Method of obtaining a product sugar stream from cellulosic biomass

A technology of cellulose and biomass, applied in the direction of biofuel, fermentation, etc., can solve the problems that the temperature required for separation is unrealistic, expensive, and cannot be effectively removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

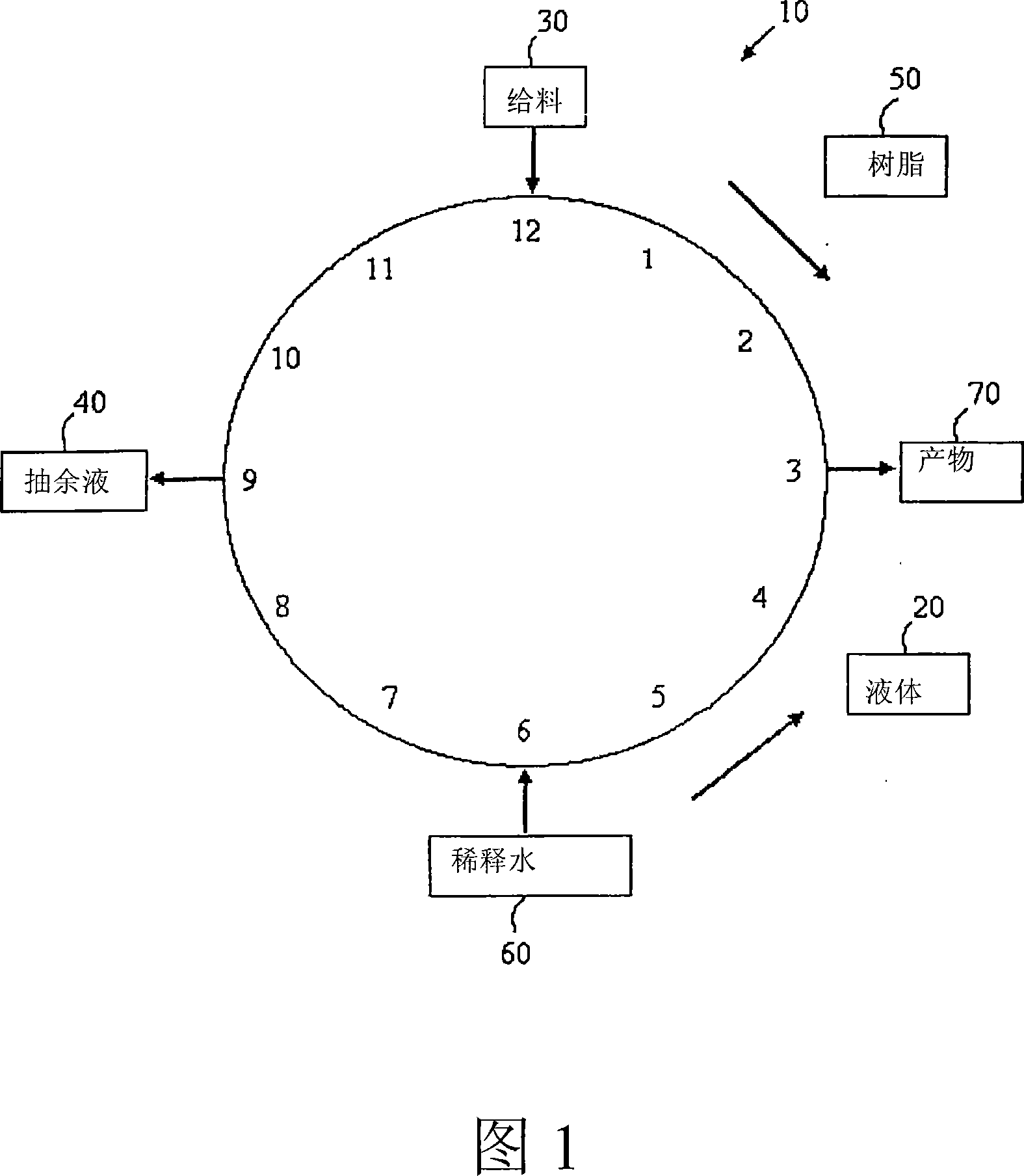

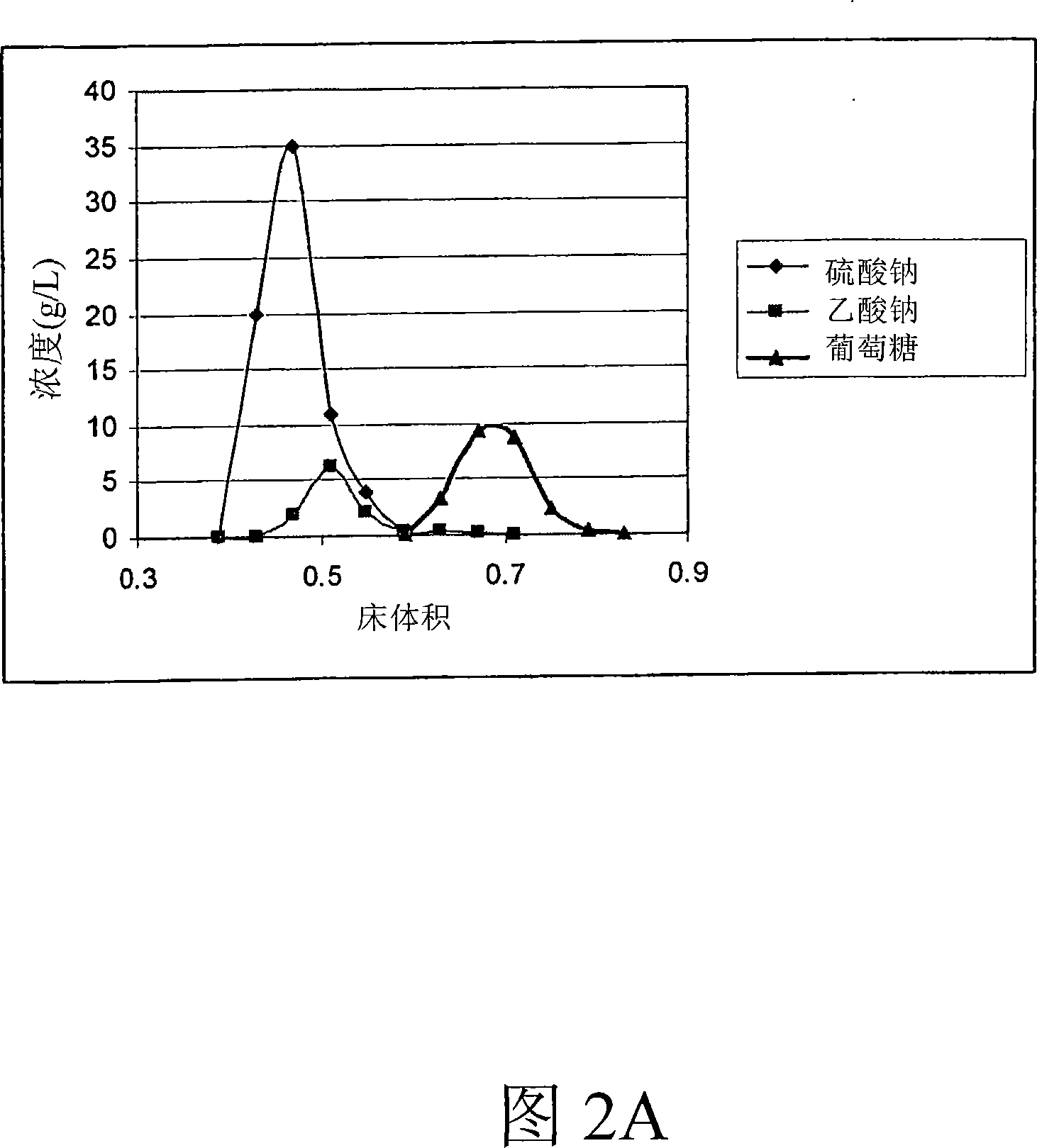

[0147] Embodiment 1: Separation of sodium sulfate, sodium acetate and glucose by ion exclusion

[0148] This example illustrates the effectiveness of ion exclusion as a method of removing sodium acetate and sodium sulfate from glucose at pH 8

[0149] The fixed bed ion exclusion column was packed with Mitsubishi Chemical resin #UBK530. Before packing the column, 135 ml of resin was suspended in 1 liter of deionized water and allowed to settle. The supernatant was decanted, and this step was performed three times, which was sufficient to remove any visible particulates. After decanting the third supernatant, deionized water twice the volume of the resin was added to the resin, and the slurry was poured into a 127 ml column. The column includes a hot water jacket, but this jacket is not used during the resin filling step. The top of the column was sealed with a rubber stopper attached to the water pump. Handle with care to ensure airtight seal.

[0150] Rinse the packed co...

