Patents

Literature

304 results about "Bismuth compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth forms chemical compounds in two main oxidation states: +3 and +5. +3 is more common. +3 compounds are weak oxidizing agents and are normally light yellow. +5 compounds are strong oxidizing agents. Bismuthates are the most common +5 compounds. Bismuth(V) fluoride is another +5 compound.

Process for producing oxide films

ActiveUS20070148347A1Group 5/15 element organic compoundsFixed capacitor dielectricSource materialBismuth compound

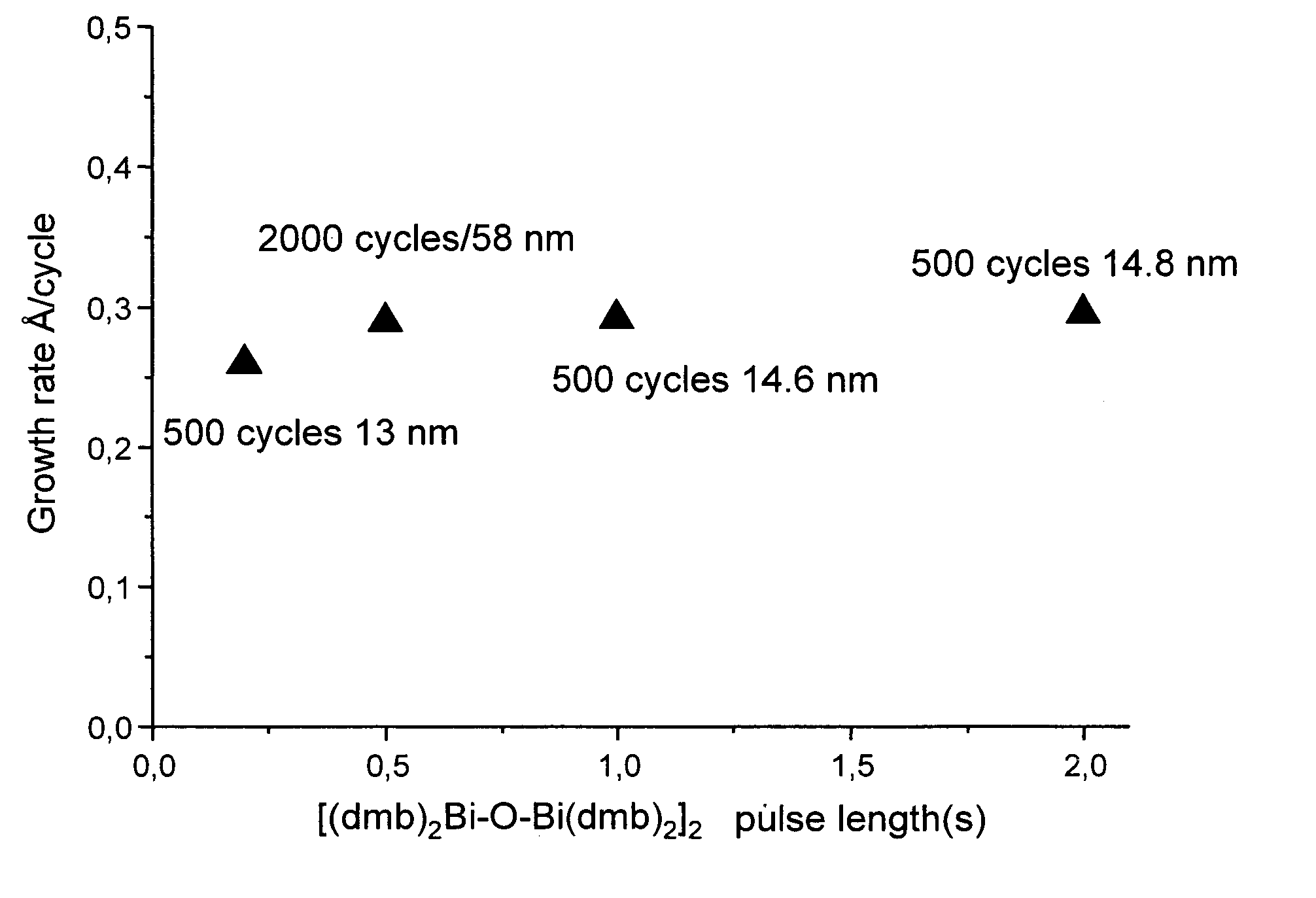

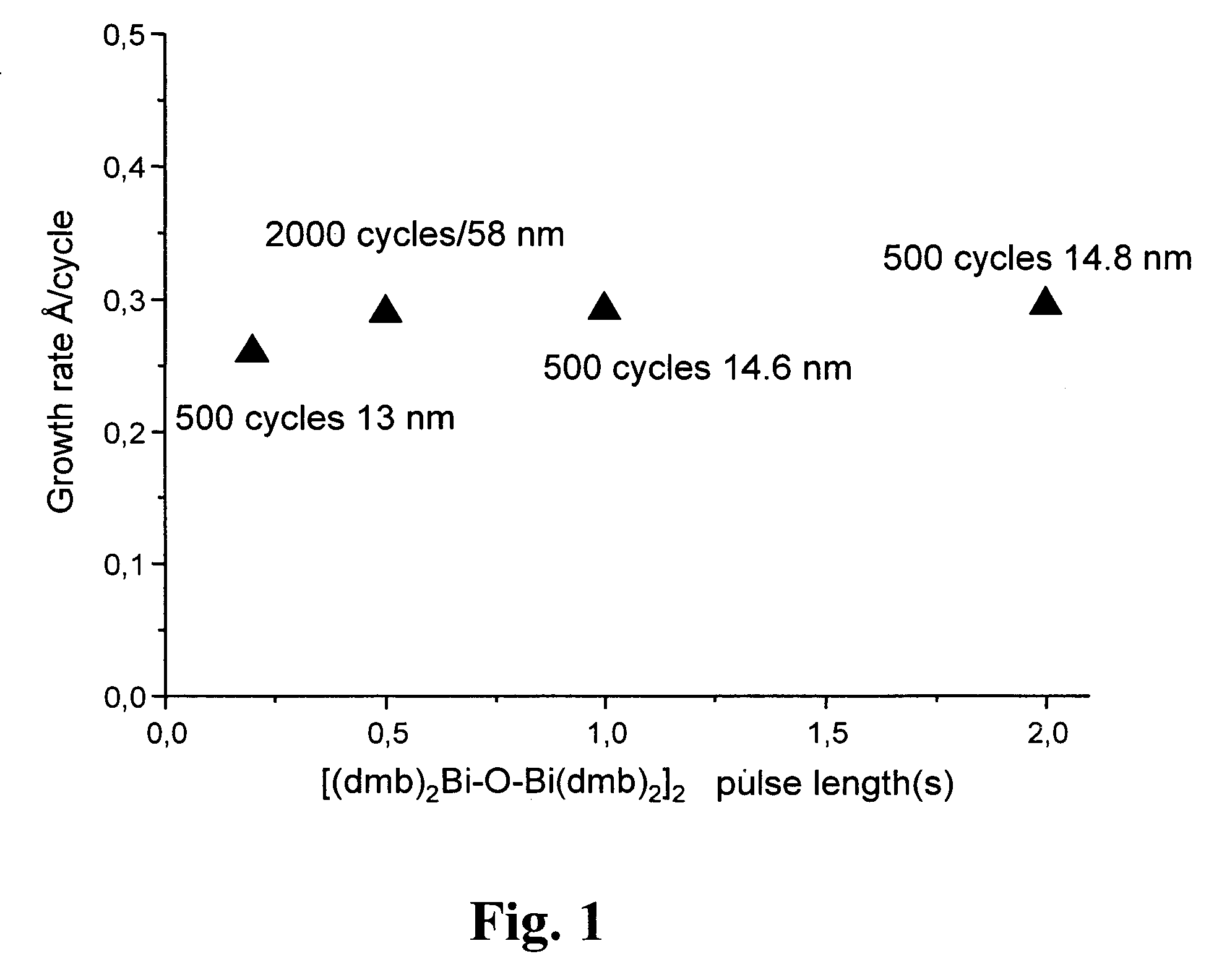

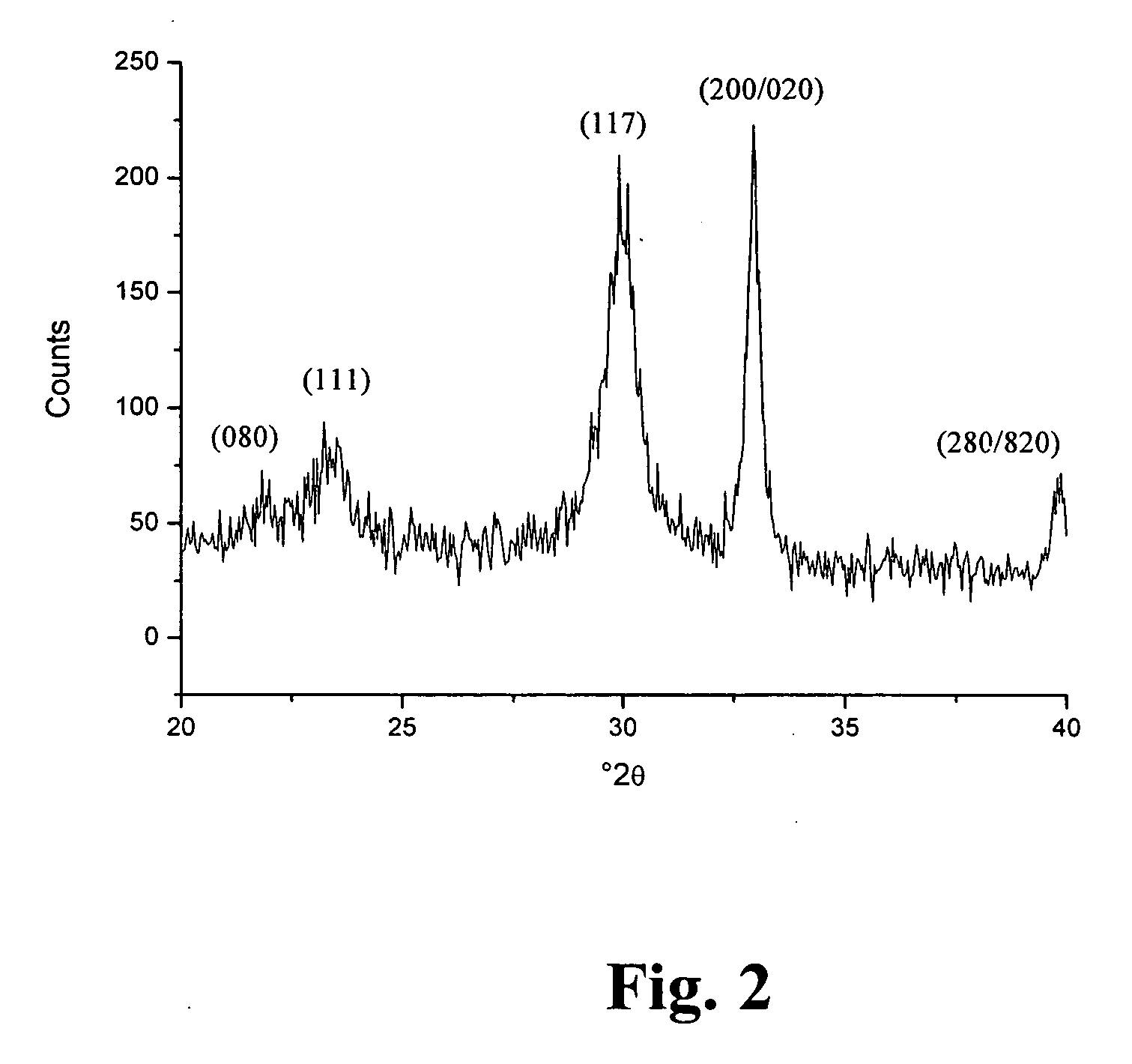

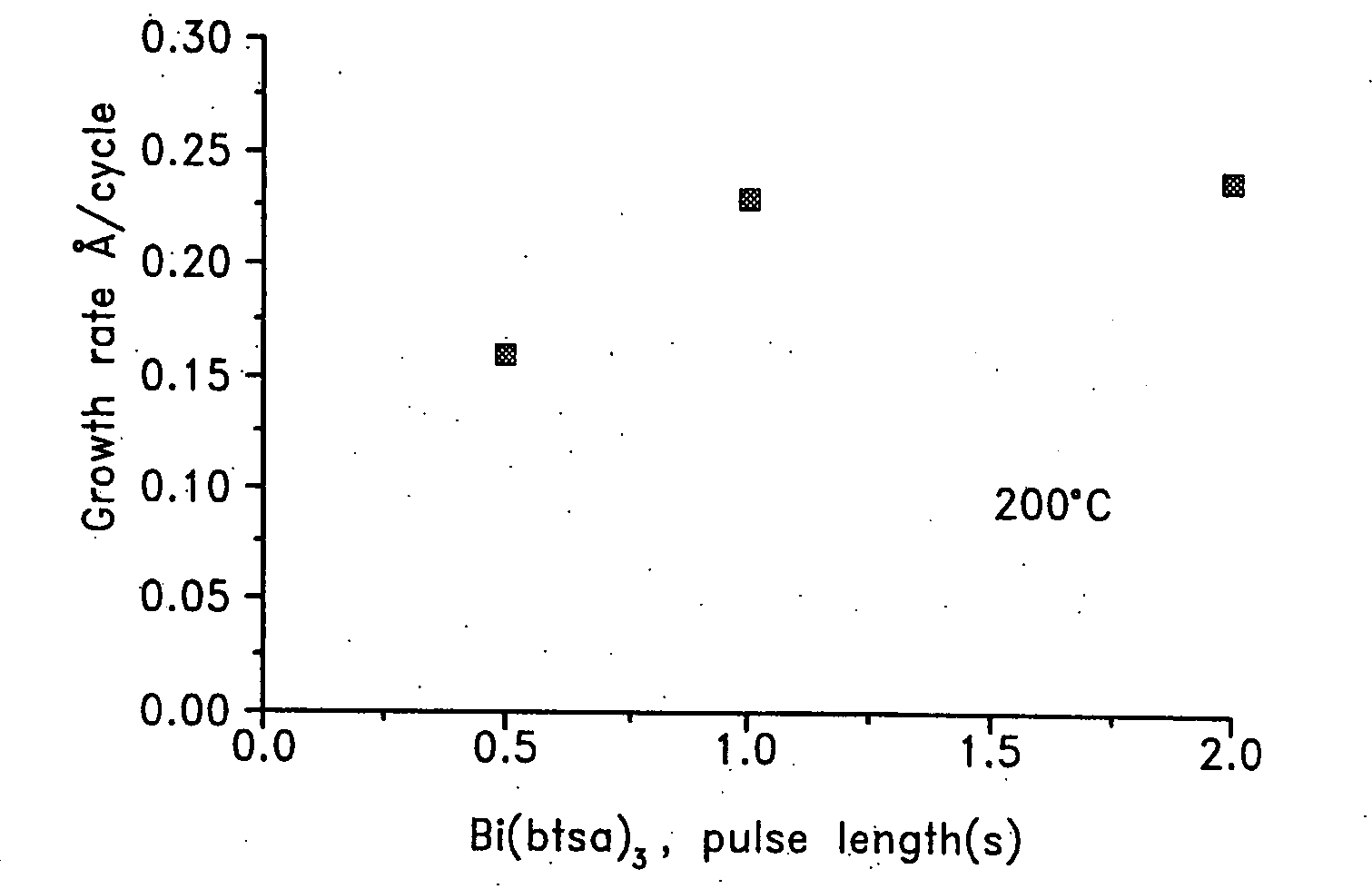

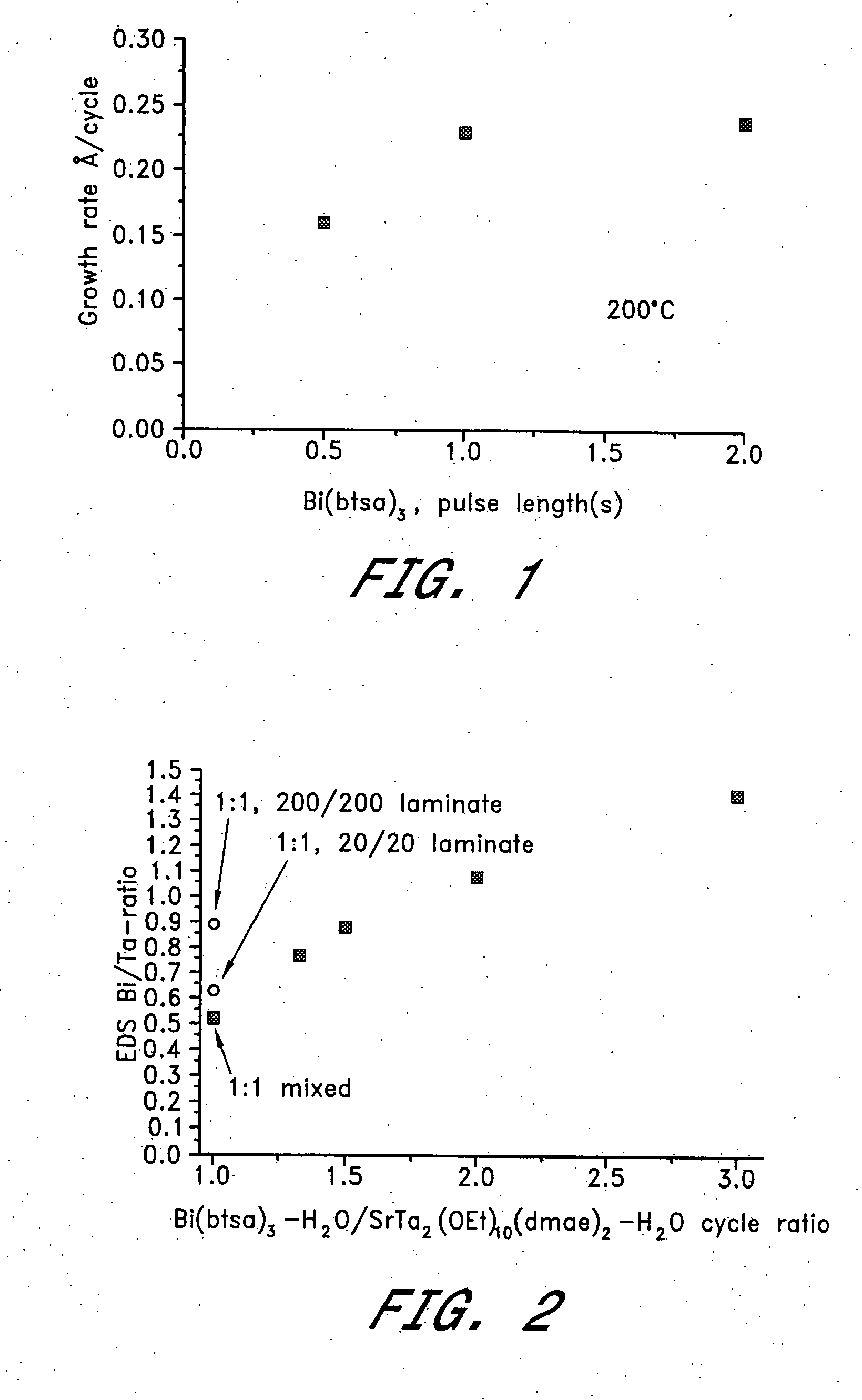

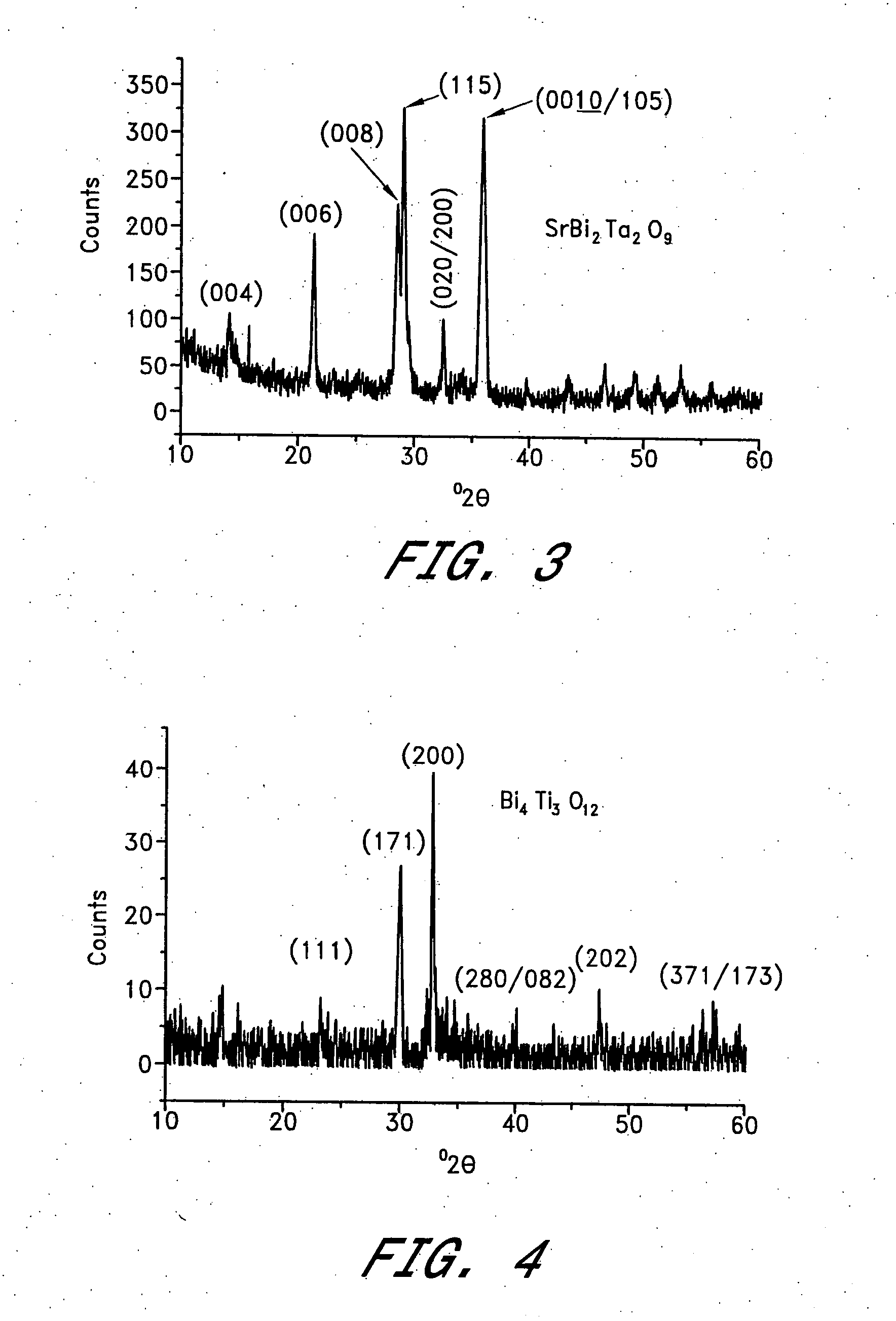

Processes are provided for producing bismuth-containing oxide thin films by atomic layer deposition. In preferred embodiments an organic bismuth compound having at least one monodentate alkoxide ligand is used as a bismuth source material. Bismuth-containing oxide thin films can be used, for example, as ferroelectric or dielectric materials in integrated circuits and as superconductor materials.

Owner:ASM INTERNATIONAL

Process for producing oxide films

ActiveUS20050089632A1Reduce decreaseImprove film propertiesCeramicsSolid-state devicesSilyleneBismuth compound

A process for producing bismuth-containing oxide thin films by Atomic Layer Deposition, including using an organic bismuth compound having at least one silylamido ligand as a source material for the bismuth oxide. Bismuth-containing oxide thin films produced by the preferred embodiments can be used, for example, as ferroelectric or dielectric material in integrated circuits and / or as superconductor materials.

Owner:ASM INTERNATIONAL

Process for preparing visible light responding photo catalytic film layer

InactiveCN1683074ATightly boundSmooth and dense surfaceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventPhoto catalytic

The preparation process of visible light responding photocatalytic film layer features that the core or substrate to be coated is set inside water solution with water soluble inorganic or organic Bi compound and V compound, additive, complexing agent, NaOH, KOH and HNO3 while ultrasonically stirring, and after processing for 1-360 min, the core or substrate with obtained visible light responding photocatalytic bismuth vanadate film layer in the surface is taken out and washed with water or organic solvent. Thus obtained material with loaded bismuth vanadate photocatalyst has powerful sterilizing, deterging and deodorizing functions.

