Patents

Literature

769 results about "Acetate salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An acetate /ˈæsɪteɪt/ is a salt formed by the combination of acetic acid with an alkaline, earthy, metallic or nonmetallic and other base. 2. The neutral molecules formed by the combination of the acetate ion and a positive ion (called a cation) are also commonly called "acetates" (hence, acetate of lead, acetate of aluminum, etc.).

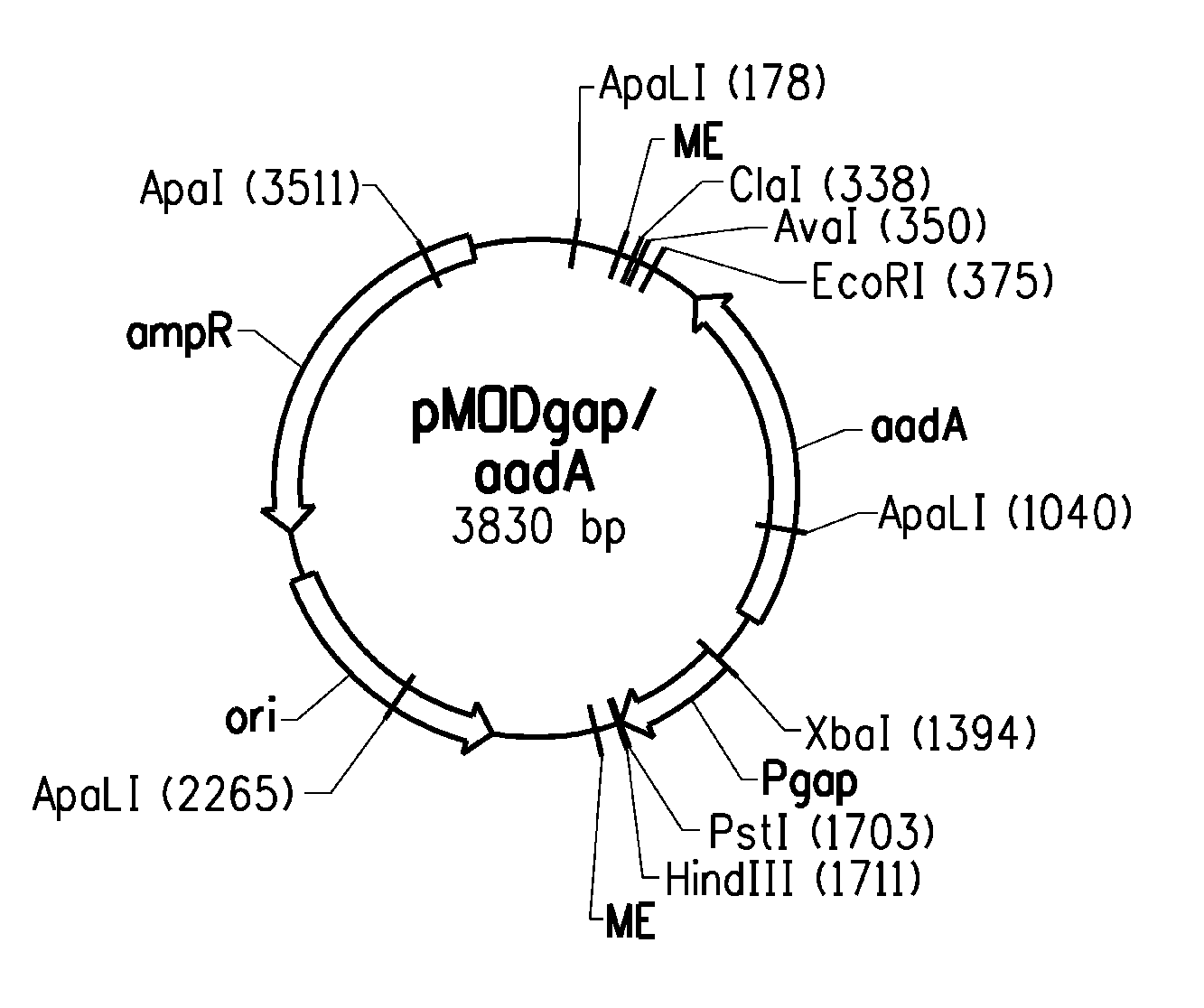

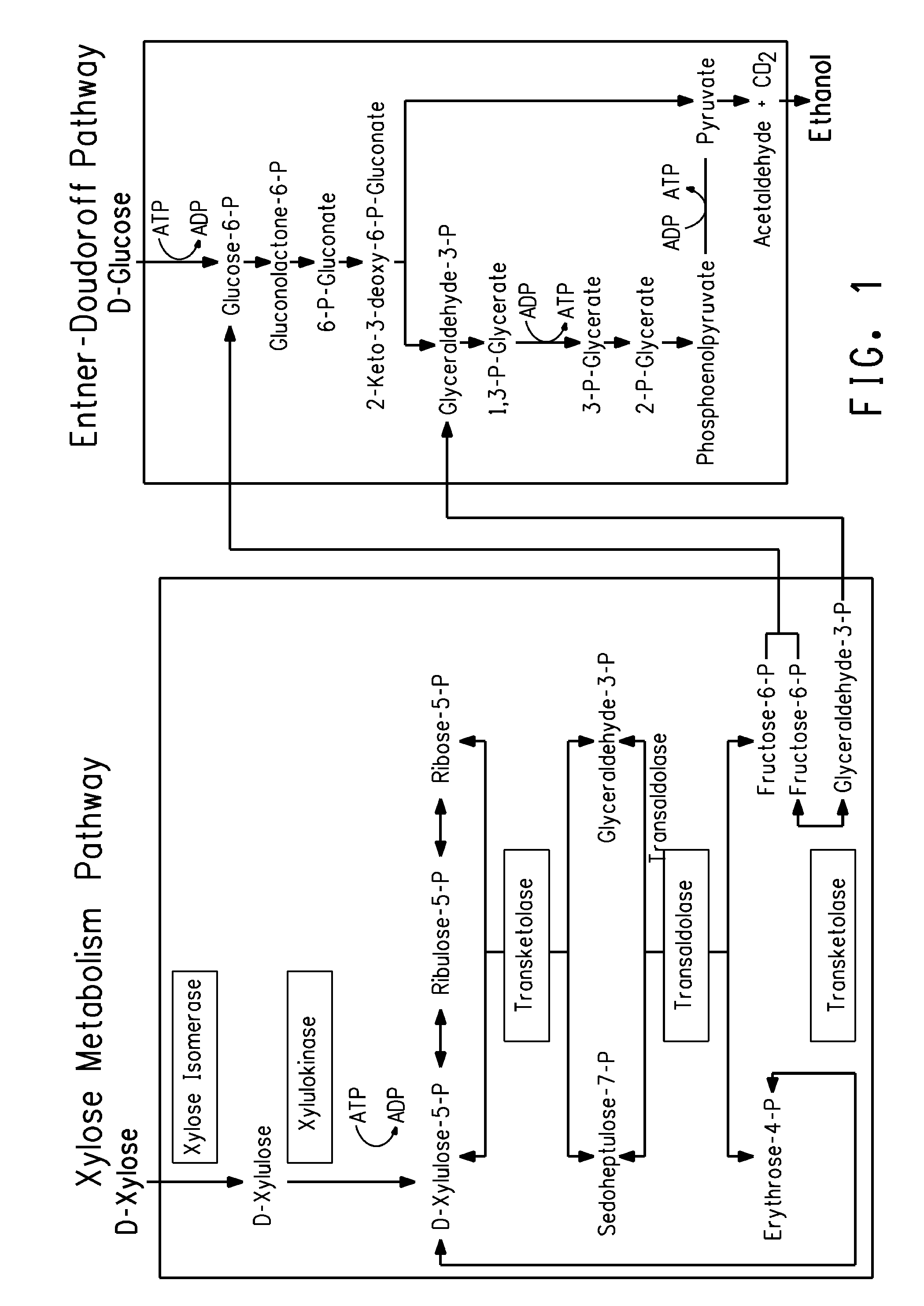

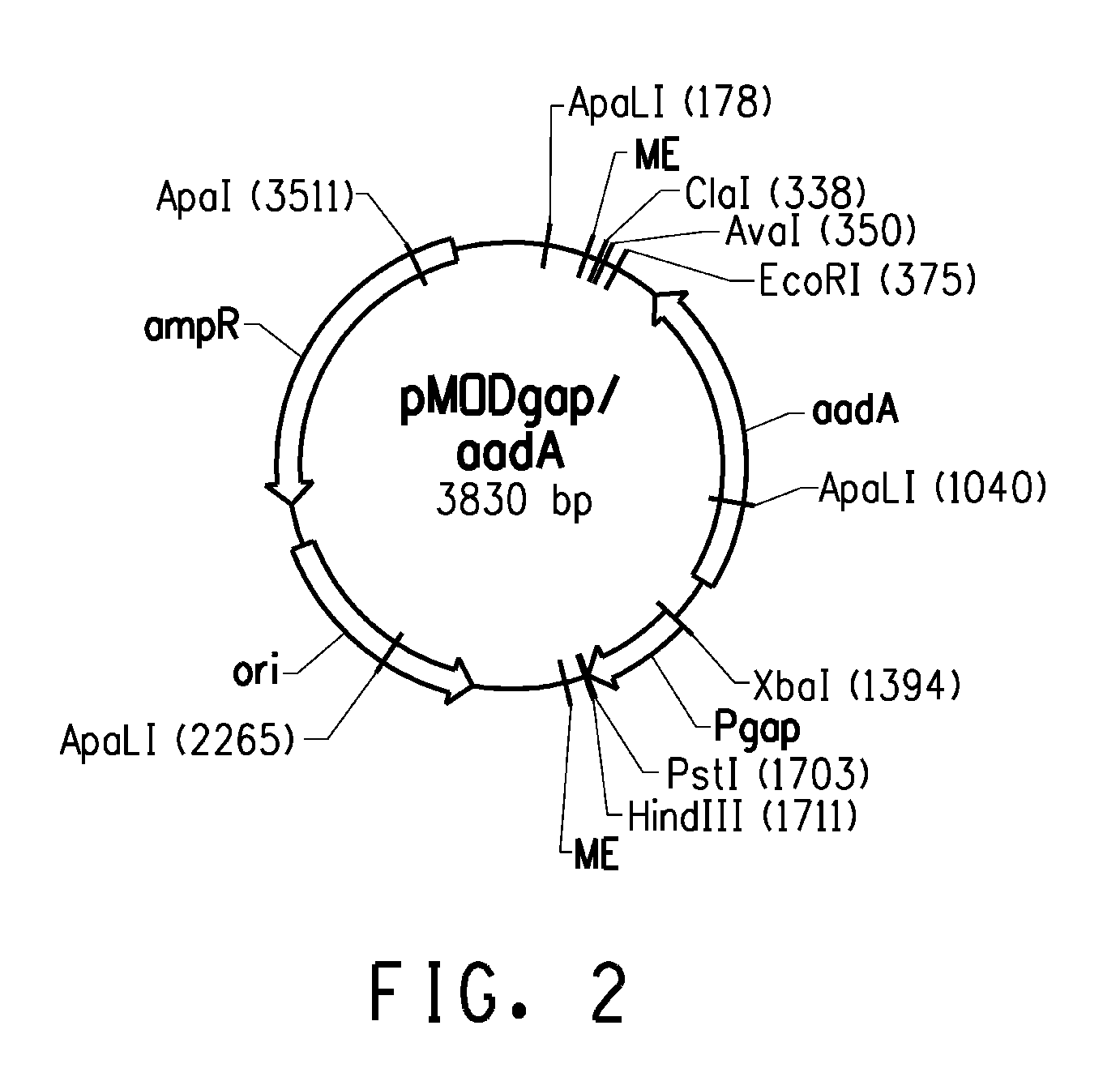

Zymomonas with improved ethanol production in medium containing concentrated sugars and acetate

InactiveUS20090203099A1Improve performanceIncreased acetate toleranceBacteriaBiofuelsAcetic acidSugar

Through screening of a Zymomonas mutant library the himA gene was found to be involved in the inhibitory effect of acetate on Zymomonas performance. Xylose-utilizing Zymomonas strains further engineered to reduce activity of the himA gene were found to have increased ethanol production in comparison to a parental strain, when cultured in mixed-sugars medium comprising xylose, and, in particular, in the presence of acetate.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Method of obtaining a product sugar stream from cellulosic biomass

InactiveUS20090023187A1Improve performanceHigh yieldSugar derivativesBiofuelsInorganic saltsAcetic acid

