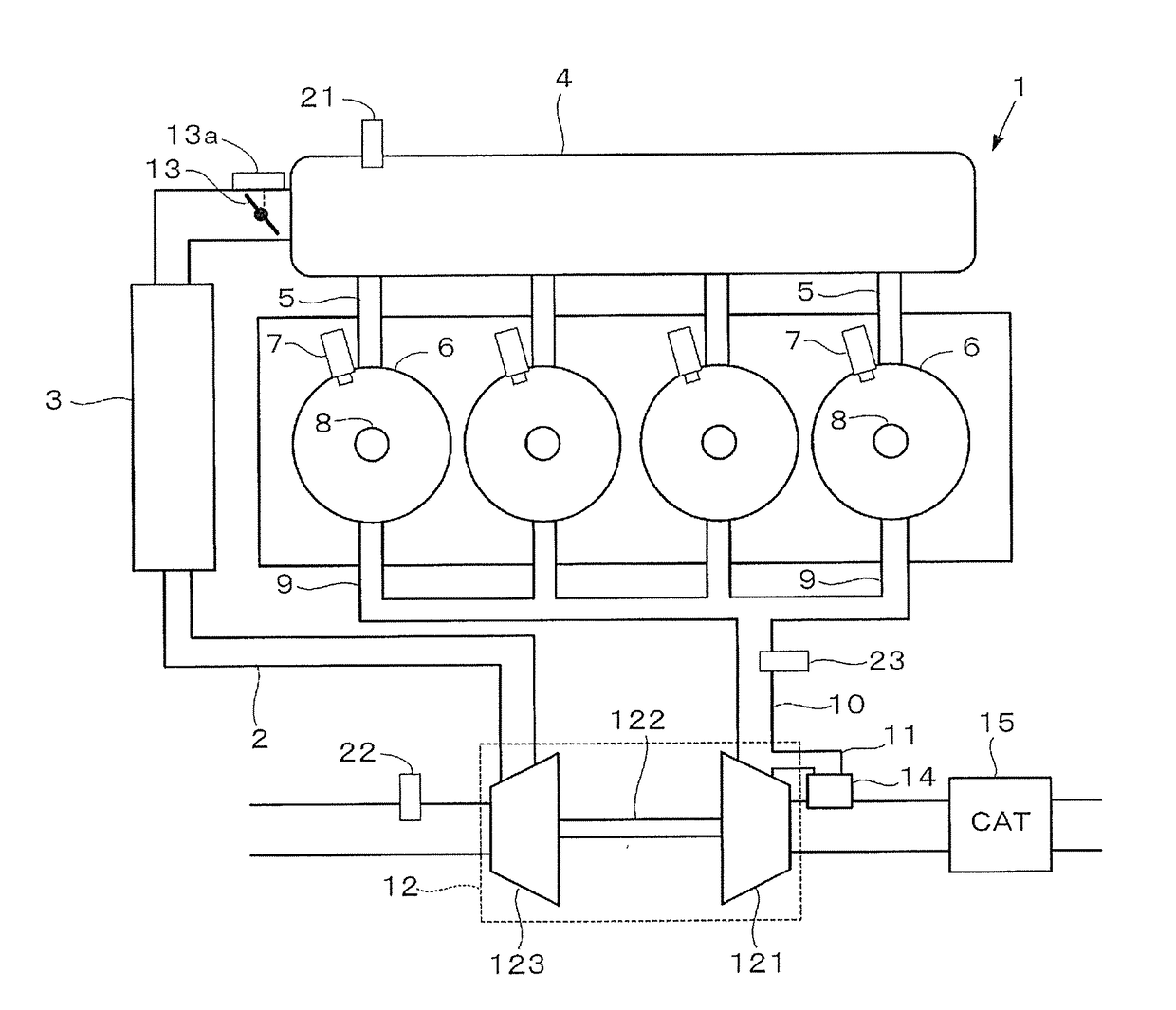

Lean-burn gas duel-fuel spark-ignition-type internal combustion engine based on EGR system and control method

InactiveCN105114174AReduce lossesCurb emissionsElectrical controlNon-fuel substance addition to fuelExternal combustion engineExhaust gas recirculation

The invention relates to a lean-burn gas duel-fuel spark-ignition-type internal combustion engine based on EGR (Exhaust Gas Recirculation) system and a control method, and can solve the problems of unstable combustion, high NOx emission and the like of a gas fuel spark-ignition-type internal combustion engine caused during lean burn. Based on the in-fuel-gas-cylinder direct injection and inlet duct spray combined duel-fuel spark-ignition-type internal combustion engine technology and the EGR technology, the internal combustion engine and the control method ensure that the duel-fuel spark-ignition-type internal combustion engine can realize stable and efficient lean burn and reduce the phenomena of cyclical variation and fire accident at a high compression ratio; meanwhile, part of exhaust gas is re-guided into the cylinder to participate in combustion, the EGR ratio is changed according to the requirements of working conditions, the in-cylinder combustion temperature is lowered, and the generation of NOx is inhibited; and besides, as lean burn and EGR co-exist, the opening degree of a throttle valve can be increased and the pumping loss is reduced. In conclusion, reduction of energy consumption and super-low emission of pollutants can be fundamentally realized.

