Two-dimensional carbon plate electrode material with uniform sub-nanopore distribution as well as preparation method and application of two-dimensional carbon plate electrode material

A kind of electrode material and sub-nanometer technology, which is applied in the direction of hybrid capacitor electrode, hybrid/electric double layer capacitor manufacturing, etc., can solve the uneven distribution of sub-nano micropores in two-dimensional carbon materials, affect the application of two-dimensional carbon sheets, and complex methods, etc. problems, achieve high specific capacity, controllable structure and morphology, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

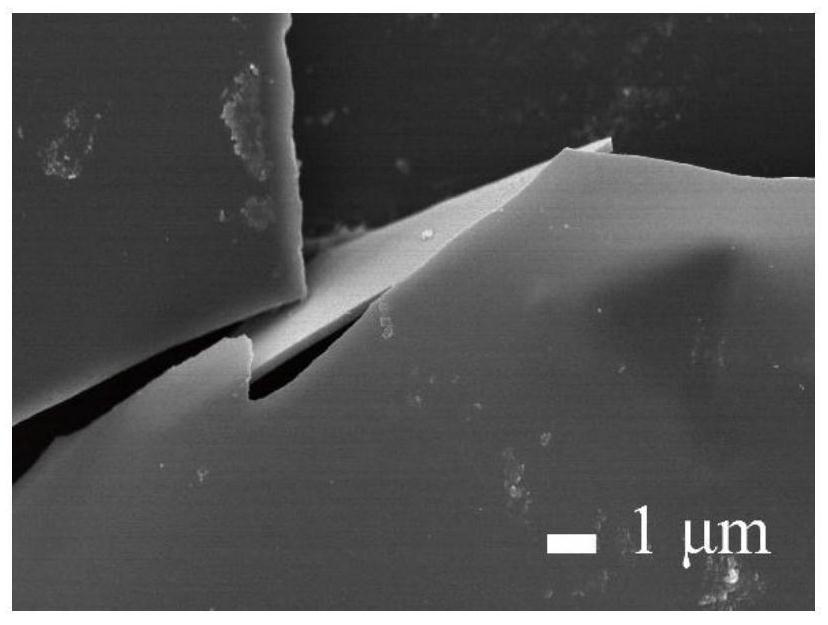

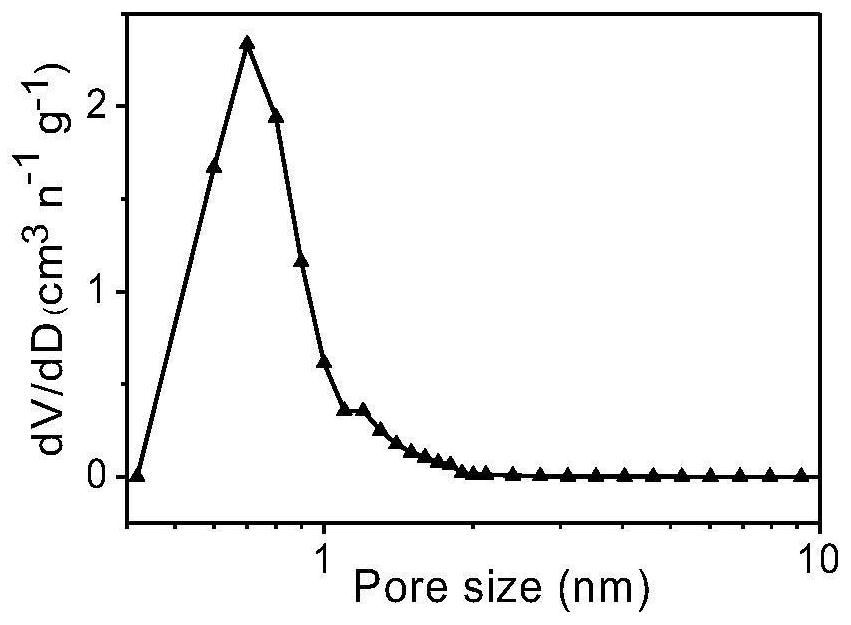

[0029] A method for preparing a two-dimensional carbon sheet electrode material with uniform subnanopore distribution, comprising the following steps:

[0030] Step 1: Weigh phthalimide potassium salt and put it in a clean boat for subsequent use;

[0031] Step 2: Place the metal substrate treated in step 1 in the constant temperature zone of the tube furnace, seal the nozzle of the quartz tube at the same time, and heat at 750° C. for 3 hours at a heating rate of 2° C. / min in a nitrogen atmosphere. Then, the obtained material was washed with 1 M dilute hydrochloric acid and deionized water until its pH reached neutrality. Finally, the precipitate was dried at 60 °C for 12 h to prepare a two-dimensional carbon sheet with uniform subnanometer pore distribution.