Embodiment 2

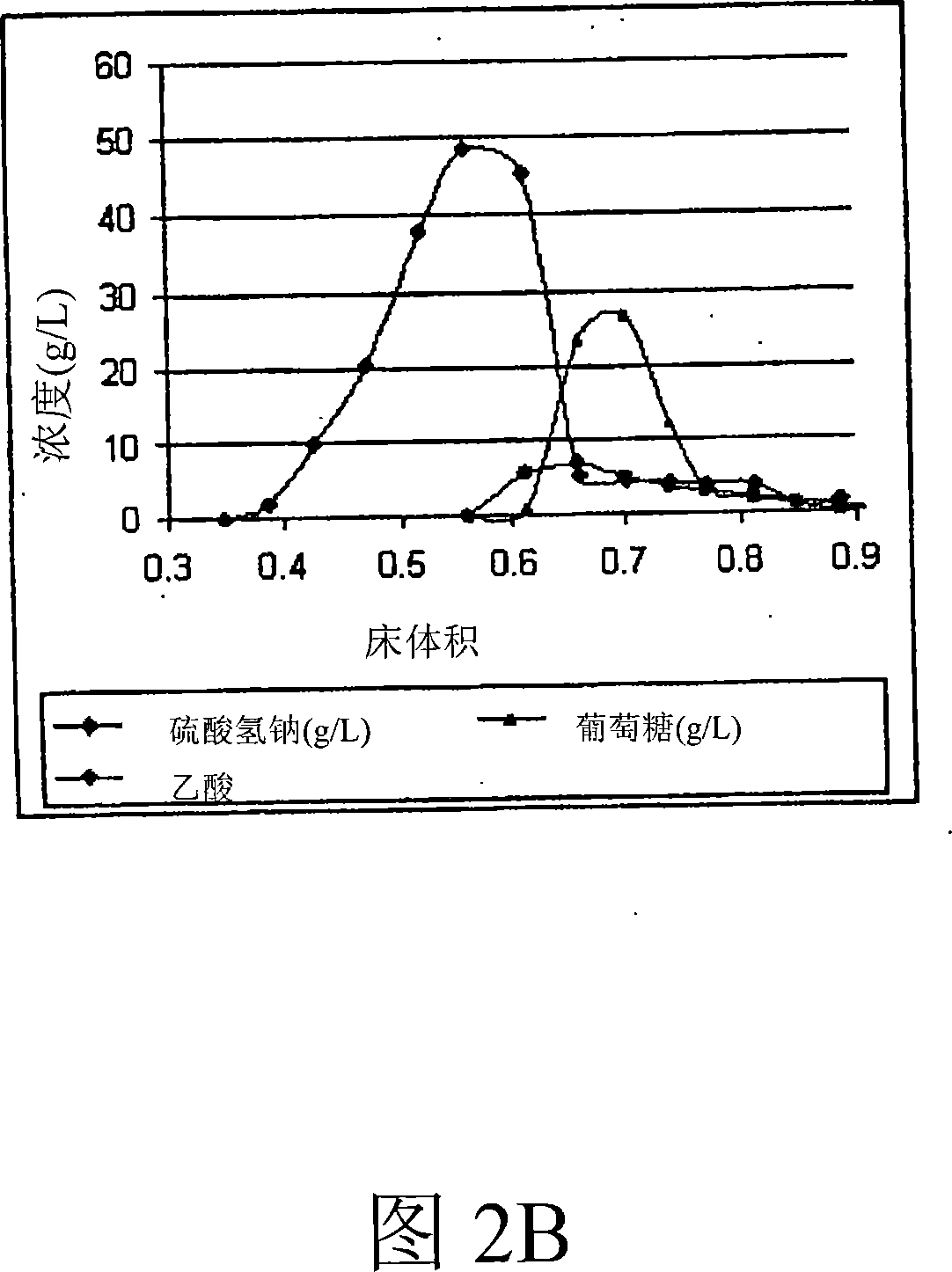

[0156] Example 2: Comparative Example - Separation of Glucose and Acetic Acid at pH 3

[0157] This example illustrates the separation of sugars from acetic acid and sodium bisulfate at pH 3 using ion exclusion. Acetic acid was poorly separated from glucose at pH 3 because the two components co-eluted (see Figure 2B). Excellent separation of acetic acid and sugars is provided using the methods described herein.

[0158] The fixed bed ion exclusion column was packed with Mitsubishi Chemical resin #UBK530. Before filling, suspend 135 ml of resin in 1 liter of deionized water and allow to settle. The supernatant was decanted, and this step was performed three times, which was sufficient to remove any visible particulates. After decanting the third supernatant, deionized water twice the volume of the resin was added to the resin, and the slurry was poured into a 122 ml column. The column includes a hot water jacket, but this jacket is not used during the resin filling step. ...

Embodiment 3

[0165] Embodiment 3: Elution of biomass sugar

[0166] A feedstock sample of biomass sugar was prepared by pretreating wheat straw with sulfuric acid under the conditions described in U.S. 4,461,648. The pH of the pretreatment was 1.4, and the pH of the resulting pretreated raw material was adjusted to 5 with sodium hydroxide. The neutralized cellulosic biomass is enzymatically hydrolyzed with cellulosicum produced by the Trichoderma fungus to produce a raw sugar stream. The raw sugar stream is separated from the insoluble residue, mainly lignin, by plate and frame filtration. The clarified sugar stream was evaporated to 44% of total solids and contained sodium and potassium sulfate salts, 300 g / L glucose, 44 g / L xylose, 5.3 g / L arabinose, 10.9 g / L sodium acetate at a concentration of 109 g / L (measured as acetic acid) and various trace metals. The clear sugar stream was evaporated, the pH adjusted to 8, then applied to the column and eluted as described in Example 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com