Owner:JILIN UNIV

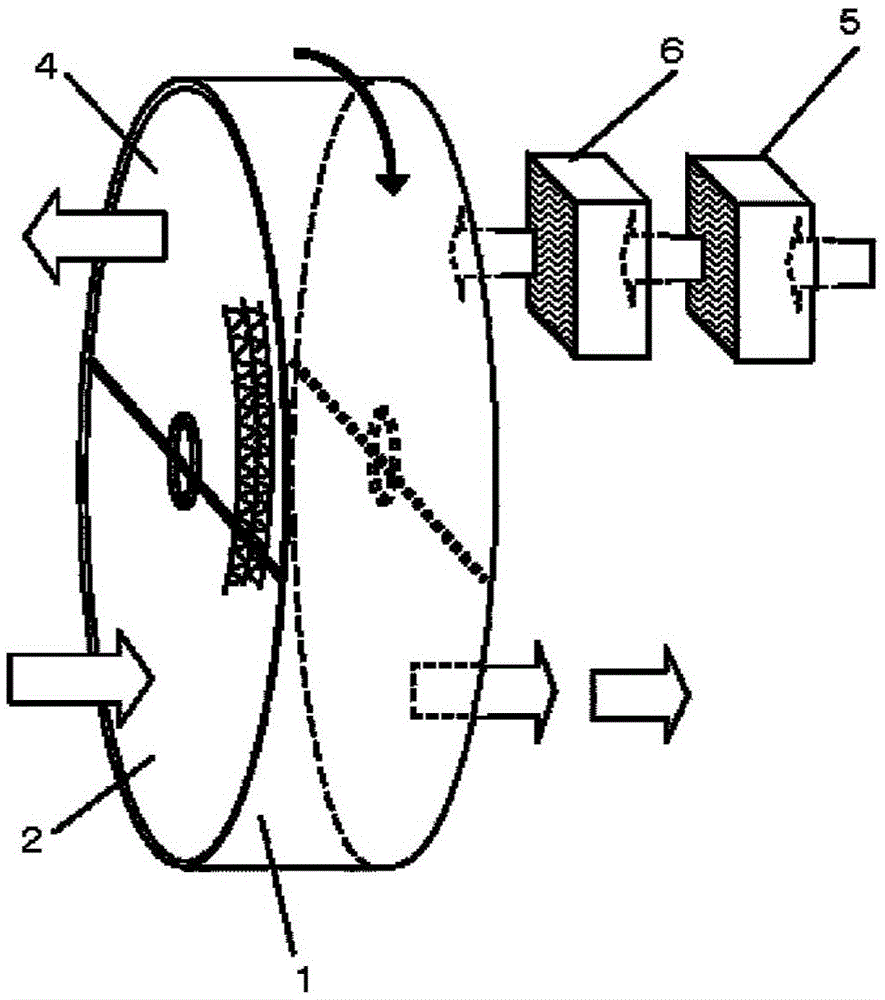

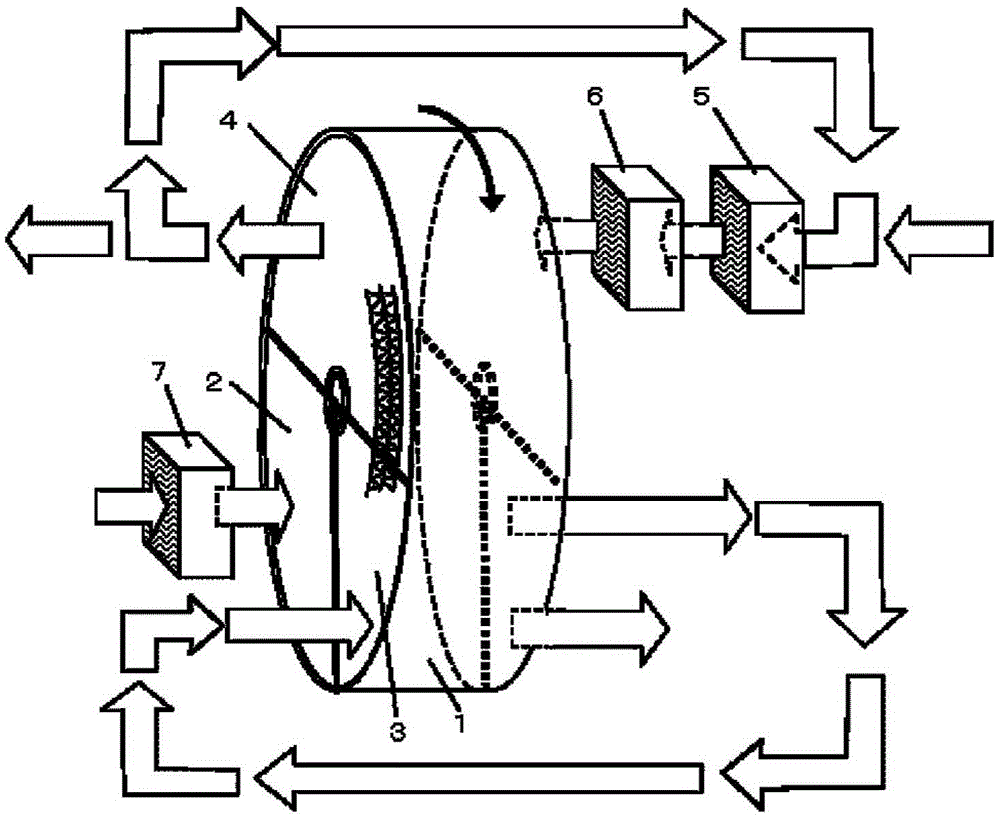

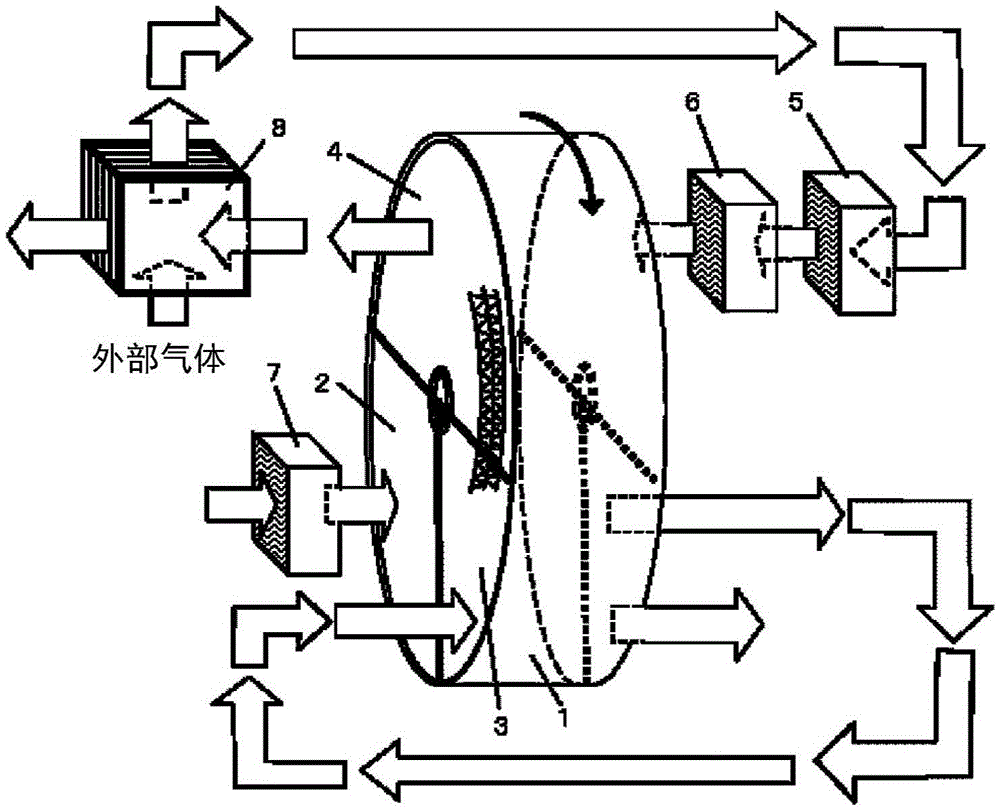

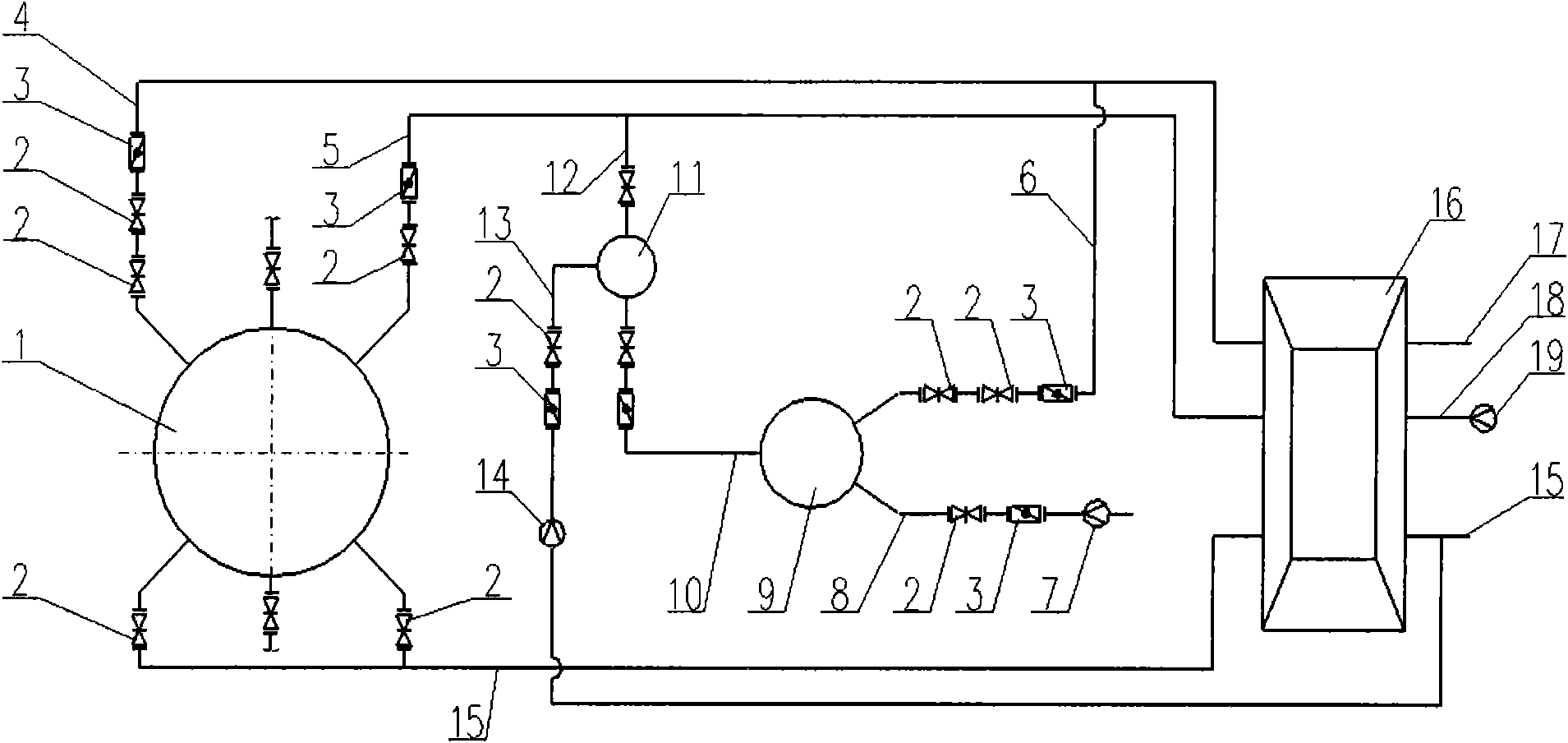

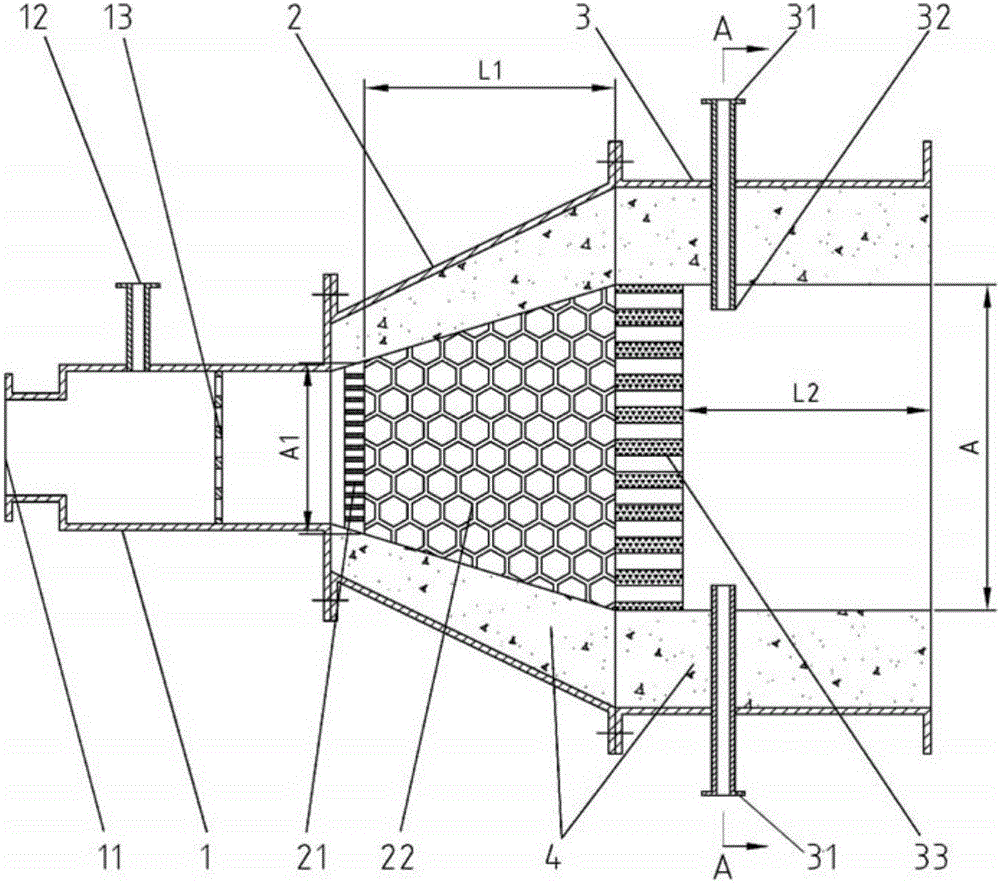

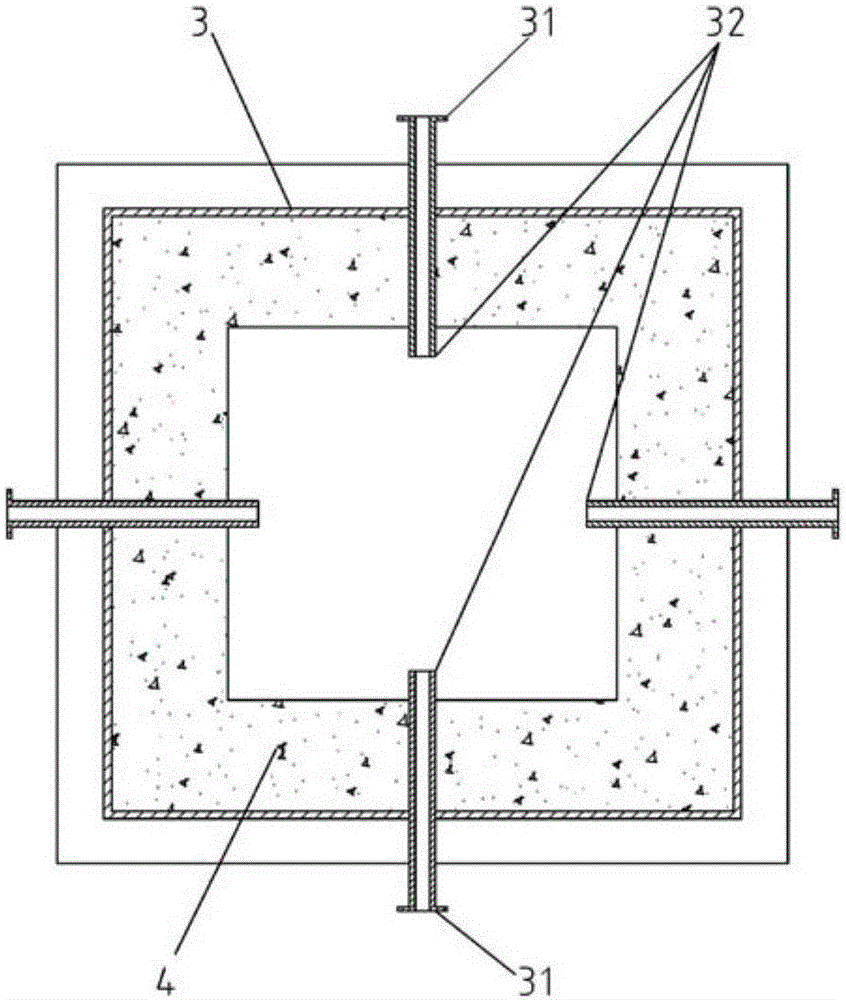

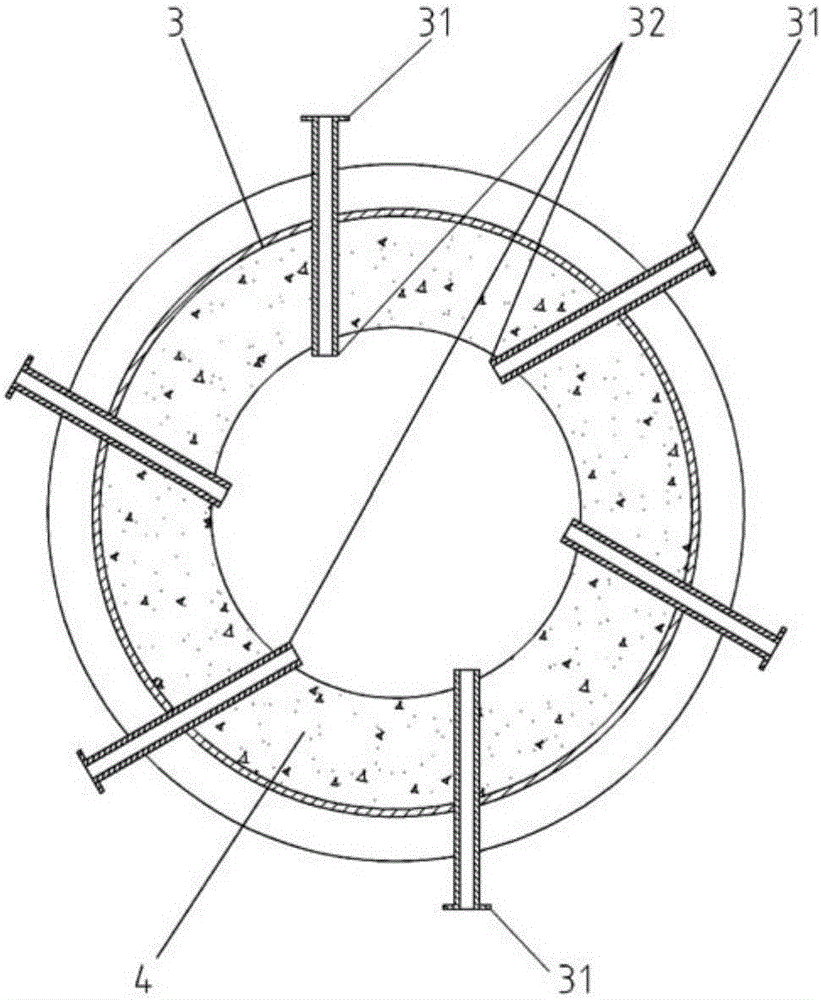

Absorption Type-Removal/Condensing Apparatus

ActiveCN105709563AGood removal effectImprove concentrationGas treatmentDispersed particle separationHoneycombRelative humidity

The invention provides an absorption type-removal / condensing apparatus for removing or condensing carbon dioxide with high recovery efficiency comprises: a honeycomb rotor which has an absorption function of carbon dioxide as an amine support solid absorbent, said honeycomb rotor being divided into a processing zone and a reproduction zone at least, carbon dioxide being removed from subject air to be processed by making a maintenance absorbent of a rotor portion absorb the carbon dioxide contained in the air to be processed by ventilating the subject air to be processed through said processing zone, and the carbon dioxide absorbed in said processing zone by the maintenance absorbent being made to be contained into the air to be reproduction by ventilating the air to be reproduced through said reproduction zone to reproduce the maintenance absorbent of said rotor portion, wherein said apparatus has a humidity adjustment device which makes high a relative humidity of any of the air to be reproduced ventilated through said reproduction zone and the air to be processed ventilated through the processing zone or both, so that absorbing performance and condensing performance are improved.

Owner:SEIBU GIKEN CO LTD

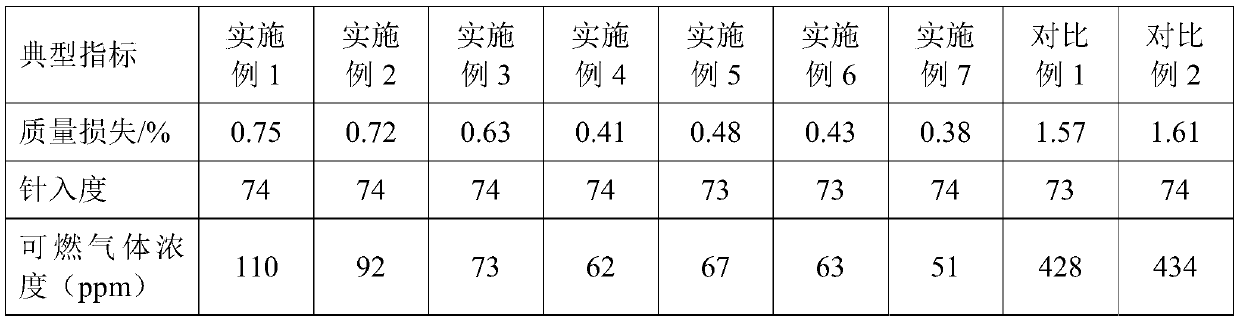

Smoke suppressing and deodorizing additive, preparation method thereof and modified asphalt

ActiveCN109749466AReduce generationEmission reductionBuilding insulationsOdor sourceMetal-organic framework

The invention discloses a smoke suppressing and deodorizing additive, a preparation method thereof and a modified asphalt. The smoke suppressing and deodorizing additive is composed of free radical capturing agent, metal-organic framework compounds, inorganic adsorbing materials, reaction type odor inhibitor and base materials. According to the s smoke suppressing and deodorizing additive, the free radical capturing agent has termination reaction with micromolecular free radicals to reduce micromolecular