Patents

Literature

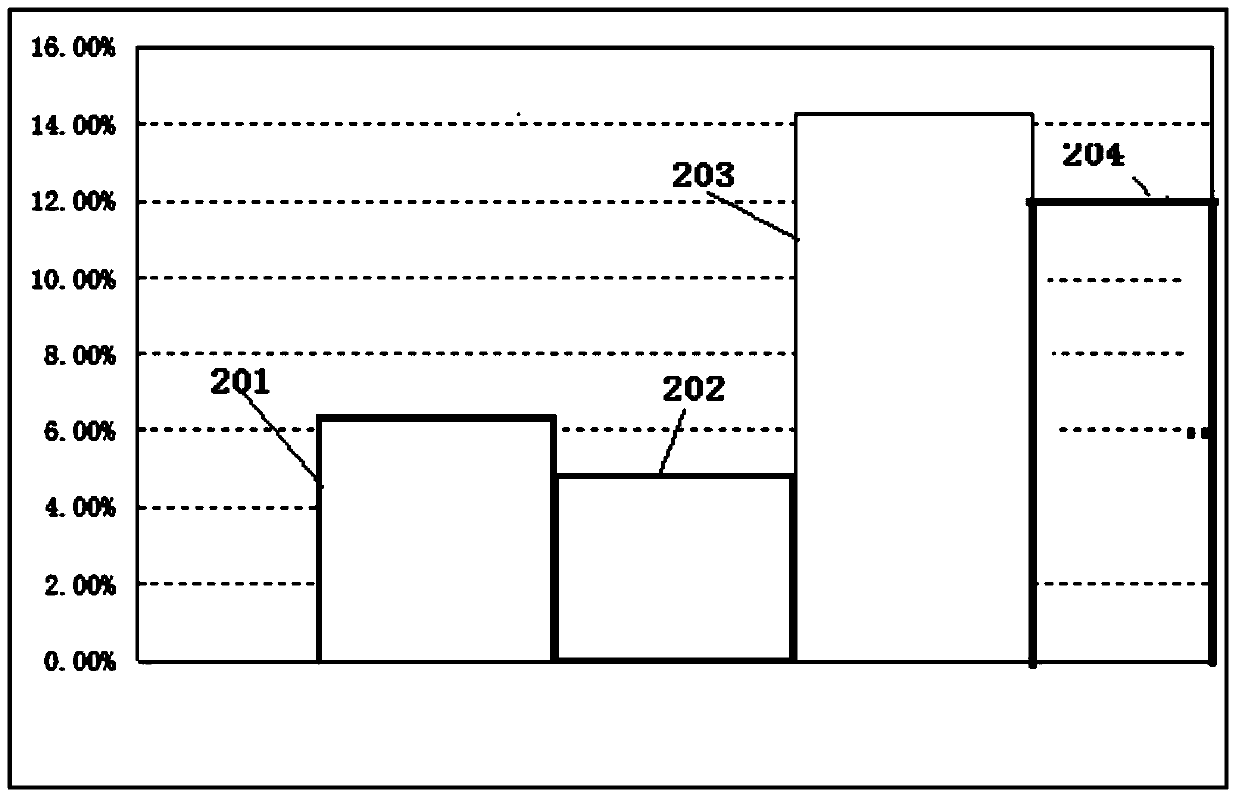

105results about How to "Restore capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite blocking remover and method for removing blockage of compact sandstone reservoir pressing crack commissioning horizontal well in composite manner

ActiveCN103740353AGood retarding performanceDecontamination of reservoirCleaning apparatusDrilling compositionSolid phasesOrganic acid

The invention discloses a composite blocking remover and a method for removing blockage of a compact sandstone reservoir pressing crack commissioning horizontal well in a composite manner. The composite blocking remover comprises a preposition liquid, a main treating fluid, an active blocking remover and a subsequent fluid. The preposition liquid is composed of organic acid, inorganic acid, a stabilizer, an oxidizing agent, a chelating agent, a corrosion inhibitor, polyol ether and water. The main treating fluid is composed of organic acid, inorganic acid, the stabilizer, the oxidizing agent, a fluorine carbon surfactant and water. The active blocking remover is composed of a zwitterionic surfactant, the stabilizer and water. The subsequent fluid is water. The composite blocking remover can remove the blockage of routine colloid, asphalt mass and inorganic solid phase particles, and can remove the damage of water blocking and crude oil emulsification by pertinency, and has the advantages of good slow performance, effectively preventing secondary deposition pollution such as the iron ion deposition and acid sludge generation, the horizontal well near-well and deep reservoir pollution can be effectively released, the oil well production power is recovered, and the recovery efficiency can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

New method for forming manual well wall in oil and gas well by water-absorbing resin

InactiveCN102134979APrevent leakageEasy to transformDrilling compositionSealing/packingFresh water organismVolumetric Mass Density

The invention relates to a new method for forming manual well walls in an oil and gas wells by water-absorbing resin. In the method, the water-absorbing resin is mixed with freshwater or saline to form a well completion fluid or a workover fluid; the water-absorbing resin is starch-type water-absorbing resin or cellulose-type water-absorbing resin or synthetic water-absorbing resin and comprises the following components by weight percentage: 1 to 2% of water-absorbing resin, 0.2 to 0.5% of water-absorbing initiator, 0.2 to 0.5% of colloid protective agent, and the remaining quantity of water or monovalent saline. The density of the water-absorbing resin well-completion fluid or the workover fluid can be adjusted by adding monovalent salt NaCl or KCl; the solution apparent viscosity can be controlled by adjusting the concentration of the water-absorbing resin; and the dosage of the well completion fluid or the workover fluid can be designed according to the volume of a shaft. In the method, the physical and the chemical changes can occur under the high temperature to form a manual well wall, namely a gelatine temporary plugging layer; therefore, the bearing capability of the high-and low-pressure stratum can be effectively improved; the leakage of the well completion fluid or the workover fluid can be prevented at the producing layer, the operation safety and the capacity of the oil and gas well can be ensured, the construction technology is simple, and the cost is relatively low.

Owner:CHINA NAT OFFSHORE OIL CORP +3

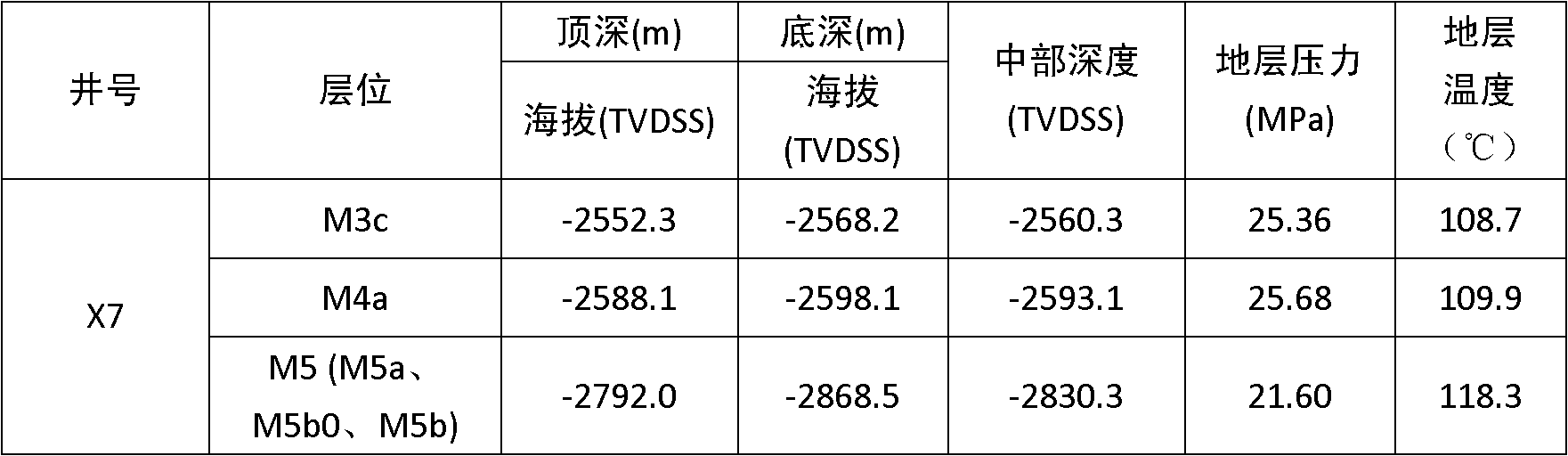

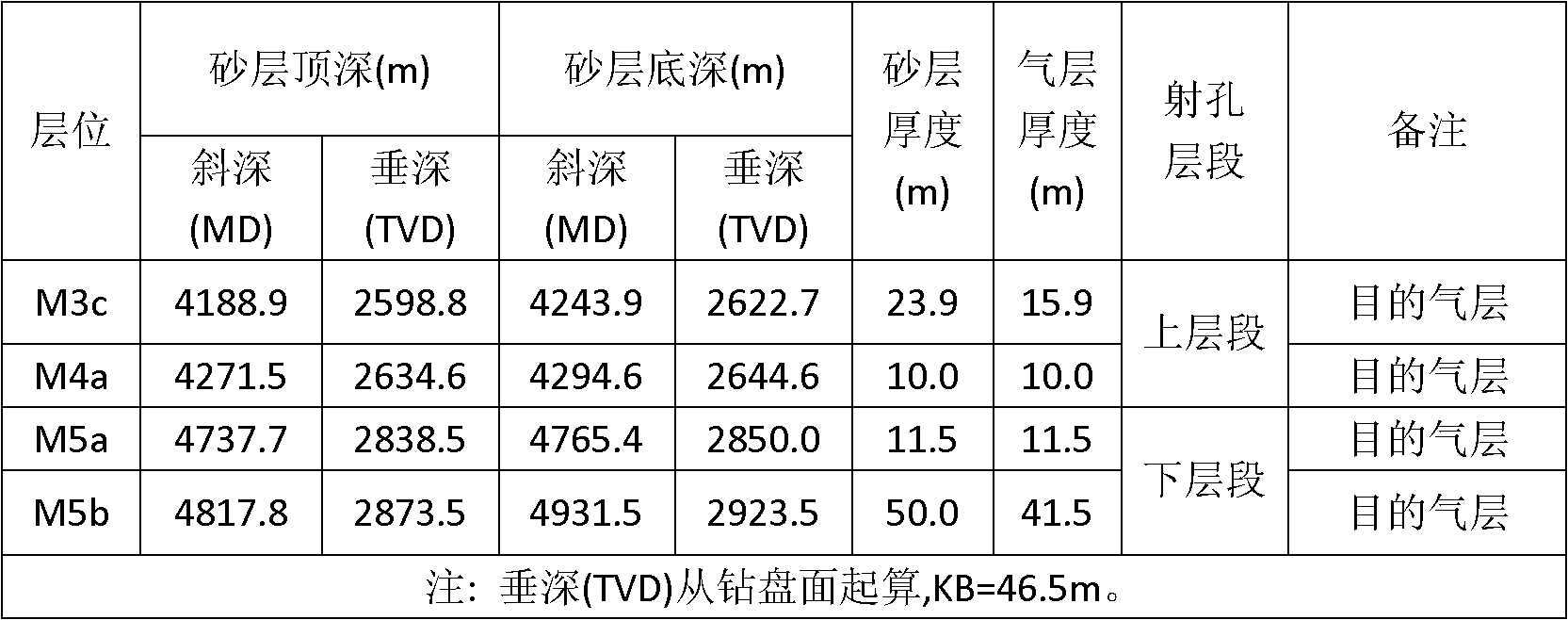

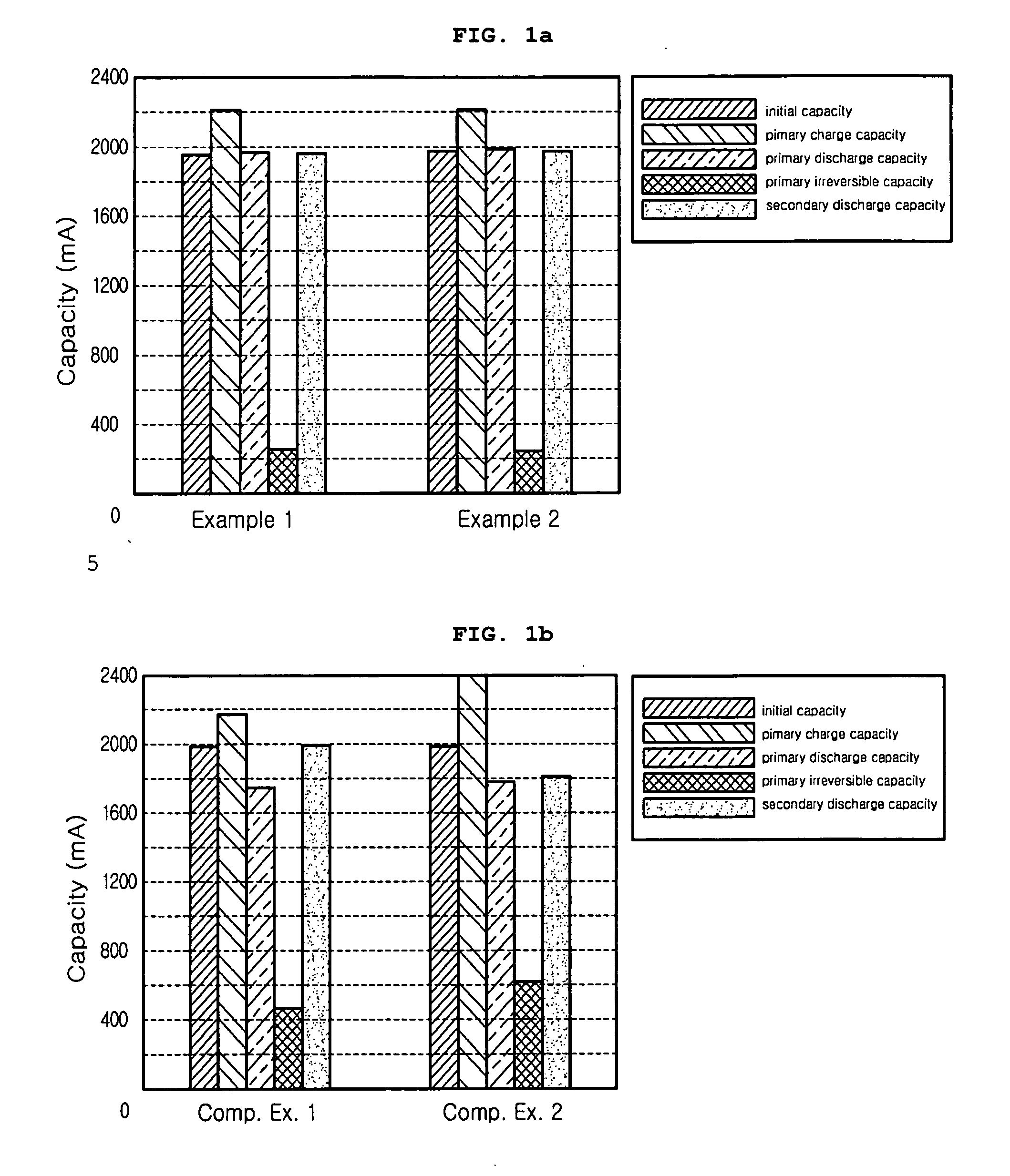

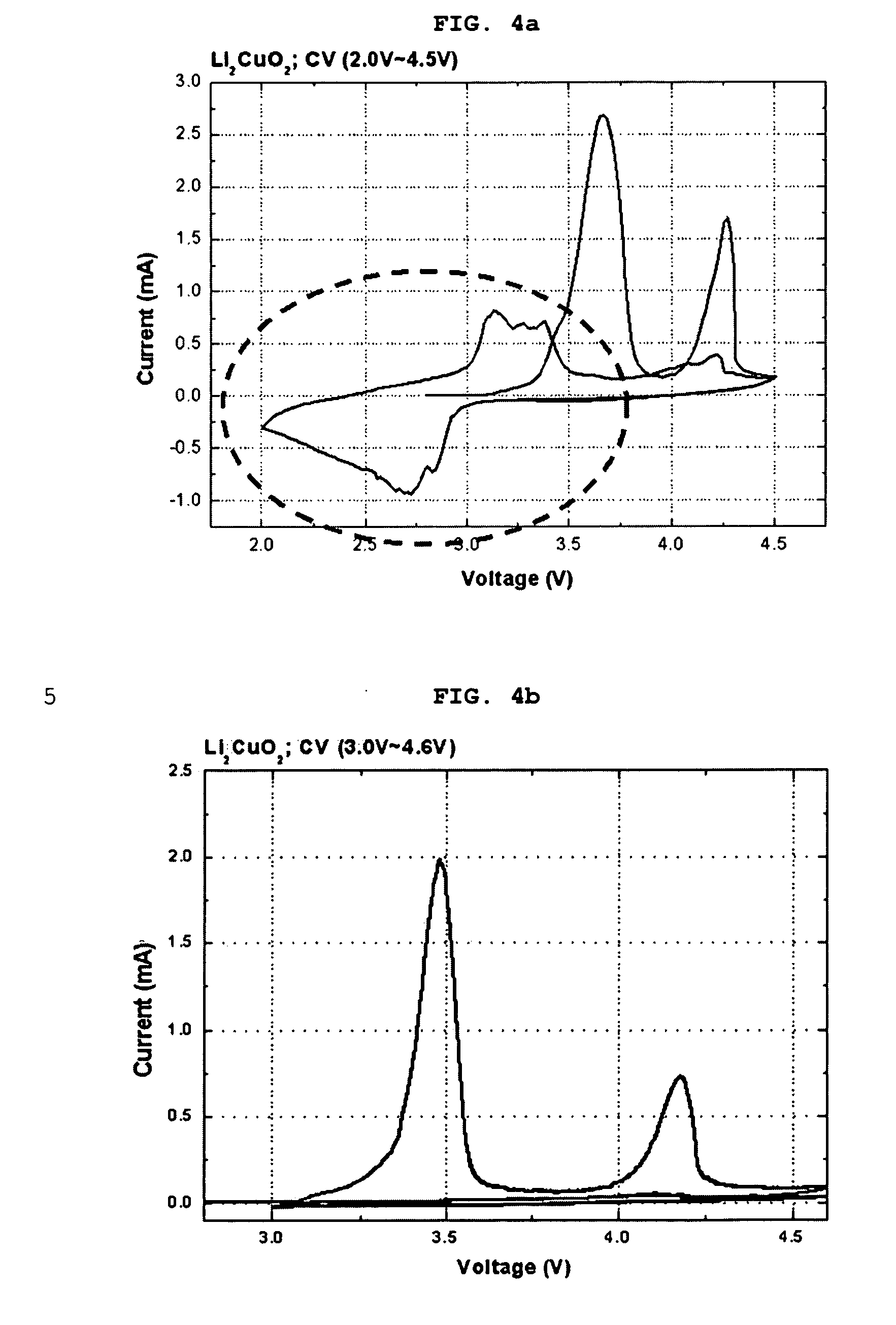

Electrode for lithium secondary battery comprising electrode additive and lithium secondary battery using the same

InactiveUS20060251967A1Increase capacityPrevent the electric potential of the anodeSecondary cellsNon-aqueous electrolyte accumulator electrodesEngineeringLithium

Disclosed are an electrode including Li2CuO2 as an additive, and a lithium secondary battery having the same. The additive is added to a cathode as to adjust unbalance of the irreversible reaction between the cathode and an anode of the lithium secondary battery, thereby increasing the capacity of the lithium secondary battery without degrading performance of the lithium secondary battery after over-discharge of the lithium secondary battery.

