High-efficiency coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, heating method and application

A heating furnace and coal-fired technology, which is applied in the field of high-efficiency coal-fired heating furnace and heating, can solve the problems of low universality of coal-fired types, reduce the effect of graded combustion and emission reduction, etc., to improve the efficiency of sulfur fixation and reduce nitrogen oxides Generation and emission, and the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

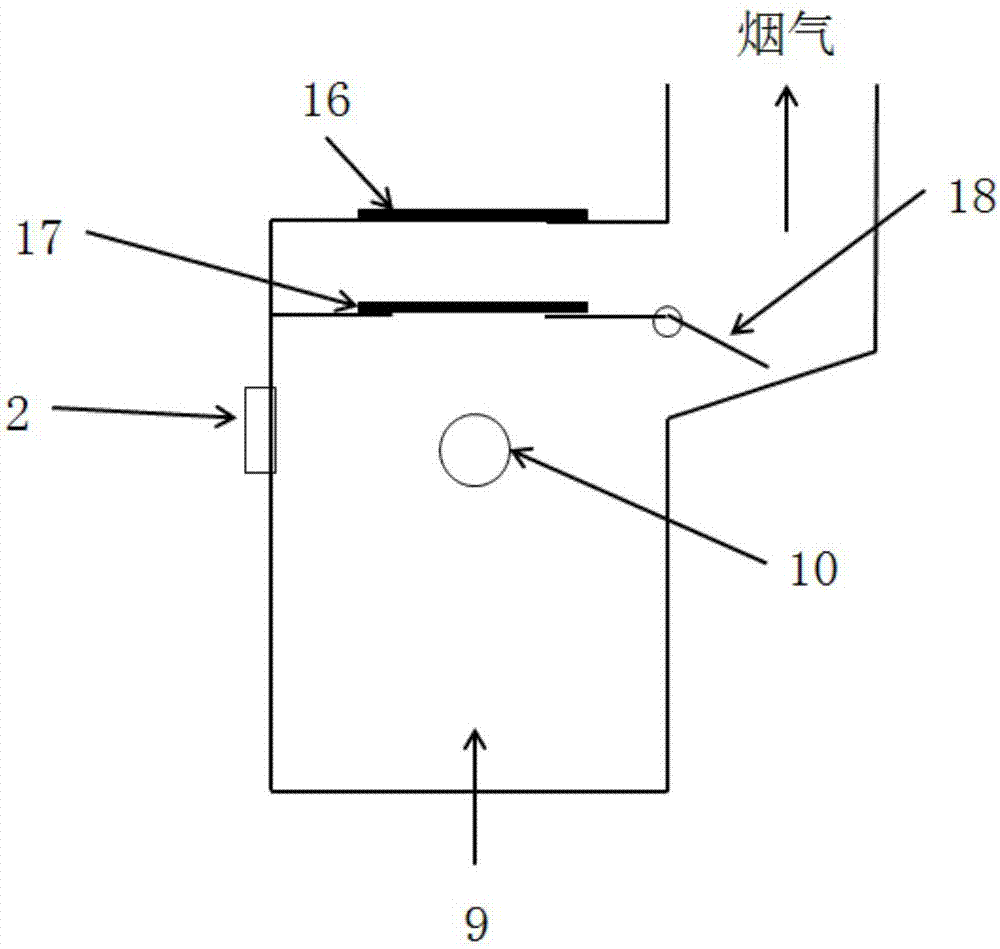

[0086] like Figure 4 As shown, the present embodiment provides a coal-fired heating furnace and a coal-fired heating method based on staged combustion. The top side of the main body 1 of the coal-fired heating furnace is provided with a coal filling port 2, and the top of the main body 1 of the coal-fired heating furnace is connected to the heating furnace. A chimney 3 is arranged on the opposite side of the coal mouth 2; a water jacket partition 4 is arranged vertically on the upper part of the main body 1 of the coal-fired heating furnace and the furnace roof, and the water jacket partition 4 divides the upper part of the main body 1 of the coal-fired heating furnace into a The dry distillation pyrolysis zone 5 connected to the port 2 and the flue gas burnout heat exchange zone 6 connected to the chimney 3; the lower area of the water jacket partition 4 in the main body 1 of the coal-fired heating furnace is the semi-coke combustion zone 7; the semi-coke A furnace grate 8...

Embodiment 2

[0095] This embodiment provides a coal-fired heating furnace based on staged combustion and its heating method. The structure of the coal-fired heating furnace refers to Example 1, the difference is that the grate 8 is movable, and there is a Air distribution holes; the height-to-diameter ratio H / D of the hearth in the dry distillation pyrolysis zone 5 is 2.

[0096] The heating method of the coal-fired heating furnace refers to Example 1.

Embodiment 3

[0098] This embodiment provides a coal-fired heating furnace based on staged combustion and its heating method. The structure of the coal-fired heating furnace refers to Example 1, the difference is that the height-to-diameter ratio H / D of the furnace in the carbonization pyrolysis zone 5 is 5.

[0099] The heating method of the coal-fired heating furnace refers to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com