Preparation method of regenerated cellulose material

A technology of regenerated cellulose and cellulose, applied in the production of bulk chemicals, etc., can solve the problems of low elongation at break, reduced tensile strength, reduced strength and modulus of regenerated cellulose film, etc., to achieve improved mechanical properties, High tensile strength and improved elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

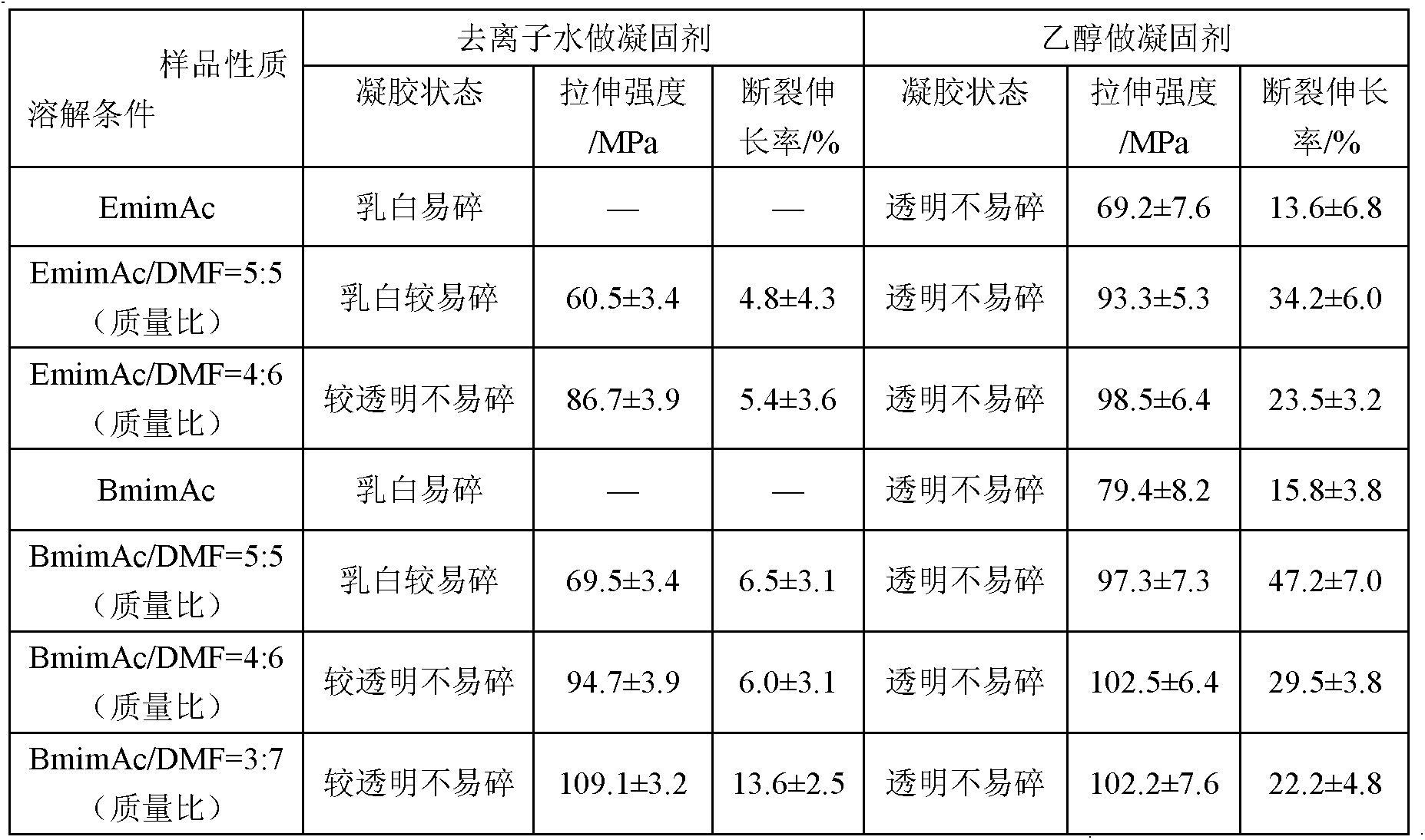

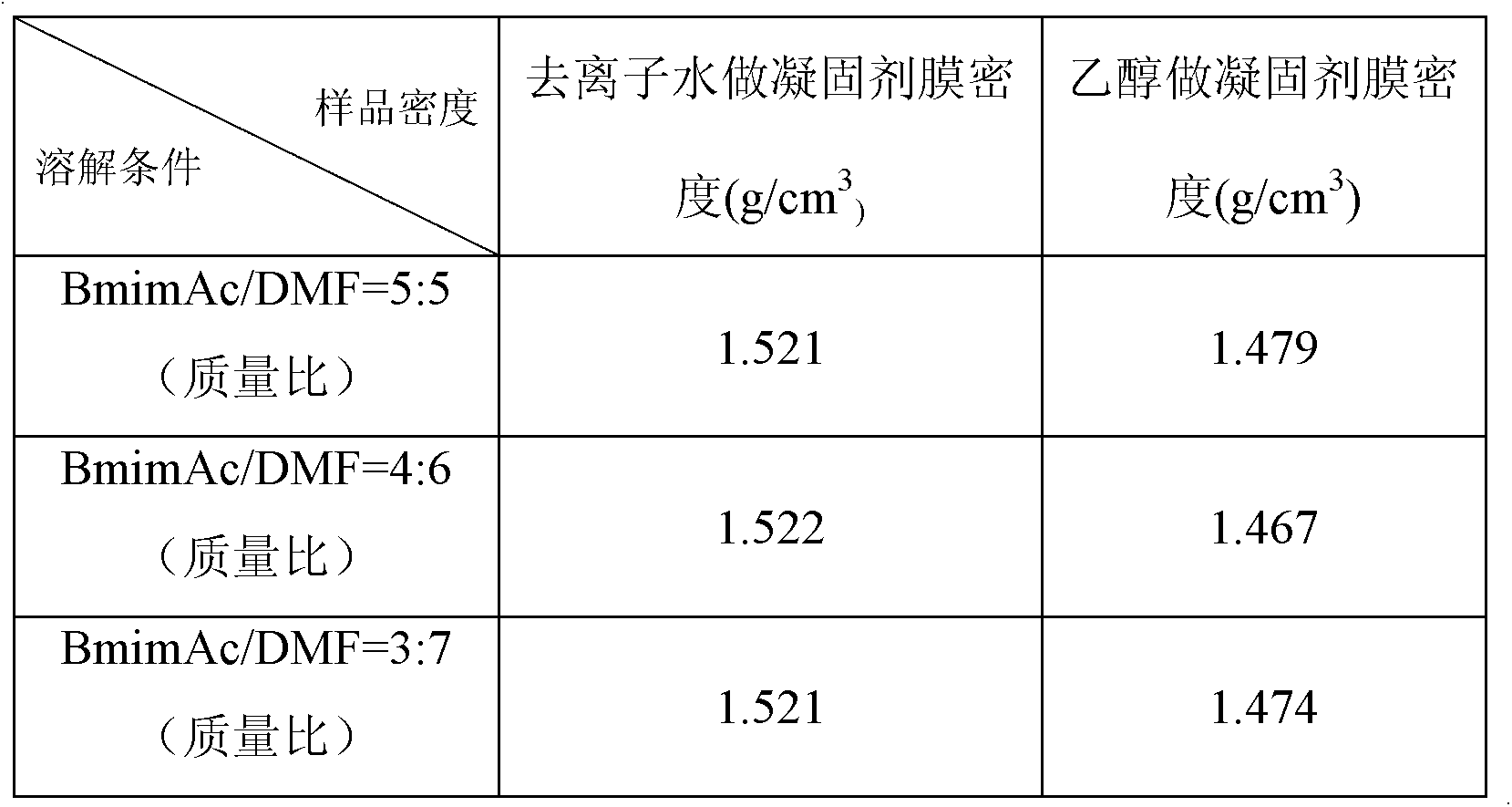

Embodiment 1

[0019] Add 2g cotton pulp and 23g EmimAc into a 50mL three-necked flask, heat in an oil bath at 80°C, and use mechanical stirring. After stirring for 2 hours, the cellulose is completely dissolved to obtain a clear and transparent cellulose solution. Stop stirring to completely remove the bubbles in the solution.

[0020] Take a small amount of solution and pour it on a pre-prepared glass plate, scrape the cellulose solution in one direction with a film spreader, and spread it on the glass plate to form a uniform film of cellulose solution.

[0021] Take a sink and fill it with enough ethanol. A glass plate covered with a cellulose solution is placed in the water tank, and the cellulose film solidifies and falls off from the glass plate.

[0022] Drying operations used glass plates and a vacuum oven. The cleaned cellulose film was sandwiched between two layers of glass plates, and dried in a vacuum oven until completely dry to obtain a regenerated cellulose film. The prepare...

Embodiment 2

[0025] Add 2g cotton pulp and 23gEmimAc / DMF (11.5gEmimAc, 11.5gDMF) co-solvent into a 50mL three-necked flask, heat in an oil bath at 80°C, and use mechanical stirring. After stirring for 2 hours, the cellulose is completely dissolved to obtain a clear transparent cellulose solution. Stop stirring to completely remove the air bubbles in the solution.

