Method for preparing bismuth-boron-based flexible catalytic electrode in organic phase

A catalytic electrode, organic phase technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of limiting the industrial application of bismuth materials, uncontrollable reaction rate, complicated preparation methods, etc., achieving controllable structure and morphology, working environment The effect of low requirements and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] refer to Figure 1-5 , a method for preparing a bismuth boron-based flexible catalytic electrode in an organic phase, comprising: S1, by using a metal bismuth boron compound as a precursor, adding a reducing agent, a complexing agent, a buffer and an organic solution, according to a given The dosage ratio is mixed to prepare the plating solution;

[0026] S2. After ultrasonic cleaning of the base material in deionized water, the base material is then soaked in deionized water, ethanol and acetone in sequence to remove surface stains;

[0027] S3, immersing the flexible substrate material in the metal salt solution, and dipping it in borohydride for 2 s at the same time to complete the activation of the flexible non-conductive substrate, and then washing it with deionized water and ethanol in turn for use;

[0028] S4. Immerse the pretreated base material in step S3 into the plating solution prepared in step S1, take out the base material after electroless plating react...

Embodiment example 1

[0037] Example 1, Preparation of Bi-B@Cloth Electrode Catalytic Materials

[0038] Use deionized water to sonicate the cloth for 5 minutes to remove stains on the surface of the cloth substrate;

[0039] (2) using sodium borohydride solution and nickel sulfate solution dropwise on the cloth in step (1) to activate, and the activation time is 1-2s;

[0040] (3) The chemical plating solution containing Bi-B is configured, and the amount ratio of each substance and the experimental conditions are shown in the following table:

[0041]

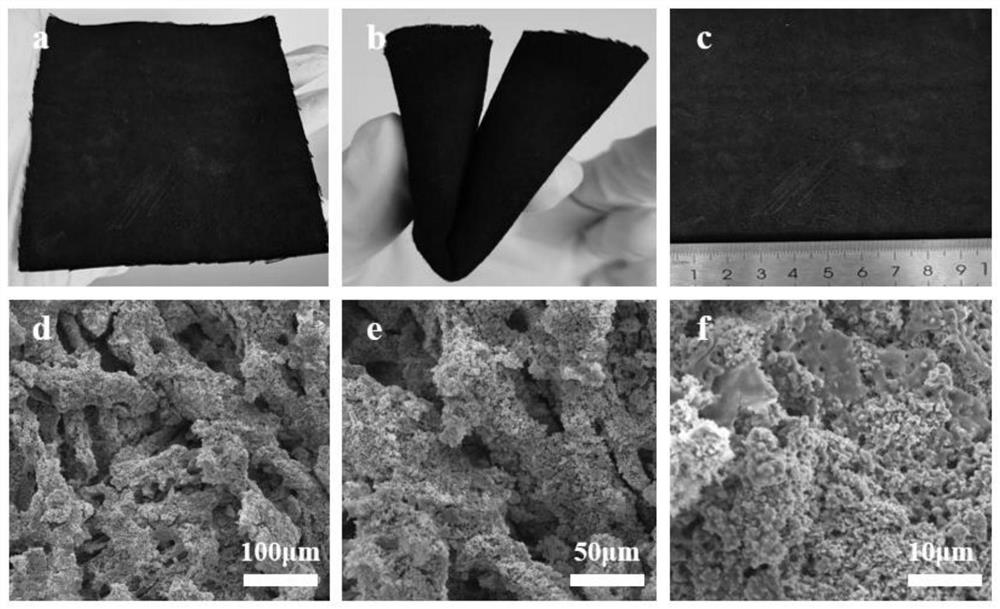

[0042] The cloth substrate in step (2) is immersed in a Bi-B electroless plating solution, and chemically deposited at 5-40° C. for 30 minutes to 8 hours to obtain catalytic electrode materials with different deposition thicknesses. After washing with deionized water, After drying, Bi-B@Cloth electrodes can be prepared. The electrode photo and SEM image are as follows figure 2 (a-f);