Owner:NANJING UNIV

Bismuth compounds composite

InactiveUS20050258404A1High glossSimilar surface material propertyDiffusing elementsNuclear engineering problemsBismuth compoundCompound (substance)

A bismuth compound composite having a polymer matrix and a bismuth compound therein. The bismuth compound may be bismuth oxide, or other bismuth compounds. The polymer may be any of a very wide range of materials or combinations thereof. Binder, secondary fillers or other third components may be added. By means of use of various bismuth compounds, polymers, and third components, the physical, radiological and electrical properties of the finished products may be tailored to achieve desired properties. In addition, the invention teaches that radiation shielding, insulators, and combined radiation shield / insulators may be fashioned from the composite. A wide range of production methods may be employed, including but not limited to liquid resin casting.

Owner:MCCORD STUART JAMES

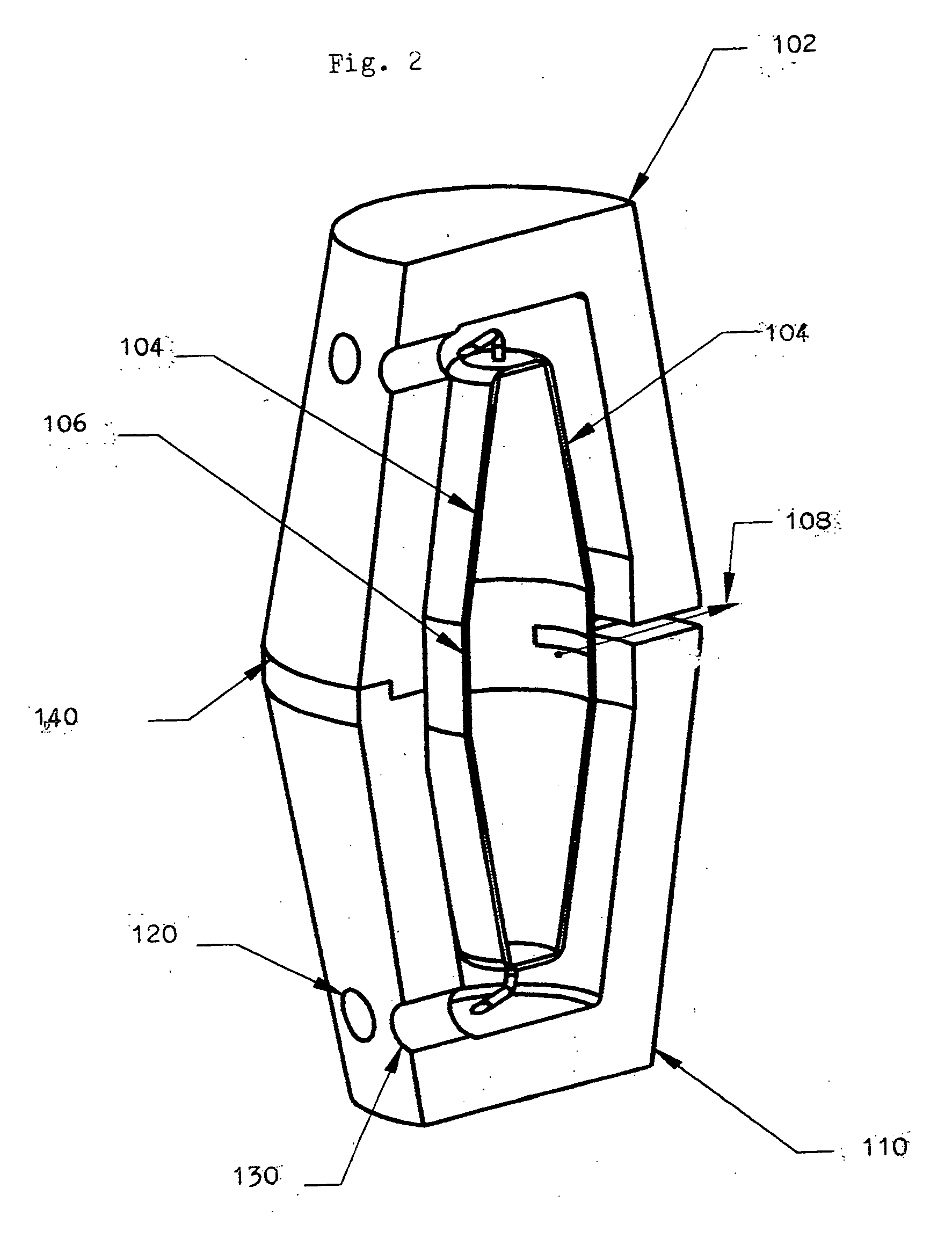

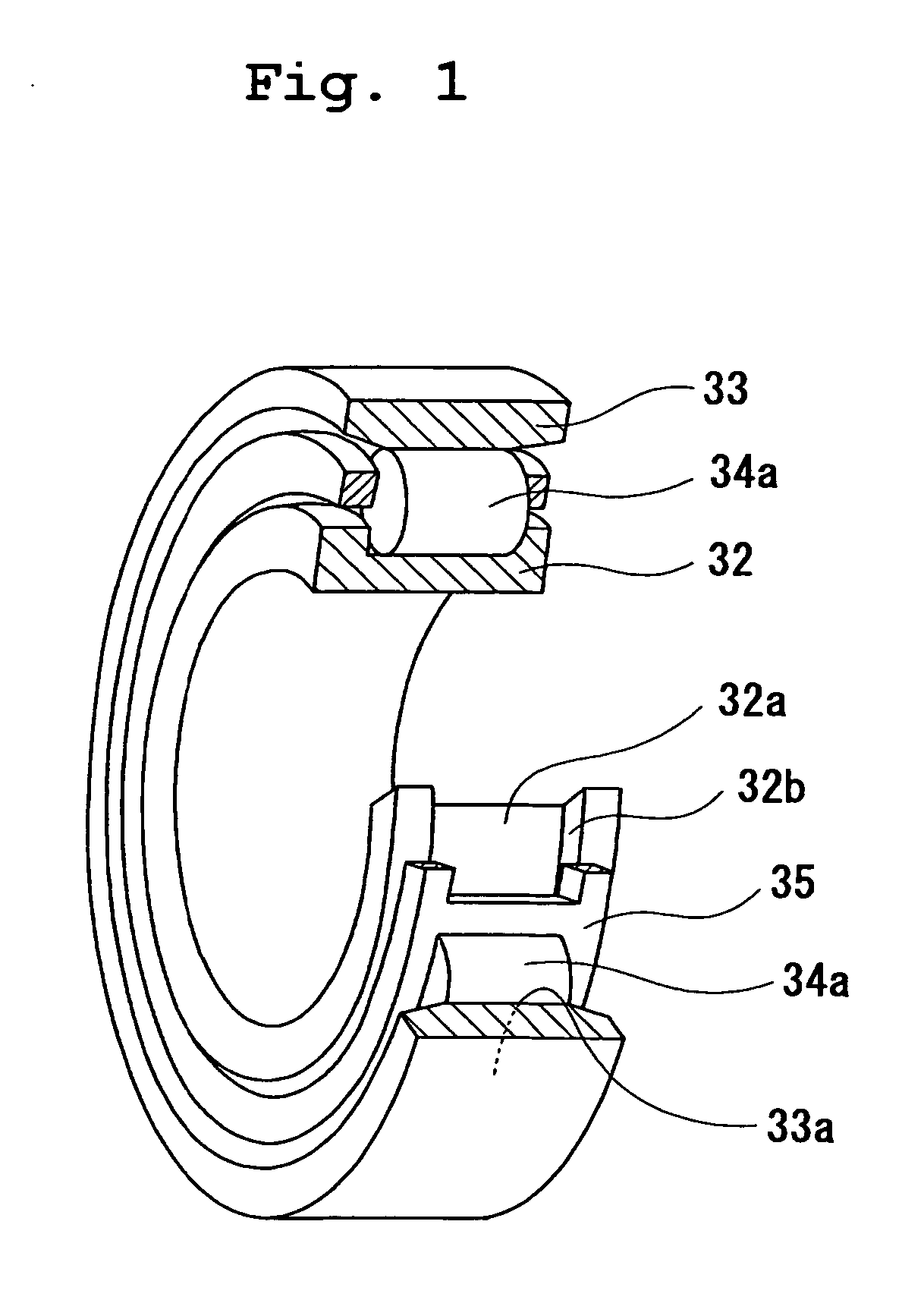

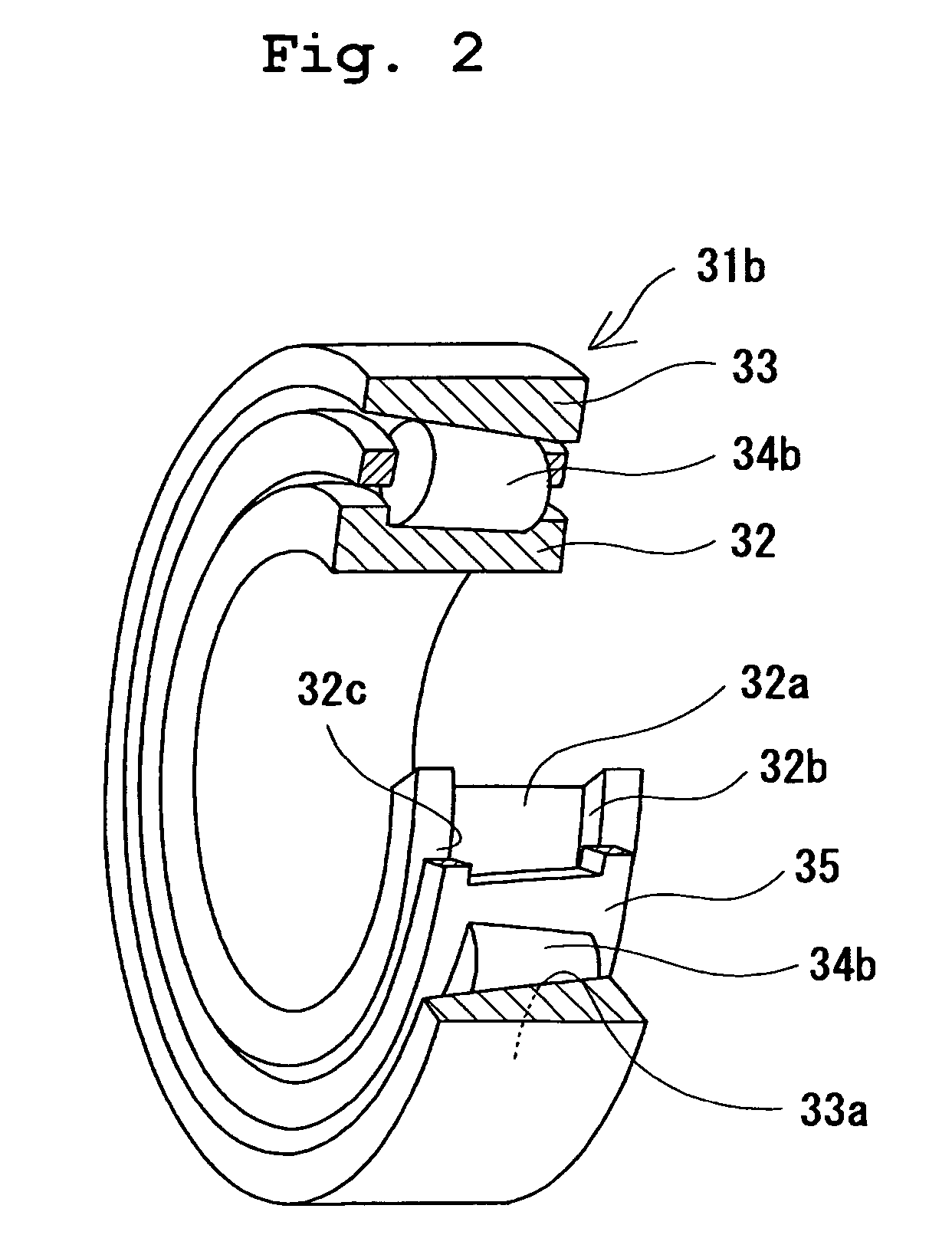

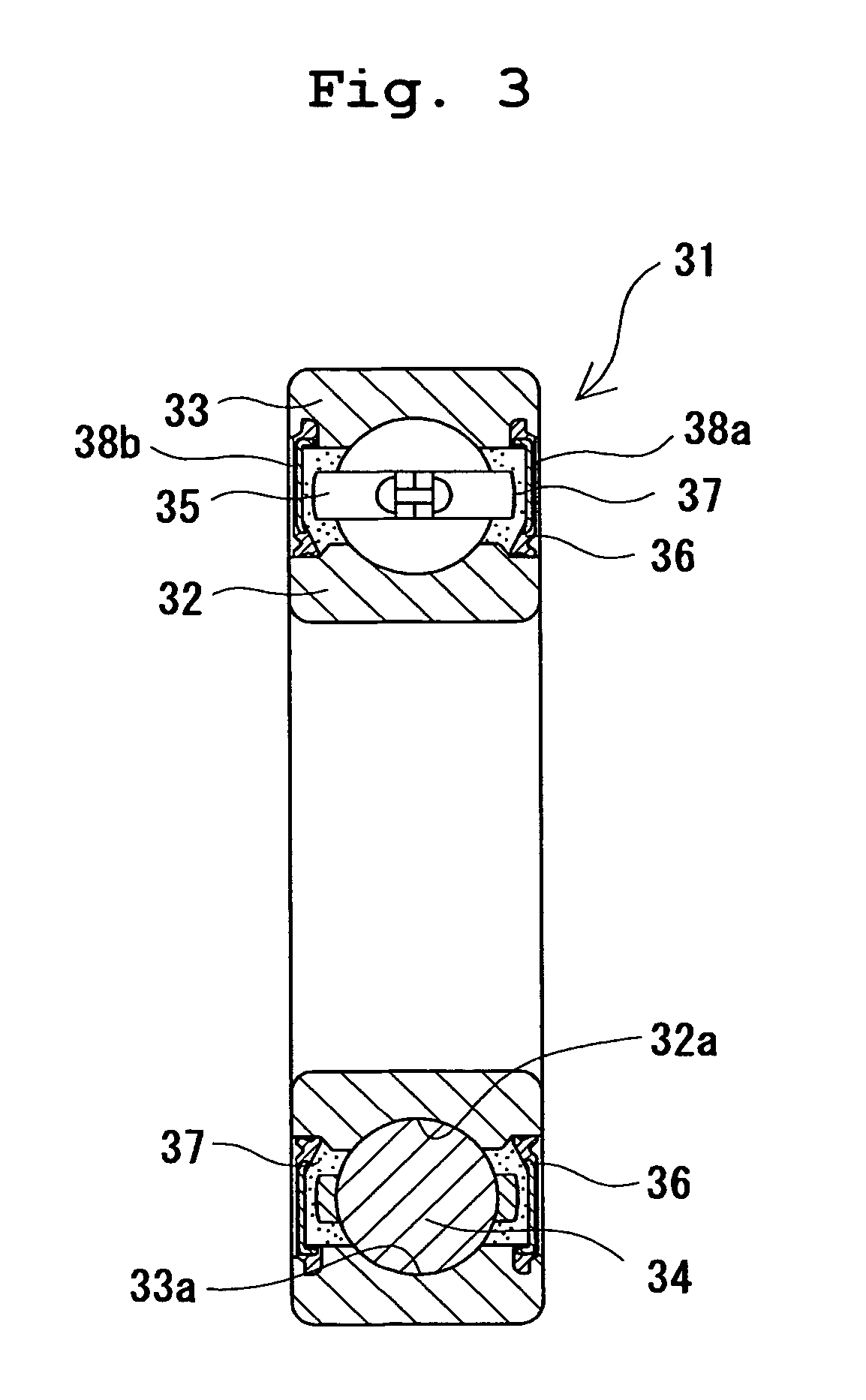

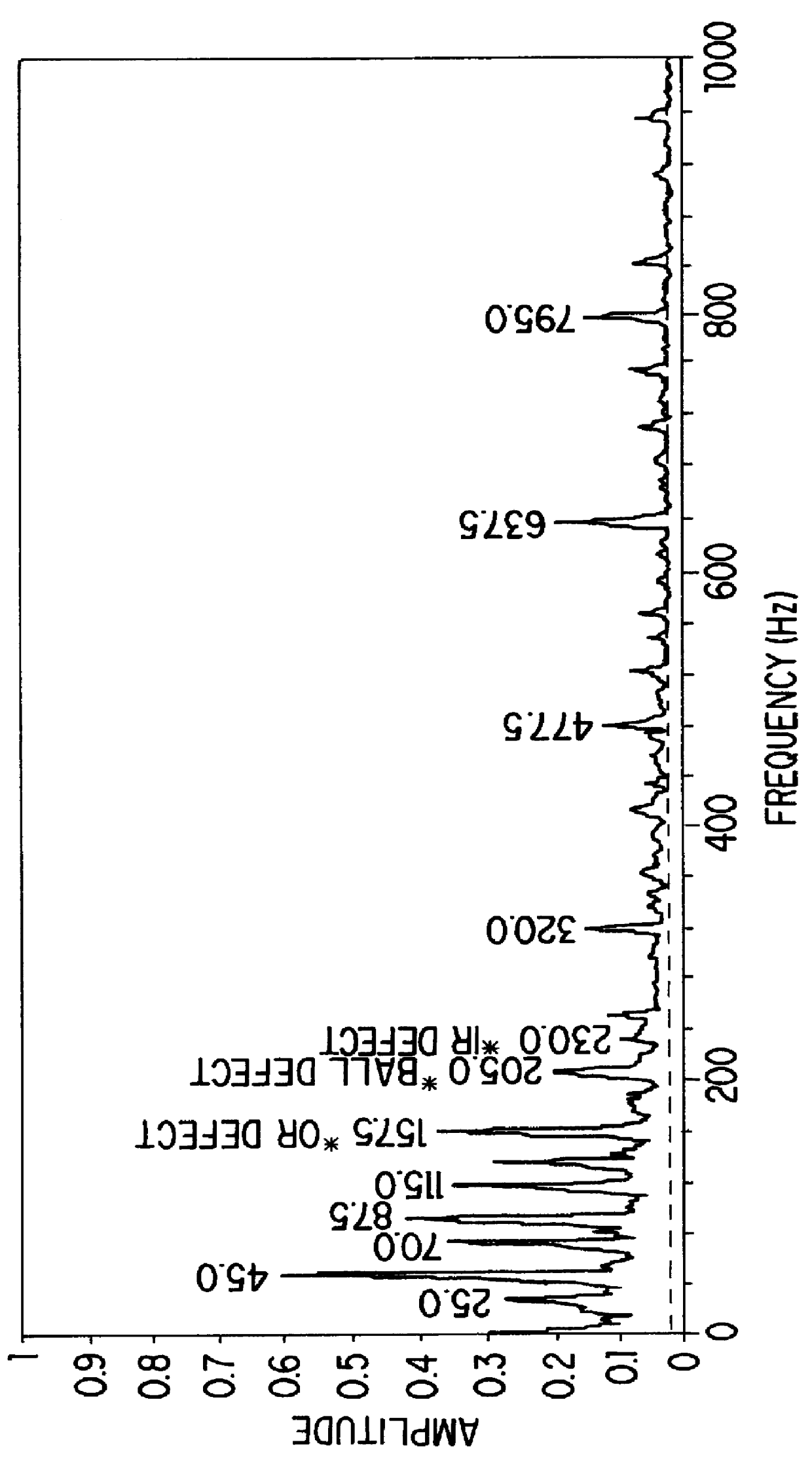

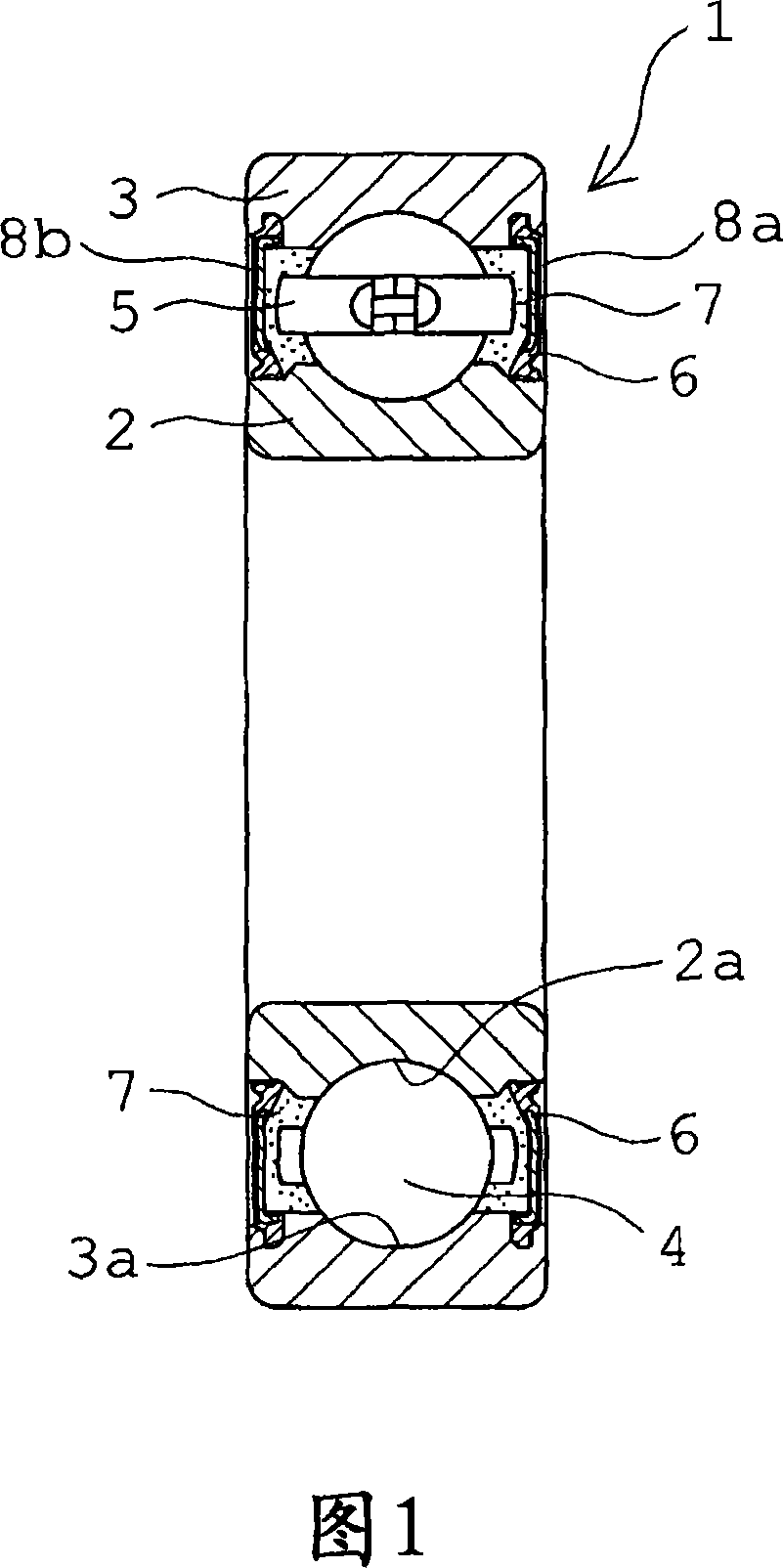

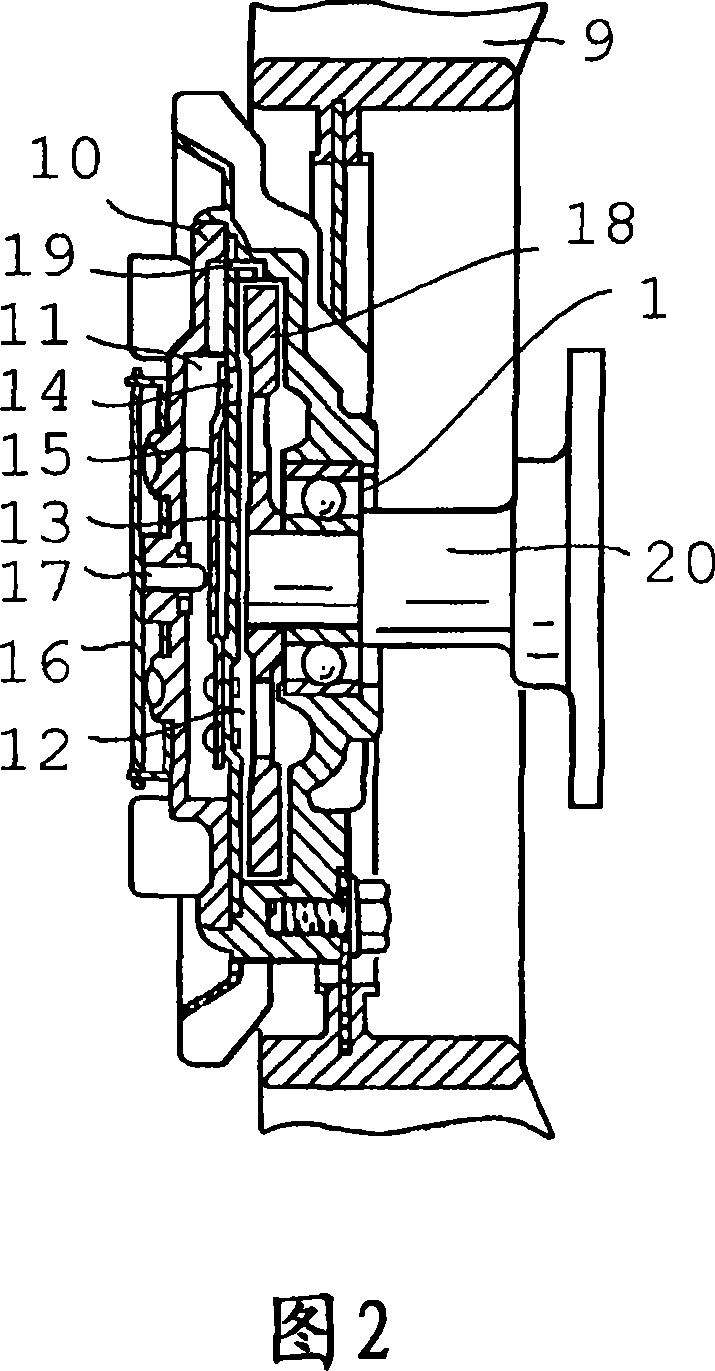

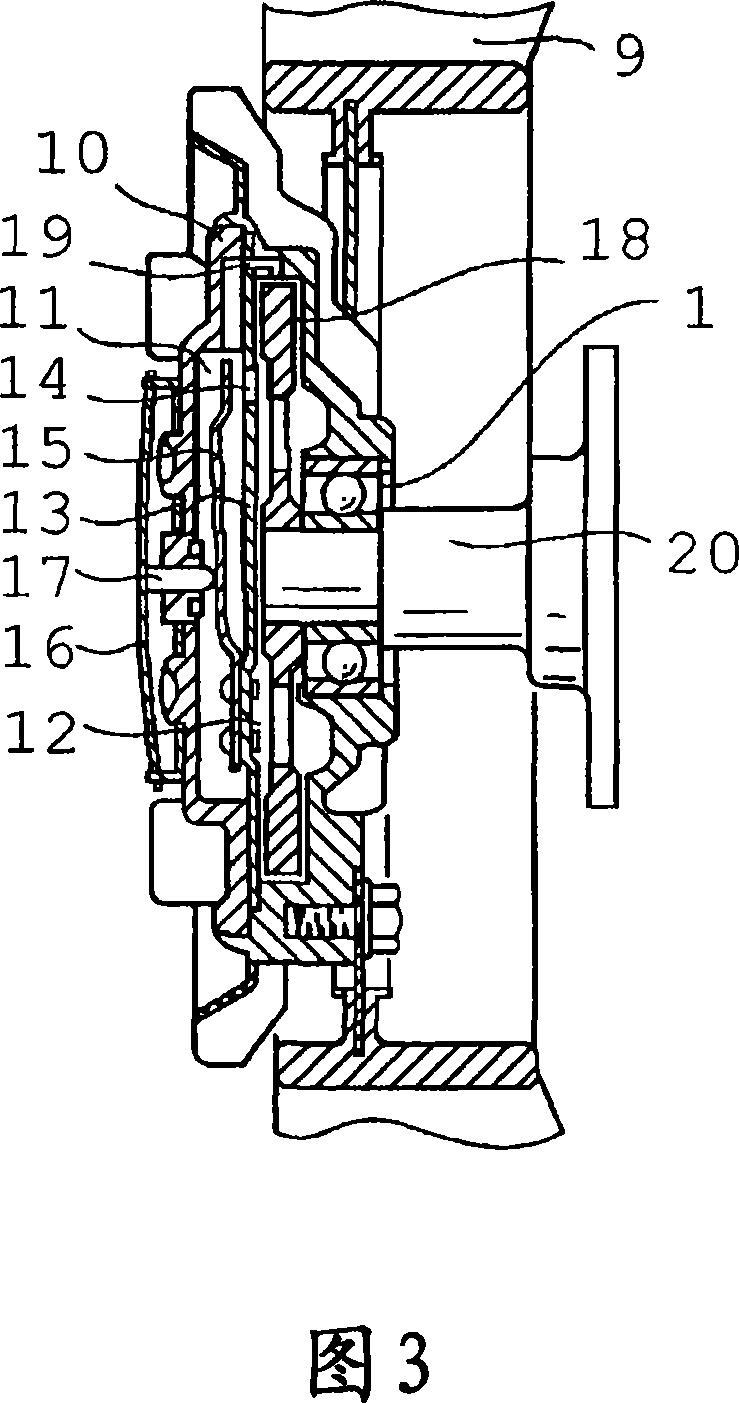

Grease, rolling bearing, constant velocity joint and rolling parts

InactiveUS20070154128A1Resistance to durabilityHeat resistantClutchesMachines/enginesBismuth compoundSulfate

The present invention provides grease which prevents frictional wear on a lubricating surface and excellent in performance of preventing occurrence of flaking, heat-resistant performance, and long-term durability, a grease-enclosed rolling bearing, a constant velocity joint, and rolling parts. Grease is composed of base grease, essentially containing a thickener, to which at least 0.01 to 15 wt % of one substance selected from among bismuth and inorganic bismuth compounds is added. The inorganic bismuth compounds are at least one inorganic bismuth selected from among bismuth sulfate, bismuth trioxide, bismuth carbonate, and sodium bismuthate. The above-described grease is used for the rolling bearing and the constant velocity joint. A coating film of at least one substance selected from among the bismuth and the inorganic bismuth is formed on surfaces of the rolling parts.

Owner:NTN CORP

Cationic electrodeposition coating composition

InactiveUS6333367B1Satisfactory corrosion resistanceReduce resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyAcrylic resin