volatile gas produced by free radical reaction; the metal-organic framework compounds canefficiently selectively adsorb and reduce discharged multiring hydrocarbon sulfur-containing thiophene materials; the inorganic adsorbing materials can enhance interaction between volatile organic compounds and an asphalt matrix to reduce overall emission; the reaction type odor inhibitor reacts with mercaptan in asphalt to reduce mission of one of odor sources, namely mercaptan, as well as hydrogen sulfide. Testing results show that by adding in the smoke suppressing and deodorizing additive, the smoke volatile amount of the asphalt at 180 DEG C is reduced by 70-88%, and emission of pollutants and odor sources can be significantly reduced.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

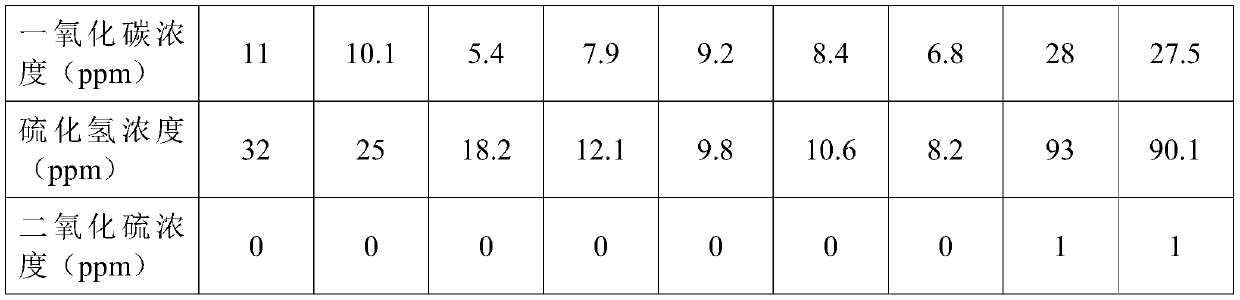

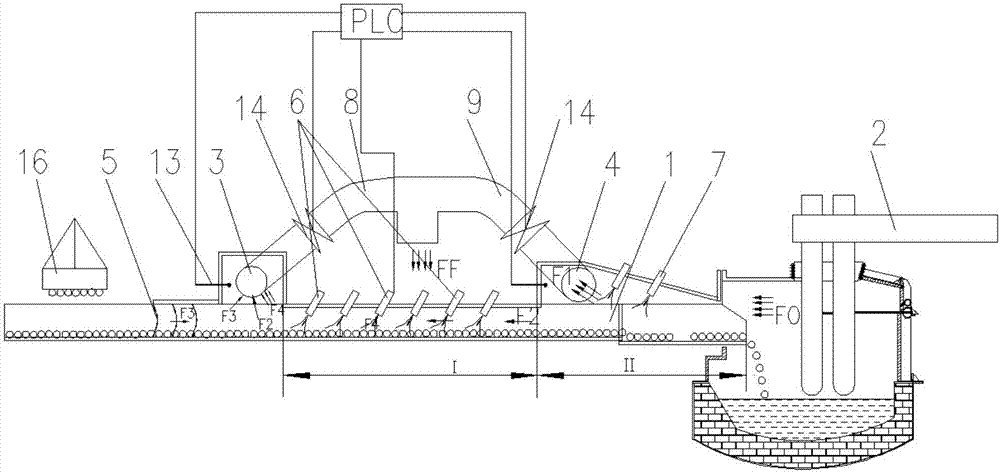

Horizontal continuous feeding and preheating device and strengthened preheating method thereof

ActiveCN107460274AImprove combustion thermal efficiencyImprove heat transfer effectCharge manipulationPreheating chargesCold airElectric arc furnace

The invention belongs to the field of metallurgical technologies and discloses a horizontal continuous feeding and preheating device and a strengthened preheating method of the horizontal continuous feeding and preheating device. According to the scheme, two dust removal openings are correspondingly formed in the front portion and the rear portion of a horizontal continuous feeding and preheating duct, and the horizontal continuous feeding and preheating duct is divided into a strengthened preheating region and a smoke preheating region by the front dust removal opening and the rear dust removal opening; burners are mounted in the strengthened preheating region, and the two dust removal openings are correspondingly connected with smoke adjustment distributors through smoke pipelines; the dust removal negative pressure of the second dust removal opening is balanced by the jet flow dynamic pressure of the multiple rows of bruners in the strengthened preheating region; and the micro-negative pressure requirement of the first dust removal opening is controlled through a pressure sensor, so that the mixing amount of cold air of the first dust removal opening is reduced, the preheating efficiency of the burners and smoke of an electric arc furnace on steel scrap is improved, and the production is more environmentally-friendly.

