Composite carbon-coated metal oxide and preparation method thereof

A composite carbon and oxide technology, applied in electrochemical generators, structural parts, electrical components, etc., can solve the problems of poor cycle performance and rate performance, and achieve good rate performance, easy control, and improved electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

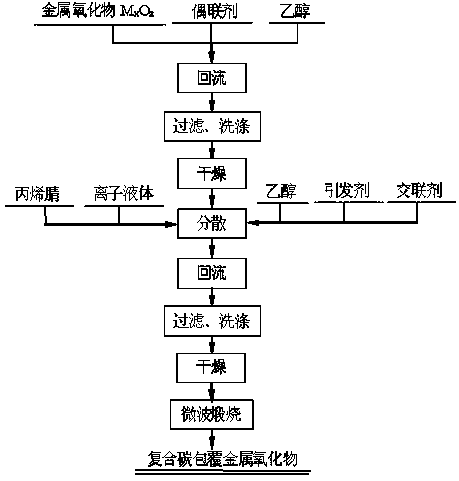

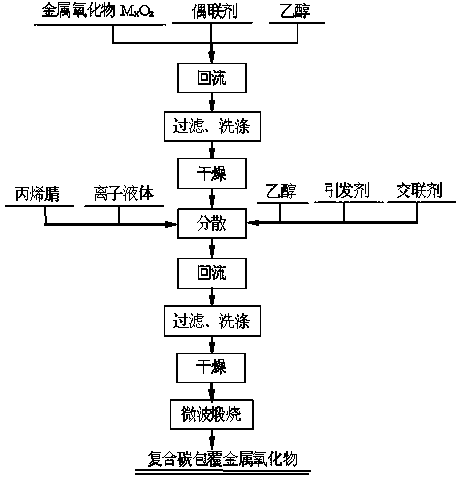

[0016] Such as figure 1 Shown, the preparation method of composite carbon-coated metal oxide of the present invention, its steps are:

[0017] (1) Metal oxide surface modification: the metal oxide M x o z Mix with the coupling agent at a mass ratio of 1:1 to 1:20, and in the mass ratio M x o z : Ethanol=1:20~1:50 Add ethanol, reflux at 30℃ for 20~40h, then filter, wash, and then dry at 60℃ for 10~30h;

[0018] (2) Metal oxide surface-coated ionic liquid polymer: M obtained in step (1) x o z According to the mass ratio M x o z : Ethanol=1:20~1:50 Add ethanol, ultrasonically disperse for 1~10h; x o z : Acrylonitrile=1:1~1:10 Add acrylonitrile monomer, with mass ratio M x o z : Ionic liquid=1:1~1:10 Add ionic liquid monomer; use azobisisobutyronitrile as initiator, the total mass ratio of initiator to monomer is 0.01:1~0.1:1; use polyethylene glycol Diacrylate (PEGDA-200) is used as a cross-linking agent, and the total mass ratio of cross-linking agent to monomer is 0...

Embodiment 1

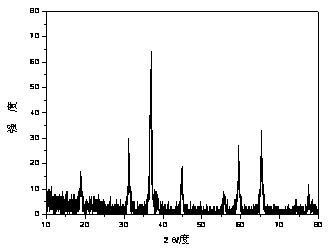

[0024] 6.0gCo 3 o 4 Add 200mL of ethanol, add 50.0g of coupling agent KH570, reflux at 30°C for 24h, filter, wash and dry at 60°C for 12h to obtain surface-modified Co 3 o 4 Powder; add 200mL of ethanol to the powder and ultrasonically disperse for 10min, then add 9.0g of acrylonitrile, 1.0g of 1-allyl-3-methylimidazolium tetrafluoroborate, 0.04g of azobisisobutyronitrile and 0.2g of polyethylene glycol diacrylate (PEGDA-200) was refluxed at 70°C for 4h under the protection of an inert gas to obtain ionic liquid polymer-coated Co 3 o 4 . Co coated with ionic liquid polymer 3 o 4 Heated in a microwave oven protected by an inert atmosphere for 30min to obtain composite carbon-coated Si 4+ Doped Co 3 o 4 Powder (XRD such as figure 2 shown).

[0025] The battery performance test of the obtained powder materials adopts CR2025 button batteries, which are assembled in a glove box filled with an inert atmosphere. The positive electrode is made of metal lithium sheet, and ...

Embodiment 2

[0027] 6.0gCo 3 o 4 Add 200mL ethanol, add 50.0g coupling agent XY-11, reflux at 30°C for 24h, filter, wash and dry at 60°C for 12h to obtain surface-modified Co 3 o 4 Powder; add 200mL of ethanol to the powder and ultrasonically disperse for 10min, then add 9.0g of acrylonitrile, 1.0g of 1-allyl-3-methylimidazolium tetrafluoroborate, 0.04g of azobisisobutyronitrile and 0.2g of polyethylene glycol diacrylate (PEGDA-200) was refluxed at 70°C for 4h under the protection of an inert gas to obtain ionic liquid polymer-coated Co 3 o 4 . Co coated with ionic liquid polymer 3 o 4 Heated in a microwave oven protected by an inert atmosphere for 30min to obtain composite carbon-coated Ti 4+ Doped Co 3 o 4 Powder.

[0028] The battery was assembled according to the method of Example 1 and tested. Under the condition of charge and discharge rate of 0.5C, the initial discharge capacity of the material reached 840mAh / g, and the capacity retention rate after 50 cycles was 89.4%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com