A cationic electrodeposition coating composition containing (A) an acrylic resin obtained by subjecting a mixture of 10 to 60% by weight of a hydroxyl group-containing acrylic monomer (a), 5 to 35% by weight of an amino group-containing acrylic monomer (b), 5 to 55% by weight of an aromatic vinyl monomer (c) and optionally another acrylic monomer (d) to a radical copolymerization reaction; (B) a hydroxyl group-containing acrylic resin-modified epoxy resin obtained by reacting 65 to 95% by weight of a resin composition consisting of 10 to 90% by weight of an epoxy resin (e) and 90 to 10% by weight of a hydroxyl group-containing acrylic resin (f) with 5 to 35% by weight of an amine compound (g); (C) a aliphatic and / or alicyclic blocked polyisocyanate compound, and (D) a bismuth compound component, a mixing ratio of the components (A), (B) and (C) being such that the component (A) is in the range of 40 to 90% by weight, the component (B) is in the range of 5 to 55% by weight and the component (C) is in the range of 5 to 40% by weight based on a total weight of solid contents in the components (A), (B) and (C), the component (D) being contained in such an amount as to be in the range of 0.01 to 10 parts by weight as a bismuth content per 100 parts by weight of a resin solid content in the electrodeposition coating composition.

Owner:KANSAI PAINT CO LTD

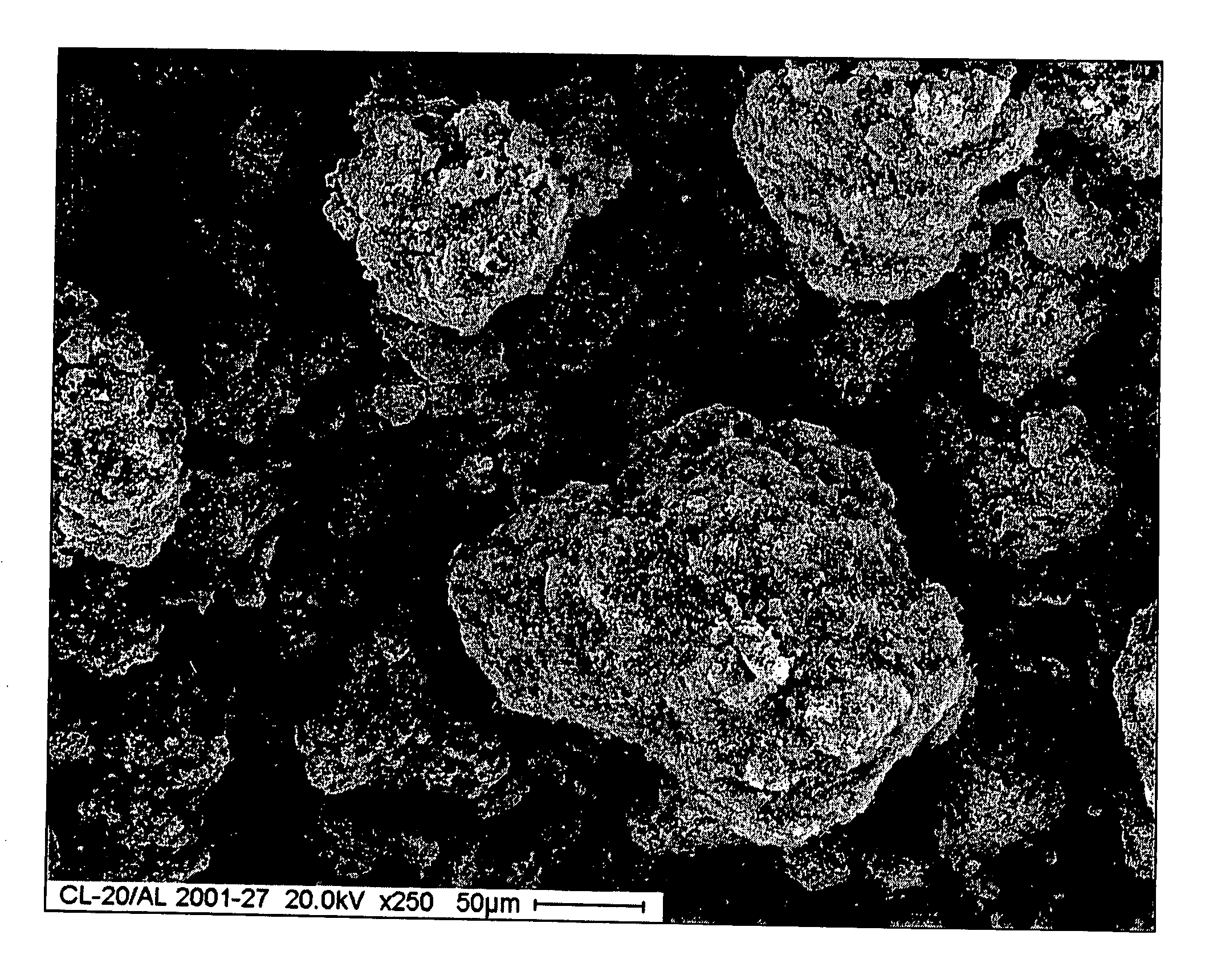

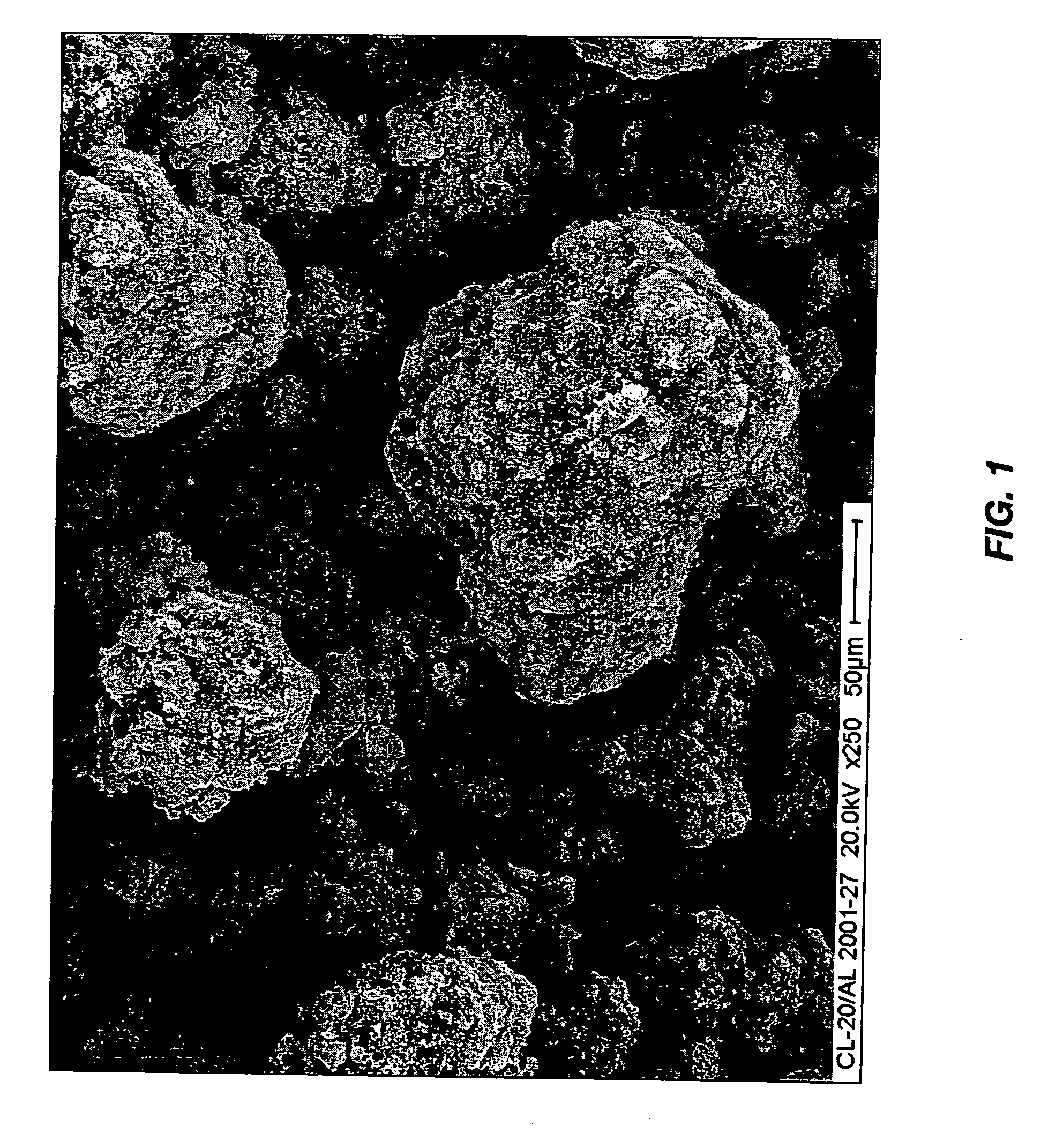

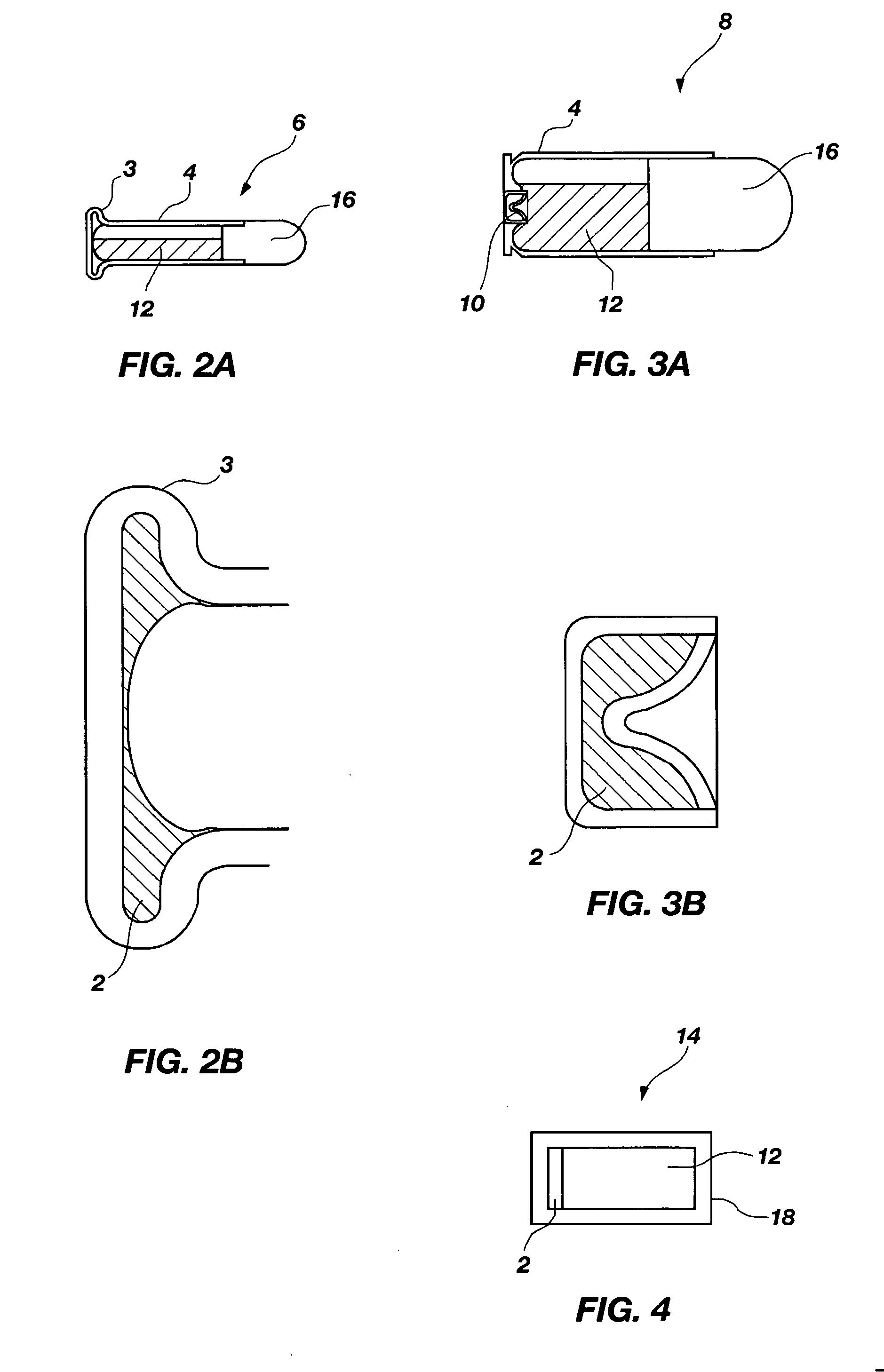

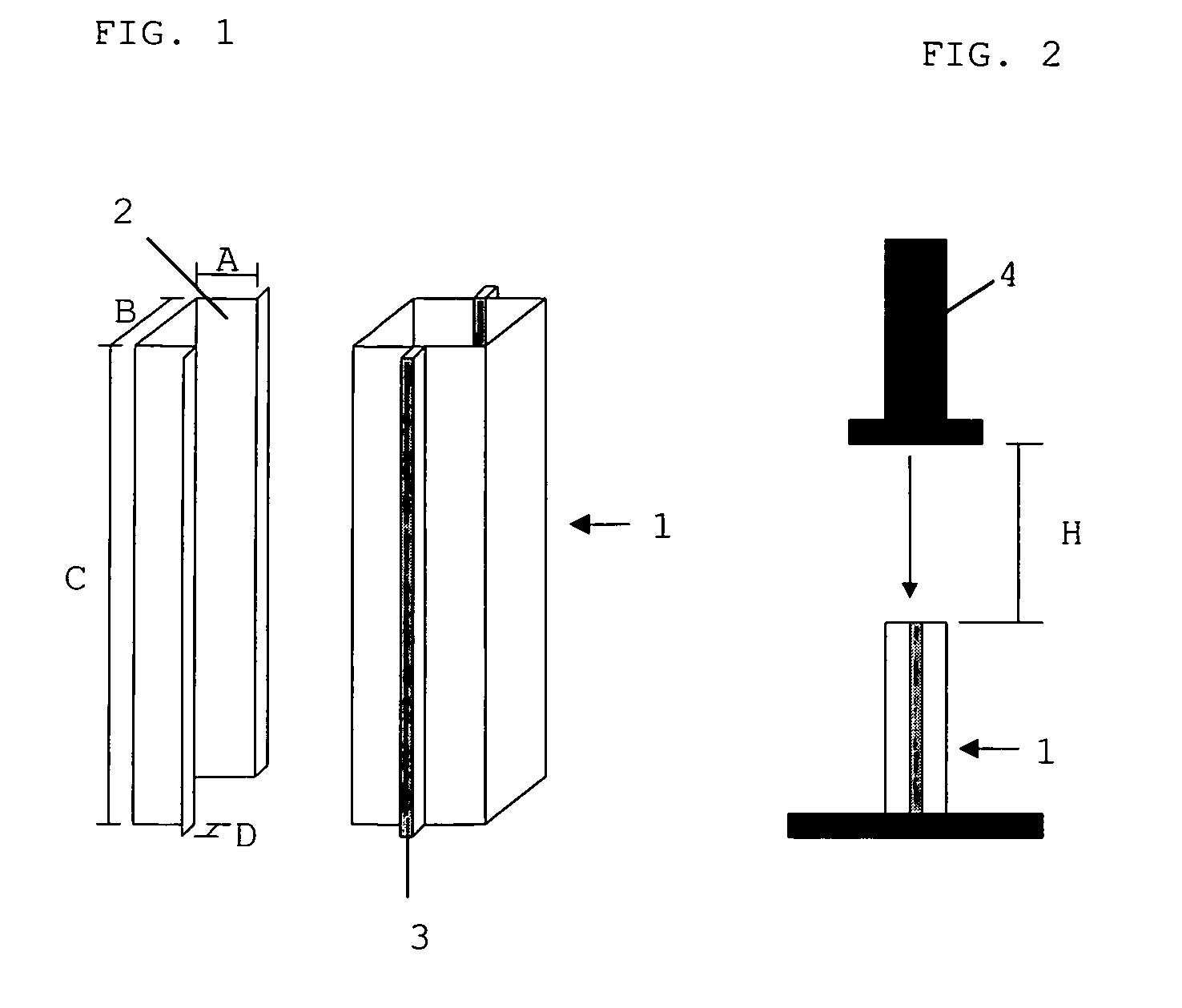

Heavy metal free, environmentally green percussion primer and ordnance and systems incorporating same

A sensitized explosive that comprises an explosive precipitated onto a sensitizer. The explosive is CL-20, PETN, RDX, HMX, or mixtures thereof and the sensitizer is aluminum, titanium, zirconium, magnesium, melamine, styrene, lithium aluminum hydride, or mixtures thereof. The sensitized explosive is used in a percussion primer that includes a bismuth compound and a melt binder. The bismuth compound is bismuth oxide, bismuth subnitrate, bismuth tetroxide, bismuth sulfide, or mixtures thereof and the melt binder is a wax having a melting point above ambient temperature, trinitrotoluene, poly(3,3-bis(azidomethyl)oxetane), poly(3-azidomethyl-3-methyloxetane), ethyl-3,5-dinitrobenzoate, or mixtures thereof. A gun cartridge and other primer-containing ordnance assemblies employing the percussion primer are also disclosed. Methods of forming the sensitized explosive and the percussion primer are also disclosed.

Owner:ORBITAL ATK INC

Polyurethane reactive composition

The invention relates to a polyurethane reactive composition comprising an isocyanate, an isocyanate reactive polymeric compound and a catalyst for the reaction of the isocyanate with the isocyanate reactive compound. The isocyanate reactive compound is a diol or a higher functional polyol of a polyester, of a polyester polyurethane, of a polycarbonate or of a mixture thereof, the polyester being derived from a hydroxy carboxylic acid or from its corresponding lactone, and the catalyst is a sterically hindered bismuth compound.