Owner:CISDI ENG CO LTD +1

Energy-saving environment-protective methanol gasoline for vehicle and preparation thereof

InactiveCN101372636ACurb emissionsLower free energyLiquid carbonaceous fuelsGasolinePollutant emissions

The invention relates to an energy-saving and environment-friendly vehicle methanol gasoline and a preparation method thereof, belonging to the technical field of alternative energy sources. The vehicle methanol gasoline is prepared by the following materials by weight percentage: 30-88.5% of white gasoline component oil, 10-55% of methanol and 1.5-15% of composite additive; the composite additive is composed of the following components: 60-77.5% of latent solvent, 17-30% of heat value enriching substance, 0.08-1.3% of power synergistic agent, 3.5-10% of homogeneous catalysis combustion improver, 0.6-3.0% of corrosion and swelling inhibitor and 1.5-3.5% of vapor pressure regulator, after being evenly mixed, the materials are added into 10-55% of methanol, after being slightly stirred, the mixture is filled in 30-85.5% of white gasoline, evenly stirred and is subject to static reaction for 4-8 hours. The methanol gasoline can effectively solve the technical difficult problems of power reduction, high gasoline consumption, corrosiveness, swelling, difficult cold start, high-temperature air resistance, and the like, when the content of methanol gasoline is 10-55%; the vehicle methanol gasoline can be directly used on automobiles, while engines do not need to be modified; the vehicle methanol gasoline can also be mixed or interchanged with white gasoline and ethanol gasoline for application. The invention has the advantages of easily available raw materials, low cost, simple preparation technique and significant energy-saving benefit, and can greatly reduce tail gas pollutant emission.

Owner:TIANJIN LANDUN PETRO CHEM TECH

Low-nitrogen-oxide gas combustor and combustion method of combustor

ActiveCN104595900AUniform flame temperatureSuppression of nitrogen oxide emissionsGaseous fuel burnerNitrogen oxidesProcess engineering

Owner:SHANGHAI HANZHUO ENERGY TECH

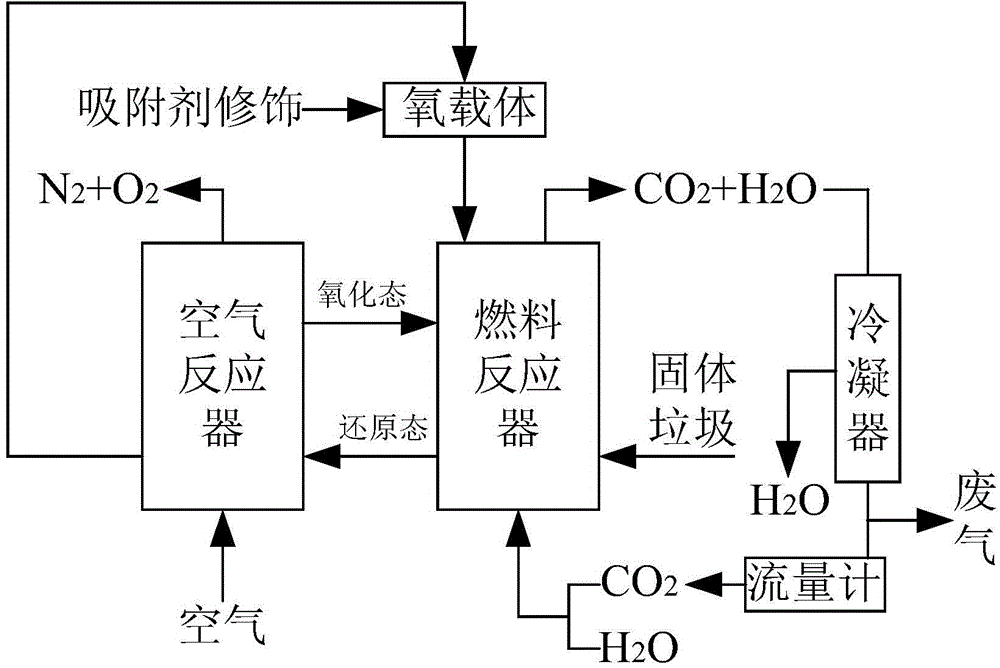

Method for treating solid waste in low-carbon mode and restraining generation of dioxin

ActiveCN104930518AReduce carbon emissionsAchieve recyclingIndirect carbon-dioxide mitigationIncinerator apparatusCarbon dioxideSorbent

The invention discloses a method for treating solid waste in a low-carbon mode and restraining generation of dioxin. The method for treating solid waste in the low-carbon mode and restraining generation of dioxin comprises the following steps that S1, solid waste is smashed; and S2, chemical looping combustion treatment is conducted on the smashed solid waste, wherein the chemical looping combustion temperature ranges from 800 DEG C to 1000 DEG C, oxygen carriers modified through an adsorbing agent is used for chemical looping combustion, the particle sizes of the oxygen carriers modified through the adsorbing agent is 0.1 mm-0.3 mm, the adsorbing agent can adsorb and fix gaseous chlorine elements and condensate and capture carbon dioxide obtained during chemical looping combustion. The method solves the technical problems that at present, during solid waste combustion, carbon emission is high, and dioxin is generated easily.

Owner:HUAZHONG UNIV OF SCI & TECH

Environment-friendly high temperature low oxygen hot blast furnace

ActiveCN101792839AFlexible adaptation to smelting intensityFlexible process adaptationBlast furnace detailsHeating stovesHot blastFlue

An environment-friendly high temperature low oxygen hot blast furnace belongs to the technical field of hot blast furnaces in the metallurgy industry. The invention comprises a hot blast furnace, shut-off valves, regulating valves, a gas flue for the hot blast furnace, a combustion air pipeline for the hot blast furnace, a gas flue for a combustion furnace, a combustion air fan for the combustion furnace, a combustion air pipeline for the combustion furnace, the combustion furnace, a high temperature flue for the combustion furnace, a gas mixing furnace, a gas mixing pipeline, a low temperature flue, a flue gas pressing machine, flues for the hot blast furnace, a low temperature preheating system, a gas main from a pipe network, a combustion air main and a combustion air fan for the hot blast furnace. The hot blast furnace has the following advantages: the hot blast furnace is suitable for different metallurgical technological processes, can be used in combination with various combustion air and gas low temperature preheating devices, fully recover the flue gas waste heat and further improve the heat efficiency, and realizes high blast temperature, high efficiency, environment friendliness and long life.