[0026] Take a small amount of solution and pour it on a pre-prepared glass plate, scrape the cellulose solution in one direction with a film spreader, and spread it on the glass plate to form a uniform film of cellulose solution.

[0027] Take a sink and fill it with enough ethanol. A glass plate covered with a cellulose solution is placed in the water tank, and the cellulose film solidifies and falls off from the glass plate.

[0028] Drying operations used glass plates and a vacuum oven. The cleaned cellulose film was sandwiched between two layers of glass plates, and dried in a vacuum oven until completely dry to obtain a r...

Embodiment 3

[0031]Add 2g cotton pulp and 23gEmimAc / DMF (9.2gEmimAc, 13.8gDMF) co-solvent into a 50mL three-neck flask, heat in an oil bath at 80°C, and use mechanical stirring. After stirring for 2 hours, the cellulose is completely dissolved to obtain a clear and transparent cellulose solution. Stop stirring to completely remove the air bubbles in the solution.

[0032] Take a small amount of solution and pour it on a pre-prepared glass plate, scrape the cellulose solution in one direction with a film spreader, and spread it on the glass plate to form a uniform film of cellulose solution.

[0033] Take a sink and fill it with enough ethanol. A glass plate covered with a cellulose solution is placed in the water tank, and the cellulose film solidifies and falls off from the glass plate.

[0034] Drying operations used glass plates and a vacuum oven. The cleaned cellulose film was sandwiched between two layers of glass plates, and dried in a vacuum oven until completely dry to obtain a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com