Owner:LG CHEM LTD

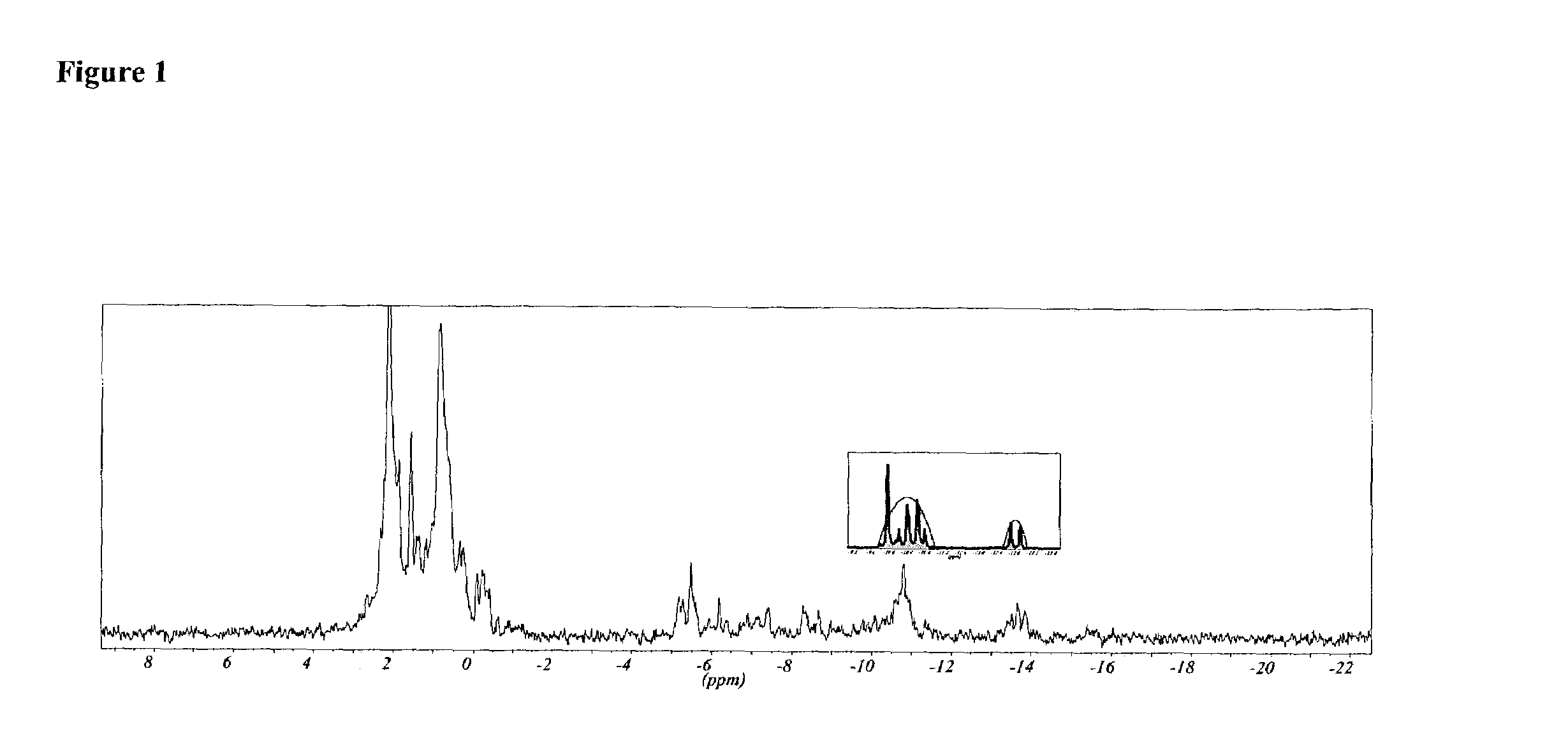

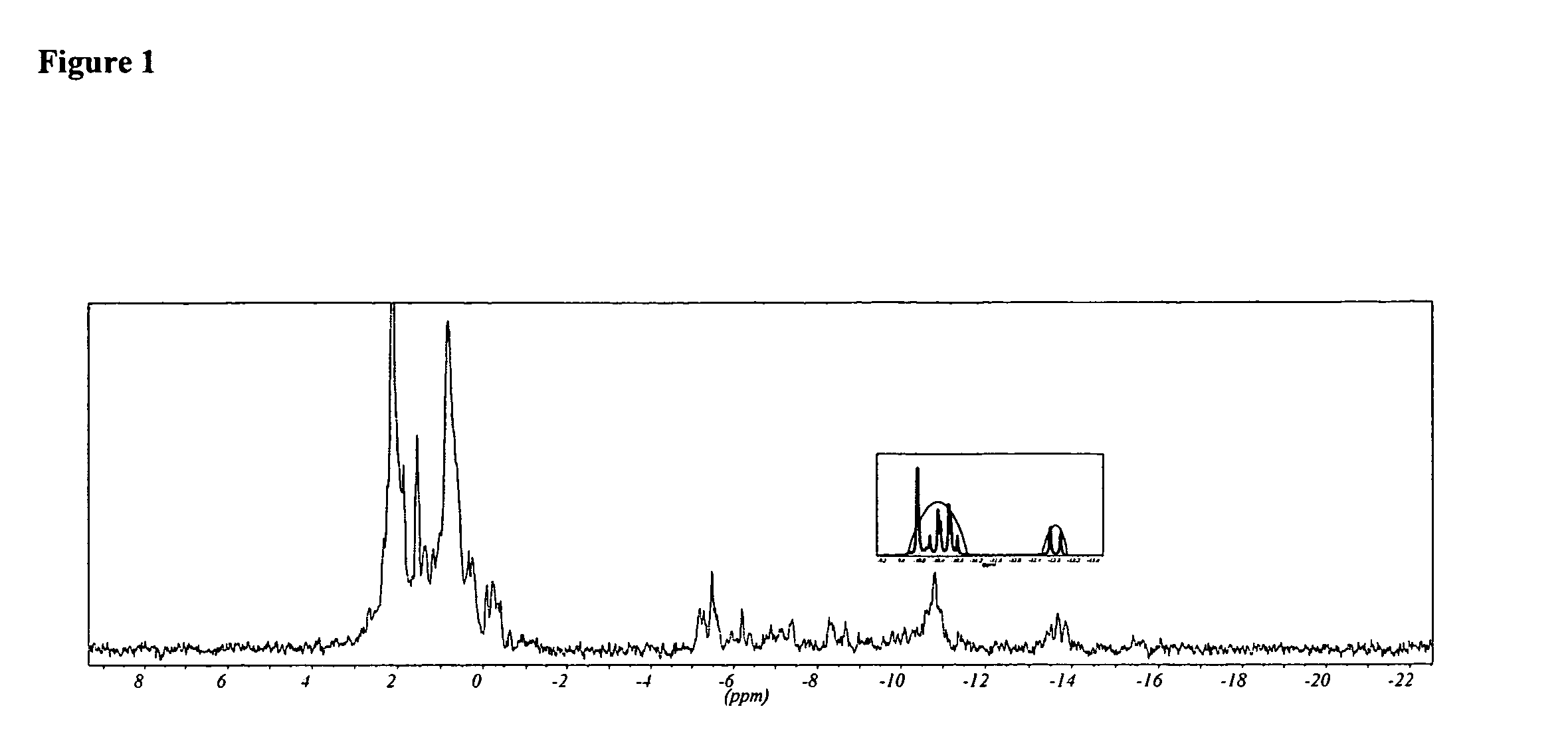

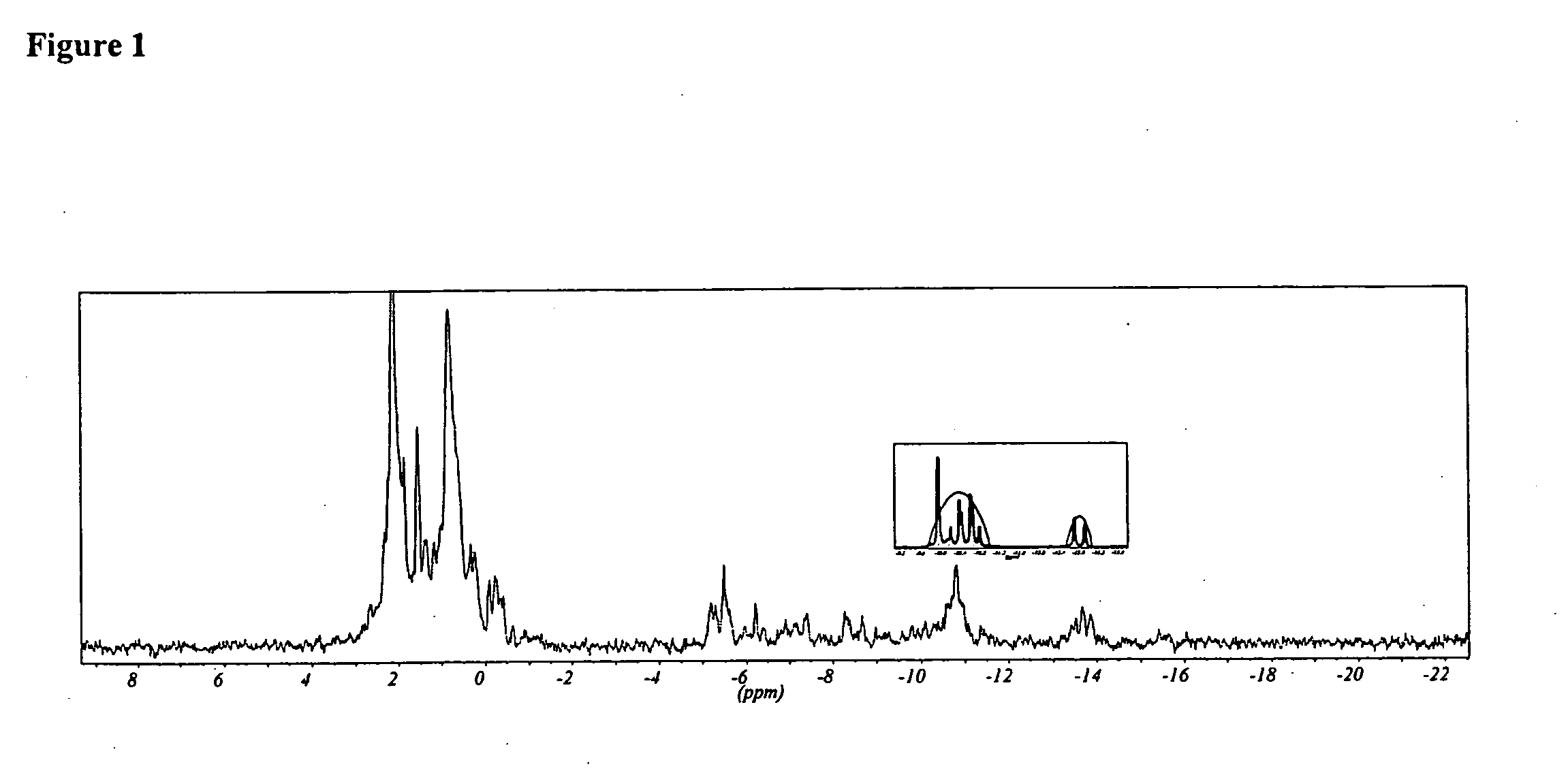

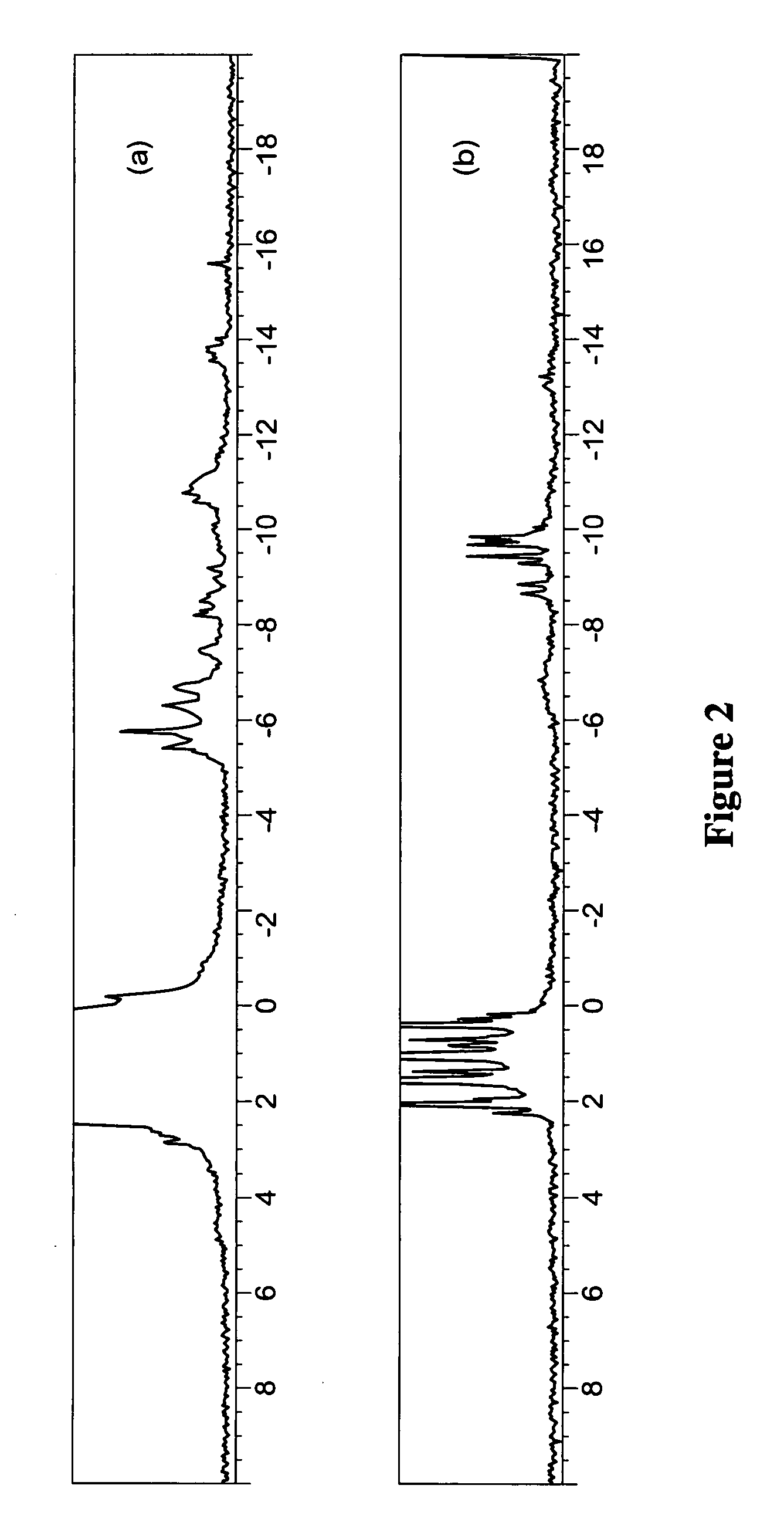

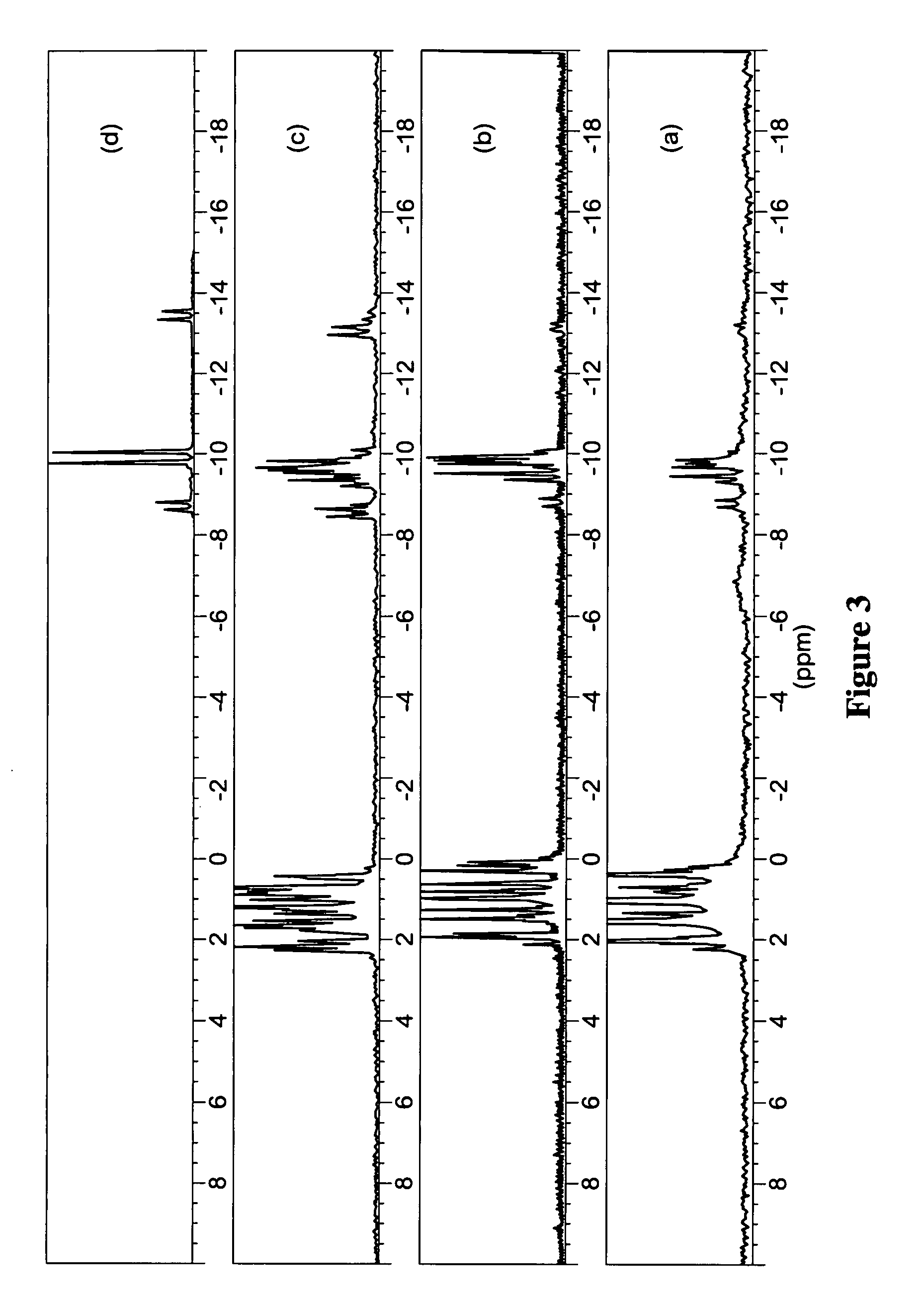

Inositol pyrophosphates, and methods of use thereof

InactiveUS7084115B2Low affinityRestore capacityBiocidePeptide/protein ingredientsInositol HexakisphosphateRed blood cell

The present invention comprises compounds, compositions thereof, and methods capable of delivering modified inositol hexaphospahte (IHP) comprising an internal pyrophosphate ring to the cytoplasm of mammalian cells. In certain embodiments, the present invention relates to compounds, compositions thereof, and methods that enhance the ability of mammalian red blood cells to deliver oxygen, by delivering IHP to the cytoplasm of the red blood cells.

