A metal-based array carbon nanotube electrode material without a transition layer support and its preparation method and application

A carbon nanotube and electrode material technology, applied in the directions of carbon nanotubes, nanocarbons, non-metallic elements, etc., can solve the problems of complex preparation process, affecting the application of metal-based array carbon tubes, poor conductivity of transition layer, etc., and achieves simple preparation. , excellent electrochemical performance, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

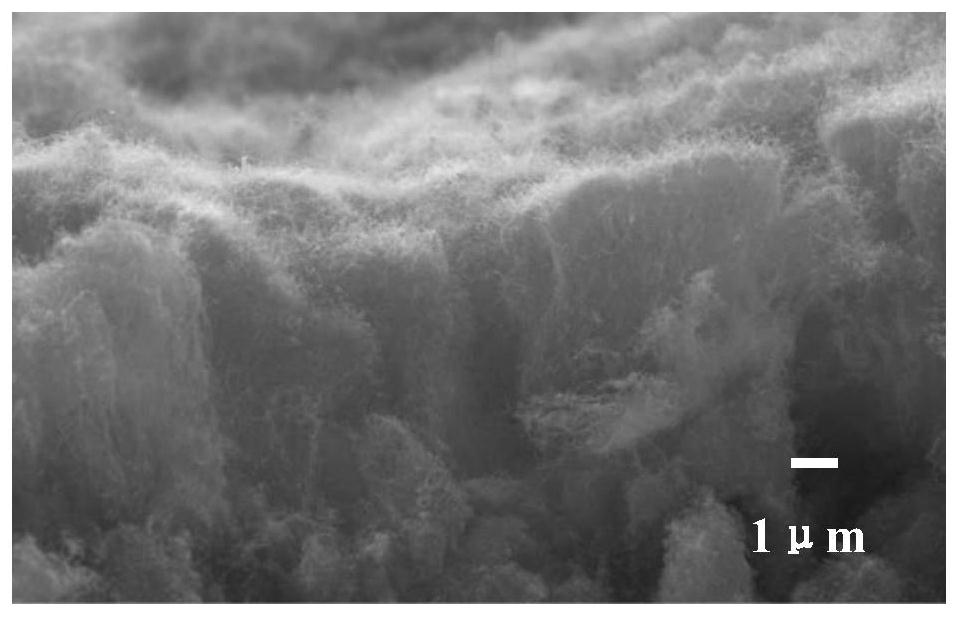

[0031] A method for preparing a metal-based array carbon nanotube electrode material supported by a transition layer, comprising the following steps:

[0032] Step 1: use the through-hole aluminum foil obtained by electrochemical corrosion with an acidic electrolyte as the metal substrate for growing arrayed carbon nanotubes. The metal substrate is ultrasonically cleaned in acetone, alcohol and deionized water in sequence, then dried and set aside;

[0033] Step 2: dissolving ferrocene in xylene solution to form a solution with a ferrocene concentration of 0.06 g / ml, which is used as a catalyst for subsequent use;

[0034] Step 3: Place the metal substrate treated in step 1 in the constant temperature zone of the tube furnace, seal the nozzle of the quartz tube at the same time, and raise the tube furnace under the carrier gas atmosphere with the ratio of argon to hydrogen at 8:2 to 600°C (the growth temperature required for the cracking reaction), and then pass through the ca...

Embodiment 2

[0038]The difference from the parameter conditions in the preparation method of Example 1 is: the concentration of the catalyst is 0.1 g / ml; the cracking reaction growth temperature required for adjusting the tube furnace is 620° C., and the cracking reaction growth time is 3 min. Other conditional parameters are with embodiment 1.