Owner:BEIJING SHOUGANG INT ENG TECH

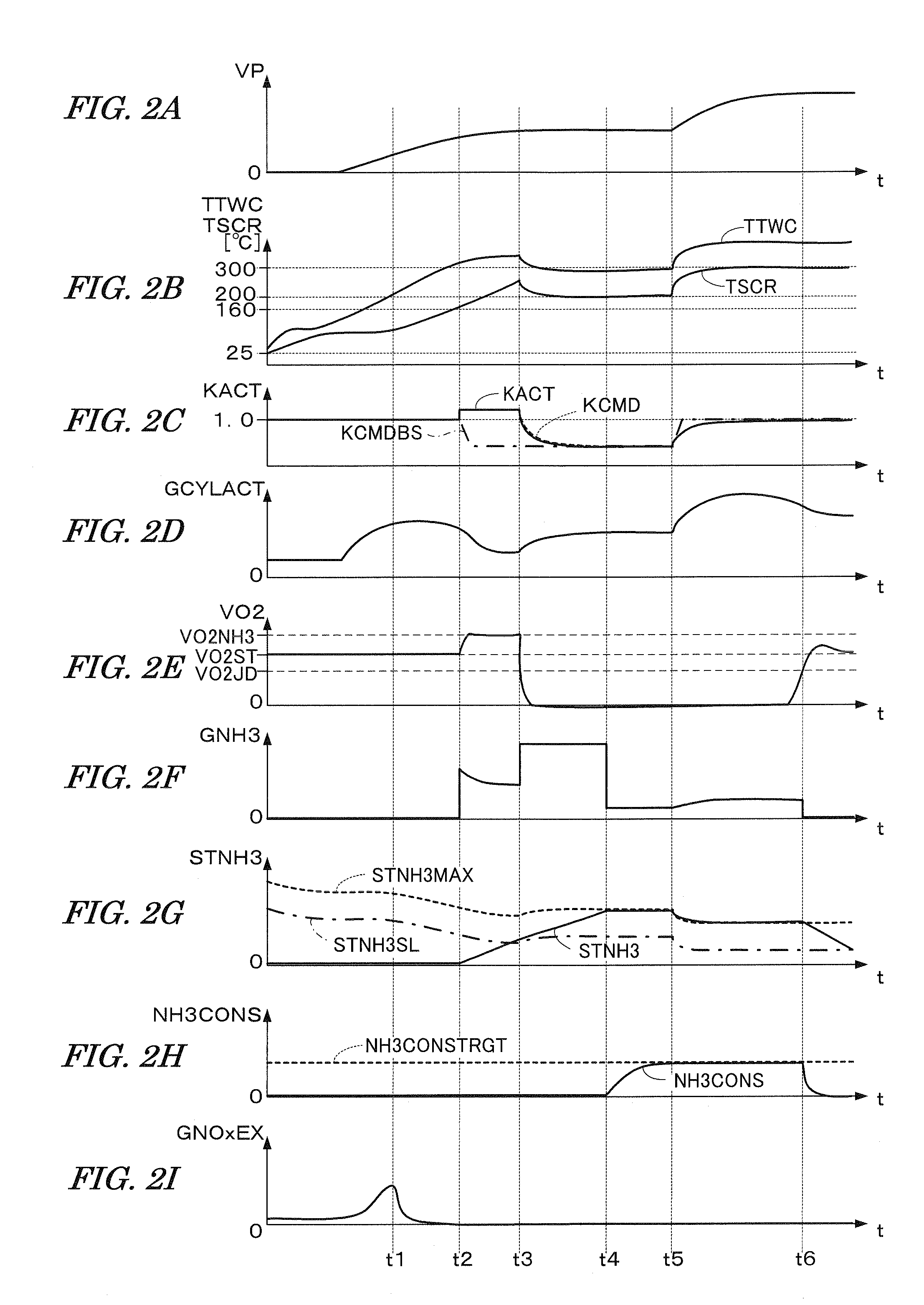

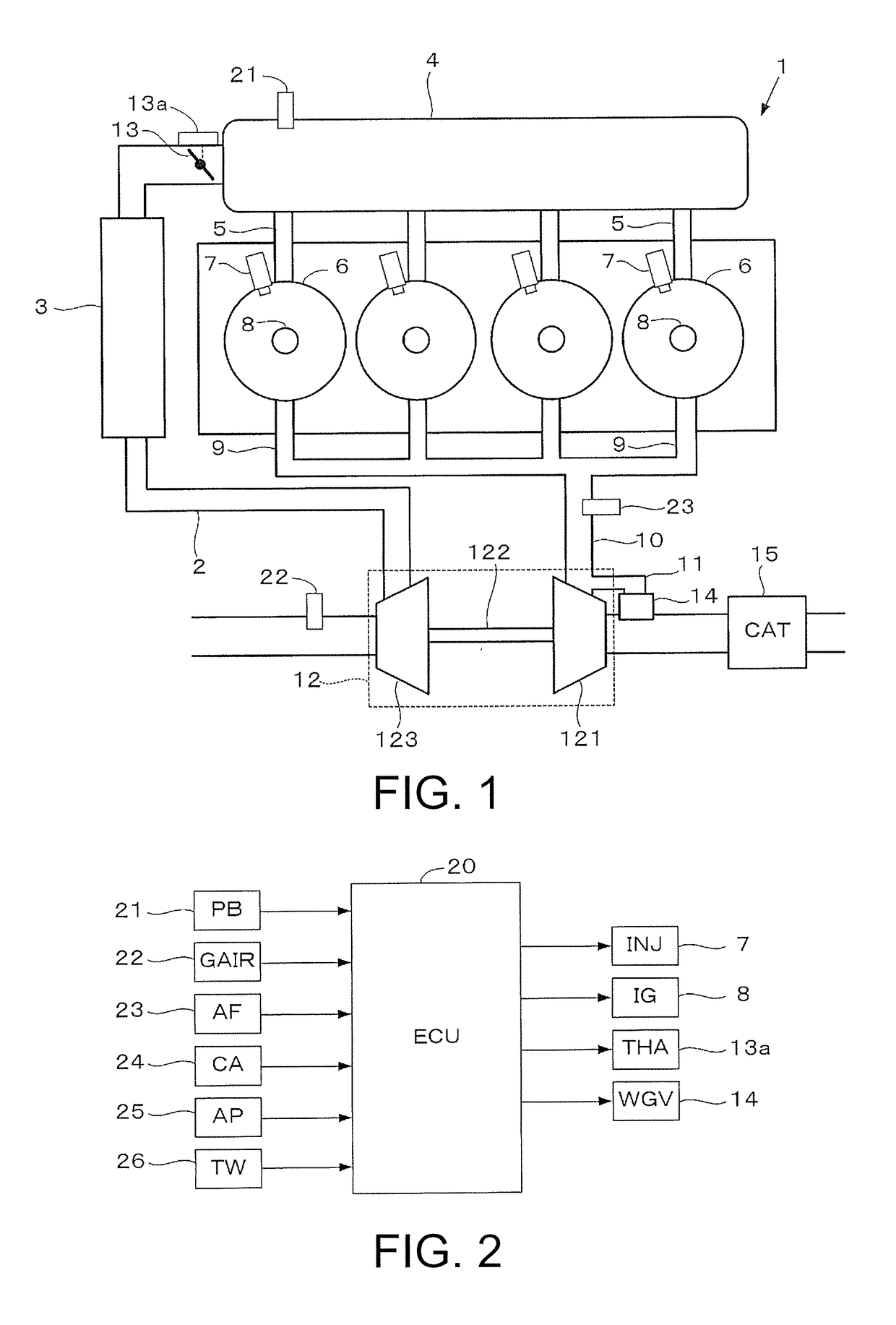

Exhaust gas purifying apparatus for internal combustion engine

ActiveUS8671665B2Reduce the amount of solutionCurb emissionsElectrical controlInternal combustion piston enginesExhaust fumesChemical measurement

Owner:HONDA MOTOR CO LTD

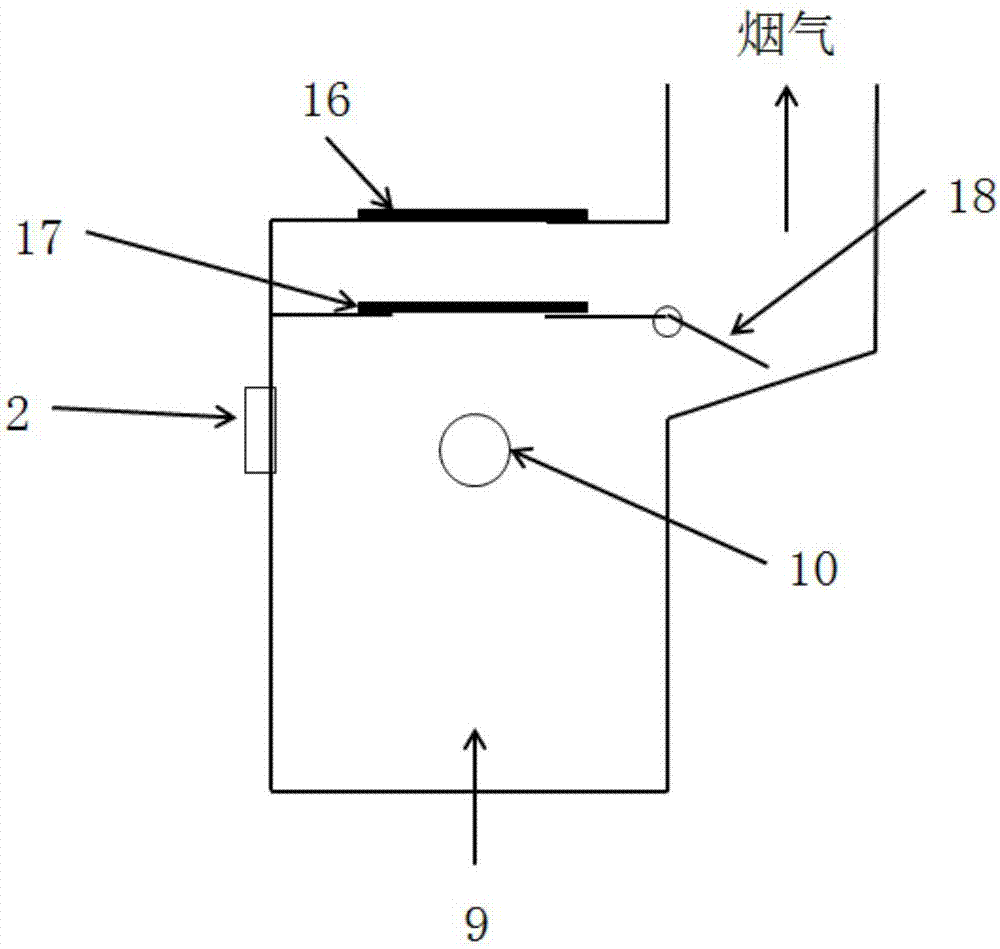

Treatment system for reducing household refuse incineration smoke Dioxin and application method

ActiveCN106678805ASuppress generationReduce harmful ingredientsEmission preventionIndirect carbon-dioxide mitigationAir preheaterCombustion chamber

The invention discloses a treatment system for reducing household refuse incineration smoke Dioxin. The treatment system comprises a refuse receiving chamber and a refuse storage chamber which are isolated through a door; a bad smell outlet of the refuse storage chamber is connected with a refuse incineration furnace secondary combustion chamber zone (oxygen enrichment zone); a refuse incineration furnace is further provided with an air inlet and a refuse inlet used for receiving refuse of the refuse storage chamber; a smoke outlet of the refuse incineration furnace is connected with an inlet of a waste heat power generation boiler, and an outlet of the waste heat power generation boiler is connected with an inlet of a first bag type dust collector; an outlet of the bag type dust collector is connected with an inlet of an SCR reactor, an outlet of the SCR reactor is connected with an air preheater smoke inlet, an air preheater smoke outlet is connected with an inlet of a second bag type dust collector, and an outlet of the second bag type dust collector is connected with an inlet in the lower portion of a deacidification demisting tower; and an outlet in the upper portion of the deacidification demisting tower is connected with a chimney. In addition, the invention comprises a method of the system. According to the treatment system and the application method, the HCi, SO2, NOx and dust removal rate is high, and the Dioxin concentration is smaller than 0.01 ngTEQ / Nm3.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Treatment method of organic waste material for gasification cracking multi coproduction

InactiveCN1786112ASolve a single illImprove heat transfer performanceBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisSolid carbon

The present invention relates to an organic wastes gasification pyrolysis multiple coproduction integrated treatment process. Said process includes the following steps: physical pretreatment: feeding broken organics for gasification into gasification furnace to make gasification; discharging produced high-temperature gasified combustible gas from gasification furnace; heating pyrolysis furnace to pyrolysis temperature, feeding broken organics for pyrolysis into pyrolysis furnace to make pyrolysis reaction to produce oil-gas mixture and solid carbon; making oil-gas mixture undergo the process of heat exchange and be reached to proper temperature for making catalytic pyrolysis to make catalytic pyrolysis; feeding discharged oil-gas mixture into oil-gas fractional equipment so as to obtain fuel oil, non-condensable combustible gas and residuum.

