A kind of ag-doped tio2 material, its preparation method and application

A preparation step, silver nitrate technology, applied in nanotechnology, chemical instruments and methods, nanotechnology and other directions for materials and surface science, can solve the problems of affecting performance, complex preparation process, difficult structure of nanomaterials, etc. The effect of easy separation, simple preparation process and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.1125g of silver nitrate and dissolve it in 15ml of ethylene glycol, and disperse it evenly by ultrasonication for 30min; weigh 0.6ml of butyl titanate, drop it into the above solution under mechanical stirring at a speed of 300r / min, and continue stirring for 2.5 h, make it mix evenly; transfer the obtained mixture to a 50ml reaction kettle, keep it warm at 200°C for 24h, after it cools down, filter it with suction, wash it repeatedly with ethanol, and dry it in vacuum at 60°C for 12h to get Ag-doped Urchin-like TiO 2 Nano-structure.

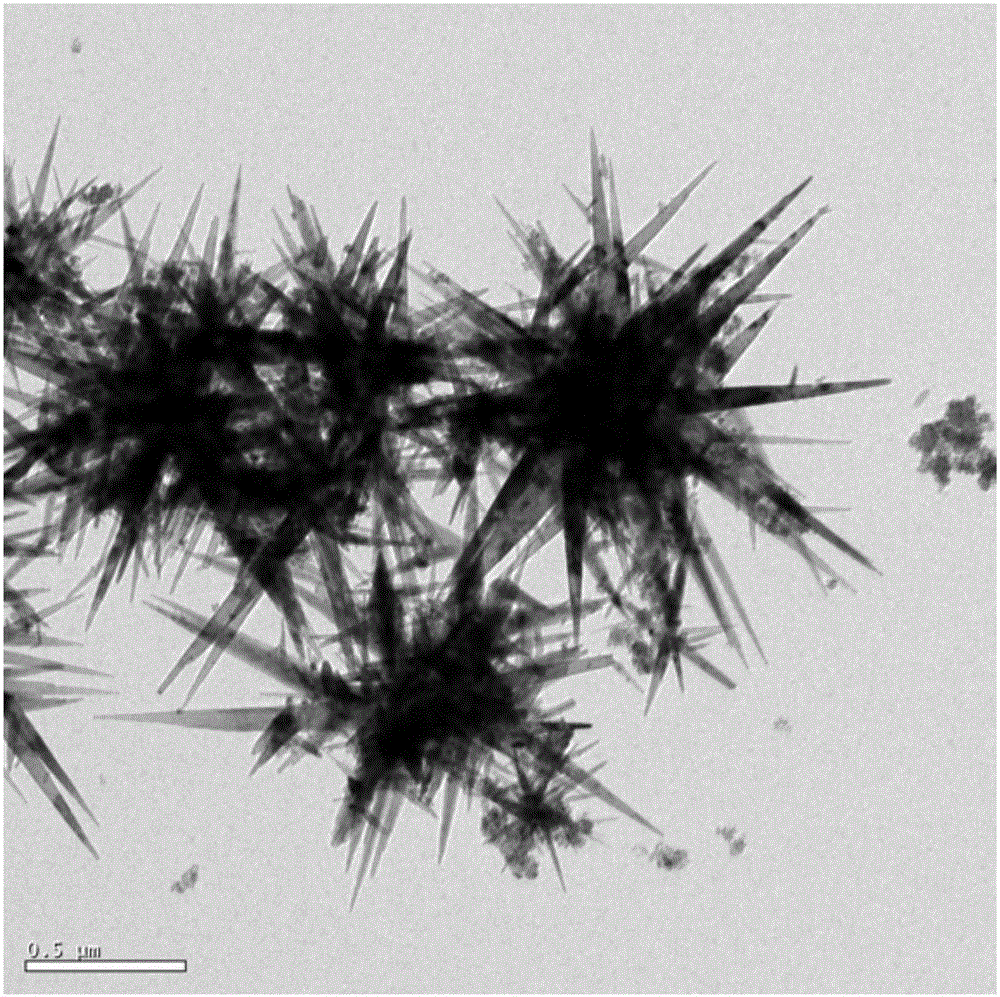

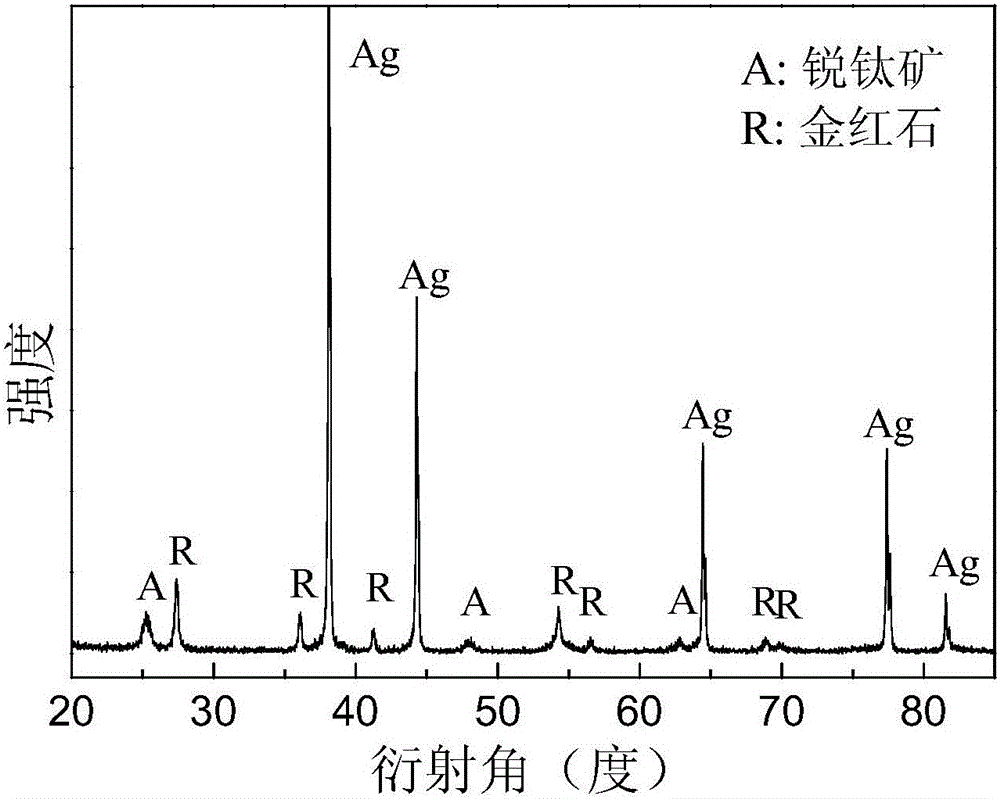

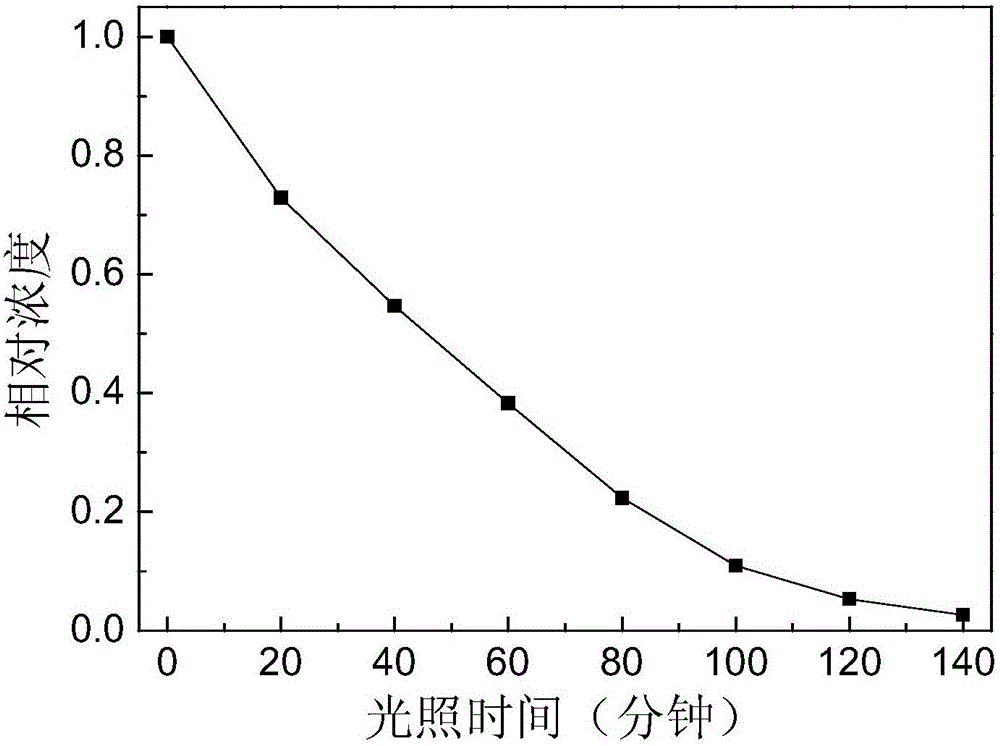