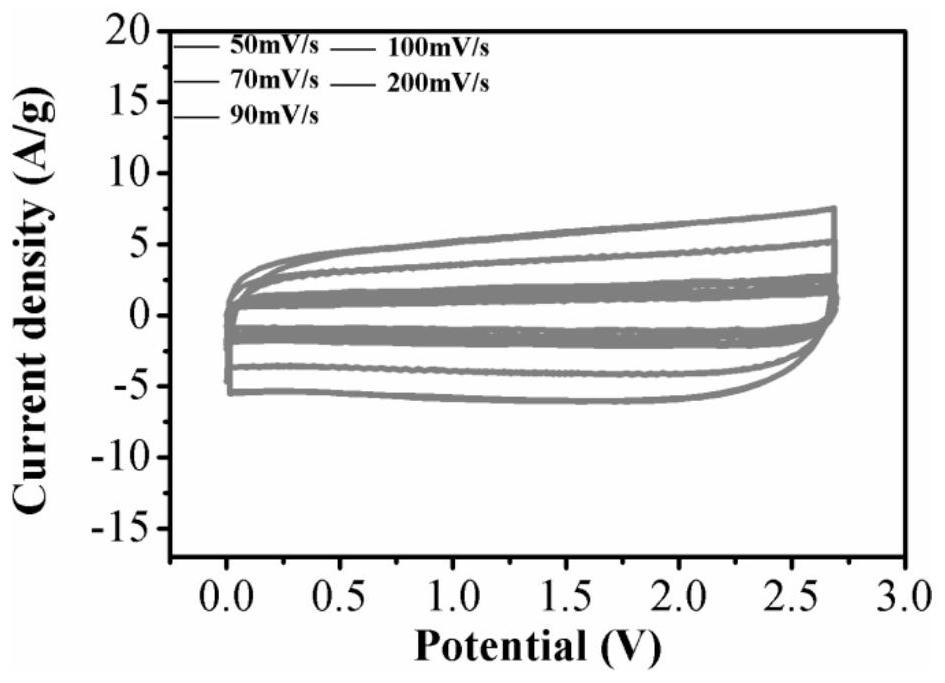

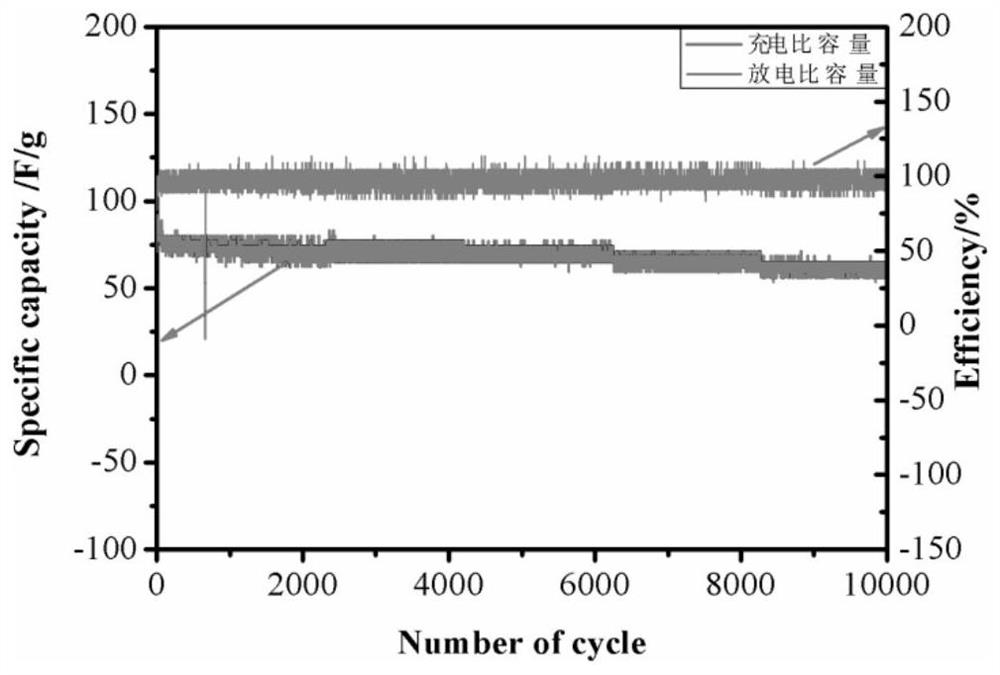

[0039] The metal-based array carbon nanotubes prepared without transition layer support were assembled into supercapacitors as electrode materials, and the assembly sequence was as follows: positive electrode shell + positive electrode material (aluminum-based array carbon tubes) + separator + electrolyte + negative electrode material (aluminum-based array carbon tube) + gasket + negative shell. The assembled device was tested by Princeton Electrochemical Workstation for performance tests such as cyclic voltammetry, impedance, constant current charge and discharge, and cycle stability. The test results are as follows:

[0040] The cyclic voltamme...

Embodiment 3

[0042] The parameters and conditions in the preparation method of Example 1 are different: the concentration of the catalyst is 0.1g / ml; the ratio of argon to hydrogen is 6:4; The time is 5 minutes. Other conditional parameters are with embodiment 1.

[0043] The metal-based array carbon nanotubes prepared without transition layer support were assembled into supercapacitors as electrode materials, and the assembly sequence was as follows: positive electrode shell + positive electrode material (aluminum-based array carbon tubes) + separator + electrolyte + negative electrode material (aluminum-based array carbon tube) + gasket + negative shell. The assembled device was tested by Princeton Electrochemical Workstation for performance tests such as cyclic voltammetry, impedance, constant current charge and discharge, and cycle stability. The test results are as follows:

[0044] The cyclic voltammetry characteristic curve of the arrayed carbon nanotubes prepared in this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com