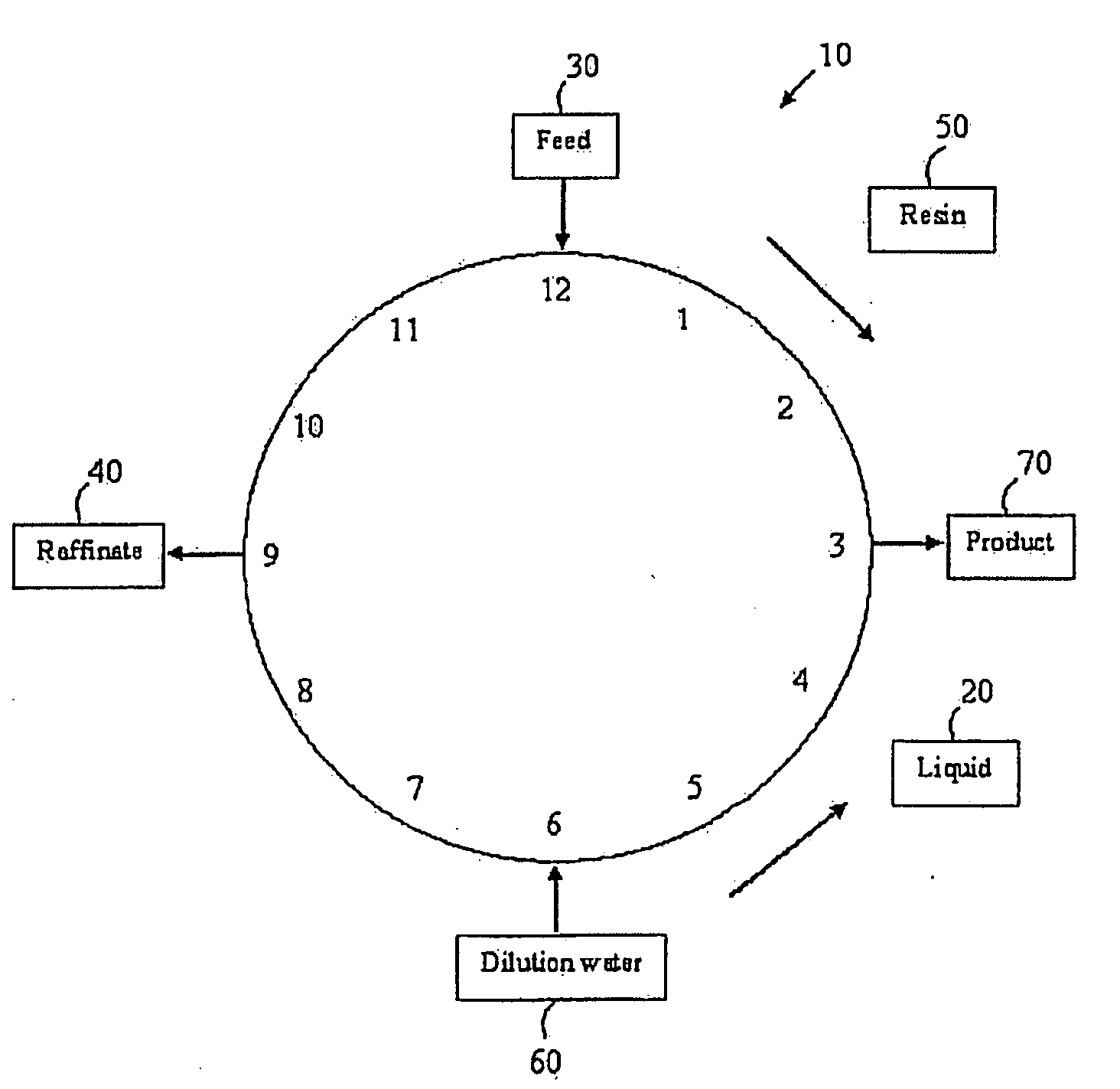

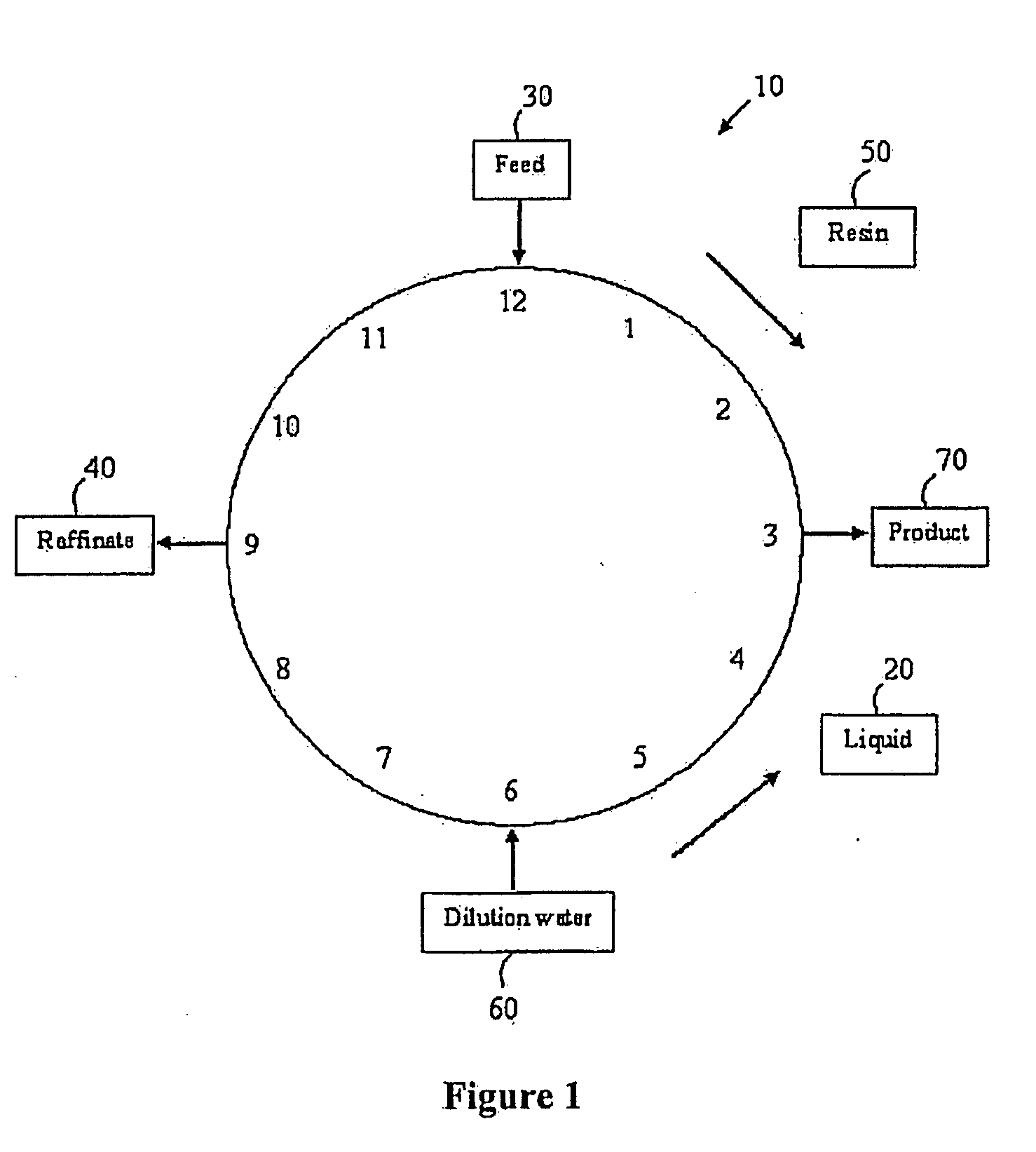

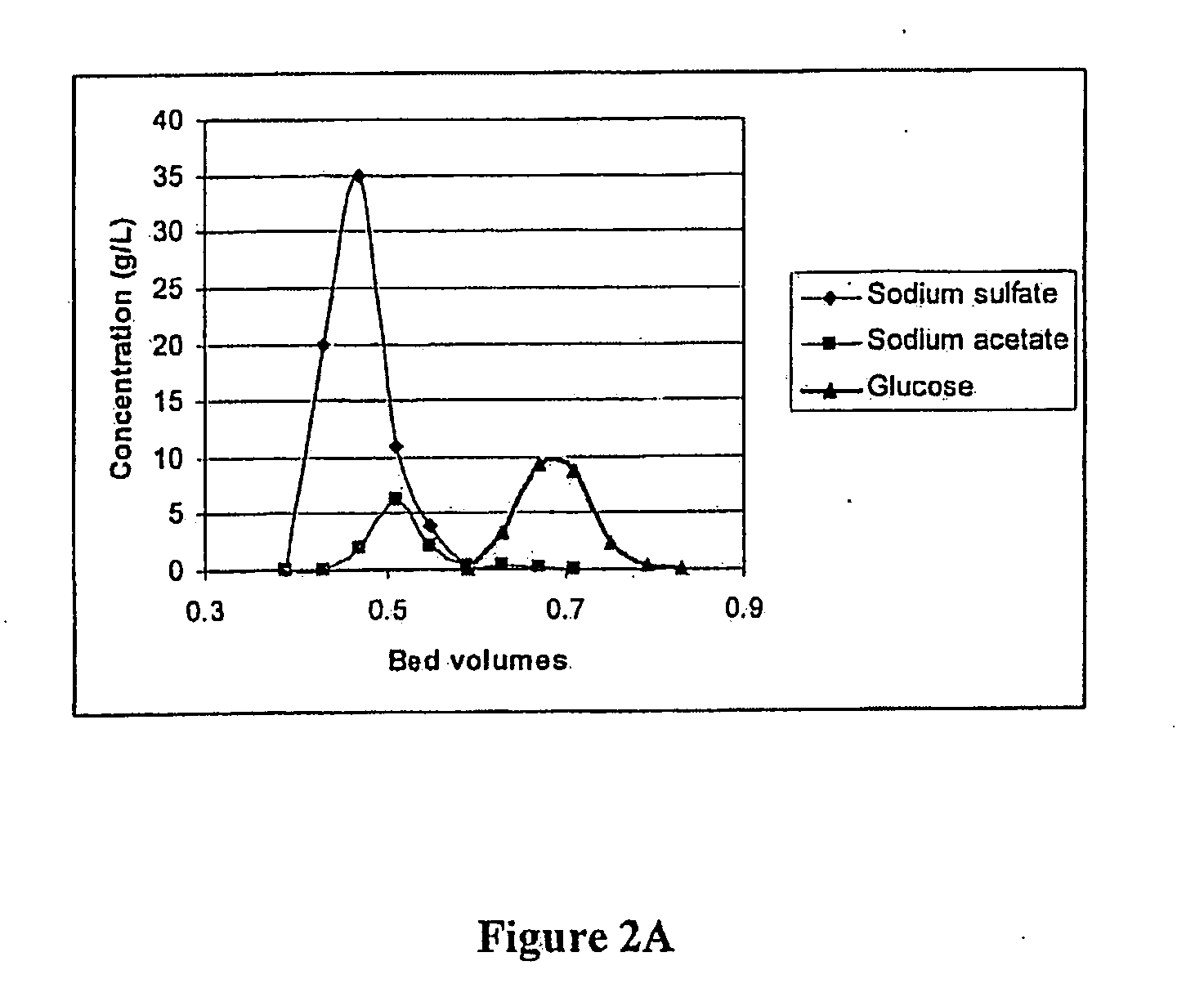

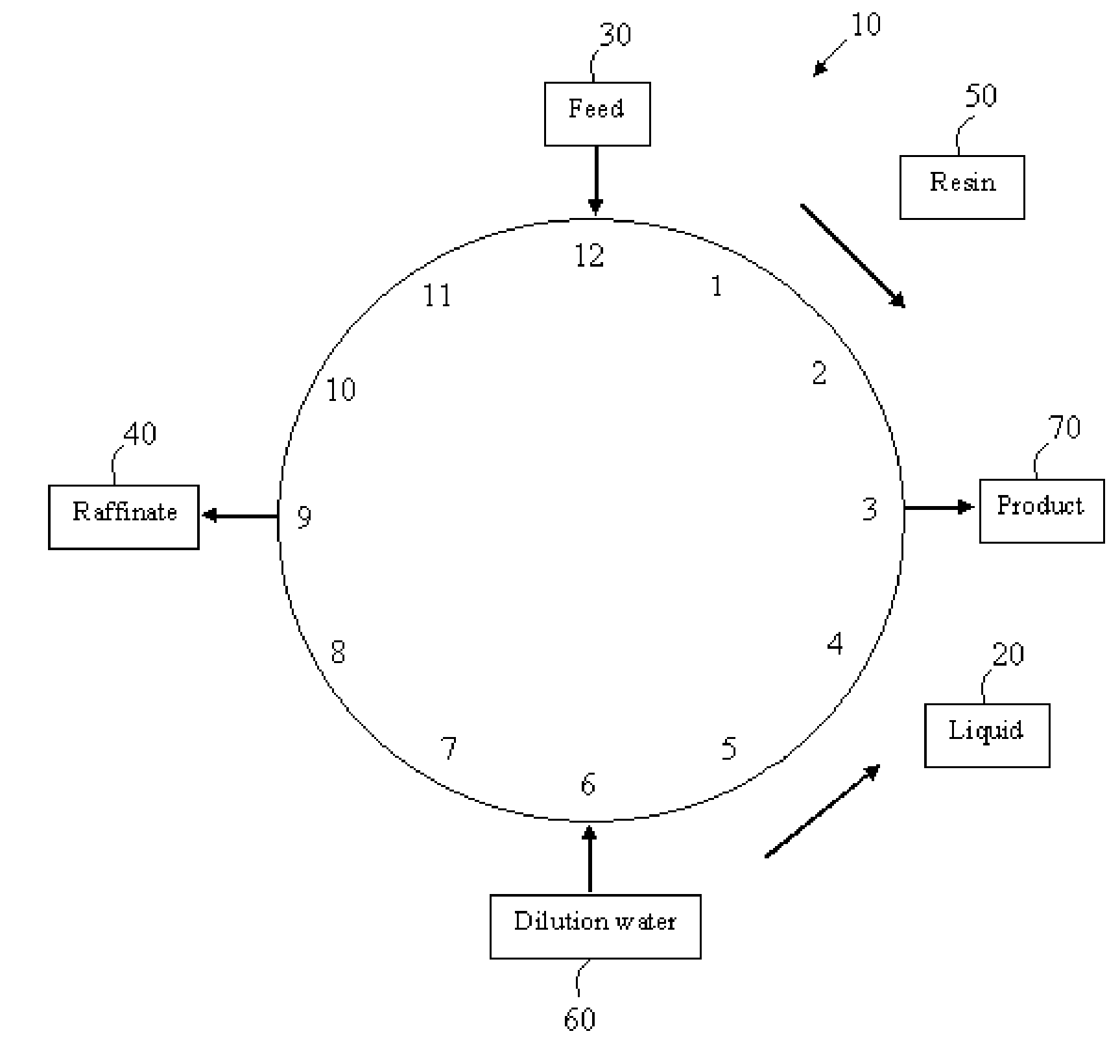

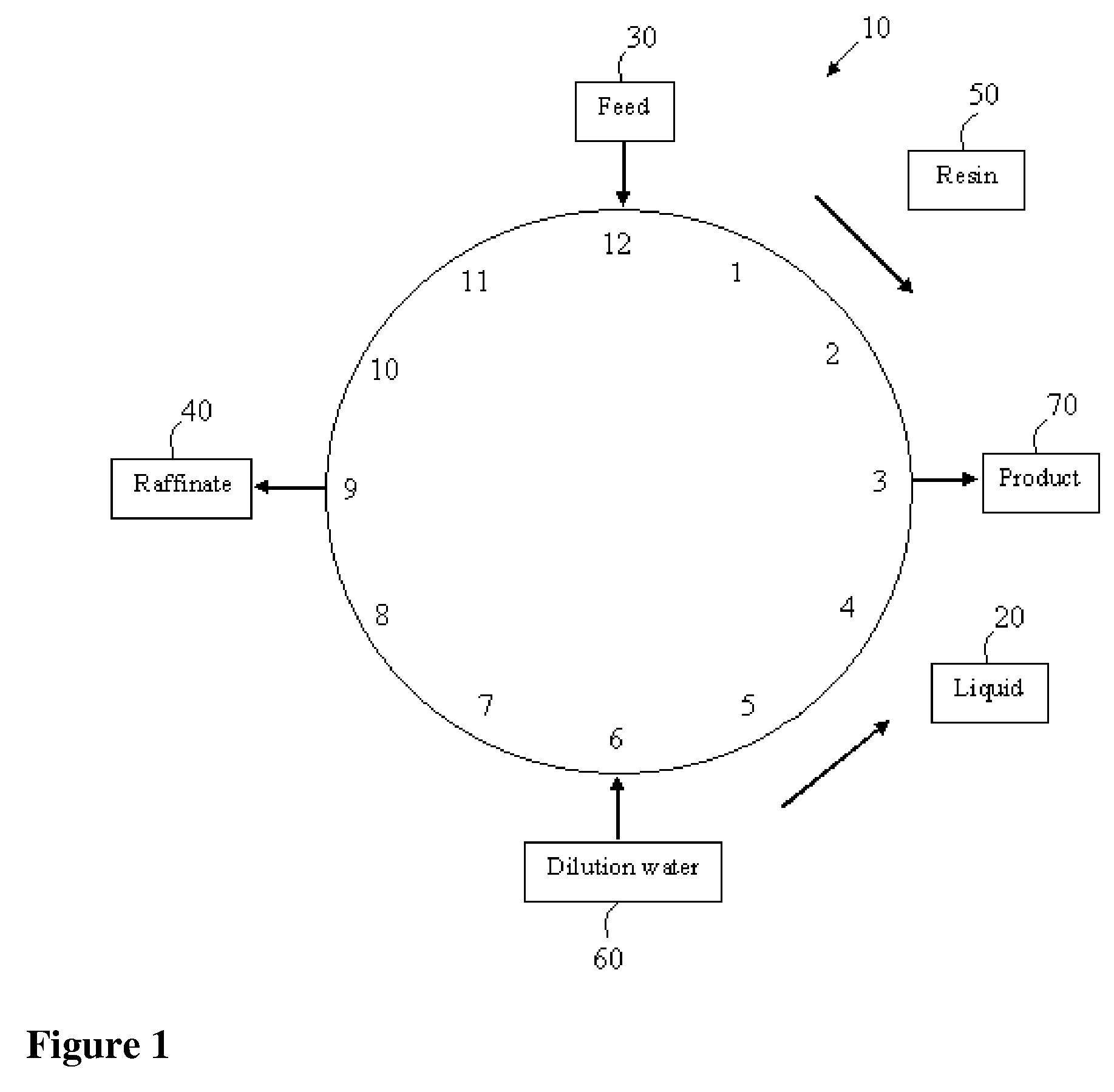

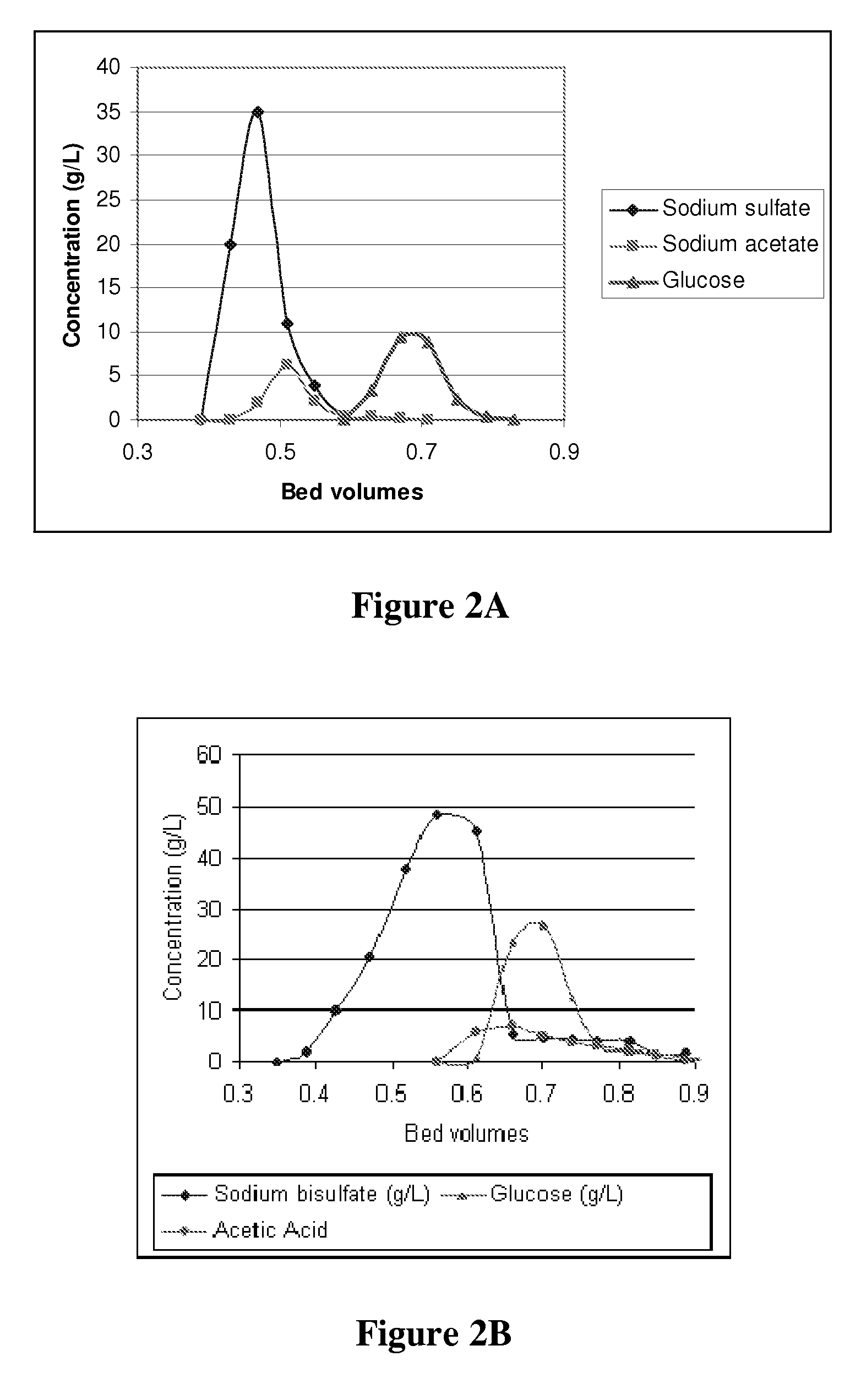

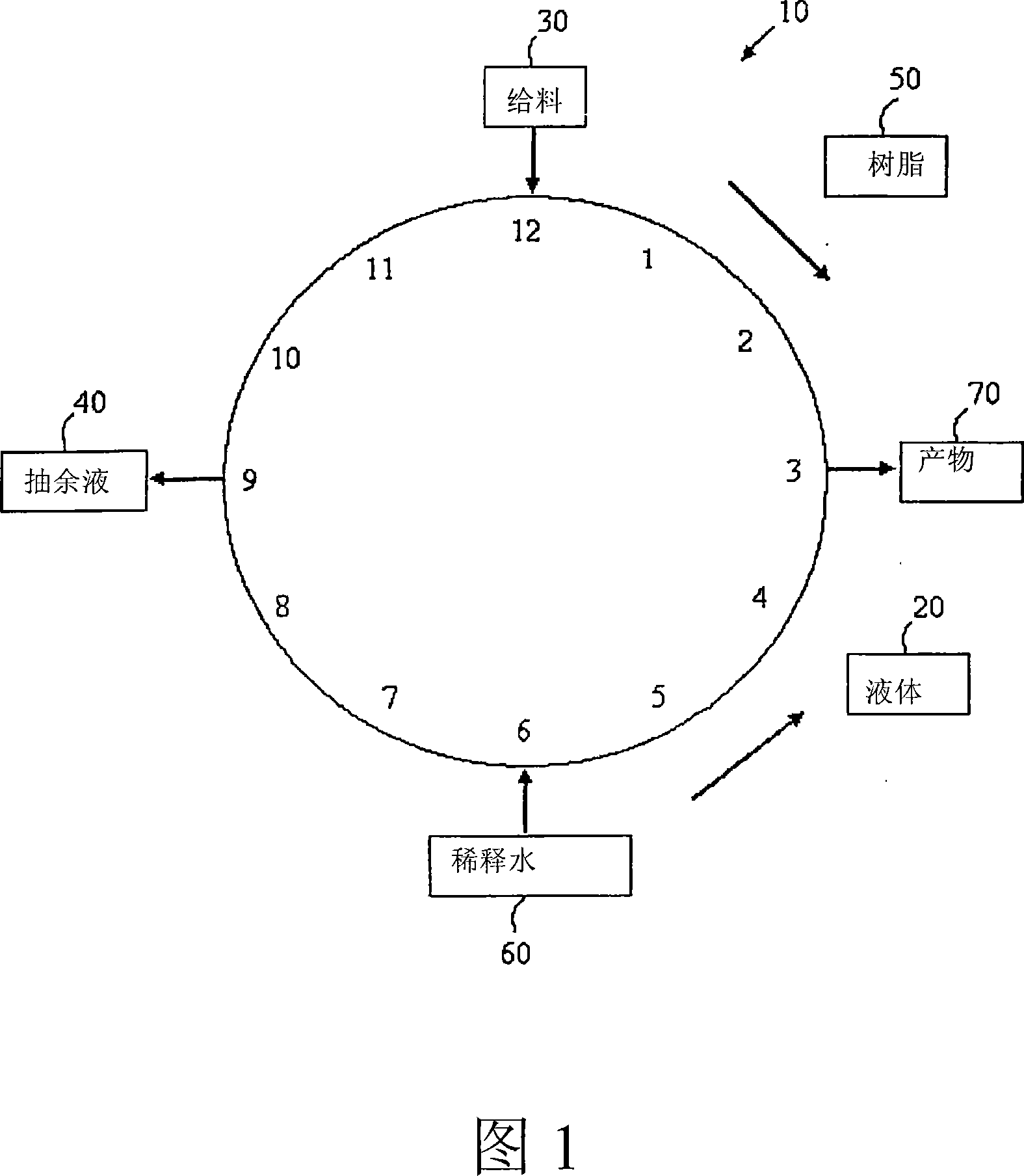

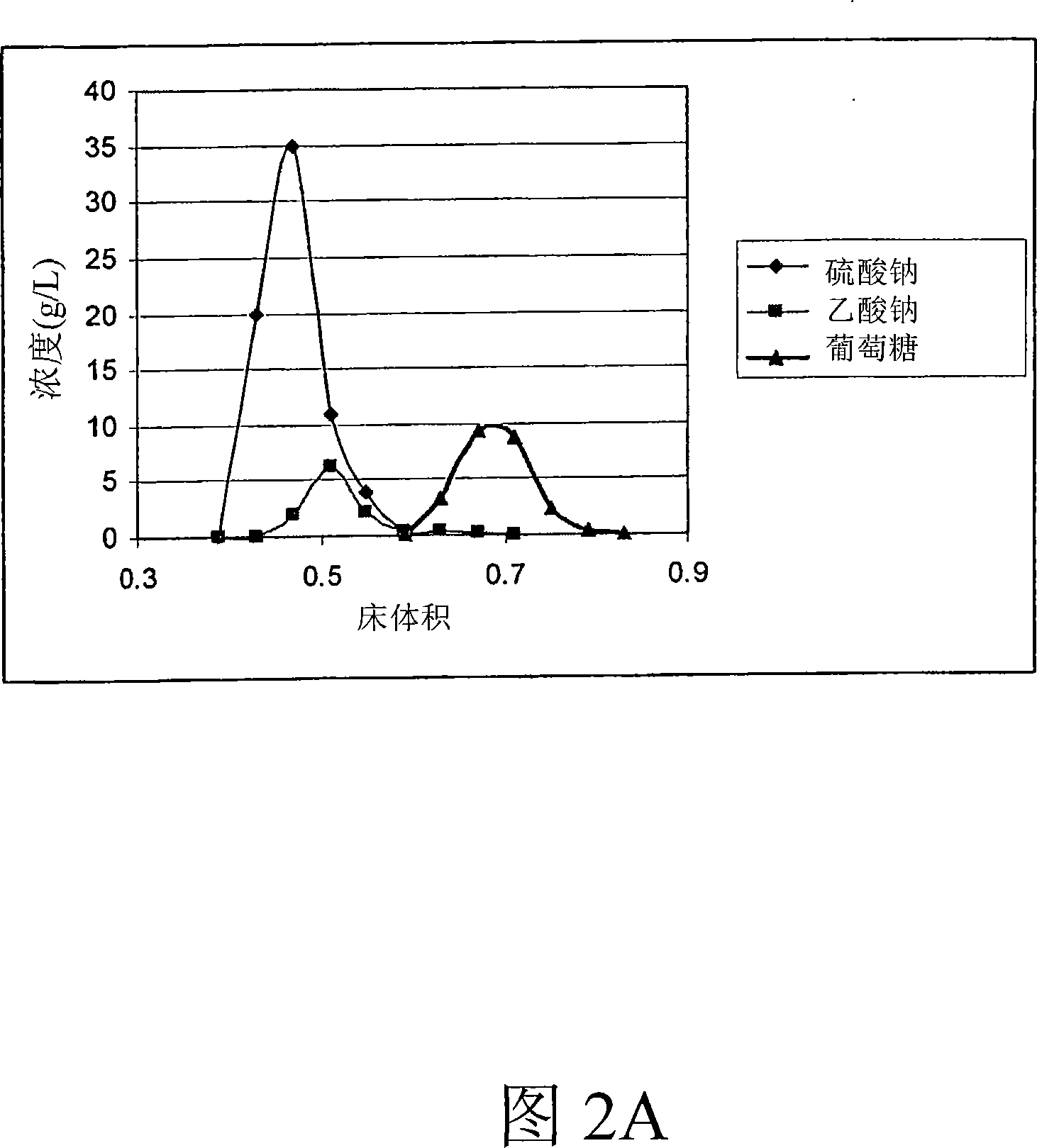

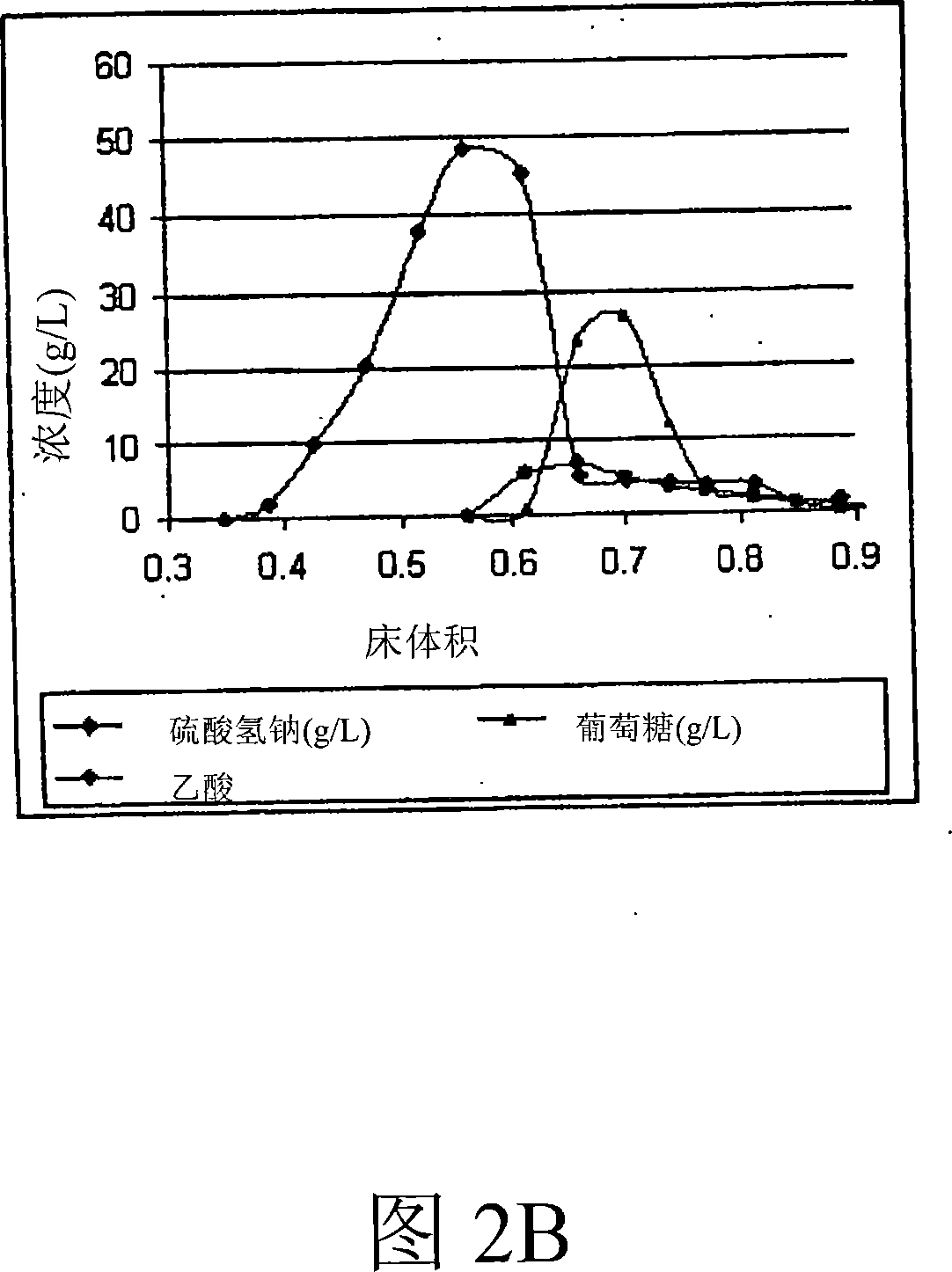

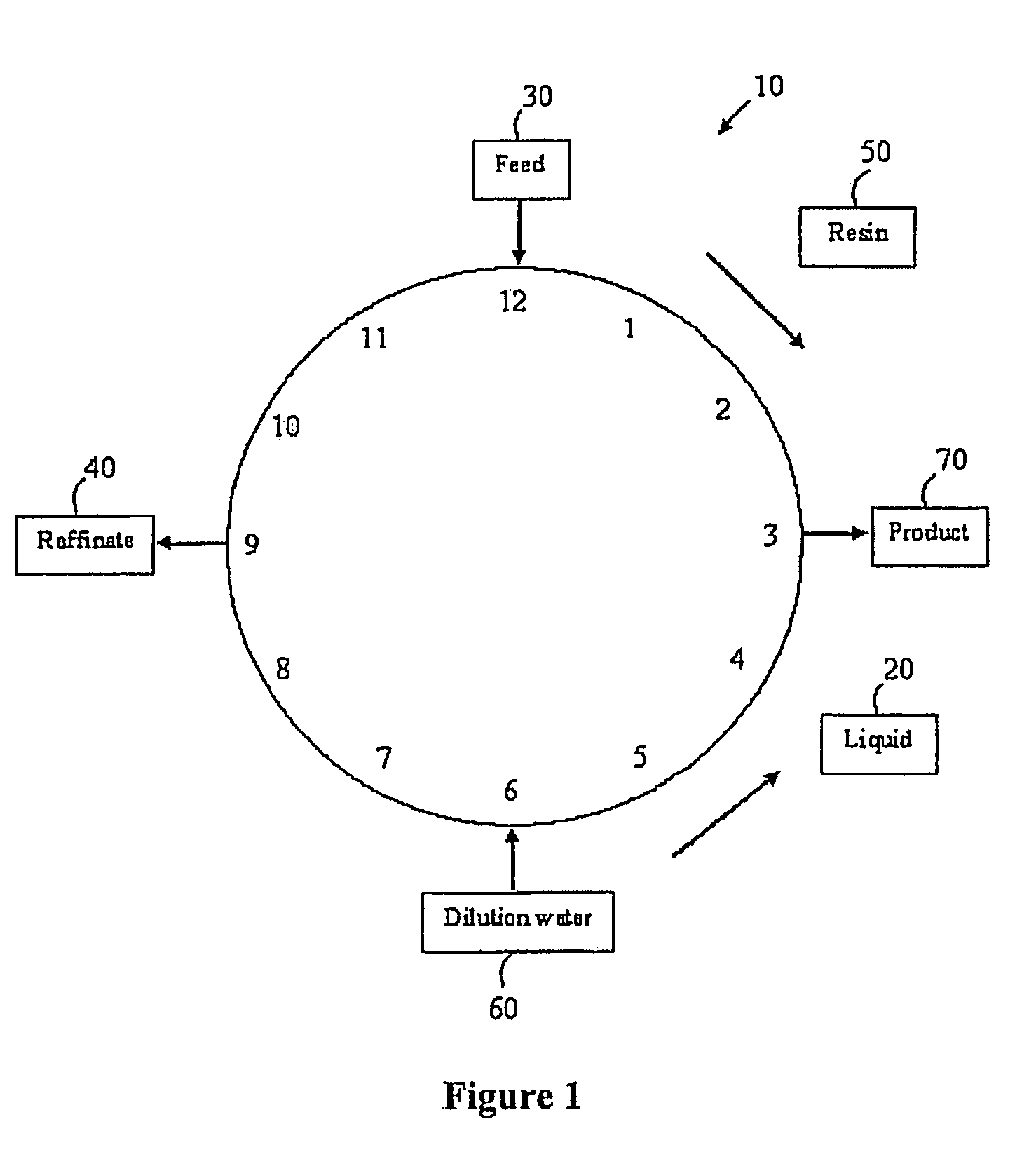

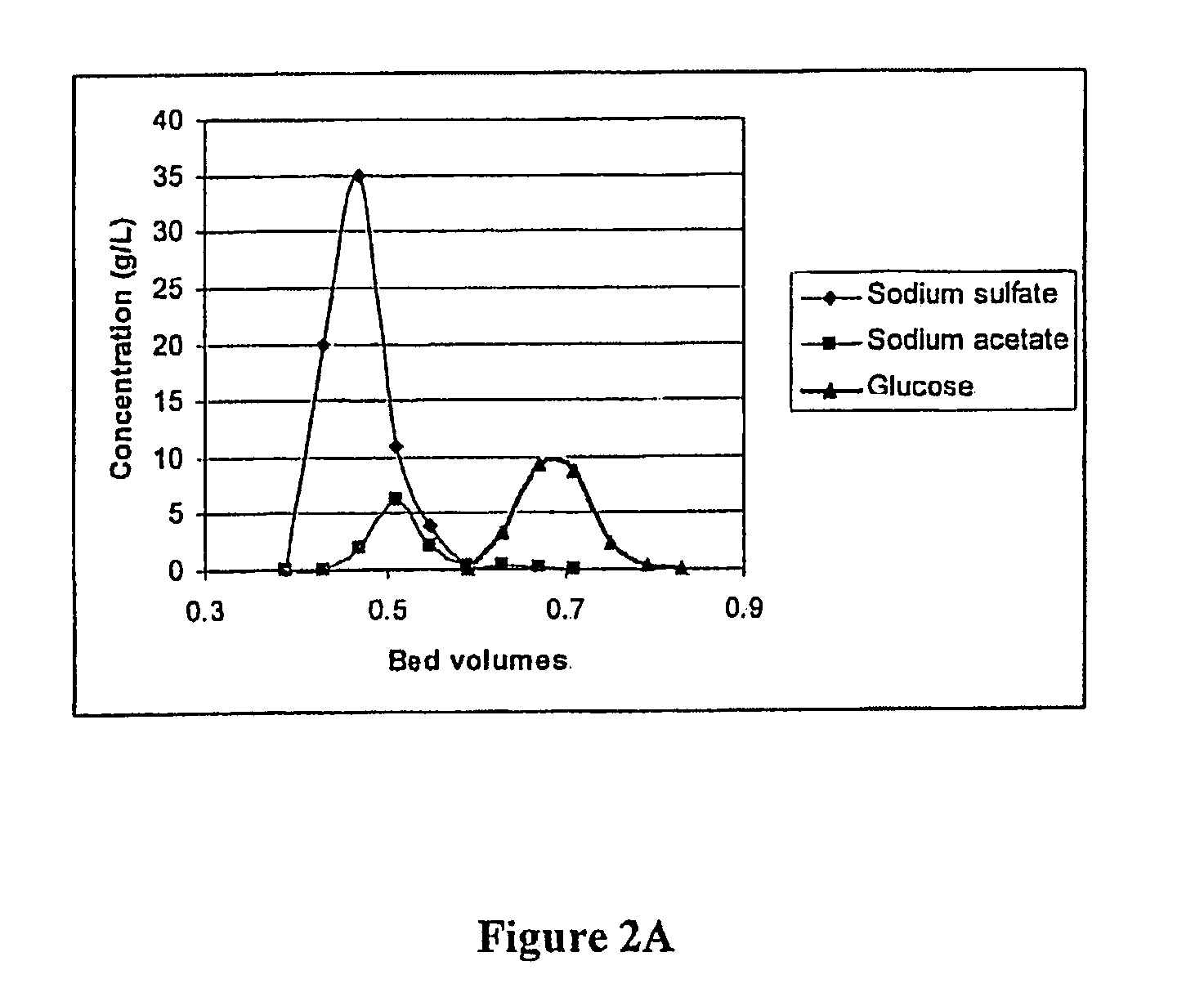

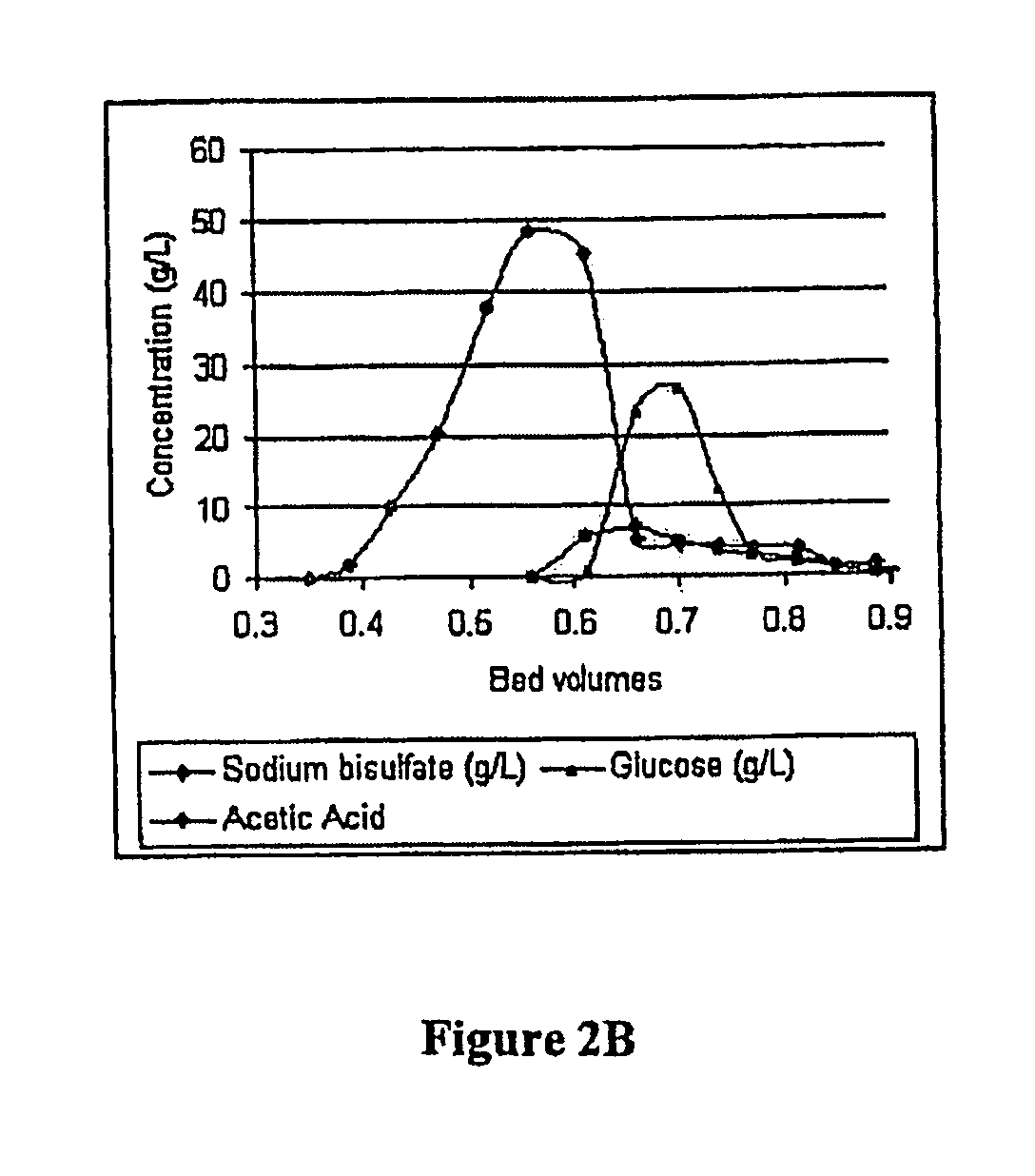

A process for obtaining a product sugar stream from cellulosic biomass is disclosed. In one process, the cellulosic biomass is pretreated at a pH between about 0.4 to 2.0 by adding one or more than one acid to produce a pretreated cellulosic biomass comprising acetic acid. One or more than one base is then added to the pretreated cellulosic biomass to adjust the pretreated cellulosic biomass to a pH of about 4.0 to about 6.0 to produce a neutralized cellulosic biomass comprising inorganic salt and acetate salt. The neutralized biomass is then hydrolyzed by cellulase enzymes to produce a crude sugar stream. Insoluble residue is separated from the crude sugar stream and the resulting clarified sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more raffinate streams and a product stream. The raffinate stream comprises inorganic salts and acetate salts, and the product stream comprises sugar. The product stream may then be fermented or otherwise further processed. In an alternate process, a product sugar stream is obtained from a crude sugar stream that is produced from conversion of cellulosic biomass to sugar. The cellulosic biomass may be produced using any suitable method. In this process the crude sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more than one raffinate stream comprising sulfate and acetate salts, and a product stream comprising sugar, and the product sugar stream is obtained.