Owner:DOW GLOBAL TECH LLC

Cationic electrodeposition paint composition

InactiveUS6624215B1Organic-compounds/hydrides/coordination-complexes catalystsAnti-corrosive paintsOrganic acidBismuth compound

This invention relates to cationic electro-coating composition which comprises blending which an aqueous dispersion or an aqueous dispersion paste which contains an organic acid-modified bismuth compound in a non-water-soluble state, and which is obtained by mixing and grinding a bismuth compound and an organic acid in an aqueous medium. Said cationic electro-coating composition, although containing no lead compounds, is capable of forming an electrocoated film which is excellent in corrosion resistance, appearance, etc.

Owner:KANSAI PAINT CO LTD

Preparation of aqueous clear solution dosage forms with bile acids

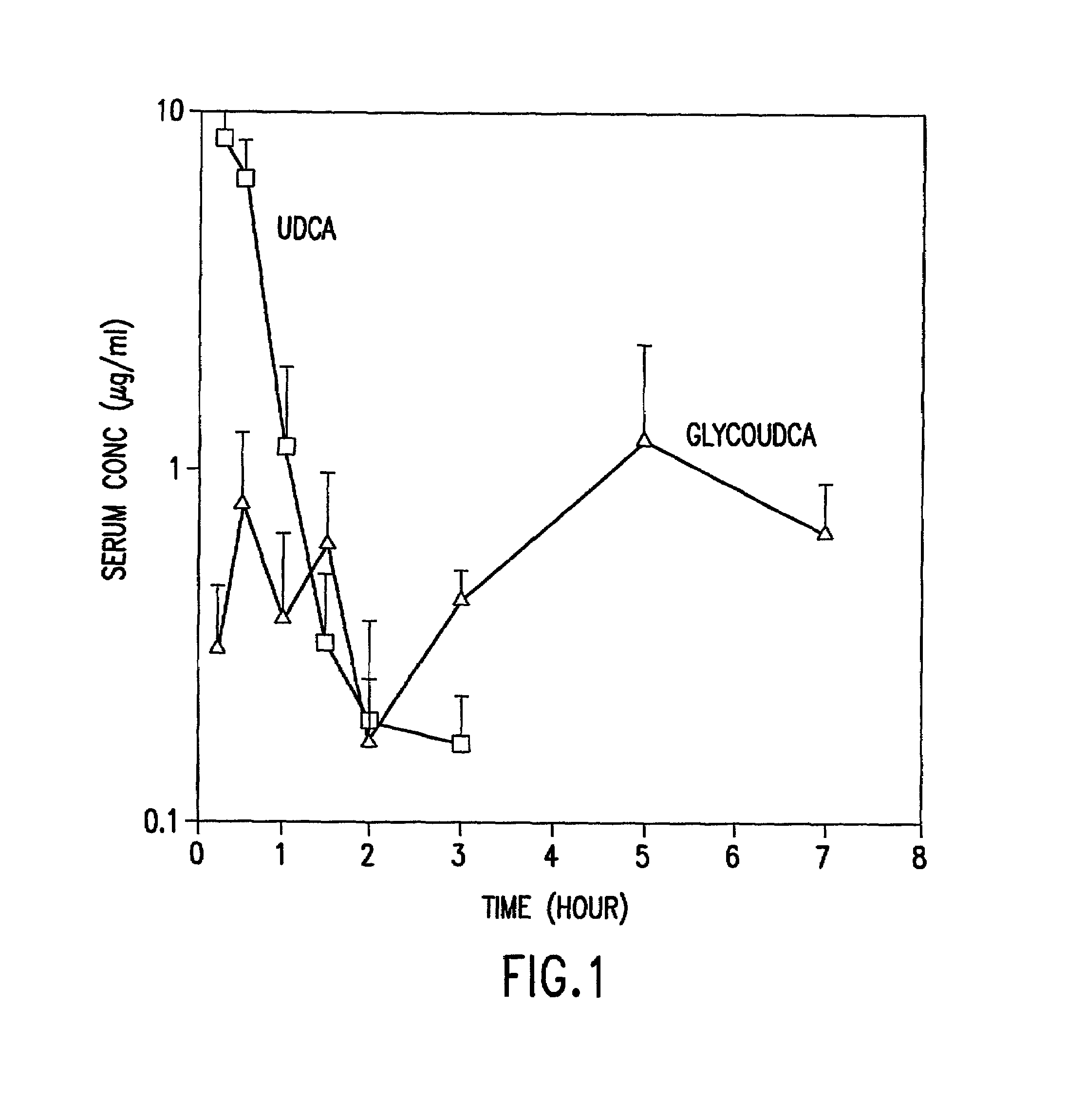

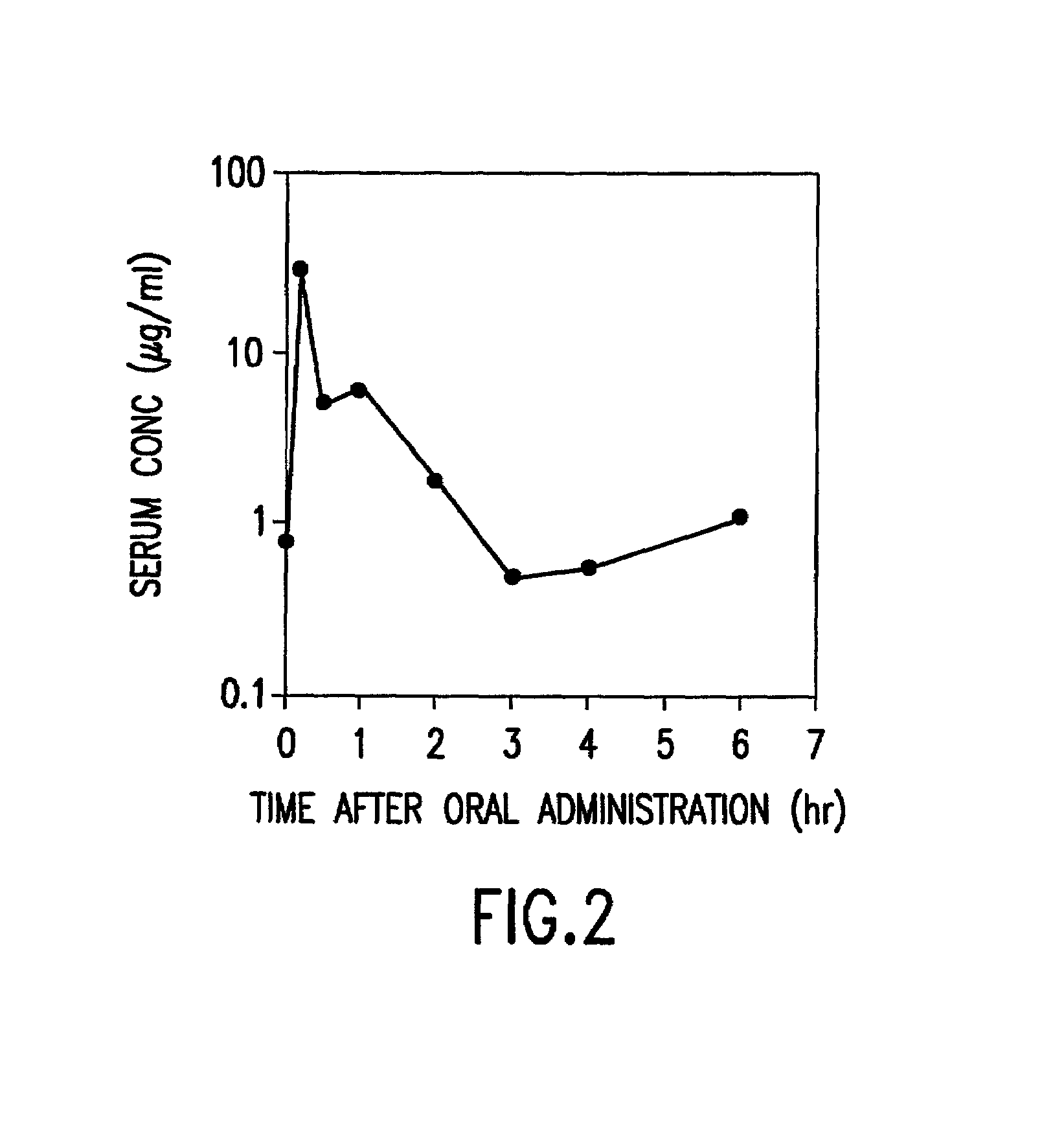

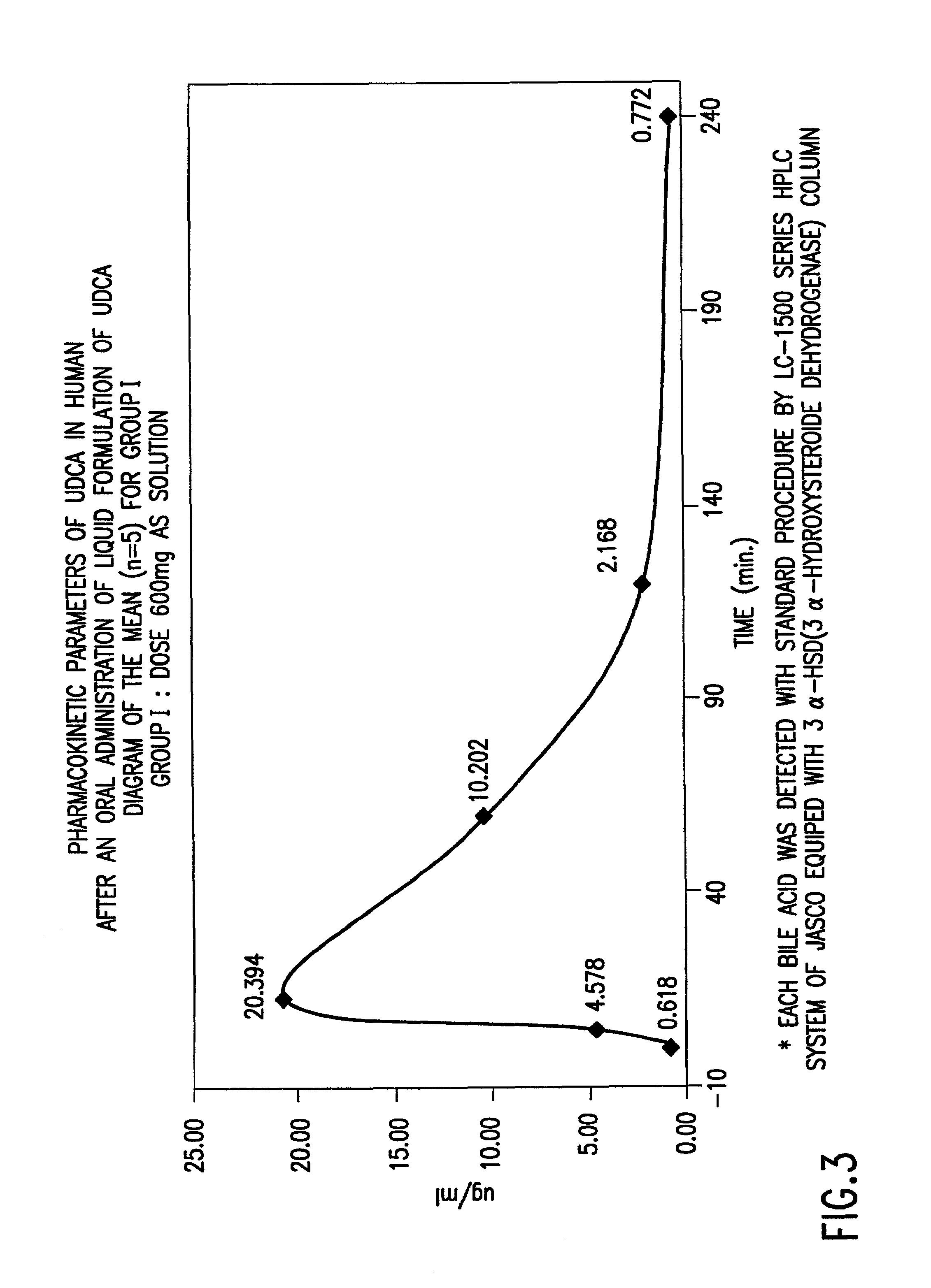

InactiveUS7303768B2Improve efficacyAlter absorptionOrganic active ingredientsHeavy metal active ingredientsBile fluidBile acid

Compositions for pharmaceutical and other uses comprising clear aqueous solutions of bile acids which do not form any detectable precipitates over selected ranges of pH values of the aqueous solution and methods of making such solutions. The compositions of the invention comprise water; a bile acid in the form of a bile acid, bile acid salt, or a bile acid conjugated with an amine by an amide linkage; and either or both an aqueous soluble starch conversion product and an aqueous soluble non-starch polysaccharide. The composition remains in solution without forming a precipitate over a range of pH values and, according to one embodiment, remains in solution for all pH values obtainable in an aqueous system. The composition, according to some embodiments, may further contain a pharmaceutical compound in a pharmaceutically effective amount. Non-limiting examples of pharmaceutical compounds include insulin, heparin, bismuth compounds, amantadine and rimantadine.

Owner:YOO SEO HONG

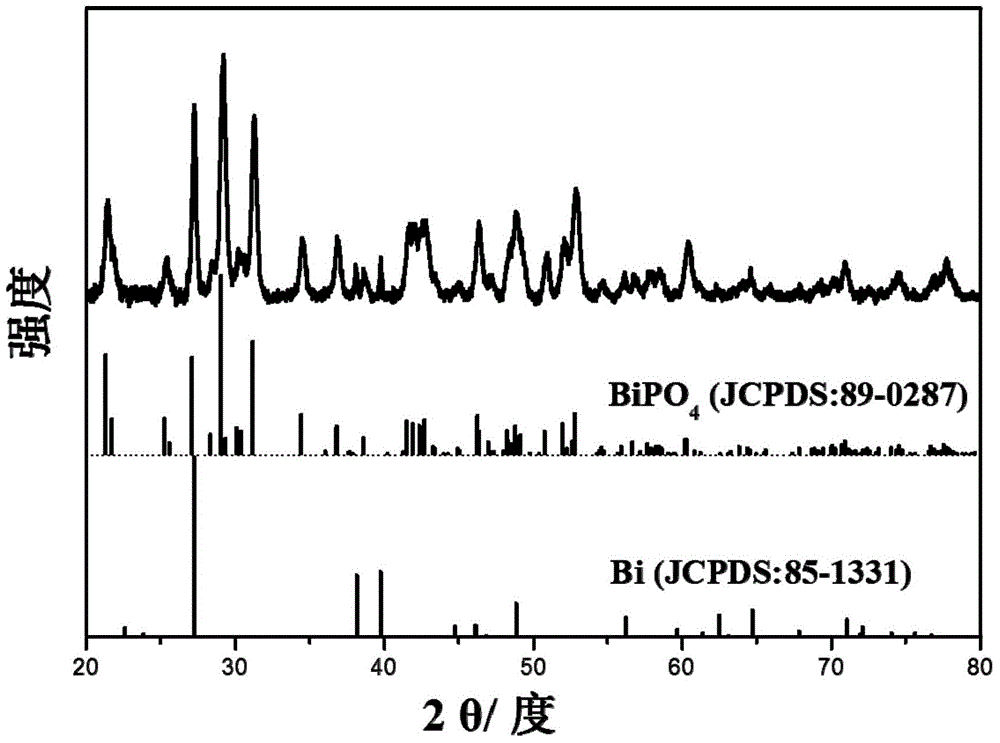

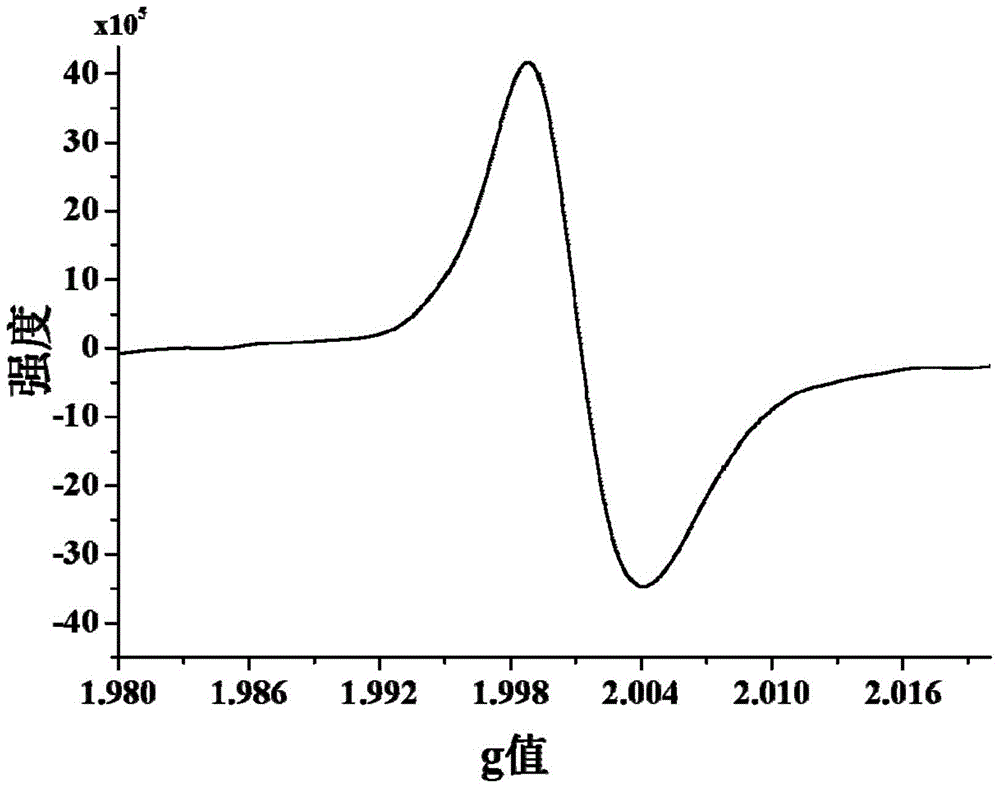

Preparing method of simple substance bismuth/bismuth compound nanocomposite with oxygen vacancies

ActiveCN104874811AAvoid disadvantages that are not easy to controlUniform sizeNanotechnologyOxygen vacancyBismuth compound

The invention relates to a preparing method of a simple substance bismuth / bismuth compound nanocomposite with oxygen vacancies. The method includes the following steps that a certain amount of bismuth nitrate pentahydrate and precursors are added into ethylene glycol, centrifugal washing is performed on obtained products after a solvent thermal condition reaction so that residual impurities can be removed, drying and cooling are performed, and then the simple substance bismuth / bismuth compound nanocomposite with the oxygen vacancies can be obtained. The method has the advantages that firstly, the method is universally applicable; secondly, the ethylene glycol serves as a solvent and a reducing agent, the oxygen vacancies and simple substance bismuth are produced through weak reducibility of the ethylene glycol, other reducing agents do not need to be added, and the defect that control is difficult because other reducing agents need to be added is avoided; thirdly, the simple substance bismuth / bismuth compound nanocomposite with the oxygen vacancies can be synthesized and is uniform in size; fourthly, a solvent thermal method is adopted, the synthesizing technology is simple, production cost is effectively reduced, and large-scale production of products can be achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

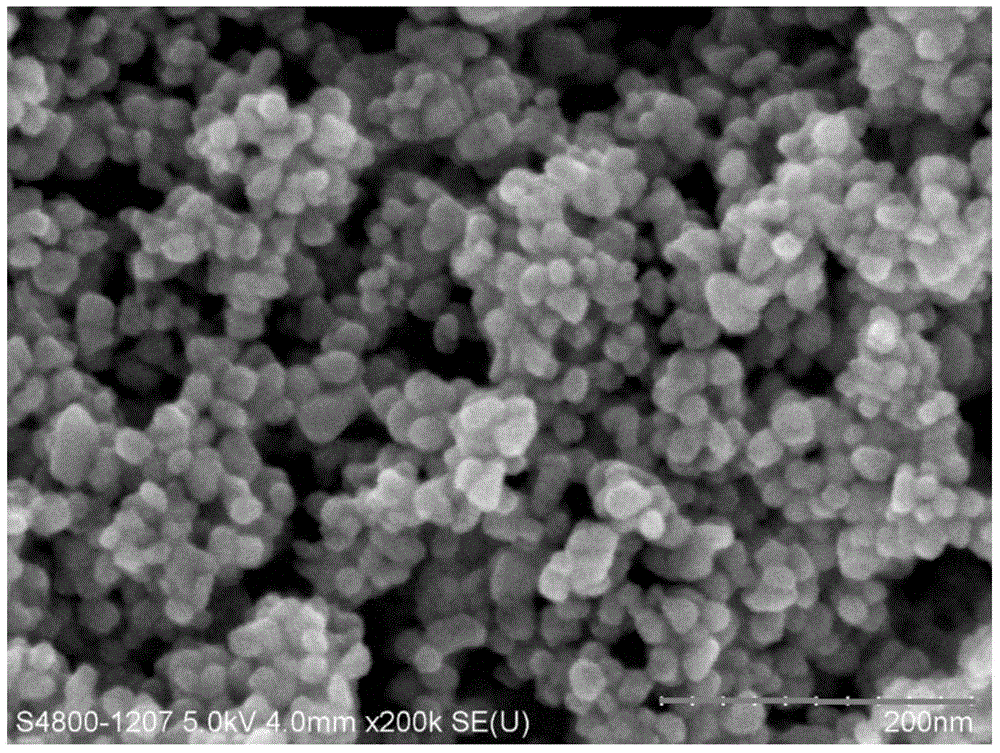

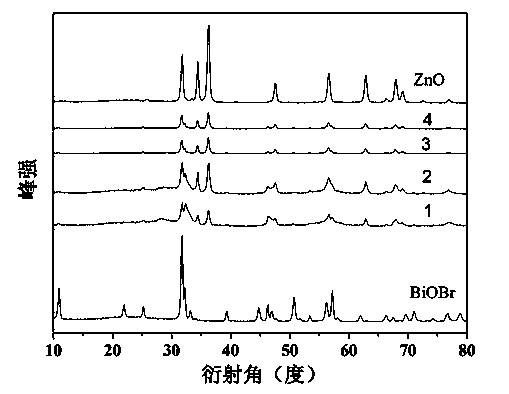

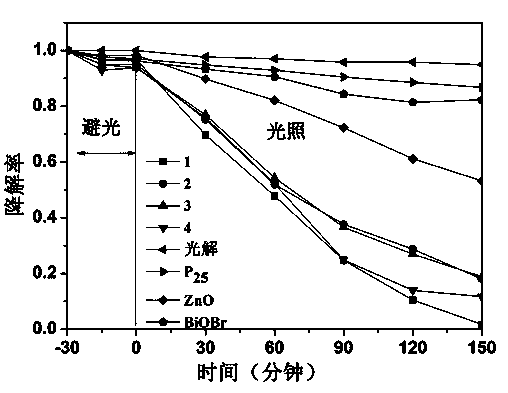

Preparation method of BiOBr/ZnO nano photocatalyst powder

InactiveCN103464184AHigh reuse ratePromote degradationPhysical/chemical process catalystsBismuth compoundPhysical chemistry

The invention discloses a preparation method of BiOBr / ZnO nano photocatalyst powder, belonging to the field of nano photocatalyst preparation. The method is characterized by comprising the steps of adding two bromine compounds CTAB (cetyl trimethyl ammonium bromide) and potassium bromide or sodium bromide at a proper proportion and a zinc-containing compound into an ethanol solvent, adding a bismuth-containing compound, and uniformly mixing; transferring the solution into a Teflon high-pressure reaction kettle, and performing a solvothermal reaction at certain temperature to generate precipitates; washing the precipitates with water and ethanol, and drying at 80 DEG C to obtain novel efficient BiOBr / ZnO nano photocatalyst powder. The method disclosed by the invention is quick, simple, convenient and high in operability, and the prepared BiOBr / ZnO heterojunction nano photocatalyst powder has perfect photocatalytic degradation efficiency on organic pollutants as well as good reusability.