Owner:NORMOXYS

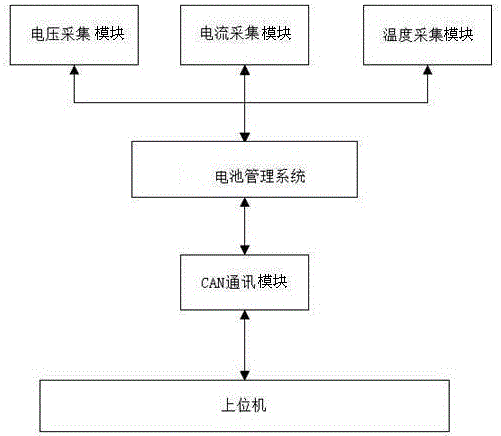

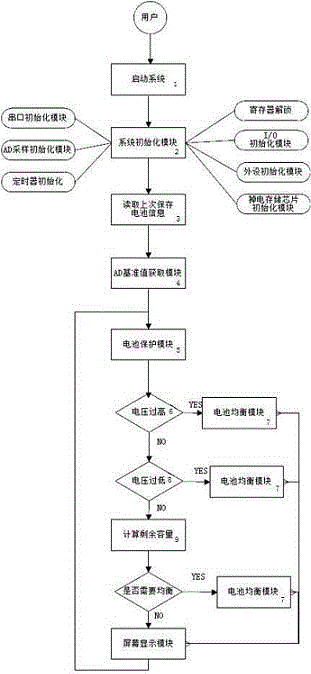

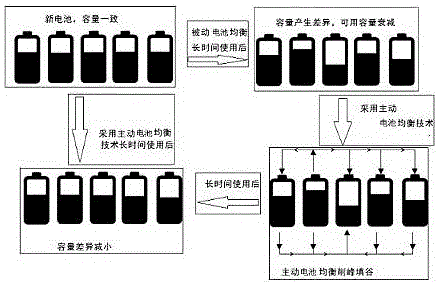

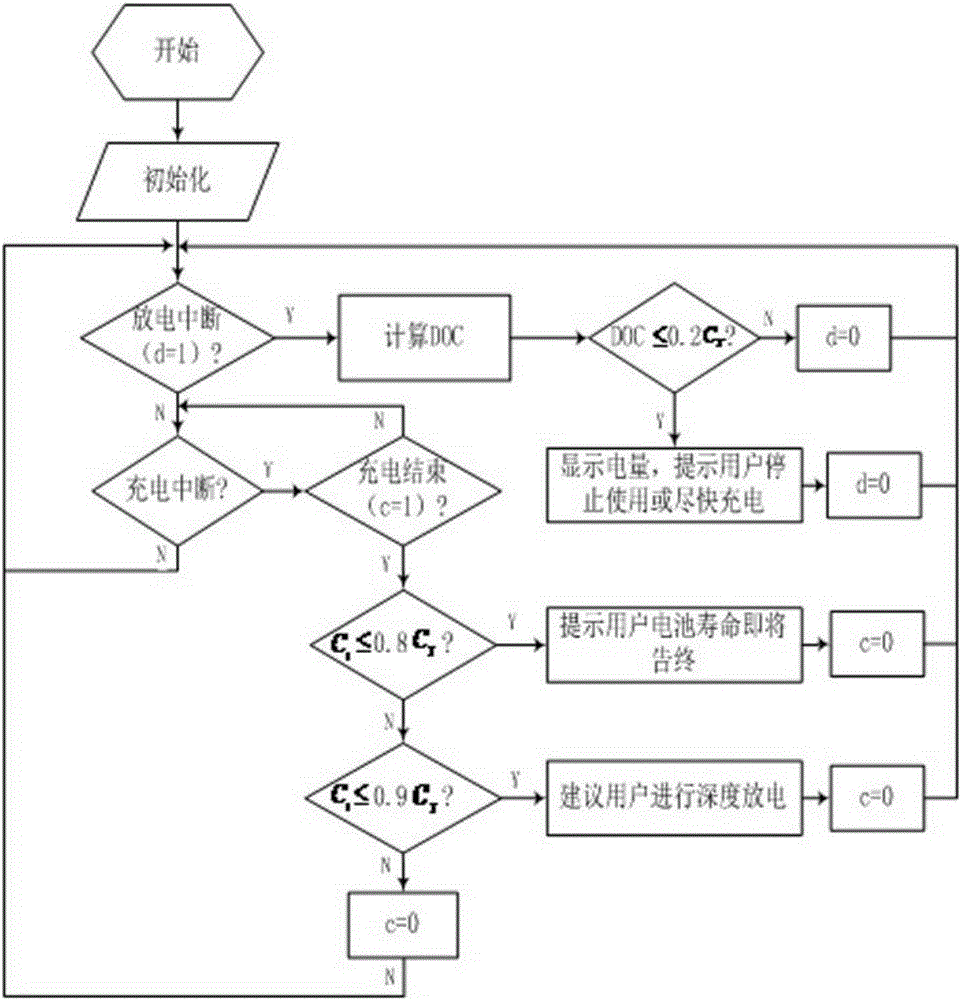

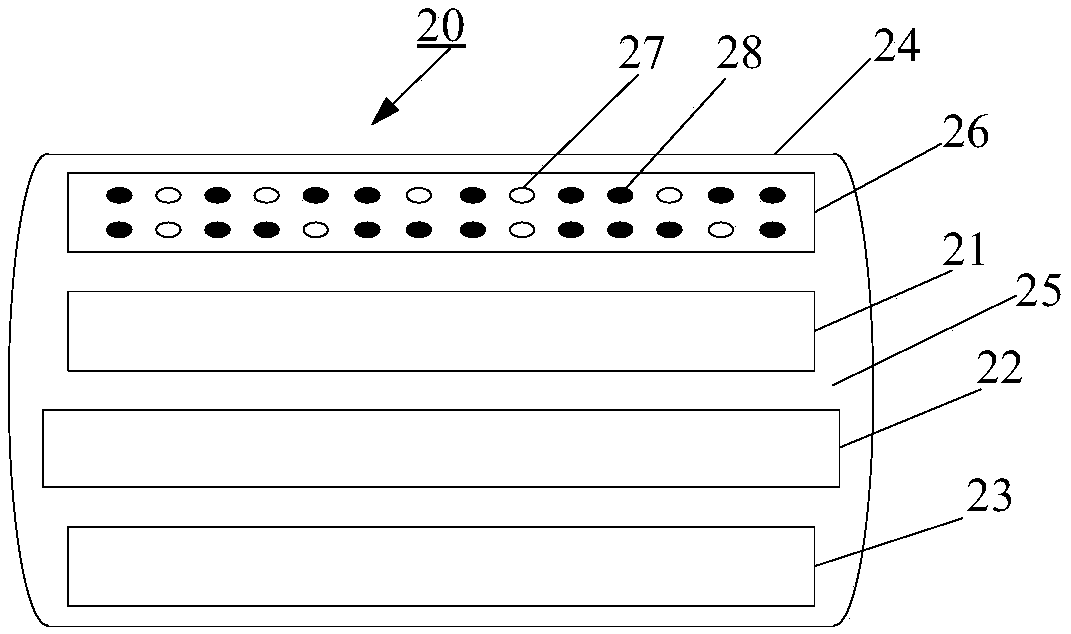

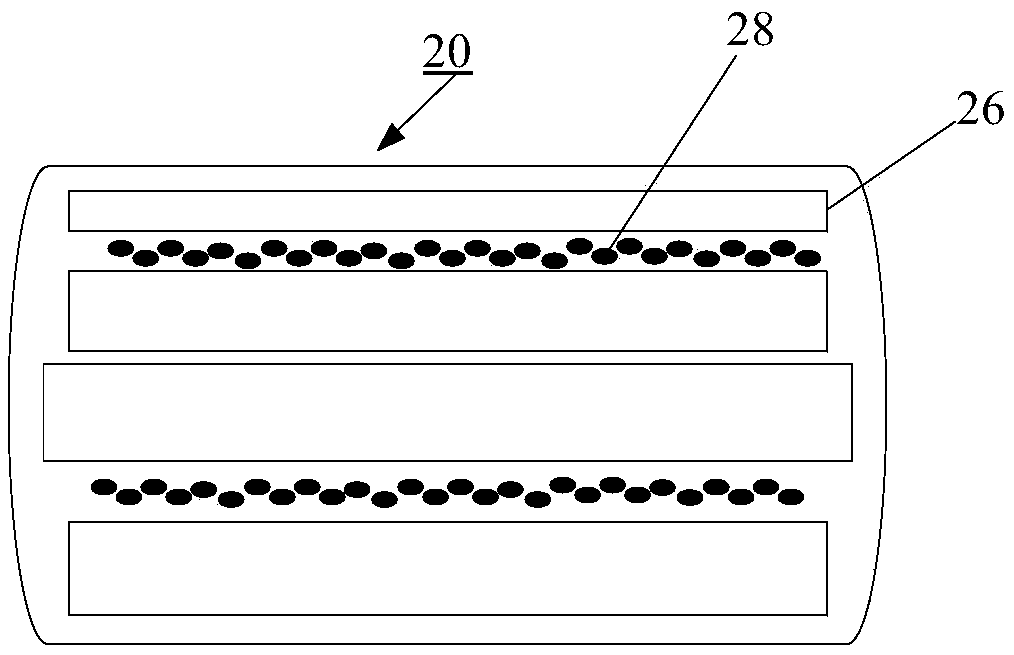

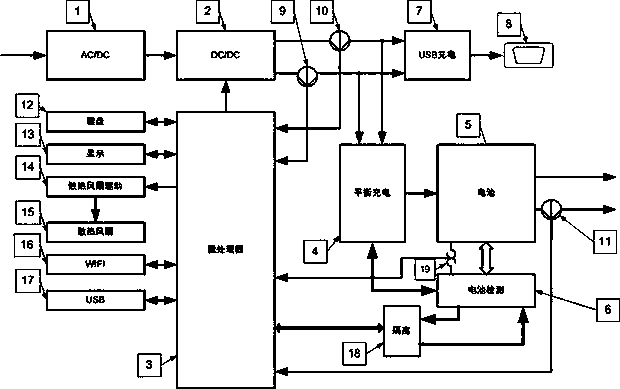

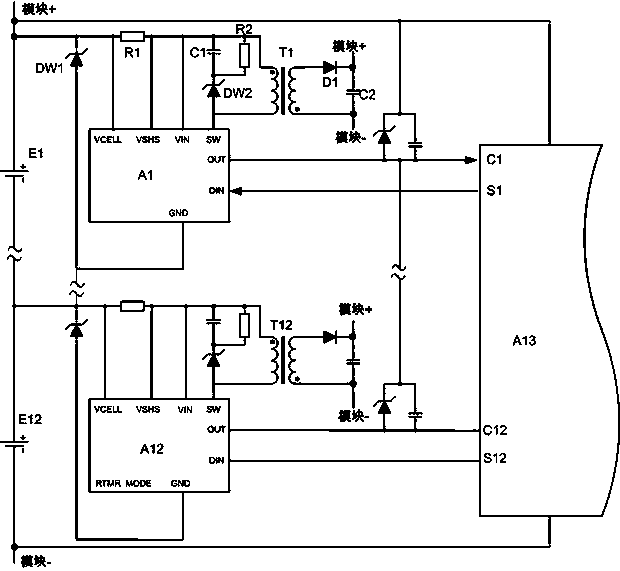

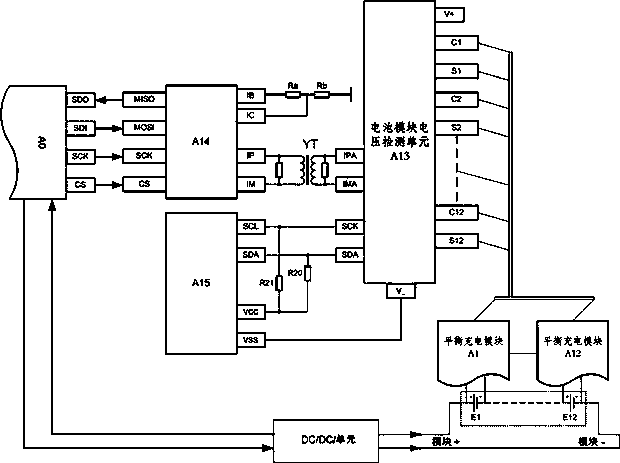

Active balanced battery management system

ActiveCN106100022AImprove uniform efficiencySolve problems that affect the work of the entire battery packBatteries circuit arrangementsElectric powerLower limitOn board

The invention provides an active balanced battery management system, which comprises a host computer and a CAN communication module, wherein the host computer transmits a control instruction to the battery management system through the CAN communication module; the battery management system transmits data to the host computer through the CAN communication module and is connected with an on-board control system and a charger through the CAN communication module; and the battery management system is also connected with a voltage collection module, a current collection module and a temperature collection module through an RS232 and obtains AD sampled data of voltage, current and temperature of a battery. A novel SOC calculation mode is provided, so that the problem that the prior art is inaccurate in calculation accuracy of the battery capacity is solved. The parameters of an upper limit and a lower limit of the battery capacity, charging and discharging current, a battery temperature and the like are set through the host computer; and the battery is effectively protected. The invention provides a novel charging mode standard, so that the battery can be more effectively charged.

Owner:江苏瀚海芯云网络科技有限公司

Preparation method of spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide

InactiveCN102142547AImprove liquidityFully dispersedAlkaline accumulator electrodesLithium hydroxidePhysical chemistry

The invention relates to a preparation method of a spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide, comprising the following steps: heating cobalt hydroxide coated spherical nickel hydroxide which is utilized as a precursor, and spraying an alkali metal hydroxide aqueous solution; evenly mixing the precursor with the alkali metal hydroxide aqueous solution; introducing oxygen to oxidize the cobalt hydroxide to convert the cobalt hydroxide into high-valency gamma-hydroxy cobalt oxide; and during oxidation, combining mechanical agitation and ultrasonic agitation to prevent the spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide from gathering and cause alkali metal ions to be embedded into a crystal lattice with the laminated structure of the gamma-hydroxy cobalt oxide. After oxidation reaction is over, a lithium hydroxide alkaline solution at certain temperature is added into an oxidation reaction pot to carry out heat preservation on the spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide; when heat preservation is carried out, mechanical agitation and ultrasonic agitation are adopted to cause the lithium ions to be embedded into the laminated structure of the gamma-hydroxy cobalt oxide; and the obtained spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide is screened by an ultrasonic sieve shaker after being washed and dried.

Owner:JIANGMEN CHANCSUN UMICORE IND

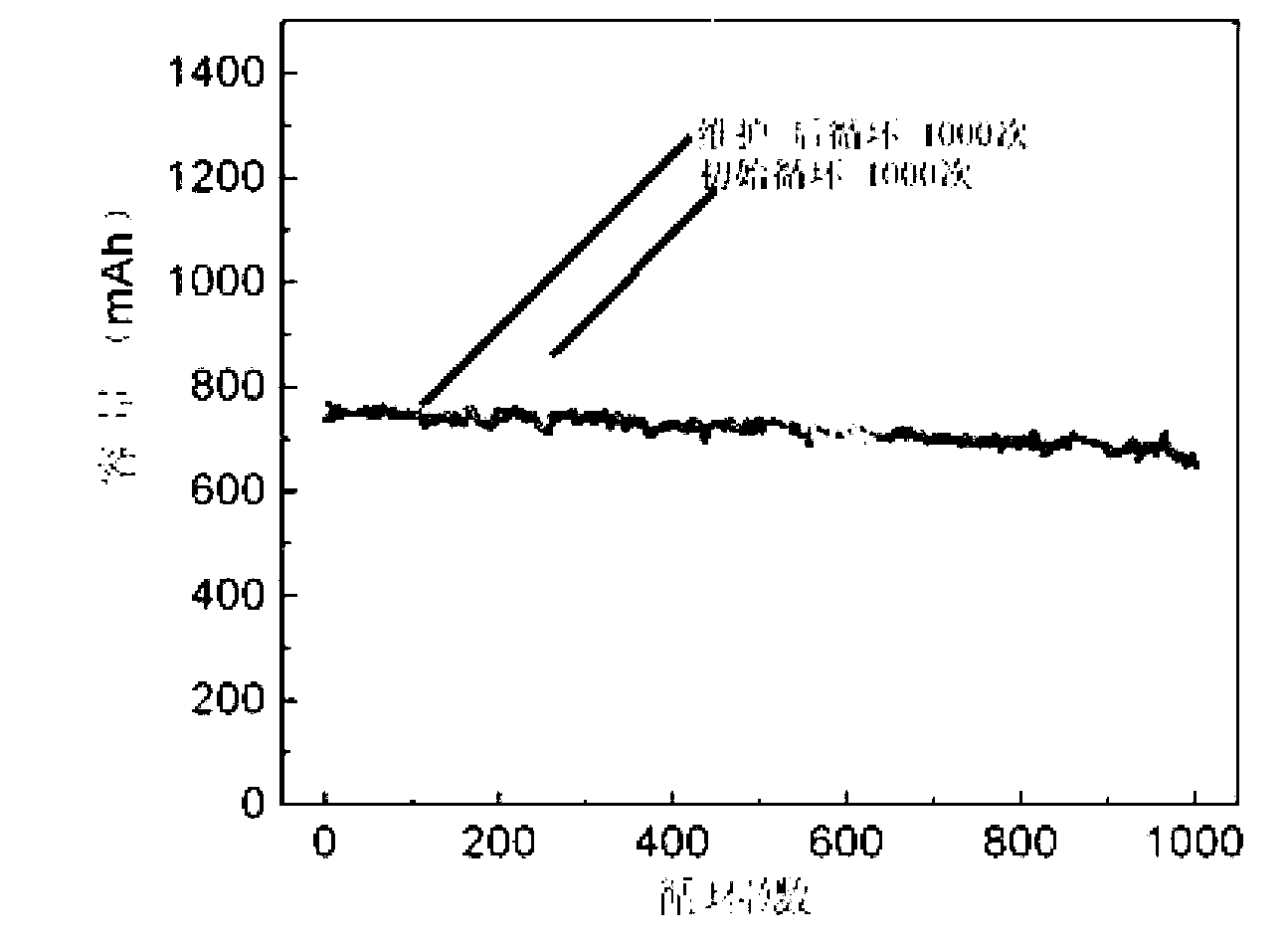

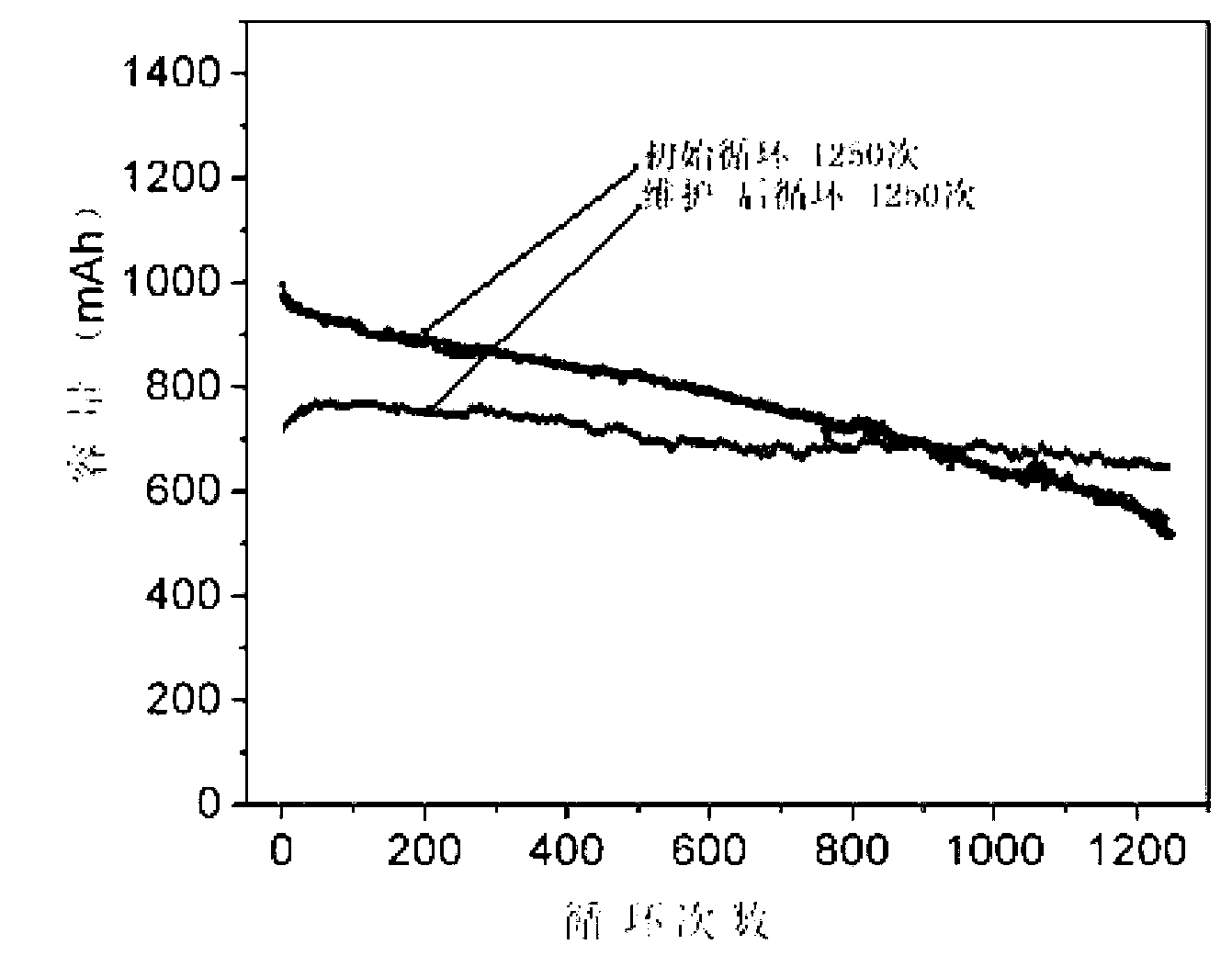

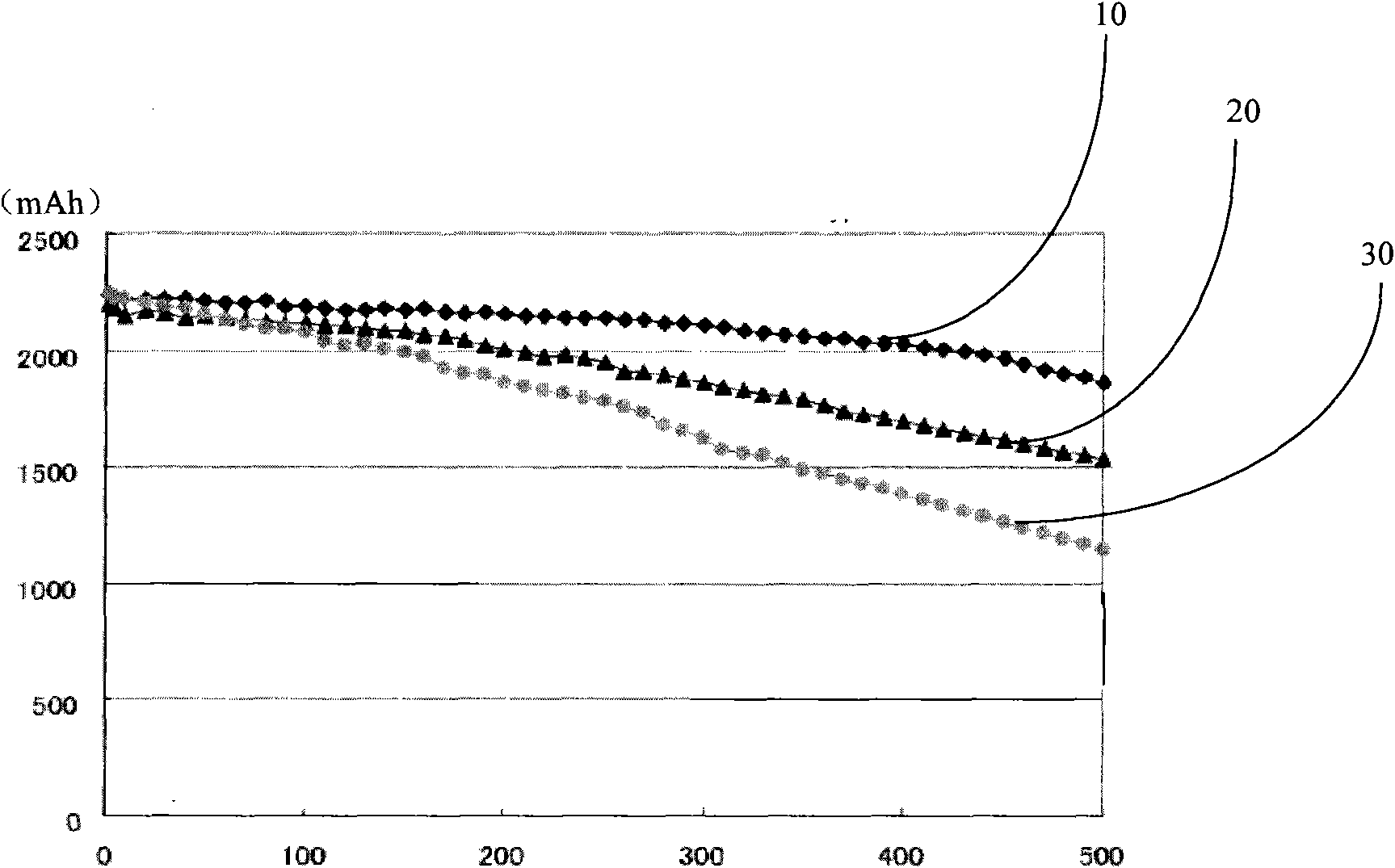

Maintenance method for capacity recovery type lithium ion battery

ActiveCN103187595AExtended service lifeRestore battery capacitySecondary cells servicing/maintenanceState of artEngineering

The invention provides a maintenance method for a capacity recovery type lithium ion battery, and aims to overcome the defect that the capacity of the current lithium ion battery can not be effectively recovered. The method comprises the following steps: (1), damaging an SEI film; (2), adding an SEI film restoration agent; and (3), forming and sealing. The method has the benefits that through simple design, the formed SEI film can be regenerated after being damaged, so that the service life of the lithium ion battery is prolonged to 3000-5000 times from 1000 times, and accordingly the purpose of repeated regeneration is achieved and the capacity of the battery is effectively recovered during the regeneration process.