[0027] The as-prepared samples were observed with a high-resolution transmission electron microscope, such as figure 1 As shown, the morphology is a sea urchin-like structure, and the extended nanofibers have a diameter of 20-80nm and a length of about 500nm. Ag doped TiO 2 The overall diameter of the material is 1 μm, and the diameter of doped Ag clusters is 1-2 nanometers distributed in TiO 2 Inside and on the surface of the ...

Embodiment 2

[0029] Weigh 0.225g of silver nitrate and dissolve it in 15ml of ethylene glycol, and ultrasonically disperse it evenly for 30min; weigh 0.6ml of butyl titanate, and drop it into the above solution under mechanical stirring at a speed of 300r / min, and continue to stir for 2.5 h, make it mix evenly; transfer the obtained mixture to a 50ml reaction kettle, keep it warm at 240°C for 14h, after cooling, filter it with suction, wash it repeatedly with ethanol, and dry it in vacuum at 60°C for 12h to obtain Ag-doped Urchin-like TiO 2 Nano-structure.

[0030] After characterization and analysis, it can be seen that the sample presents a sea urchin-like structure, the extended nanofibers have a diameter of 10-60nm and a length of about 300nm, the overall diameter of the catalyst is 500nm, and the doped Ag clusters have a diameter of 0.1-2nm and are distributed on TiO 2 Inside and on the surface of the fiber; the diameter of Ag nanoparticles is about 2-40nm, most of them adhere to the...

Embodiment 3

[0032]Weigh 0.45g of silver nitrate and dissolve it in 15ml of ethylene glycol, and disperse it evenly by ultrasonication for 30min; weigh 0.6ml of butyl titanate, drop it into the above solution under mechanical stirring at a speed of 300r / min, and continue stirring for 2.5 h, make it mix evenly; transfer the obtained mixture to a 50ml reaction kettle, keep it warm at 280°C for 4h, after it cools down, filter it with suction, wash it repeatedly with ethanol, and dry it in vacuum at 60°C for 12h to get Ag-doped Urchin-like TiO 2 Nano-structure.

[0033] After characterization and analysis, it can be seen that the sample presents a sea urchin-like structure, and many black Ag nanoparticles aggregates are gathered around the sea urchin shape. The extended nanofibers have a diameter of 10-40nm and a length of about 230nm. The overall diameter of the catalyst is 450nm. Miscellaneous Ag clusters with a diameter of 0.1-2 nm are distributed on TiO 2 Inside and on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com