Preparation method and application of graphene and fullerene composite nano material

A technology of composite nanomaterials and fullerenes, which is applied in the field of graphene-based composite material preparation, can solve the problems of high cost, cumbersome preparation process, and high energy consumption, and achieve the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

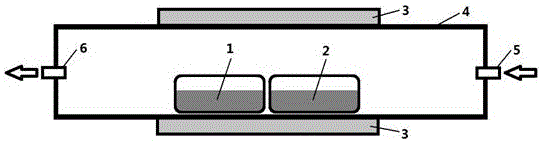

[0034] Place the solid-phase carbon source / sulfur source "thiourea resin" in an oven to dry at 80°C for 12 hours, and then crush it with a pulverizer. The average particle size after crushing is 100 μm; put the catalyst precursor "nickel acetate" in a ball mill for Ball milling, the average particle size after ball milling is 5 μm; get 20g of the obtained "thiourea resin" particles and 7g of the obtained "nickel acetate" particles and place them in a tube furnace, and carry out heat treatment under the protection of an inert gas (such as figure 1 shown), the heat treatment temperature is 700°C, the heating time is 30min, and the heating rate is 5°C / min; finally, the obtained catalytic product is collected, soaked in 2mol / L hydrochloric acid for 2h, washed with distilled water, filtered, and dried That is, the "graphene / fullerene" composite nanomaterial is obtained.

[0035] The "graphene / fullerene" nanocomposite material prepared by the above method, wherein the graphene size ...

Embodiment 2

[0037] Place the solid-phase carbon source / sulfur source "thiourea resin" in an oven to dry at 80°C for 12 hours, and then crush it with a pulverizer. The average particle size after crushing is 100 μm; put the catalyst precursor "nickel acetate" in a ball mill for Ball milling, the average particle size after ball milling is 5 μm; get 20g of the obtained "thiourea resin" particles and 7g of the obtained "nickel acetate" particles and place them in a tube furnace, and carry out heat treatment under the protection of an inert gas (such as figure 1 shown), the heat treatment temperature is 700°C, the heating time is 30min, and the heating rate is 10°C / min; finally, the obtained catalytic product is collected and soaked in 2mol / L hydrochloric acid for 2h, then washed with distilled water, filtered, and dried That is, the "graphene / fullerene" composite nanomaterial is obtained.

[0038] The "graphene / fullerene" composite nanomaterial prepared by the above method, wherein the size ...

Embodiment 3

[0040] Place the solid-phase carbon source / sulfur source "thiourea resin" in an oven to dry at 80°C for 12 hours, and then crush it with a pulverizer. The average particle size after crushing is 100 μm; put the catalyst precursor "nickel acetate" in a ball mill for Ball milling, the average particle size after ball milling is 5 μm; get 20g of the obtained "thiourea resin" particles and 7g of the obtained "nickel acetate" particles and place them in a tube furnace, and carry out heat treatment under the protection of an inert gas (such as figure 1 shown), the heat treatment temperature is 700°C, the heating time is 30min, and the heating rate is 20°C / min; finally, the obtained catalytic product is collected, soaked in 2mol / L hydrochloric acid for 2h, washed with distilled water, filtered, and dried That is, the "graphene / fullerene" composite nanomaterial is obtained.

[0041] The "graphene / fullerene" composite nanomaterial prepared by the above method, wherein the size of graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com