Owner:常州孚达新能源科技有限公司

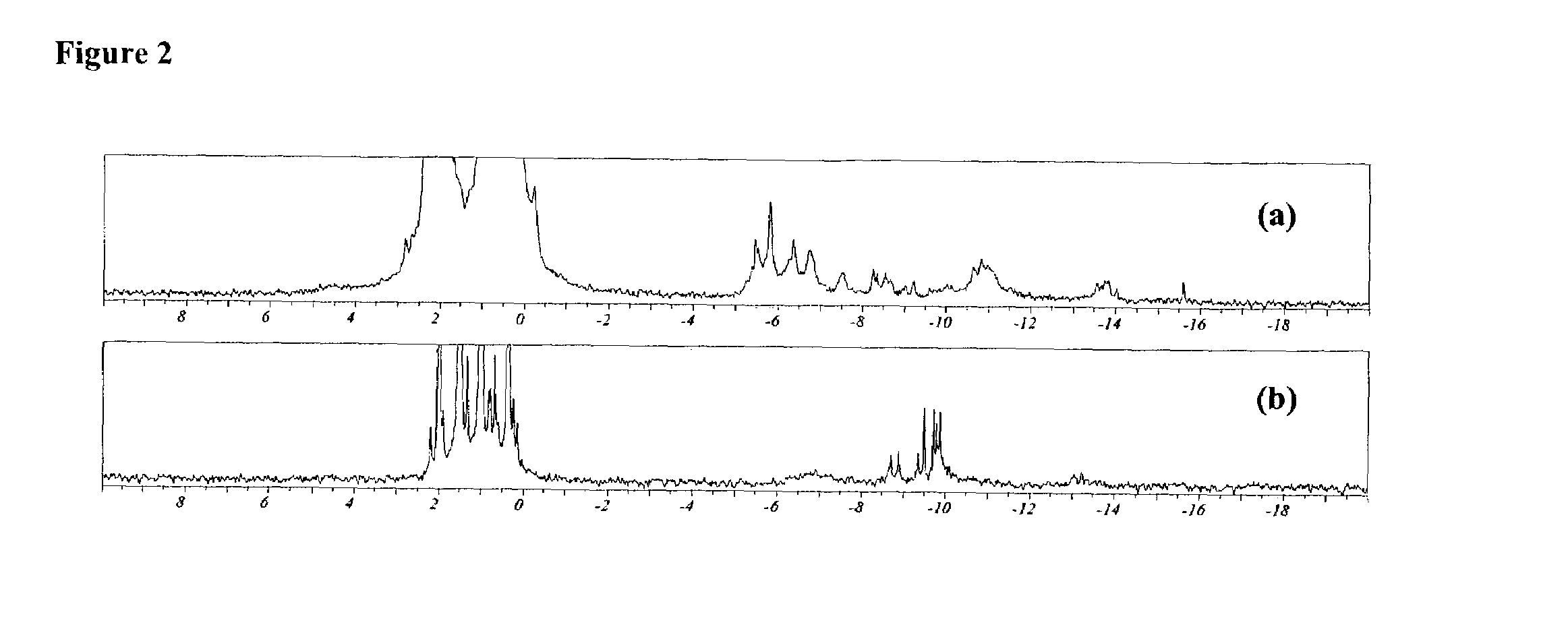

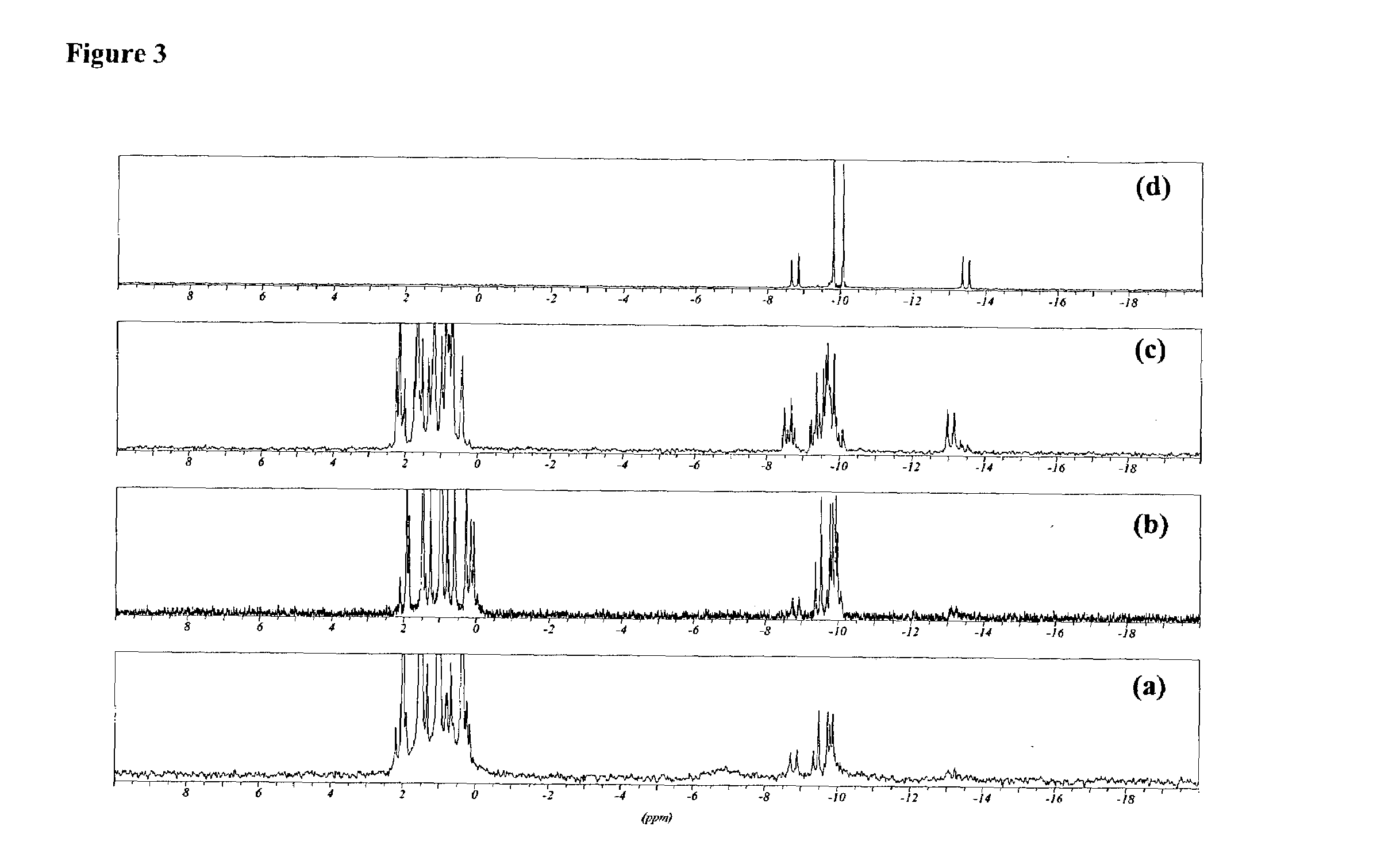

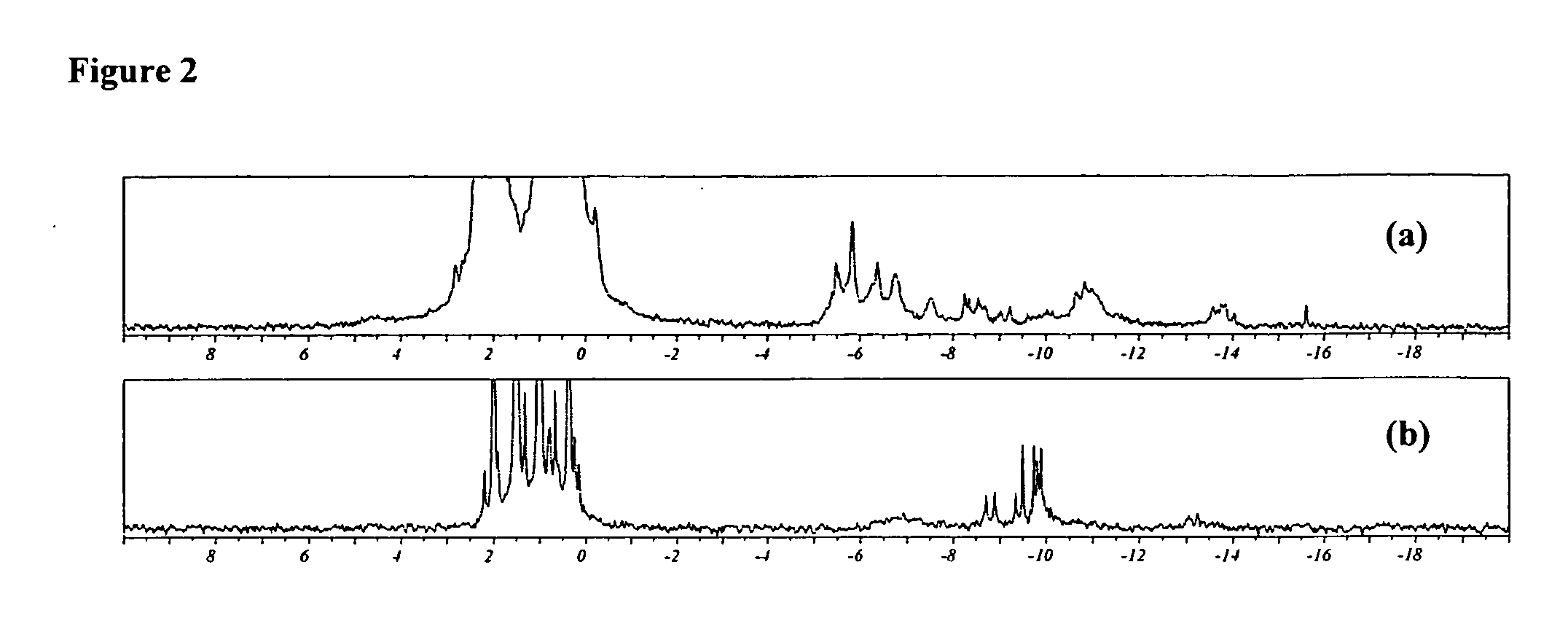

Inositol pyrophosphates, and methods of use thereof

InactiveUS20060116358A1Low affinityRestore capacityBiocideMammal material medical ingredientsRed blood cellPyrophosphate

The present invention comprises compounds, compositions thereof, and methods capable of delivering modified inositol hexaphospahte (IHP) comprising an internal pyrophosphate ring to the cytoplasm of mammalian cells. In certain embodiments, the present invention relates to compounds, compositions thereof, and methods that enhance the ability of mammalian red blood cells to deliver oxygen, by delivering IHP to the cytoplasm of the red blood cells.

Owner:NORMOXYS

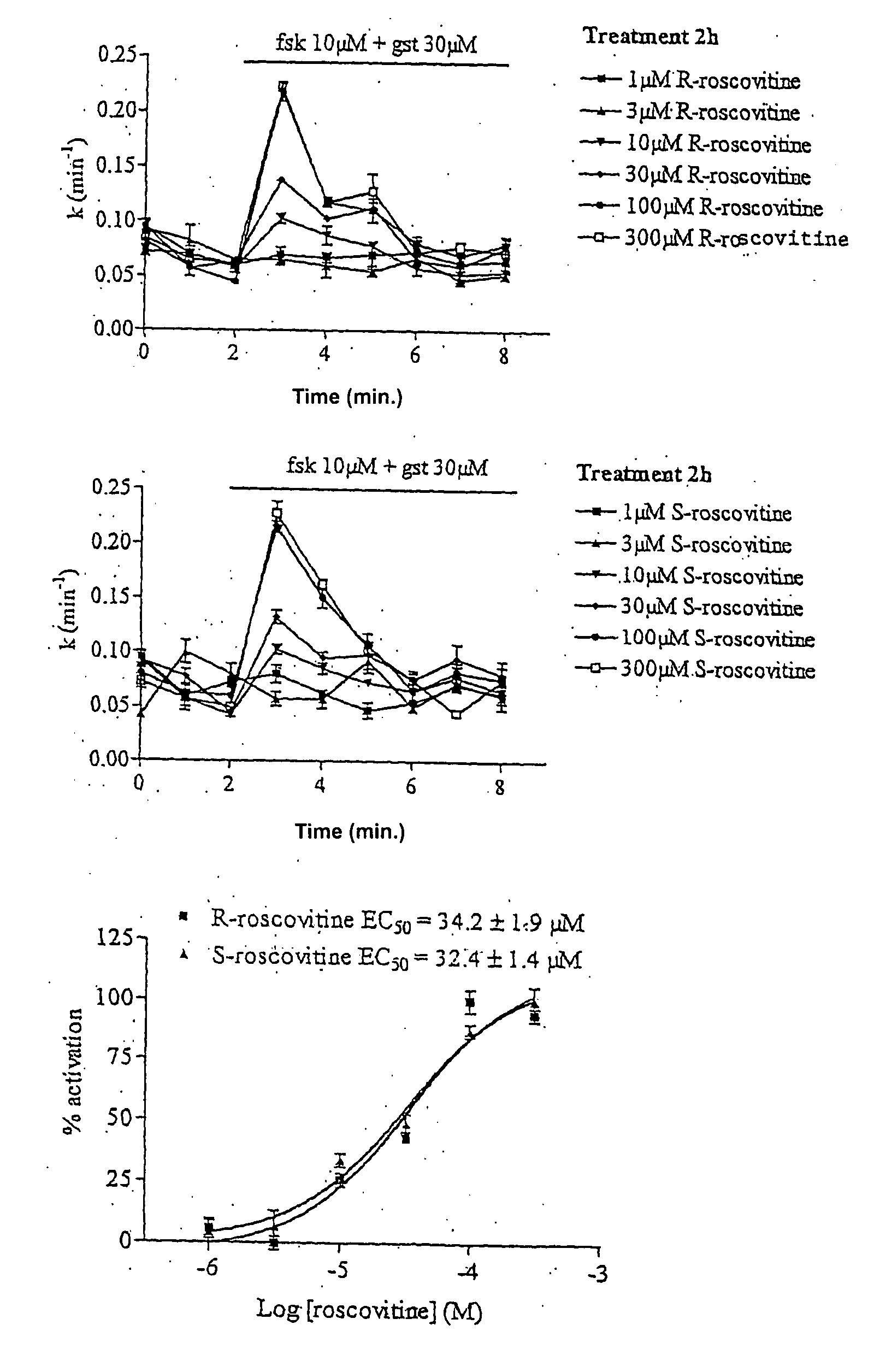

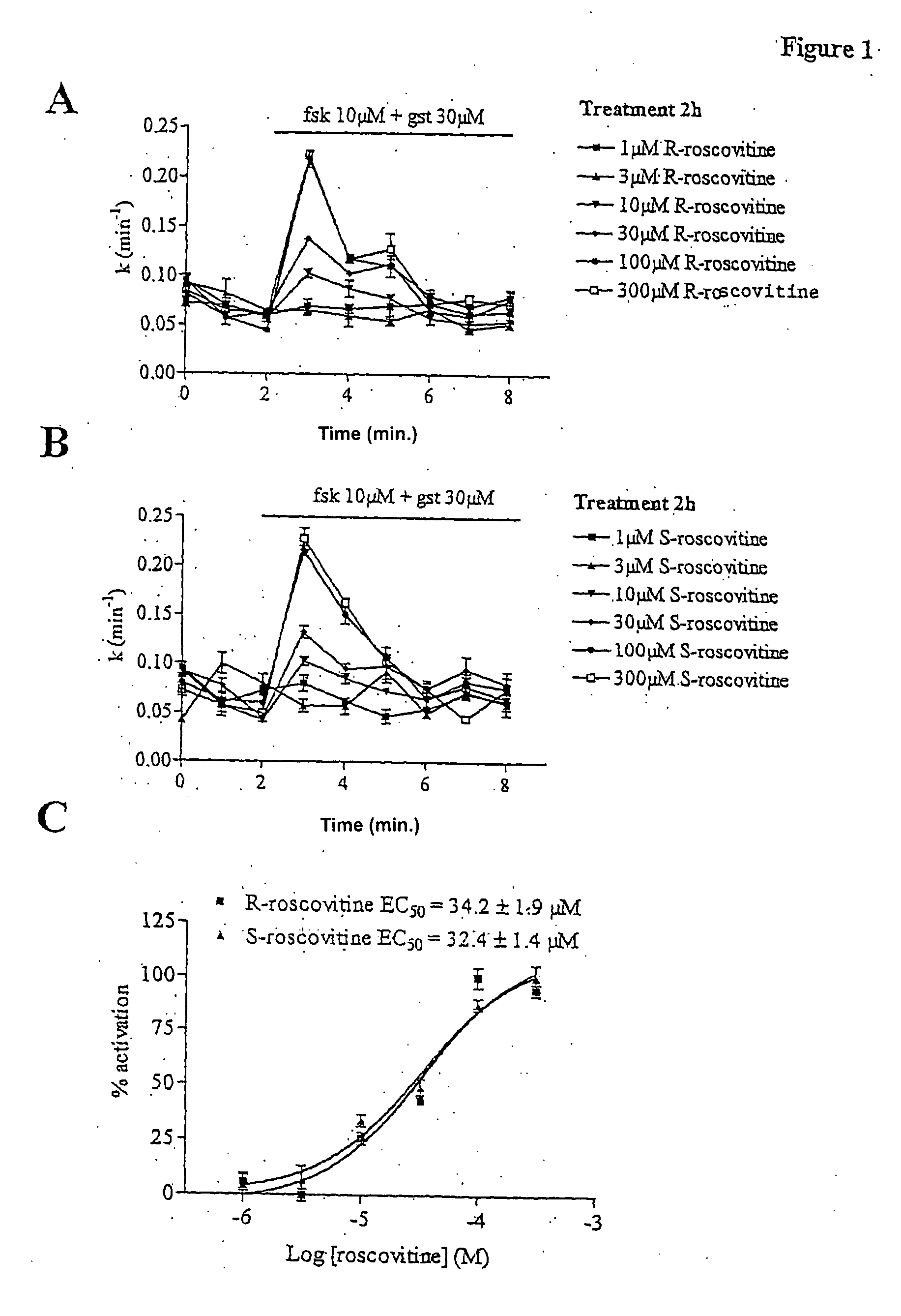

Use of purine derivatives for the production of medicaments for the treatment of mucoviscidosis and diseases related to protein addressing errors in cells

The invention relates to the use of purine derivatives for the production of medicaments for the treatment of mucoviscidosis and diseases related to protein addressing errors in cells, said derivatives being of formula (I): where R2, R6 and R9, independently=halogen, a R—NH—, R—NH—NH—, NH2—R′—NH or R—NH—R′—NH— group, where R=straight or branched chain saturated or unsaturated alkyl, aryl, cycloalkyl, or heterocyclyl group, R′=straight or branched chain, saturated or unsaturated alkylene, arylene or cycloalkylene, R and R′ each include 1 to 8 carbon atoms optionally substituted with one or more —OH, halogen, amino or alkyl groups, R2 furthermore may be a heterocycle optionally with a straight or branched chain saturated or unsaturated alkyl, aryl or cycloaryl or a heterocycle optionally substituted by one or more —OH, halogen, amino or alkyl groups, R9 furthermore may be a straight or branched chain saturated or unsaturated alkyl, aryl or cycloalkyl and R2 and R9 furthermore may be hydrogen with the exception of 2-(2-hydroxyethylamino)-6-benzylamino-9-methylpurine.

Owner:UNIV DE POITIERS +1

Method for restoring battery capacity in situ

ActiveCN103035963ASolve the problem of recovery and regenerationRestore capacitySecondary cells servicing/maintenancePhysical chemistryCharge discharge

The invention relates to the field of battery application and energy restoration, in particular to a method for restoring battery capacity in situ. The method comprises the following steps: after a long-term charge-discharge use, taking positive electrolyte of a vanadium battery with a fading capacity as a raw material, adding an organic, inorganic or composite reductant into the positive electrolyte, and performing reduction reaction on the reductant and pentavalent vanadium ions in the positive electrolyte so as to reduce the pentavalent vanadium ions into tetravalent vanadium ions and restore the battery capacity. By adding a proper proportion of organic-inorganic reductant into the positive electrolyte, the capacity fading problem in a running process of the battery is solved and recycle of the battery electrolyte is achieved; and the method is simple in process, easy to operate, easy to obtain the raw material and obvious in effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

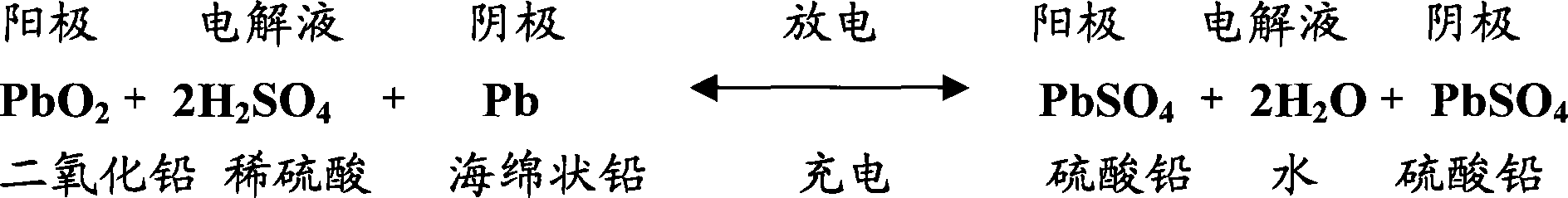

Sulfuration restoration agent for lead acid battery

ActiveCN101093905ASmall self-dischargePromote decompositionLead-acid accumulatorsWaste accumulators reclaimingElectrochemical responseLead sulfate

Formula of the restoring agent includes following materials and mass percent: potassium sulfate 3-9%; sodium sulfate 4-8%; potassium bicarbonate 0.5-2%; potassium carbonate 1-3%; sodium silicate 0.2-0.8%; potassium acid phthalate 0.015-0.06%; aluminum powder 0.005-0.02 etc and deionized water as surplus. Using quite active metallic ions in the restoring agent to replace quite inert lead ions in crystal of lead sulfate, the method ionizes and hydrolyzes lead sulfate to the sulfate ions and lead ions, which take part in normal electrochemical reaction of lead acid battery again. At the same time, matter in the restoring agent together with quite active metallic ions, which accomplishes replacement, forms stable salt so as to reduce self-discharge inside battery caused by harmful metal ions to retain capacity for long time. The invention restores capacity of accumulator effectively, and lightens environmental pollution from old accumulators.

Owner:苏州泽元科技有限责任公司

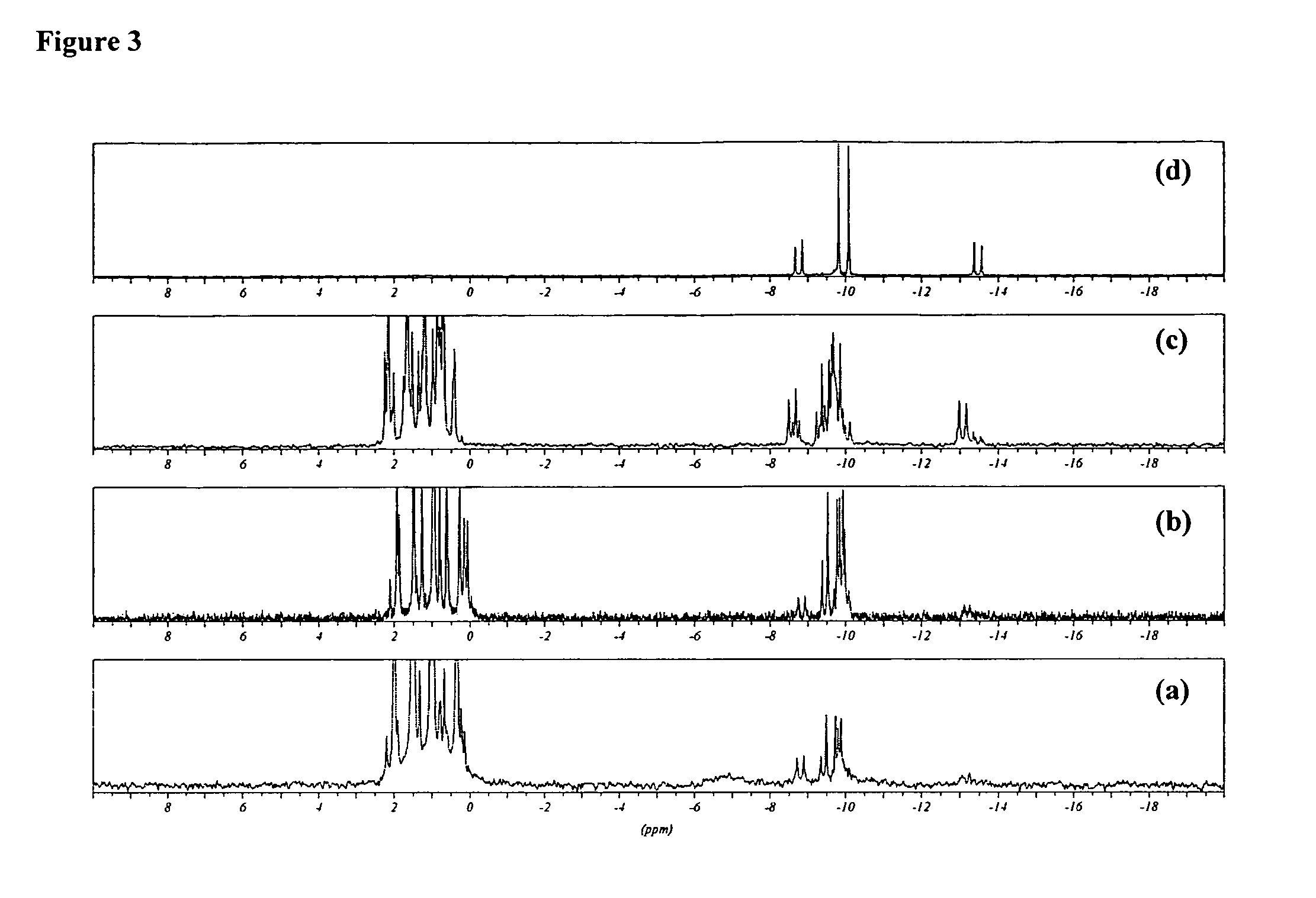

Inositol pyrophosphates, and methods of use thereof

InactiveUS20070207986A1Low affinityRestore capacityBiocideMammal material medical ingredientsPyrophosphateRed Cell

The present invention comprises compounds, compositions thereof, and methods capable of delivering modified inositol hexaphosphate (IHP) comprising an internal pyrophosphate ring to the cytoplasm of mammalian cells. In certain embodiments, the present invention relates to compounds, compositions thereof, and methods that enhance the ability of mammalian red blood cells to deliver oxygen, by delivering IHP to the cytoplasm of the red blood cells.

