Low self-discharge ferrous electrode material

A technology of iron electrode and carbonyl iron powder, applied in the field of low self-discharge iron electrode materials, can solve the problems of large self-discharge and low self-discharge rate of iron electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

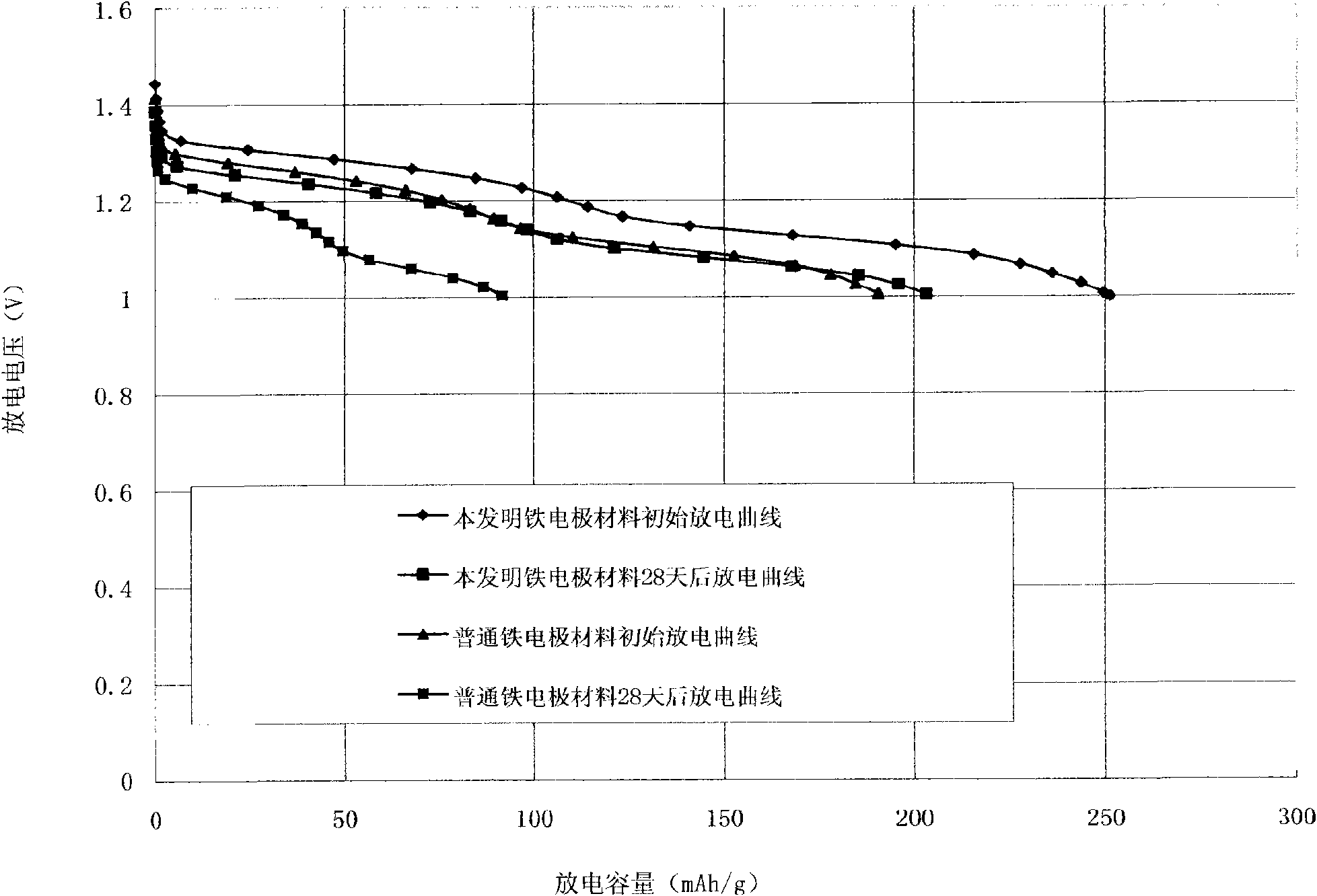

Examples

Embodiment

[0008] Embodiment: the chemical composition of high-capacity iron electrode material of the present invention is:

[0009] Fe prepared as above 3 o 4 The content is 82-90%, In 2 o 3 The content of SnO is 0.05-0.07%, the content of SnO is 3-5%, the content of Bi 2 o 3 The content of graphite powder is 2-4%, and the content of graphite powder is 6-8%.

[0010] The preparation method of iron electrode is: (1) take a certain amount of Fe 3 o 4 , by Fe 3 o 4 The amount of adding 0.05-0.07% In2O3, 3-5% SnO, 2-4% Bi 2 o 3 . 7-8% graphite powder. (2) Add a certain amount of PVA binder with a concentration of 5-10%, and after stirring evenly, apply the slurry on the negative electrode current collector (the current collector is one of nickel foam, iron foam or steel strip) . (3) After the electrode is dried, the electrode is pressed into shape with a pressure of 24 MPa on a hydraulic press.

[0011] Charge-discharge test of the iron electrode: the iron electrode prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com