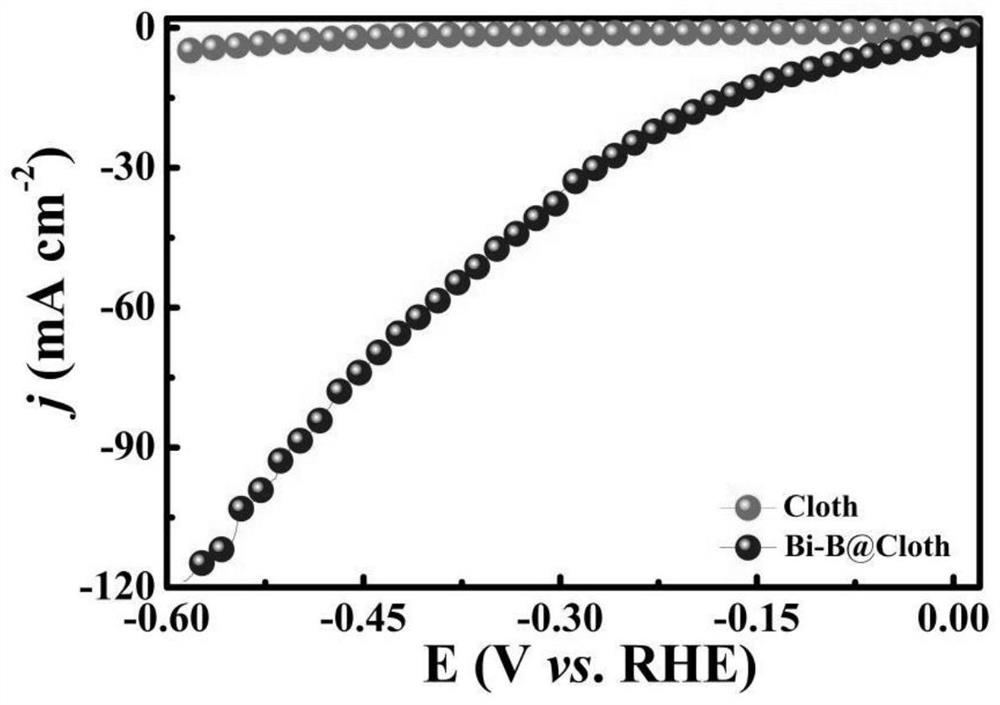

[0043] (4) The hydrogen evolution reaction test was ca...

Embodiment 2

[0044] Example 2, Preparation of Bi-B-Ni@Paper Electrode Catalytic Material

[0045] (1) Ultrasonic cloth with deionized water for 5 minutes to remove stains on the surface of the paper substrate;

[0046] (2) dropwise on the paper sheet of step (1) with sodium borohydride solution and nickel sulfate solution, carry out activation for 2 seconds (s);

[0047] (3) The chemical plating solution containing Bi-B-Ni is configured, and the amount ratio of each substance and the experimental conditions are shown in the following table:

[0048]

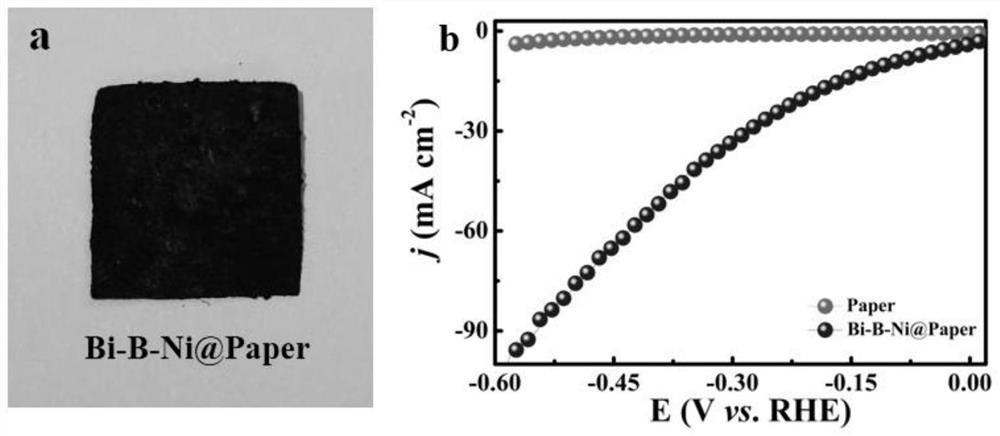

[0049] The paper substrate in step (2) is immersed in the above solution, and chemically deposited at 5-40° C. for 30 minutes to 8 hours; catalytic electrode materials with different deposition thicknesses can be obtained, rinsed with deionized water, and dried to obtain electrodes. . Electrode photos such as image 3 (a);

[0050] (4) The hydrogen evolution reaction test was carried out using an electrochemical workstation at a room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com