Sulfuration restoration agent for lead acid battery

A lead-acid battery and repair agent technology, applied in lead-acid battery, secondary battery repair/maintenance, battery recycling, etc., can solve problems such as difficulty and irreversible sulfate repair, achieve capacity recovery, and reduce battery internal self-discharge , to ensure the effect of the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

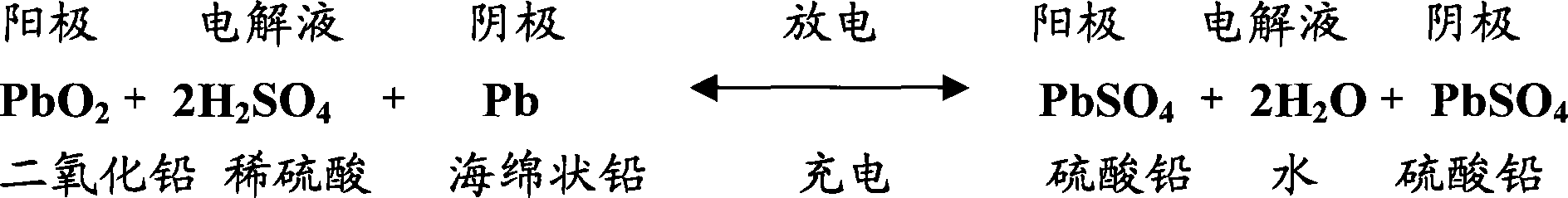

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of lead-acid battery vulcanization restoration agent

[0032] 1. The restorative agent is composed of the following substances in mass percentage:

[0033] Potassium sulfate 7%;

[0034] Sodium sulfate 5%;

[0035] Potassium bicarbonate 1.5%;

[0036] Potassium carbonate 2.5%;

[0038] Potassium hydrogen phthalate 0.035%;

[0039] Potassium tetrasulfonate 0.3%;

[0041] Aluminum powder 0.015%;

[0042] Deionized water 82.25%.

[0043] 2. Use this repair agent to repair a group (24 pieces) of 300AH / 2V scrap lead-acid batteries used in communication base stations. The battery numbers are 1#-II24#, and the ambient temperature during the repair operation is 23°C.

[0044] Add this lead-acid battery vulcanization repair agent to the "vulcanized" battery, and use the active metal ions in the repair agent to replace the more inert lead ions in lead sulfate, so that lead sulfate is ioni...

Embodiment 2

[0049] Embodiment 2: a kind of lead-acid storage battery vulcanization restoration agent, is made up of the material mixing of following mass percent content:

[0050] Potassium sulfate 4%;

[0051] Sodium sulfate 5%;

[0052] Potassium bicarbonate 0.6%;

[0053] Potassium carbonate 1.2%;

[0054] Sodium silicate 0.3%;

[0055] Potassium hydrogen phthalate 0.02%;

[0056] Potassium tetrasulfonate 0.1%;

[0057] Aluminum powder 0.007%;

[0058] Sodium hydroxide 0.5%;

[0059] Deionized water 88.273%.

Embodiment 3

[0060] Embodiment 3: a kind of lead-acid storage battery vulcanization restoration agent, is made up of the material mixing of following mass percentage content:

[0061] Potassium sulfate 8%;

[0062] Sodium sulfate 7%;

[0063] Potassium bicarbonate 1.9%;

[0064] Potassium carbonate 2.8%;

[0065] Sodium silicate 0.7%;

[0066] Potassium hydrogen phthalate 0.05%;

[0067] Potassium tetrasulfonate 0.35%;

[0068] Sodium hydroxide 1.2%;

[0069] Aluminum powder 0.018%;

[0070] Deionized Water 77.982%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com