Owner:TAIYUAN UNIV OF TECH

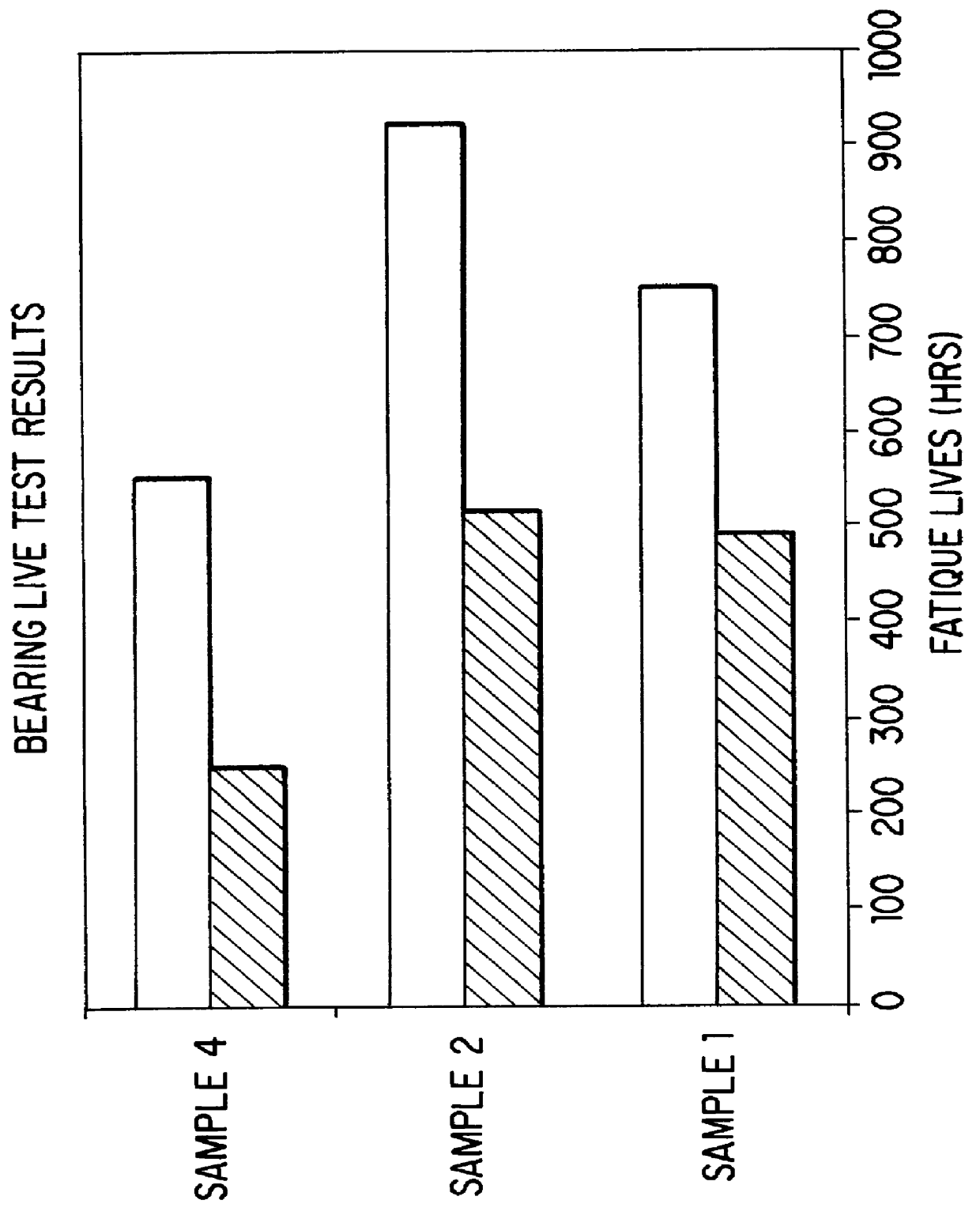

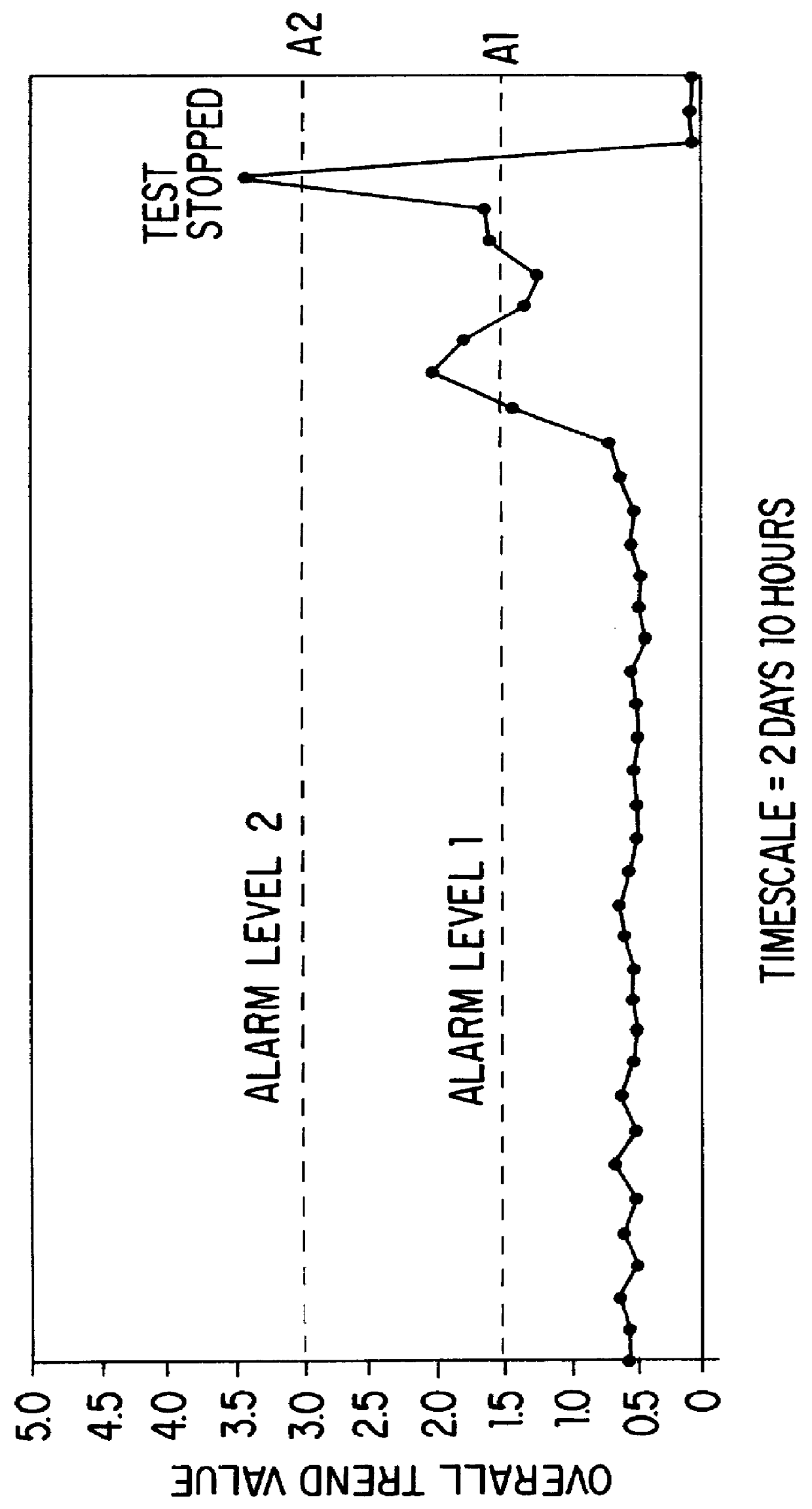

Use of bismuth compounds in extreme pressure grease lubricant compositions for rolling bearing applications with extended service life

InactiveUS6090755AIncrease relubrication intervalUseful life of lifeSolid fuelsBearing componentsBismuth compoundRolling-element bearing

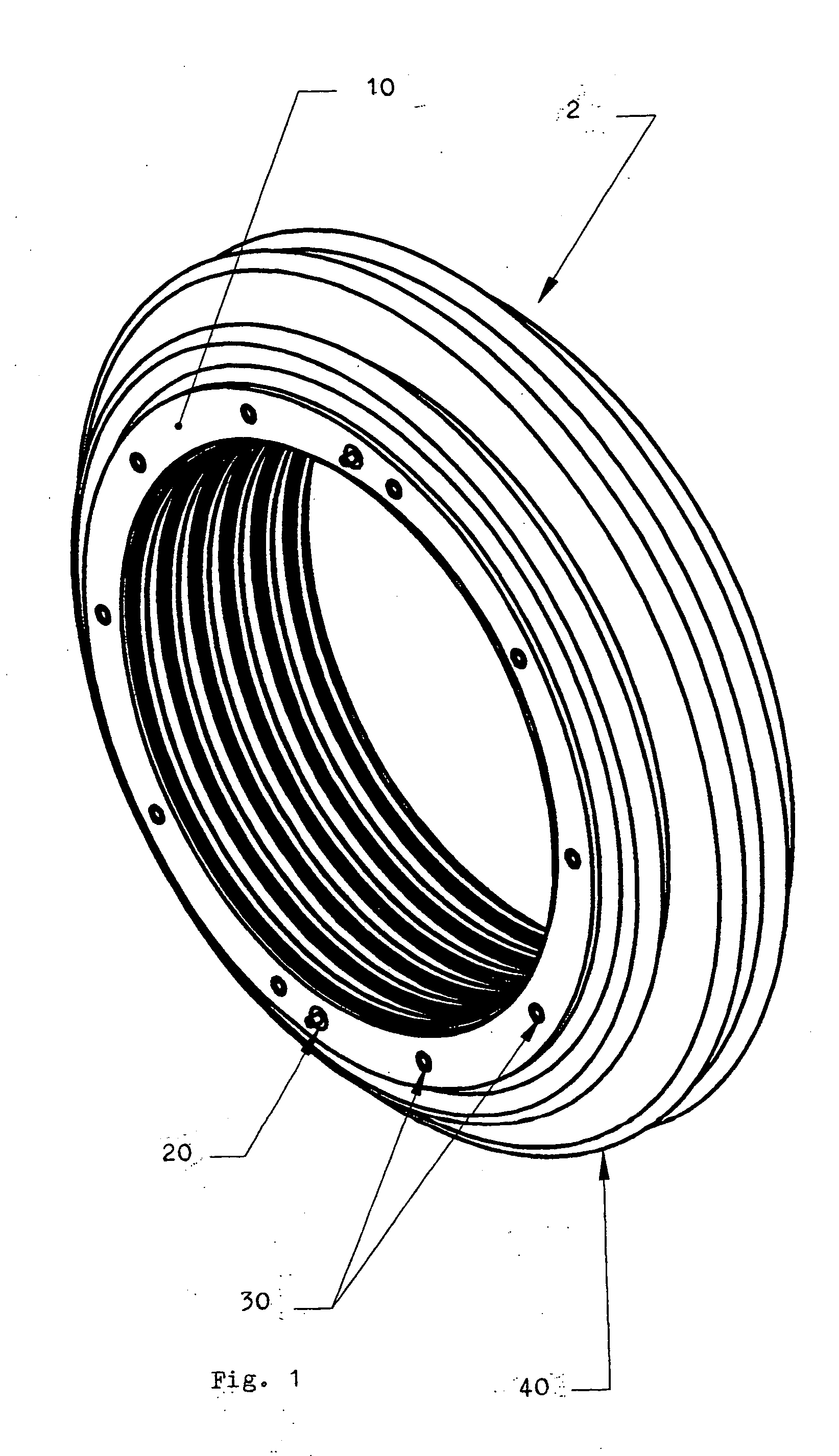

The use of bismuth-compounds in an extreme pressure grease lubricant composition for rolling bearing applications can extend the useful service life of rolling bearings. The bismuth can be used as an additive, preferably an EP additive, or as a soap or non-soap thickener. The invention further relates to a method for preparing an extreme pressure lubricant composition in which a bismuth containing soap or thickener is mixed with an oil and optionally one or more EP- or other additives.

Owner:SKF IND TRADING & DEV CO NV

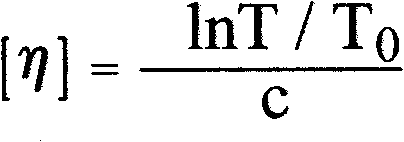

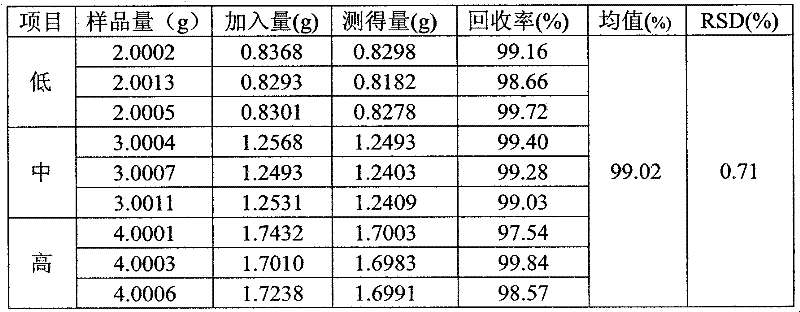

Colloid bismuth pectin compound and quality control method of pharmaceutical compositions thereof

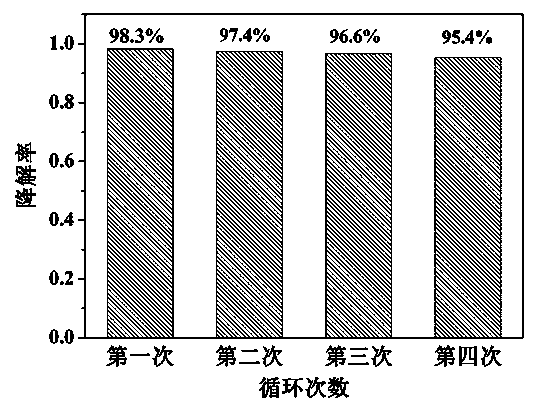

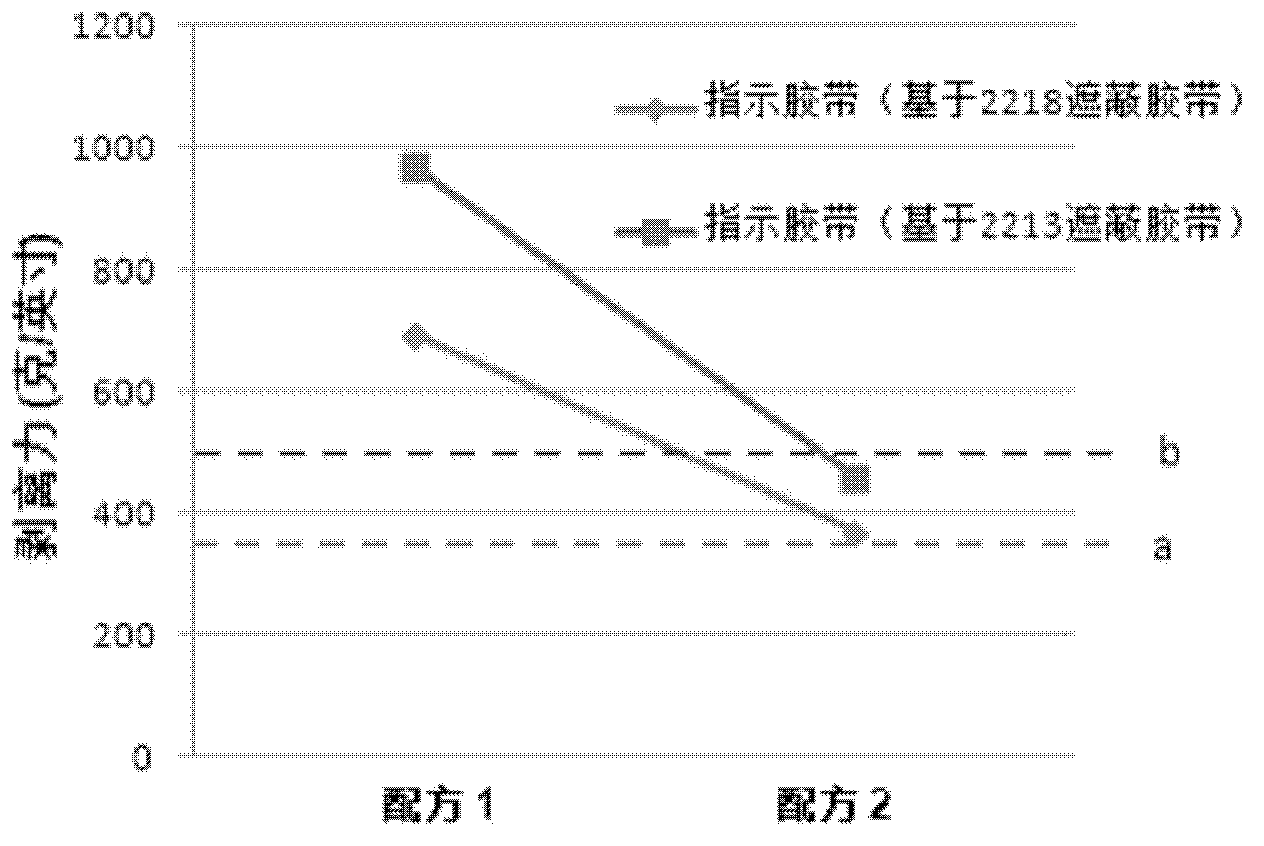

InactiveCN102507381AStrong selective adhesionGood selective adhesionMaterial analysis by observing effect on chemical indicatorDirect flow property measurementClinical efficacyBismuth / pectin

The invention relates to a colloid bismuth pectin compound and a quality control method of pharmaceutical compositions of the colloid bismuth pectin compound, and specifically provides a colloid bismuth pectin compound, new quality control indexes of pharmaceutical compositions of the colloid bismuth pectin compound and a detection method of the colloid bismuth pectin compound and the pharmaceutical compositions of the colloid bismuth. In the prior art, the quality of products having poor efficacy can not be well controlled because the efficacy-related indexes are not controlled strictly in the existing quality control methods of colloid bismuth pectin and pharmaceuticals thereof. Based on the existing quality control methods of colloid bismuth pectin and pharmaceuticals thereof, the following detection items and indexes are added: intrinsic viscosity, gel property, uniformity and galacturonic acid content. The invention can effectively ensure clinical efficacy of products, make the product quality standards more scientific, reasonable and controllable, and has great significance in quality control of the colloid bismuth pectin and the pharmaceutical preparation of colloid bismuth pectin.

Owner:于学敏

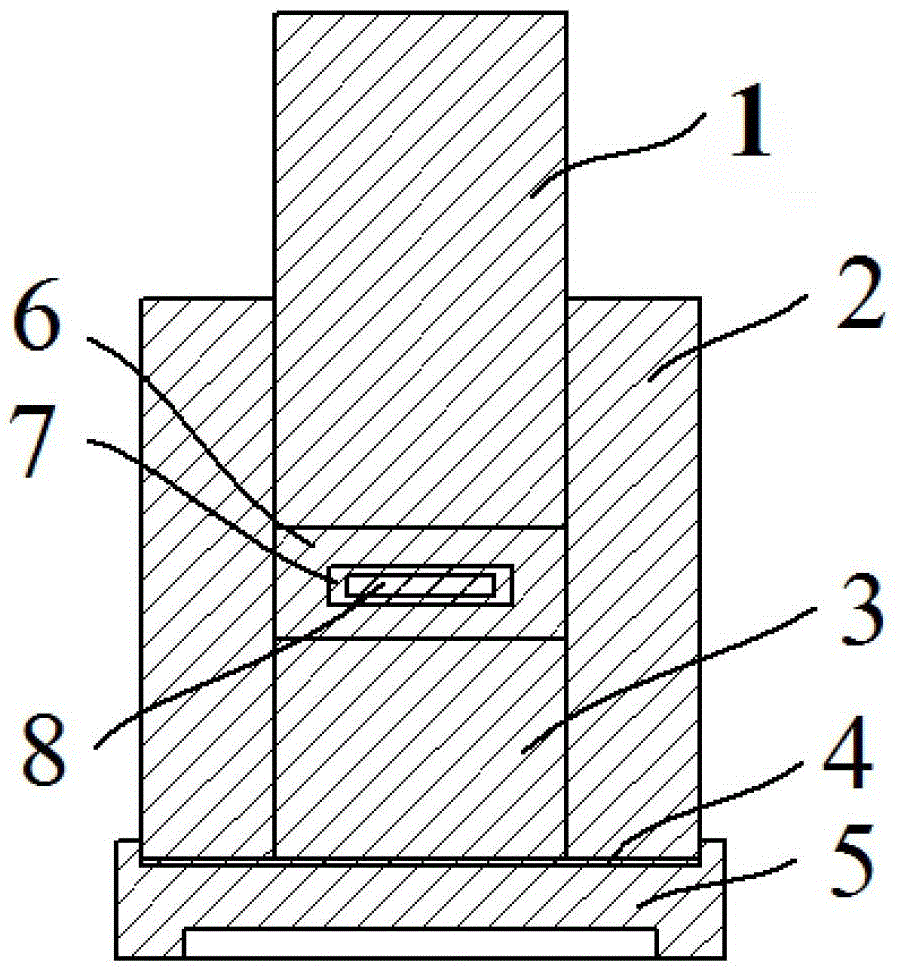

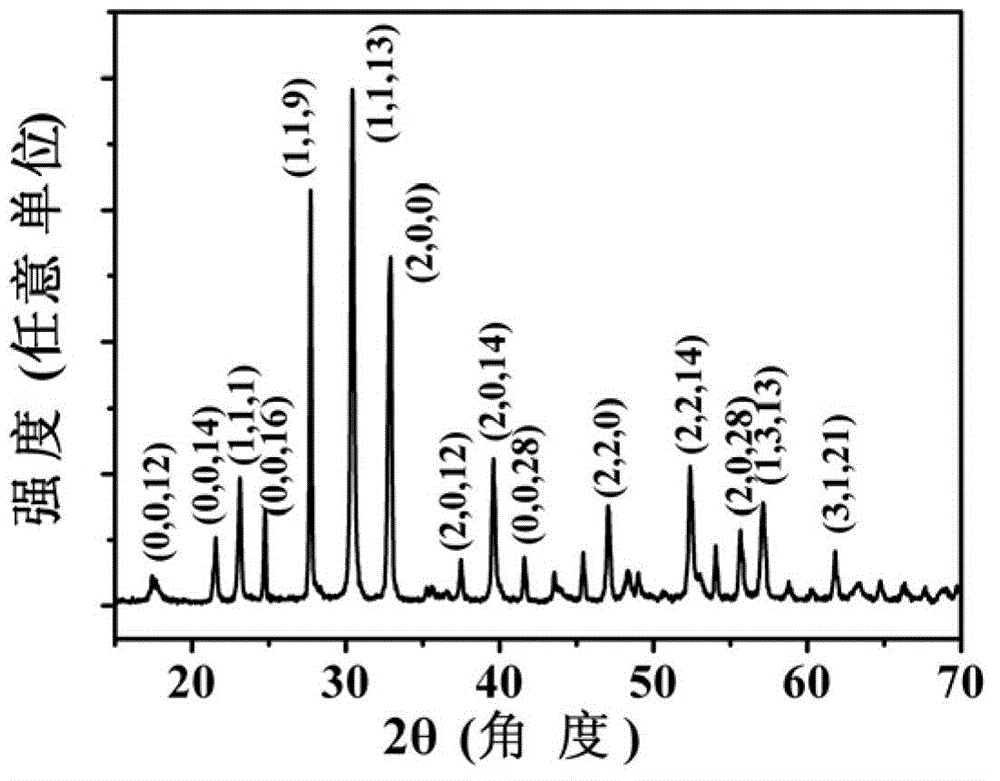

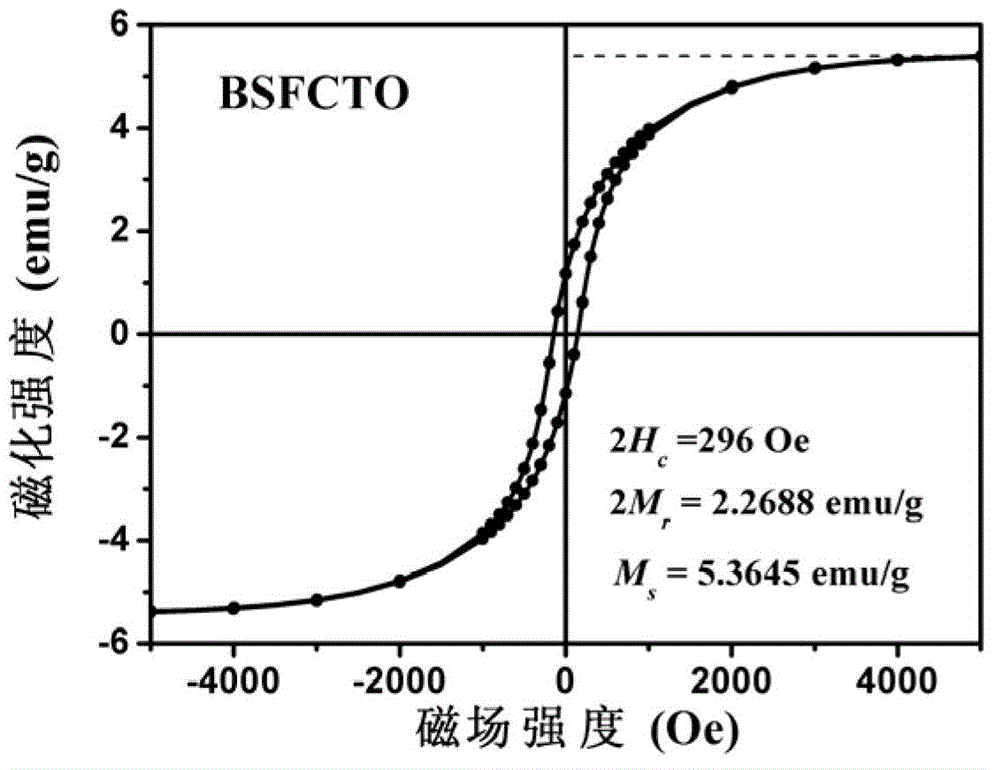

Layered perovskite structural ceramic and preparation method thereof

The invention provides layered perovskite structural ceramic and a preparation method thereof. The preparation method includes mixing well titanate compounds, bismuth compounds, strontium compounds, iron compounds, cobalt compounds and complexing agent in solvent, heating, drying and combusting to obtain powder, and presintering to obtain powder; performing the powder, and performing hot-pressing sintering to obtain the structural ceramic in in a formula (I). Compared with ceramics prepared in the prior art by solid phase sintering process, the structural ceramic in the formula (I) is prepared by solution process and hot pressing sintering. The preparation method has the advantages that less volatile low-valence strontium ions are introduced, increased leakage current due to volatilization of the strontium ions is improved, and ferroelectric properties are improved; the raw materials are evenly spread by the solution process, the power is even in component and has high reactivity, and Fe-Co ions are coupled fully; and the materials processed by hot pressing sintering are high in density and orientation, and the layered perovskite structural material can be obtained, namely Bi(n+1-x)SrxF3(n-3) / 2Co(n-3) / 2Ti3O3(n+1) (I).

