A kind of polyethersulfone anion exchange membrane that can be used for alkaline polymer electrolyte fuel cell and its preparation method and application

An anion exchange membrane, fuel cell technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as hindering development and market application, electrode catalyst poisoning, fuel permeation, etc., and achieve low electrolyte permeation performance and cost. The effect of low, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

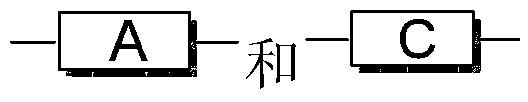

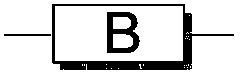

[0066] With 10mmol of cyclohexane monomer (formula 10), 10mmol of bisphenol monomer B (formula 11), 10mmol of halogen-containing aromatic monomer A (formula 14) and 10mmol of halogen-containing aromatic monomer C (Formula 14) is added in the 250ml there-necked flask that water trap, stirrer and nitrogen inlet and outlet are housed, the potassium carbonate of 50mmol is added as catalyst, the toluene of 30ml is as water-carrying agent, the sulfolane of 100ml is added as solvent, 140 ℃ After reacting for 3 hours, the temperature was raised to 210°C for 3 hours. The polymer solution was poured into ethanol to precipitate, washed repeatedly with ethanol and deionized water for 3 times, and dried in vacuum at 80°C for 24 hours to obtain a white polymer resin CHPES with a yield of 92 %; Dissolve 1g of cyclohexane resin (CHPES) in 20ml (31.86g) of 1,1,2,2-tetrachloroethane, add 1.27g of N-bromosuccinimide as brominated benzoyl peroxide and 0.086g of benzoyl peroxide as the initiator, ...

Embodiment 2

[0071] With 10mmol of cyclohexane (formula 10), 10mmol of bisphenol monomer B (formula 12), 10mmol of halogen-containing aromatic monomer A (formula 15) and 10mmol of halogen-containing aromatic monomer C (formula 15) Add it to a 250ml three-neck flask equipped with a water separator, a stirrer and a nitrogen inlet and outlet, 30ml of toluene as a water-carrying agent, add 50mmol of sodium carbonate as a catalyst, and add 100ml of N,N-dimethylacetamide As a solvent, react at 140°C for 3h, then heat up to 165°C for 12h, pour the polymer solution into the ethanol solution to precipitate, wash with ethanol and deionized water repeatedly for 3 times, and vacuum dry at 80°C for 24h to obtain the white polymer resin CHPES , yield 90%; 1g of cyclohexane resin (CHPES) was dissolved in 20ml (31.86g) of 1,1,2,2-tetrachloroethane, 1.27g of N-bromosuccinyl was added Use amine as brominating agent and 0.086g of benzoyl peroxide as initiator, conduct bromination reaction at 85°C for 5 hours...

Embodiment 3

[0074] With 2mmol of cyclohexane monomer (formula 10), 18mmol of bisphenol monomer B (formula 13) and 2mmol of halogen-containing aromatic monomer A (formula 15) and 18mmol of halogen-containing aromatic monomer C (Formula 15) was added to a 250ml three-necked flask equipped with a water separator, a thermometer and a nitrogen inlet and outlet, 20ml of toluene was used as a water-carrying agent, 50mmol of cesium carbonate was added as a catalyst, and 100ml of N,N-dimethyl Formamide was used as a solvent, reacted at 140°C for 3 hours, then heated up to 150°C for 16 hours, poured the polymer solution into ethanol solution to precipitate, washed with deionized water and ethanol solution repeatedly for 3 times, and dried in vacuum at 80°C for 24 hours to obtain white Polymer resin CHPES, yield 94%; 1g of cyclohexane resin (CHPES) was dissolved in 20ml (24.70g) of 1,2-dichloroethane, 1.27g of N-bromosuccinyl was added Amine as the brominating agent and 0.086g of benzoyl peroxide as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com