Owner:NORMOXYS

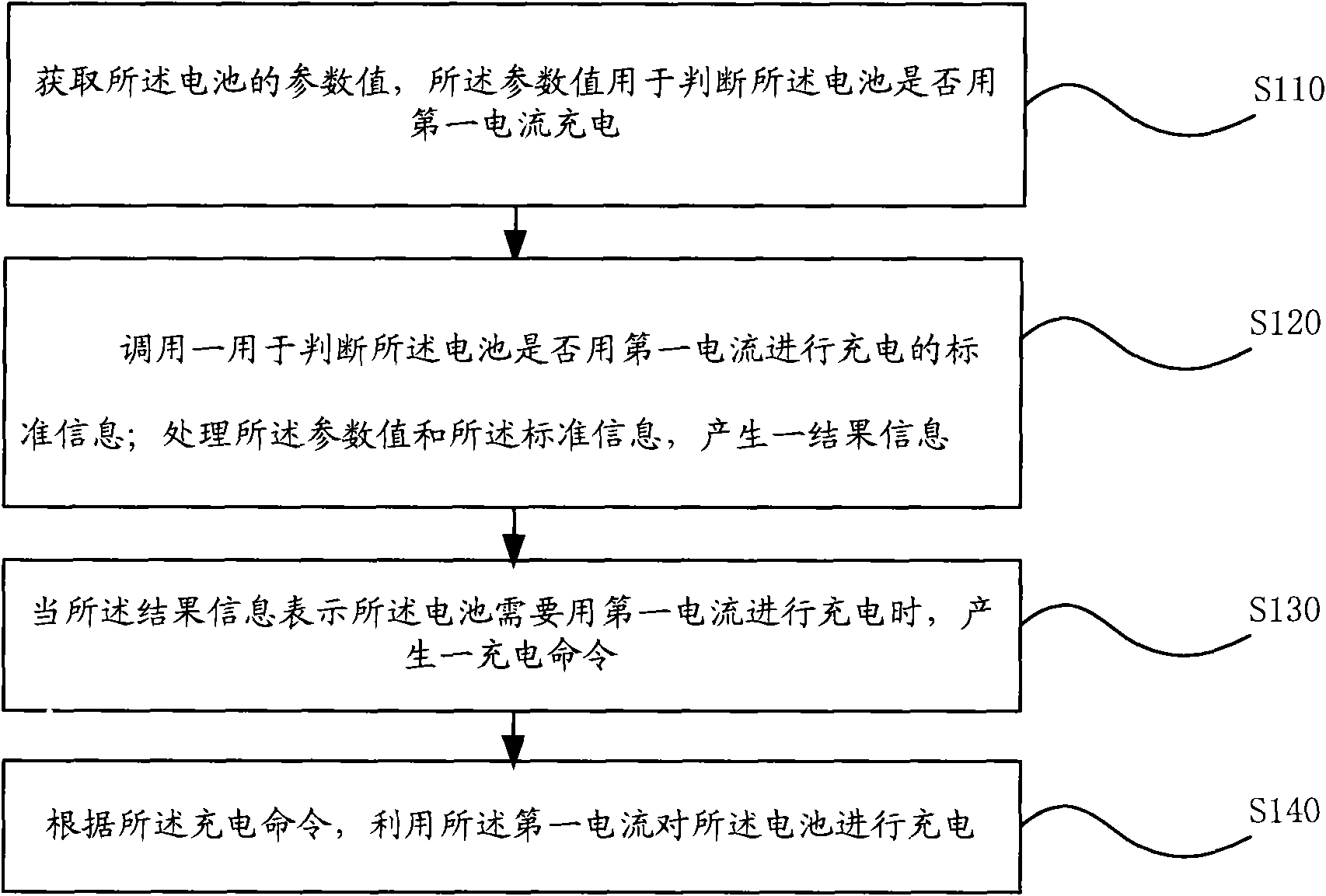

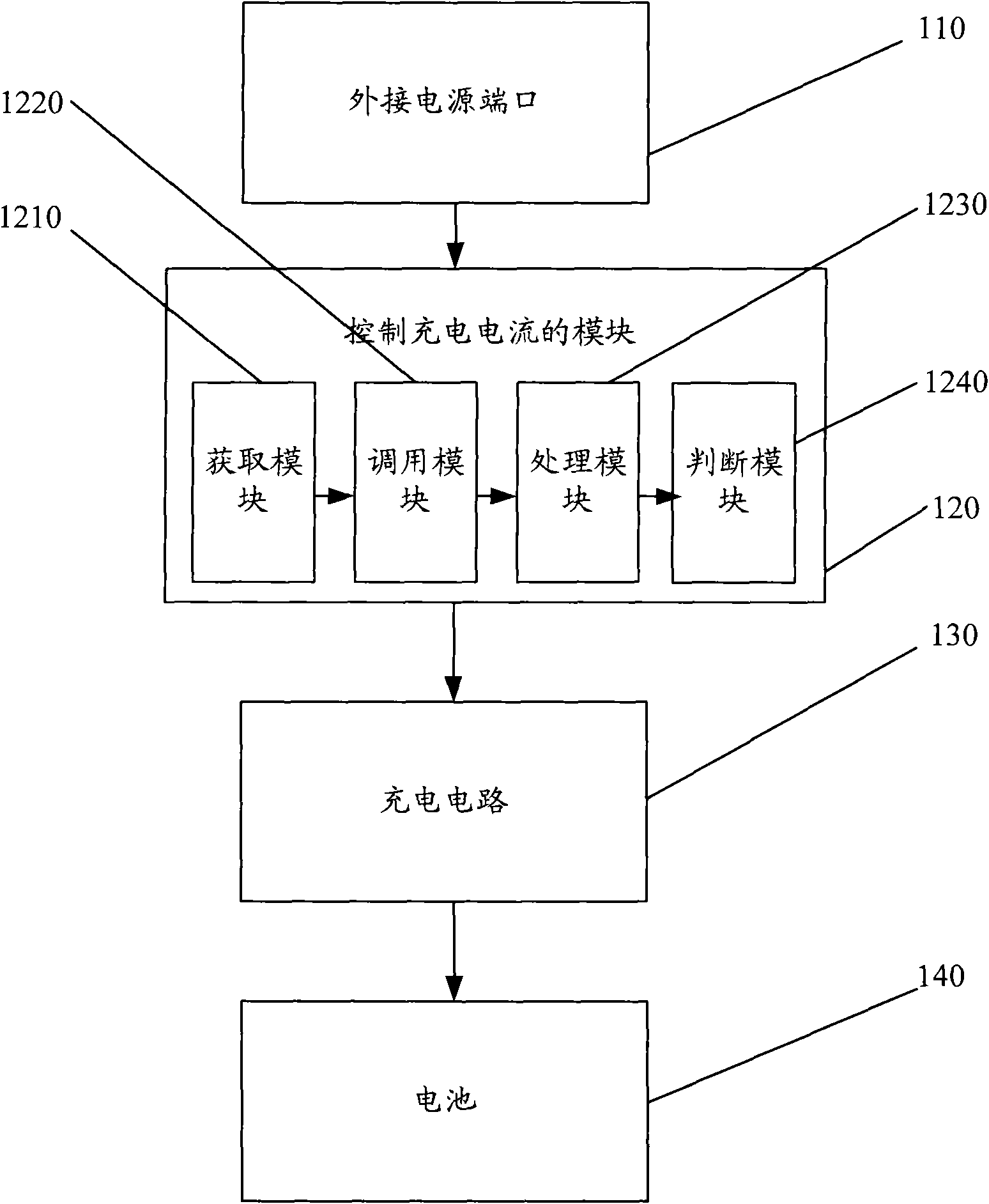

Battery charging method, portable mobile equipment and notebook computer

ActiveCN101685981AAchieve capacity reductionGuaranteed time costBatteries circuit arrangementsVolume/mass flow measurementBattery chargeElectrical battery

The invention discloses a battery charging method, portable mobile equipment and a notebook computer. The battery charging method comprises the following steps: the battery parameter value which is used for judging whether a battery is charged by a first current is acquired; the standard information which is used for judging whether the battery is charged by the first current is modulated; the battery parameter value and the standard information are processed, and processing result information is generated; a battery charging command is generated when the processing result information shows that the battery needs to be charged by the first current; and the battery is charged by the first current according to the battery charging command. The first current is less than the battery chargingcurrent which corresponds to the preset standard of the battery. The invention solves the problem that the capacity of the rechargeable battery is reduced in the rechargeable battery charging process.

Owner:LENOVO (BEIJING) CO LTD

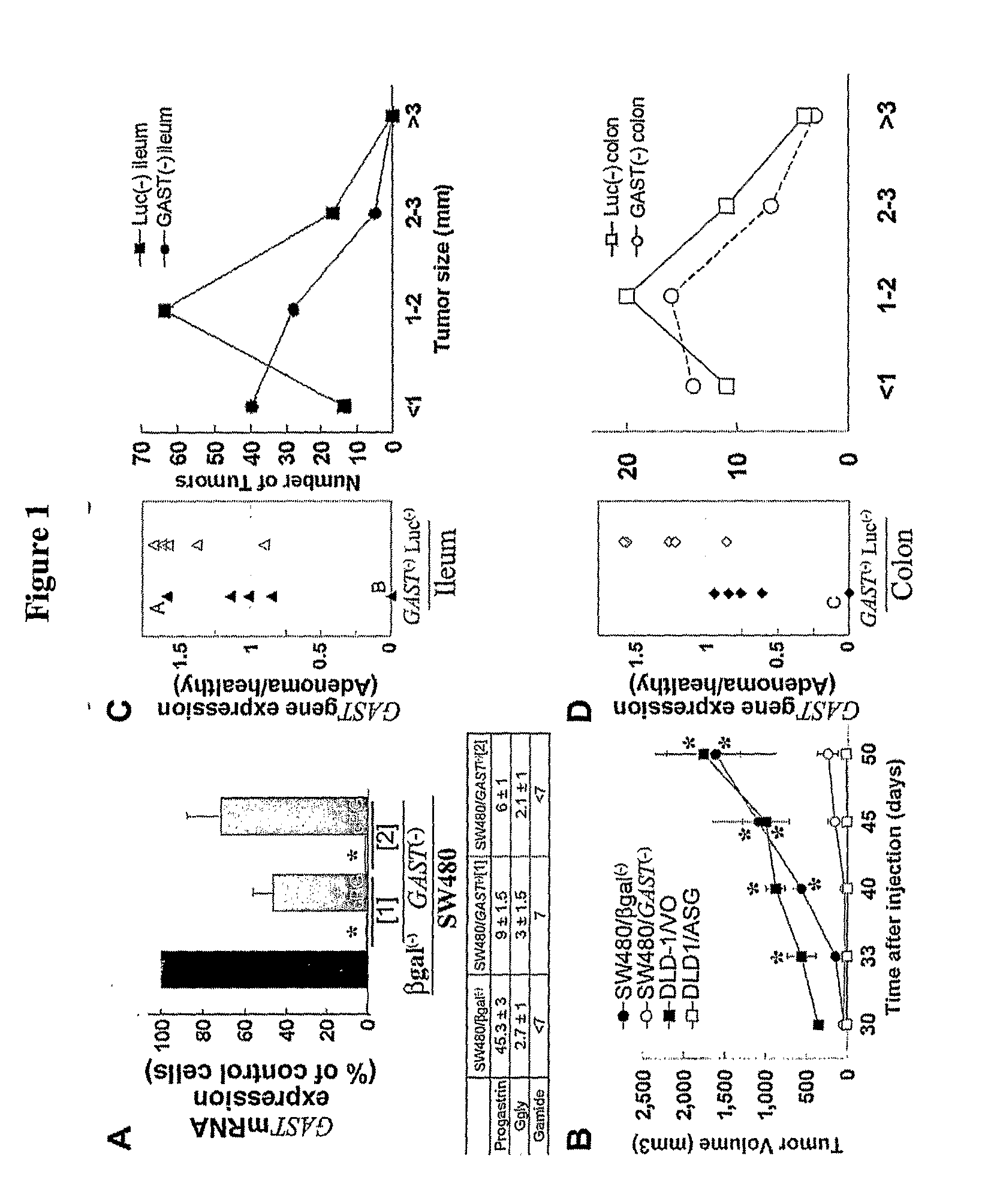

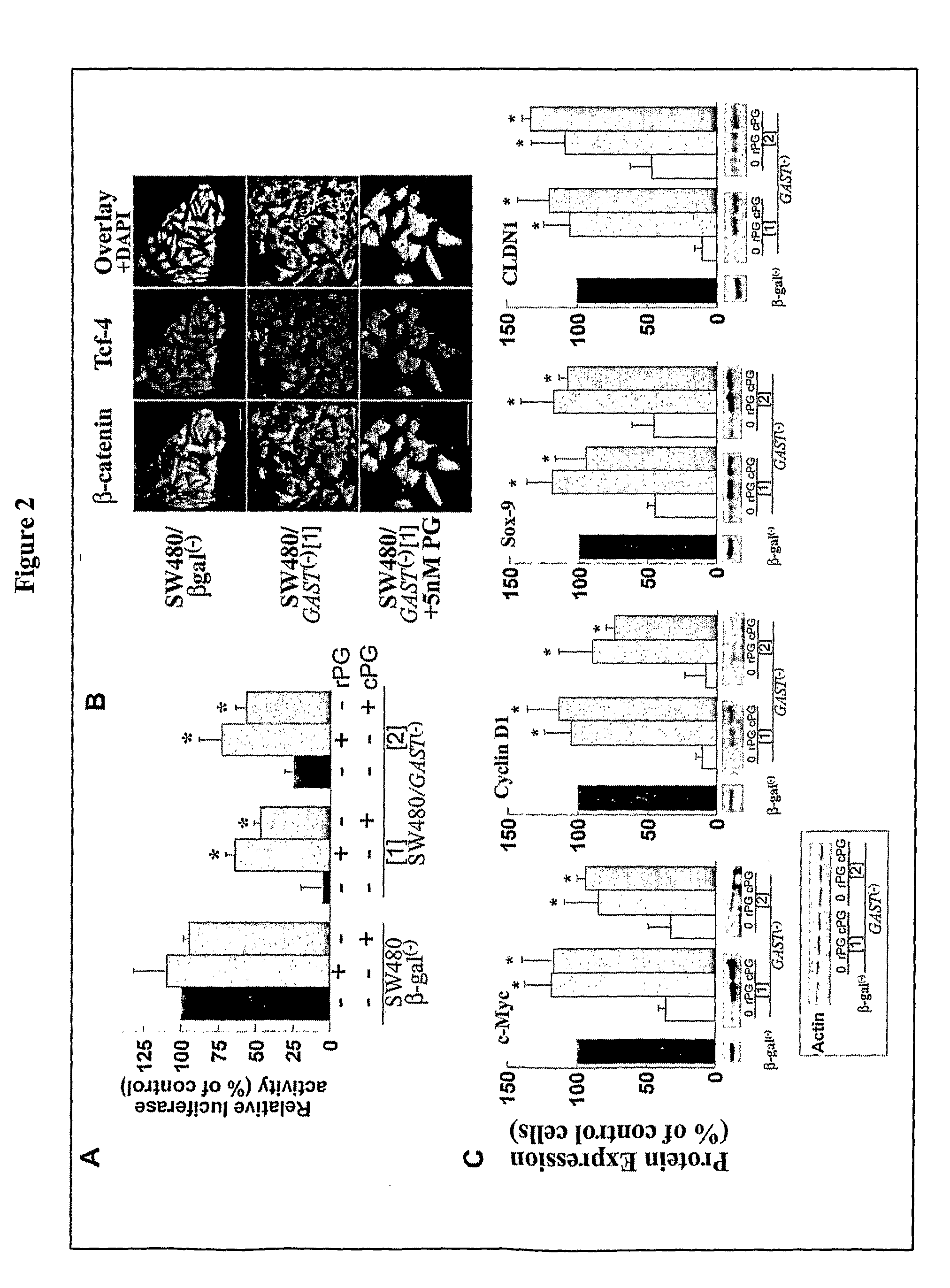

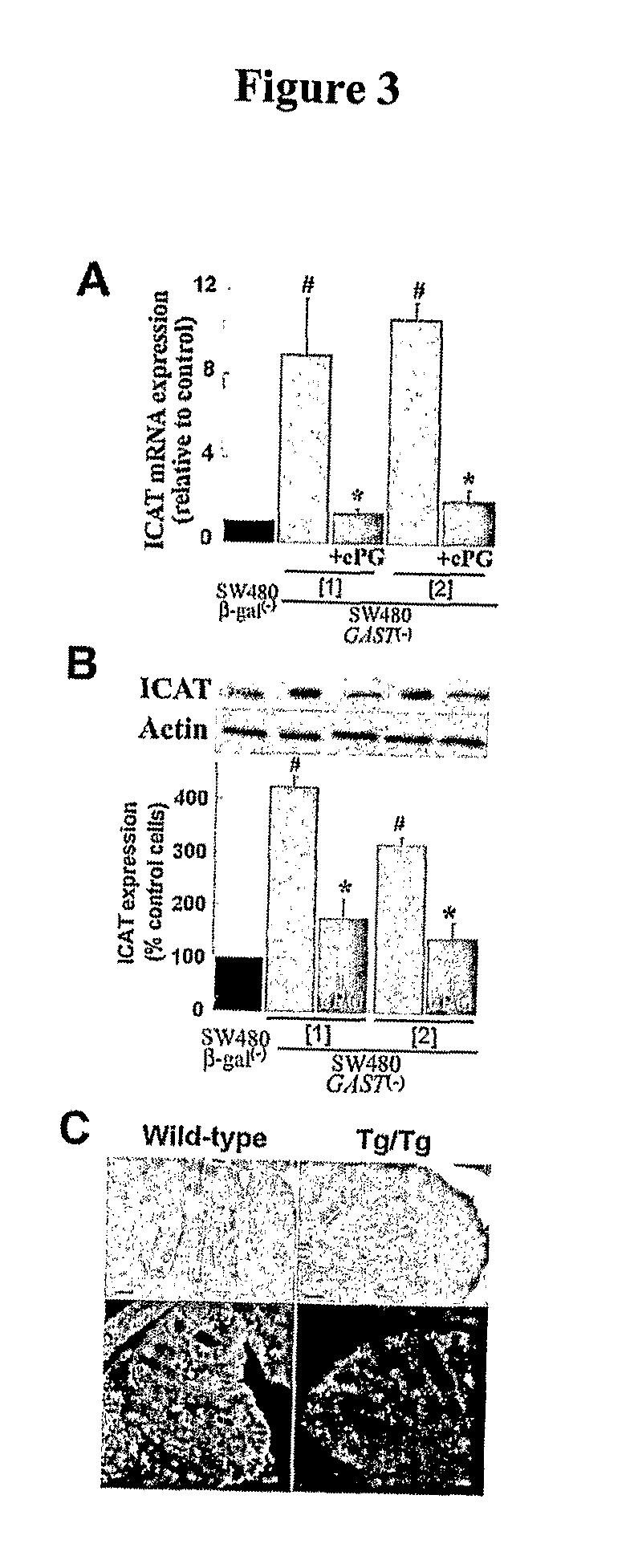

Inhibitors of progastrin-induced repression of icat for treating and/or preventing colorectal cancer, adenomatous polyposis or metastasis displaying progastrin-secreting cells and cells in which the beta-catenin/tcf-mediated transcriptional pathway is constitutively active

InactiveUS20100209426A1Restore capacityPromote migrationSugar derivativesMicrobiological testing/measurementGastrin-Secreting CellsConstitutively active

The present invention relates to inhibitors of progastrin induced repression of ICAT for treating and / or preventing colorectal cancer, adenomatous polyposis or metastasis displaying progastrin-secreting cells and cells in which the beta-catenin / Tcf-4-mediated transcriptional pathway is constitutively active.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