Owner:南京绿展能源有限公司

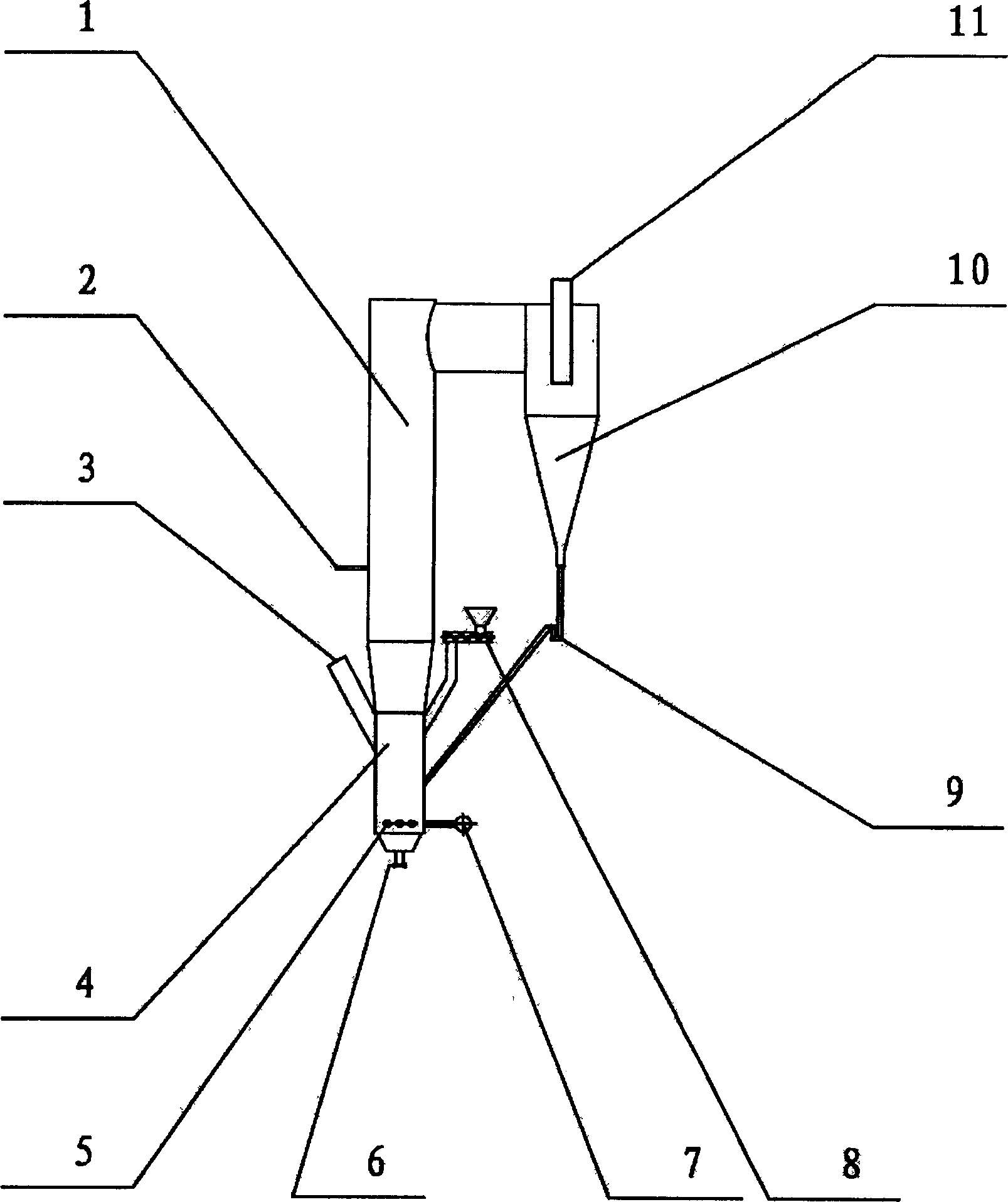

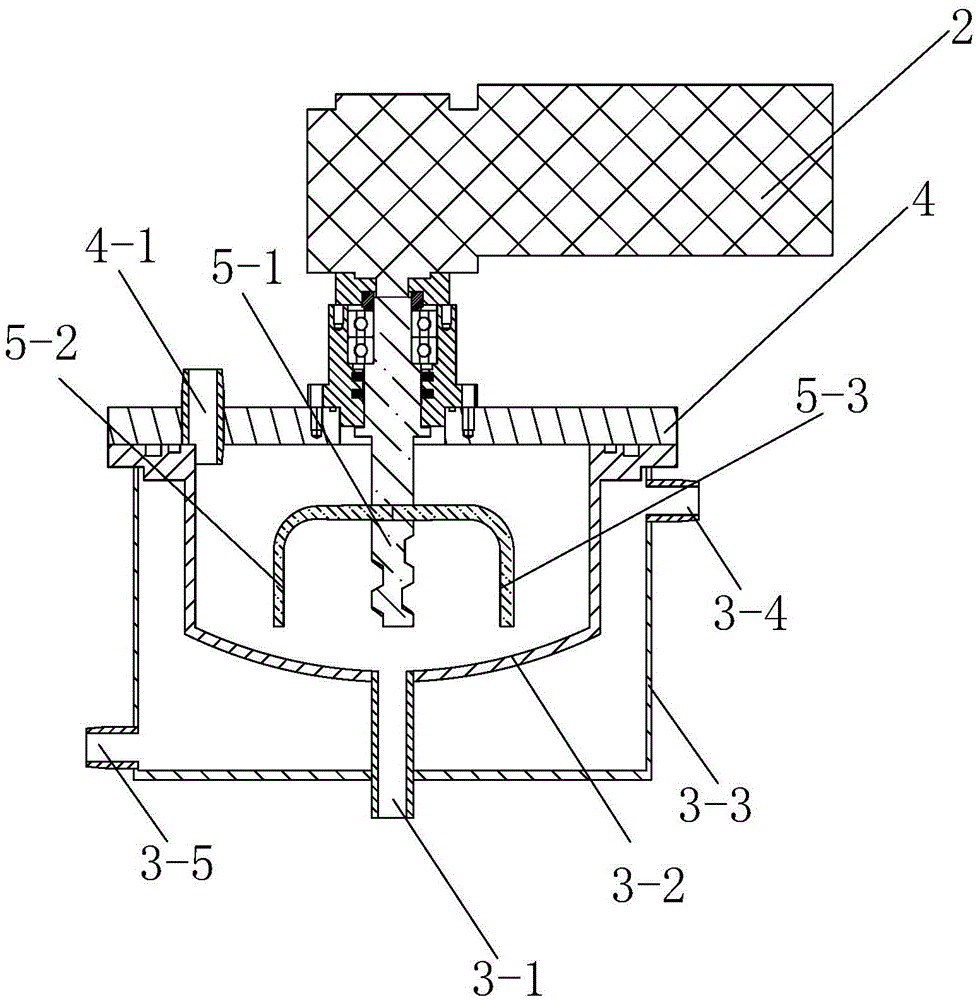

Medical refuse circulating fluidized bed burning furnace and burning method thereof

This invention is involved in a recycled fluid burning furnace of medical garbage and corresponding burning method. The furnace consists of suspension section firebox, dense phase section firebox. There is a secondary inlet of air on the side wall at the lower end of suspension section firebox; there is an inlet of medical garbage and feeding device of limestone on the side wall of intersection of suspension section firebox and dense phase section firebox; there is a solid-gas separation firebox at the upper end of suspension section firebox; there is a central cylinder at the middle of solid-gas separation firebox; there is return devices between the low end of solid-gas separation firebox and dense phase section firebox. The limestone is inert bed material, and decomposes to CaO, CaO reacts with hypochlorous in garbage and hydrogen chloride generated in burning to reduce the acidic gas emission, and prolong the service life of the furnace.

Owner:ZHEJIANG UNIV

Novel cyclone bias pulverized coal burner

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

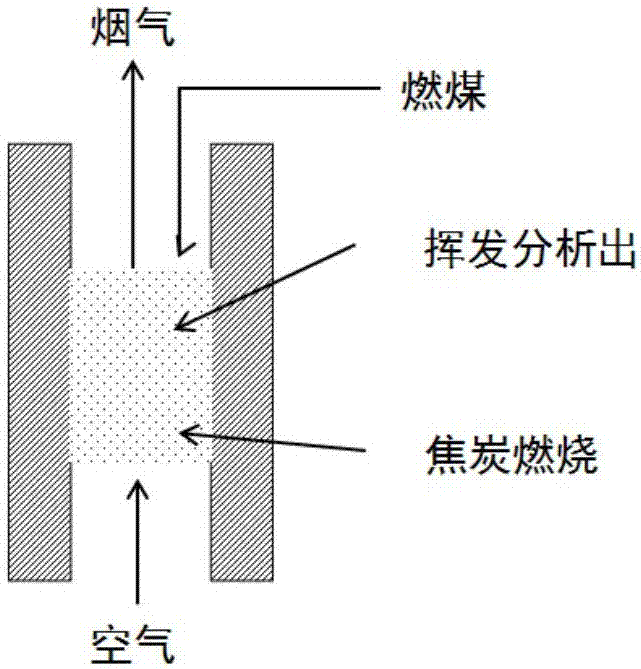

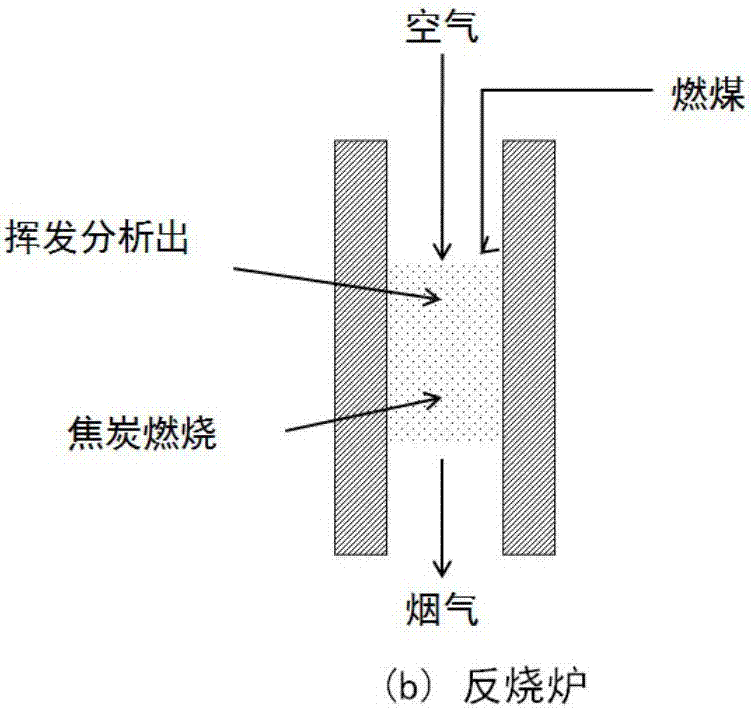

High-efficiency coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, heating method and application

PendingCN107238111ALow universalityReduce generationLighting and heating apparatusStove/ranges for heating waterWater jacketSulfur dioxide

The invention provides a coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, a heating method and application. A coal feeding port is formed in one side of the top of a coal heating furnace body, and a chimney is arranged on the side, opposite to the coal feeding port, of the top of the main body. A water jacket partition plate is vertically arranged on the upper portion inside the coal heating furnace body and divides the upper portion inside the coal heating furnace body into a dry distillation pyrolysis zone which is connected with the coal feeding port and a smoke burnout heat exchanging zone which is connected with the chimney. The zone which is not provided with a partition plate on the lower portion inside the coal heating furnace body is a semi-coke burning zone. A furnace grate is obliquely arranged on the lower portion of the semi-coke burning zone, and a primary air opening is formed below the furnace grate. A burnout zone above the semi-coke burning zone is provided with a secondary air opening. The burnout zone is internally provided with water heat exchanging pipes for heating. The coal heating furnace is stable in burning, high in heat efficiency and suitable for smoke-free emission of all kinds of soft coal, biomass and other fuels, especially when high-sulfur smoke-free burns, and meanwhile the smoke, SO2 and NOx emission is effectively reduced.

Owner:YANKUANG GRP CO LTD +1

Gas burner and burning method achieving ultra-low nitrogen oxide emission

InactiveCN105805741APrevent backfireImprove securityNon-combustible gases/liquids supplyGaseous fuel burnerExhaust gasNitric oxide

The invention relates to the technical field of energy conservation, emission reduction and low-pollution burning, in particular to a gas burner and burning method achieving ultra-low nitrogen oxide emission. The gas burner achieving ultra-low nitrogen oxide emission comprises a mixer, a pre-mixing burning section and an after-burning section. Total gas is divided into primary fuel and secondary fuel; the primary fuel accounts for 25%-55% of the total gas and is evenly mixed with total combustion-supporting air, and emission of nitric oxide is restrained through the low-fuel-concentration pre-mixing burning principle; the secondary fuel accounts for 45%-75% of the total gas, and emission of the nitric oxide is restrained through the low-oxygen-concentration diffusive burning principle; and meanwhile the low content of residual oxygen in a burnt product is ensured, and the temperature of exhaust gas is high. In the pre-mixing burning section, ceramic porous filler is used as a medium for stable flames, and the stability of low-fuel-concentration pre-mixing burning is achieved; and the ceramic porous filler is of a divergent structure, so that tempering is effectively avoided, and safety is improved. Compared with a conventional burning mode, the nitrogen oxide emission can be reduced by 50%-90%, and the nitrogen oxide emission concentration under rated loads is lower than 30 mg / m<3>.