Owner:UNIV OF SCI & TECH OF CHINA

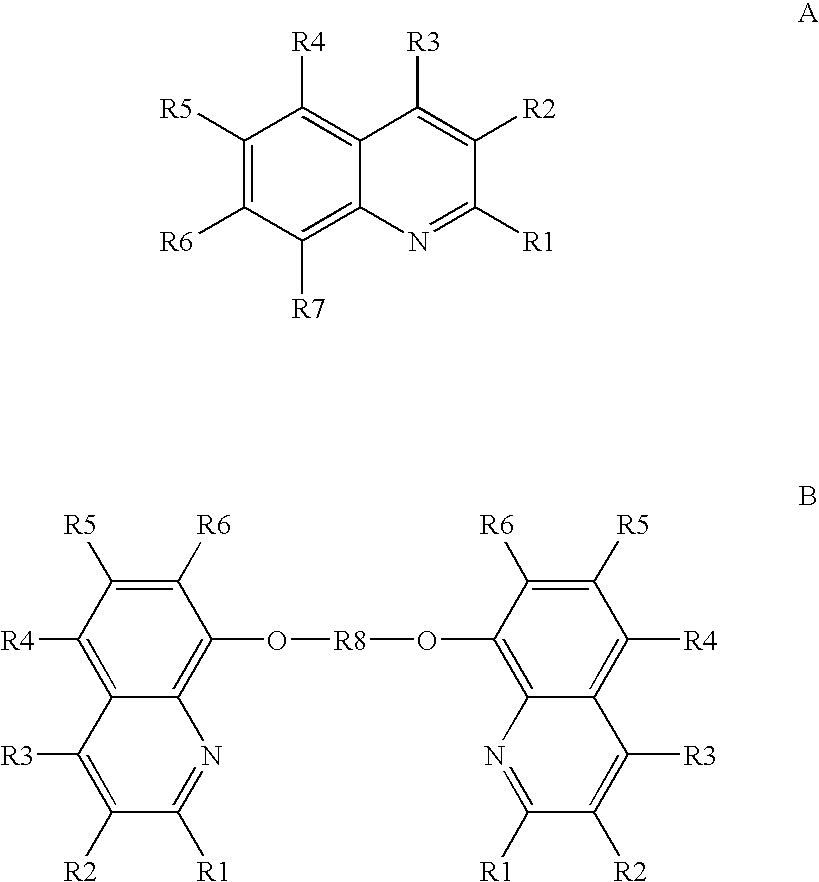

Bismuth-catalyzed polyurethane composition

ActiveUS20060180274A1Improve adhesionStable storageIsocyanic acid derivatives preparationCarbamic acid derivatives preparationPolyolAdhesive

The present invention relates to a one-component polyurethane composition comprising at least one polyurethane prepolymer having terminal isocyanate groups which is prepared from at least one polyisocyanate and at least one polyol, and to at least one catalyst system which is obtainable from at least one bismuth compound and at least one aromatic nitrogen compound. The invention additionally relates to a use of this polyurethane composition as an adhesive, sealant, coating or lining. Finally, catalysts for polyurethane compositions are disclosed which represent coordination compounds between bismuth and at least one aromatic nitrogen compound.

