Combined type lead-acid battery restorer

A technology of composite lead-acid and lead-acid batteries, which is applied in the fields of lead-acid batteries, secondary battery repair/maintenance, battery recycling, etc. It can solve the problems of irreparable batteries, damaged battery life, long repair time, etc., and achieve rapid recovery The effect of battery capacity, prolonging service life, and reducing battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Other features and specific embodiments of the present invention can be further understood in the following detailed description with accompanying drawings:

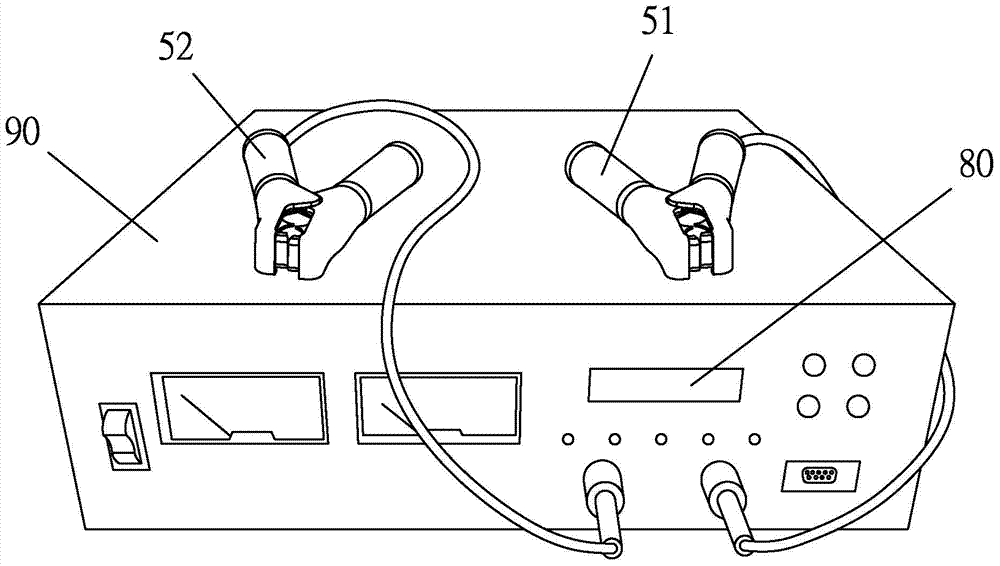

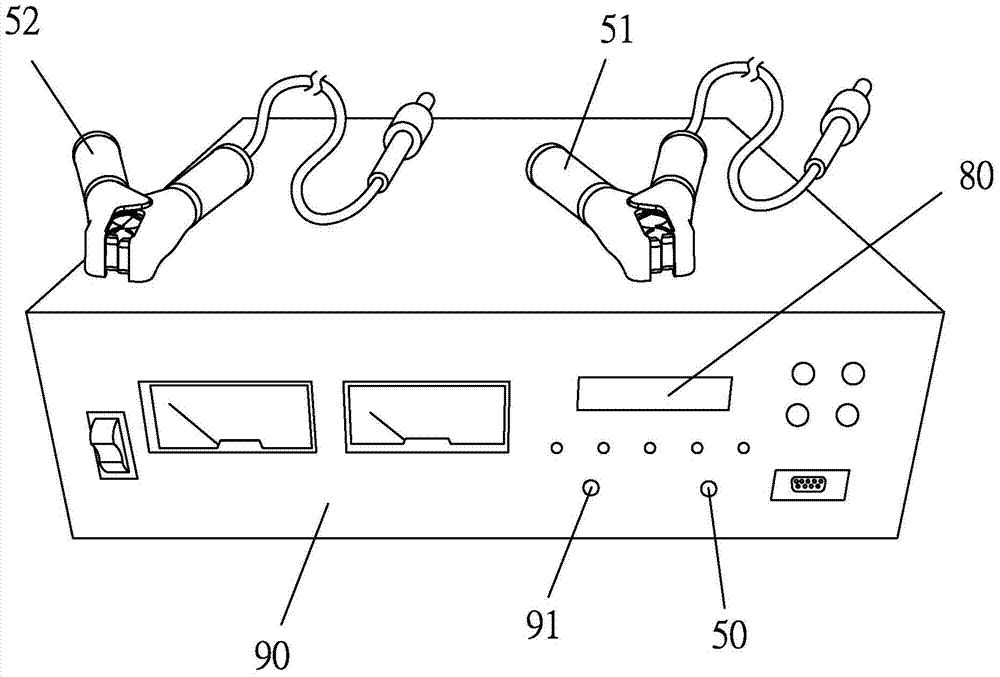

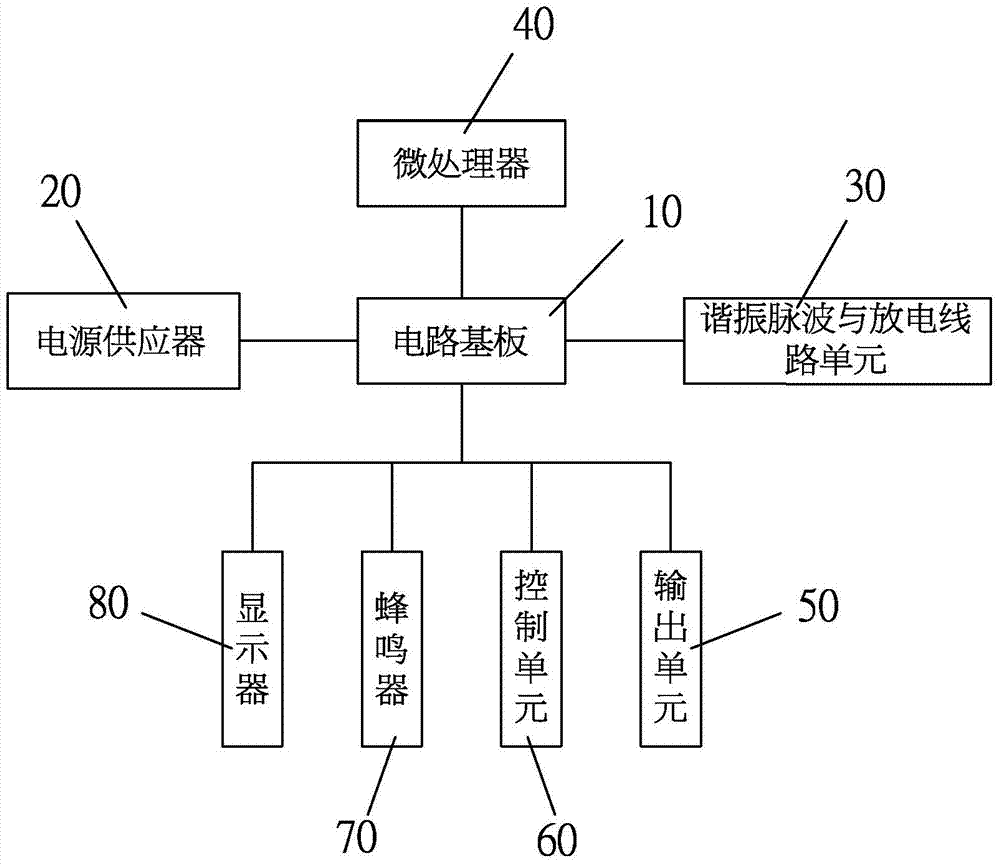

[0043] Please refer to Figure 1 to Figure 3 As shown, a composite lead-acid battery repairer includes: a circuit substrate 10, a power supply 20, at least one resonance pulse unit and discharge circuit unit 30, at least one microprocessor 40, and an output unit 50, of which,

[0044] The power supply 20 is arranged on the circuit substrate 10 and provides an electrical connection to an external power source (not shown in the figure), thereby providing power to the circuit substrate 10.

[0045] The external power source is AC power, and the AC power is converted into DC power through the power supply 20 and output to the circuit board 10.

[0046] The resonant pulse wave unit and the discharge circuit unit 30 are arranged on the circuit board 10.

[0047] The microprocessor 40, which is arranged on the circuit substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com