Owner:IOGEN ENERGY CORP

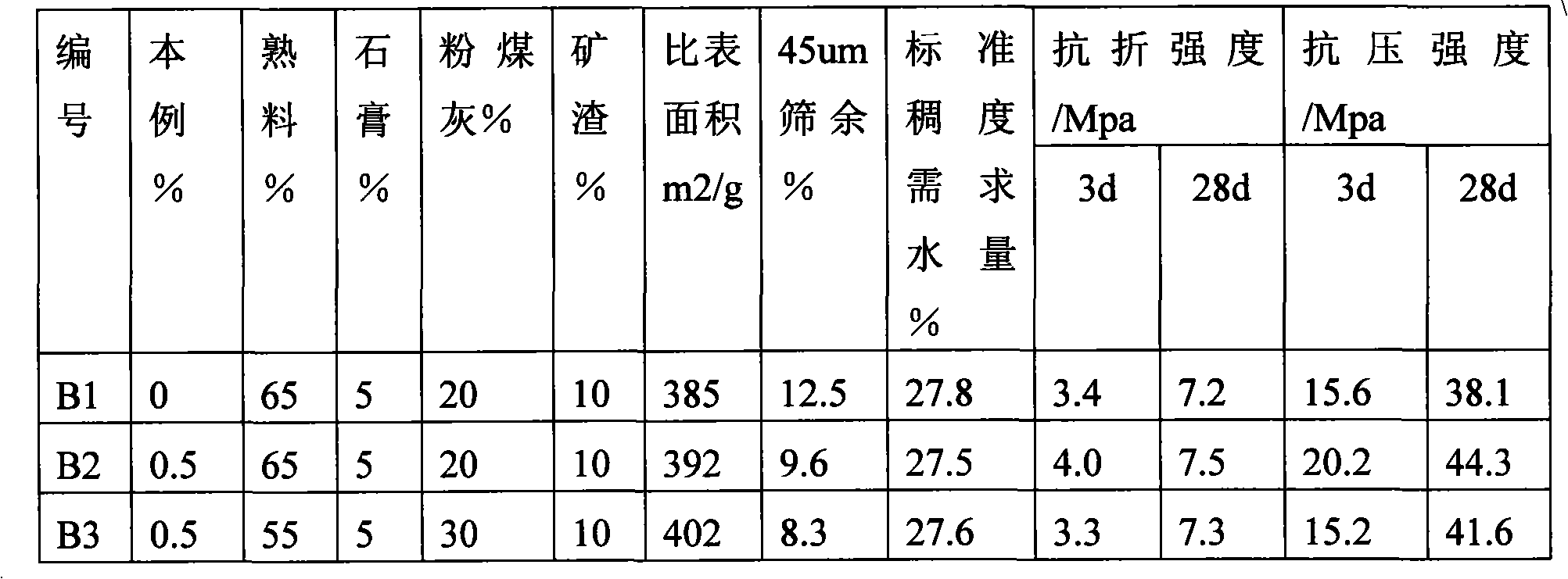

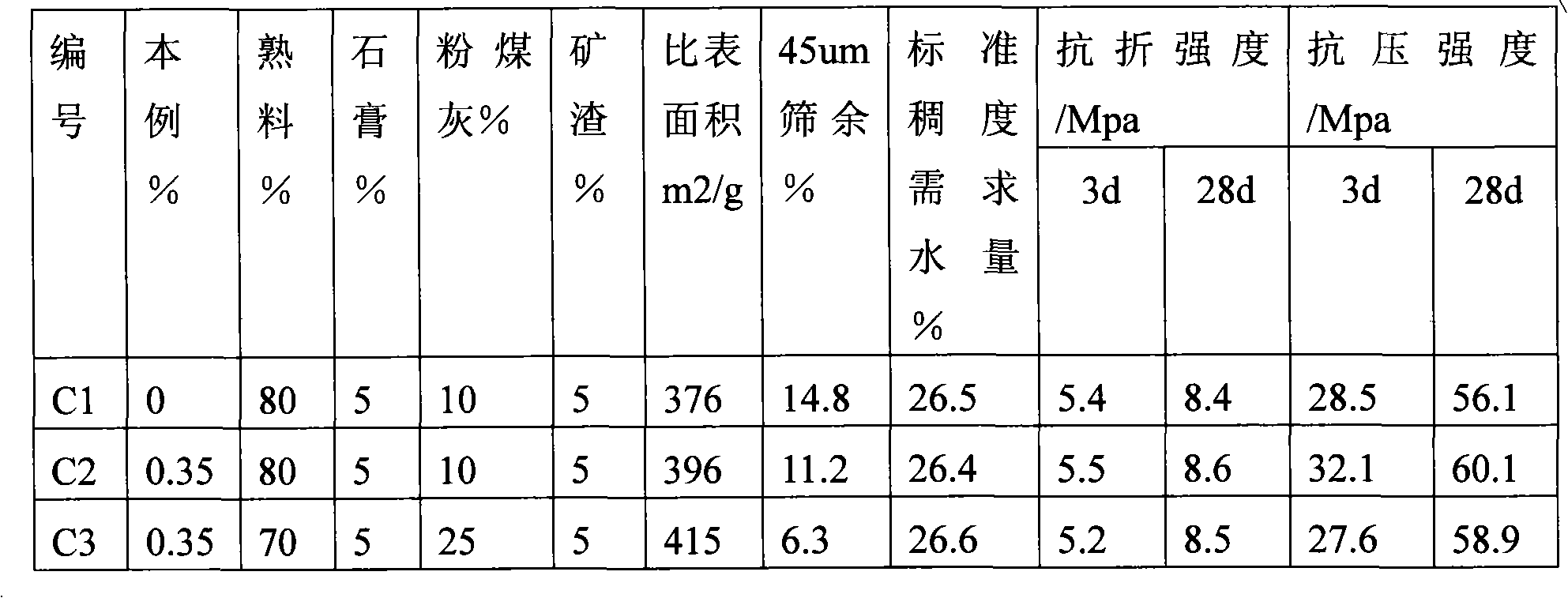

Chlorine-free powdery cement grinding aid and preparation method thereof

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

Acetate supplemention of medium for butanologens

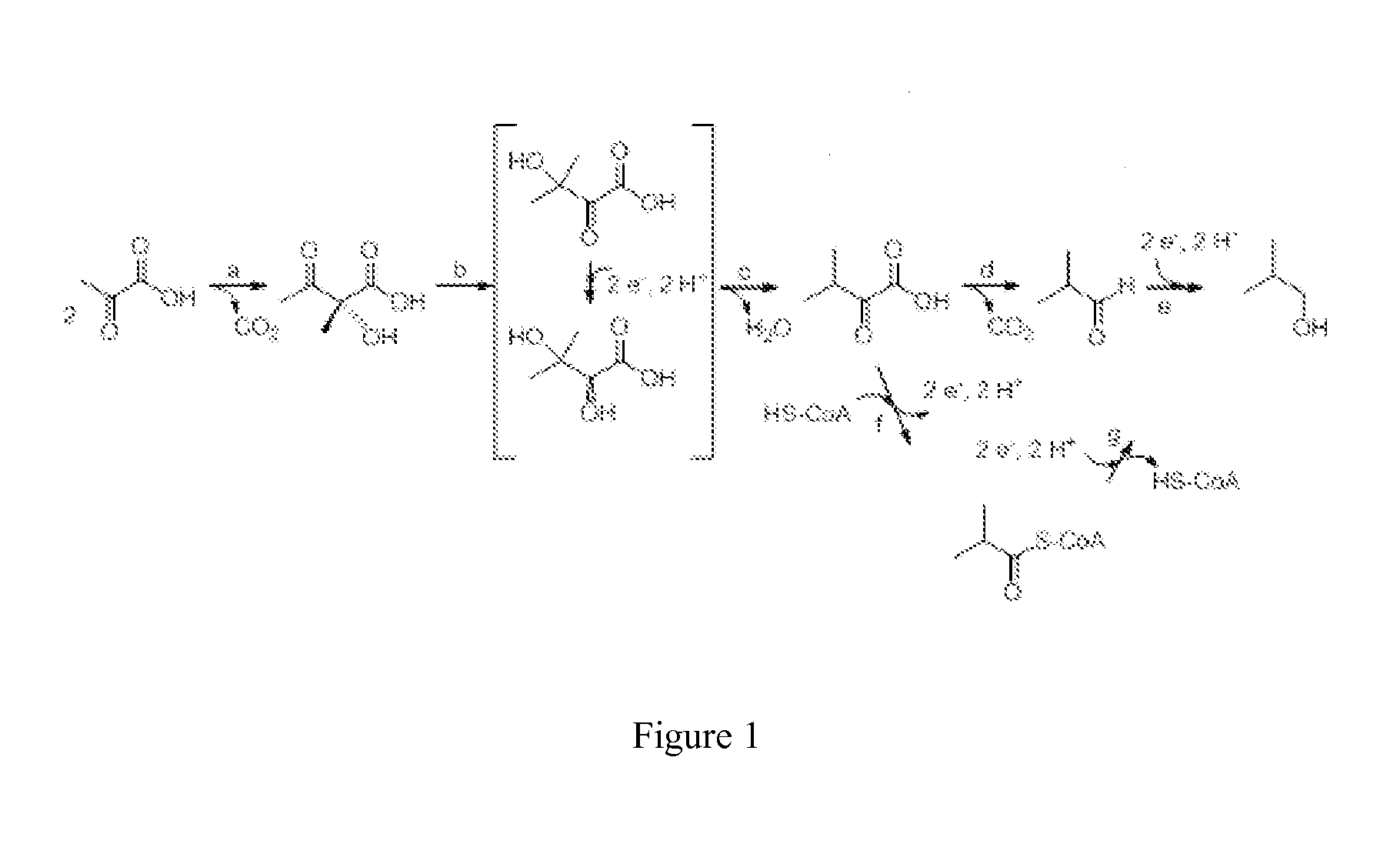

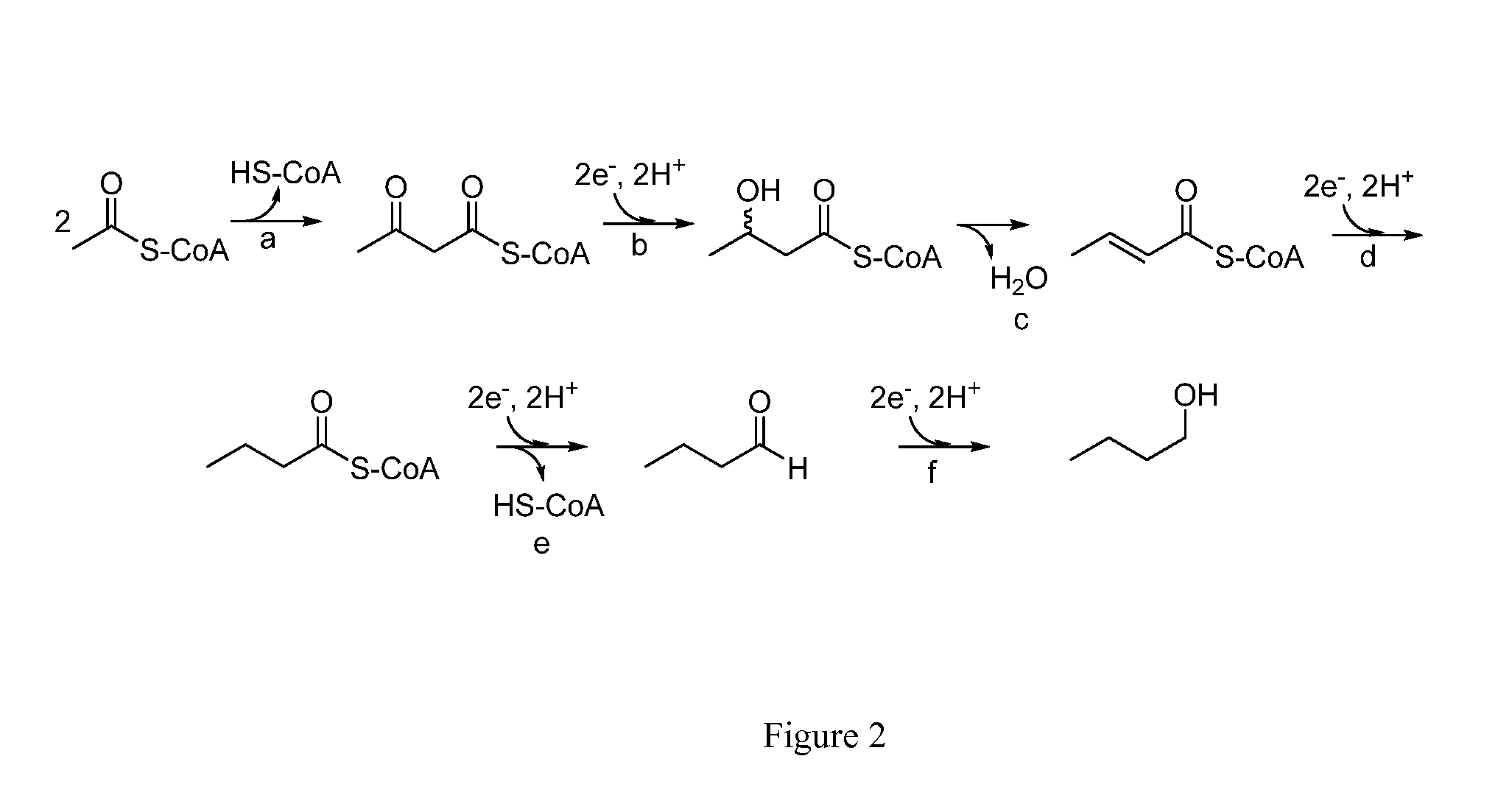

The invention relates to the fields of industrial microbiology and alcohol production. More specifically, the invention relates to improved production of butanol isomers by recombinant microorganisms containing an engineered butanol pathway and disrupted activity of the genes in pathways for the production of by-products during the fermentation when the microorganisms are grown in a fermentation medium containing acetate. In embodiments, recombinant microorganisms have an increased growth rate in a fermentation medium containing acetate as a C2 supplement.