Owner:SIKA TECH AG

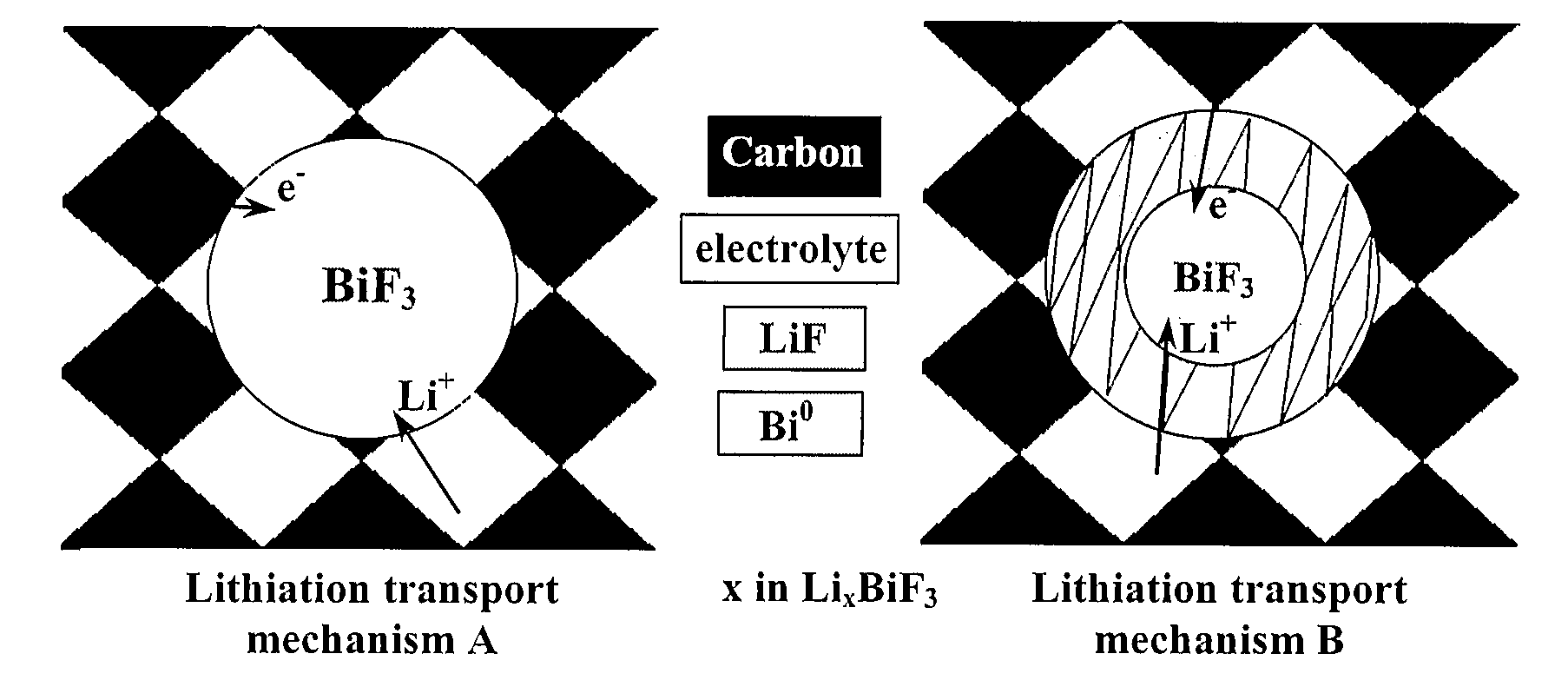

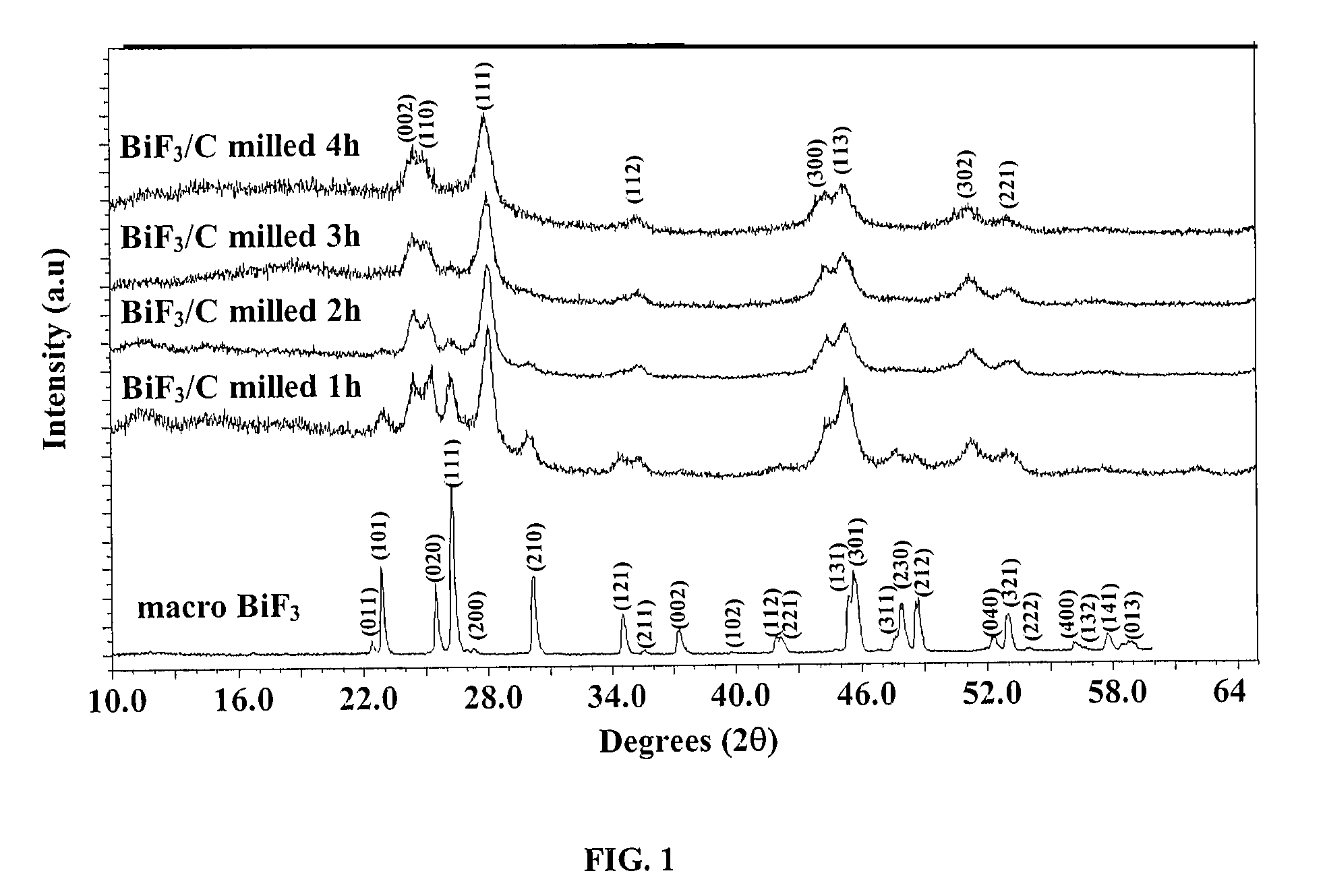

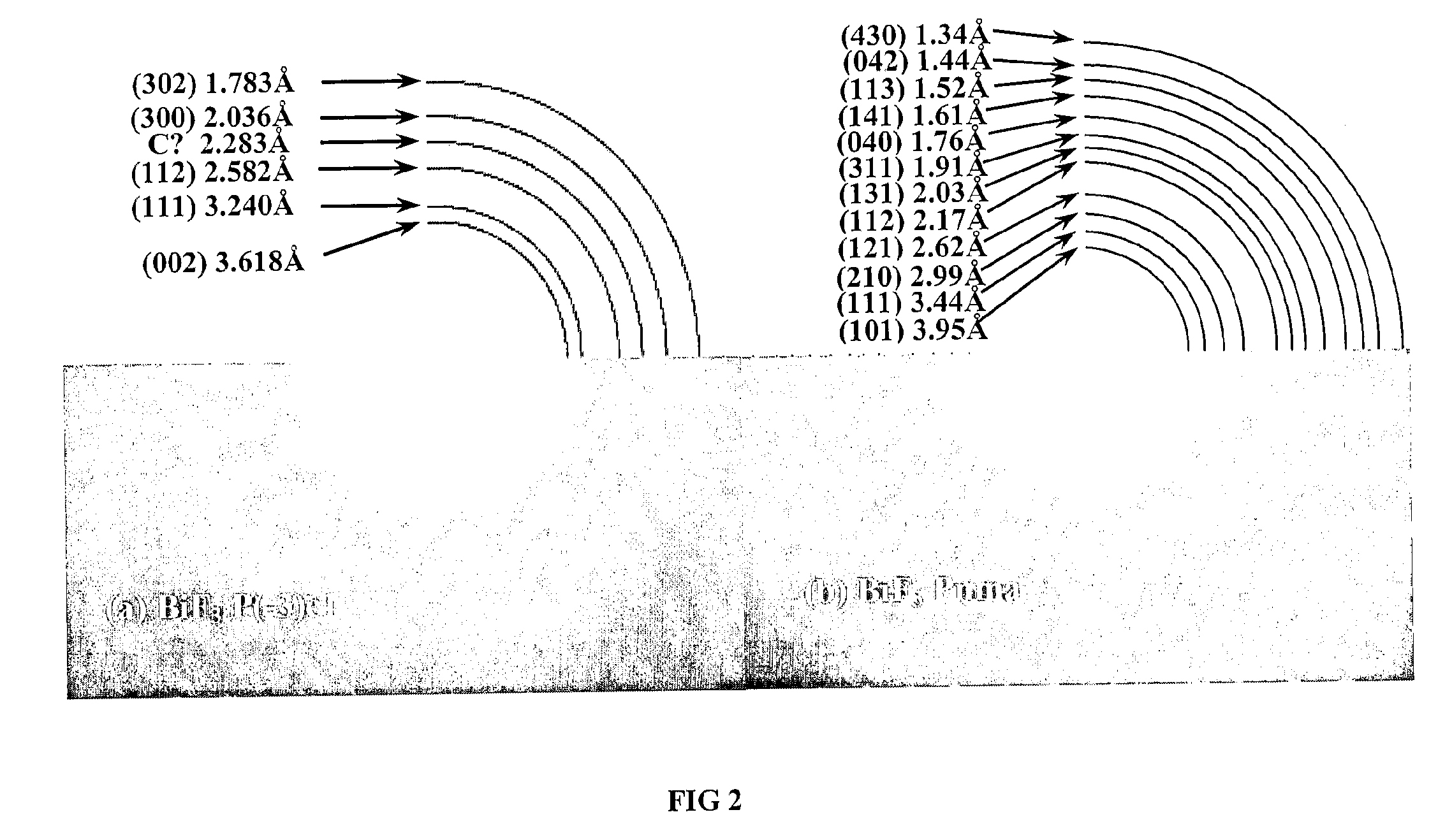

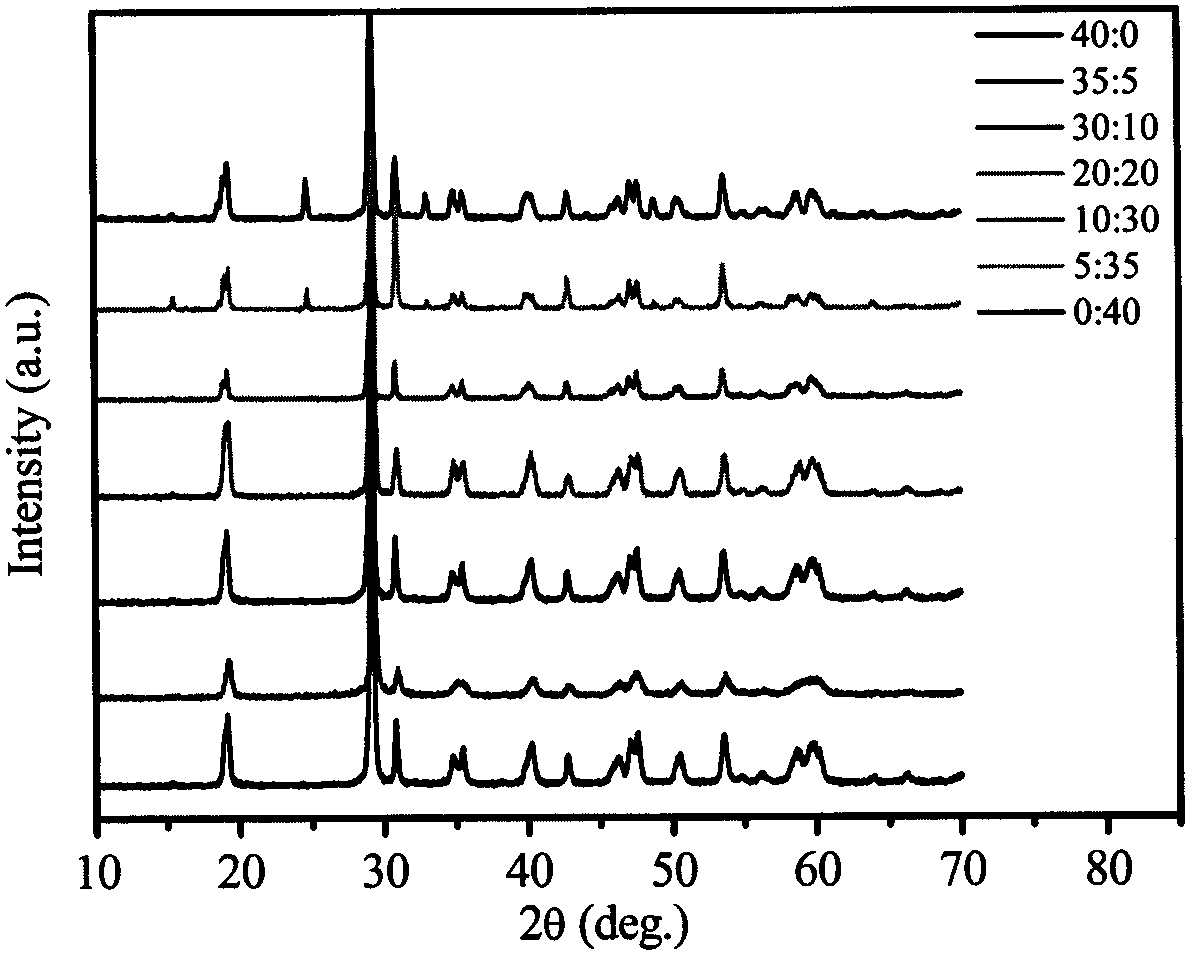

Bismuth fluoride based nanocomposites as electrode materials

Owner:RUTGERS THE STATE UNIV

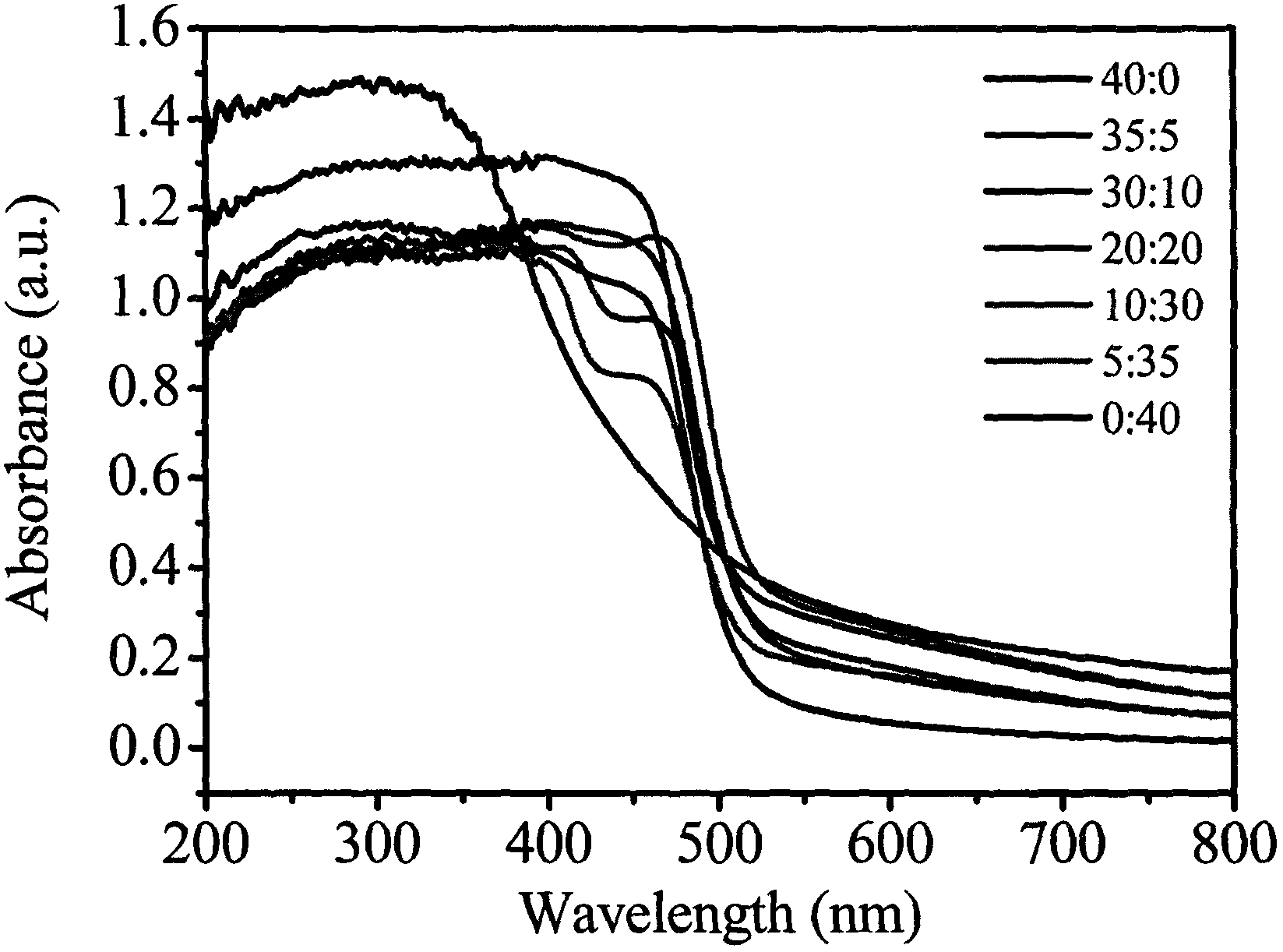

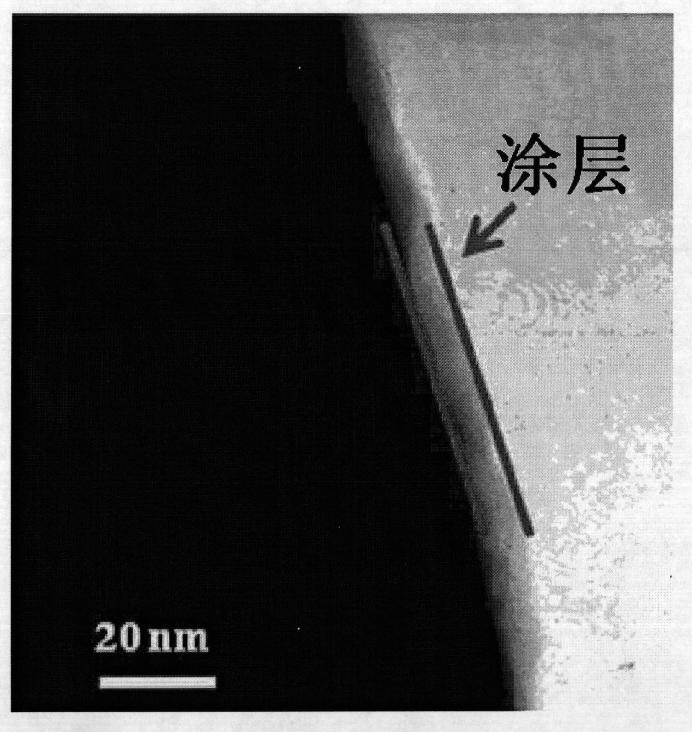

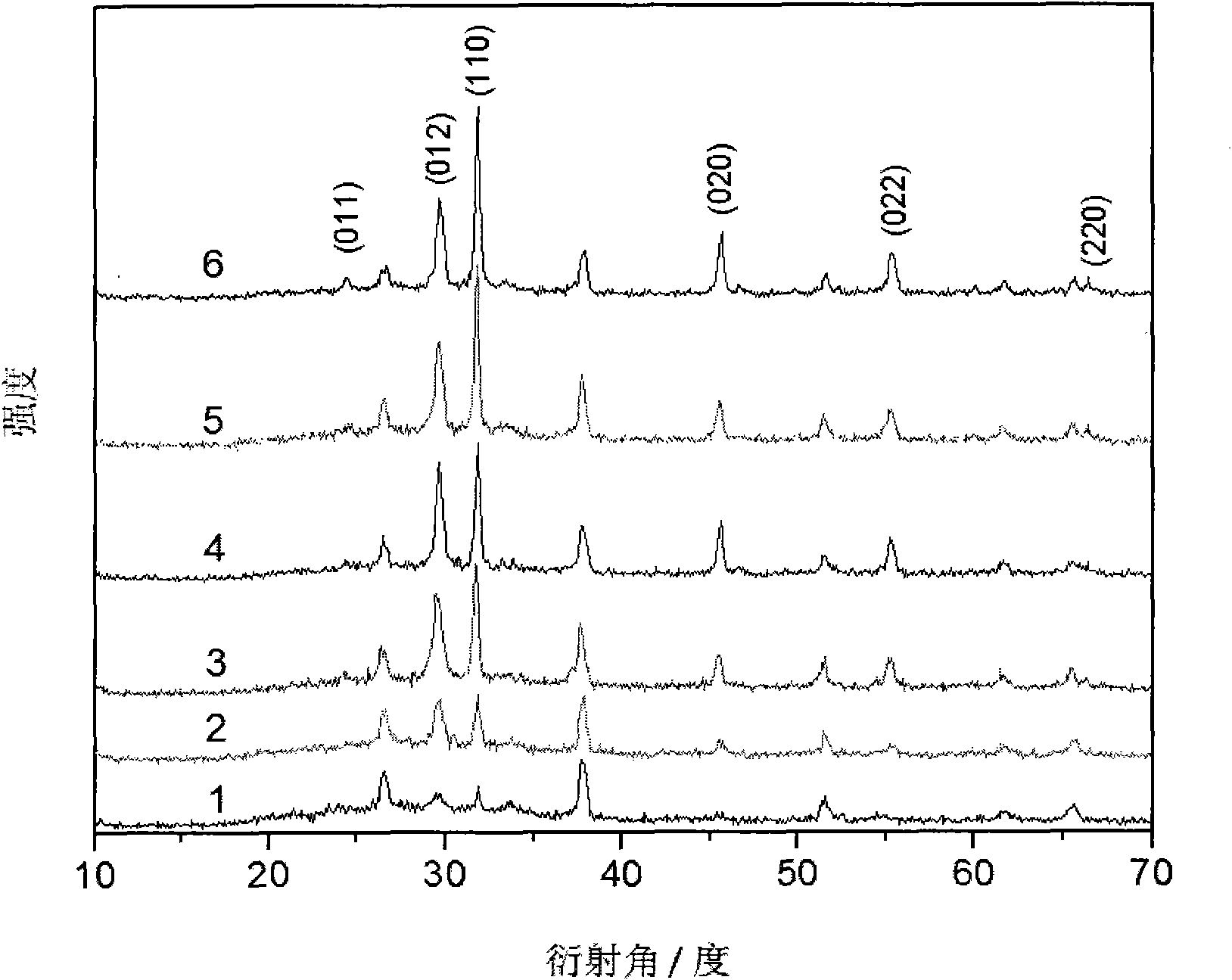

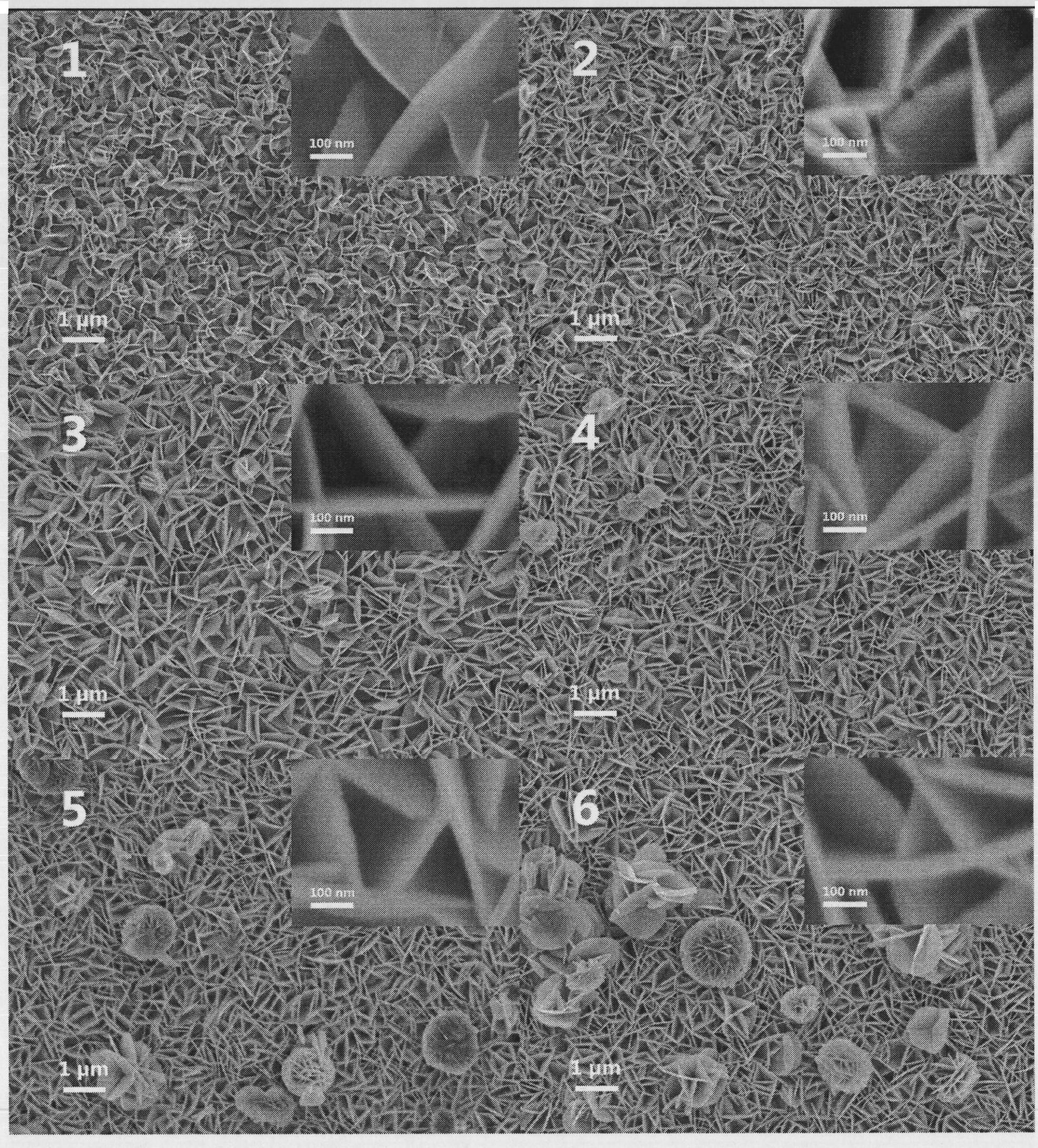

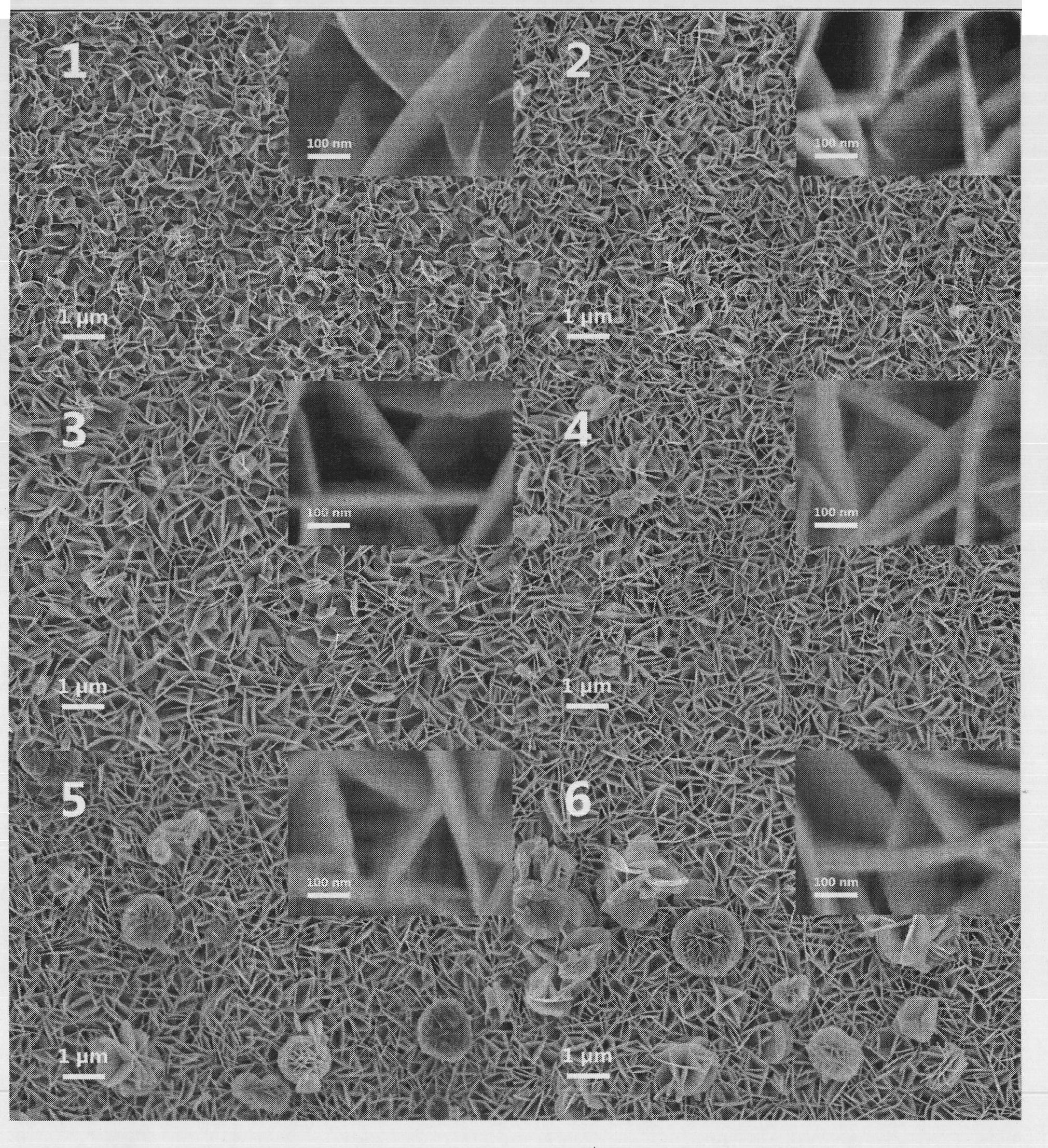

Preparation for visible-light responsible BiVO4 catalyst

InactiveCN104108753AImprove photocatalytic efficiencyEasy to prepareMaterial nanotechnologyVanadium compoundsVanadium CompoundsAlcohol

The invention discloses a preparation method for a visible-light responsible BiVO4 catalyst. The method comprises: taking a bismuth compound and a vanadium compound respectively as a bismuth source and a vanadium source, taking mixtures of water and an organic alcohol with different ratios as reaction solvents, and performing a hydro-thermal synthesis reaction, so as to obtain a catalytic material in the forms of a nanometer small particle, a nanometer ellipsoid, a flower-shaped structure or a branch structure. The visible-light responsible catalyst containing BiVO4 with different morphologies helps to greatly improve the photocatalysis degradation efficiency when being applied to the field of photocatalytic degradation of pollutants. The preparation method has the advantages of simple operation, mild reaction conditions, low equipment cost, relatively strong visible-light absorption, good visible-light catalytic performance and the like.

Owner:HAINAN NORMAL UNIV

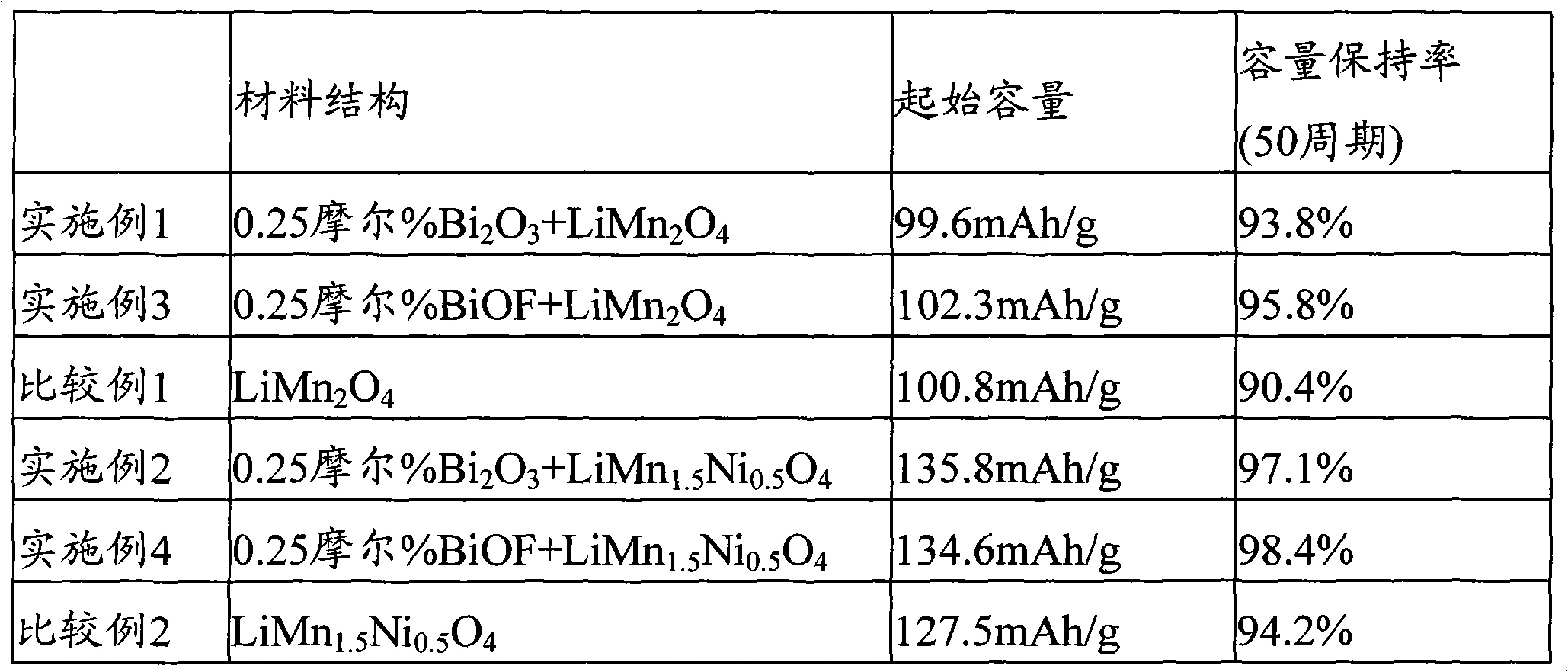

Anode active material and secondary lithium battery

InactiveCN101931072AInhibition of dissolutionImprove featuresMolybdeum compoundsZirconium compoundsHigh temperature storageBismuth compound

The invention relates to an anode active material for a secondary lithium battery and a secondary lithium battery containing the anode active material. The anode active material contains an active compound which can be embedded with and separated from a lithium ion and a bismuth (Bi) compound on the surface of the active compound. The bismuth compound on the surface of the active compound can suppress possibly generated structural change of the anode active material and solve the reaction problem between the anode active material and electrolyte due to impedence reduction of acid generated near the anode active material, so as to prevent a transition metal which is composed of the anode active material from being dissolved. Therefore, the anode active material can improve the high-temperature storage characteristic and high-temperature cycle life characteristic of the secondary lithium battery, improve the lithium ion mobility in the electrolyte, bring an improved effect on a discharge potential and also enhance the charging and discharging characteristics, service life characteristic and multiplying power characteristic of the secondary lithium battery.

Owner:ENERCERAMIC

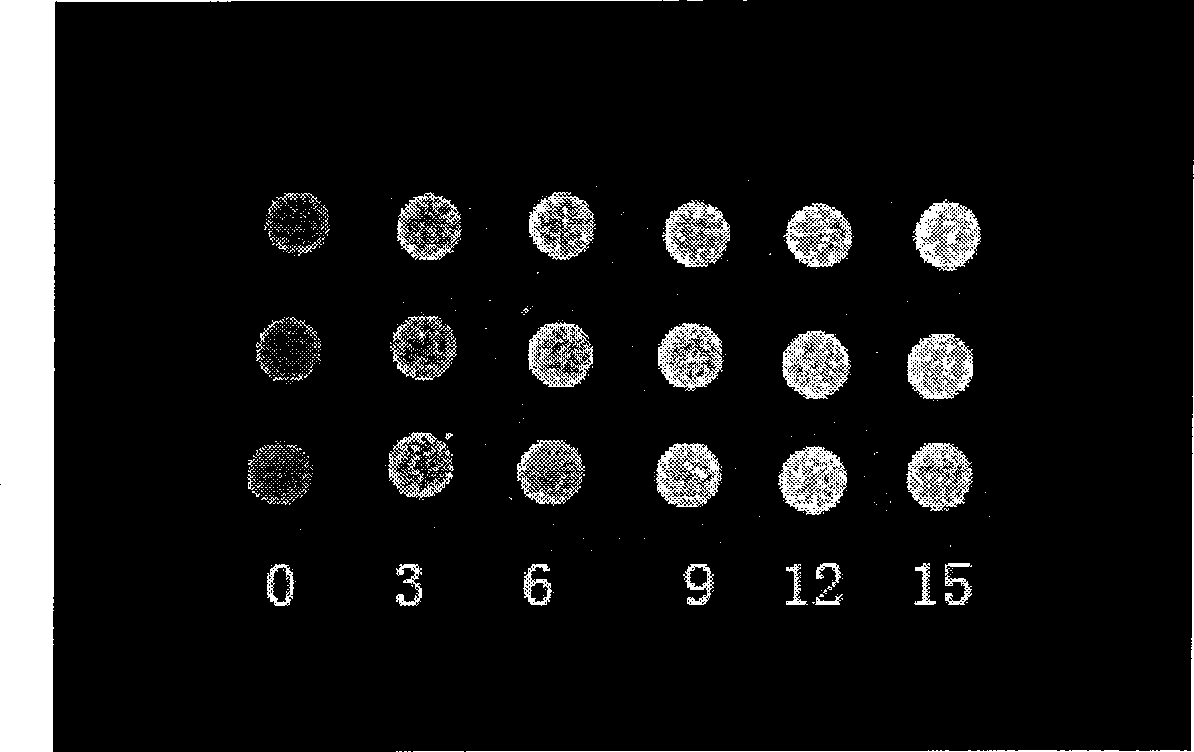

Method for preparing sheet-shaped bismuth oxyiodide (BiOI) nano-film electrode

The invention provides a method for preparing a sheet-shaped bismuth oxyiodide (BiOI) nano-film electrode, and belongs to the technical field of film preparation. The method comprises the following steps of: dissolving a bismuth compound in water to obtain solution of bismuth ions; dissolving an iodide in the water to obtain solution of iodide ions; immersing a conductive glass which is plated with a titanium dioxide blocking layer into the two solution sequentially, washing the conductive glass with water after reaction; and then repeating the process for 15 to 90 times, washing the conductive glass with the water and drying the conductive glass to obtain the sheet-shaped BiOI nano-film electrode. The preparation method is simple; the prepared bismuthyl iodide crystals are distributed on the conductive glass uniformly; and the product can be used for producing a solar battery.

Owner:HUAZHONG NORMAL UNIV

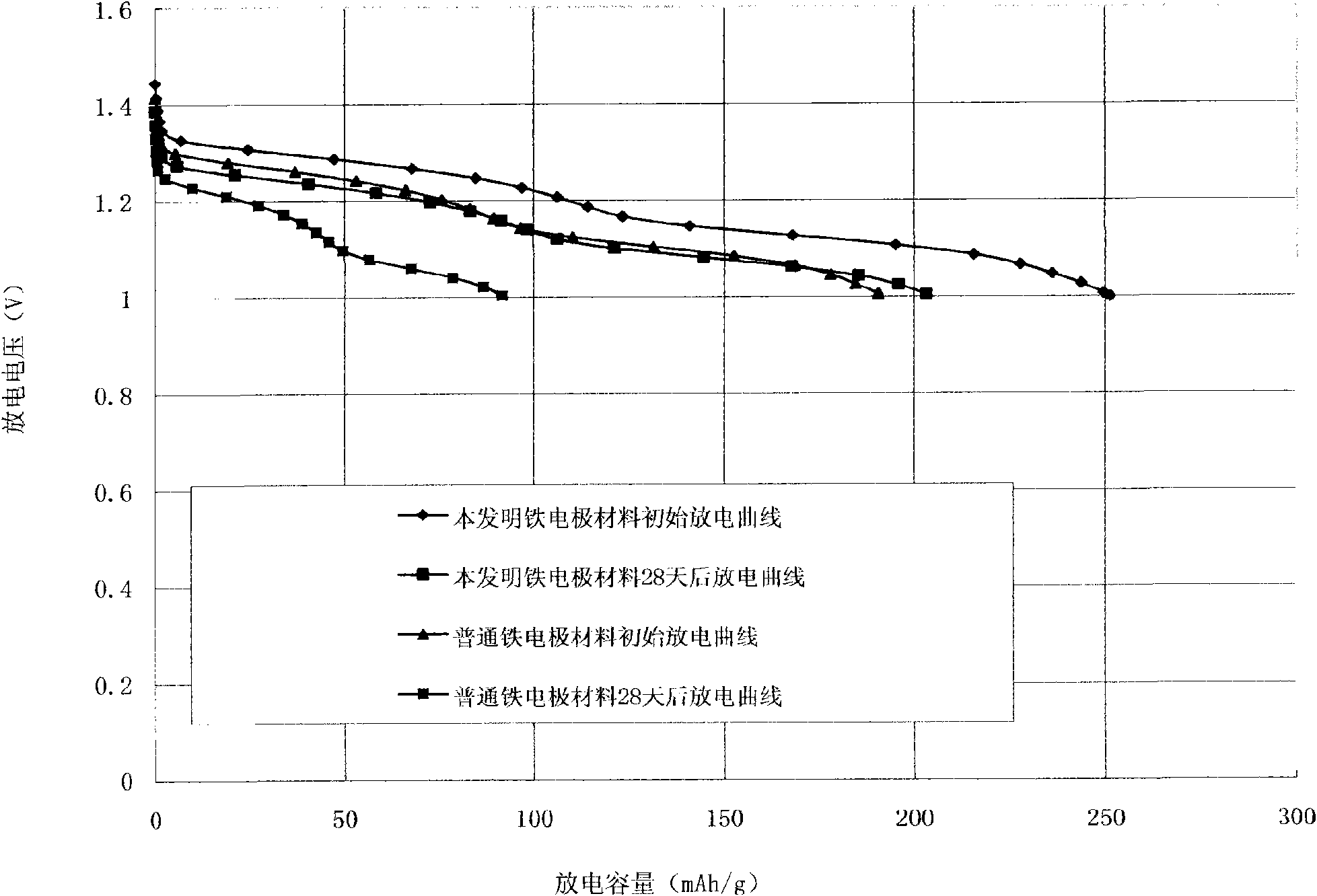

Low self-discharge ferrous electrode material

ActiveCN101651208ASmall self-dischargeAlkaline accumulatorsAlkaline accumulator electrodesIndiumStannate

The invention provides a low self-discharge ferrous electrode material. The ferrous electrode material is characterized by consisting of an active substance and an additive, wherein the composition ofthe active substance is ferrum or ferrous compounds including one or more of Fe3O4, Fe(OH)2, Fe(OH)3, Fe2O3, reduced ferrous powder and carbonyl ferrous powder; and the additive comprises: 1) 0.02 to0.15 percent of indium or indium compounds including one or more of In, In2O3, In2(SO4)3, In(OH)3, InCl3 and the like; 2) 2 to 8 percent of stannum or stannum compounds including one or more of Sn, SnO, SnO2, SnCl2, SnCl4 and stannate; 3) 1 to 7 percent of bismuth or bismuth compounds including one or more Bi, Bi2O3, Bi(NO3)3 and the like; and 4) 5 to 10 percent of graphite powder. The ferrous electrode material has the advantages that: 1) no toxic heavy metals (such as Hg, Cd, Pb and the like) are added, so the electrode material is an environment-friendly electrode material 2) the cost foran electrode is quite low; and 3) the self-discharge rate of the electrode is less than 20 percent at a temperature of 20 DEG C after 28 days. The material is used for manufacturing environment-friendly ferrum-nickel storage batteries.