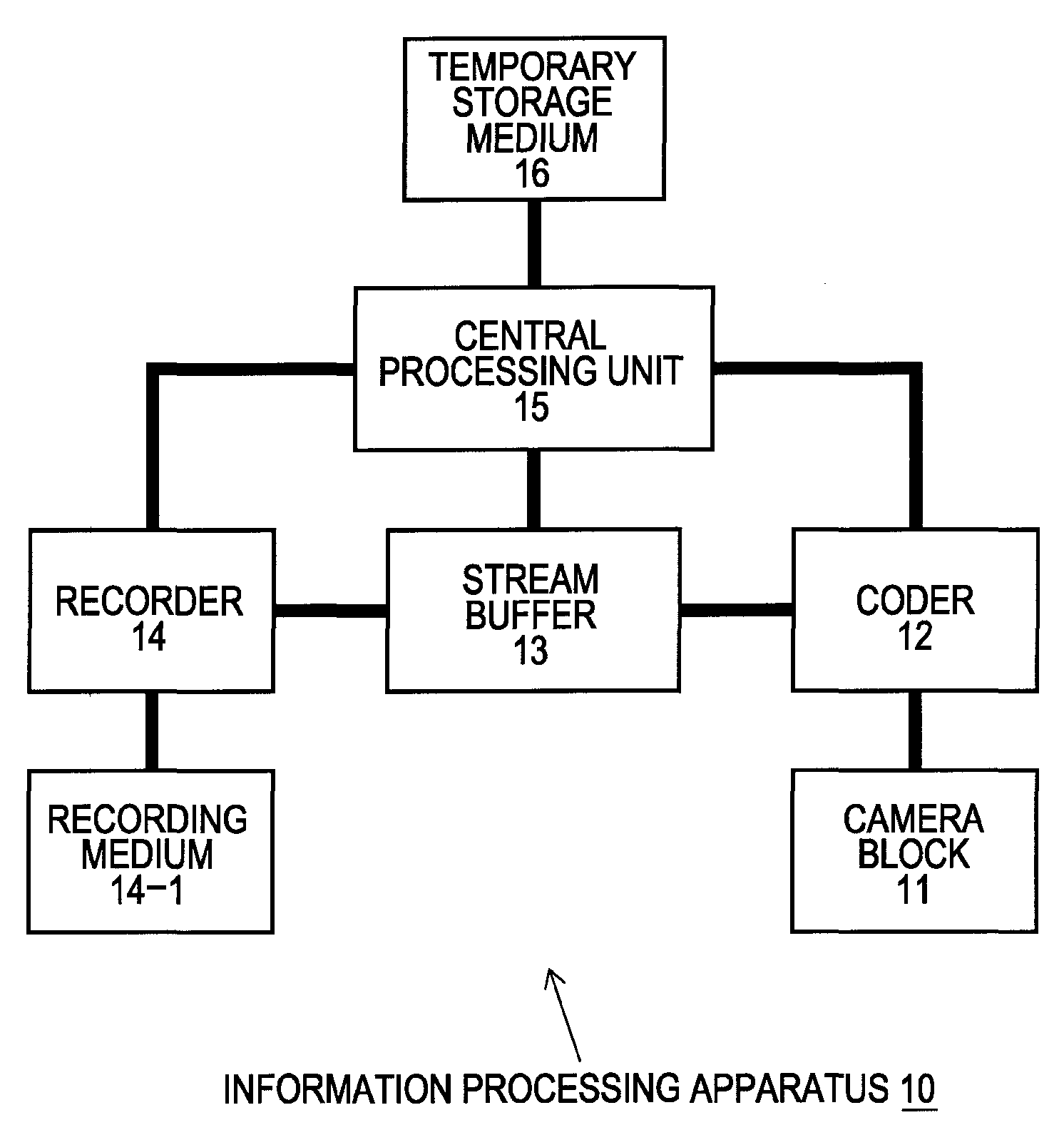

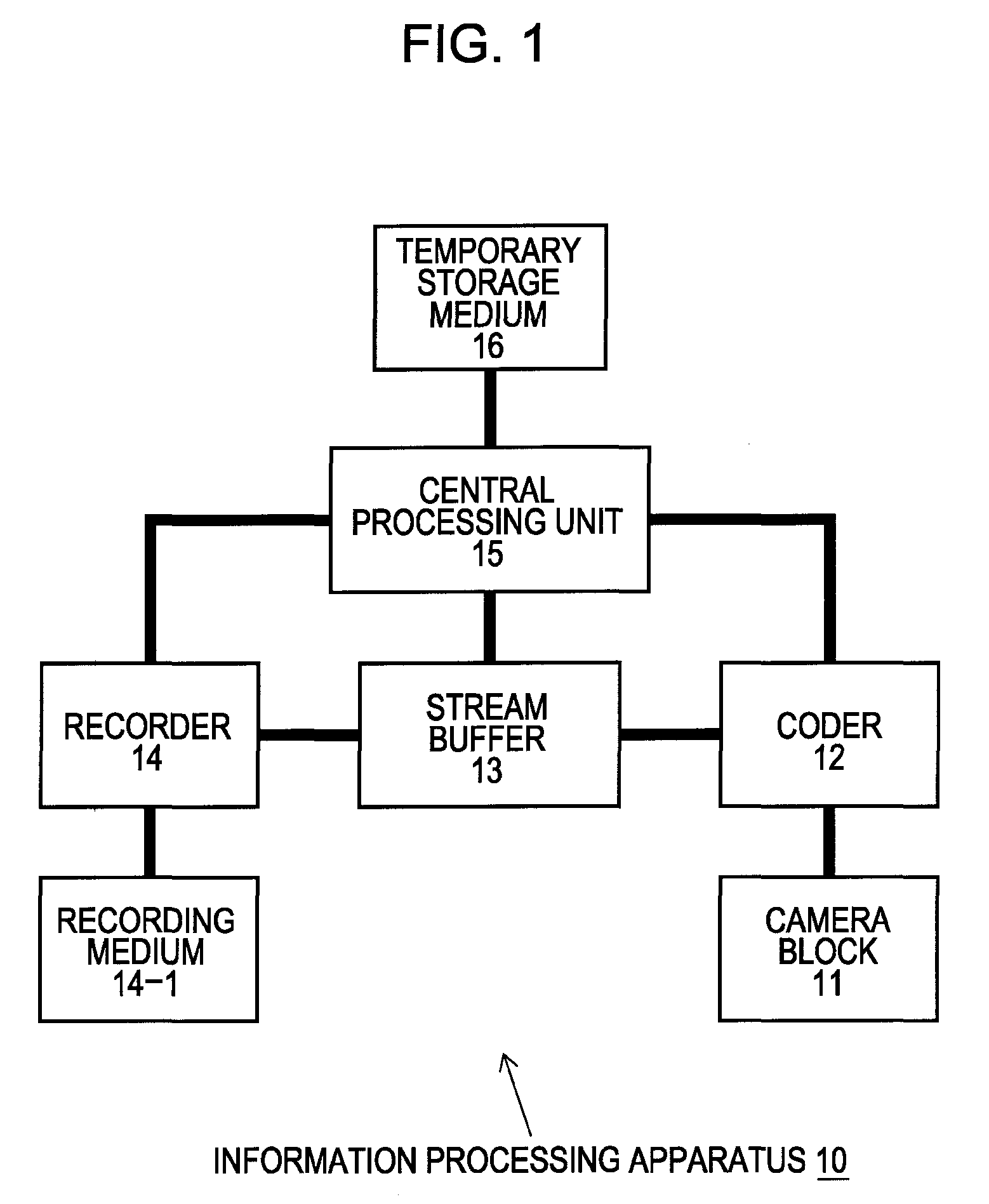

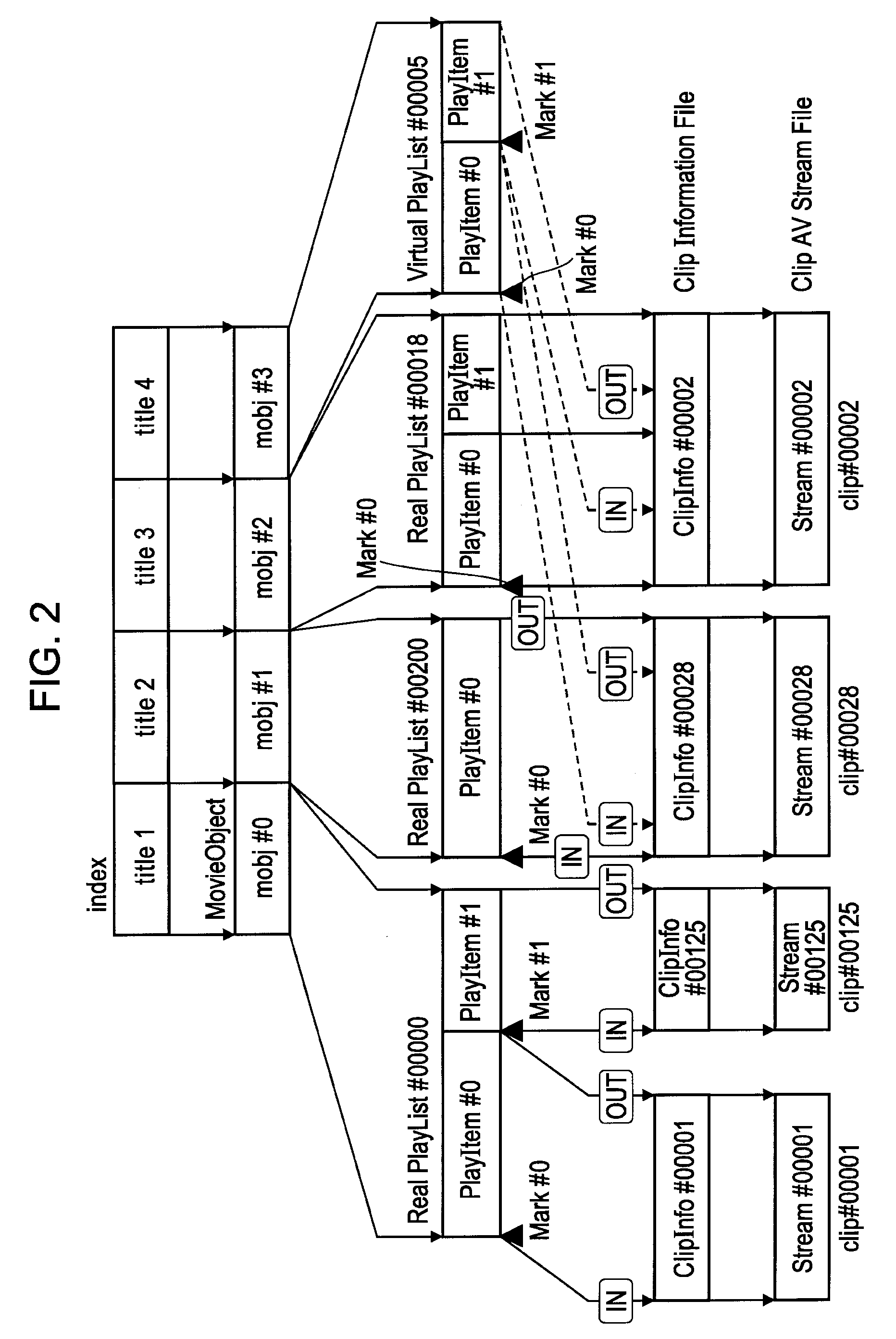

Information processing apparatus, information processing method, and computer program

InactiveUS20090129738A1Superior computer program.Restore capacityTelevision system detailsElectronic editing digitised analogue information signalsInformation processingComputer graphics (images)

An AV stream stored on a recording medium is edited in such a manner as to not conflict with a play-only standard format.When an intermediate portion of a stream file is to be deleted, the original clip AV stream file is divided at a deletion section, and a single ATC is provided for each file. When a play item is to be deleted in an intermediate portion of a playlist, the setting of seamless play with the immediately preceding play item is released in the final play item on the forward side, which is left after deletion is performed, and the setting of seamless play with the immediately preceding play item is released in the clip information file at the beginning on the backward side, which is left after deletion is performed.

Owner:SONY CORP

Intelligent maintenance method for low-voltage accumulator of new energy automobile

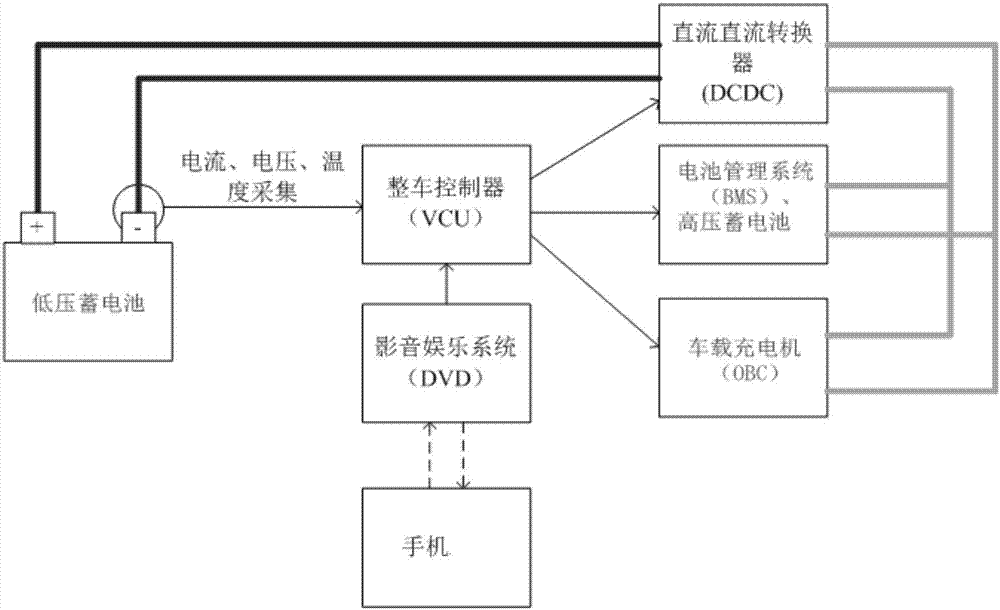

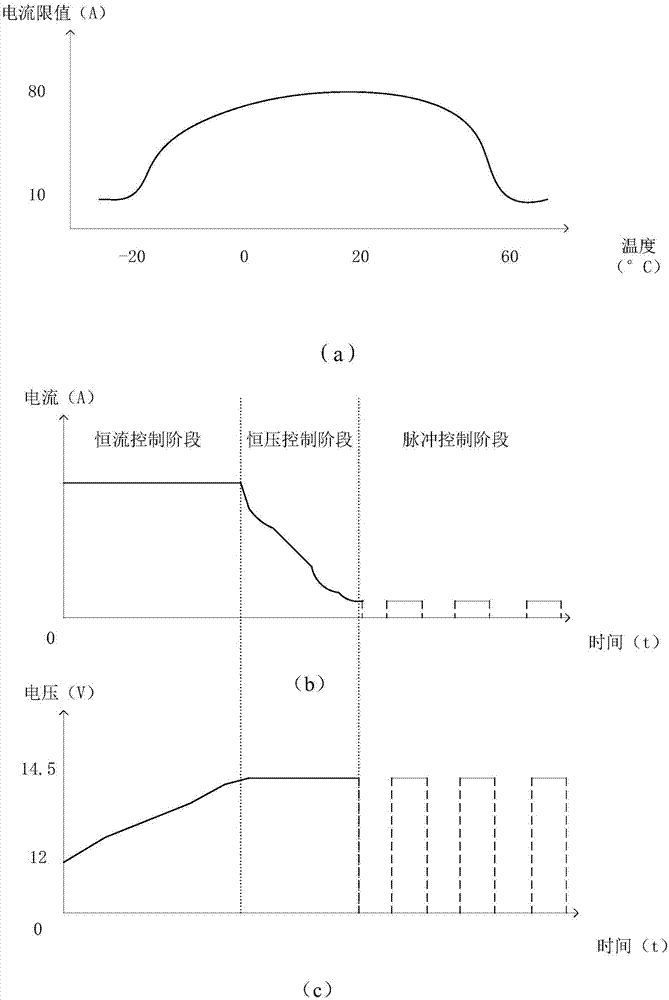

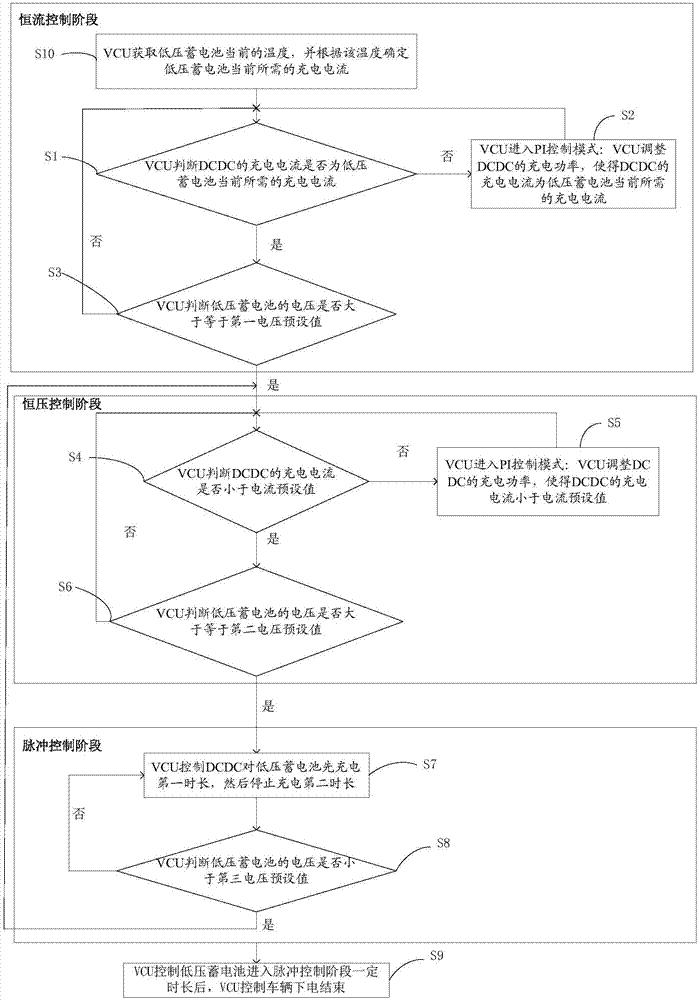

ActiveCN107264435AEffective monitoringAvoid damagePropulsion by batteries/cellsVehicular energy storageElectricityPulse control

The invention discloses an intelligent maintenance method for a low-voltage accumulator of a new energy automobile and belongs to the technical field of electric automobiles. The intelligent maintenance method for the low-voltage accumulator of the new energy automobile comprises an intelligent charging maintenance process, specifically, a VCU controls the low-voltage accumulator to enter the intelligent charging maintenance process when detecting the situation that a user conducts charging operation on the automobile, wherein the intelligent charging maintenance process sequentially comprises a constant current control stage, a constant voltage control stage and a pulse control stage. According to the intelligent maintenance method, under the condition that normal working of the low-voltage accumulator is guaranteed, capacity fading of the low-voltage accumulator can be slow down while it can be guaranteed that the low-voltage accumulator is not lack of electricity, and the service life of the low-voltage accumulator is prolonged.

