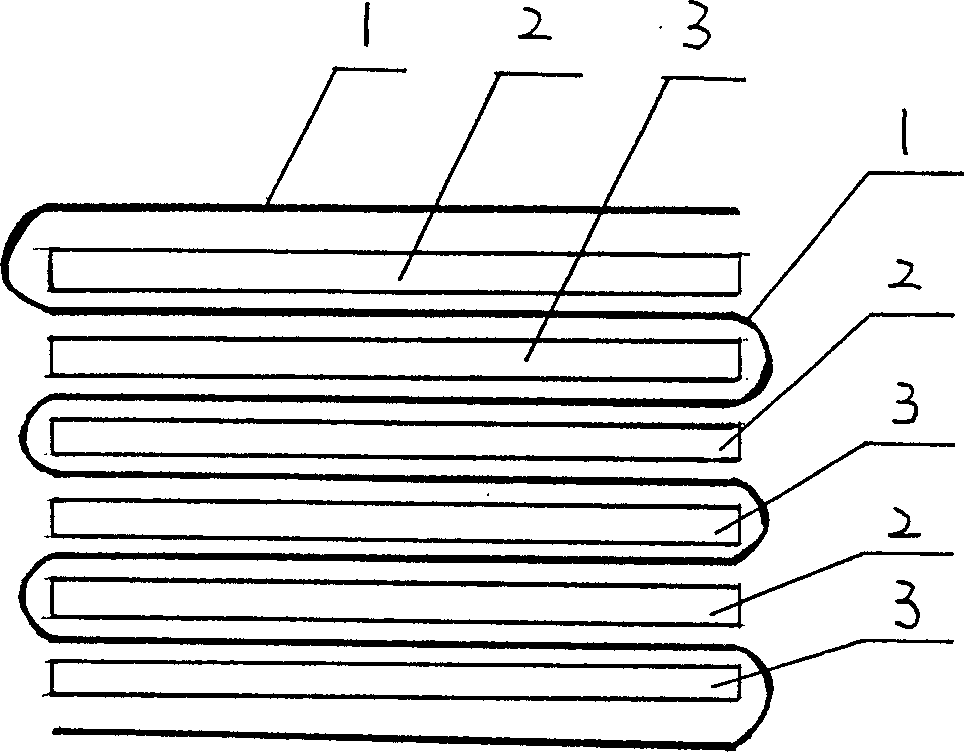

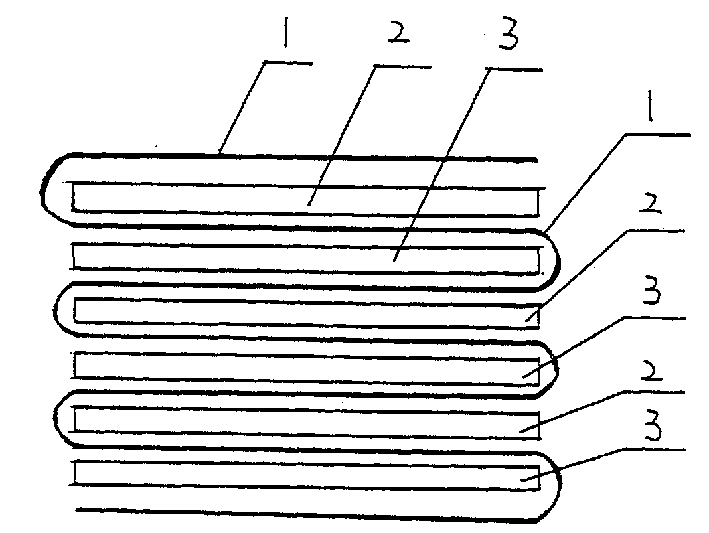

Lithium ion polymer cell

A polymer, lithium ion technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve the problems of large thickness of positive and negative plates, incomplete DBP removal, poor ductility, etc., and achieve low cost , The effect of using a wide temperature range and a simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In parts by weight, take 2 parts of polyvinylidene fluoride, 2 parts of modified polydiene, 96 parts of carbon powder, 90 parts of N-methylpyrrolidone in a stainless steel tank after stirring and mixing with a high-speed mixer to form a uniform slurry, It is coated on copper foil and dried in an oven at 100°C to 200°C to obtain a negative electrode sheet, which is cut into required shapes.

Embodiment 2

[0024] In parts by weight, take 2 parts of polyvinylidene fluoride, 1 part of polyacrylate, 7 parts of conductive carbon black, 90 parts of lithium cobalt oxide, 40 parts of N-methylpyrrolidone in a stainless steel barrel and mixed with a high-speed mixer to obtain a uniform The slurry is coated on aluminum foil, and dried in an oven at 80°C to 200°C to obtain a positive electrode sheet, which is cut into the required shape.

Embodiment 3

[0026] In parts by weight, 1 part of polyacrylate, 1 part of modified polyethylene, 6 parts of conductive carbon black, 92 parts of lithium cobaltate, and 35 parts of N-methylpyrrolidone were mixed in a stainless steel bucket with a high-speed mixer to obtain The uniform slurry is coated on aluminum foil and dried in an oven at 100°C to 210°C to obtain a positive electrode sheet, which is then cut into the required size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com