Owner:宝生集团有限公司

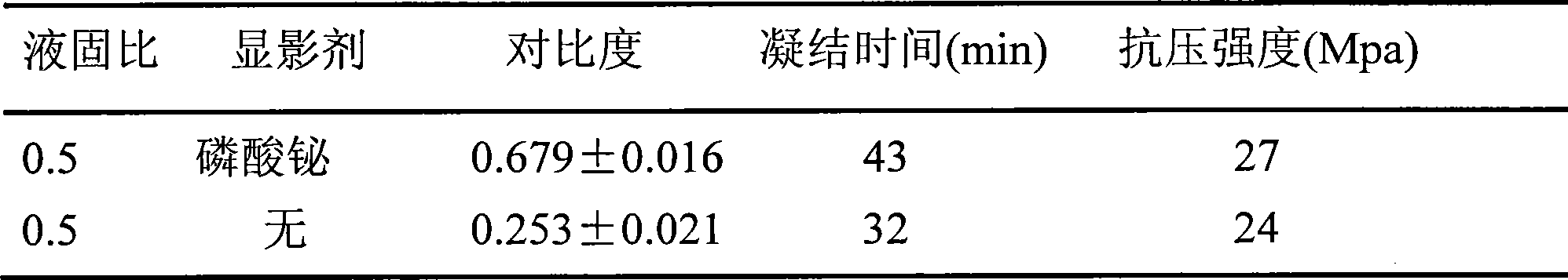

X-ray developing calcium phosphate cement and preparation method and application thereof

The invention discloses X-ray developing calcium phosphate cement and a preparation method and application thereof. The method comprises the following steps: (1) adding a developer in calcium phosphate cement powder and carrying out dry mixing or wet mixing by adding organic dispersant for 0.5-5h, drying and sifting out to obtain the X-ray developing calcium phosphate cement powder; (2) evenly mixing hardening liquid and the X-ray developing calcium phosphate cement powder based on liquid-solid ratio of 0.3-0.6mL / g to obtain X-ray developing calcium phosphate cement paste. In the method, bismuth compound and iodide are successfully applied to the calcium phosphate cement as the developers for the first time, thus remarkably enhancing the developing property of the calcium phosphate cement while keeping intrinsic curing characteristic of the calcium phosphate cement, effectively improving the success ratios of operations and broadening the application prospect of the calcium phosphate cement.

Owner:SOUTH CHINA UNIV OF TECH

Compositions and methods for topical treatment of skin infection

InactiveUS7258875B2Simple and rapid methodHeal fastHeavy metal active ingredientsBiocideChromium CompoundsEtiology

The present invention describes an extremely effective, simple, novel, inexpensive, safe and quick method to treat both acne and warts, each with a different etiology and different clinical symptoms, by topically applying an effective amount of one or more polyvalent metal compounds. The polyvalent metal compounds include, but are not limited to, bismuth compounds, zinc compounds, magnesium compounds, aluminum compounds, calcium compounds, copper compounds, titanium compounds, manganese compounds, chromium compounds, barium compounds and iron compounds. The present invention can also be applied to the treatment of rosacea. The present invention can also be employed to prevent scarring and to facilitate healing or elimination of the scars once formed.

Owner:CHIOU CONSULTING

Electroless palladium plating liquid

ActiveUS7704307B2Improve stabilityExcellent corrosion resistance and solder bondability and wire bondabilitySolid-state devicesPretreated surfacesPhosphorous acidHydrazine compound

Owner:JX NIPPON MINING & METALS CORP

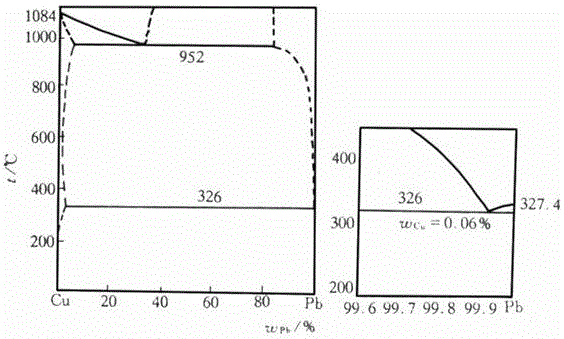

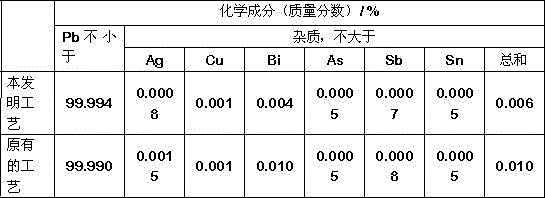

Regenerated lead fire method basic refining bottom-blowing process

The invention discloses a regenerated lead fire method basic refining bottom-blowing process. The process comprises the following steps: discharging lead of crude lead liquid from a melting furnace, casting the lead in a refining furnace, introducing argon from the bottom of the furnace, when the temperature of the lead liquid is reduced to about 330 DEG C, removing the slag, reducing the lead-containing copper to about 0.1% through liquation decoppering, injecting sulfur powder at the bottom of the refining furnace for removing copper after slag removal, heating the material to 450-480 DEG C, reacting the material for 30-60 min, taking the sulfuration slag out to complete a copper-removal process; when the lead liquid temperature is about 45 DEG C, blowing powdery sodium nitrate and sodium hydroxide into the bottom of the refining furnace, reacting the materials for 30 min, and blowing NaCl powder at the bottom of the refining furnace by following with argon to complete arsenic, antimony and tin removal. According to the bottom-blowing process, a refining agent and / or alloy loss are greatly reduced; the lead liquid contains inert gas with little solid solubility, the lead liquid and a lead ingot are difficulty oxidized, no lead slag is generated in the lead liquid and the lead ingot, lead slag is little when the regenerated lead is used, the slag yield is low; the lead liquid surface is protected by argon during a refining process, high temperature Ag removal can be carried out, the content of Ag in the regenerated lead is low; argon at the bottom and the minimal bismuth compound particles are floated, and the bismuth content in the lead ingot is low.

Owner:安徽省陶庄湖废弃物处置有限公司

Electroless Palladium Plating Liquid

ActiveUS20090081369A1Improve stabilityImprove corrosion resistanceSolid-state devicesPretreated surfacesPhosphorous acidHydrazine compound

An electroless palladium plating liquid, with excellent bath stability, that can provide a film with excellent corrosion resistance, solder bondability, and wire bondability is provided. The invention is an electroless palladium plating liquid, comprising: a water soluble palladium compound; at least one of ammonia, an amine compound, an aminocarboxylic acid compound, and carboxylic acid as a complexing agent; and bismuth or a bismuth compound as a stabilizer. Preferably the electroless palladium plating liquid further comprises at least one of hypophosphorous acid, phosphorous acid, formic acid, acetic acid, hydrazine, a boron hydride compound, an amine borane compound, and salts thereof as a reducing agent.

Owner:JX NIPPON MINING& METALS CORP

Grease composition, bearing prelubricated with grease, and rotation-transmitting apparatus with built-in one-way clutch

InactiveCN101163781APrevent peelingInhibition of too many switching timesBearing componentsThickenersBismuth compoundSulfur

A grease composition which can effectively prevent the flaking on, e.g., rolling / sliding surfaces mainly caused by hydrogen embrittlement; a prelubricated bearing containing the grease composition enclosed therein; and a rotation-transmitting apparatus of the built-in one-way clutch type which contains the grease composition enclosed in the sliding part. The grease composition is obtained by incorporating an additive into a base grease comprising a base oil and a thickener. The grease composition can prevent hydrogen embrittlement and resultant flaking from occurring on the frictional / wearing surfaces of a sliding part or on a ferrous metal surface newly exposed by wearing. The additive comprises a bismuth additive or a magnesium additive, the bismuth additive being at least one member selected among inorganic bismuth compounds and organobismuth compounds containing no sulfur ingredient and the magnesium additive being at least one member selected among inorganic magnesium compounds and organomagnesium compounds.

Owner:NTN CORP

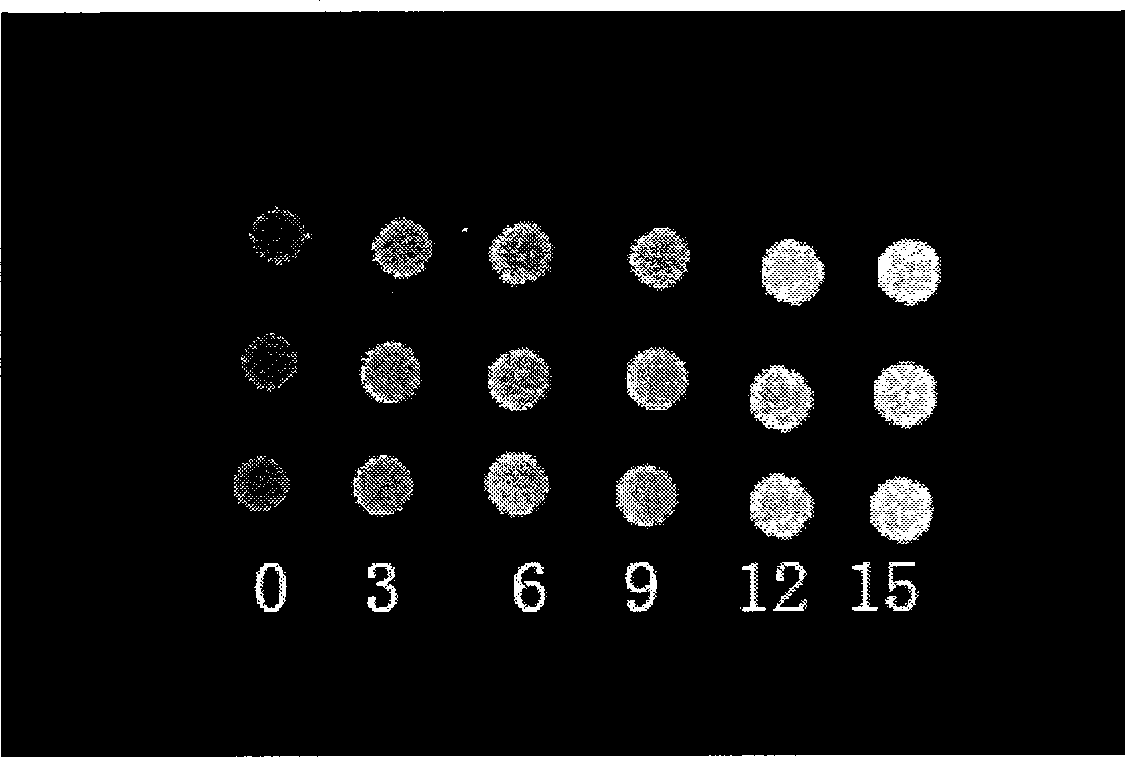

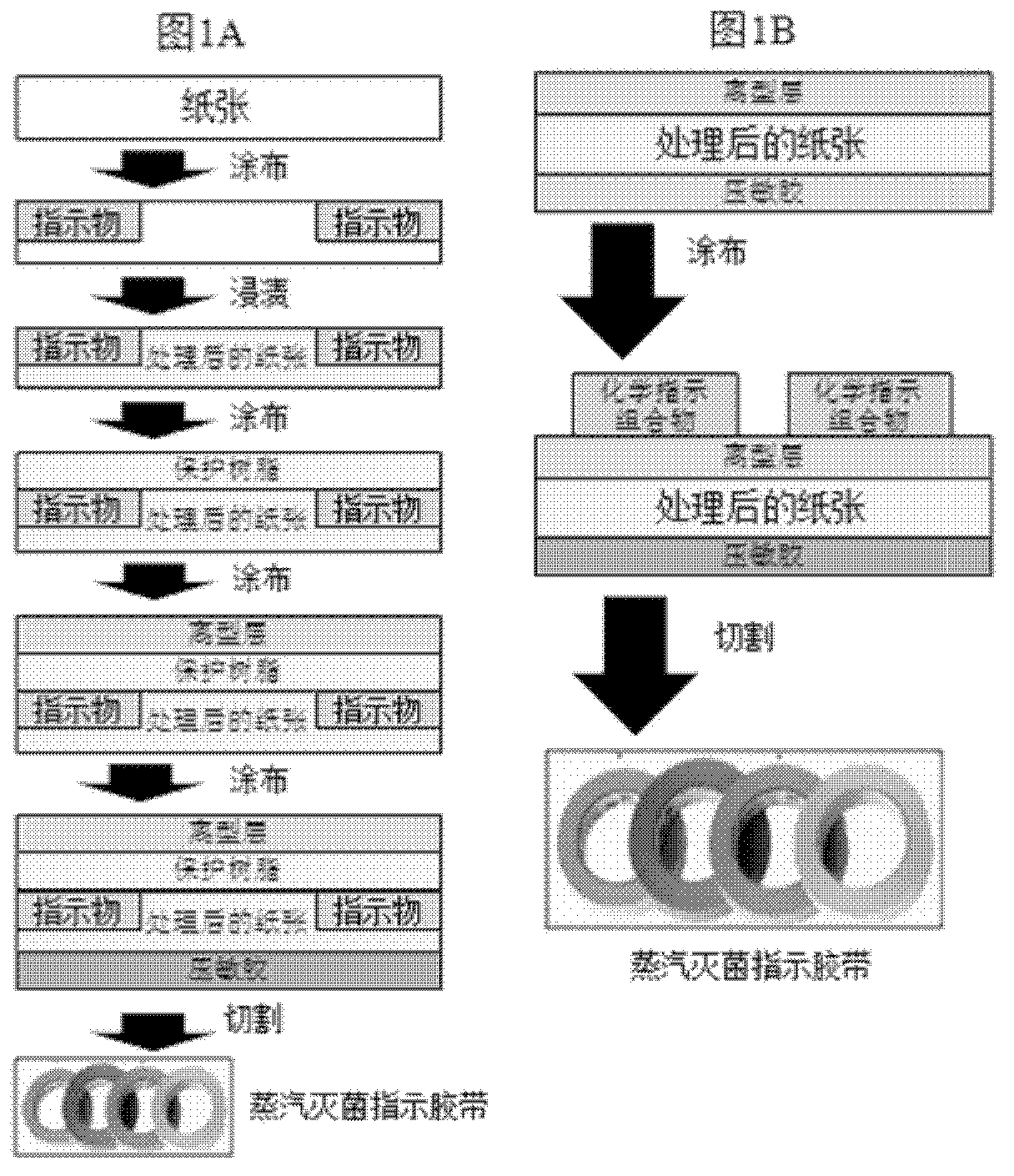

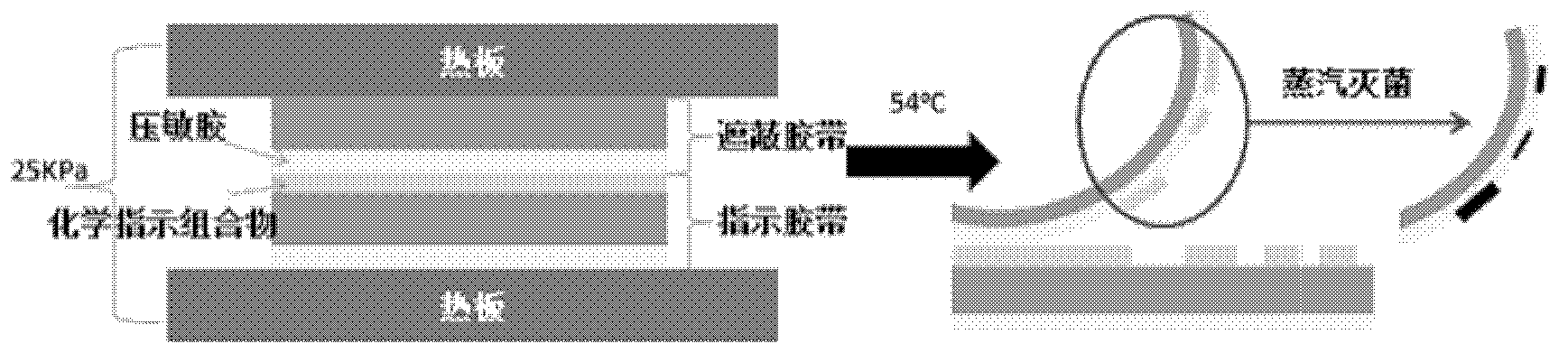

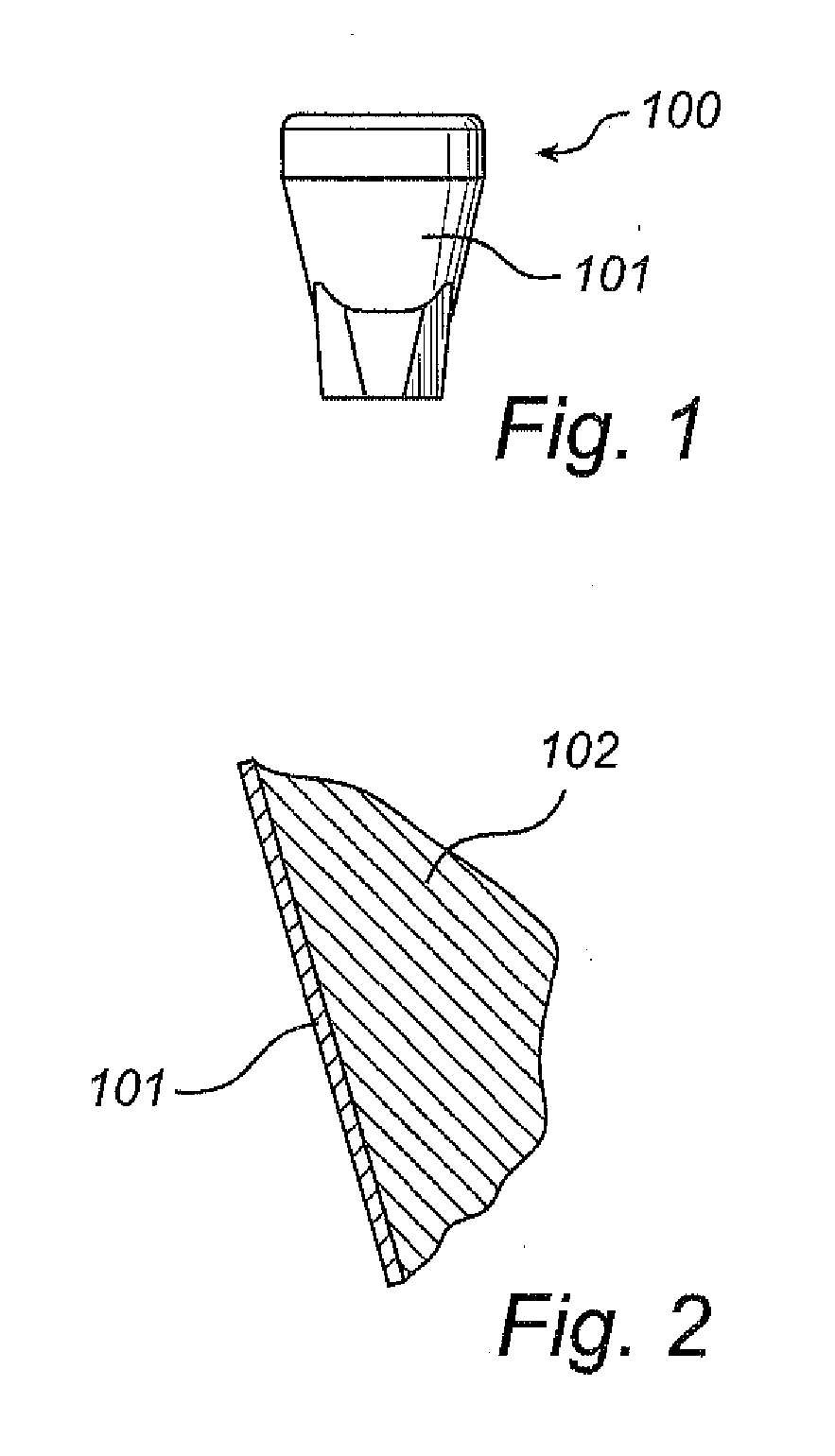

Chemical indication composition, steam sterilization indication tape and manufacturing method thereof

ActiveCN103910956AAchieve preparationLavatory sanitoryInvestigating sterilization degreeSulfurWater vapor

The invention relates to a chemical indication composition, a steam sterilization indication tape using the chemical indication composition and a manufacturing method thereof. The chemical indication composition provided by the invention comprises: an indicator, an organosilicon modified polymer and a solvent, wherein the indicator comprises a bismuth compound, a sulfur source and a compound that can generate alkaline conditions when it is exposed to high temperature water vapor. The chemical indication composition can be directly applied to a non-adhesive surface of an adhesive tape, thus realizing preparation of the steam sterilization indication tape by one step.

Owner:3M INNOVATIVE PROPERTIES CO

Medical device having a surface comprising antimicrobial metal

InactiveUS20130266629A1Reduce the risk of infectionPrevent bacterial growthHeavy metal active ingredientsBiocideChemical compoundBismuth compound

A medical device intended for contact with living tissue comprises a substrate having a surface, which surface comprises a layer comprising one or more compound(s)) of at least one non-toxic post-transition metal, such as a gallium or bismuth compound. A layer comprising a compound of a non-toxic post-transition metal has been shown to inhibit biofilm formation on the surface of the medical device, which may reduce the risk for infection e.g. around a dental implant. A method of producing the medical device comprises: a) providing a substrate having a surface; and applying a compound of a non-toxic post-transition metal onto said surface to form a layer, e.g. using a thin film deposition technique.

Owner:DENTSPLY SIRONA INC

Preparation method of biological dressing containing nano silver, zinc and bismuth

InactiveCN101927030ABroad spectrum antibacterialGood for wound dressingAbsorbent padsBandagesBiological dressingBismuth compound

The invention discloses a preparation method of a biological dressing containing nano silver, zinc and bismuth, which comprises the steps of: synthesizing chitosan and / or a nano silver, zinc and bismuth compound as a chitosan derivative by using a solid phase synthesis method; dissolving into a solution; adding a proper quantity of glycerol, collagen and the like; and obtaining a film dressing by adopting a curtain coating film-forming method or obtaining a sponge dressing by using a freezing drying method. The biological dressing has the functions and the advantages of nano silver, zinc and bismuth, and chitosan or chitosan derivative, and has the characteristics of better contact bacteriostasis, wide antimicrobial spectrum, durable action time, wound repairmen, ulcer curing and the like.

Owner:LIAOCHENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com