Owner:天津中科华誉科技有限公司

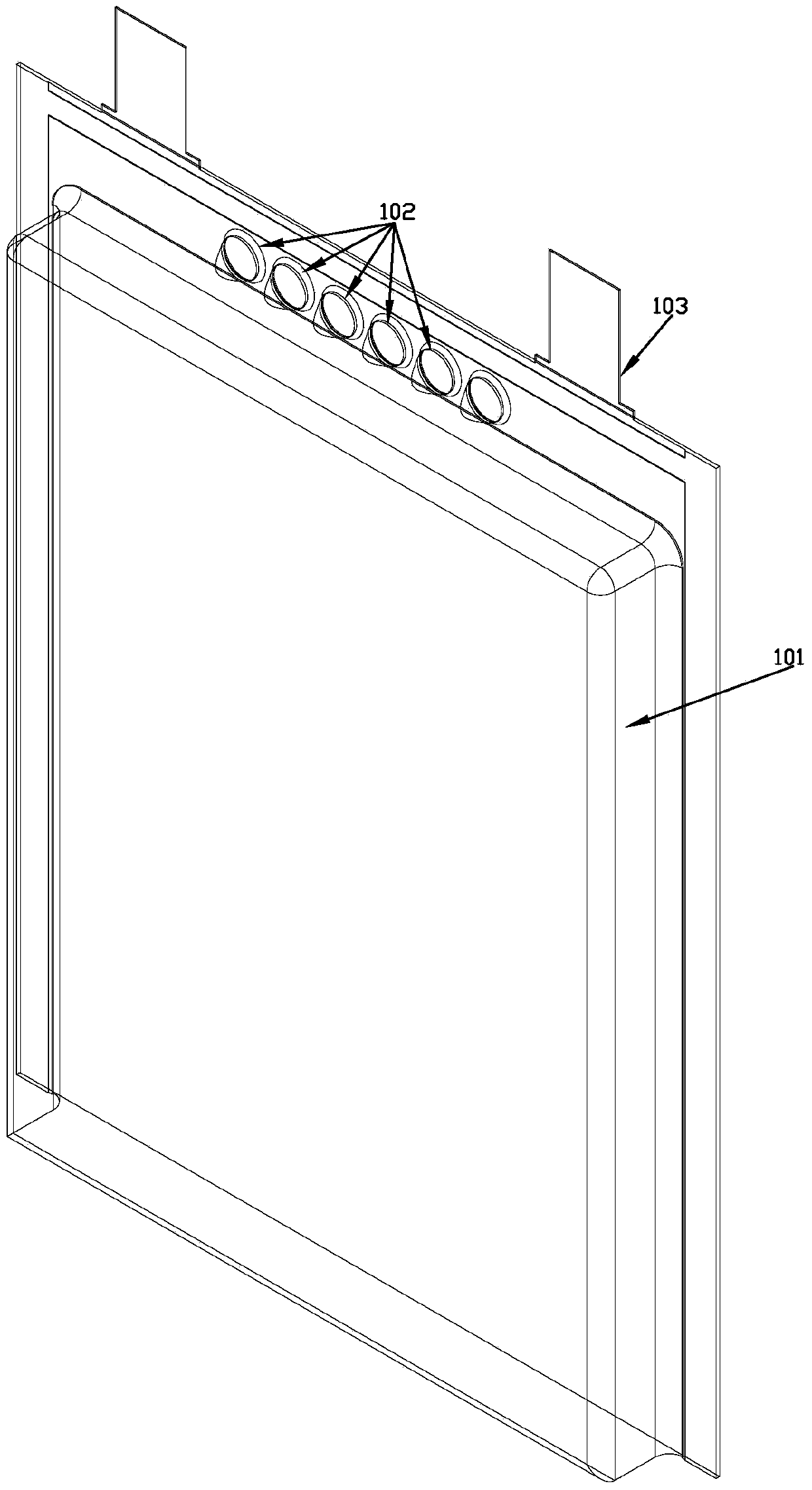

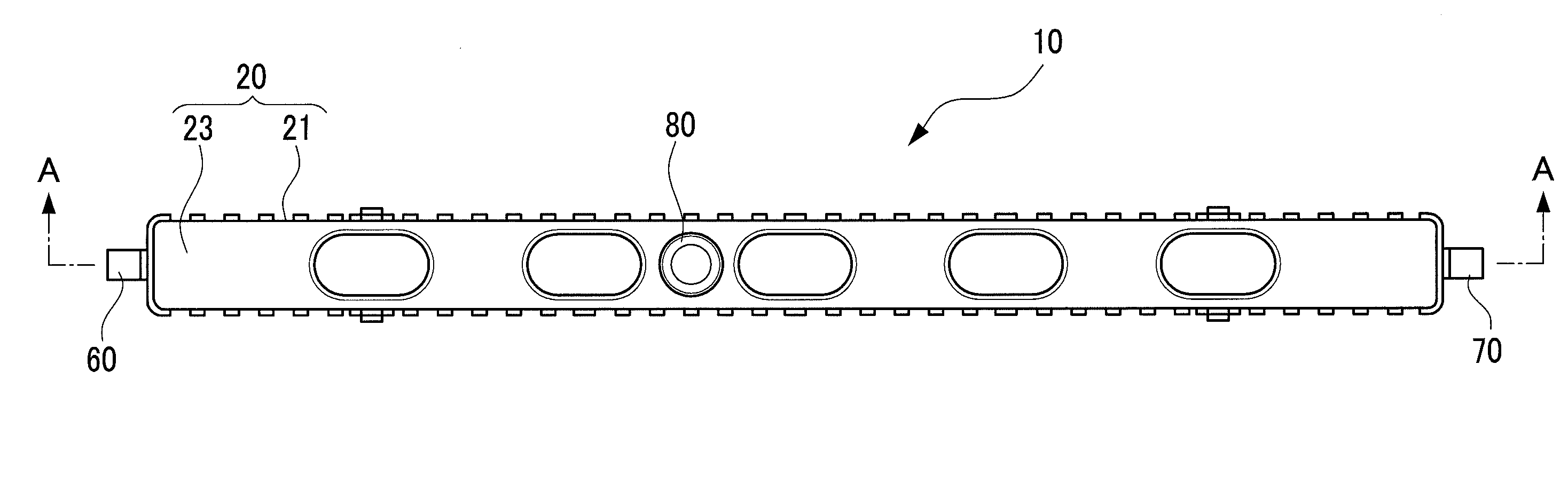

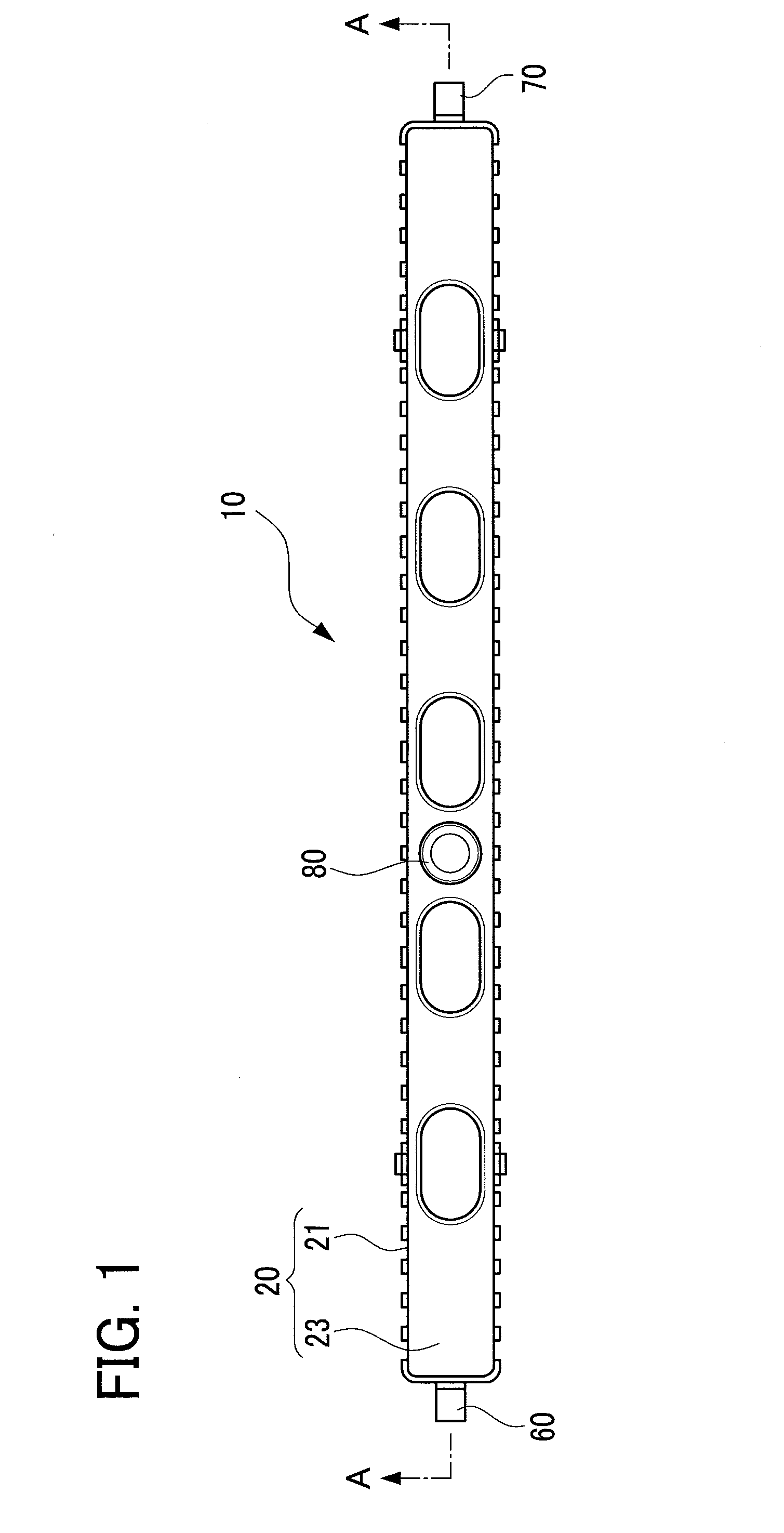

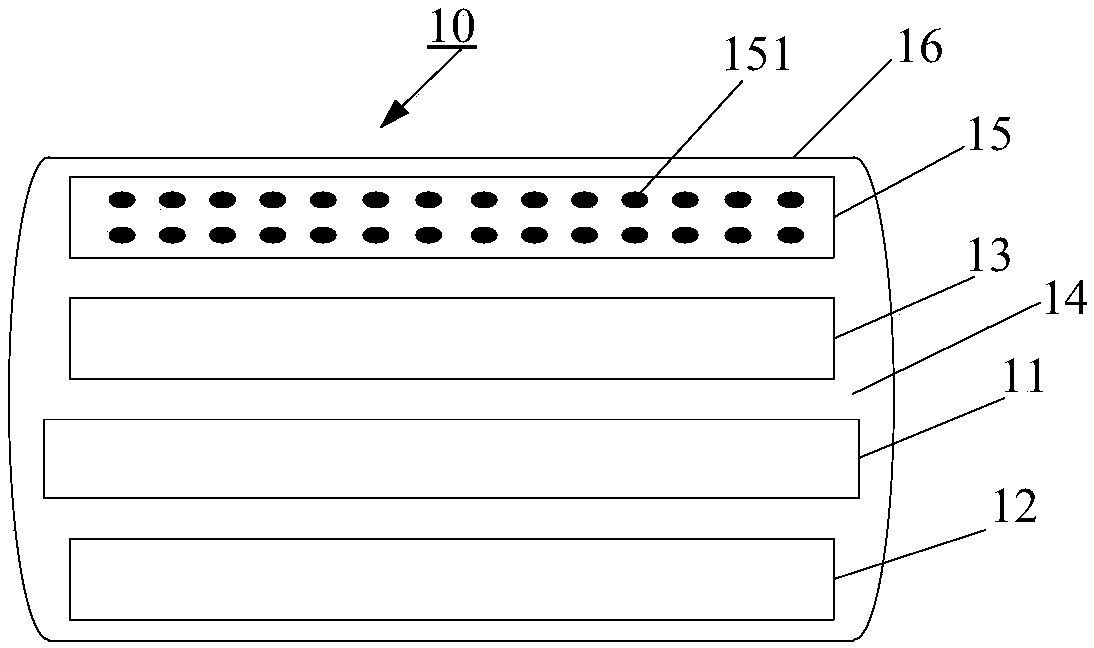

Lithium ion battery with capsule

InactiveCN103811711AImprove cycle performanceRestore capacityCell component detailsSecondary cells servicing/maintenanceEngineeringLithium-ion battery

The invention relates to the field of lithium ion batteries and discloses a lithium ion battery with a capsule. The lithium ion battery comprises a battery core body and electrolyte which are packaged in a shell, wherein the battery core body comprises separation membranes, positive pole pieces and negative pole pieces; each separation membrane is arranged between any positive pole piece and any negative pole piece; an inner cavity of the shell is fully filled with the electrolyte; the electrolyte immerses the battery core body and penetrates into the battery core body; second electrolyte is packaged in the capsule and the capsule is fixed inside the shell and is located outside the battery core body.

Owner:SHENZHEN GREPOW BATTERY CO LTD

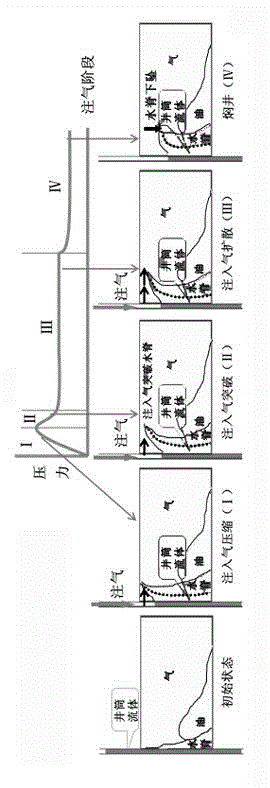

Method for removing sandstone condensate gas reservoir water lock through nitrogen injection

InactiveCN104453806AImprove seepage capacityEnhanced overall recoveryFluid removalSoil scienceGas phase

The invention relates to a method for removing a sandstone condensate gas reservoir water lock through nitrogen injection. The method includes the steps of the nitrogen injection initial stage, the nitrogen injection breakthrough stage, the nitrogen injection diffusion stage and the closing-in stage, wherein at the nitrogen injection initial stage, flow in a shaft and a water crest of a near-shaft region are gradually compressed through the nitrogen and are displaced towards the periphery of a well, and the injected nitrogen tongues along the top of a reservoir stratum; at the nitrogen injection breakthrough stage, the nitrogen is ceaselessly injected, and after the difference value between the pressure at the bottom of the well and the pressure of the stratum during gas injection is larger than the pressure of the water lock, the nitrogen is injected to break through a water lock barrier; at the nitrogen injection diffusion stage, the nitrogen is ceaselessly injected, the water crest on the periphery of the well is dispersed to a farther place, and the gas-phase seepage capacity is improved; at the closing-in stage, the nitrogen injection stops, the water crest is further compressed to fall, and the gas-phase seepage capacity is further improved. By injecting the high-pressure nitrogen to displace the water of the near-shaft region, communication is achieved for natural gas at a far end, and the gas-phase seepage capacity is improved; meanwhile, through the high compressibility and expansibility of the nitrogen, the good emission assisting, displacing and gas lifting effects are achieved when energy is released, and finally the gas well yield is recovered and the condensate gas reservoir recovery efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Lead-acid storage battery vulcanization repair process

InactiveCN101834321ARestore capacityPromote softening and decompositionSecondary cells servicing/maintenanceNameplate capacityVulcanization

The invention discloses a lead-acid storage battery vulcanization repair process, which is characterized by comprising the following steps: performing battery vulcanization repair by steps of storage battery preparation, water and power supply, primary discharge test, assembly, repair solution making, repair, secondary discharge test, delivery and clearing up. The lead-acid storage battery vulcanization repair process of the invention can effective promote the softening and decomposition of lead sulfate crystals and restore the capacity of the lead-acid storage battery considerably. The process can restore over 96 percent of used storage batteries and make the capacity of the storage batteries close to the rated capacity of the storage batteries and the service life of the storage batteries to design service life. The repair process avoids causing damages to the internal physical and electrochemical structures of the lead-acid storage battery, reduces the environmental pollution caused by waste storage batteries, saves resources, energy resources and is low in carbon; due to high maneuverability, the process is easy to promote; and with high efficiency and low cost, the process isexpected to bring great economic benefits to the society.

Owner:CHANGZHOU YINGNAITE ENERGY S&T

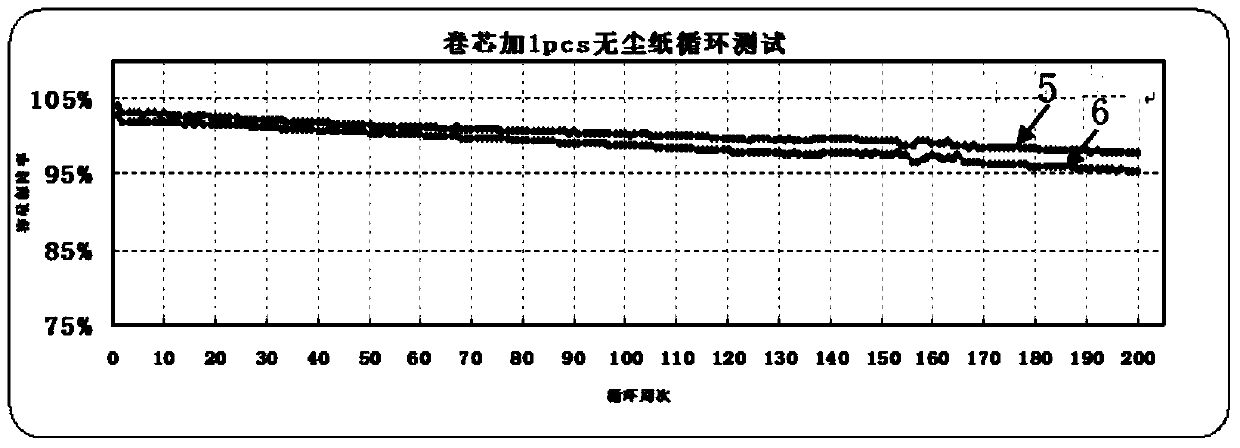

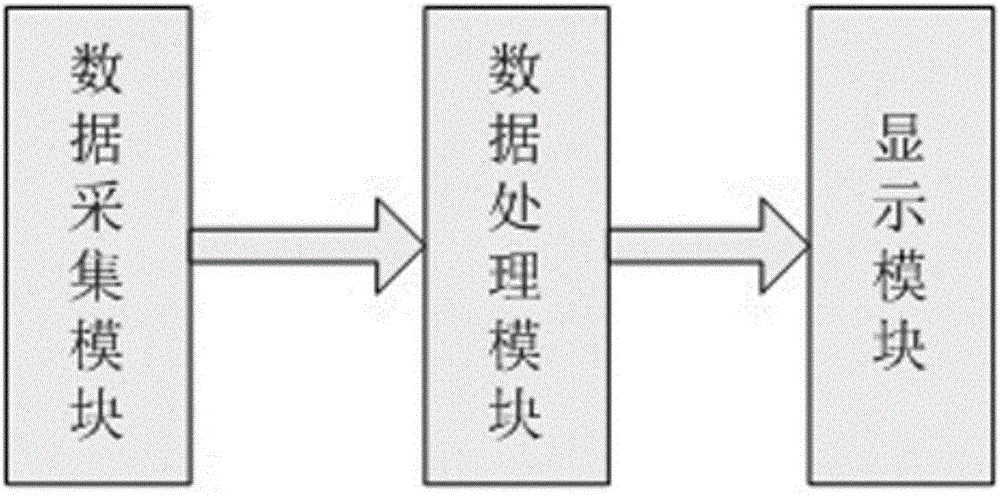

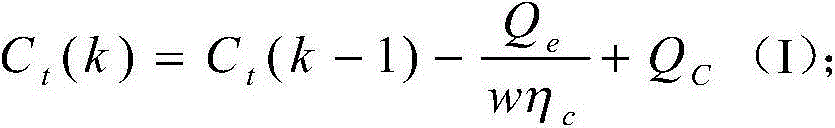

Lead-acid battery residual energy on-line measuring system

ActiveCN105203968AImprove accuracyRestore capacityElectrical testingElectrical batteryData acquisition

The invention discloses a lead-acid battery residual energy on-line measuring system which comprises a data acquisition module, a data processing module and a display module which are connected in sequence, wherein a current sensor is arranged in the data acquisition module, and is used for conducting real-time monitoring on charge-discharge current of a battery; the data processing module is used for conducting time integral of signals collected by the current sensor to acquire the real-time discharge quantity of the battery. The measuring system adopts the depth of charge (DOC) as the parameter for reflecting the charged state of the battery, and the parameter is calculated by adopting the actual capacity of the battery but not the non-nominal capacity, and can better reflect the actual condition of the battery; besides, the measuring system can periodically conduct deep discharge on the battery, the capacity can be restored, the Ct value can be rectified, and the accuracy of the measuring system can be improved.

Owner:NANJING DELTO TECH

Fracturing production-increasing method for 3.5-inch slim hole sidetracked well in ultra-low permeability oil reservoir

The invention discloses a fracturing production-increasing method for a 3.5-inch slim hole sidetracked well in a ultra-low permeability oil reservoir. A strong-washing interval is quickly recognized though a logging response value of the ultra-low permeability oil reservoir, a production-increasing potential residual oil enrichment segment suitable for being transformed is divided by combining thereservoir interlayer stress characteristics, crakes are controlled by small-scale perforation fracturing to extend in the potential segment, the water breakthrough risk of an oil well is reduced by combining a water shutoff material, and finally, the fracturing production-increasing method for the 3.5-inch slim hole sidetracked well in the ultra-low permeability oil reservoir is formed. It can beensured the sidetracked well is precisely transformed in the longitudinal and transverse directions of the reservoir, reservoir residual oil is utilized maximally, by controlling the perforation thickness, controlling the construction scale and supporting key materials, the comprehensive water content is decreased, the single well output is increased, and the oil field production capacity is recovered.

Owner:PETROCHINA CO LTD

Method for restoring battery capacity, method for restoring battery pack capacity, device for restoring battery capacity, and device for restoring battery pack capacity

ActiveUS20160020495A1Restore discharge capacitySuppress mutationElectrolyte/reactants regenerationVent arrangementsEngineeringSafety valve

This method for restoring battery capacity is provided with an oxygen-generating / exhausting step for charging a nickel-metal-hydride storage battery, causing the generation of oxygen gas in a positive electrode, opening a safety valve device, and discharging at least a portion of the oxygen gas through the safety valve device to the outside of the battery. The battery temperature when starting the step is in the range of −30 to 10° C. and the SOC is in the range of (30-Ta) to 100%, or the battery temperature (Ta) is in the range of 10 to 50° C. and the SOC is in the range of 20-100%.

Owner:PANASONIC EV ENERGY CO LTD +1

Temporary plugging and acidization method for multiple seams among sections of horizontal wells

The invention provides a temporary plugging and acidization method for multiple seams among sections of horizontal wells. The temporary plugging and acidization method for the multiple seams among thesections of the horizontal wells comprises the following specific steps: 1) selecting a target well from the horizontal wells of which the daily fluid production rate is smaller than 2 cubic meters or the daily oil production rate is smaller than 1 ton; 2) performing shut-in pressure survey; 3) treating a shaft; 4) lowering a drilling rig to the corresponding position; and 5) performing pressuretest before acidization construction, and constructing after the pressure test is qualified, and connecting a plurality of acid tanks to an acid feeding pipeline synchronously. The method can achievethe purpose that the capacity of the horizontal wells with low capacity caused by results such as formation plugging and low stratum energy is recovered. An alternative well is subjected to pressure test first, and if the stratum energy of the alternative well is kept lower, the stratum energy is first supplemented, and then through temporary plugging and acidization, the sweep area is increased,and the permeability of a low permeability zone is increased, and the capacity of low-yield horizontal wells can be recovered.

Owner:PETROCHINA CO LTD

Barium sulfate scale dissolving agent

PendingCN112745820ASolve solid phase cloggingSolve the problem of solid phase cloggingDrilling compositionActive agentEthyl group

The invention provides a barium sulfate scale dissolving agent which is composed of the following components: chelating agents: 8-12% of ethylenediamine tetraacetic acid, diethyl triamine pentaacetic acid and diethylene triamine penta (methylene phosphonic acid); solubilizers: sodium formate and sodium hydroxide with the content of 6-12%; the synergist comprises oxalic acid, salicylic acid, cinnamic acid and citric acid with the content of 0.4-1%; dispersing agents: polyethylene acid and polymethylacrylic acid with the content of 8-14%; corrosion inhibitor: hydroxyethylidene phosphonic acid with the content of 0.8-1.0%; surface active agent: alkylbenzene sulfonate, monoethanolamine and diethanolamine with the content of 3-5%; demulsifying agent: nonylphenol polyoxyethylene sodium sulfate with the content of 0.6-1.2%; a discharge aiding agent: perfluorononenyloxy sodium benzenesulfonate with the content of 1-2.4%; and clay stabilizer: epoxy chloropropane-dimethylamine condensation polymer with the content of 0.6-1.2%. The barium sulfate scale dissolving agent is suitable for dissolving barite solid-phase blockage in natural fractures, the scale dissolving rate reaches up to 97.19%, reservoir damage can be relieved, and the productivity of an oil and gas well can be recovered.

