Method for increasing safe performance of square lithium ion secondary battery

A technology of secondary battery and safety performance, applied in secondary batteries, secondary battery manufacturing, battery electrodes, etc., can solve the problems of metal lithium dendrites easily pierced through diaphragm batteries, low reliability, etc., to reduce battery positive and negative Opportunity for extreme short circuit, effect of improving cycle life and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

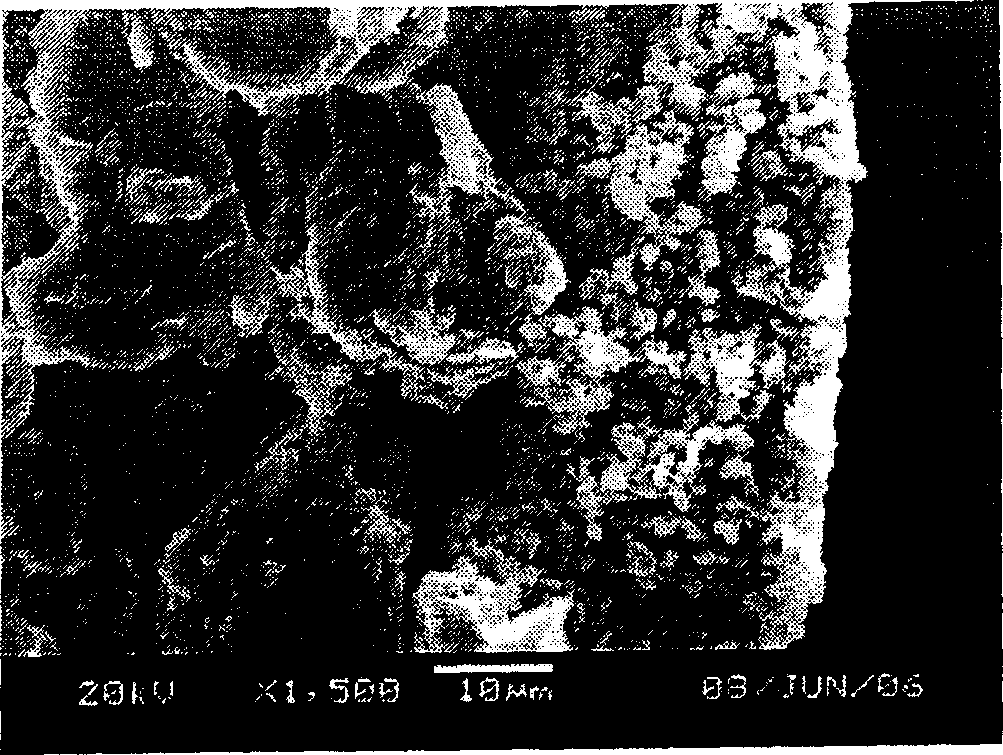

[0026] The active material on the positive electrode is LiCoO 2 , which is evenly coated on the aluminum foil; the active material on the negative plate is graphite, which is evenly coated on the copper foil. It is improved according to the surface treatment method of the negative plate of the square lithium-ion secondary battery, and the specific steps are as follows: Al2O3 is added to the binder (Al2O3 99g, PVDF1g) solution of N-methylpyrrolidone, at a constant speed Stir for 4 hours to obtain a slurry, apply it evenly on the surface of the negative electrode, and let it stand for 60 seconds. The purpose is to fully integrate the binder of the inorganic oxide and the binder of the negative electrode material. Adhesion; drying at 110°C to obtain the negative electrode sheet, the cross section of the electrode sheet is as follows figure 1 As shown, the coating effect is very obvious. Then, the positive and negative electrodes and the diaphragm are wound as usual, and the ele...