Owner:GEVO INC

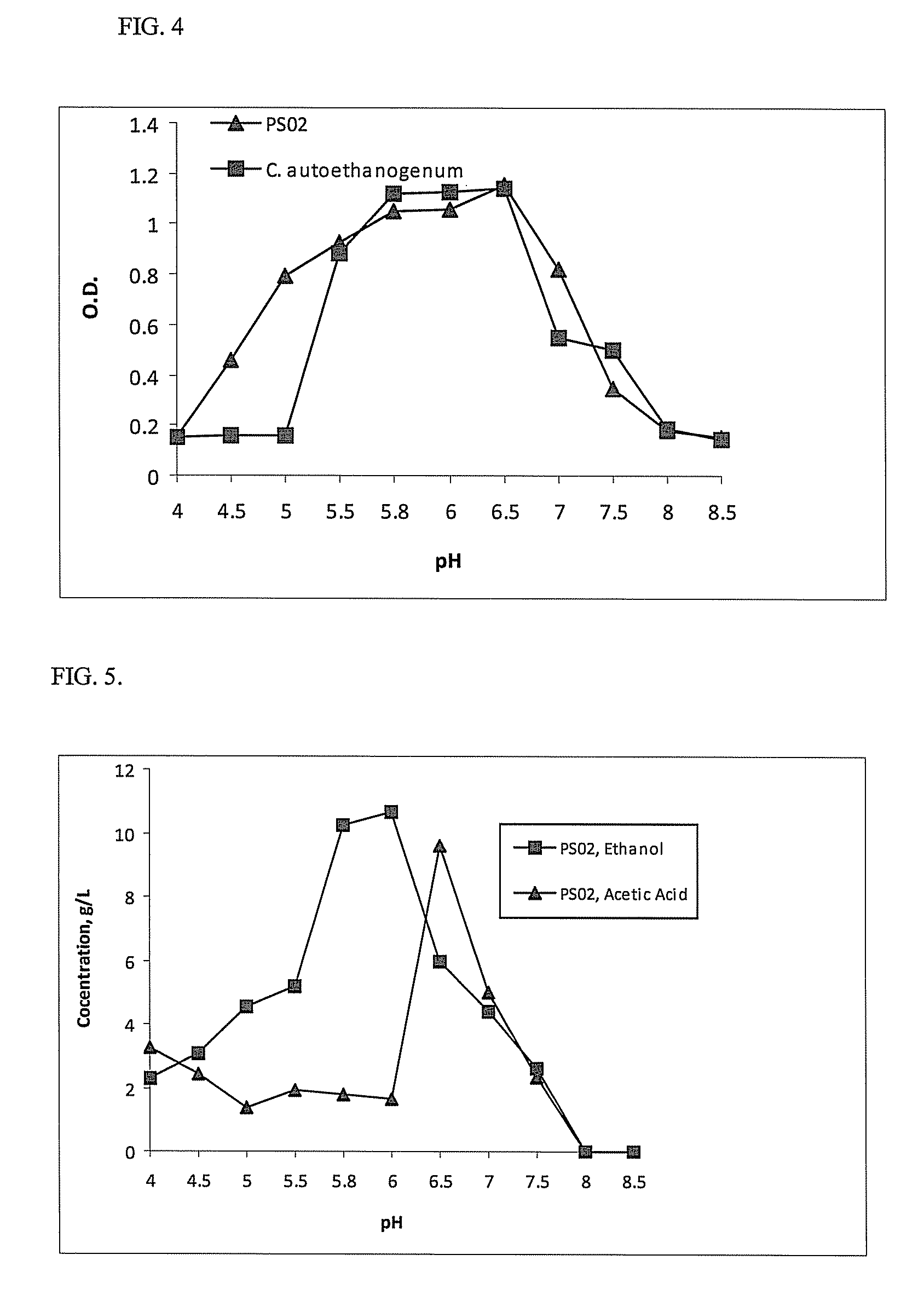

Ethanologenic Clostridium species, Clostridium coskatii

Owner:SYNATA BIO INC

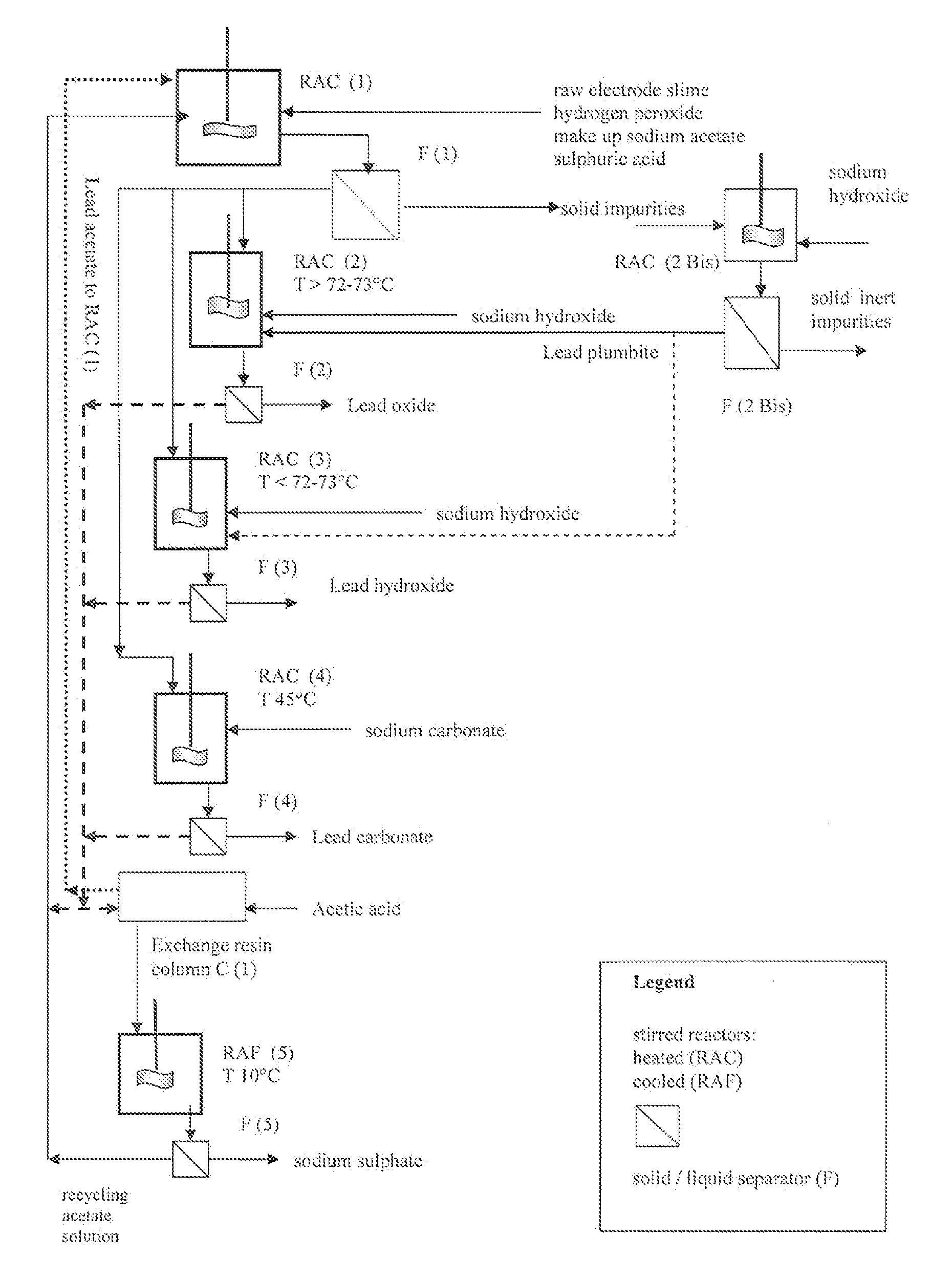

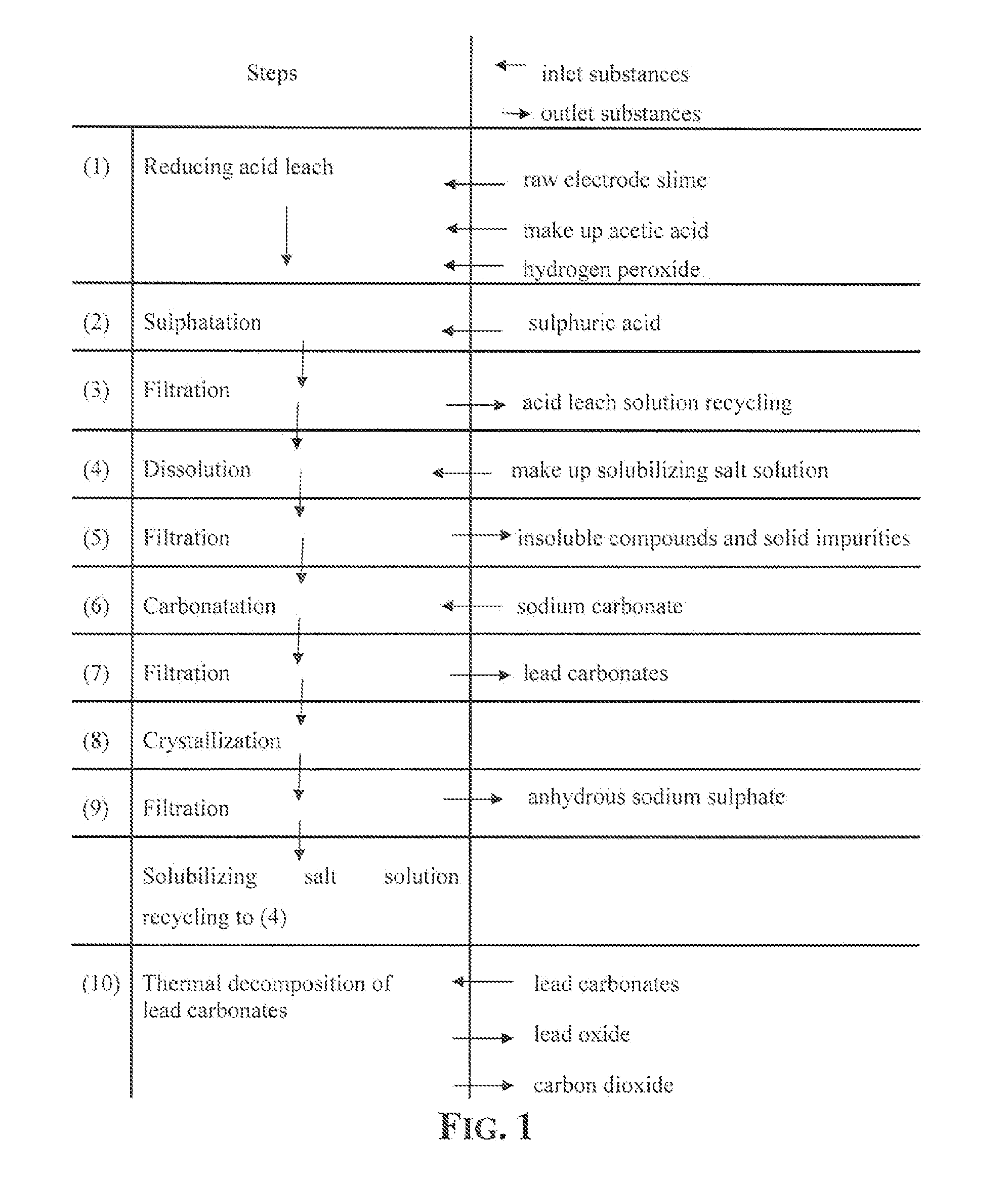

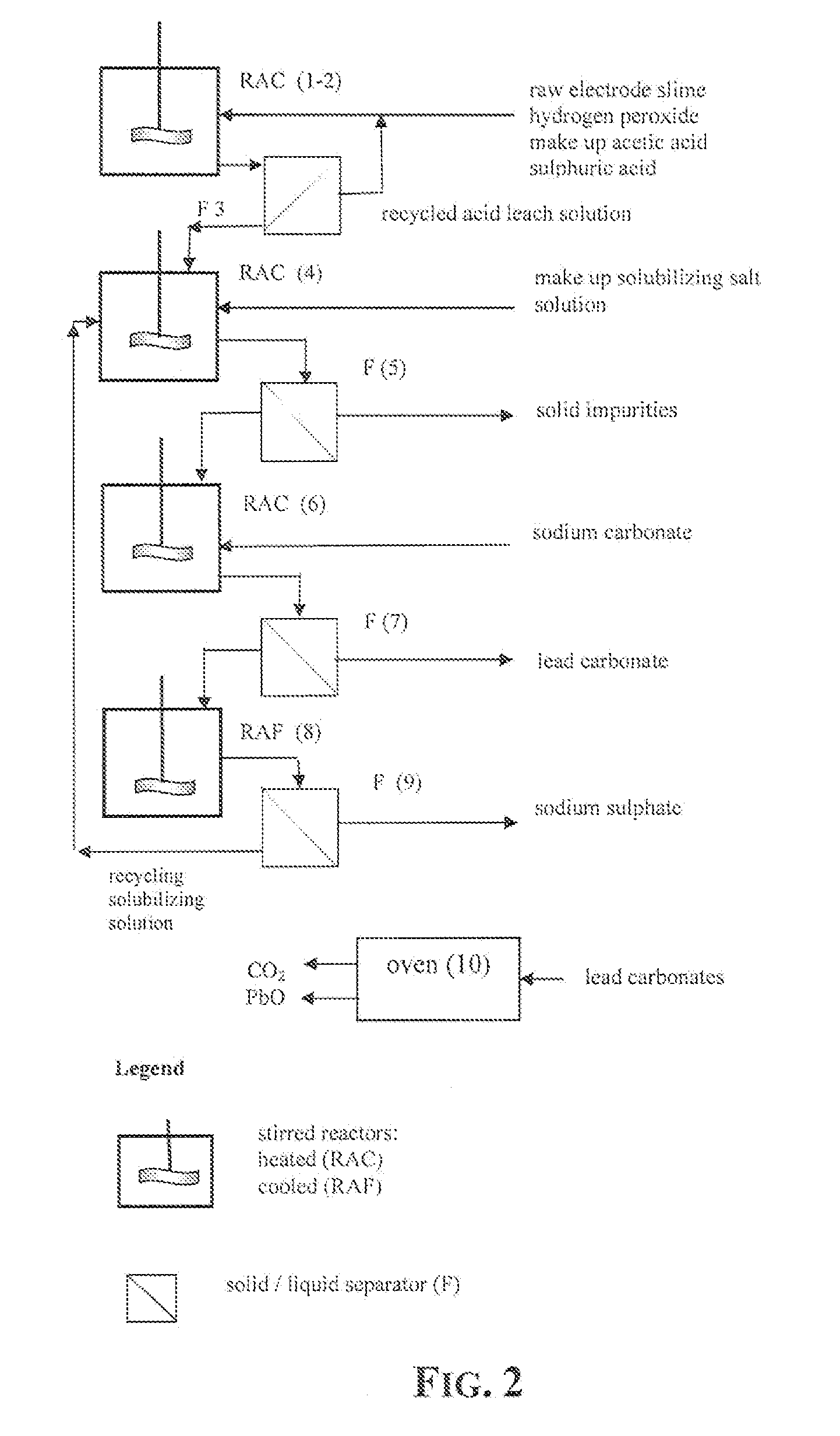

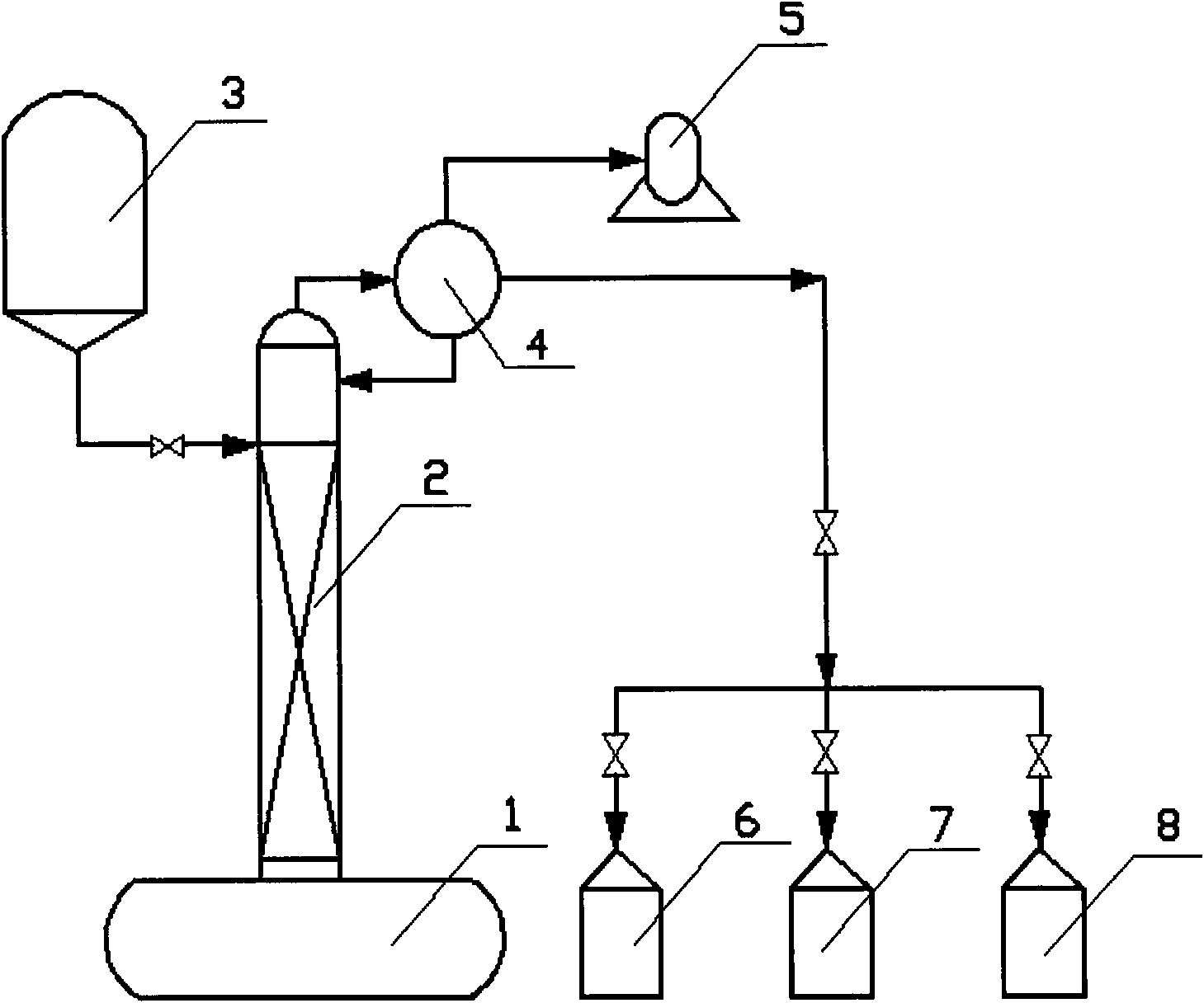

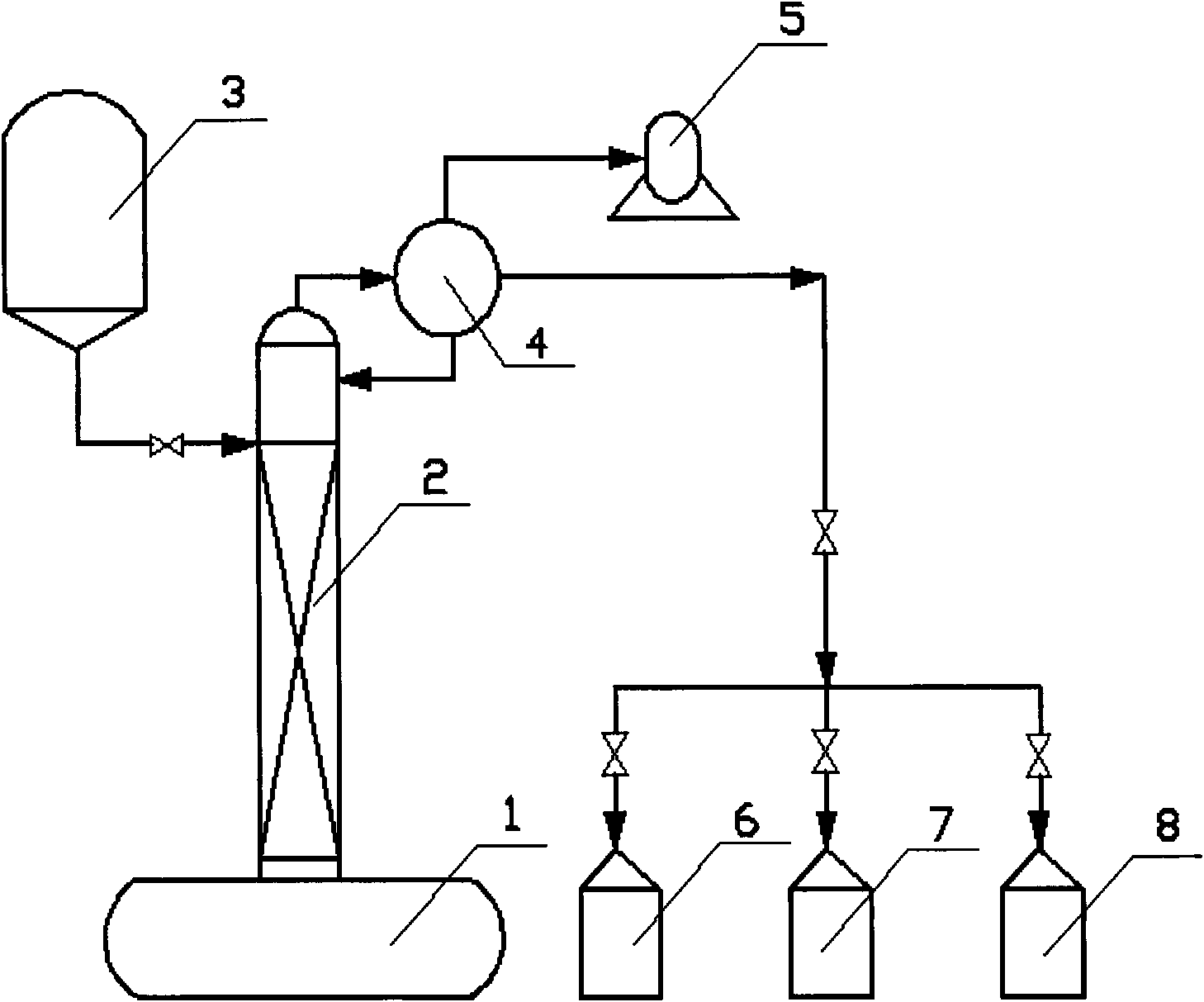

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

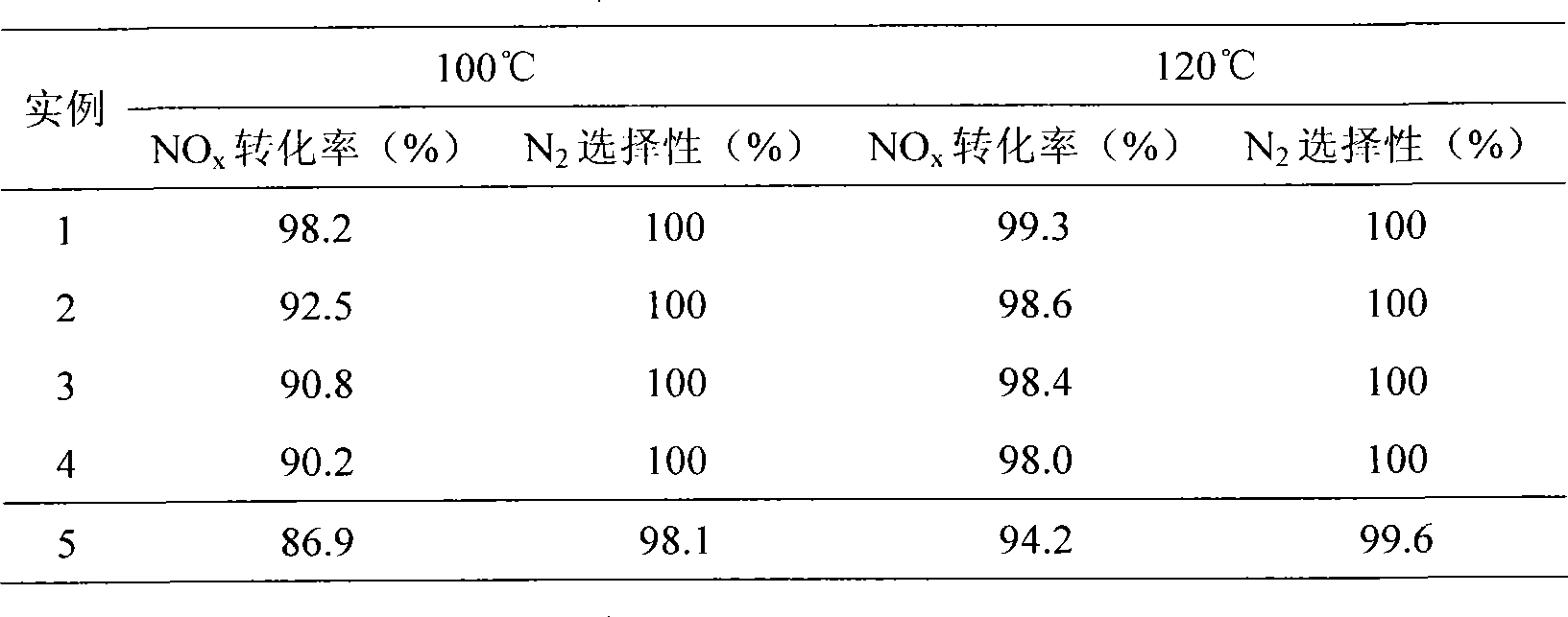

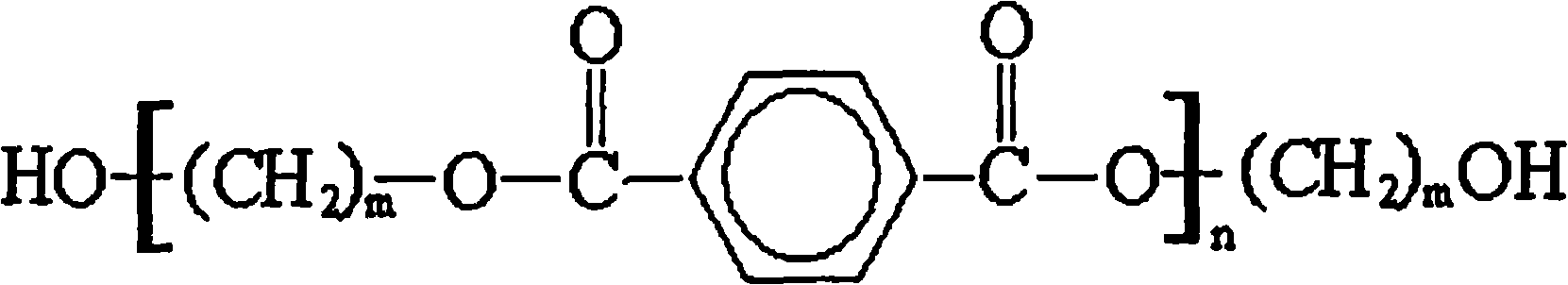

High-activity catalyst and its application in synthesizing polyester

A high-activity catalyst for both esterification and polycondensation contains anti-hydrolytic high-activity glycol titanium, the acetate, carbonate or oxalate of (1-4)-valence metal ions, and at least one of alkoxyl compound, organic acid and phosphorous compound. Its advantages are high activity, short reaction period, and no environmental pollution. Its resultant polyester has high photochemical performance and whiteness.