Owner:SOUTHWEST PETROLEUM UNIV

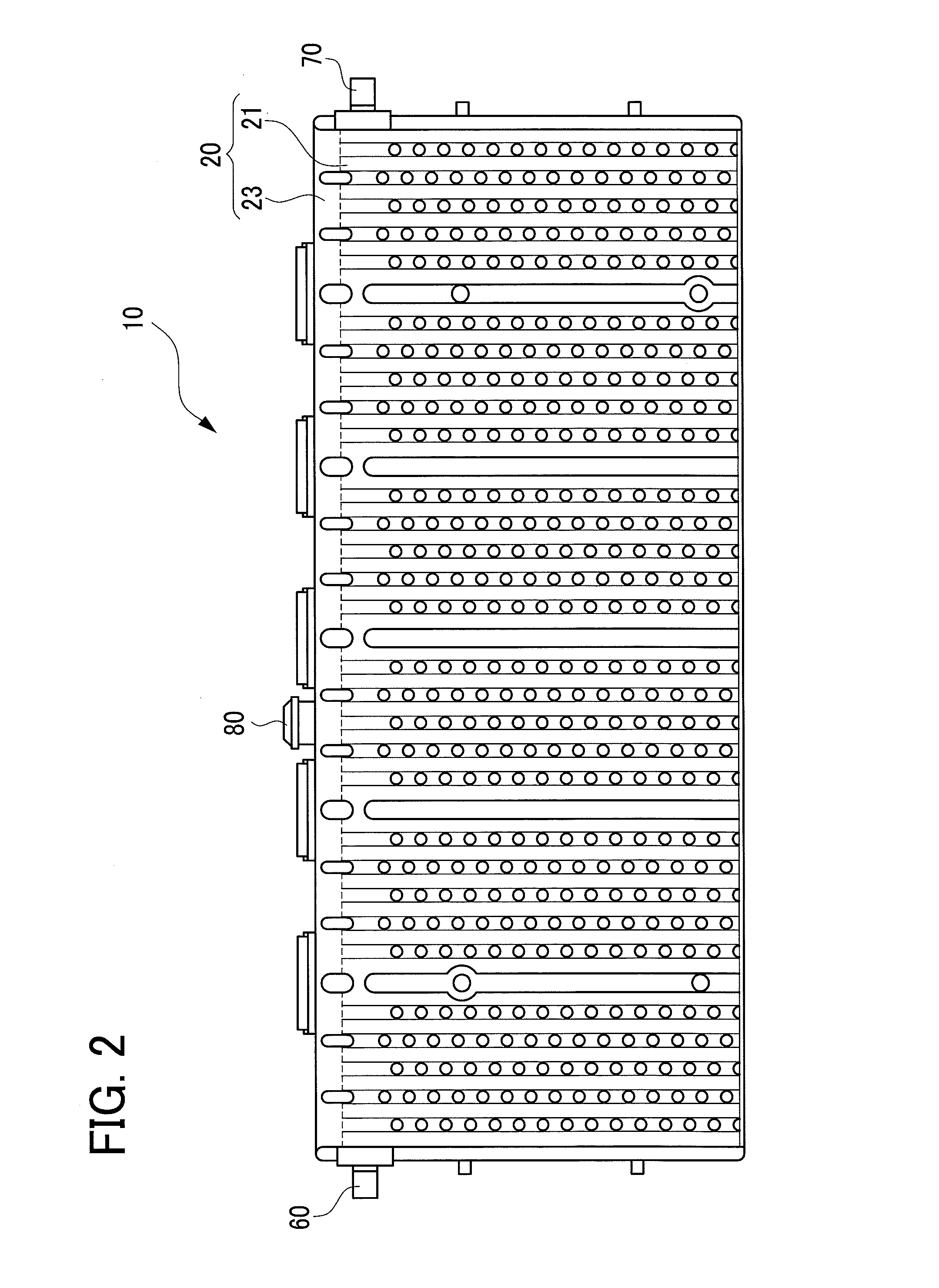

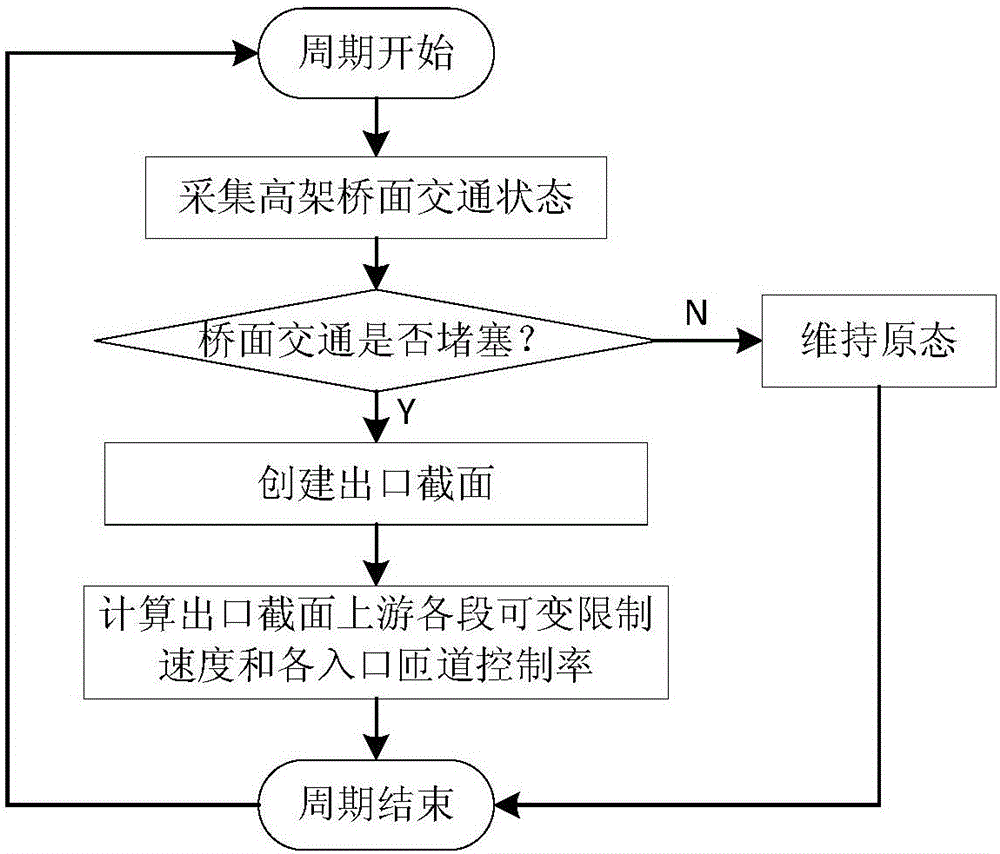

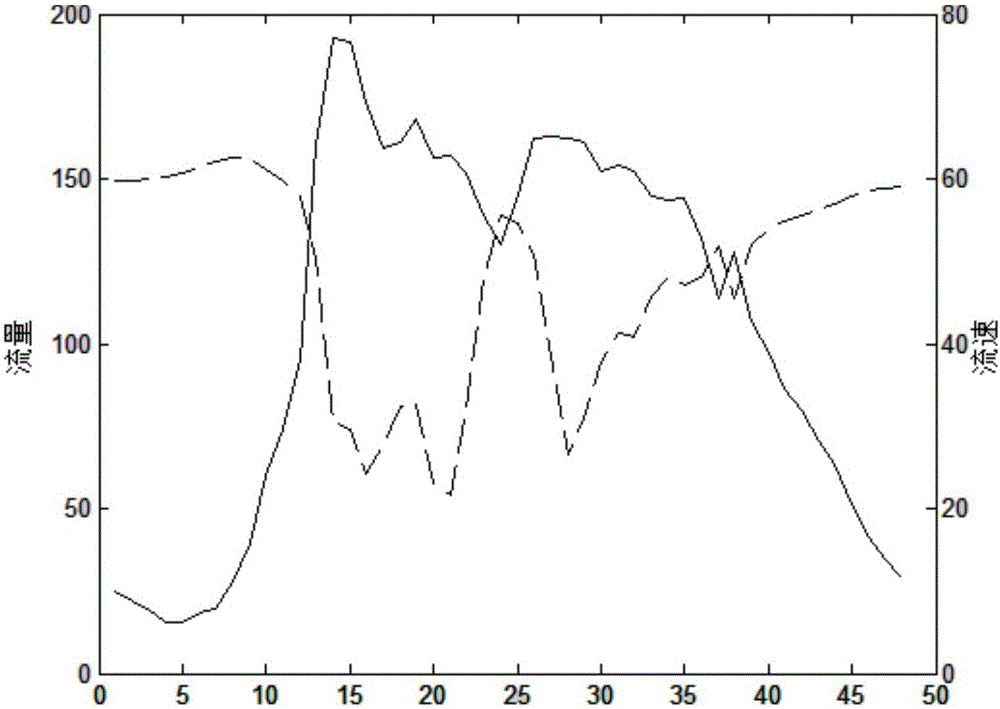

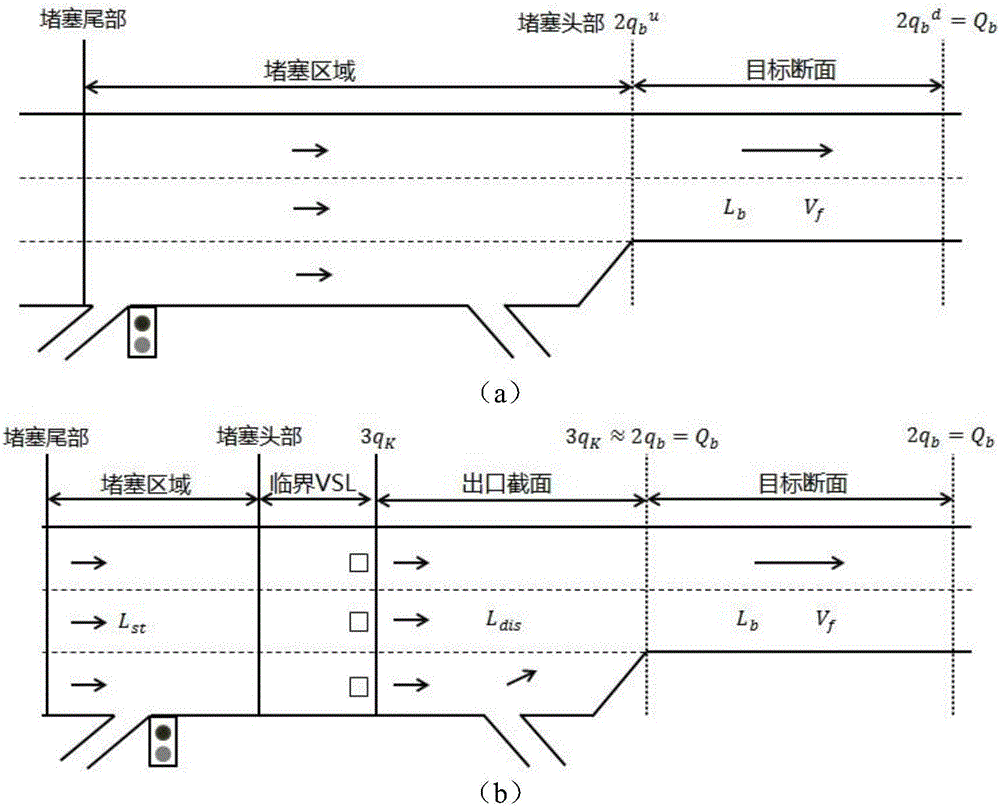

Intelligent signal regulation and control method for elevated ramp

ActiveCN106530757ALow costRestore capacityControlling traffic signalsDetection of traffic movementData acquisitionTraffic flow

The invention discloses an intelligent signal regulation and control method for an elevated ramp, and the method comprises the following steps: 1, collection of traffic condition data of a viaduct surface: collecting the real-time traffic flow data of the viaduct surface; 2, comparison of a collected viaduct surface flow and a set flow threshold value: judging that the viaduct surface is in a congested state if the real-time traffic flow exceeds the threshold value, or else, judging that the viaduct surface is not in the congested state; 3, building of an exit cross section; 4, calculation of variable limiting speeds of all upstream segments of the exit cross section and the control rate of each entrance ramp: supposing that the viaduct can be divided into a plurality of road segments, wherein each road segment is provided with an exit ramp, the number of entrance ramps is not limited, TTS is a function of rk(t), wherein k =1, 2,...,K; minimizing TTS, i.e., calculating the combination of rk(t) to enable TTS to be minimum, wherein k=1, 2,...,K; calculating rk(t) through a linear programming method, and obtaining the exit ramp control rate of each ramp, wherein k=1, 2,...,K. The method is simple and effective, is lower in cost, and is good in instantaneity.

Owner:ENJOYOR COMPANY LIMITED

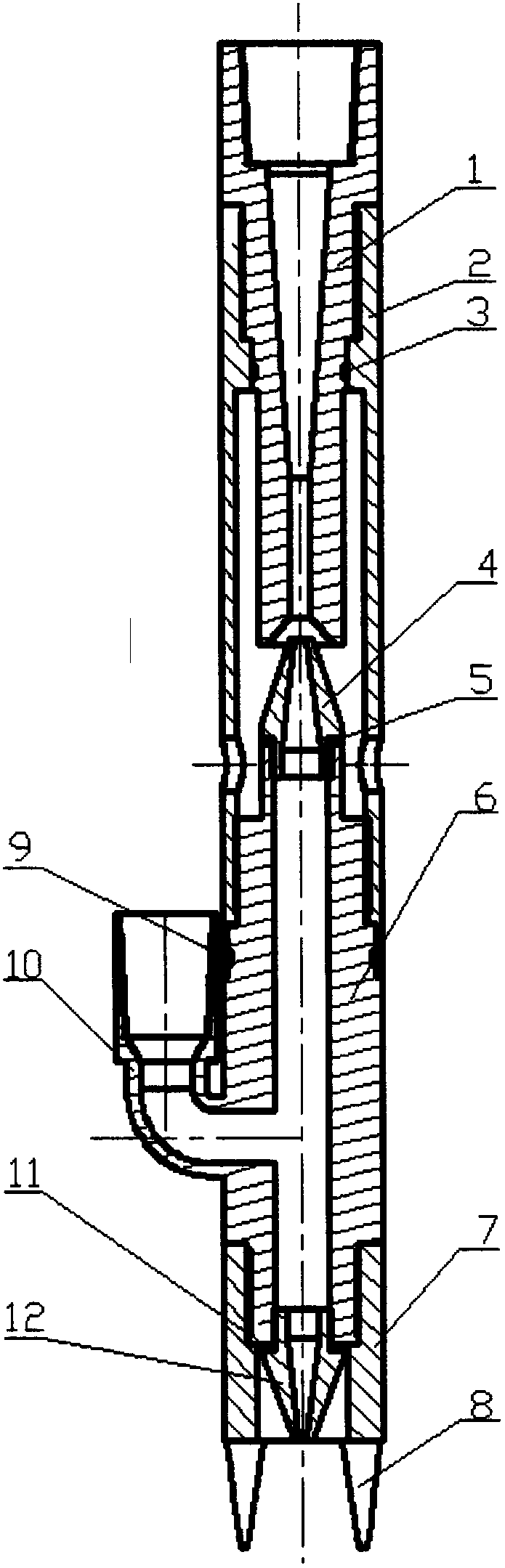

Downhole device using hydraulic jets of parallel tubes to flush pulverized coal

InactiveCN103388465AFast, efficient and thorough dischargeWon't hurtFluid removalFlushingEngineeringFormation fluid

The invention relates to a downhole device using hydraulic jets of parallel tubes to flush pulverized coal for the field of development of a gas field and a coal-bed gas field. The downhole device consists of a throat diffusion tube 1, an outer cylinder 2, O-shaped sealing rings 3 and 9, a high-pressure nozzle 4, copper washers 5 and 11, a high-pressure chamber 6, a sleeve 7, sand flushing teeth 8, a mixing nozzle 12 and a guide connector 10. The guide connector 10 is connected with the high-pressure chamber 6 in a welding way; the internal circular surfaces of the upper end and the lower end of the high-pressure chamber 6 are respectively connected with the high-pressure nozzle 4 and the mixing nozzle 12 via threads; the internal circular surfaces of the upper end and the lower end of the outer cylinder 2 are respectively connected with the external circular surfaces of the throat diffusion tube 1 and the high-pressure chamber 6 through threads; and the sleeve 2 is connected with the sand flushing teeth 8 in a welding way and connected with the high-pressure chamber 6 through threads. The structure of the device is simple, part of power liquid is used for exerting impact on downhole pulverized coal so that the pulverized coal is fully mixed with formation fluid; and the rest of power liquid is sprayed by the high-pressure nozzle to form a negative pressure area, the formation liquid is sucked in a rolling way after being mixed into a returning liquid tube, and thus the downhole pulverized coal can be discharged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Battery and battery production method

InactiveCN109309257ARestore capacityDoes not affect energy densityFinal product manufactureCell component detailsElectrical resistance and conductanceElectrical conductor

Owner:LENOVO (BEIJING) LTD

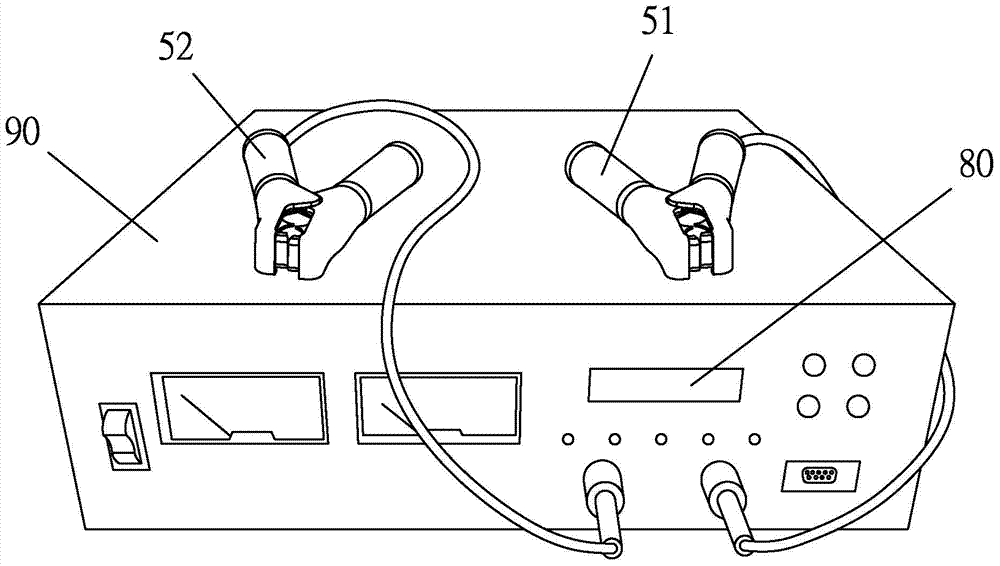

Unmanned aerial vehicle intelligent charger

InactiveCN105375597AProtection lifeProtect the safety of useBatteries circuit arrangementsElectric powerCommunication interfaceCurrent sensor

The invention discloses an unmanned aerial vehicle intelligent charger. The unmanned aerial vehicle intelligent charger comprises an AC / DC unit, a DC / DC unit, a microprocessor, a balance charging module, a battery module, a battery module voltage detection unit, a USB power supply unit, a USB output charging jack, a voltage / current sensor, a keyboard, a display unit, a heat dissipation fan driving unit, a heat dissipation fan, a wifi unit, a USB interface, an isolated type communication interface chip and a thermistor sensor. Since an active balancing technology is employed, the charging efficiency and the charging speed are improved, and the service life and the safety of a lithium battery are effectively protected; the microprocessor is provided with the USB interface and supports program updating of hardware with a USB port or an SD card; the microprocessor is connected with the WIFI unit so as to realize such functions as real-time monitoring of a client through an mobile phone APP and the like; the microprocessor unit automatically adjusts and controls the size of DC / DC output signals according to the DC / DC output signals detected by the voltage and current sensor; by use of the isolated type communication interface chip, EMI (electromagnetic interference) is reduced, and the wiring length and the signal-to-noise performance of a system are greatly improved; and by use of the battery module voltage detection unit, each independent battery in the battery module can be monitored, and each battery is effectively controlled.

Owner:重庆瑞升康博电气有限公司

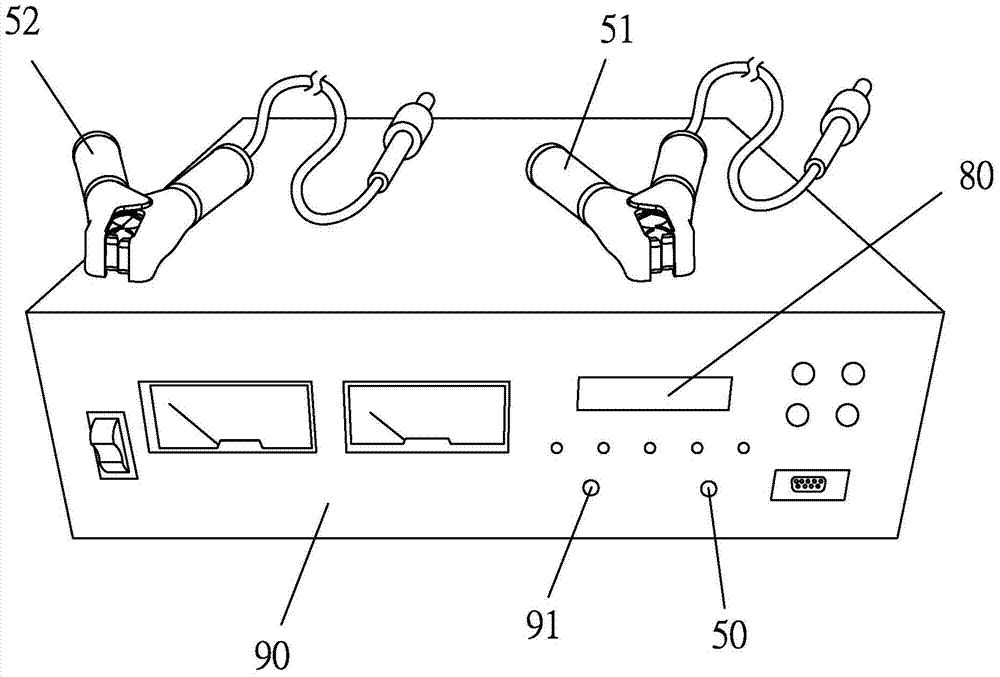

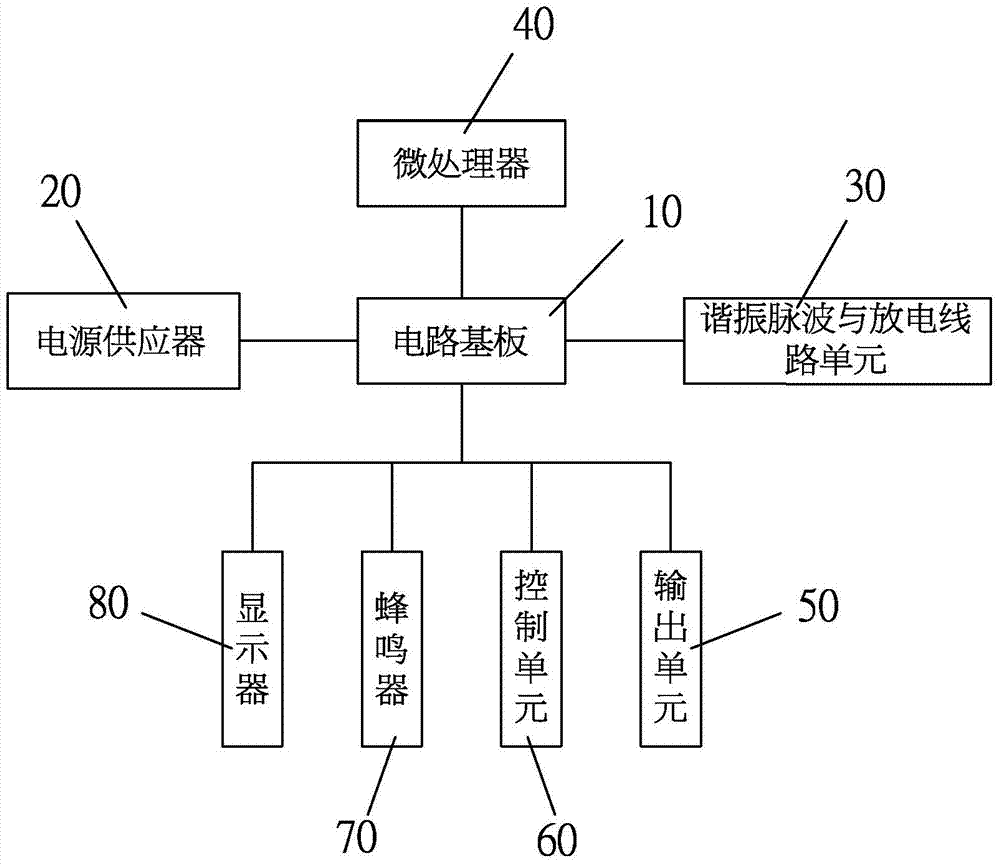

Combined type lead-acid battery restorer

InactiveCN104779418ANo need to worry about damageLower internal resistanceLead-acid accumulatorsWaste accumulators reclaimingLead sulfateElectric power

A combined type lead-acid battery restorer comprises a circuit board, a power supply, at least one resonant pulse unit, at least one discharge line unit, at least one microprocessor and an output unit. The power supply is arranged on the circuit board and is electrically connected to an external power supply, and supplies power to the circuit board. The at least one resonant pulse unit and the at least one discharge line unit are arranged on the circuit board. The at least one microprocessor is arranged on the circuit board, and the interior of the microprocessor is provided with a first procedure in advance, and the first procedure is a positive / negative frequency conversion pulse procedure. The output unit is provided with a positive electrode electric clamp and a negative electrode electric clamp, the positive electrode electric clamp is clamped on the positive electrode of a lead-acid battery with lead sulfate crystals, the negative electrode electric clamp is clamped on the negative electrode of the lead-acid battery with lead sulfate crystals, the lead-acid battery is detected by means of the microprocessor, and the resonant pulse unit and the discharge line unit output at least one positive / negative frequency conversion pulse through the output unit, the positive / negative frequency conversion pulse and the lead sulfate crystals in the lead-acid battery resonate, and therefore the lead sulfate crystals are crushed.

Owner:杨铭程

Plugging resin system and application thereof

InactiveCN111793480AImprove liquidityImprove mechanical propertiesDrilling compositionPolymer scienceFirming agent

The invention provides a plugging resin system and application thereof. The plugging resin system is obtained by a reaction of a component A and a component B, the mass ratio of the component A to thecomponent B is 1: 1 to 3: 2, the component A at least comprises epoxy resin, and the component B at least comprises an epoxy resin curing agent. Epoxy resin and a curing agent are mixed and stirred according to different proportions, the mixture is pumped into a casing leakage breaking section, the resin and the curing agent are subjected to addition polymerization reaction within specified timeand under the condition of proper formation temperature to generate a cured product of a net structure, and the purpose of plugging is achieved. And the gelling time can be controlled by the dosages of the components A and B. The compressive strength is greater than 80 MPa, and the chemical plugging construction requirements of the casing damage well are met. According to the plugging resin system, the compressive strength is met, meanwhile, the resin hardness is reduced, the resin toughness is improved, and the resin drillability is improved. And the plug drilling speed can reach 2.5 m / h under the same condition of the plug drilling process, so that the plug drilling time is greatly saved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com