Owner:王建学

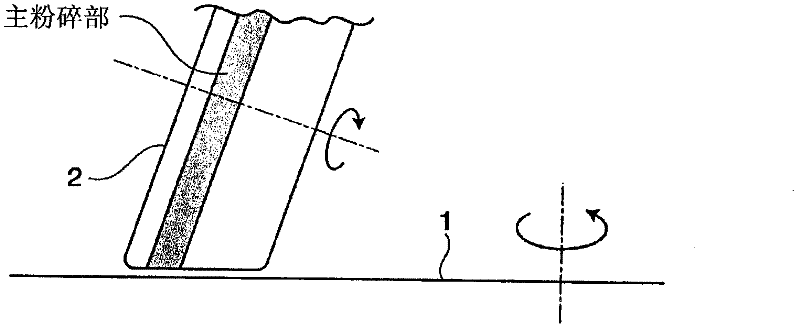

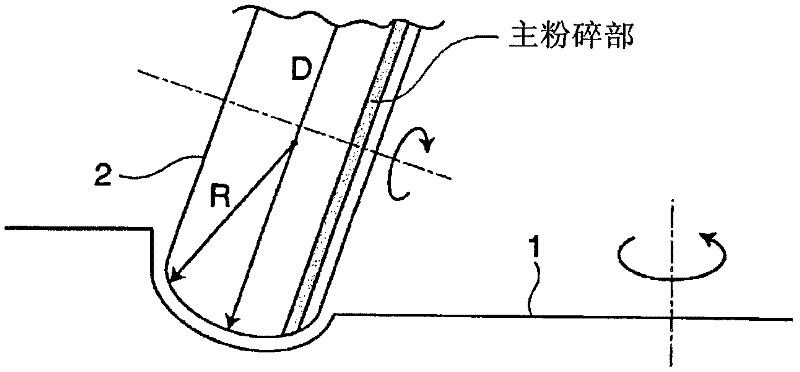

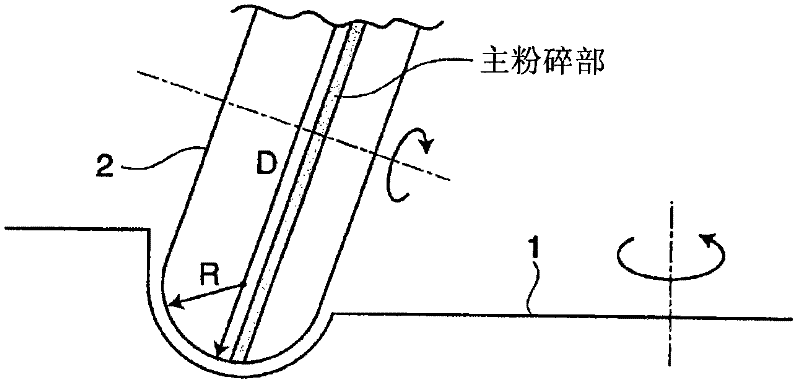

Vertical roller mill

Provided is a vertical roller mill which is equipped with a rotary table (1) driven to rotate, and a plurality of grinding rollers (2) comprising free rollers placed at fixed positions on the rotary table (1) so as to surround the rotation center line of the rotary table (1) to bite and crush a material to be ground between the turn table (1) and grinding rollers (2) with rotary driving of the rotary table (1). The vertical roller mill has a plurality of oblique slit grooves (6) placed at predetermined intervals in the perimeter direction on the annular crushing portion (3) on the upper face of the rotary table: each of the oblique silt grooves (6) is inclined to the table rotation direction or the reverse rotation direction thereof and is placed in a region of the angle of 45 degrees or more to the table radius line. The above constitution enables improvement of performance of feed control of the raw material like coal or petrol cokes as well as improvement of the performance of biting and crushing of a material.

Owner:ING SHOJI

Method for preparing photocatalytic degradation-type dust suppressant

InactiveCN102703030APromote degradationBlocking dischargeOther chemical processesPlant rootsEmulsion

The invention discloses a method for preparing a photocatalytic degradation-type dust suppressant; TiO2 nano particle material is used as a photocatalyst; beta modified starch is used as a film forming agent; processed soil powder is used as a filler, and above materials are heated and mixed to prepare emulsion liquid; the method comprises the following steps: 1) removing impurities such as plant root hairs, leaves and the like in the soil, and crushing to obtain the soil powder; 2) crushing the beta modified starch to obtain the powder, adding water to the powder so as to obtain emulsion; heating and gelatinizing; adding the photocatalyst TiO2 nano particle material in a stirring manner so as to obtain the emulsion liquid; and 3) mixing the emulsion liquid with the soil powder evenly so as to obtain a product. According to advantages of the invention, a covering layer formed by the dust suppressant can effectively prevent particle-shaped material from discharging dust to air; the TiO2 nano particle material has high photocatalysis activity; therefore, the covering layer has good degradability in natural environment; and the method for preparing the dust suppressant is characterized by simple technology, easy implementation and is benefit for large-scale popularization and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Smoke suppression low-odor modified asphalt coiled material coating material, preparation method thereof and modified asphalt coiled material

ActiveCN109705734AReduce generationEmission reductionOther rubber coatingsBituminous coatingsMetal-organic frameworkBULK ACTIVE INGREDIENT

The invention discloses a smoke suppression low-odor modified asphalt coiled material coating material, a preparation method thereof and a modified asphalt coiled material. The coating material comprises matrix asphalt, a softening agent, a free radical scavenger, a metal organic framework compound, an inorganic adsorption material, a reaction type odor inhibitor, a high polymer modifier, tackifying resin, rubber powder and a filler. According to the invention, the free radical scavenger is added, so that a small molecule volatile gas generated by free radical reaction is reduced; the metal organic framework compound can be used for efficiently selectively adsorbing polycyclic aromatic hydrocarbon sulfur-containing thiophene substances and reducing the emission of the polycyclic aromatic hydrocarbon sulfur-containing thiophene substances; the inorganic adsorption material is used for reinforcing the interaction between volatile organic matters and the asphalt matrix, so that the overall emission is reduced; the reaction type odor inhibitor reacts with mercaptan in the asphalt, and the emission of the mercaptan as one of peculiar smell sources and hydrogen sulfide is reduced. The test result shows that smoke-inhibiting and odor-removing active ingredients are added, the flue gas volatilization amount of the modified asphalt coating material is reduced by more than 80% at 180 DEGC, and pollutant emission and peculiar smell source emission are remarkably reduced.