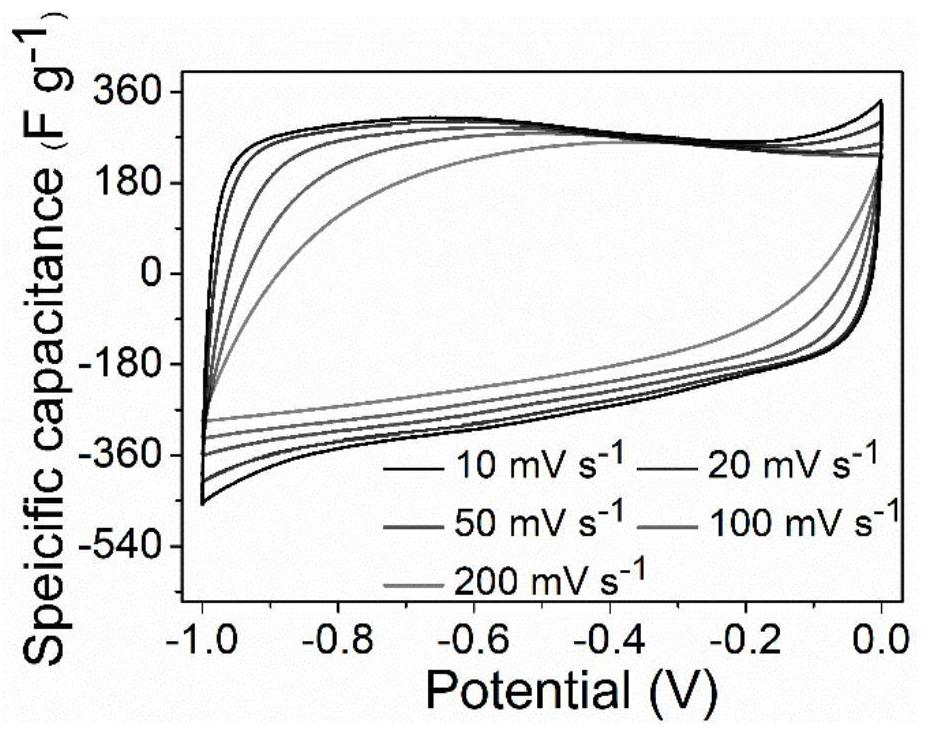

[0032] The above-prepared two-dimensional carbon sheet with uniform subnanopore distribution was used as an electrode material to test its performance in a three-electrode system, wherein: the prepared two-dimensional...

Embodiment 2

[0035] The process of this embodiment is the same as that of Example 1, except that some process parameters are changed: the pyrolysis temperature is 650°C.

[0036] The above-prepared two-dimensional carbon sheet with uniform subnanopore distribution was used as an electrode material to test its performance in a three-electrode system, wherein: the prepared two-dimensional carbon sheet with uniform subnanopore distribution was used as the working electrode, and the platinum sheet was used as the counter electrode. electrode, Hg / HgO electrode as a reference electrode. The above-assembled device was used for performance tests such as cyclic voltammetry, impedance, galvanostatic charge and discharge, and cycle stability with a Koster electrochemical workstation. The test results are as follows:

[0037] The cyclic voltammetry characteristic curve of the arrayed carbon nanotubes prepared in this embodiment is as follows Figure 5 It can be seen from the figure that changing the...

Embodiment 3

[0039] The process of this embodiment is the same as that of Example 1, except that some process parameters have changed: the pyrolysis temperature is 850°C

[0040] The above-prepared two-dimensional carbon sheet with uniform subnanopore distribution was used as an electrode material to test its performance in a three-electrode system, wherein: the prepared two-dimensional carbon sheet with uniform subnanopore distribution was used as the working electrode, and the platinum sheet was used as the counter electrode. electrode, Hg / HgO electrode as a reference electrode. The above-assembled device was used for performance tests such as cyclic voltammetry, impedance, galvanostatic charge and discharge, and cycle stability with a Koster electrochemical workstation. The test results are as follows:

[0041] The cyclic voltammetry characteristic curve of the arrayed carbon nanotubes prepared in this embodiment is as follows Figure 5 It can be seen from the figure that increasing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com