Medical refuse circulating fluidized bed burning furnace and burning method thereof

A circulating fluidized bed, medical waste technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problem of difficult to overcome acid gas corrosion, and achieve the effect of low cost, prevention of corrosion problems, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

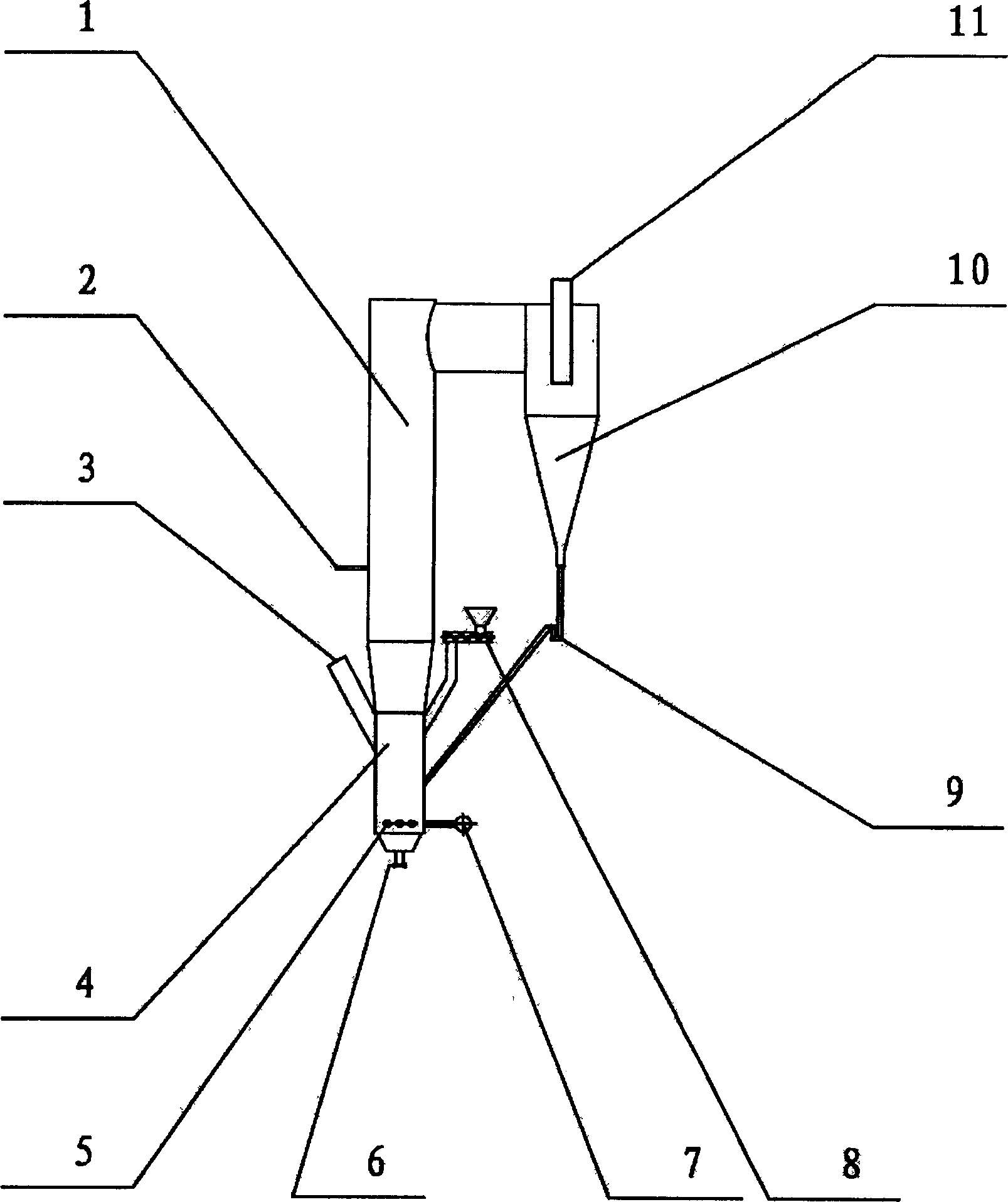

[0011] As shown in the attached figure, the medical waste circulating fluidized bed incinerator has a suspension section combustion chamber 1 and a dense phase section combustion chamber 4. The dense phase section combustion chamber 4 is equipped with an air distribution device 5, and the air distribution device 5 is connected with an equalizing air box. 7 connection, the lower end of the combustion chamber 4 of the dense phase section is provided with a slag discharge port 6, and the side wall of the lower end of the combustion chamber 1 of the suspension section is provided with a secondary air inlet pipe 2, at the intersection of the combustion chamber 1 of the suspension section and the combustion chamber 4 of the dense phase section The side wall of the medical waste feeding port 3 and the limestone feeding device 8 are provided, and the gas-solid separation combustion chamber 10 is connected to the upper end of the combustion chamber 1 of the suspension section. A return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com