Embodiment 2

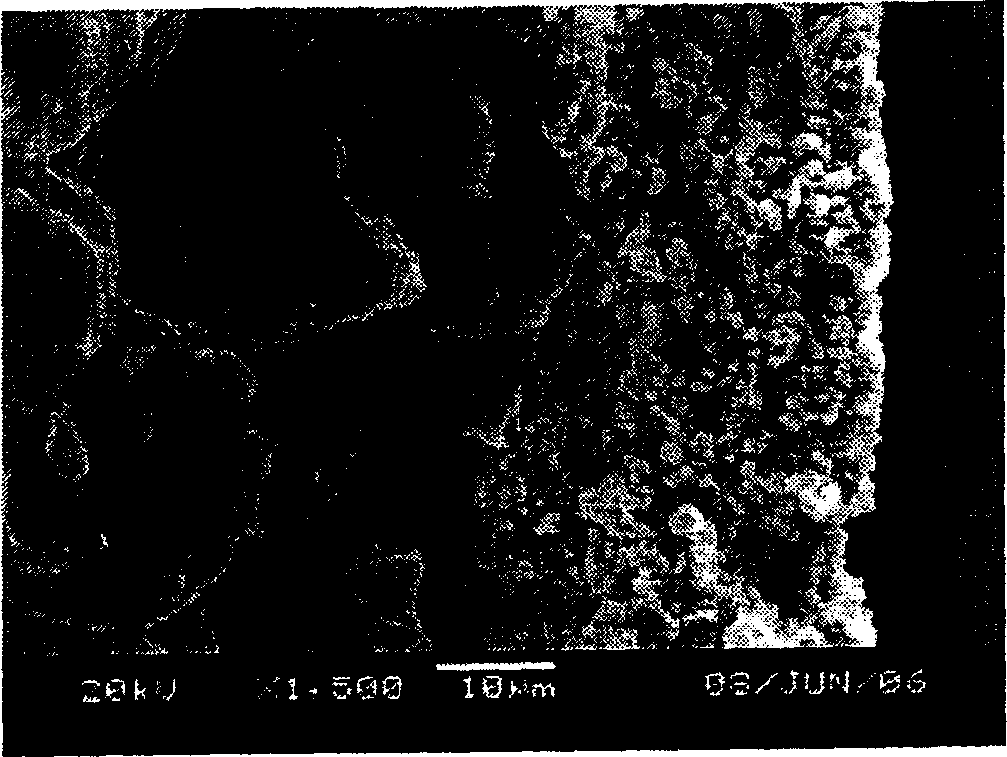

[0028] The active materials of the positive and negative electrodes are the same as in Example 1. It is improved according to the surface treatment method of the lithium-ion secondary battery negative plate, and the specific steps are as follows: add aluminum oxide to the binder (aluminum oxide 95g, PVDF 5g) solution of N-methylpyrrolidone and stir at a constant speed The slurry was obtained in 4 hours, which was uniformly coated on the surface of the negative electrode, left to stand for 60 seconds, and dried at 110°C to obtain a negative electrode sheet. The cross section of the electrode sheet is as follows: figure 2 As shown, the coating effect is very obvious. Then, the positive and negative electrodes and the diaphragm are wound as usual, and the electrolyte is injected to assemble a square battery. The cycle performance curve is as follows: Figure 4 .

Embodiment 3

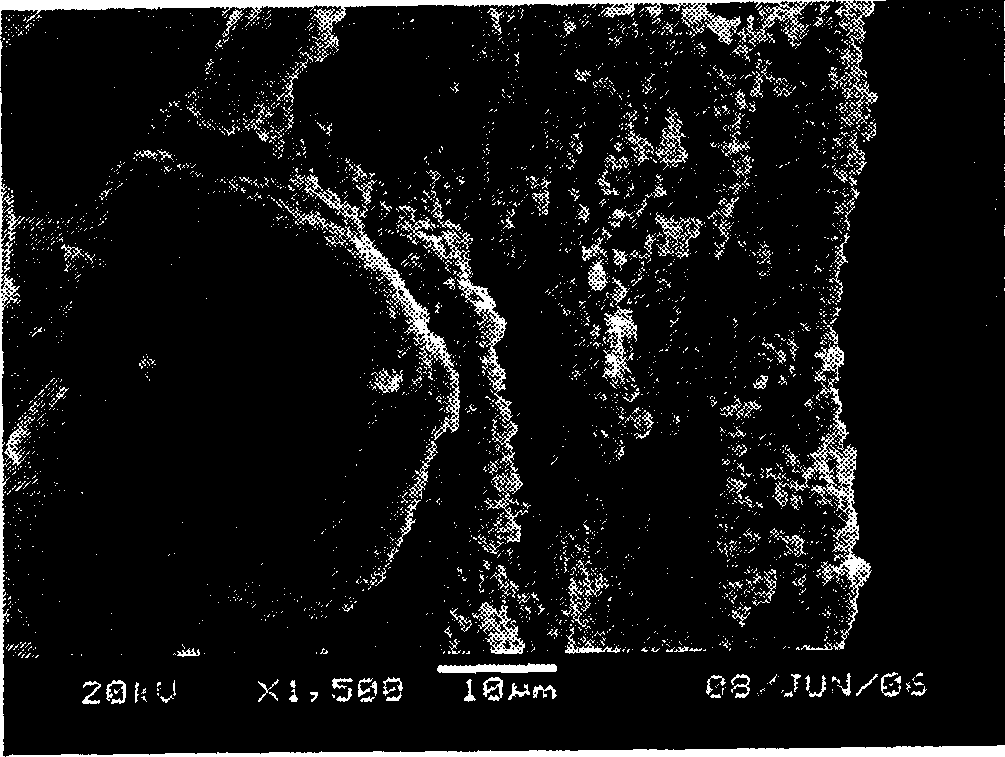

[0030] The active materials of the positive and negative electrodes are the same as in Example 1. It is improved according to the surface treatment method of the lithium-ion secondary battery negative plate, and the specific steps are as follows: adding aluminum oxide to the binder (aluminum oxide 90g, PVDF10g) solution of N-methylpyrrolidone and stirring at a constant speed for 4 hour to obtain a slurry, which is uniformly coated on the surface of the negative electrode, left to stand for 60 seconds, and dried at 110°C to obtain a negative electrode sheet. The cross section of the electrode sheet is as follows: image 3 As shown, the coating effect is very obvious. Then, the positive and negative electrodes and the diaphragm are wound as usual, and the electrolyte is injected to assemble a square battery. The cycle performance curve is as follows: Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com