Owner:苏州东方雨虹建筑材料有限公司

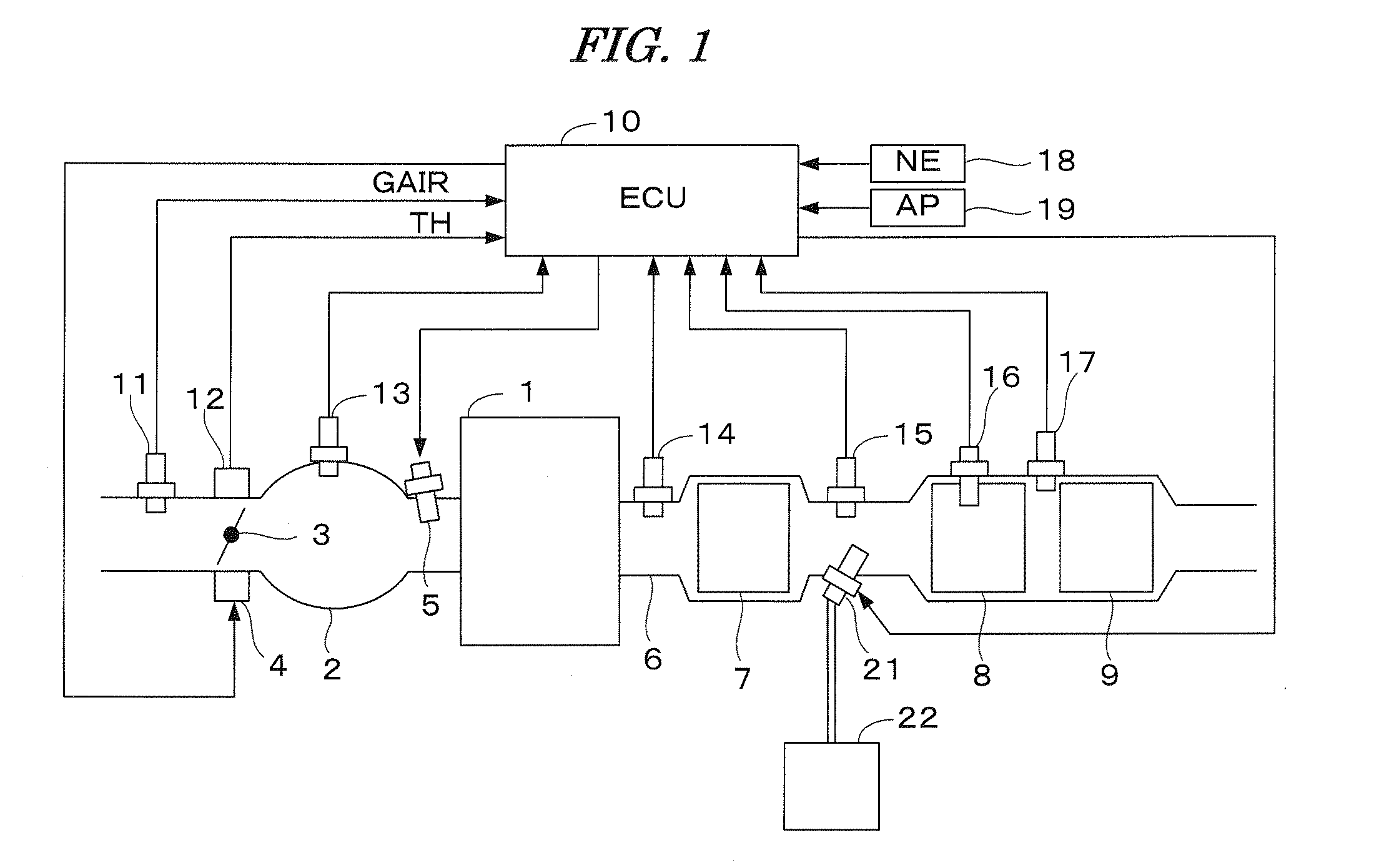

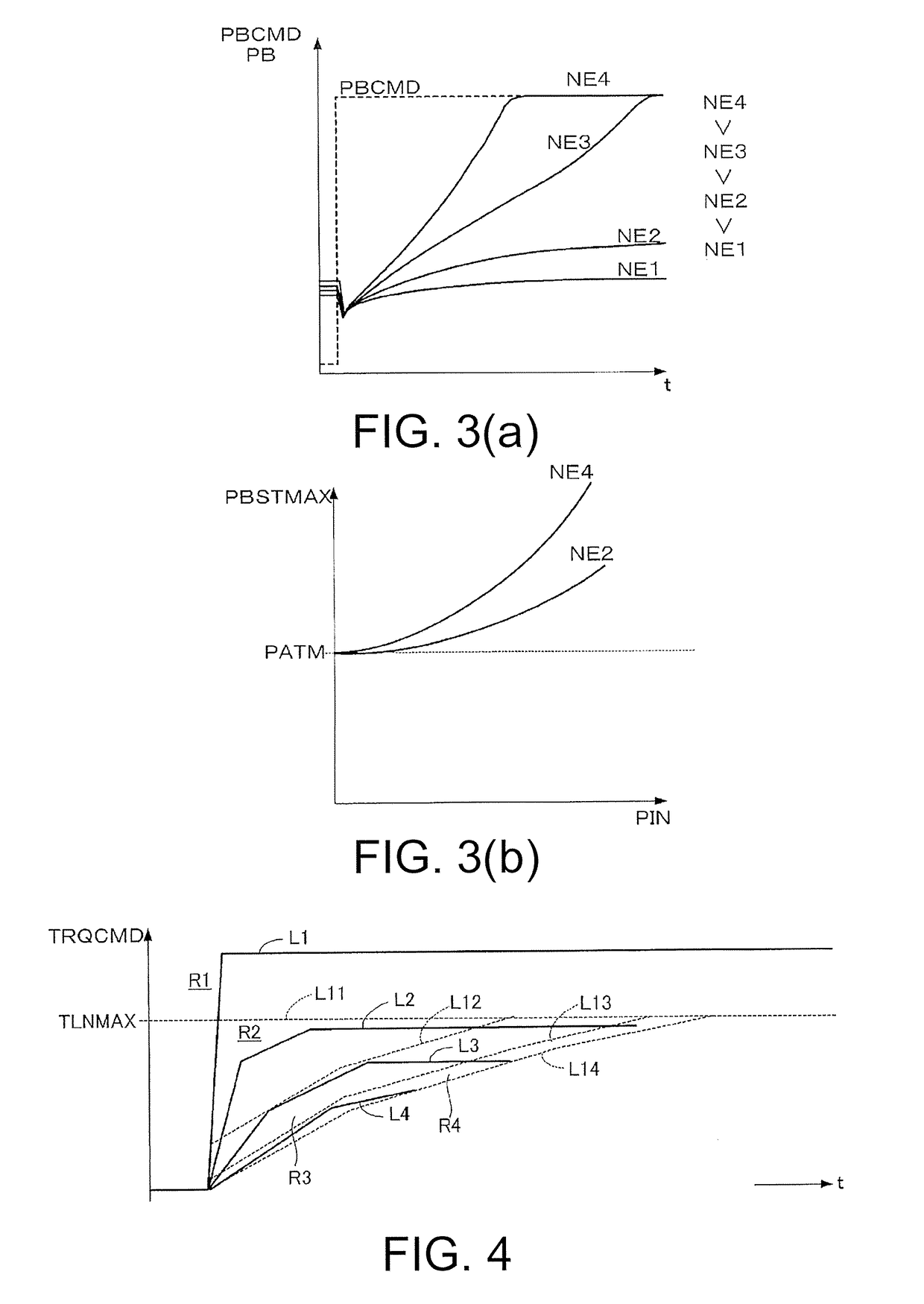

Control device of vehicle

ActiveUS20180010534A1High outputCurb emissionsHybrid vehiclesElectrical controlStable stateDriver/operator

A control device of a vehicle capable of improving acceleration responsiveness and suppressing increase in the NOx emission amount when a required torque is increased during a steady lean operation. A target air-fuel ratio (AFCMD) is set according to an accelerator pedal operation of a driver. When the driver depresses an accelerator pedal to make an acceleration request during the lean operation, in which the AFCMD is set to a predetermined lean air-fuel ratio (AFLN), air-fuel ratio reduction control is executed to reduce the AFCMD according to the acceleration request. In the air-fuel ratio reduction control, when the AFCMD calculated according to a required torque (TRQCMD) is smaller than a limit air-fuel ratio (AFLMT), the AFCMD is set to the AFLMT, and the AFLMT is set to a value smaller than the AFLN set in a steady state of the lean operation and larger than a theoretical air-fuel ratio (AFST).

Owner:HONDA MOTOR CO LTD

Dust agglomerating agent and preparation method thereof

The invention relates to a dust agglomerating agent which comprises, by weight, 2.5 to 10 parts of polyvinyl alcohol, 1 to 30 parts of acrylic acid-based copolymer emulsion, 60 to 96.5 parts of water, 0.01 to 1.0 part of anionic surfactant, 0.05 to 1.0 part of an antirust agent, 0.01 to 1.0 part of an antifoaming agent and 0.05 to 1.0 part of a thickening agent. The invention is advantaged in that the dust agglomerating agent with a simple mixing formula is brought forward and the dust agglomerating agent can effectively inhibit discharging of dust in road building, mining and related industries and reduce environmental pollution and harm to human bodies.

Owner:常州市亚邦亚宇助剂有限公司

Energy-saving coal combustion adjuvant and preparation thereof

InactiveCN101434884APromote thermal cyclingExtended service lifeSolid fuelsAdjuvantHazardous substance

The invention relates to a coal combustion-supporting agent, in particular to an energy-saving coal combustion-supporting agent which is applicable to different types of coal-fired boilers and can inhibit the emissions of harmful substances of soot, sulfur dioxide and the like and a preparation method thereof. The combustion-supporting agent is prepared by five process steps of material weighing,ball-milling screening, pre-mixing, pre-dissolving and reaction packaging and by taking potassium chlorate, potassium chloride, potassium dichromate, potassium permanganate, potassium carbonate, cerium oxide and the like as raw materials, and the combustion-supporting agent is characterized by energy conservation and environmental protection.

Owner:范伟光

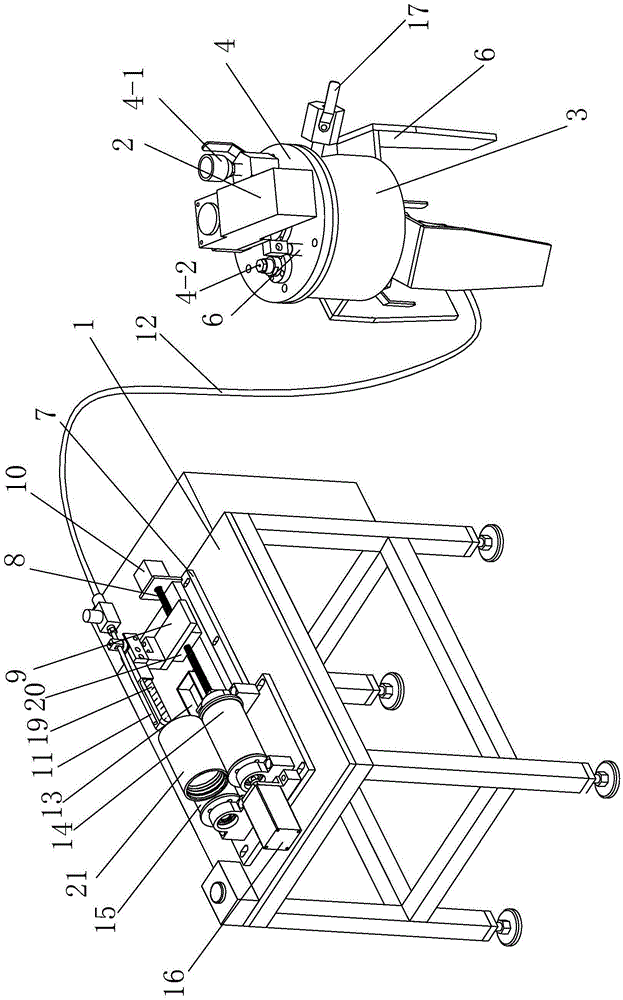

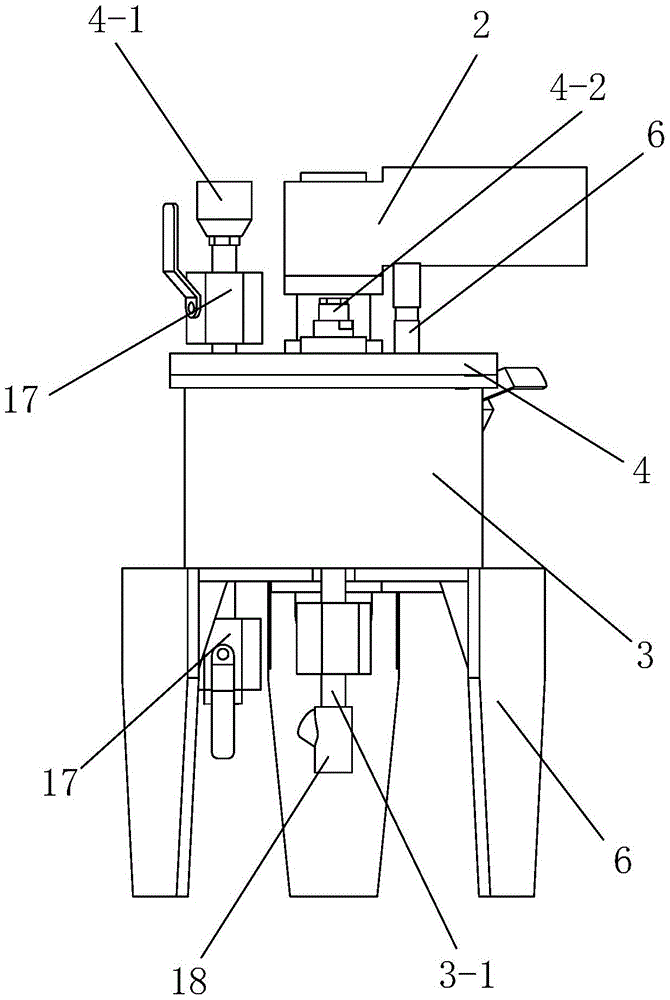

Device and method for coating inner wall of oil casing coupling with anti-friction nano coating

InactiveCN105583126ASimple structureNovel and reasonable designLiquid surface applicatorsCoatingsCouplingReciprocating motion

The invention discloses a device for coating the inner wall of an oil casing coupling with an anti-friction nano coating. The device for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises a storage mechanism, a feeding mechanism and a workpiece rotating mechanism. The storage mechanism comprises a stirring kettle and a first driving motor. The feeding mechanism comprises a base, a lead screw, a moving block and a second driving motor. A dripping pipe and a coating brush are arranged on the moving block. The workpiece rotating mechanism comprises a driving roller, a driven roller and a third driving motor. The invention further discloses a method for coating the inner wall of the oil casing coupling with the anti-friction nano coating. The method for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises the following steps that firstly, a workpiece is rotated; secondly, the anti-friction nano coating is evenly stirred; thirdly, the nano coating is brushed while the coating brush moves in a reciprocating mode; and fourthly, drying is conducted. According to the device and method for coating the inner wall of the oil casing coupling with the anti-friction nano coating, the design is novel and reasonable, the device can be obtained conveniently, and the method can be implement conveniently; the application range is wide, and the using effect is good; an oil casing coupling workpiece can be coated with the coating rapidly, and the purpose of improving the viscidity resistance of the oil casing coupling is achieved finally.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com