Owner:济南齐鲁化纤集团有限责任公司

Normal temperature formaldehyde removal catalysis material

InactiveCN104741130ALow costEfficient enrichmentDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCatalytic oxidation

The invention relates to a formula and a corresponding preparation technology of a normal temperature formaldehyde removal catalysis material, and belongs to the technical fields of normal temperature adsorption catalysis and air pollution treatment. The catalysis material is prepared by adopting a one-step co-precipitation process or a step-by-step dipping process to load active components with granular, cylindrical, spherical or honeycomb high-specific surface area shell activated carbon as a carrier, one or more non-noble metal salts as main active components, such as nitrate, sulfate or chloride of manganese, iron, cobalt, nickel, copper, zinc, lanthanum or cerium, one or more alkali metal / alkaline earth metal salts as an inorganic additive, such as oxalate, nitrate, sulfate, acetate, carbonate and bicarbonate of sodium, potassium, magnesium, calcium, and ethylenediamine tetracetic acid / ethylenediamine tetraacetic acid salt, basic amino acid, polyamide monomer and polyurethane monomer as a nitrogen-containing organic additive. The normal temperature formaldehyde removal catalysis material has the characteristics of rapid capture, high efficiency catalytic oxidation and long working cycle, and can meet requirements of long-time effective removal of formaldehyde in indoor real environment.

Owner:江苏瑞丰科技实业有限公司

Process for reversely recycling and preparing lithium nickel manganese oxide by taking waste lithium battery as raw material

ActiveCN103199230ARealize resource utilizationGood for regulating propertiesCell electrodesWaste accumulators reclaimingElectrolysisManganese oxide

The invention discloses a process for reversely recycling and preparing lithium nickel manganese oxide by taking waste lithium batteries as raw materials. The process is characterized by comprising the following steps of: (1) preprocessing a positive battery plate of a waste lithium battery to obtain anode power; (2) dissolving the anode power in inorganic acid, and eliminating impurities to obtain mixed acid liquor containing nickel and manganese; (3) adding a nickel source or a manganese source into the mixed solution; (4) adding an acetate complexing agent, and regulating the ratio of the acetate concentration to the total metal ion concentration; (5) putting the mixed solution into an electrolytic bath to be electrolyzed, and depositing nickel manganese oxide on a titanium plate; (6) stopping the conduction of a direct current, taking the titanium plate out, separating the nickel manganese oxide on the titanium plate, and drying the nickel manganese oxide to obtain nickel manganese oxide powder; (7) and uniformly mixing the nickel manganese oxide powder and a lithium source, and then calcining the mixture to obtain lithium nickel manganese oxide. According to the process, a regenerated product having the performance the same with the performance of the original product can be obtained by the waste battery through a reverse recycling process, so that the resource utilization can be realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

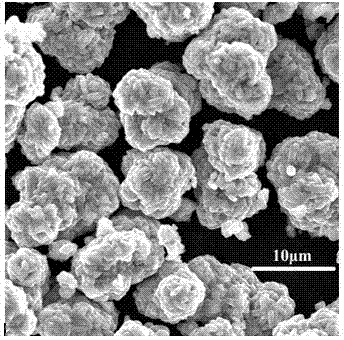

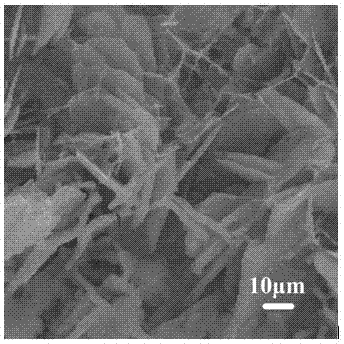

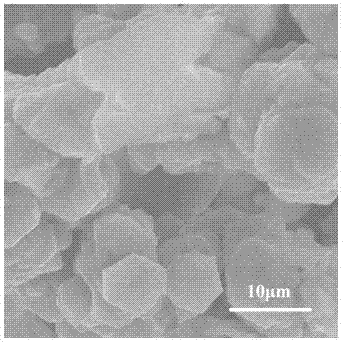

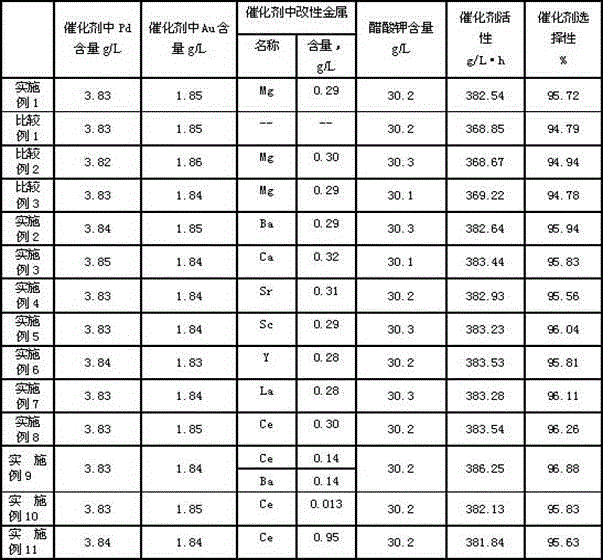

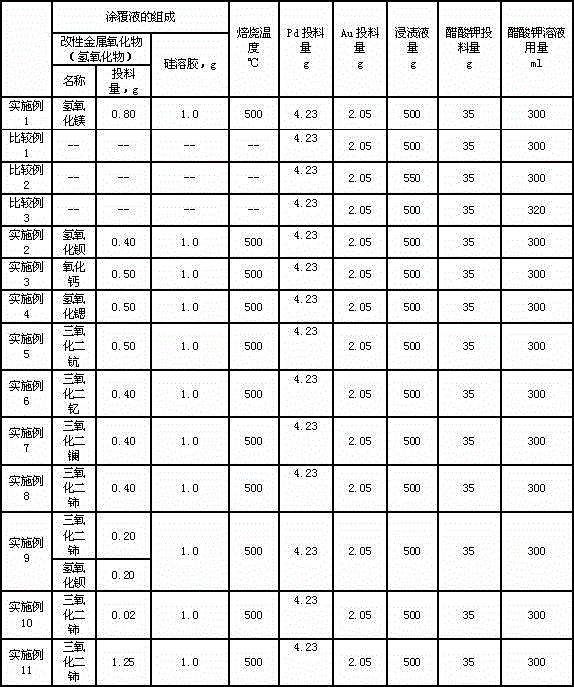

Vinyl acetate catalyst and application thereof

ActiveCN104549517AHigh activityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLow activityPtru catalyst

The invention relates to a vinyl acetate catalyst, a preparation method thereof and a method for synthesizing vinyl acetate in order to mainly solve the problem of low activity and selectivity of a catalyst in the prior art. The problem is better solved through the technical scheme that the vinyl acetate catalyst comprises a carrier, active components and a catalyst promoter, wherein the active components include metal Pd and metal Au; the catalyst promoter is alkali metal acetate; the carrier is silicon dioxide provided with a coating on the surface; the coating is prepared from modified metal elements and a silicon dioxide adhesive for adhering the modified metal elements on the surface of the carrier; 0.01-1.00g / L of the modified metal elements are contained; the modified metal elements are at least one selected from IIA metal elements and IIIB metal elements. The vinyl acetate catalyst can be used for industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of obtaining inorganic salt and acetate salt from cellulosic biomass

InactiveUS20080182305A1Improve performanceReduce system complexityFermentationAcetic acidInorganic salts

A process for obtaining inorganic salt and acetate salt from cellulosic biomass is disclosed. The cellulosic biomass is pretreated by adding one or more than one acid or base to produce a pretreated cellulosic biomass comprising acetic acid or acetate salt. One or more than one base or acid is then added to the pretreated cellulosic biomass to adjust the pretreated cellulosic biomass to a pH of about 4.0 to about 6.0 to produce a neutralized cellulosic biomass comprising inorganic salt and acetate salt. The neutralized biomass is then hydrolyzed by cellulase enzymes to produce a sugar stream. Streams arising from the processing of the cellulosic biomass to sugar are subjected to ion exclusion chromatography performed at pH 5.0 to about 10.0 to produce a stream comprising an inorganic salt and an acetate salt.

Owner:IOGEN ENERGY CORP

Method for separating methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification

InactiveCN102180791AIncrease relative volatilityNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationMethyl acetateMass content

The invention discloses a method for separating a methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification, which is realized in a way that: a rectifier of an extractive rectification tower is adopted, an ionic liquid 1-ethyl-3-methyl imidazolyl acetate is used as an extractant, and the operation is carried out intermittently, so the top of the extractive rectification tower sequentially produces a methyl acetate product of which the mass content is up to 98-99.9%, a methyl acetate-methanol transitional fraction and methanol of which the mass content is 97-99%; and finally, the extractant of which the mass percent is 99% is left in the heating kettle. The invention has the following advantages: the extractant is adopted to enhance the relative volatility of the methyl acetate-methanol system, the purity of the separated methyl acetate product is high, and the ionic liquid used as the extractant is easy to recover and does not pollute the environment; and only one single tower needs to be operated, so that operation is flexible and the equipment investment is low.

Owner:TIANJIN UNIV

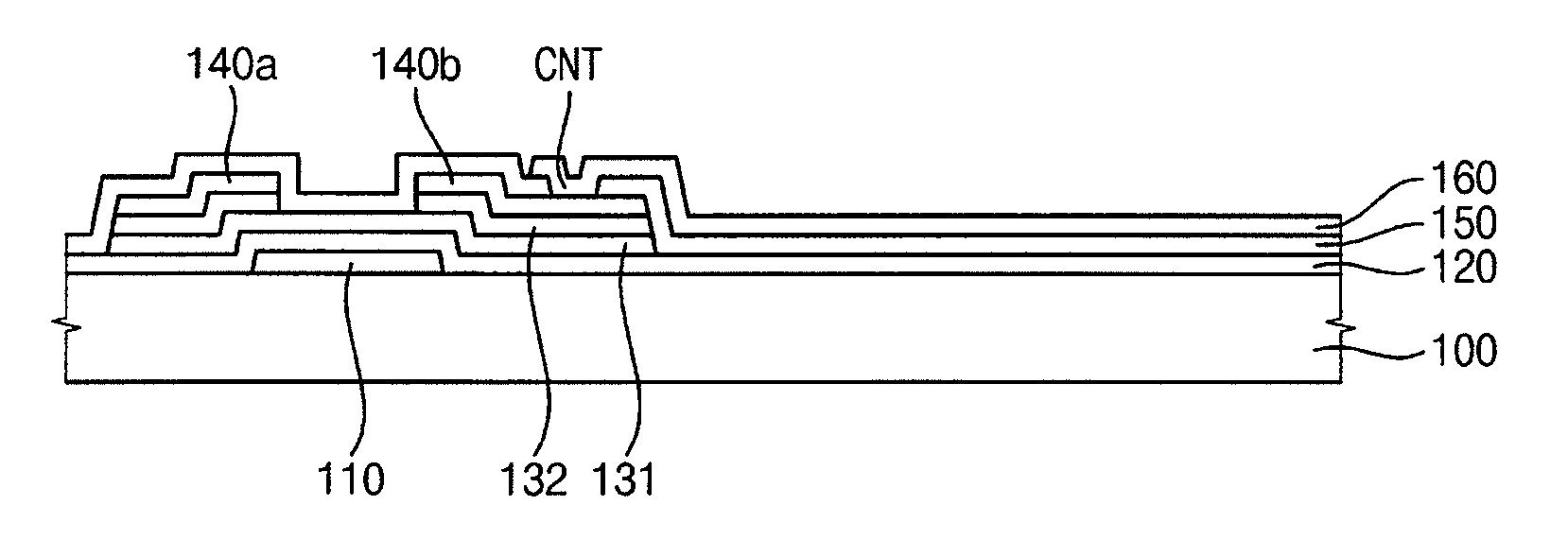

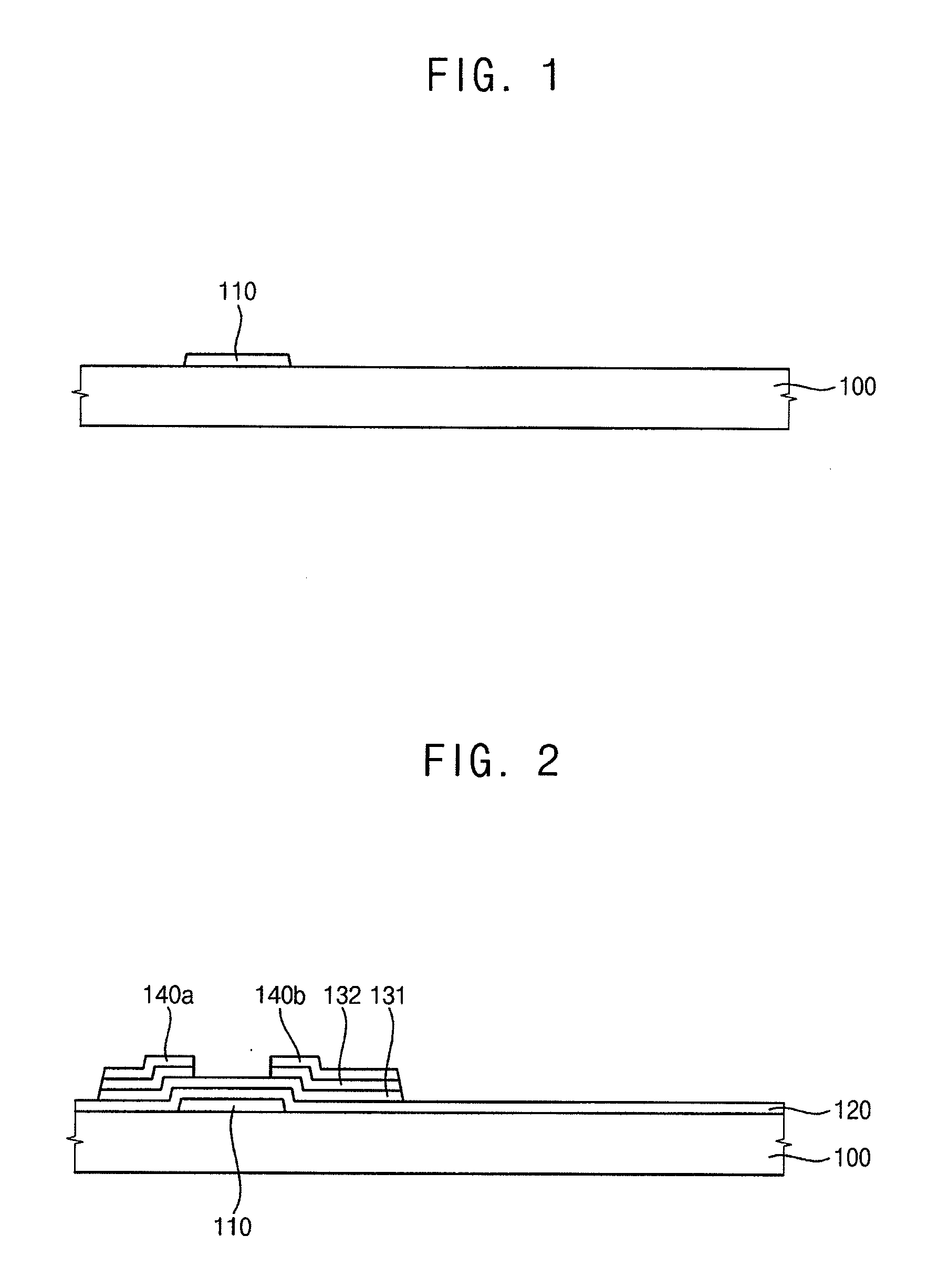

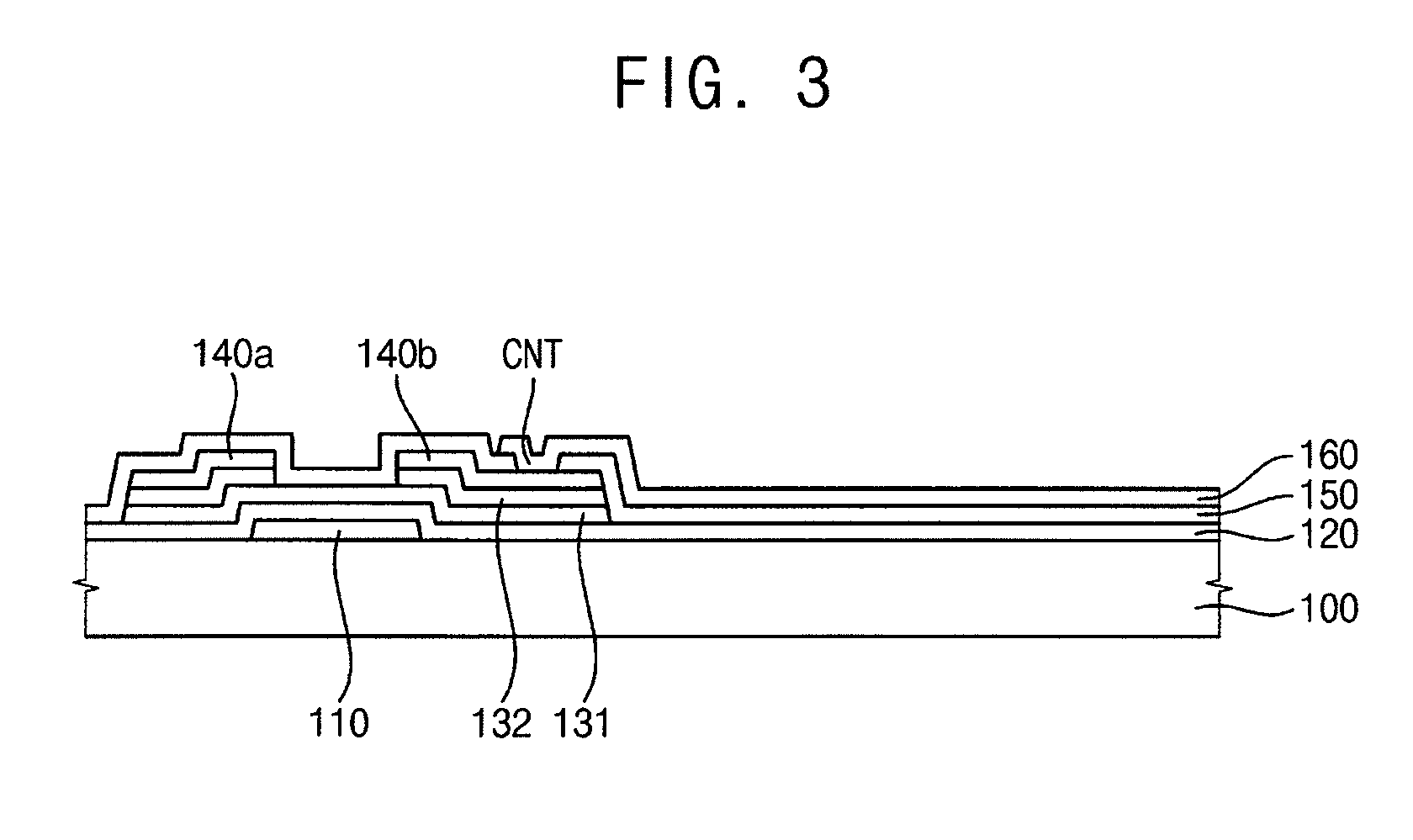

Etchant and method of manufacturing an array substrate using the same

ActiveUS20100291722A1Improve stabilityReduced stabilitySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing cost reductionFluorine containing

