Vertical roller mill

A technology of vertical roller mill and pulverizing roller, applied in combustion method, block/powder fuel preparation, block/powder supply/distribution, etc., can solve problems such as not necessarily effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

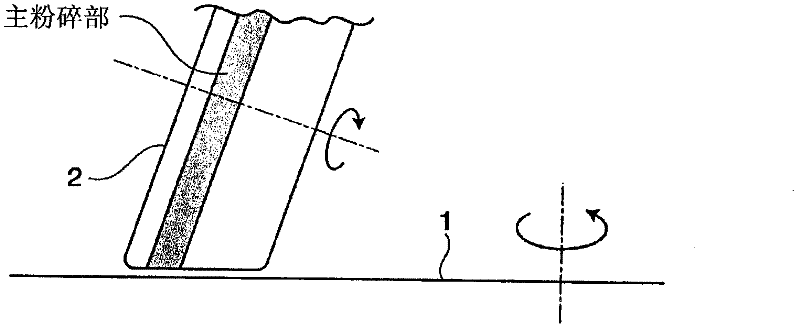

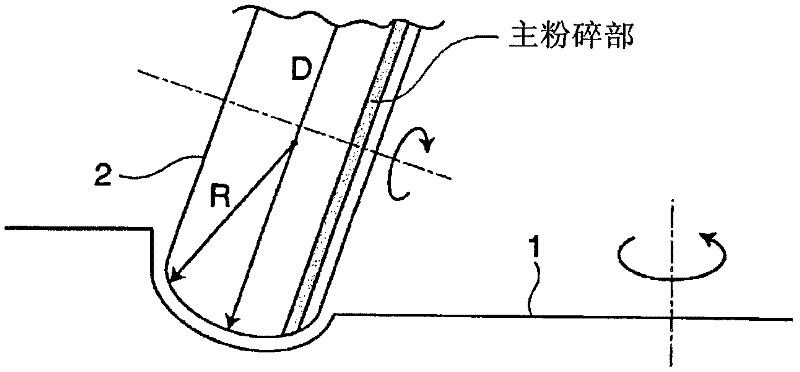

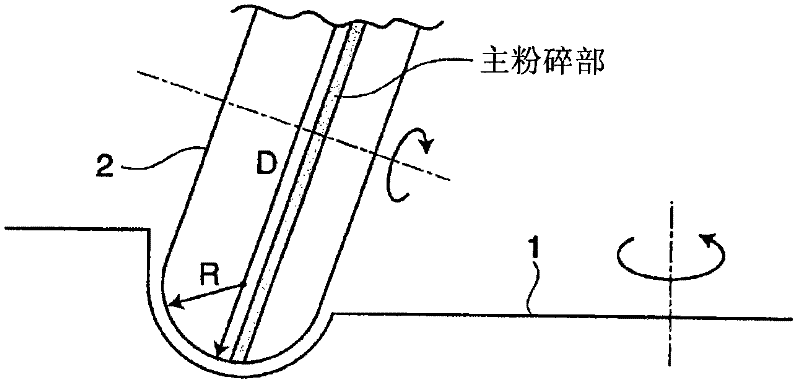

[0062] Embodiments of the present invention will be described below with reference to the drawings. In this embodiment, it was confirmed by a pulverization experiment with a small pulverizer that a large number of fine powders passing through a No. 200 sieve and a particle size of -235 No. sieve can be obtained. The combination of the crushing surface shape of the roller and the table. figure 2 Indicates a small pulverizer for experiments.

[0063] Assuming that the crusher of the vertical roller mill is as figure 2 Shown is a structure in which the pulverizing roller 2 faces the outer peripheral surface of the horizontal rotary table 1 as a base member. Crushing Roller 2 in figure 2 The medium is a truncated conical roll, but it can also be replaced with a flat tire roll with a D / R of less than 4.3, or a convex tire roll with a D / R of 4.3 or more (see Figure 1). The flat tire roller 2 is inclined so that the large-diameter side faces the outer peripheral side and the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com