An etchant includes about 0.1 percent by weight to about 30 percent by weight of ammonium persulfate (NH4)2S2O8, about 0.1 percent by weight to about 10 percent by weight of an inorganic acid, about 0.1 percent by weight to about 10 percent by weight of an acetate salt, about 0.01 percent by weight to about 5 percent by weight of a fluorine-containing compound, about 0.01 percent by weight to about 5 percent by weight of a sulfonic acid compound, about 0.01 percent by weight to about 2 percent by weight of an azole compound, and a remainder of water. Accordingly, the etchant may have high stability to maintain etching ability. Thus, manufacturing margins may be improved so that manufacturing costs may be reduced.

Owner:SAMSUNG DISPLAY CO LTD

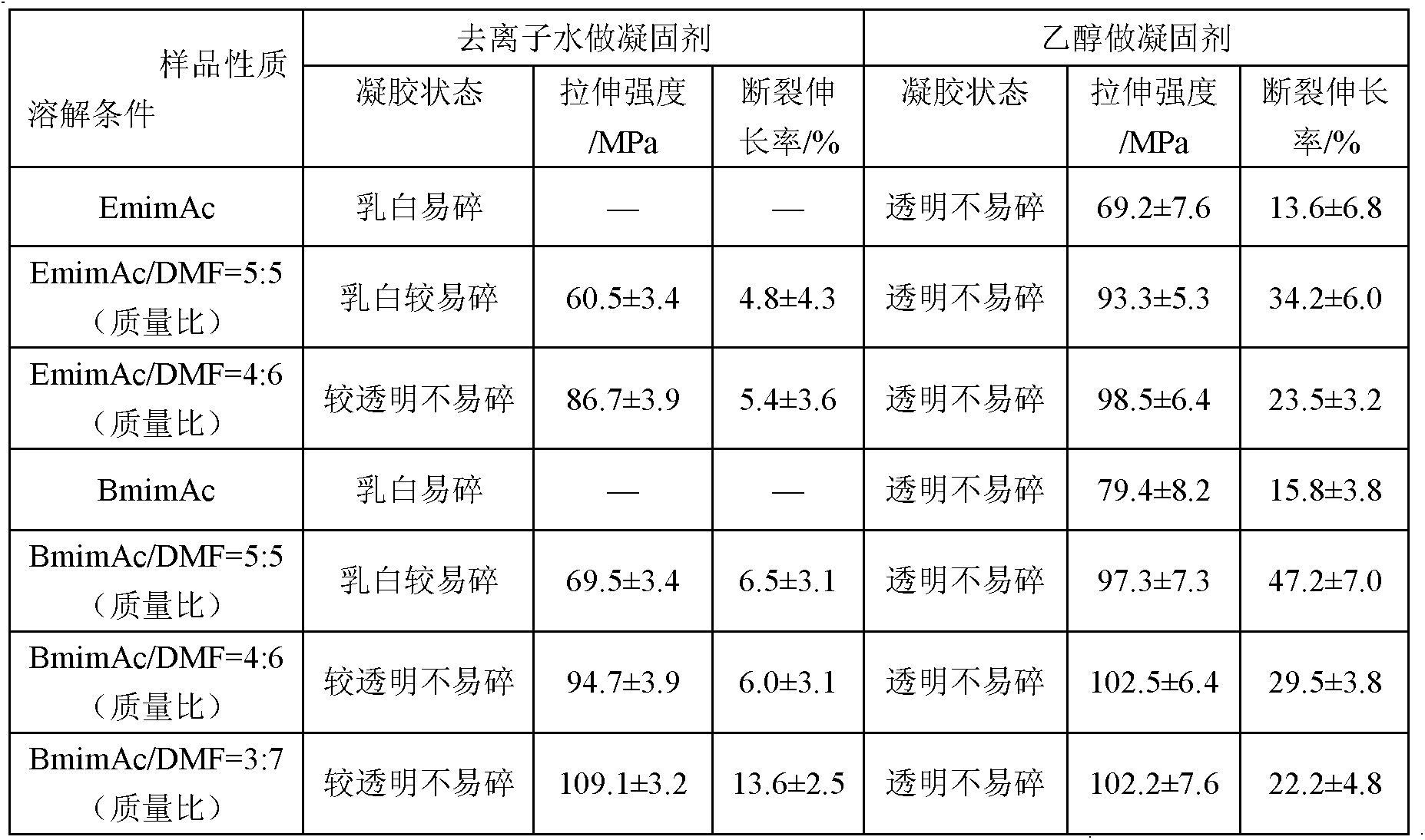

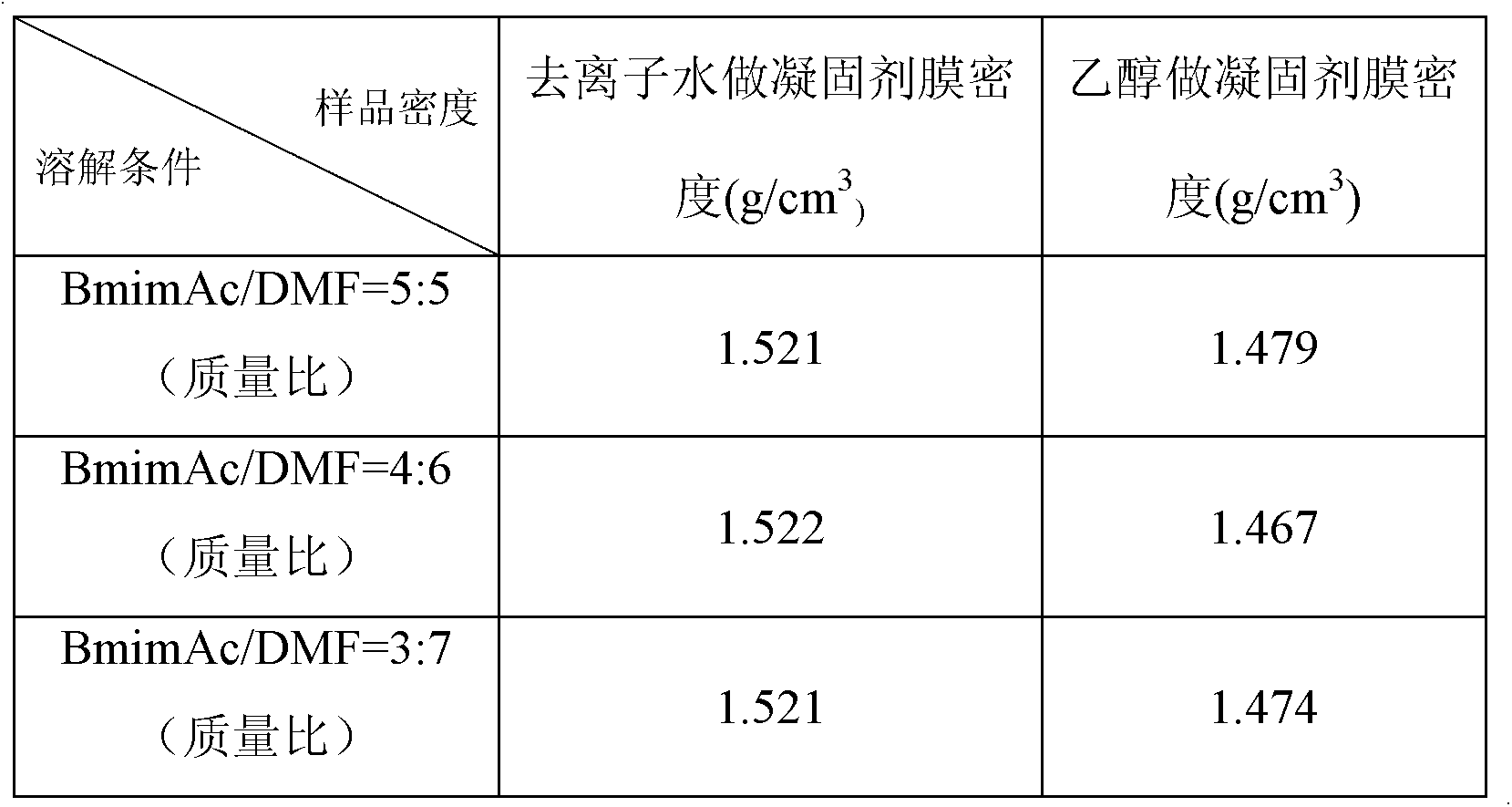

Preparation method of regenerated cellulose material

ActiveCN104130425AImprove mechanical propertiesImprove toughnessBulk chemical productionCarboxylic acidEthane Dichloride

The invention belongs to the technical field of preparation of a regenerated cellulose material and discloses a preparation method of the regenerated cellulose material. A employed solvent is a carboxylic acid type ionic liquid or is a co-solvent which is composed of the carboxylic acid type ionic liquid and an active-proton-free polar organic solvent, wherein the carboxylic acid type ionic liquid is preferably selected from 1-ethyl-3-methylimidazole acetate, 1-propyl-3-methylimidazole acetate or 1-butyl-3- methylimidazole acetate; an auxiliary solvent is selected from one or more of DMF, DMAc, DMI, DMSO, pyrrodine, acetone, dichloromethane and dichloroethane; and a solidifying agent is preferably selected from alcohol organic solvents. The carboxylic acid type ionic liquid is most preferably selected from the 1-ethyl-3-methylimidazole acetate and the 1-butyl-3-methylimidazole acetate; the auxiliary solvent is most preferably DMF; and the solidifying agent is preferably ethanol; wherein a mass ration of the carboxylic acid type ionic liquid to the auxiliary solvent is 5:5. By means of the preparation method, mechanical performances of a regenerated cellulose product can be significantly improved and environmental pollution can be reduced.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Electroreduction carbon dioxide catalytic material, preparation method and applications thereof

ActiveCN109382106ASuitable for industrial applicationsChange the catalytic active siteCell electrodesGrapheneDoped graphenePtru catalyst

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Acetaminophen compositions

InactiveUS7029698B2Maintaining clarity of appearanceSubject to degradationBiocideAmide active ingredientsAcetic acidCLARITY

The invention herein provides for an oral pharmaceutical composition adapted for use in capsular dosage forms comprising acetaminophen and a lactate salt alone or in combination with an acetate salt. Compositions of the invention exhibit improved solubility characteristics of the active ingredient per given fill volume, thereby permitting the use of smaller capsule sizes to deliver a given effective dose of the active ingredient. Compositions of the invention also exhibit improved clarity per concentration of active ingredient. The invention also provides for a capsular dosage form containing the composition.

Owner:R P SCHERER TECH INC

Method of obtaining a product sugar stream from cellulosic biomass

InactiveCN101023179AHigh recovery rateIncrease concentrationBiofuelsFermentationInorganic saltsAcetic acid

A process for obtaining a product sugar stream from cellulosic biomass is disclosed. In one process, the cellulosic biomass is pretreated at a pH between about 0.4 to 2.0 by adding one or more than one acid to produce a pretreated cellulosic biomass comprising acetic acid. One or more than one base is then added to the pretreated cellulosic biomass to adjust the pretreated cellulosic biomass to a pH of about 4.0 to about 6.0 to produce a neutralized cellulosic biomass comprising inorganic salt and acetate salt. The neutralized biomass is then hydrolyzed by cellulase enzymes to produce a crude sugar stream. Insoluble residue is separated from the crude sugar stream and the resulting clarified sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more raffinate streams and a product stream. The raffinate stream comprises inorganic salts and acetate salts, and the product stream comprises sugar. The product stream may then be fermented or otherwise further processed. In an alternate process, a product sugar stream is obtained from a crude sugar stream that is produced from conversion of cellulosic biomass to sugar. The cellulosic biomass may be produced using any suitable method. In this process the crude sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more than one raffinate stream comprising sulfate and acetate salts, and a product stream comprising sugar, and the product sugar stream is obtained.

Owner:IOJIN ENERGY LTD

Preparation method for synthesizing methanol catalyst

InactiveCN1891337AHigh activityImprove heat resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsNitrateAlcohol

This invention relates to a preparation method for synthesizing methyl alcohol catalyst-acid-alkali alternate deposition method including: 1, solving the nitrate or acetate of Cu, Zn and Al in water to get a mixed salt solution, 2, preparing alkali solution, 3, alternately adding the alkali solution and the mixed salt solution in a deposition tank while mixing to alter the PH value of the mother liquor with the PH value of 1.0-12.0, 4, aging the deposition mother liquor under mixing then to wash, filter, dry the cakes, bake to press or squeeze them to molding, in which, one nitrate or acetate of Zr, Mg, Mn, Cr, La or Ce can be added into the mixed solution in step 1.

Owner:ZHEJIANG UNIV OF TECH

Method of obtaining a product sugar stream from cellulosic biomass

The invention relates to a process for obtaining a product sugar stream from a cellulosic biomass, comprising pretreating the cellulosic biomass to hydrolyze a portion of the cellulose and hemicellulose to produce glucose, acetic acid and a sugar monomer, adding base to the pretreated cellulosic biomass to produce inorganic salt and acetate salt; hydrolyzing the neutralized cellulosic biomass with cellulase enzymes and separating insoluble residue from the resulting sugar stream; treating the clarified sugar stream using exclusion chromatography at a pH of 5 to 10 to produce a product sugar stream.

Owner:IOGEN ENERGY CORP

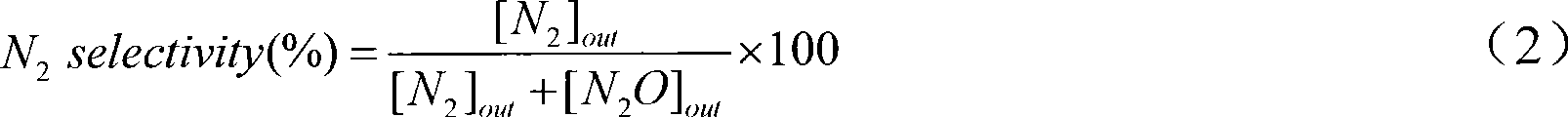

Ferro manganese composite oxides catalyst and preparation method and use thereof

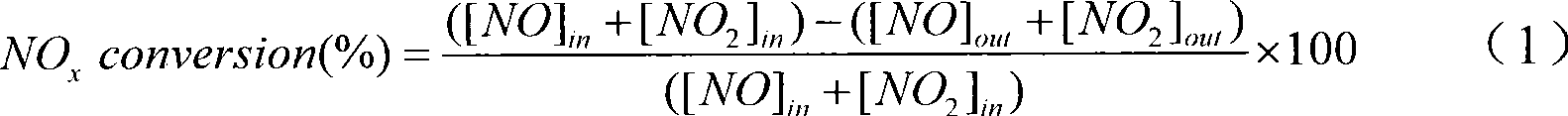

InactiveCN101507928AReduced denitrification efficiencyHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsIron saltsManganese

The invention discloses an iron-manganese compound oxide catalyst for selectively catalyzing and reducing nitric oxides in flue gas at a low temperature and a preparation method thereof and application thereof. The catalyst comprises active components such as iron element, manganese element, auxiliary agent element and the like. The method for preparing the catalyst comprises the following steps: 1, the iron salt and the manganese salt are mixed, and added with nitrate or acetate of the auxiliary agent element to obtain a mixed metal salt; 2, a solution of citric acid is added in the mixed metal salt and evenly mixed by stirring; 3, at the constant temperature of between 40 and 160 DEG C, the mixed solution is dried to give a solid; 4, the solid is calcined in the air for 1 to 8 hours, the calcination temperature is between 200 and 900 DEG C, and a mixed oxide is obtained; and 5, the mixed oxide is ground, tabletted and screened to obtain the finished product of the catalyst. The catalyst can selectively catalyze and reduce nitric oxides in the flue gas at a low temperature under the aerobic condition, so that the catalyst has the characteristics of high activity, high selectivity and high stability.

Owner:SOUTH CHINA UNIV OF TECH

Liquid titanium catalyst for polyester and copolyester and preparation method thereof

The invention relates to a preparation method of a liquid titanium catalyst for polyester and copolyester, which comprises the following steps of: (A) reacting a titanium compound, tetraethoxysilane and hydroxy carboxylic acid in a solvent at 0-100 DEG C for 0.1-24 hours, wherein the titanium compound is Ti(OR)4, and R is selected from alkyls of 1 to 10 carbon atoms; and (B) adding a phosphorous compound and acetate which is selected from metal elements of Na, Mg, Al, Zn and La into a reaction product in the step (A), reacting at 50-200 DEG C for 0.1-48 hours and removing micro-molecules to obtain the liquid titanium catalyst. By introducing a silicon element and other metal elements into the titanium catalyst and optimizing the preparation process condition of the catalyst, the catalyticactivity of the catalyst is regulated; the prepared catalyst can be mutual soluble with glycol and can be stably stored; and the polyester and copolyester prepared by using the catalyst have good hueand narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation of pyrrole gastric acid secretion inhibitor compound salt

InactiveCN105693693AMeet different clinical drug needsAntibacterial agentsOrganic chemistryDiseaseAcyl group

Belonging to the technical field of chemical drugs, the invention in particular relates to a 5-(2-fluorophenyl)-N-methyl-1-(3-pyridylsulfonyl)-1H-pyrrole-3-methyl ammonia inorganic acid salt or organic acid salt compound with the effect of treating gastric acid related diseases. The invention makes water solubility and stability study on related salt compounds, also provides a preparation method of corresponding salts, and performs crystal form study on 5-(2-fluorophenyl)-N-methyl-1-(3-pyridylsulfonyl)-1H-pyrrole-3-methyl ammonia acetate.

Owner:JIANGSU CAREFREE PHARM CO LTD

Method for preparing L-ornithine-L aspartate

ActiveCN101798275AImprove pass rateReduce productionOrganic compound preparationAmino-carboxyl compound preparationActivated carbonChemistry

The invention discloses a method for preparing L-ornithine-L aspartate, which has the characteristics of taking L-ornithine acetate as a raw material and reacting the L-ornithine acetate with L-aspartate in water. The method particularly comprises the following steps of: dissolving the L-ornithine acetate in the water; adding the L-aspartate into the solution; regulating a pH value of the solution to be between 6 and 9 with ammonia; adding activated carbon for de-coloring and filtering; adding a reasonable amount of ethanol or methanol into a filtrate for stirring and crystallizing; and filtering and drying the filtrate to obtain the finished product. The method has the advantages of overcoming the defects existing in the prior art by using the property that ammonium acetate is easy to dissolve in the aqueous solution of alcohol, and also has the advantages of high yield, moderate reaction conditions, simple operation, stable product quality and the like.

Owner:福安药业集团重庆博圣制药有限公司

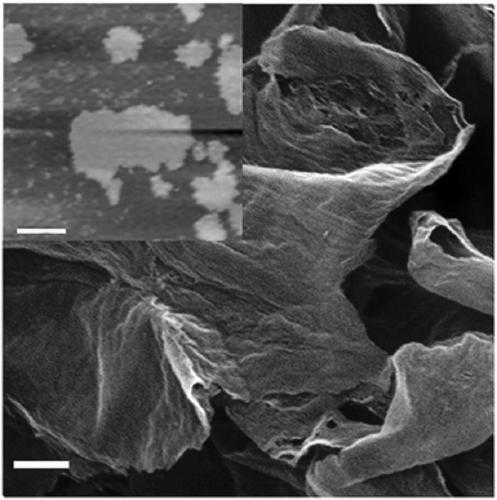

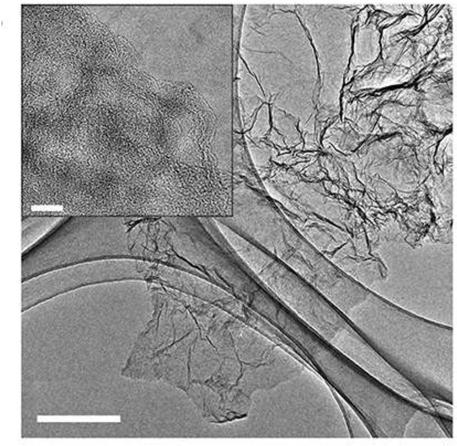

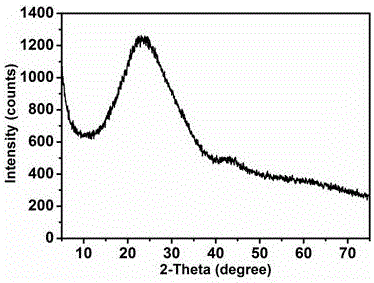

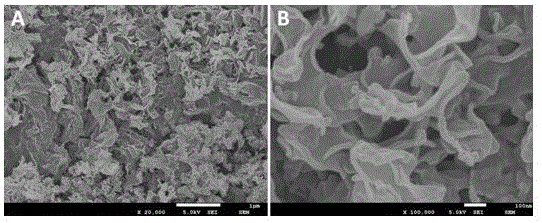

Preparation method and application of graphene and fullerene composite nano material

ActiveCN105870419AReduce manufacturing costCell electrodesSecondary cellsPtru catalystChemical vapor deposition

The invention discloses a preparation method of a graphene and fullerene composite nano material. The method comprises the steps that sulfur-containing resin serves as a solid phase carbon source and sulfur source, transition metal acetate serves as a catalyst precursor, the sulfur-containing resin is close to the air inlet end of a heating furnace, transition metal acetate is close to the air outlet end of the heating furnace, heat treatment is conducted under the protection of inert gas, heat-treated products are collected, acid treatment, washing, filtering and drying are conducted, and the graphene and fullerene composite nano material is obtained, wherein the heat treatment temperature ranges from 600 DEG C to 900 DEG C, the heat treatment time ranges from 10 min to 60 min, and the temperature rising speed ranges from 5 DEG C / min to 20 DEG C / min. The method is a chemical-vapor deposition technology on the basis that the sulfur-containing resin serves as the solid phase carbon source and sulfur source, and transition metal acetate serves as the catalyst, large-scale one-step preparation of the graphene and fullerene composite nano material is achieved, and the problems that in the prior art, the steps are complex, the equipment is expensive, operation is tedious, and batch production is difficult are solved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

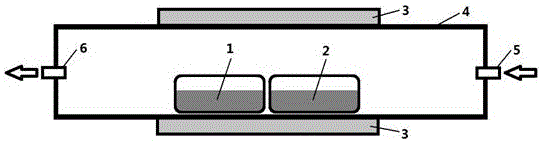

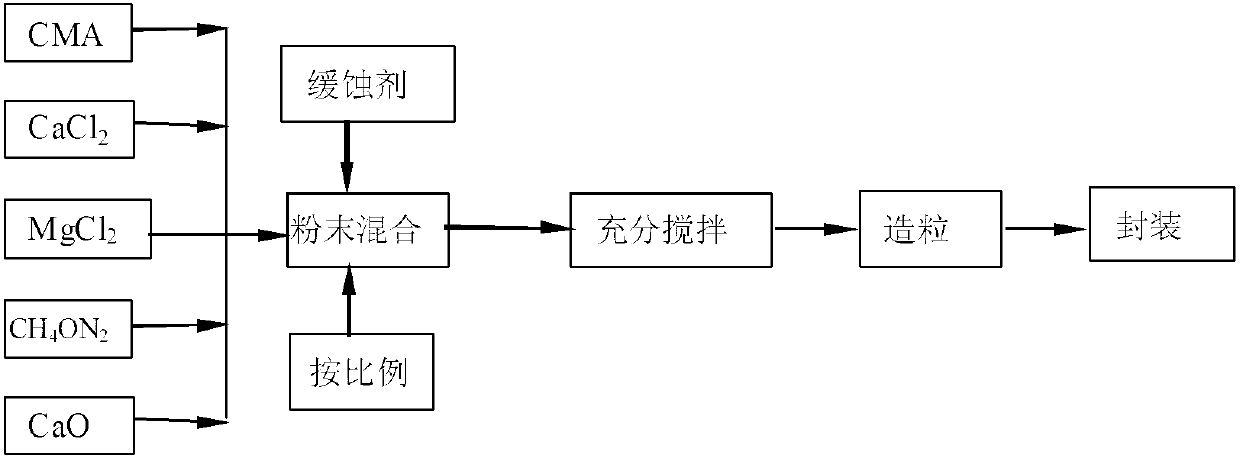

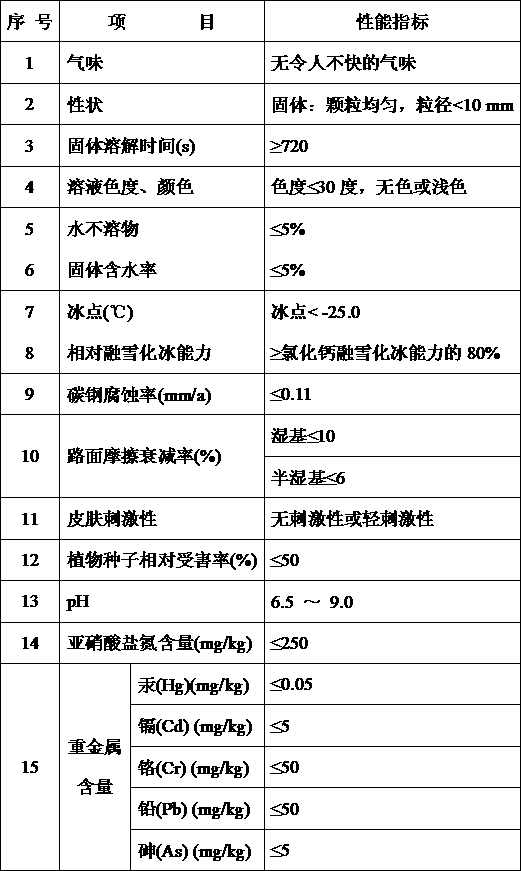

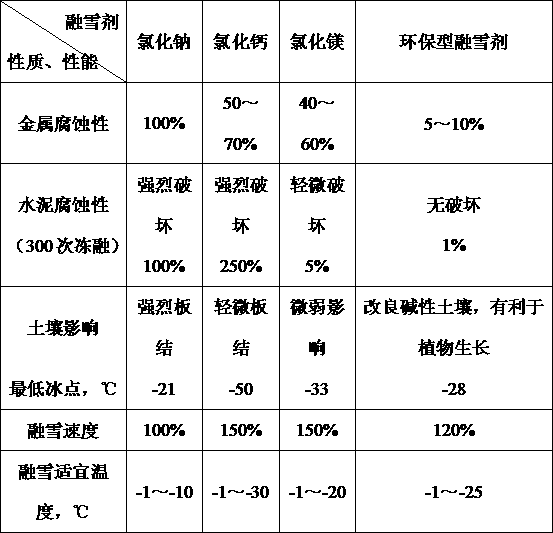

Environment-friendly snow melting agent and preparation method thereof

ActiveCN103342988AReduce manufacturing costSimple production processOther chemical processesSnow meltingEthylic acid

The invention relates to an environment-friendly snow melting agent and a preparation method of the snow melting agent, and belongs to the field of the snow melting agents. The snow melting agent is prepared from acetates and chlorine salts with low corrosivity as the main raw materials by mixing acetates including potassium acetate, magnesium acetate and calcium acetate with calcium chloride and magnesium chloride in a certain proportion, as well as a small quantity of corrosion inhibitor. The common fault that a common inorganic snow melting agent is high in corrosivity is effectively overcome, the cost is reduced, and therefore the snow melting agent is suitable for promotion and application.

Owner:SHENYANG POLYTECHNIC UNIV

Catalyst used for decomposing N2O and preparation method and application thereof

InactiveCN101745394AHigh activityImprove stabilityNitrous oxide captureDispersed particle separationNitrateDecomposition

The invention relates to a catalyst used for decomposing N2O and a preparation method and application thereof, which are characterized in that an active component is a composite oxide which contains copper oxide and zinc oxide and has a spinelle structure or a perovskite-like structure, and the composite oxide is loaded on a gamma-Al2O3 carrier, and auxiliary metallic oxides can also be added; the nitrate or the acetate of the composite oxide is dissolved in water; the gamma-Al2O3 carrier is dipped, is evaporated to remove water and then is dried to obtain a precursor; and then the precursor is baked to obtain the catalyst. The catalyst is used for decomposing N2O and has high activity and high stability; the catalyst is used for the direct decomposition of N2O; the decomposing temperature of N2O is low, and the complete decomposition temperature is lower than or equal to 615 DEG C; after an intensified experiment is carried out for 100 hours, the catalyst still keeps the advantage and effect of high activity.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Dual catalyst system thermoplastic phenolic resin preparation method and application for preparing coated sand thereof

InactiveCN101619125AFast aggregationHigh yieldFoundry mouldsFoundry coresOrganic acidRoom temperature

A dual catalyst system thermoplastic phenolic resin preparation method comprises the steps of proportioning, refluxing and reacting, and drying; the raw materials comprises phenol or m-cresol and aldehydes compound, water, organic acid or inorganic acid and bivalent acetate in a molar ratio of 1:0.5-0.9:0-3.0:0.001-0.040:0.001-0.020; wherein, acetate is used as first catalyst and organic acid or inorganic acid is used as second catalyst in reaction process. The invention adopts phenolic aldehyde addition-condensation reaction in dual catalyst system to prepare the thermoplastic phenolic resin; the method has the advantage of rapid polymerization rate, high yield and low content of free phenols; the thermoplastic phenolic resin can be applied for preparing the coated sand and the prepared coated sand has higher hot tensile strength and tensile strength at room temperature.

Owner:SHAANXI NORMAL UNIV

Polyamide resin composition

ActiveUS20090239013A1Less amountStably subjectedEnvelopes/bags making machineryBottlesPolymer scienceActive agent

A polyamide resin composition contains a resin component containing at least a polyamide (X) and a fatty acid metallic salt having from 10 to 50 carbon atoms, and contains arbitrarily an additive (A) and / or an additive (B). The polyamide (X) is obtained through melt polycondensation of a diamine component containing 70% by mol or more of m-xylylenediamine and a dicarboxylic acid component containing 70% by mol or more of an α,ω-linear aliphatic dicarboxylic acid. The additive (A) is at least one compound selected from the group consisting of a diamide compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diamine having from 2 to 10 carbon atoms, a diester compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diol having from 2 to 10 carbon atoms, and a surfactant, and the additive (B) is at least one compound selected from the group consisting of a metallic hydroxide, a metallic acetate salt, a metallic alkoxide, a metallic carbonate salt and a fatty acid.

Owner:MITSUBISHI GAS CHEM CO INC

Synthesizing method of polyimide

ActiveCN102219900AEasy to recycleImprove protectionFiber1-Butyl-3-methylimidazolium hexafluorophosphate

The invention discloses a synthesizing method of polyimide. The method comprises the following step that: an aromatic diamine compound and an aromatic dianhydride compound are subject to a polymerization reaction in an ionic liquid, such that polyimide is obtained. The ionic liquid can be any one of 1-ethyl-3-methylimidazolium tetrafluoroborate, 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium dicyanamide, 1-butyl-3-methylimidazolium tetrafluoroborate, 1-butyl-3-methylimidazolium hexafluorophosphate, 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide, and 1-butyl-3-methylimidazolium trifluoromethanesulfonate. The operation of the method is simple, the product made with the method is easy to purify and has high dissolvability (the product can be dissolved in regular solvents of N, N-dimethylacetamide, or tetrahydrofuran). The method has advantages of high yield, stable performance, good application prospect, and is suitable for industrialized production. Withthe method, polyimide films or fibers can be produced.

Owner:BEIJING RADIATION APPL RES CENT

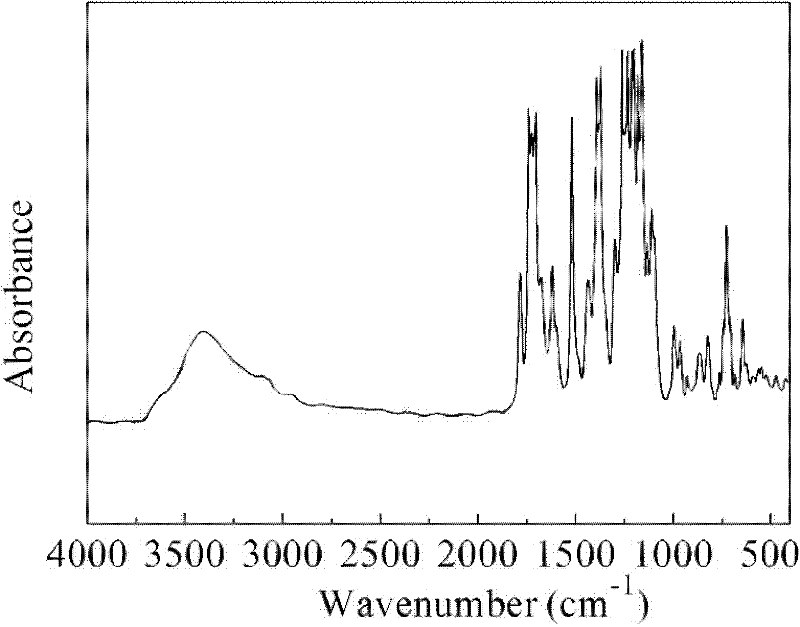

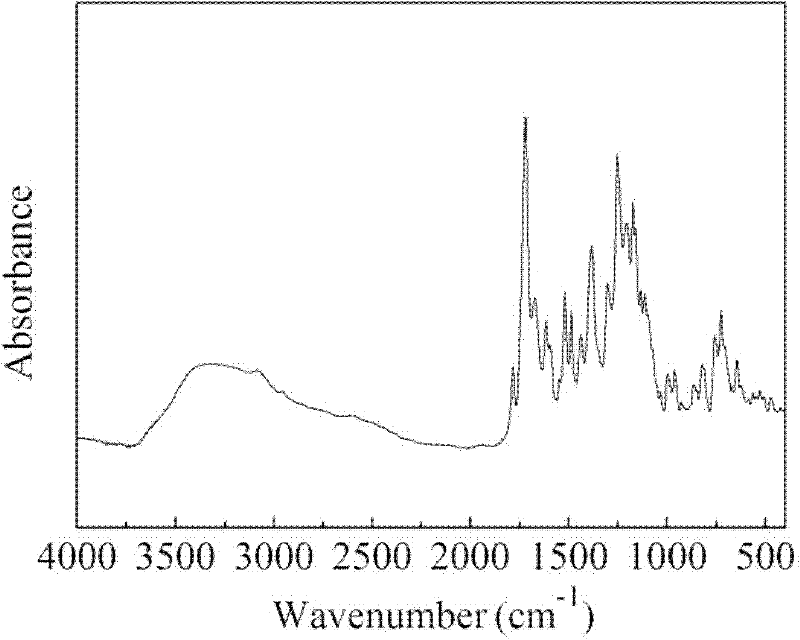

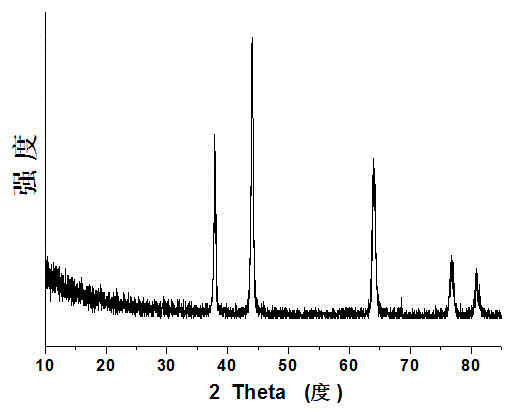

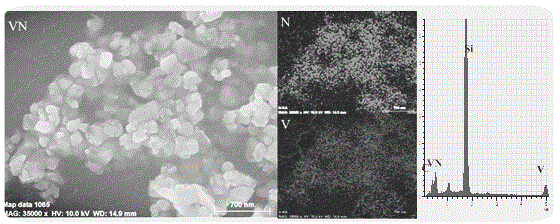

Preparation method of vanadium nitride

InactiveCN104016314AEliminate emissionsEliminate consumptionNitrogen-metal/silicon/boron binary compoundsEthylic acidMetallic materials

The invention belongs to the technical field of metal materials and in particular relates to a preparation method of a high-performance steel and iron material additive-vanadium nitride. According to the technical scheme, the method comprises the following steps: preparing vanadium nitride by adopting a liquid-phase solvothermal method, wherein a liquid phase adopts a water solution or an alcohol solvent; a vanadium source is selected from bivalent, trivalent or tetravalent chloride of vanadium, sulfate, nitrate and acetate; and a nitrogen source is selected from ammonia gas, urea, hydrazine, ammonium chloride, ammonium carbonate, ammonium acetate and ammonium sulfate. According to the method, carbon or hydrogen does not need to be adopted as a reducing agent in the preparation process, so that the discharge of greenhouse gas in the preparation process is avoided and the impurity carbon element in vanadium nitride is eliminated; the alloy synthesis temperature is lower than 400 DEG C; and the nitrogen content of vanadium nitride synthesized by adopting the method maximally and theoretically can be 21%.

Owner:JINAN SHUNYUAN NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com